SYNCHRO TAPPER SERIES :

MECHANICAL FEED TAPPING UNITS

SYNCHROTAPPER SSTB

Equipped with fast approach speed and fast return mechanism. A lightweight and compact mechanical feed type tapping unit.

“Synchro Tapper SSTB” can reduce the cycle time using the fast approach and fast return mechanism.

Compact and lightweight, with a high degree of freedom in mounting orientation, the dedicated machine can be space-saving.

The STB type has been renewed by replacing induction motor with a PM motor.

Max. tapping size… M10(Steel)/M12(Aluminum)

Features of the PM motor

1.Energy Saving

Energy consumption can be reduced by approximately 20% compared to a three-phase induction motor with the same output.

2.Global Support

Not subject to overseas high-efficiency motor regulations, making it easy to apply to equipment to be exported overseas.

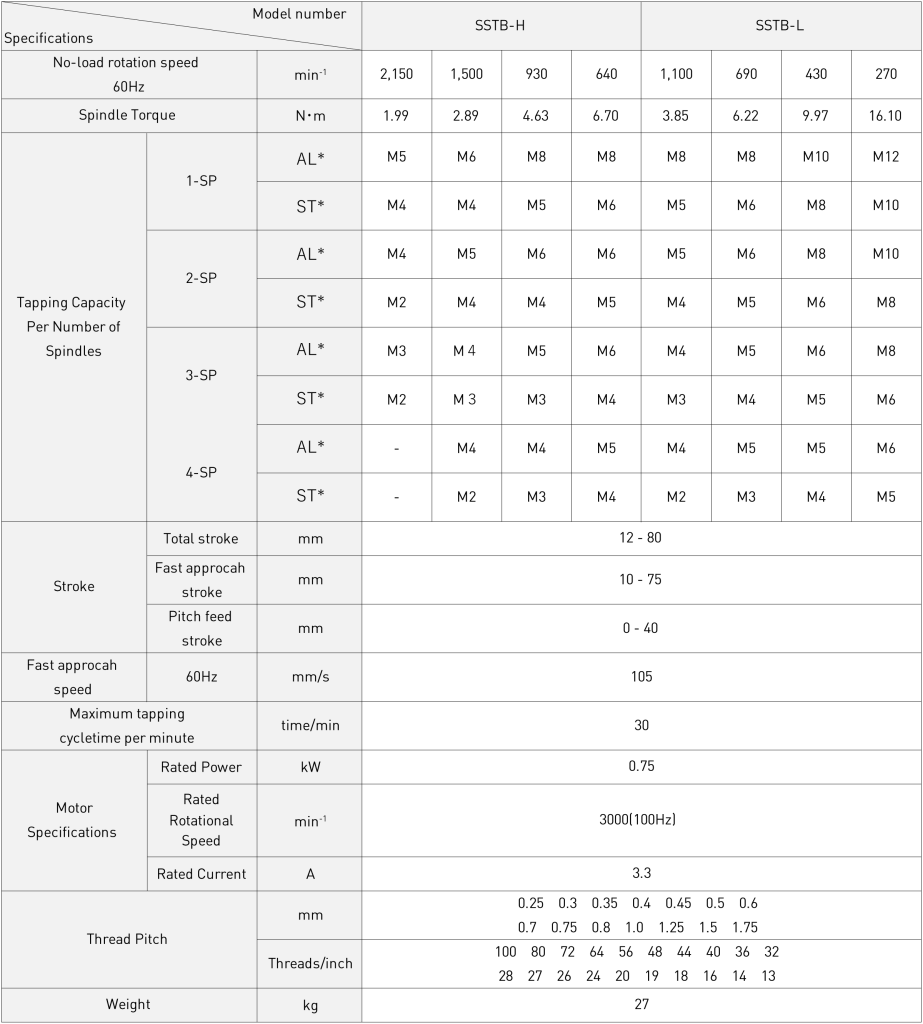

Specifications

Notes:

- Regarding the two-step description of tapping capacity per number of axis, a spiral tap or a point tap is used for the upper column of the tapping capacity chart and hand tap No.2 is used for the lower column.

- The allowance weight for the installable multi-spindle attachments is as follows: Waterproof and dust-proof measures for the Synchro Tapper main body are required for upward processing. For more information, please contact your nearest sales office.

(Sideways processing: 15 kg, Upward processing: 10 kg, Downward processing: 8 kg) - AL : Aluminum(ADC12) , FC : Cast iron(FC200) , ST : Steel(S45C)

Dimensions

Peripherals (Optional) :

Stand for unit installation

- Angle-adjustable stand “Flex Stand”

- Fixing attachment “Level Clamp”

