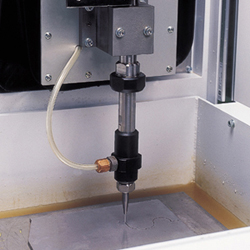

WATER JET CUTTER

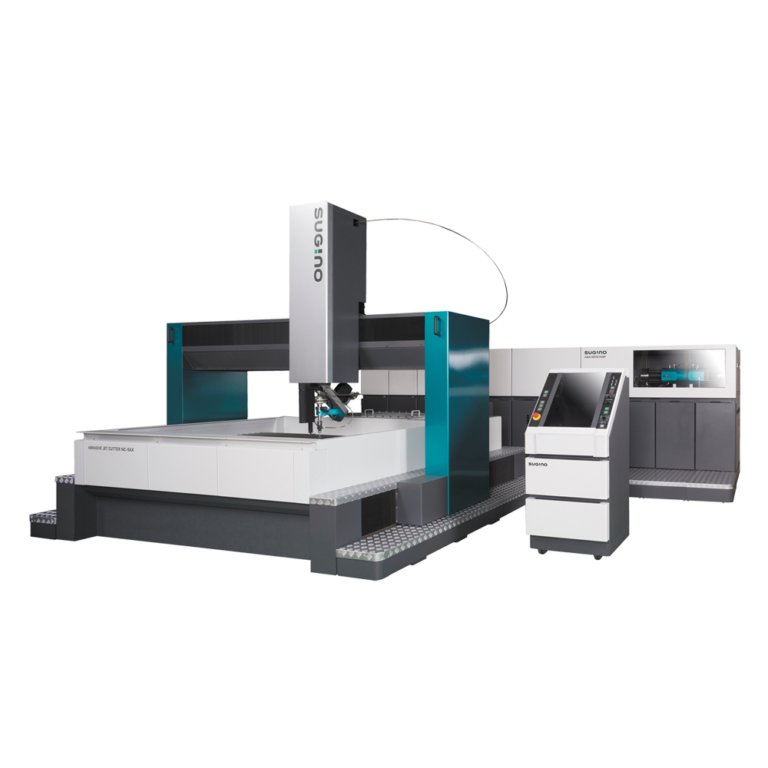

Abrasive Jet Cutter NC-5AX: Simultaneous 5-axis Control Abrasive Type Ultrahigh-Pressure Water Cutting Equipment

FEATURES :

The Abrasive Jet Cutter (NC-5AX) has been improved in response to customer feedback, addressing various aspects such as functionality, operability, ease of cleaning, and installation space. Below are its features:

Equipped with the new hydraulic intensifier type pump, “Aqua Servo Pump”

- Stable supply from low to high pressure with a servo motor-driven closed-circuit hydraulic system and proprietary control technology.

- 75% reduction in power consumption when water jet is stopped.

- 75% reduction in amount of water used.

- 82% reduction in operating oil used.

High-speed, High-precision

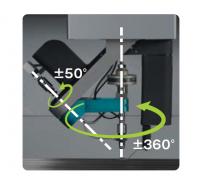

High rigidity by dual-axis gantry, low center of gravity and symmetry design, and 5-axis controlled single-point focus nozzle head with a maximum tilt angle of 50 degree realize high-speed, high-precision machining.

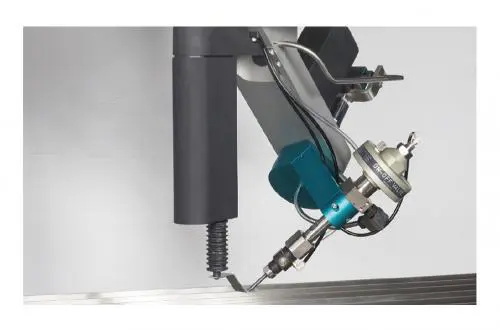

Mechanism with single-point focus specifications

It’s a single-point focus specification where the A-axis and C-axis rotate around the machining point of the nozzle.

When performing cutting operations, adjustments to angle and height can be made using the rotation of the A-axis and C-axis, enabling the quickest determination of nozzle orientation. This efficient method avoids the need to move the entire upper drive unit with each nozzle orientation change, allowing for efficient machining.

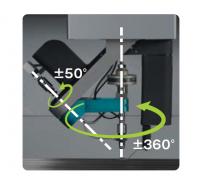

The A-axis can tilt up to ±50 degrees, while the C-axis can rotate ±360 degrees.

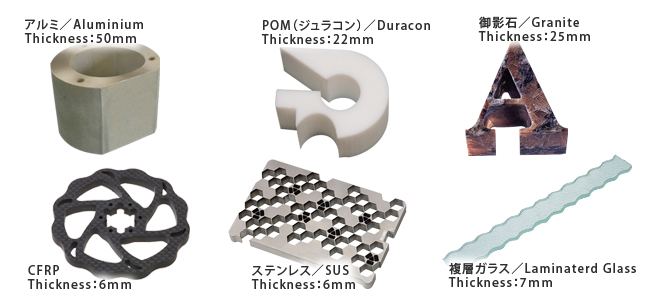

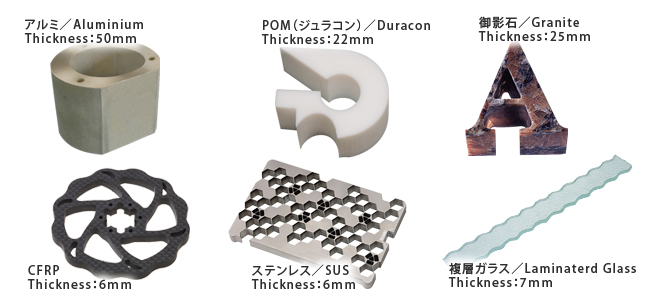

Capable of processing a wide range of materials from metals to brittle materials.

- Metal products: Efficient processing of rare materials with high yield.

- Material processing: Process materials unsuitable for laser or plasma cutting without thermal alteration, and manufacture various test specimens.

- Aerospace: CFRP, titanium, duralumin, etc.

- New materials: Glass laminates, cermets, FRP, ceramics, etc.

Simple Operations

Powered by the “Sugino Jet Processor,” which harnesses years of machining know-how compiled into a database. Simply entering data such as material and thickness allows anyone to start machining easily.

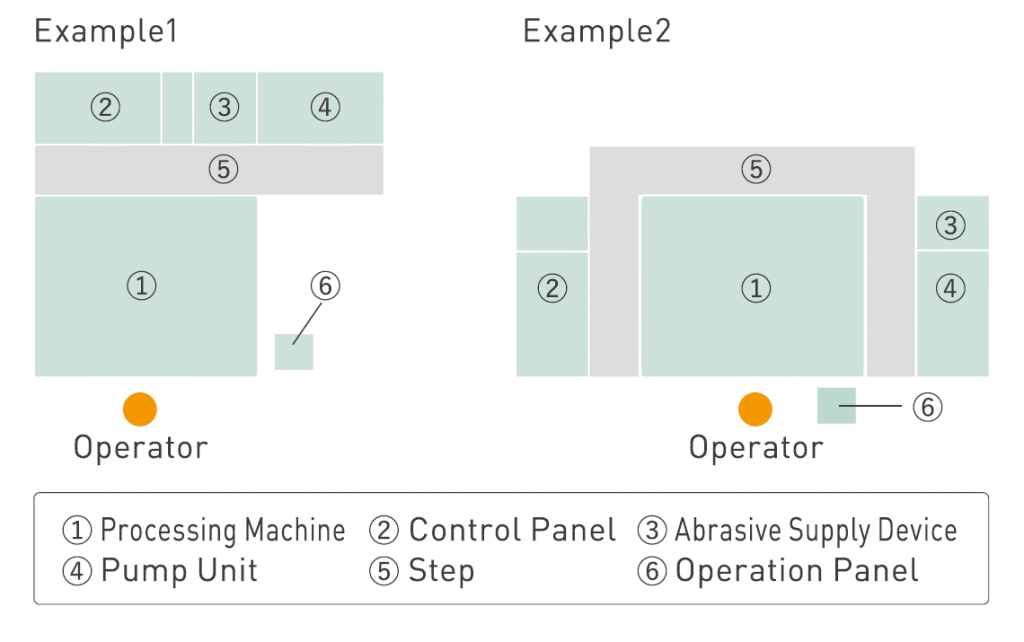

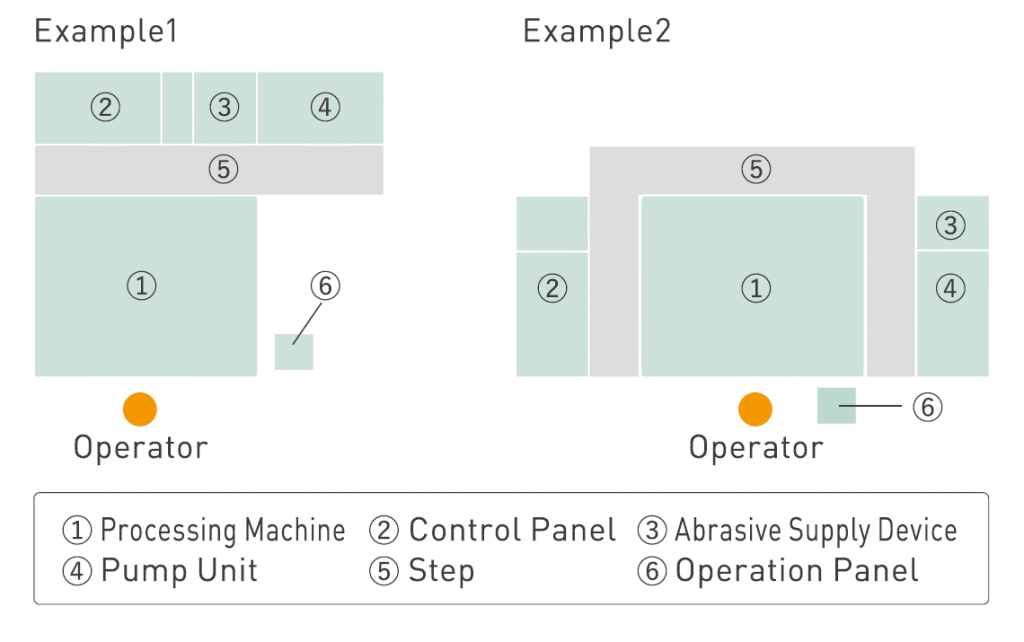

Flexible Layout Options

We have modularized the pump unit, abrasive supply device, control panel and piping cover step. This allows flexible layout adjustments to suit various working environments.

