Brother S Series

SPEEDIO :

S300Xd2/ S500Xd2/ S700Xd2

The expansion of the machining area and the inclusion of a 28-piece magazine have expanded the range of target workpieces, facilitating process integration.

The evolution of the CNC-D00 control has improved environmental performance and productivity.

Highlights

Processing Area

Expanded range of applications due to increased Y/Z axis travel and table size

Productivity

Relentless pursuit of high productivity

Reducing waste through optimized control of integrated mechanical and electrical development

Processing Capability

A wide range of machining is possible with various spindle specifications and NC functions

Reliability

Reliability to maintain high productivity

Specifications

| Model | S300Xd2 / S300Xd2-5AX |

|---|---|

| Maximum spindle speed (min -1 ) | 12,000 10,000 High Torque (optional) 16,000, 27,000 (optional) |

| Axis travel distance (mm) | X:300 Y:450 Z:300 |

| Rapid feed speed (m/min) | X/Y/Z: 50/50/56 |

| Required floor space (mm) | 1,080×2,161 |

| Tool storage capacity (pieces) | 14/21 |

| Simultaneous 5-axis specification (5AX) | Selectable |

| Model | S500Xd2 / S500Xd2-5AX |

|---|---|

| Maximum spindle speed (min -1 ) | 12,000 10,000 High Torque (optional) 16,000, 27,000 (optional) |

| Axis travel distance (mm) | X:500 Y:450 Z:300/380* |

| Rapid feed speed (m/min) | X/Y/Z: 50/50/56 |

| Required floor space (mm) | 1,560×2,081 |

| Tool storage capacity (pieces) | 14/21/28 |

| Simultaneous 5-axis specification (5AX) | Selectable |

| Model | S700Xd2 / S700Xd2-5AX |

|---|---|

| Maximum spindle speed (min -1 ) | 12,000 10,000 High Torque (optional) 16,000, 27,000 (optional) |

| Axis travel distance (mm) | X:700 Y:450 Z:300/380* |

| Rapid feed speed (m/min) | X/Y/Z: 50/50/56 |

| Required floor space (mm) | 2,050×2,081 |

| Tool storage capacity (pieces) | 14/21/28 |

| Simultaneous 5-axis specification (5AX) | Selectable |

*380 is the value for the Z-axis 380mm specification (optional).

Processing Area

the Y/Z axis travel and table size. The expanded Y/Z axis travel and table size, as well as the inclusion of a 28-tool magazine,

expand the range of applications to process integration such as multi-faceted machining and variable-volume production.

Together with the wide range of specifications, it can handle a wide range of machining.

Increased Y-axis travel

The increased Y-axis travel expands the range of workpieces that can be machined.

Y-axis travel

400mm (conventional model) → 450mm

Increasing table size

The larger table size allows for a wider range of jig selection.