Attachment

- Multi-Spindle Tapper Head

- 1-SP Tapper Head

Controller

- UC-30

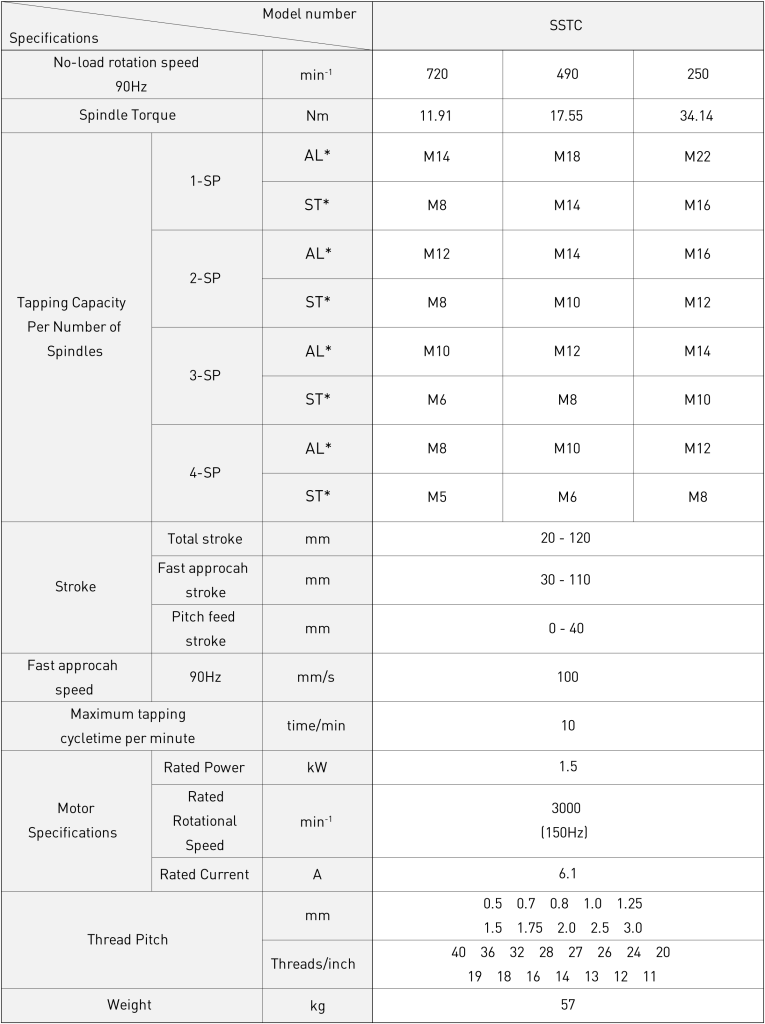

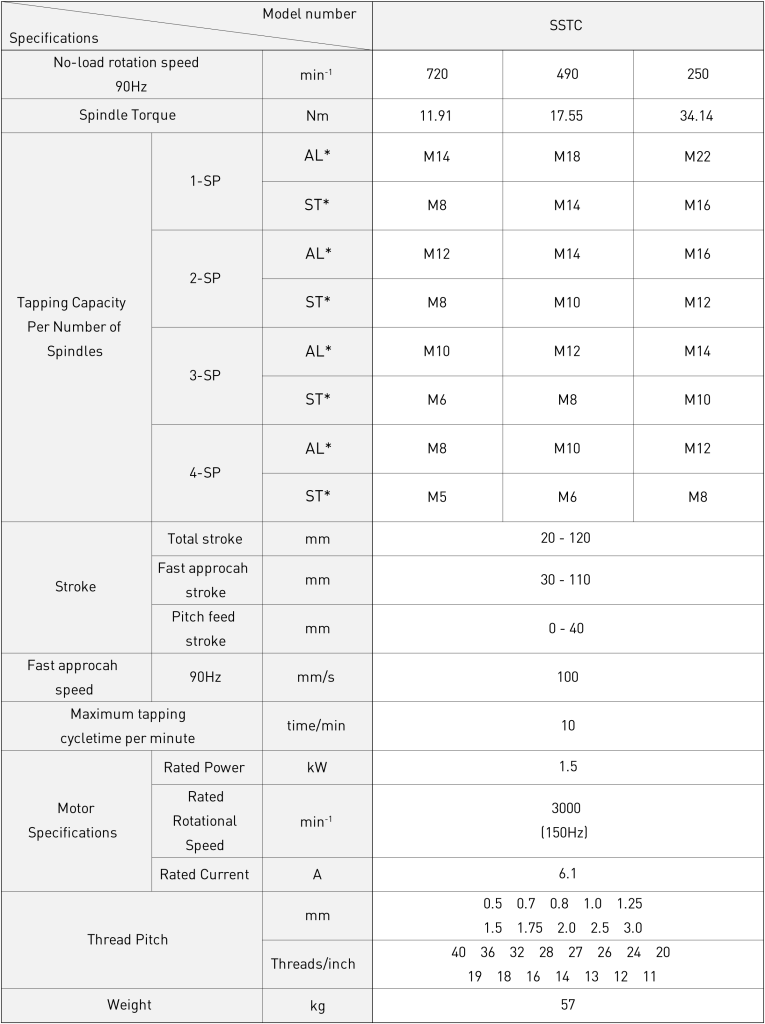

SYNCHROTAPPER SSTC

Mechanical Feed Tapping Unit allowing effective tapping with long stroke and equipped with fast approach and fast return mechanism to provide effective tapping!

“Synchro Tapper SSTC” can reduce the cycle time using the fast approach and fast return mechanism.

The long stroke specification makes it possible to avoid interference with peripheral equipment such as jigs.

Max. tapping size… M16(Steel)/M22(Aluminum)

Features of the PM motor

1.Energy Saving

Energy consumption can be reduced by approximately 20% compared to a three-phase induction motor with the same output.

2.Global Support

Not subject to overseas high-efficiency motor regulations, making it easy to apply to equipment to be exported overseas.

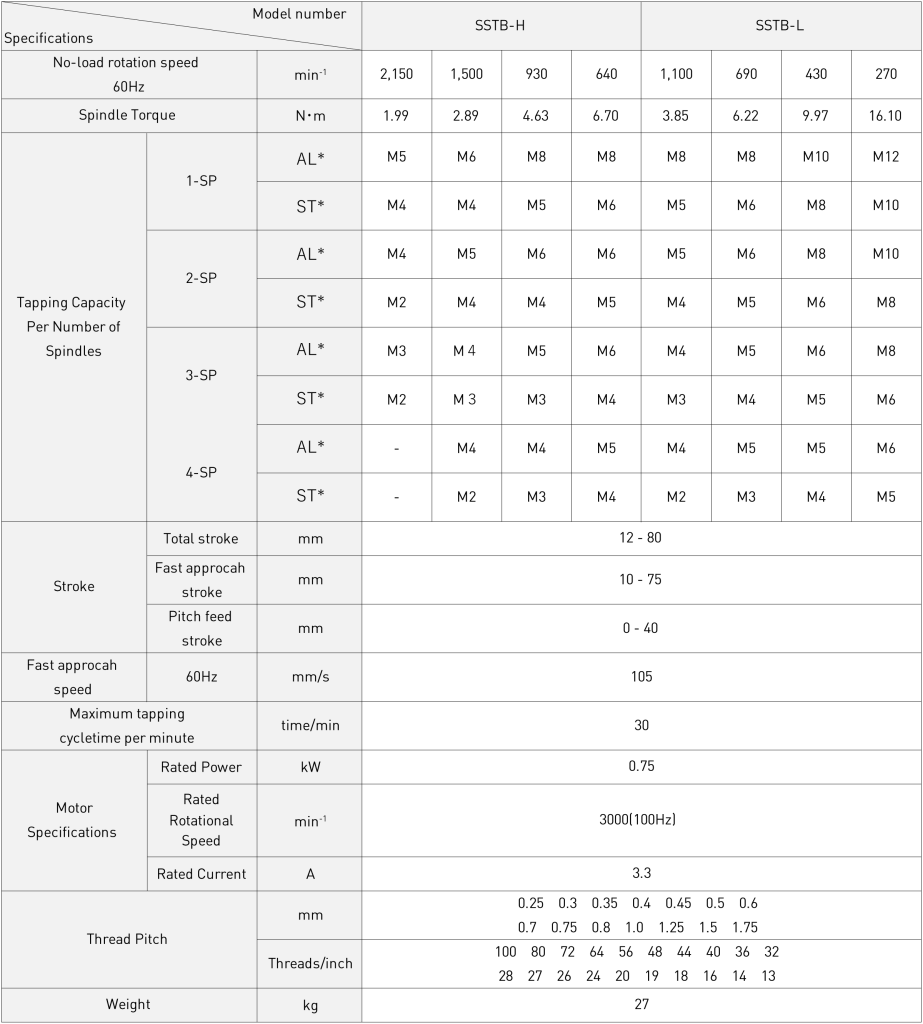

Specifications

- Regarding the two-step description of tapping capacity per number of spindle, a spiral tap or a point tap is used for the upper column of the tapping capacity chart and hand tap No.2 is used for the lower column.