Wide Range of Convenient Functions

Wireless manual pulse controller

Boost prductivity with the wireless controller

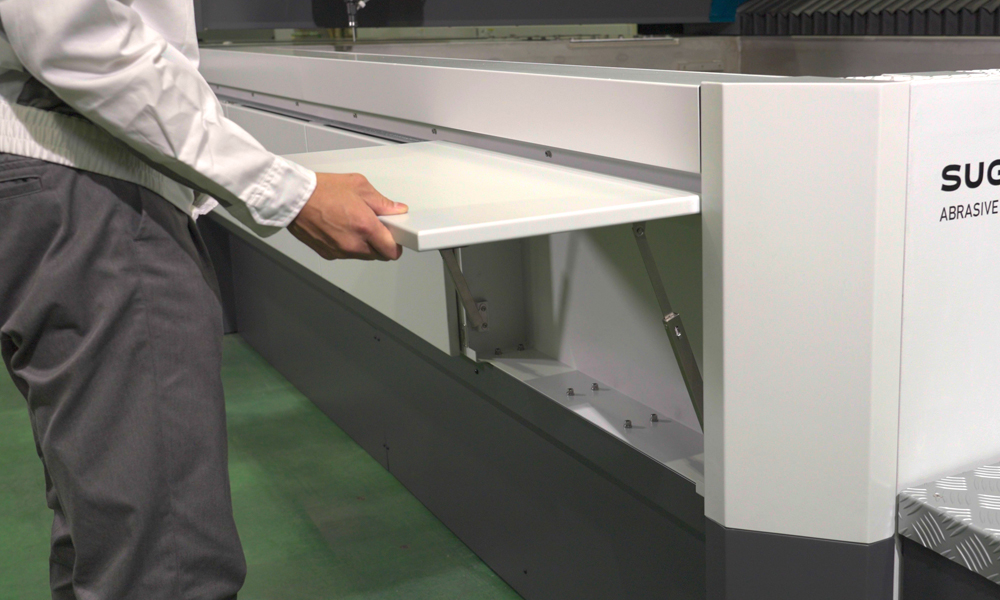

Automatic machining bit correction unit. An unit that automatically measures and corrects machining points that are misaligned after maintenance, such as nozzle replacement. Designed for Functionality. Storage box, foldable work table. Recess for toe, side step, auxiliary handle

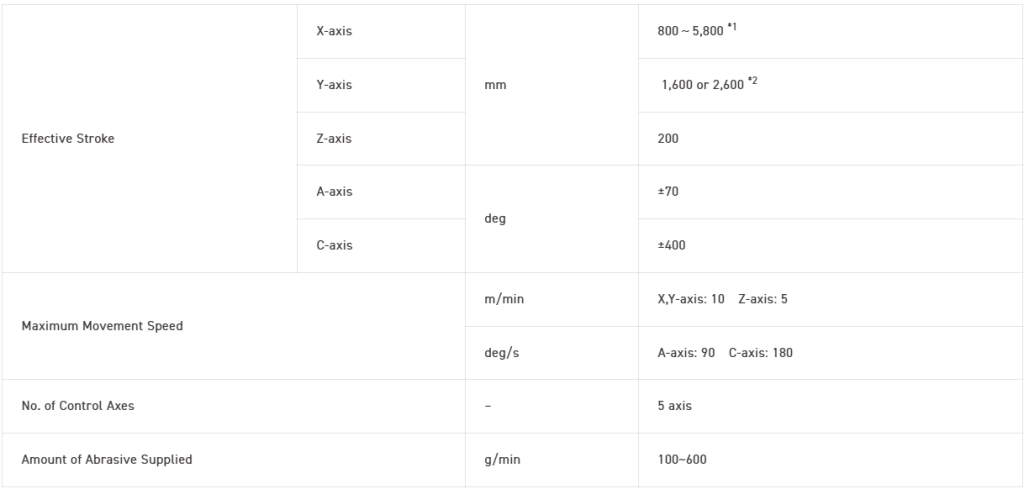

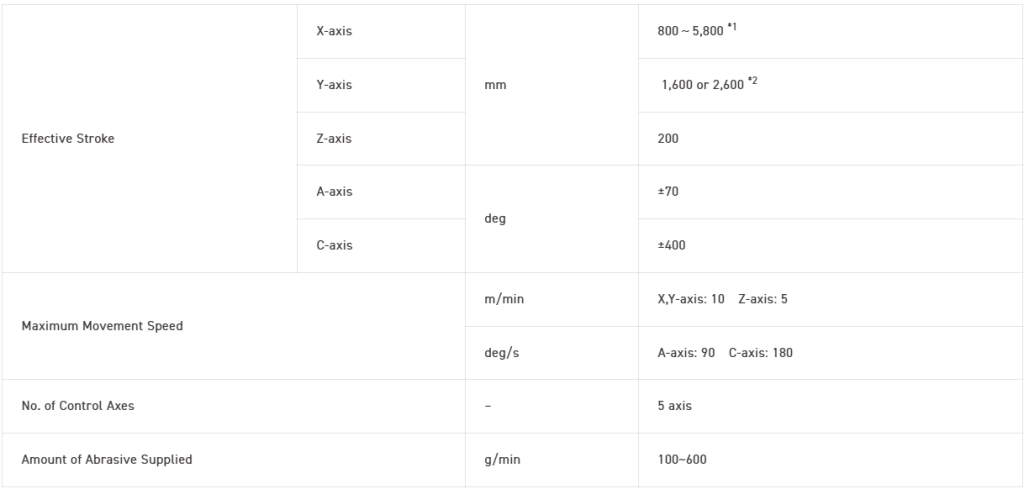

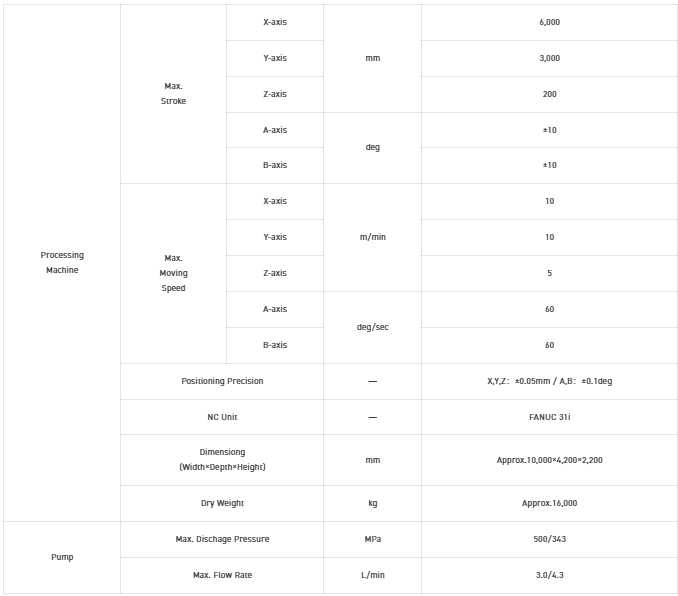

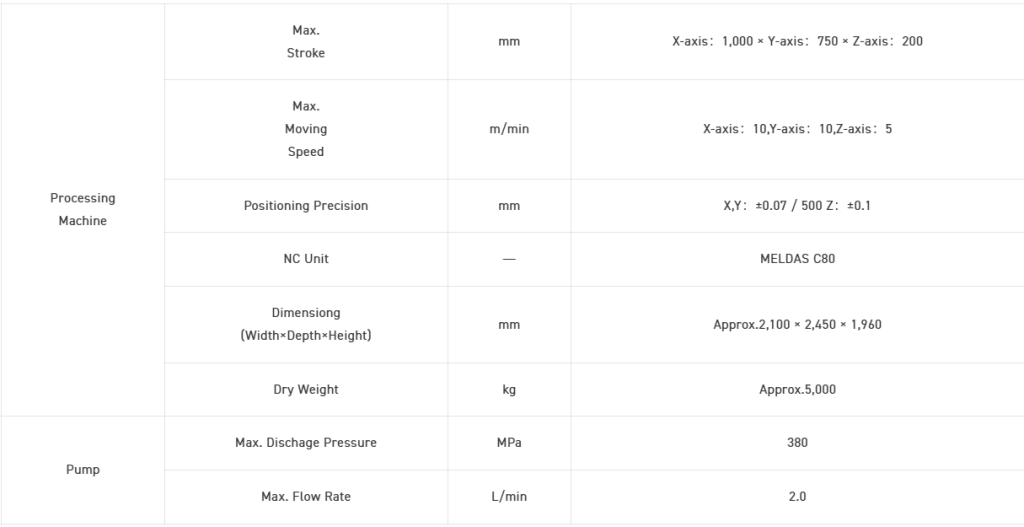

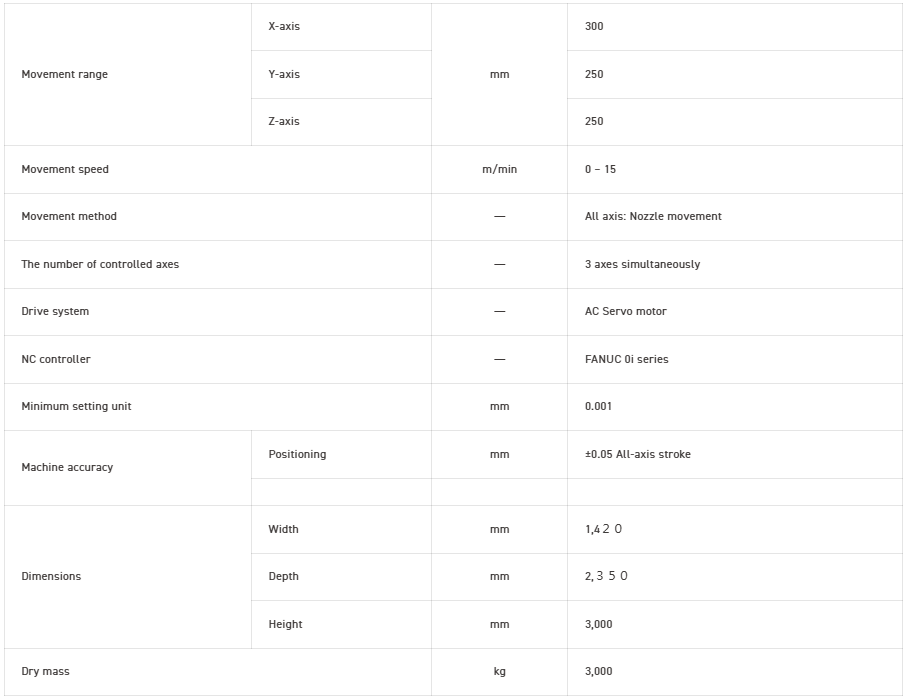

Specifications :

Abrasive Jet Cutter NC-5AX: 5-axis Control Abrasive Type Ultrahigh-Pressure Water Cutting Equipment [standard]

FEATURES :

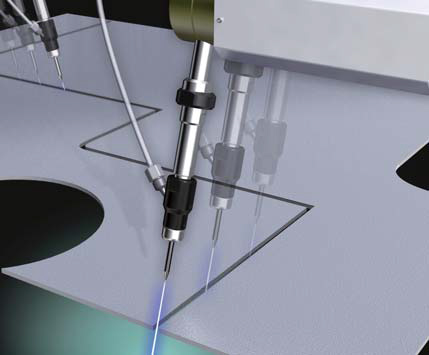

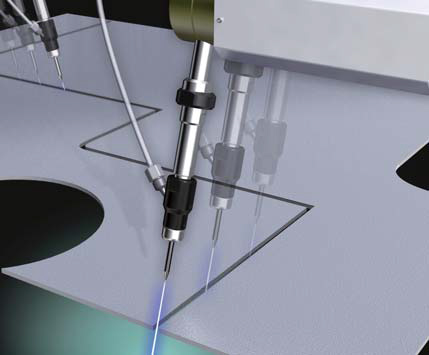

Mechanism with single-point focus specifications

It’s a single-point focus specification where the A-axis and C-axis rotate around the machining point of the nozzle.