S300/S500Xd2 600X400 *

S700Xd2 800X400 *

↓

600 x 450mm

800 x 450mm

* Values for previous models

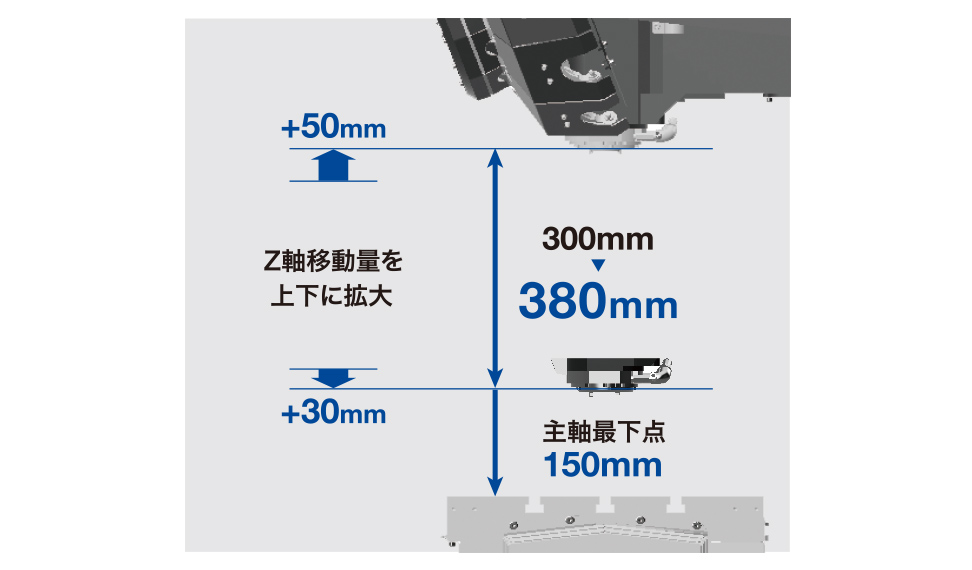

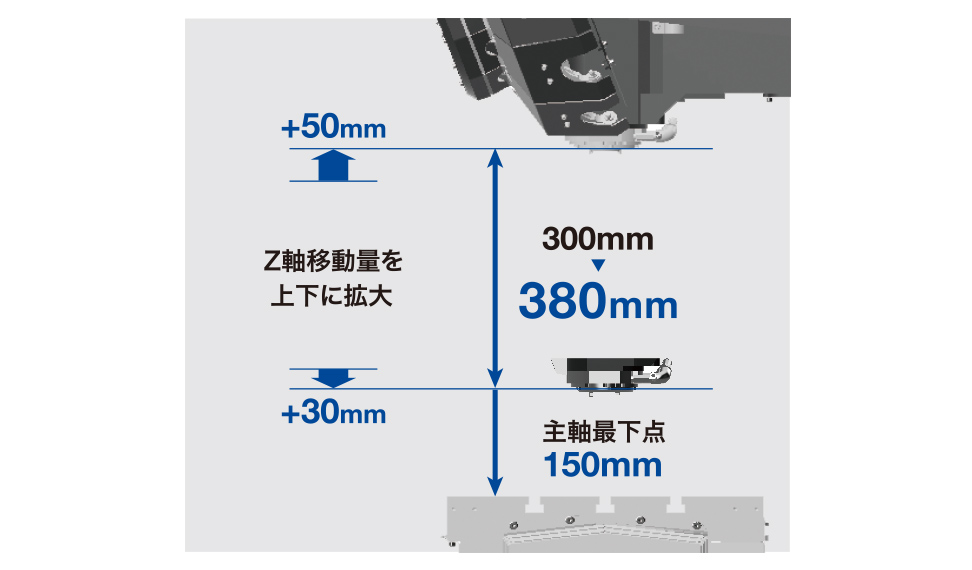

Z-axis 380mm specification added (optional) *

In addition to 300mm, the Z-axis travel can also be selected as 380mm. By expanding the Z-axis travel and the distance from the table top to the spindle end face both vertically, a wider machining area and improved tool accessibility in the Z-axis direction have been achieved.

* The Z-axis 380mm specification cannot be selected for the S300Xd2.

- Z-axis travel

300mm (standard) 380mm (optional)

- Distance from table top to spindle end

180-480mm (standard) 150-530mm (option)

28 magazines *

A compact drum-type magazine that allows for high-speed tool change. You can choose from 14, 21, or 28 tool magazines. The maximum tool weight can be up to 4kg.

* 28 magazines are not available for the S300Xd2.

- 28 magazines

Maximum tool size 110mm

Maximum tool mass 4kg

Total maximum mass of all tools 35kg

Tool-Tool 0.7 seconds

Productivity

Relentless pursuit of high productivity

Reducing waste through optimized control of integrated mechanical and electrical development

maximizing the performance of this highly reliable machine and achieving high productivity.