In addition, tapping depth is a value of 1.5 times the screw diameter. - The allowance weight for the installable multi-spindle attachments is as follows: Waterproof and dust-proof measures for the Synchro Tapper main body are required for upward processing.

For more information, please contact your nearest sales office.

(Sideways processing: 35 kg, Upward processing: 25 kg, Downward processing: 25 kg) - AL : Aluminum(ADC12) , FC : Cast iron(FC200) , ST : Steel(S45C)

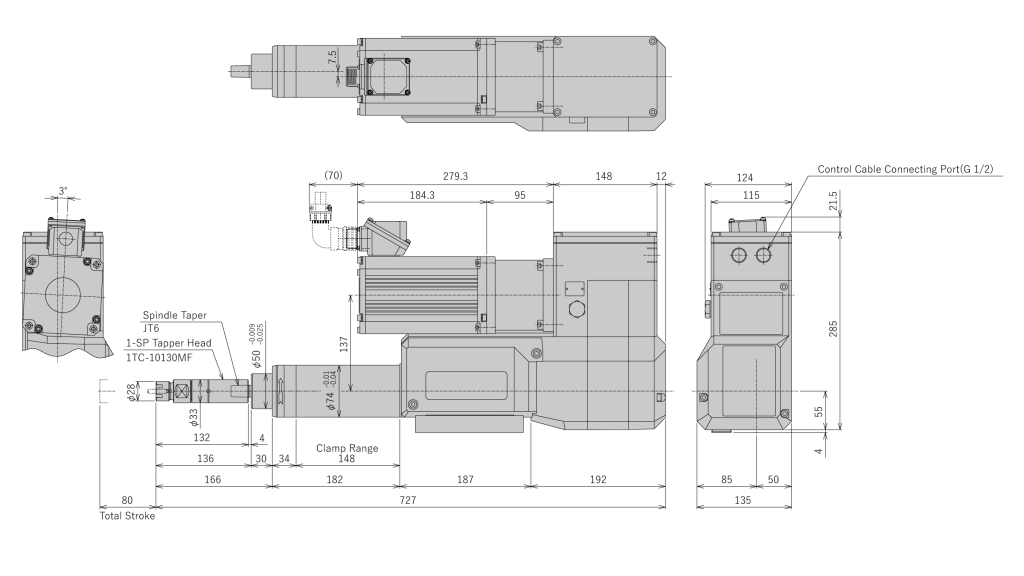

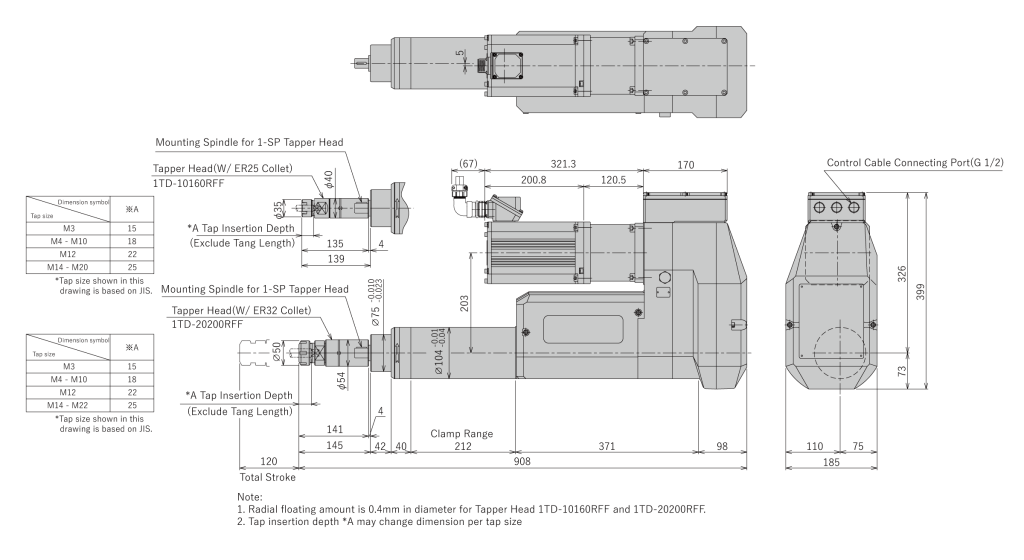

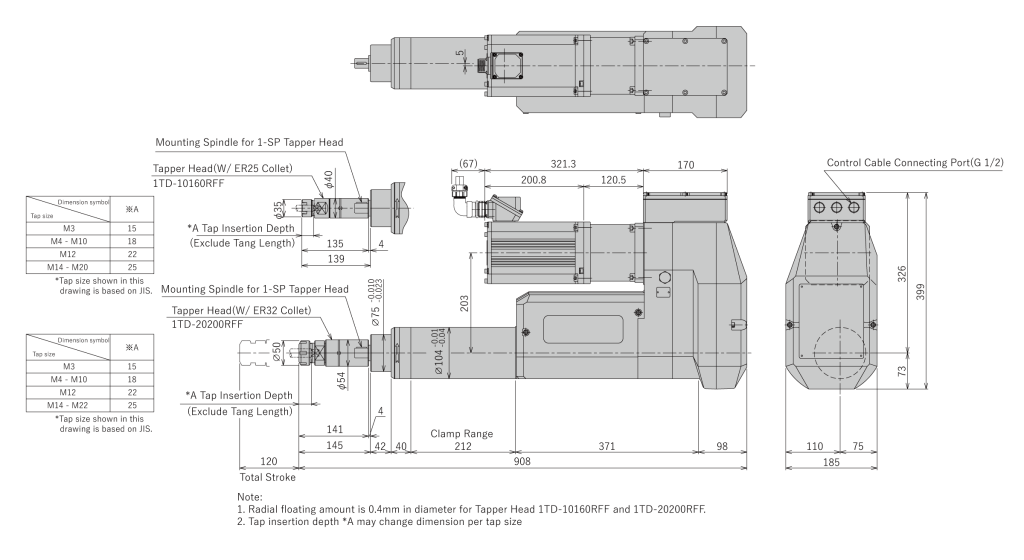

Dimensions

Peripherals (Optional) :

Stand for unit installation

- Angle-adjustable stand “Flex Stand”

- Fixing attachment “Level Clamp”

Forward/reverse end kit

- Operate Signal Kit

Hydraulic feed speed control unit

Hydro-Speed Regulator (spring return type)

Hydro-Speed Regulator (air return type)