When performing cutting operations, adjustments to angle and height can be made using the rotation of the A-axis and C-axis, enabling the quickest determination of nozzle orientation. This efficient method avoids the need to move the entire upper drive unit with each nozzle orientation change, allowing for efficient machining.

The A-axis can tilt up to ±50 degrees, while the C-axis can rotate ±360 degrees

High-speed, High-precision

High rigidity by dual-axis gantry, low center of gravity and symmetry design, and 5-axis controlled single-point focus nozzle head with a maximum tilt angle of 50 degree realize high-speed, high-precision machining.

Convenience

Capable of incorporating wireless active pulse transmitters and automatic calibration units for processing tip adjustment.

Reduction in initial costs

initial costs was reduced by standardizing the drive components of the machining unit and the catcher tank.

Energy-saving performance

Usability

Equipped with “Sugino Jet Processor”, which incorporates our proprietary machining know-how into a database. Even difficult-to-cut materials can be performed easily.

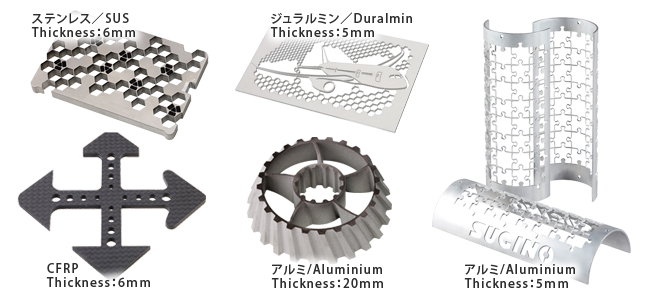

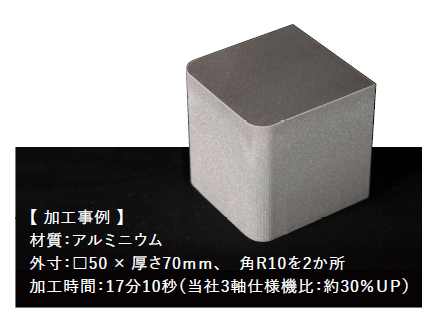

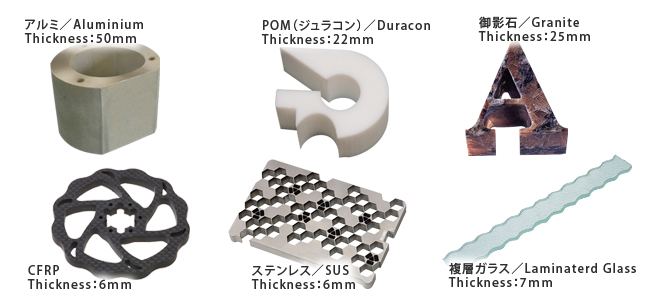

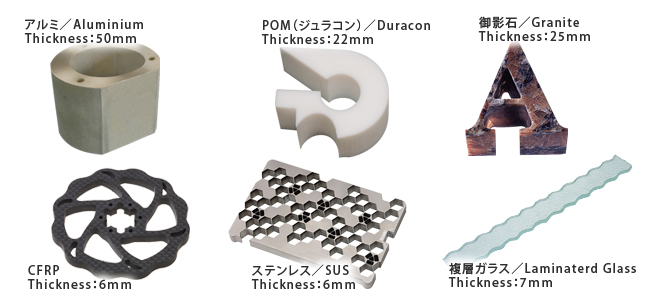

Processing Examples

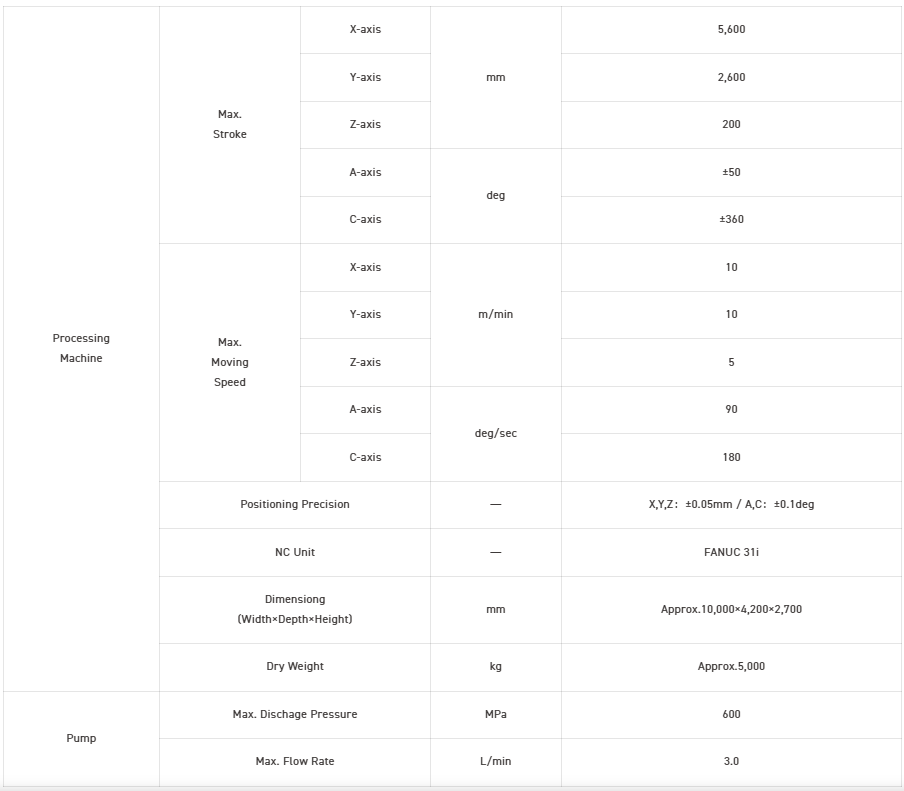

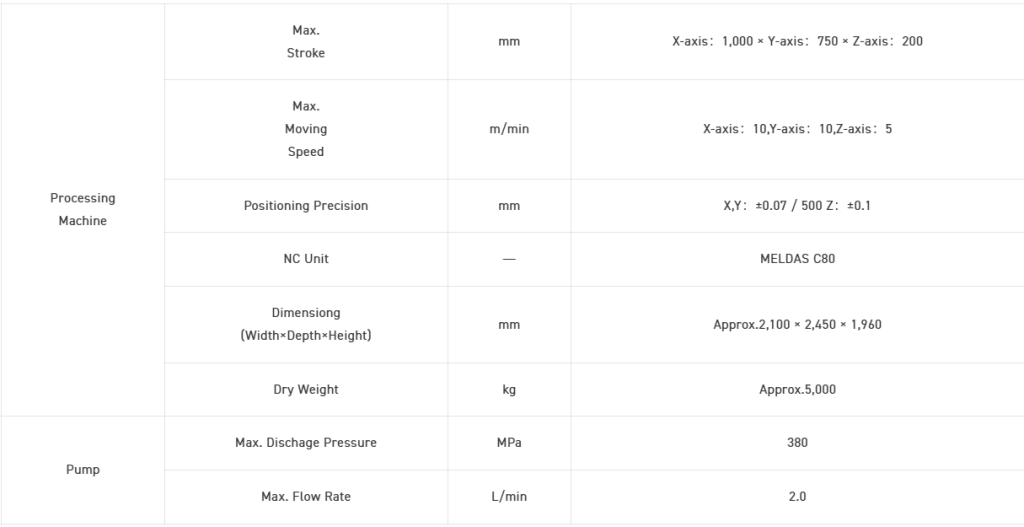

Specifications :