Non-stop ATC

High-speed tool change is achieved by accelerating and optimizing spindle start/stop, Z-axis lift, and magazine operation. Tools up to 3 kg can be changed in the shortest time, and heavy tools up to 4 kg can be changed with minimal increase in time.

14/21 pieces (Standard tool) Tool-Tool: 0.6s / Chip-Chip * : 1.2s

28 pieces (Standard tool) Tool-Tool: 0.7s / Chip-Chip * : 1.3s

28 pieces (Heavy tool) Tool- Tool: 0.8s / Chip-Chip * : 1.4s

* Value for Z axis 300mm specification

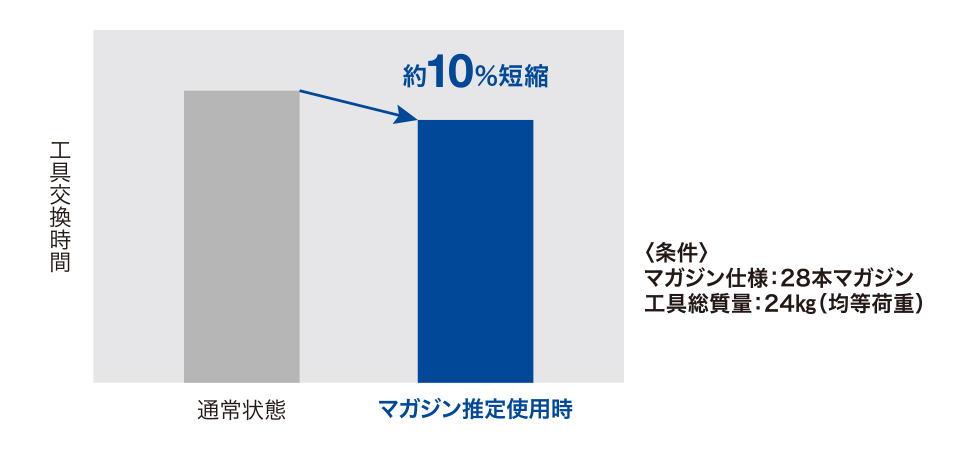

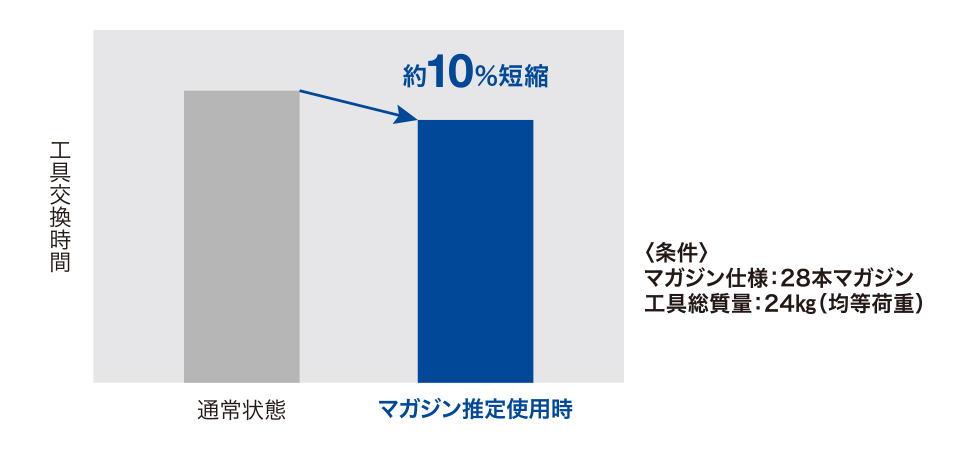

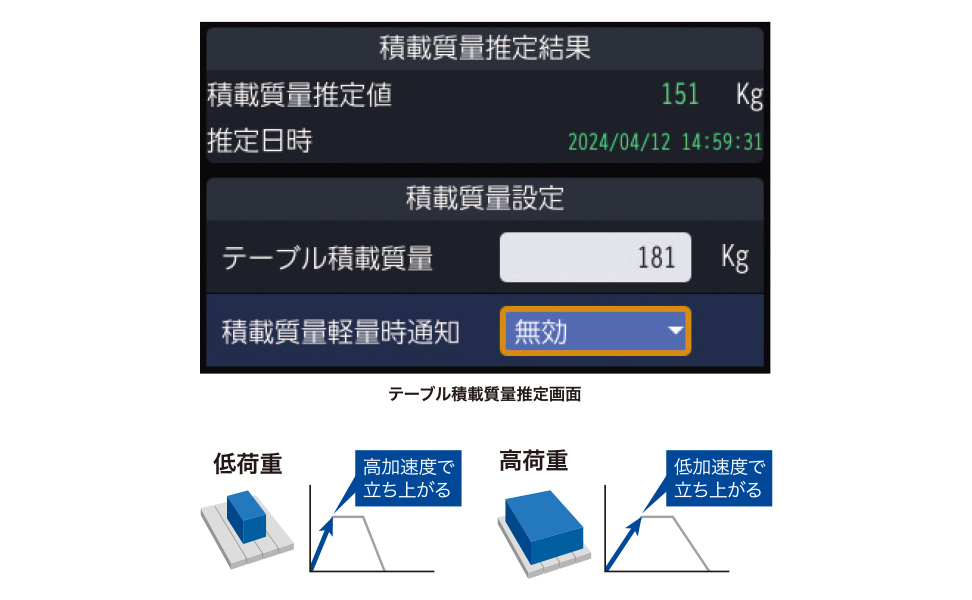

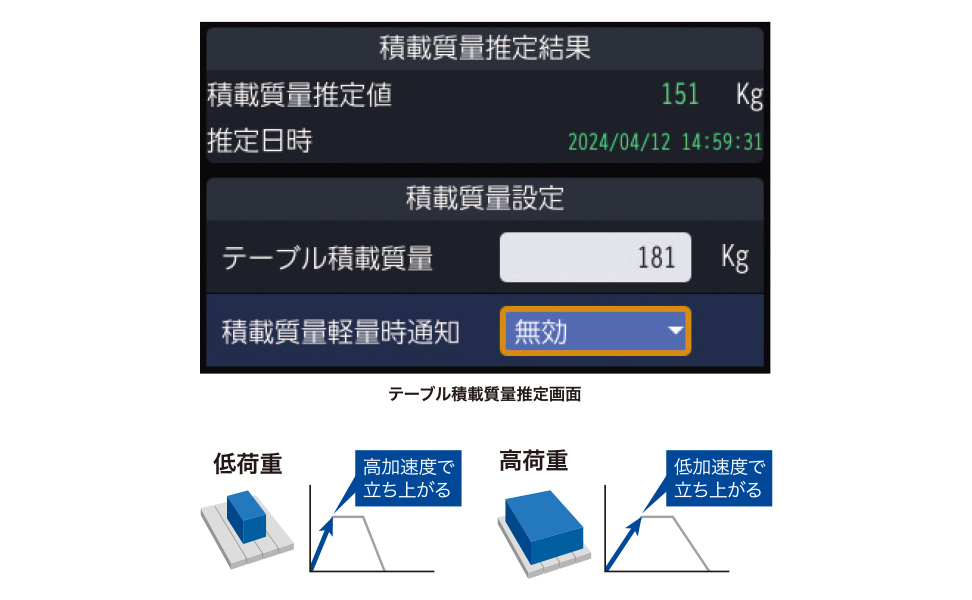

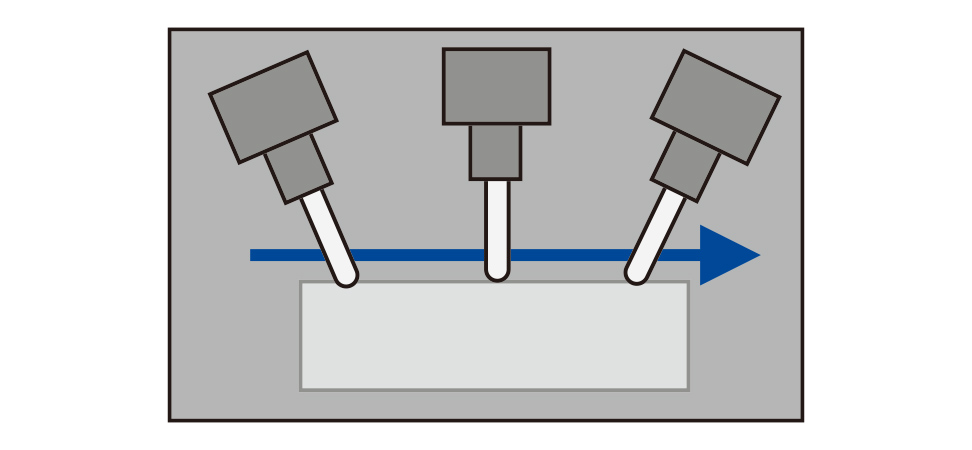