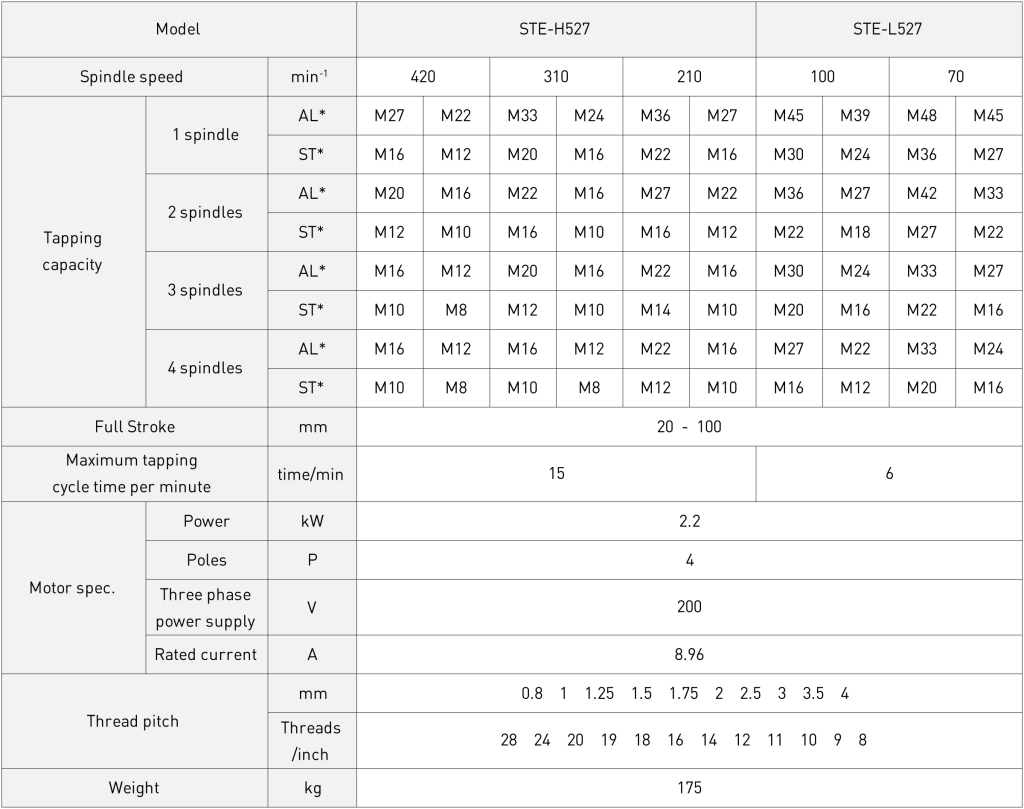

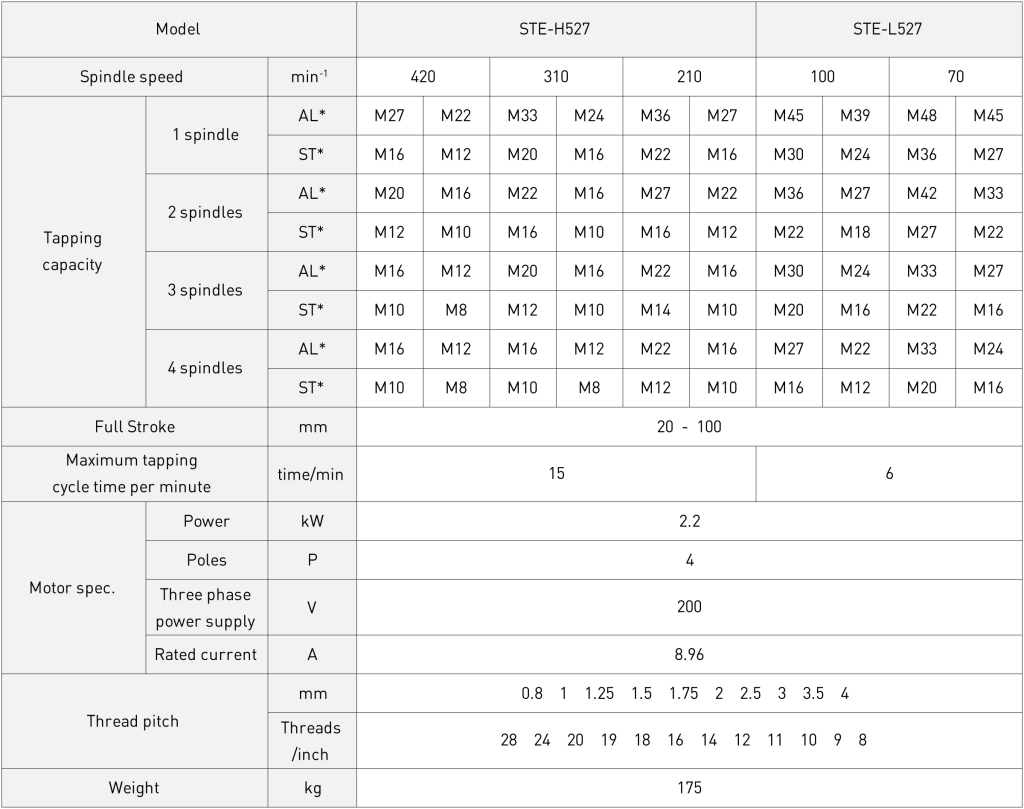

SYNCHROTAPPER STE-H/L

Mechanical Feed Tapping unit equipped with a multi spindle tapper head and with large-diameter tapping capability to provide highly efficient tapping.

“Synchro Tapper STE” is a Mechanical Feed Tapping unit equipped with a high-output motor that enables machining of large-diameter screws, tapered screws, and multi-thread screws.

In addition to tapping R3/4, M20 rolled threads in S45C steel, having a multi-axis tapper head can help bring down the cost of the tapping process.

Max. tapping size… M36(Steel)/M48(Aluminum)

Features of the PM motor

1.Energy Saving

Energy consumption can be reduced by approximately 20% compared to a three-phase induction motor with the same output.

2.Global Support

Not subject to overseas high-efficiency motor regulations, making it easy to apply to equipment to be exported overseas.

Specifications

Note:

- Regarding the two-step description of tapping capability per number of axis, a spiral tap or a point tap is used for the upper column of the tapping capacity chart and hand tap No.2 is used for the lower column. In addition, Tapping Depth is a value of 1.5 times the screw diameter.

- The rotation speed is the same for both 50 Hz and 60 Hz regions. (The motor is supplied by the inverter inside the controller, which operates at 60 Hz. )

- The rotation speed can be changed by replacing the pulleys. However, to change the rotation speed among the STE-H and STE-L models, the motor and belt must also be replaced in addition to the pulley.

- The allowance weight for the installable multi-axis attachments is as follows: Waterproof and dust-proof measures for the Synchro Tapper main body are required for upward processing. For more information, please contact your nearest sales office.