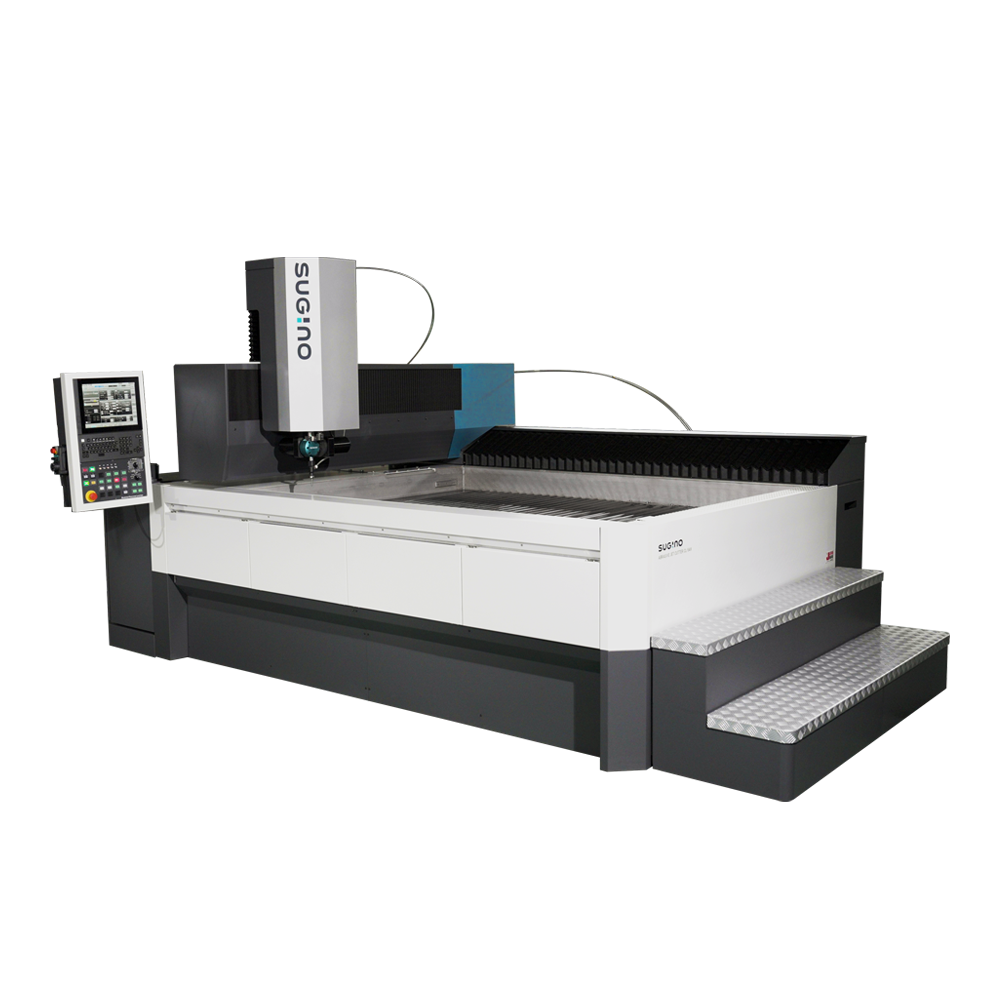

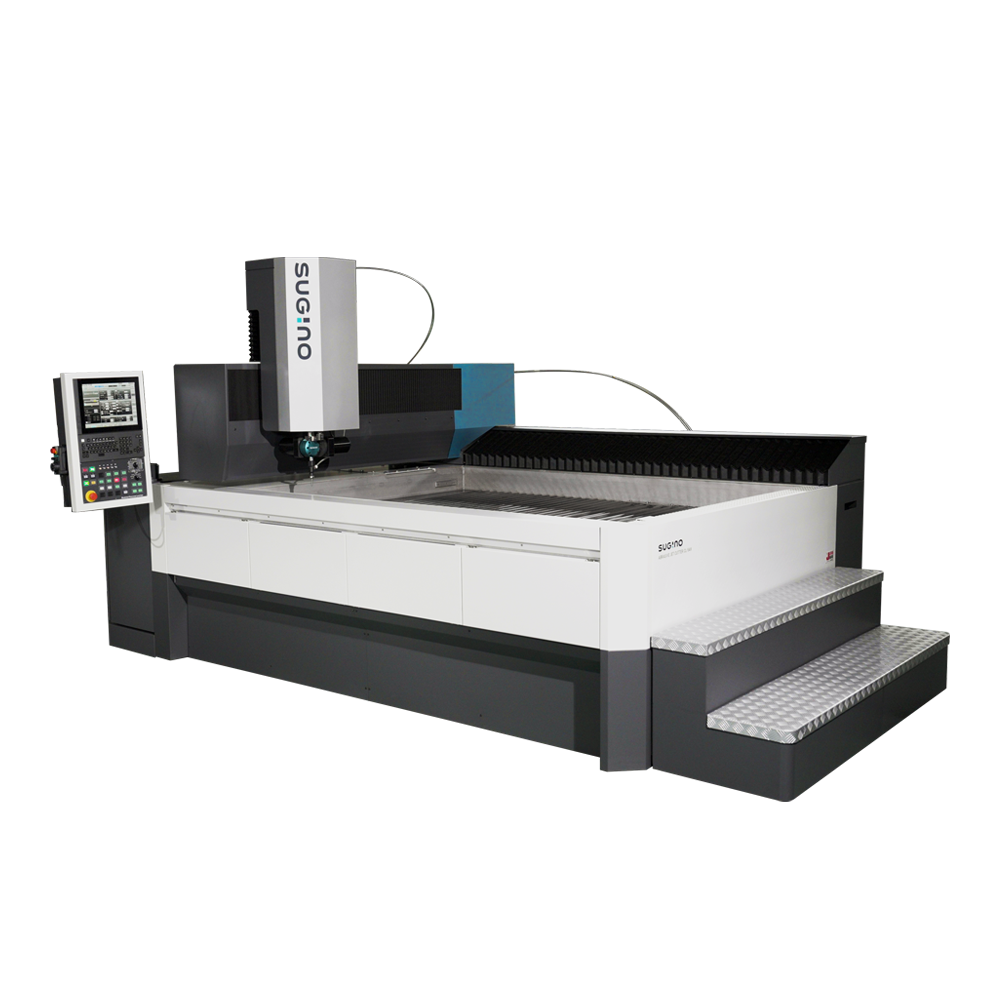

Abrasive Jet Cutter NC-5AX: 5-axis Control Abrasive Type Ultrahigh-Pressure Water Cutting Equipment (AB-axis spec.)

FEATURES :

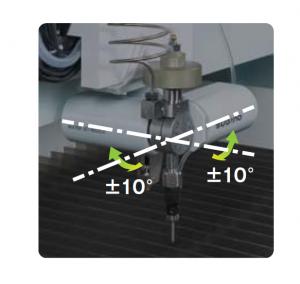

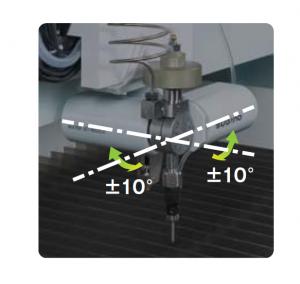

In addition to the XYZ drive axes, controlling the AB axis within a ±10° range has resolved the unique issues of “kerf taper” and “drag” associated with waterjet machining.

Mechanism with AB-axis spec.

The A-axis and B-axis each move within a range of ±10 degree.

Ideal for high-speed and high-precision cutting.

Realization of high speed and high precision processing

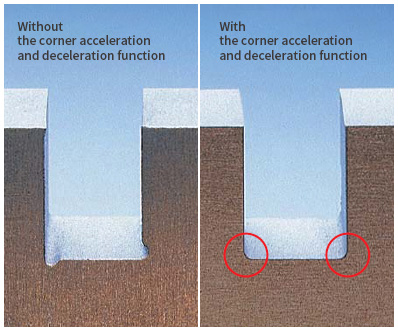

Sugino’s original “taper correction function” automatically controls the incident angle of the nozzle during the cutting process to prevent sloping of the cross sectional area. This feature simultaneously helps improve the processing speed and creates a more precise cutting.

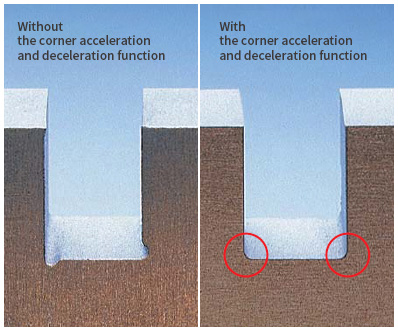

Realization of high quality processing

The corner acceleration and deceleration function eliminates the drag specific to waterjet cutting. It also resolves shape defects at the corners.