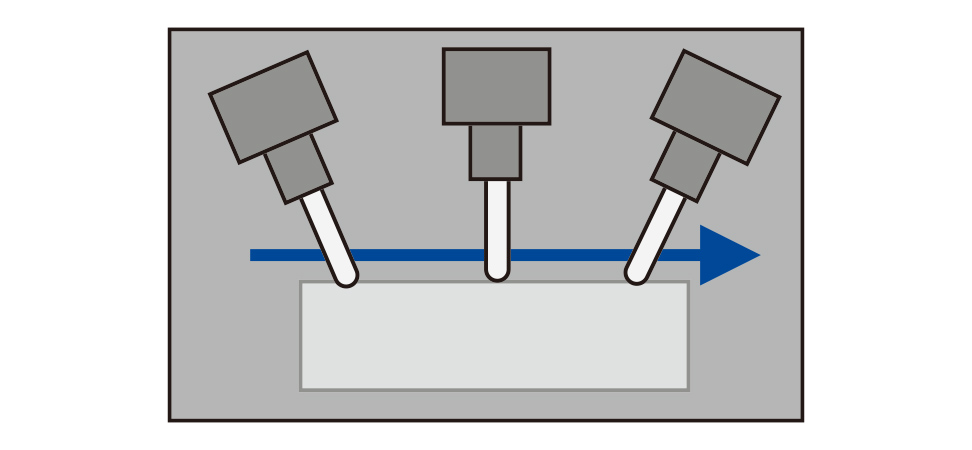

Magazine loading condition estimation

The inertia and unbalanced load of the tools loaded in the magazine are estimated, and the optimum acceleration value for the magazine axis is set. It also has a function that automatically updates the acceleration to the optimum value by estimating even during program operation.

High acceleration/deceleration spindle

High-speed tool change is achieved by accelerating and optimizing spindle start/stop, Z-axis lift, and magazine operation. Tools up to 3 kg can be changed in the shortest time, and heavy tools up to 4 kg can be changed with minimal increase in time.

Spindle start/stop time 0.15s or less *

*High torque specification

High acceleration Z axis

The acceleration of the Z-axis, which has a lot of movement, is best in its class, helping to reduce cycle times.

Z-axis acceleration up to 2.2G *

Improved automatic door opening and closing speed

Improved automatic door opening and closing speed enables significant reduction in setup time.

Automatic door opening/closing time reduced by 20%.

Simultaneous Operation

By performing tool change and positioning of the XY and additional axes at the same time, wasted time is reduced

Optimal acceleration settings XY axis

The load mass is estimated by moving the table, and the optimal values for XY-axis acceleration are set.