(Sideways processing: 100 kg, Upward processing: 90 kg, Downward processing: 90 kg) - AL : Aluminum(ADC12) , ST : Steel(S45C)

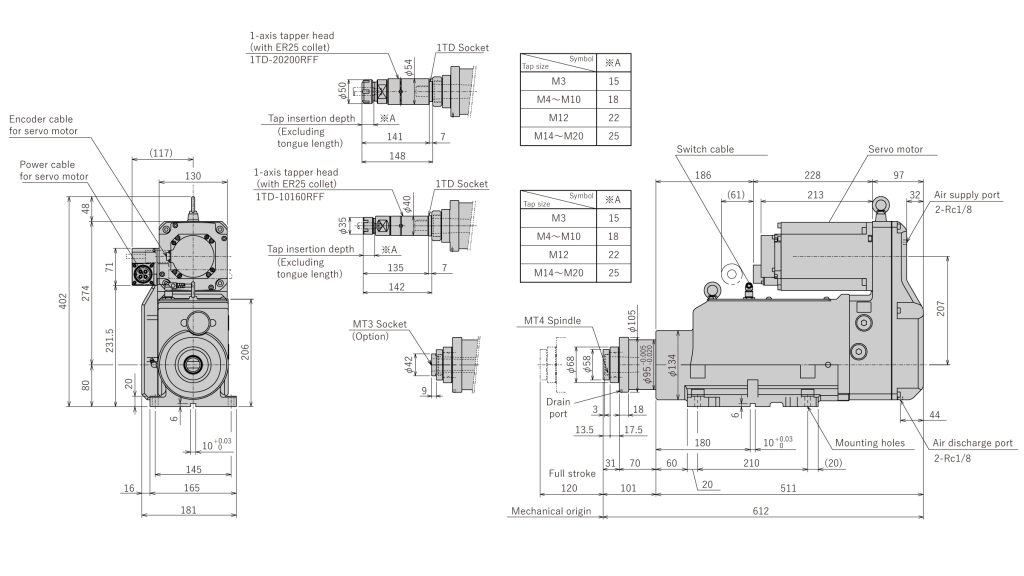

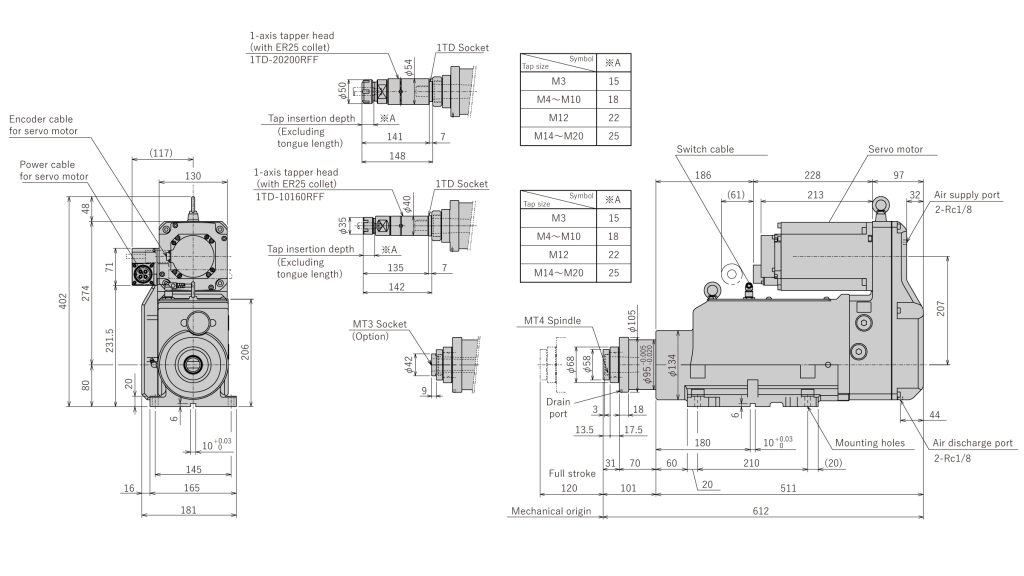

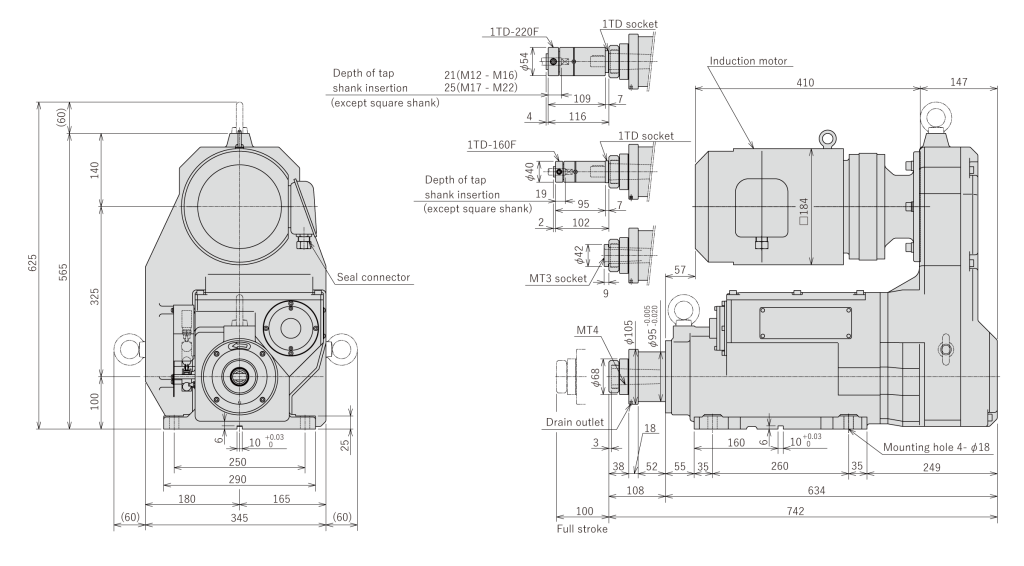

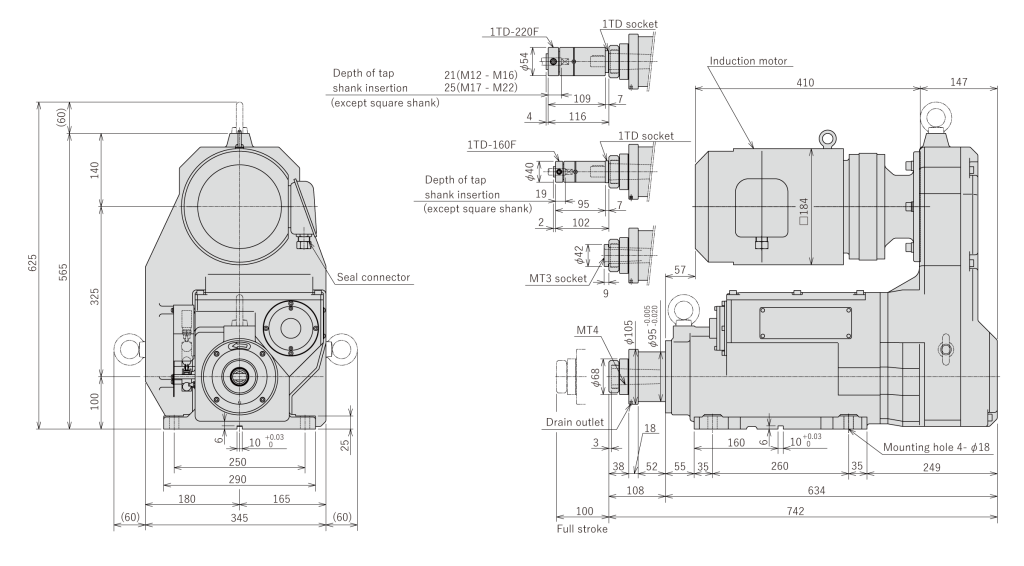

Dimensions

- A single tapper head can be attached by monting optional 1TD socket. 1TD-160F/220F is optional.