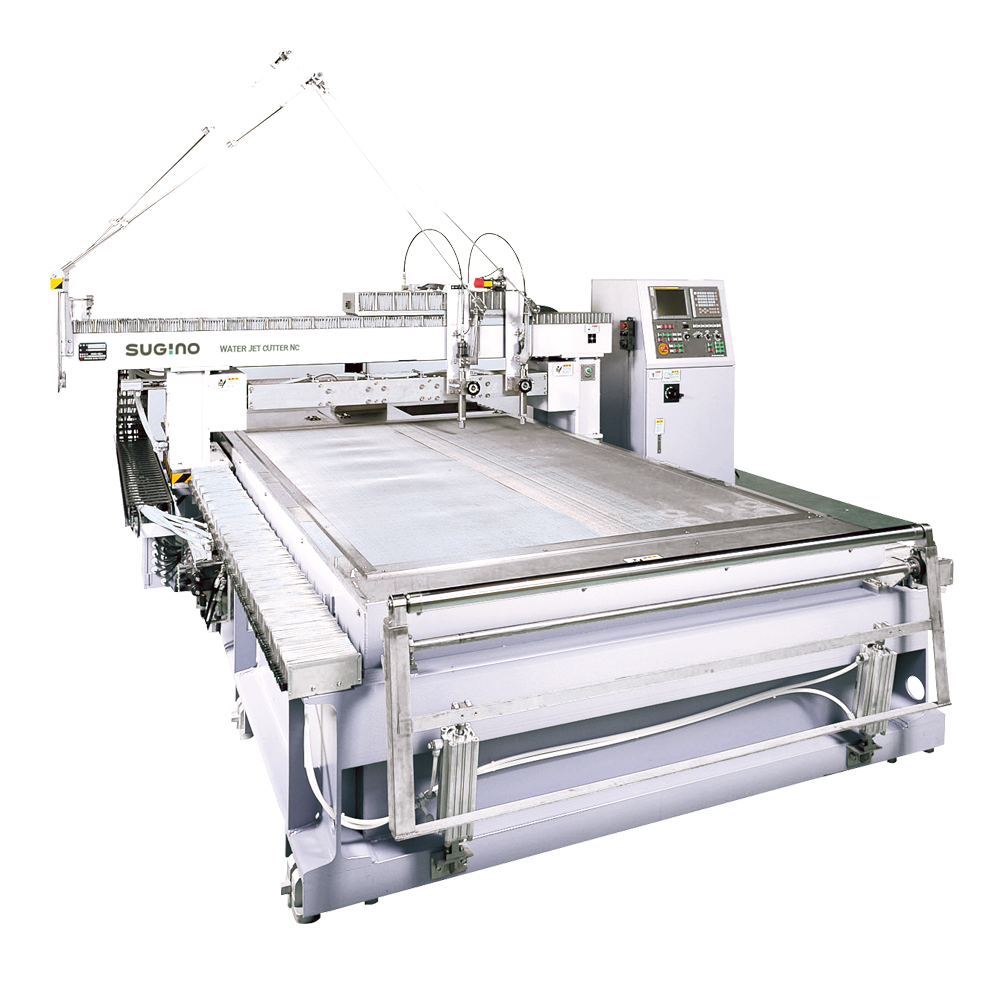

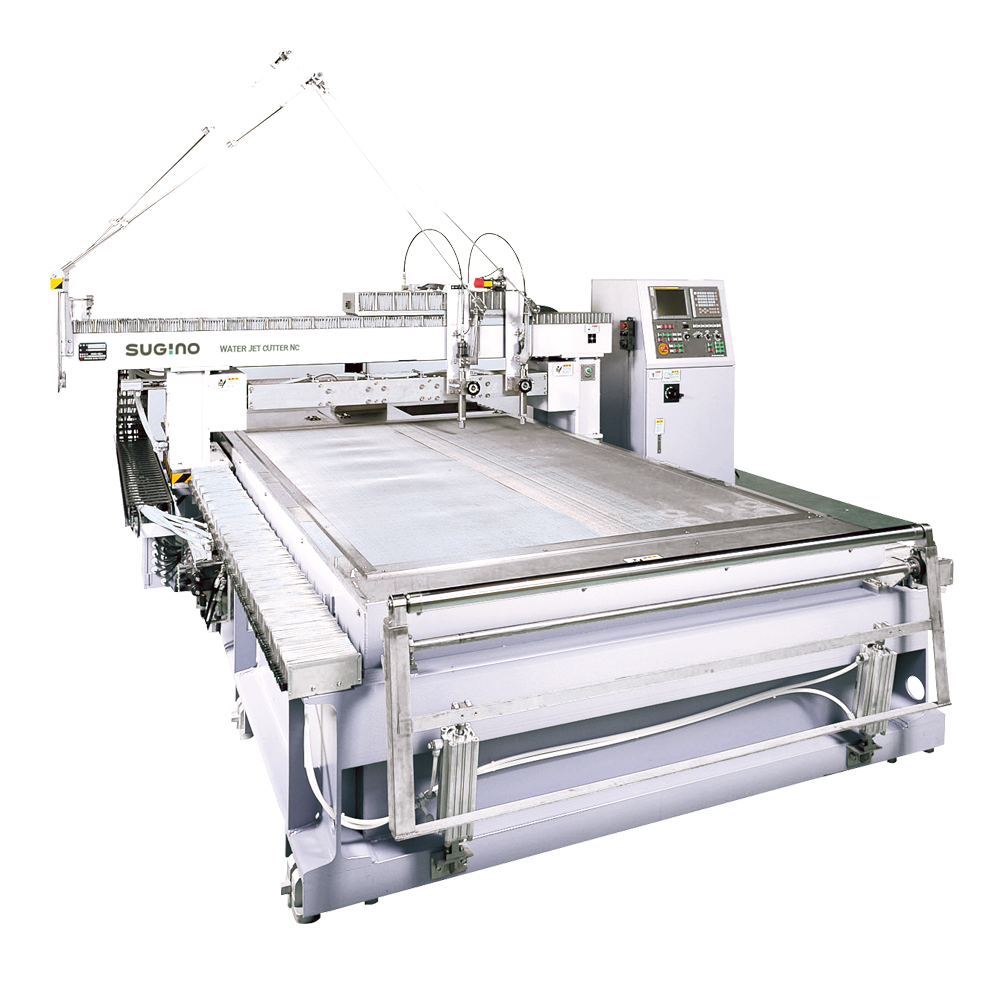

Processing of up to 6 m-long workpiece

Large size workpiece can be processed by maximum 6 x 3m stroke.

Customization

X- and Y-axis strokes can be adjusted by 1 m with modularization of the moving equipment.

Low center-of-gravity body

Stability and accessibility to the workpiece are improved by decreasing the overall height.

The dual-axis gantry, low center of gravity, and symmetrical design realize a high rigidity structure

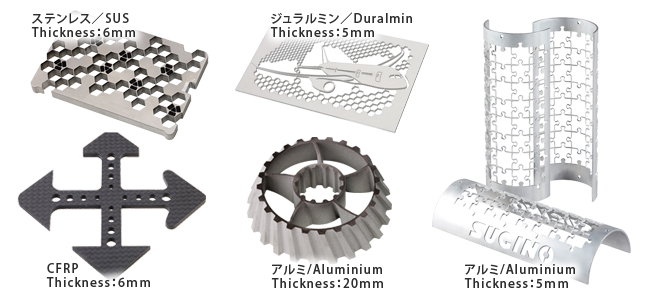

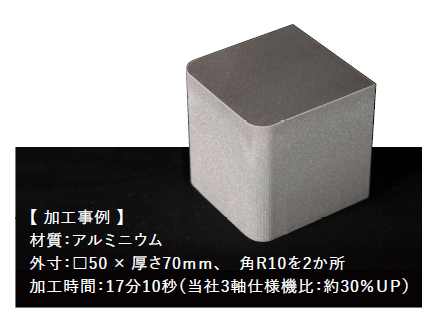

Processing Examples :

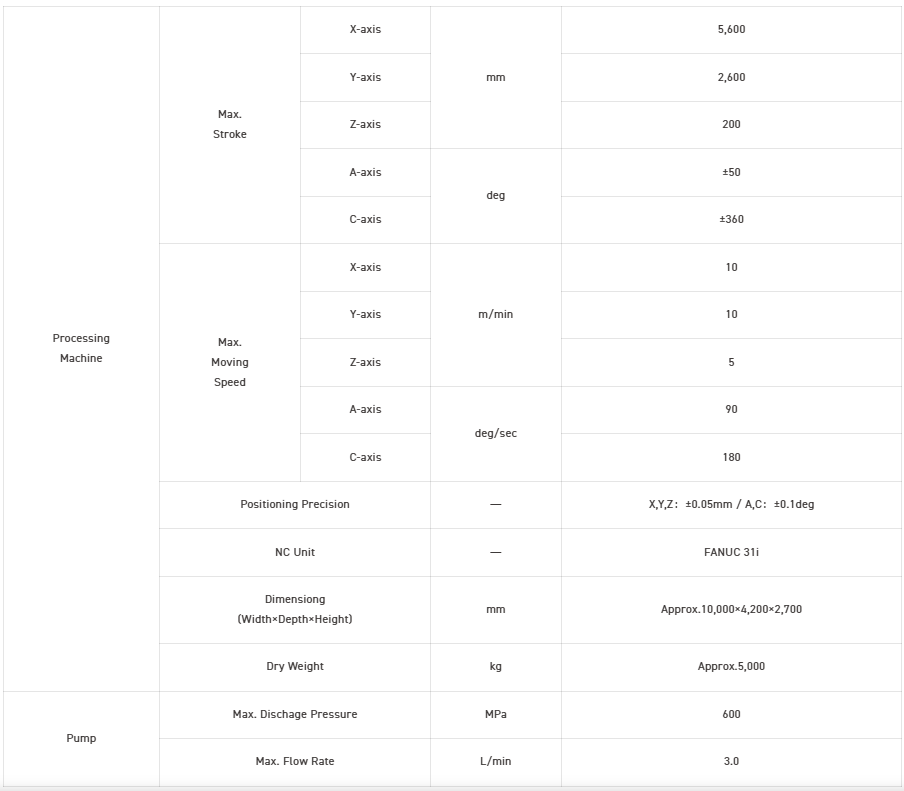

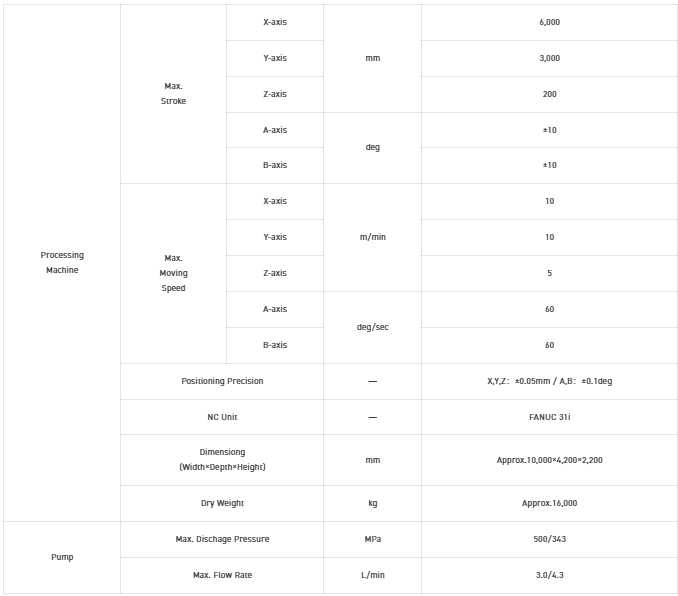

Specifications :

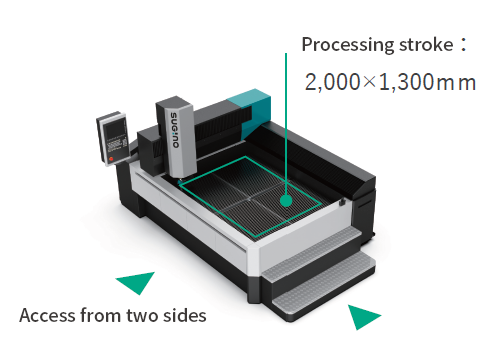

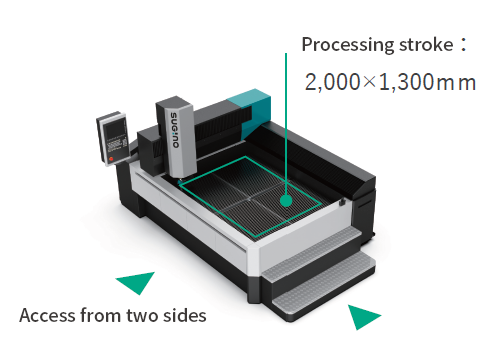

Abrasive Jet Cutter CL: Cantilever Shaped Abrasive Type Ultrahigh-Pressure Water Cutting Equipment

FEATURES :

High Speed/ High Quality

The 5-axis head, incorporating newly added A and B axes, along with an enhanced “taper correction” function, has achieved higher speeds while maintaining high-quality cut surfaces.

Wide processing area

By employing a cantilever beam structure, it ensures ample stroke capacity while maintaining a compact design that accommodates a 3×6 foot size plate with ease.

Supporting comfortable work.

It is equipped with accessibility from two sides and a variety of convenient functions to support more comfortable work.

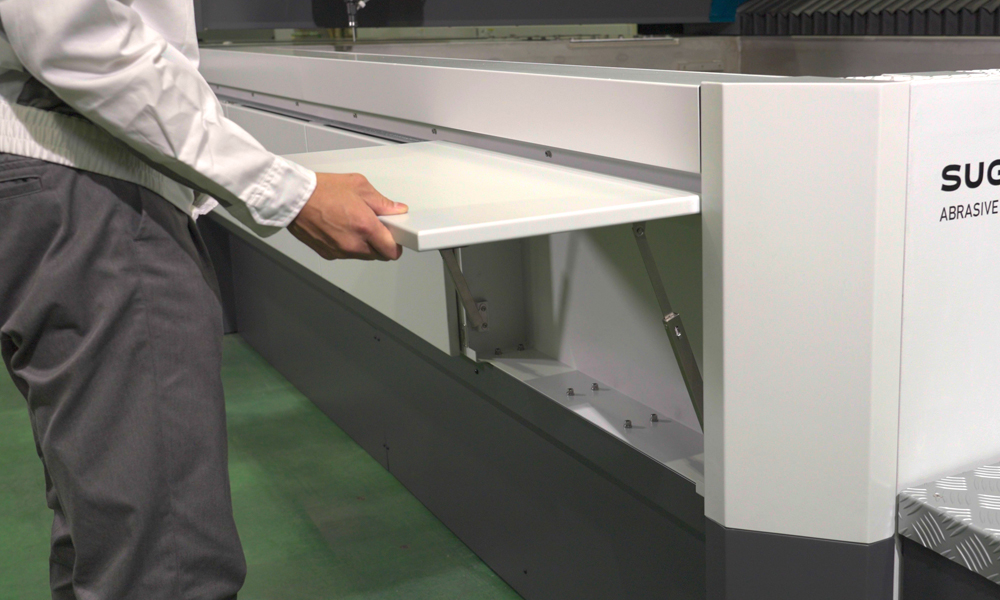

Convenient side step

Excellent accessibility

Folding work table

Hand-held storage space for cleaning guns and tools

Processing Examples :