- Tap holders WFLP340-0/MT4(M16-M38) manufactured by NT Tools, Co. are attachable to MT4 spindle. Tap holder is to be supplied to our customers.

- WFLP240-0/MT3(M8-M22) can be attached by monting optional MT3 socket. Tap holder is to be supplied to our customers.

- SYUNCROTAPPER is attached horizontally, set drain outlet downward direction.

SYNCHRO TAPPER SERIES :

SERVO FEED TAPPING UNIT

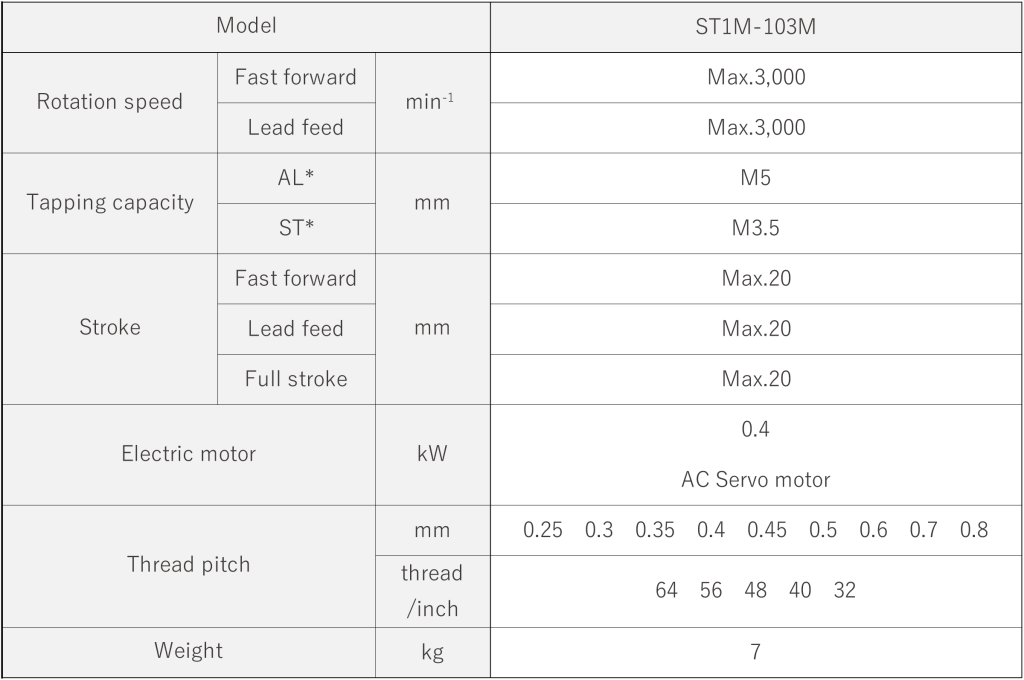

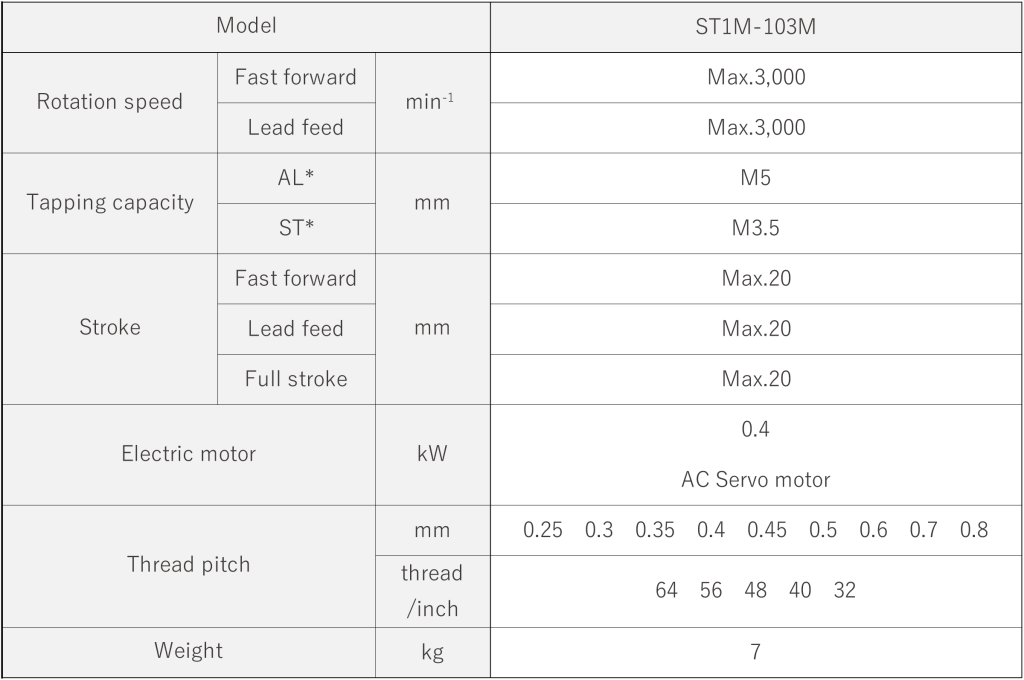

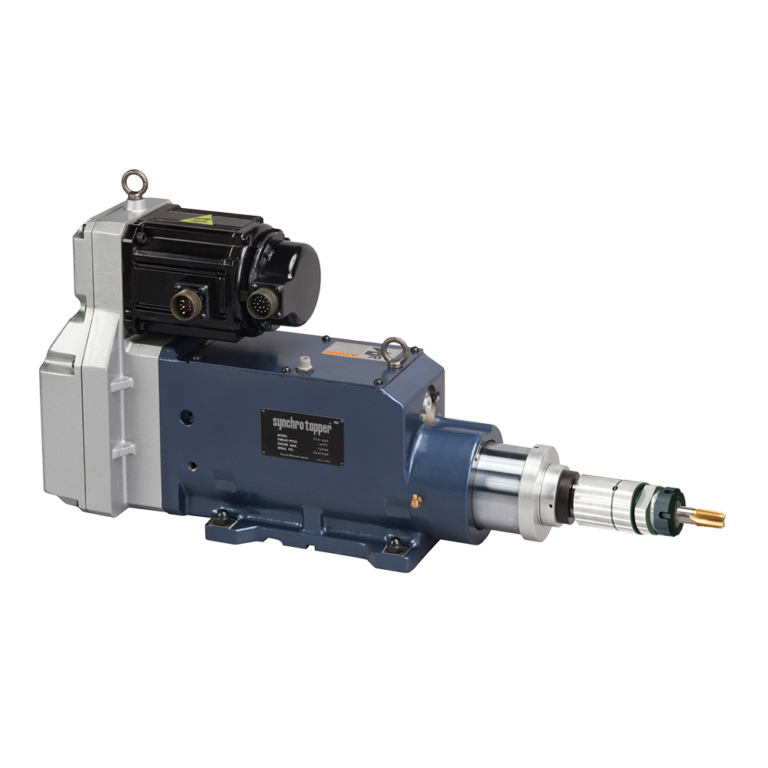

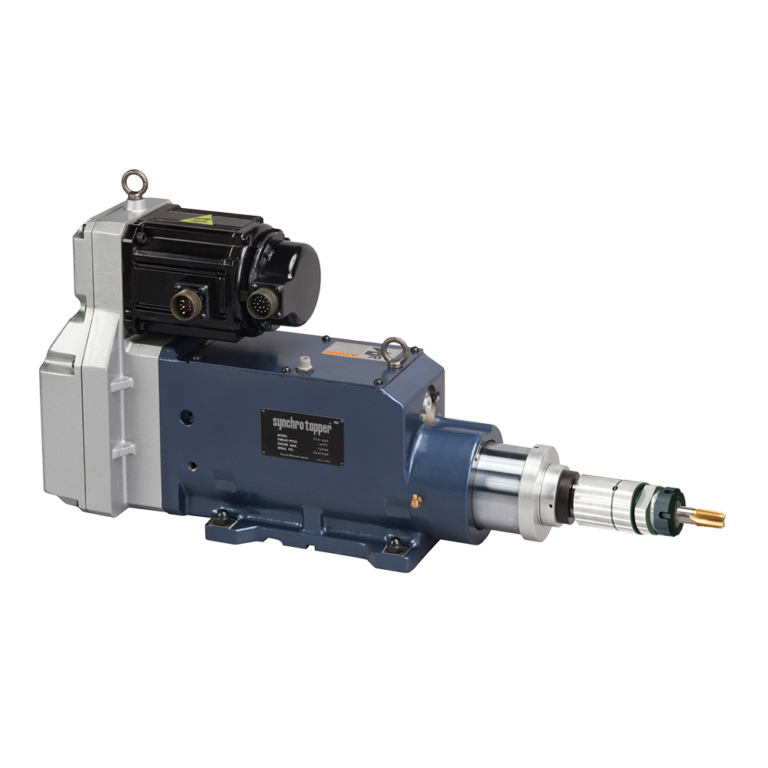

SYNCHROTAPPER ST1M

372.5 mm in full length! Compact and highly efficient servo feed tapping unit!

High-efficiency tapping is possible at a maximum of 3,000min-1

Up to 15 programs with different strokes and rotation speeds can be registered.

Max. tapping size… M3.5(Steel)/M5(Aluminum)

Specifications

Notes:

- Tapping capacity uses a spiral tap or point tap, and the tapping depth is 1.5 times the thread diameter.

- Determine the rotation speed based on the workpiece material, machinability, tap diameter and material, and cutting speed.

- Select a master screw assembly that matches the pitch of the tap you are using.

- AL : Aluminum(ADC12) , ST : Steel(S45C)

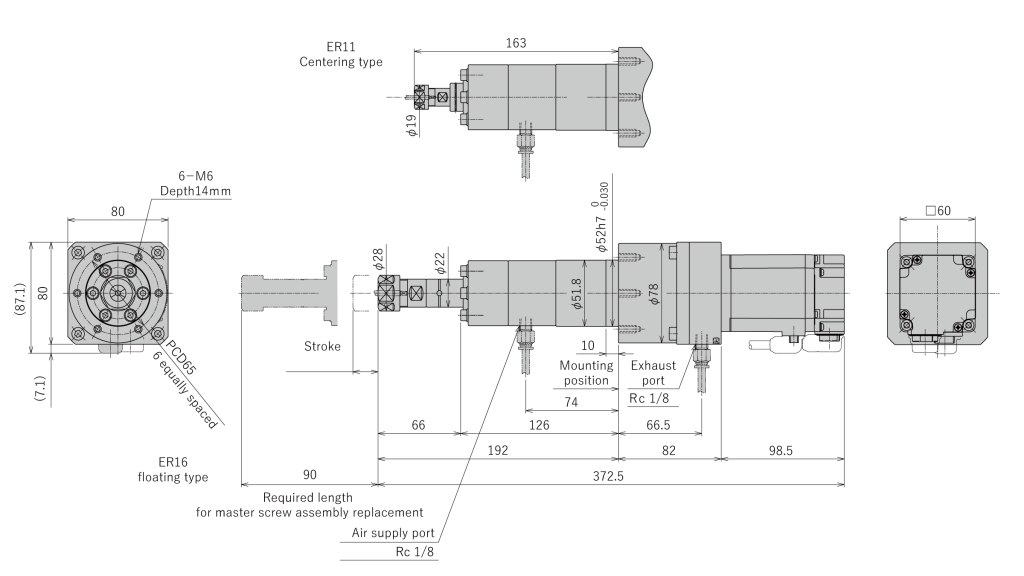

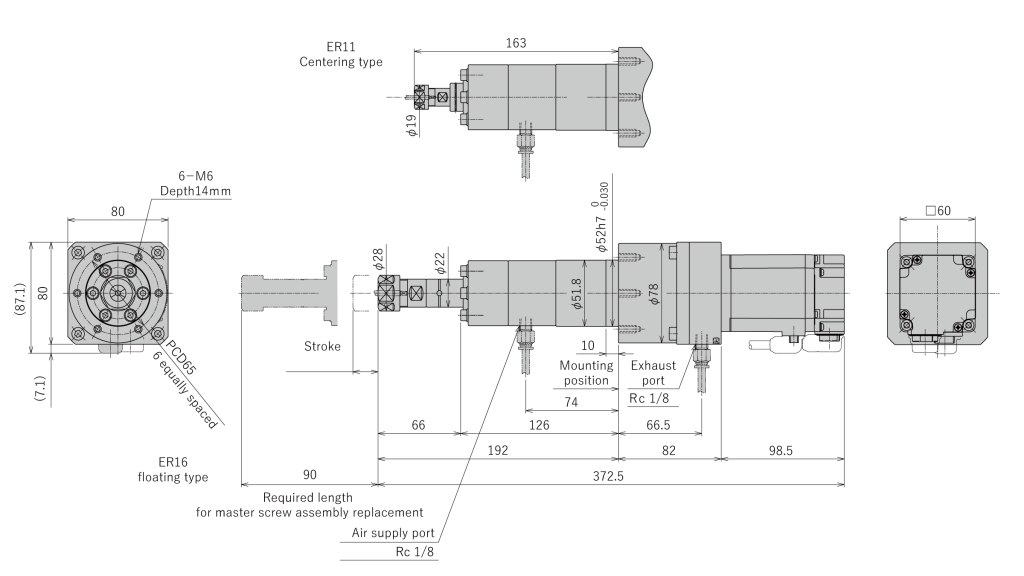

Dimensions

Note:

- There are two types of master screw assemblies available, each with a different tap retention mechanism. Please contact us for details.