Specifications :

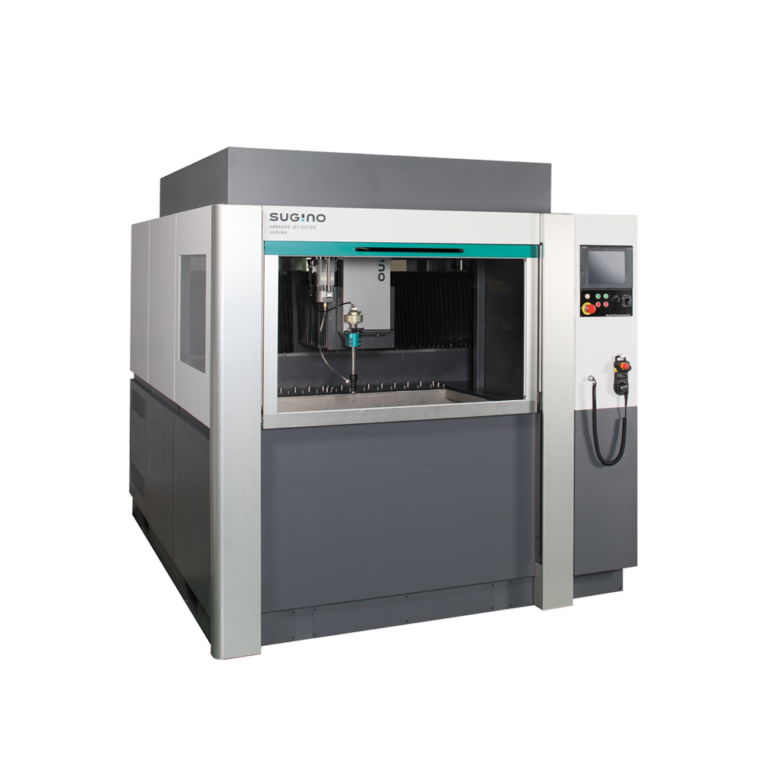

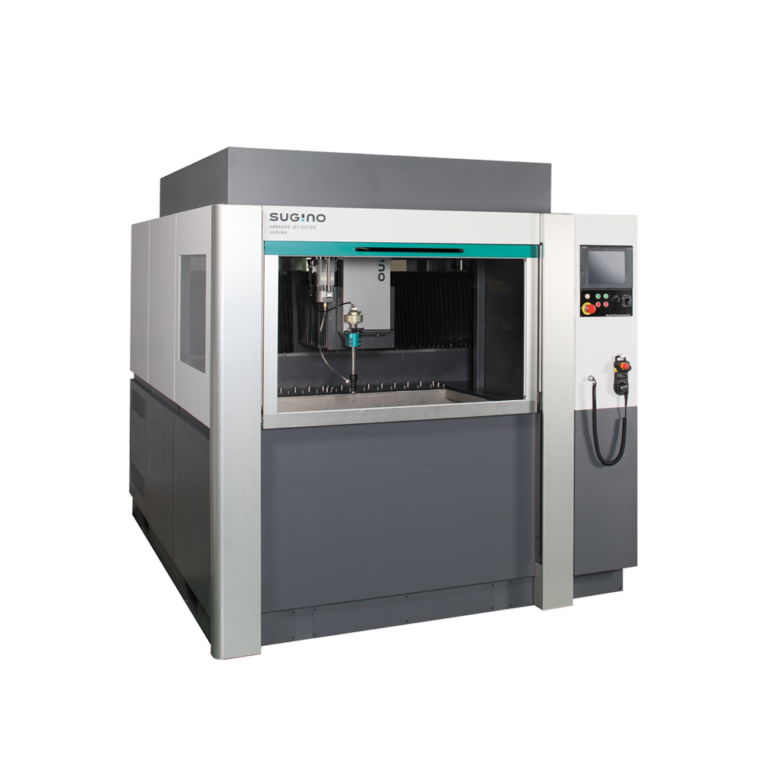

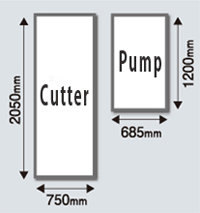

Abrasive Jet Cutter Varuna: All-in-one Abrasive Type Ultrahigh-Pressure Water Cutting Equipment

Features :

All-in-one

Equipped with all the necessary devices for water jet processing, including the pump, it features a compact design with an installation area of just 5 square meters.

It has a sufficient processing area and full functionality.

Easy installation/transfer

Relocation can be done easily with the frame-integrated structure.

Full options

Various useful options, such as abrasive collecting device and simplified drainage filter tank, are available.

Processing Examples :

Application Examples

Manufacturer prototype manufacturing and development department

Divided into 2 sections of making prototype products and evaluating the quality

Manufacture department of mechanical parts maker

Rough processing of materials which are difficult to cut

Prototype manufacturing and evaluation in training facilities and by industrial experimental stations

Processes difficult-to-cut materials such as CFRP, new materials, etc.

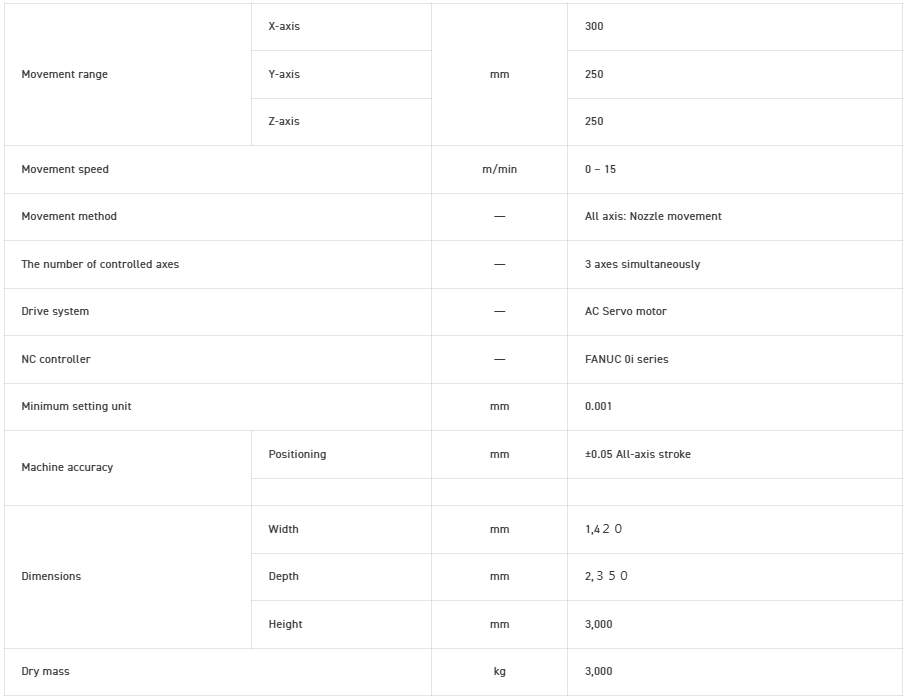

Specifications :

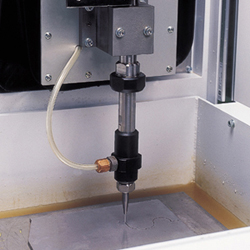

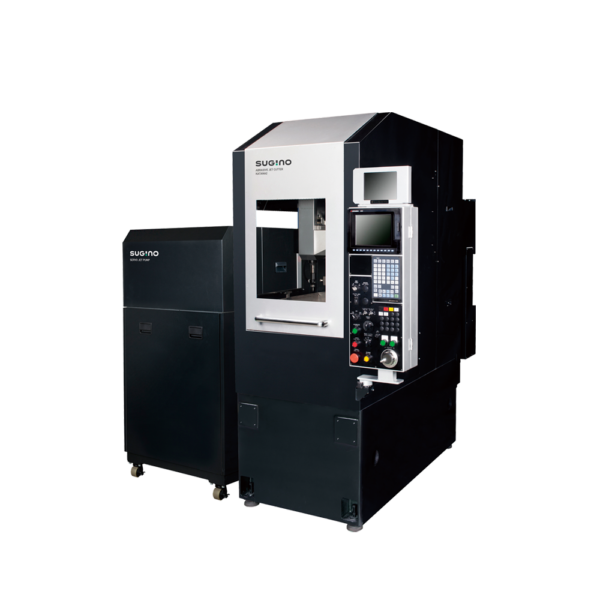

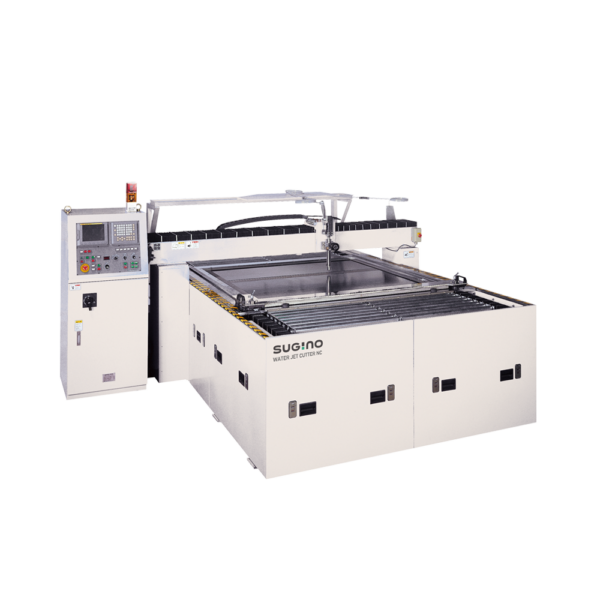

Water Jet Cutter KATANA: Ultrahigh-Pressure Water Cutting Equipment

Features :

Compact size/high accuracy

… Utilizes our compact machining center to perform the cut with high precision, even with compact size.

Compact size/high accuracy.

… Utilizes our compact machining center to perform the cut with high precision, even with compact size.

Ideal for production lines.

With a equipment width of 1.4 meters, it can be easily added to production lines.

Easy operation.

It can be operated in the same way as a machining center.

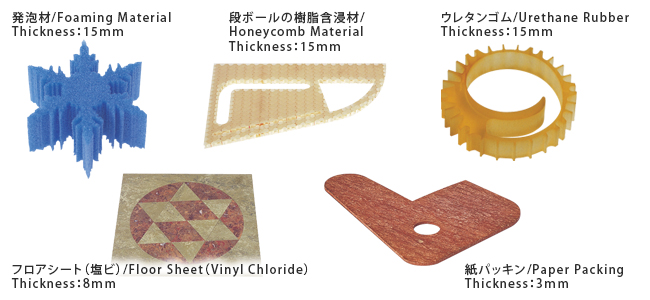

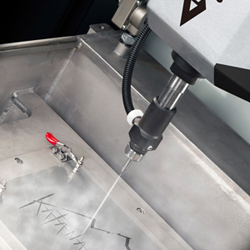

Processing Examples :

Specifications :

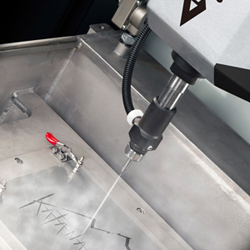

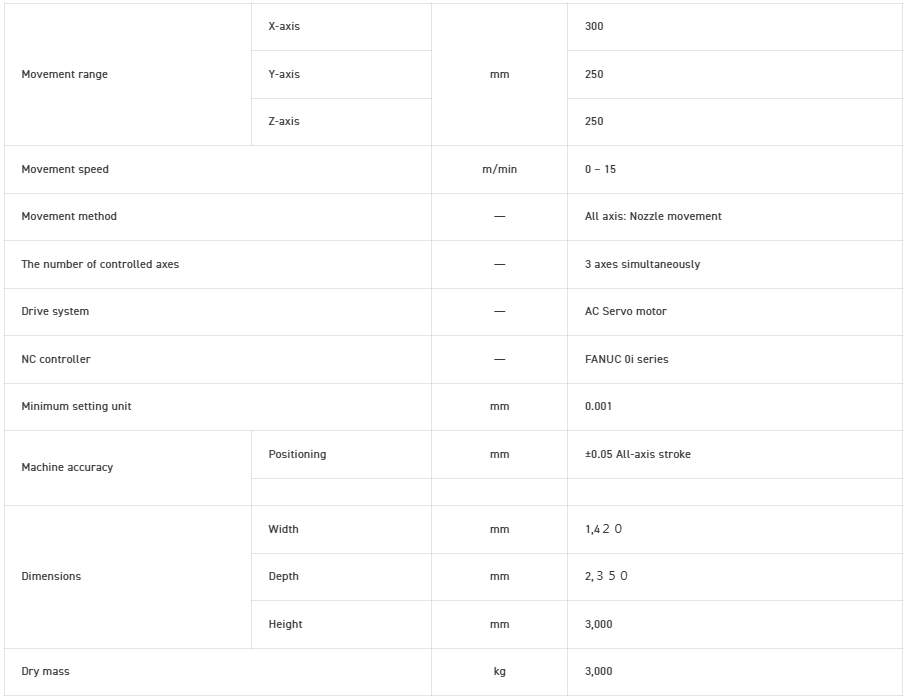

Water Jet Cutter KATANA2: Comapct Ultrahigh-Pressure Water Cutting Equipment

Features

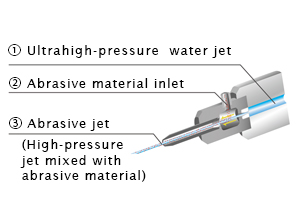

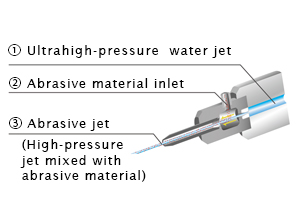

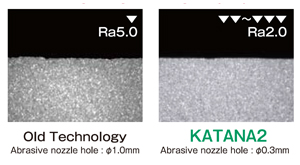

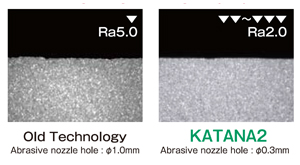

It processes more accurately!

By developing an ultrafine abrasive nozzle of Φ0.3 mm, it can process a cutting allowance as fine as 0.3mm.

Accurately processes many types of materials

Accurately processes many types of materials

Besides all the merits of water jet processing, with a newly developed nozzle it can process high-grade products and improve the roughness of the surface.

Suitable materials:

Glass, stainless steel, copper, CFRP, laminated materials, resin, rubber, foam, paper, etc…

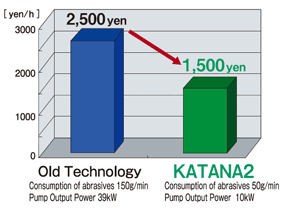

Energy saving, cost saving, space saving

Reduce 60% of abrasive materials.

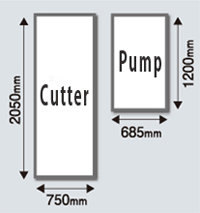

Installation space is only 3 m2.

Drastically reduces initial costs and running costs.

Specifications :