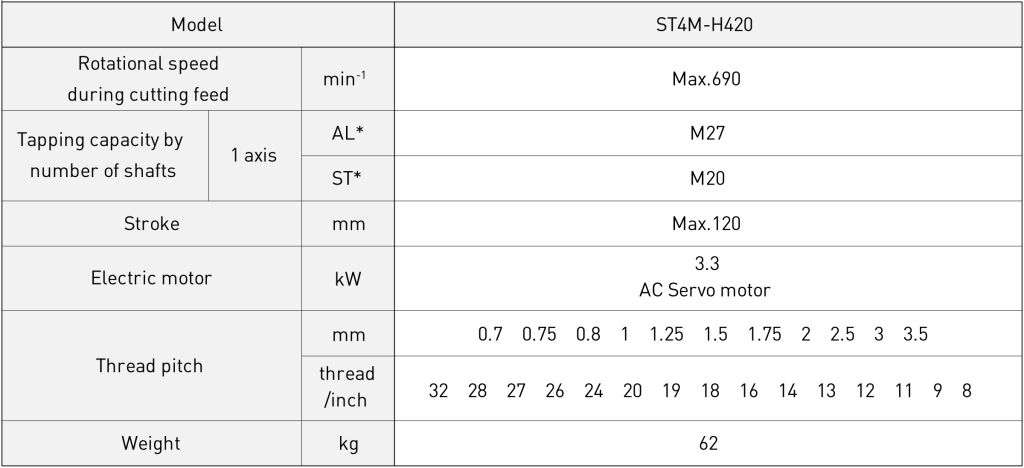

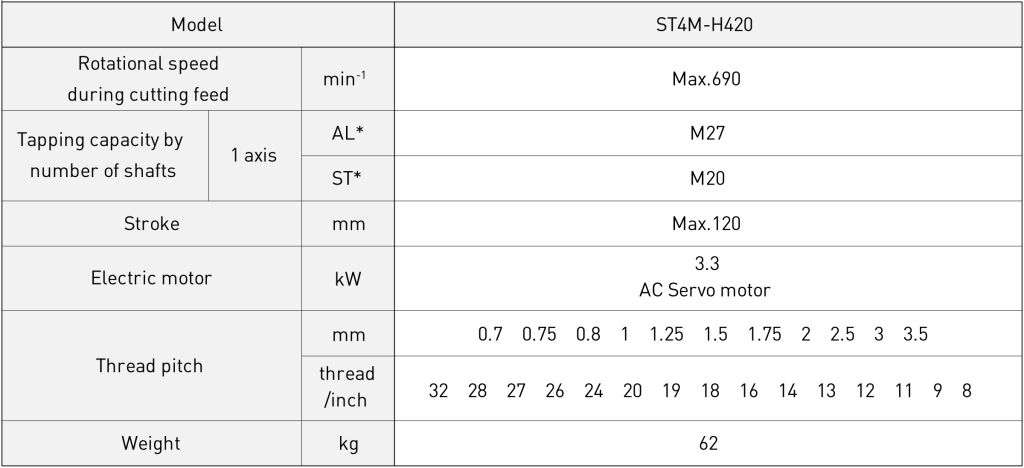

SYNCHROTAPPER ST4M-H

372.5 mm in full length! Compact and highly efficient servo feed tapping unit!

High-efficiency tapping is possible at a maximum of 3,000min-1

Up to 15 programs with different strokes and rotation speeds can be registered.

Max. tapping size… M3.5(Steel)/M5(Aluminum)

Specifications

Notes:

- Spiral taps and point taps are used for the upper level of tapping capacity, and hand tap No. 2 is used for the lower level. The tapping depth is 1.5 times the thread diameter.

- Determine the cutting feed rotation speed based on the workpiece material, machinability, tap diameter and material, and cutting speed.

- Please select a feed gear that matches the pitch of the tap you are using.

- The rapid traverse rate and cutting feed rate vary depending on the thread pitch and rotation speed. Please contact your nearest sales office for details.

- The allowable mass of attachments that can be attached is 40 kg in all directions.

- In the case of upward machining, waterproof and dustproof measures are required for the main body of the Synchro Tapper. Please contact your nearest sales office for details.

- AL : Aluminum(ADC12) , ST : Steel(S45C)

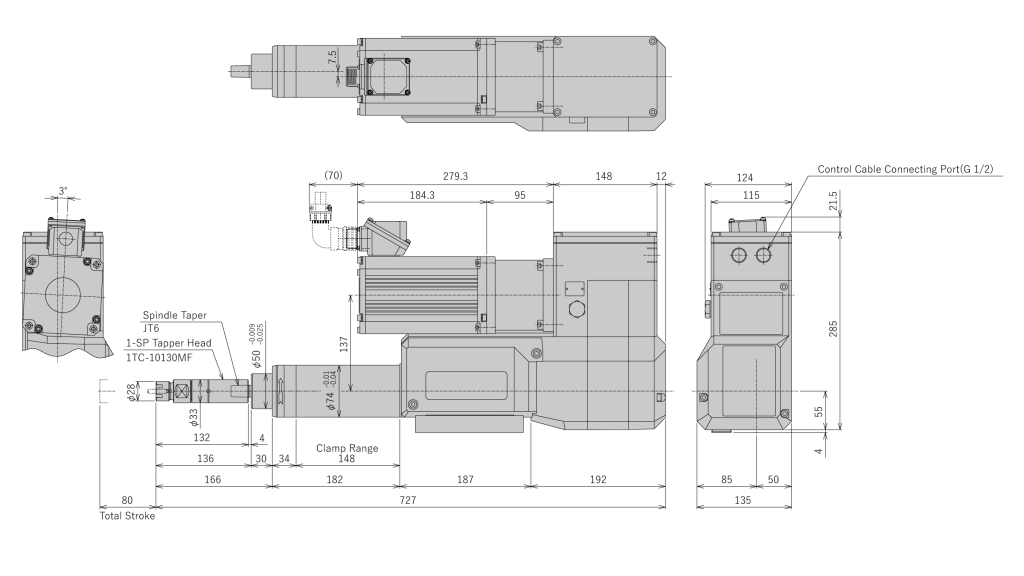

Dimensions