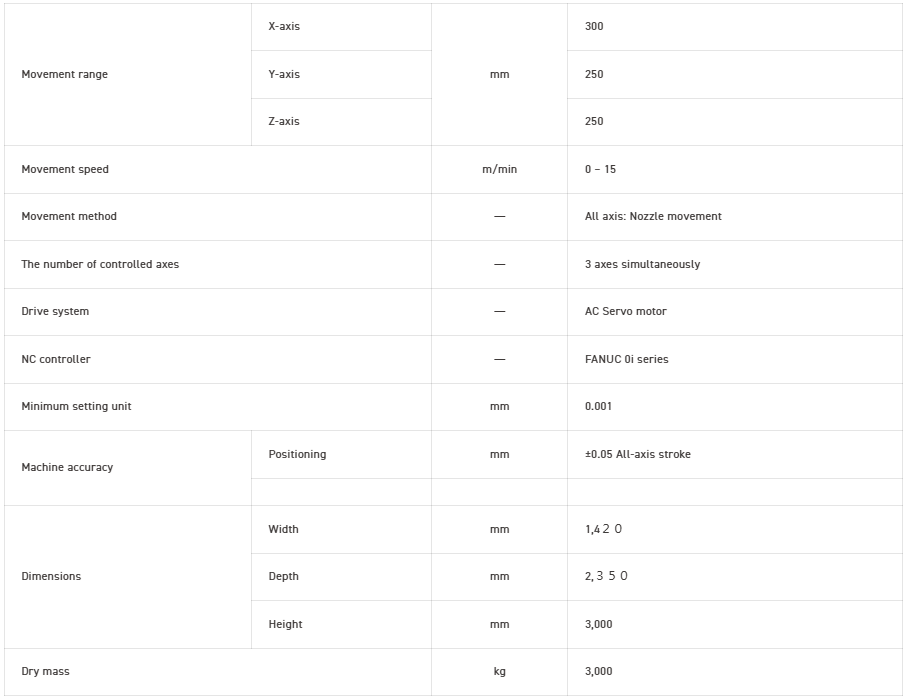

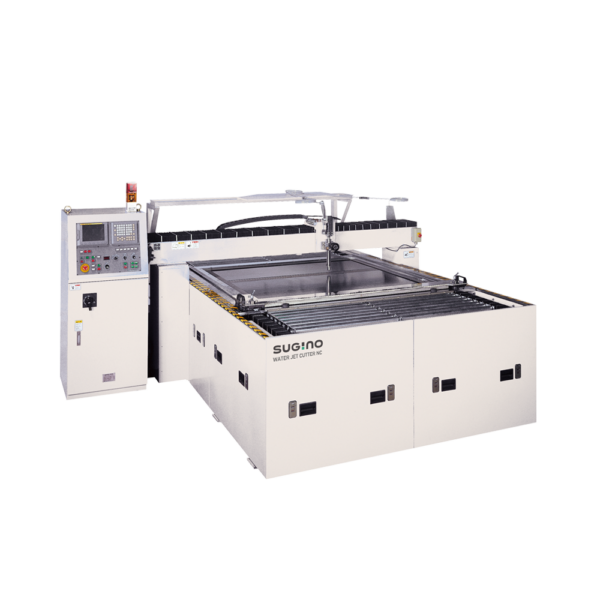

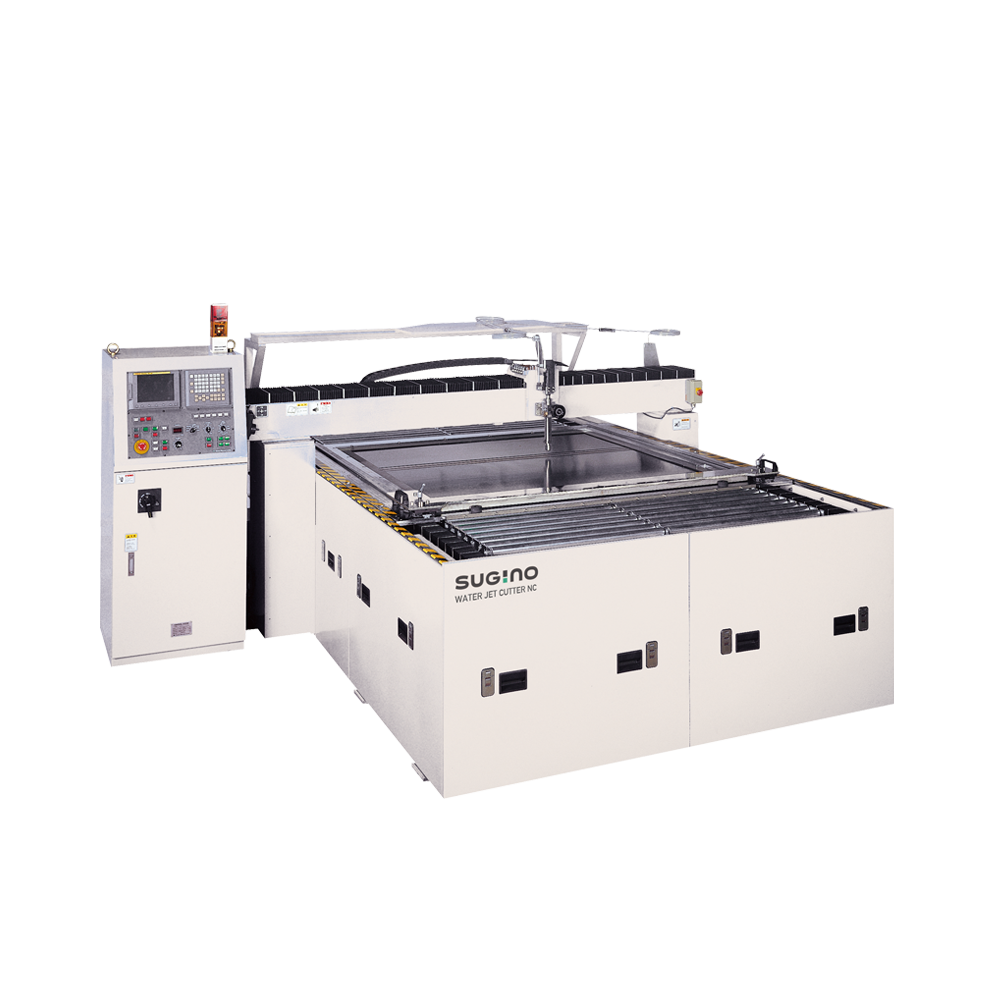

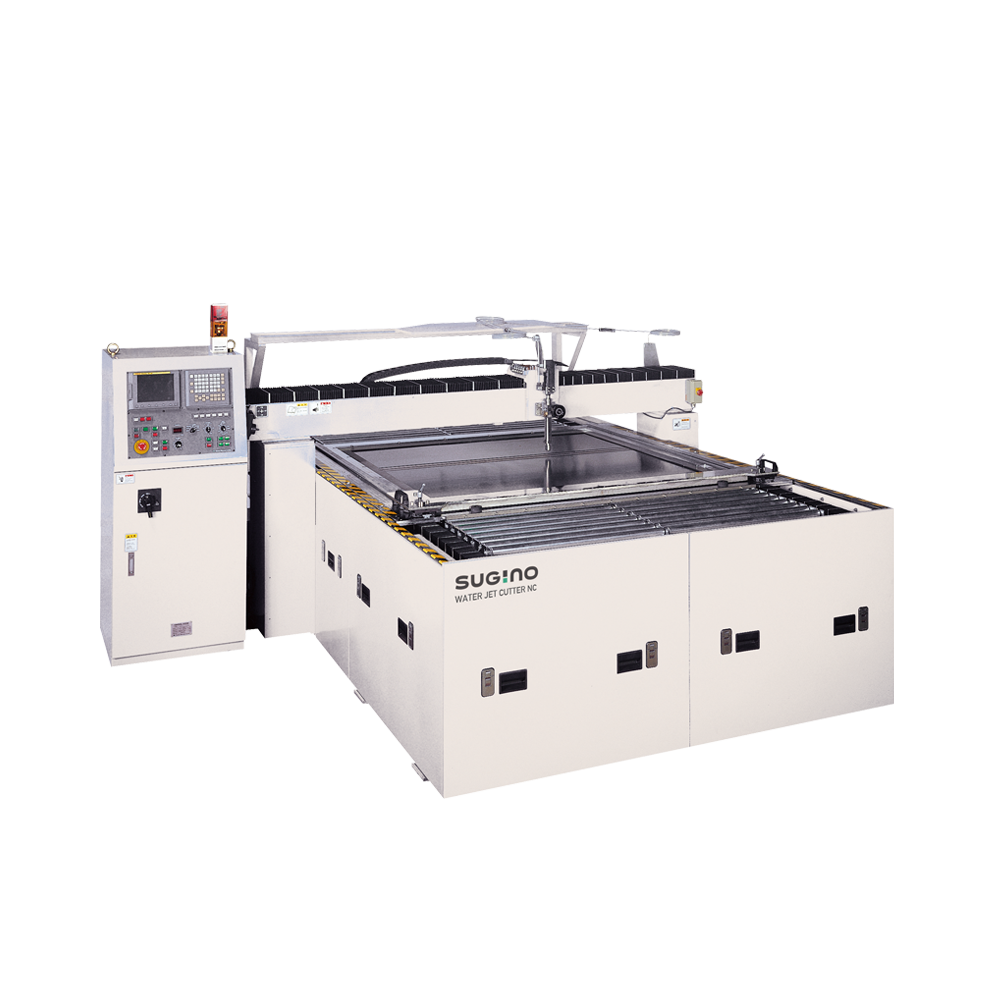

Water Jet Cutter NC: Ultrahigh-Pressure Water Cutting Equipment

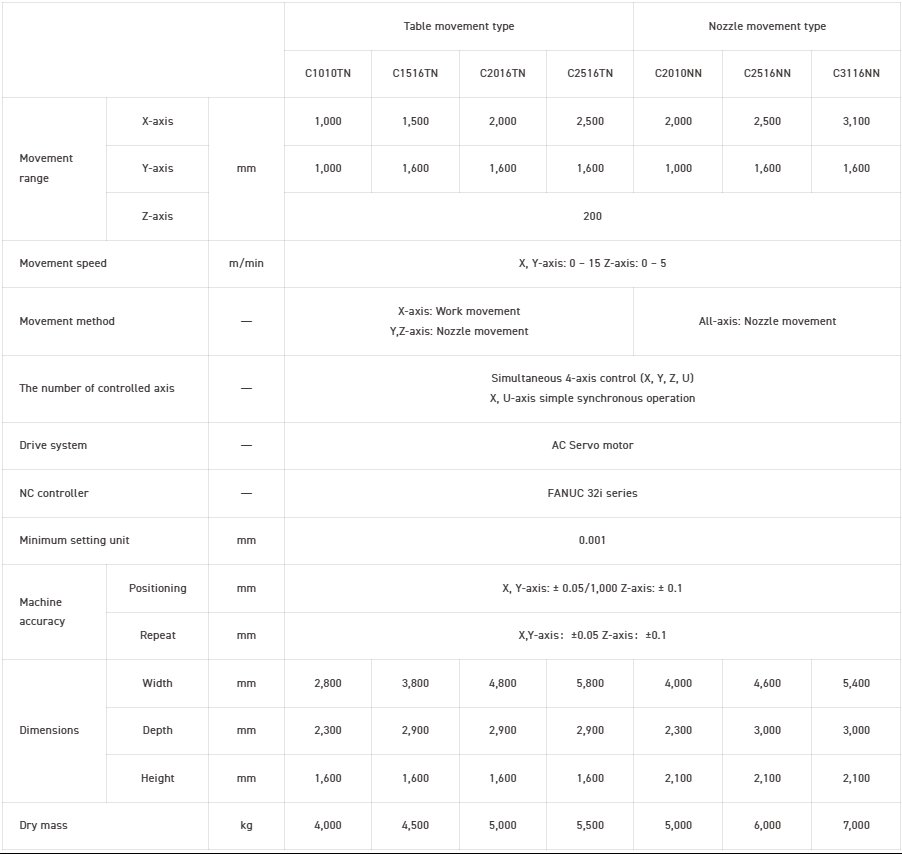

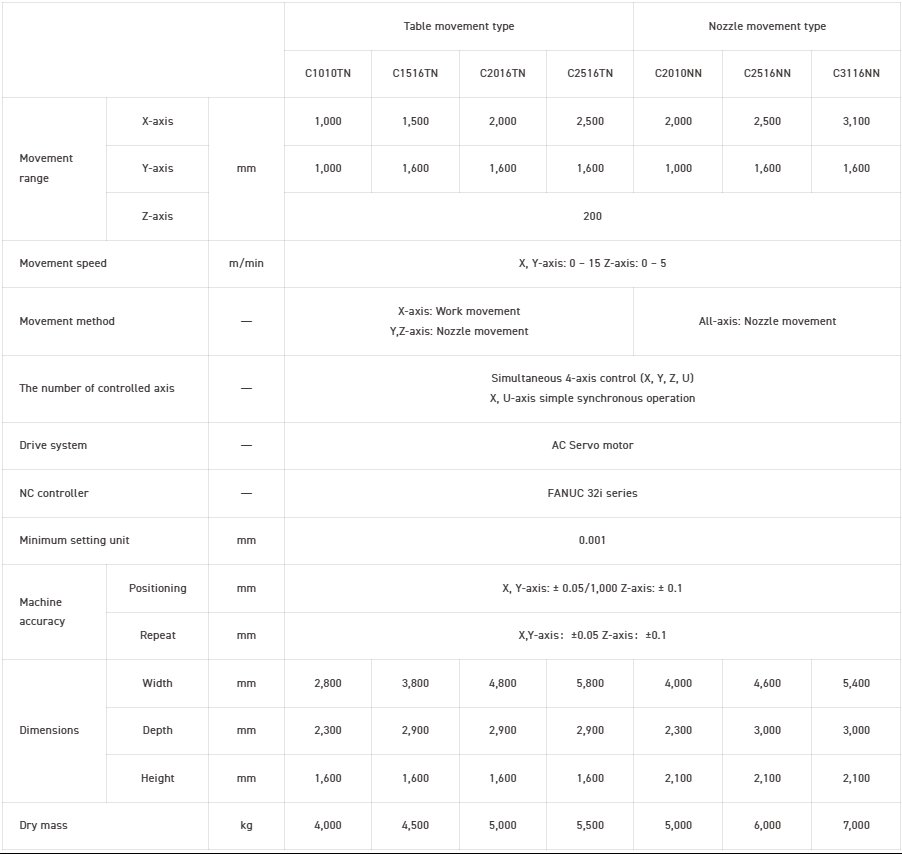

Water Jet Cutter TN/NN

Nozzle movement type

Suitable for fixing in place and cutting large objects.

■ Stroke

X-axis: Max.3,100 mm (nozzle movement)

Y-axis: Max.1,600 mm (nozzle movement)

Z-axis: 200 mm (nozzle movement)

Table movement type

Suitable for cutting small, light objects. Simultaneous movement of the nozzles and the catcher units receiving the water jets results in reduced water splash, reduced noise and easy maintenance.

■ Stroke

X-axis: Max.2,500 mm (table movement)

Y-axis: Max.1,600 mm (nozzle movement)

Z-axis: 200 mm (nozzle movement)

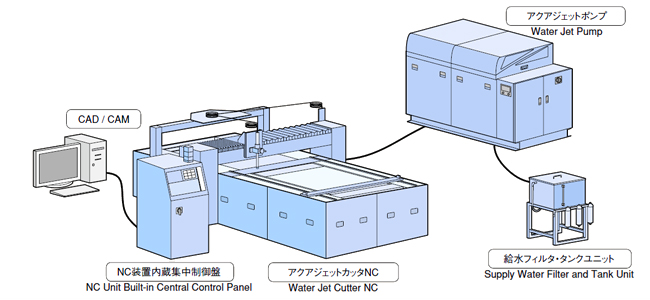

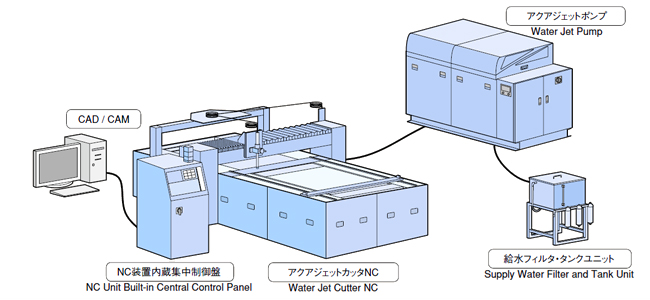

System chart :

Specifications :

Water Jet Cutter Rb: Multi-joint Robot Type Ultrahigh-Pressure Water Cutting Equipment

Robot of hanging type from the ceiling

Type in which Robot is fixed at the upper part of the device.

The device takes up little space, even when processing large workpieces.

Robot of floor setting type

Type in which Robot is fixed on the floor.

The efficiency of mounting and unmounting palette changers is drastically increased.

Processing Example :