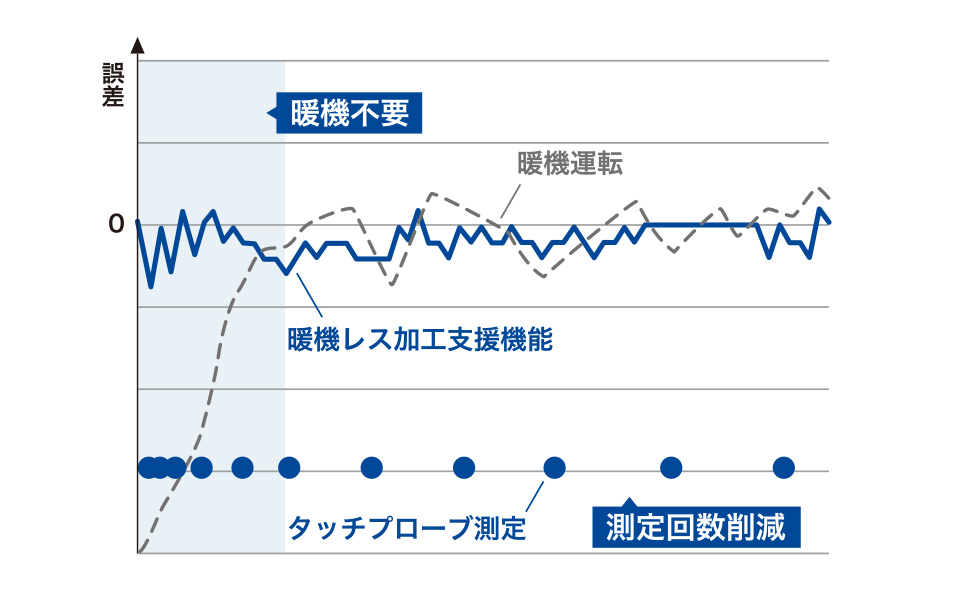

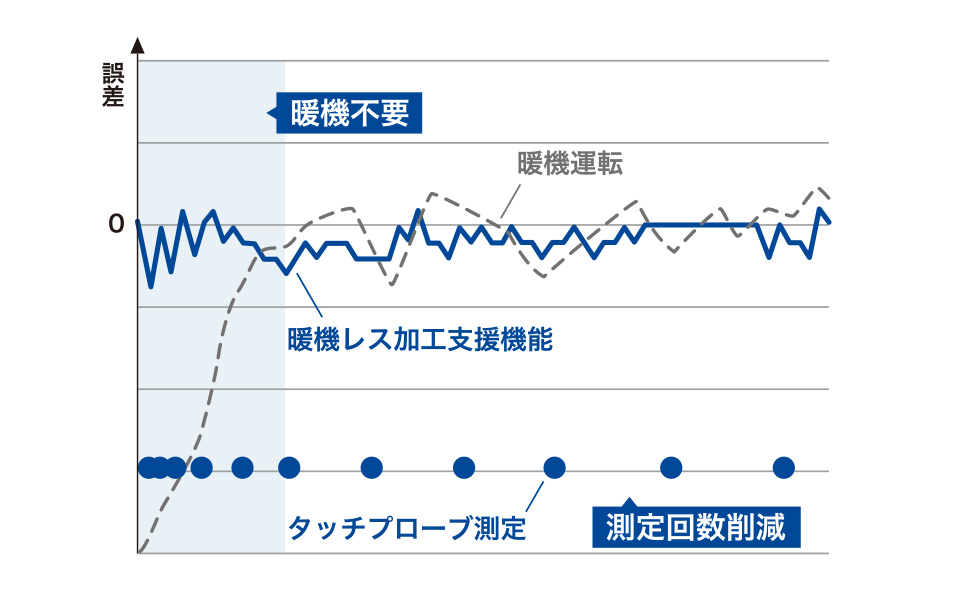

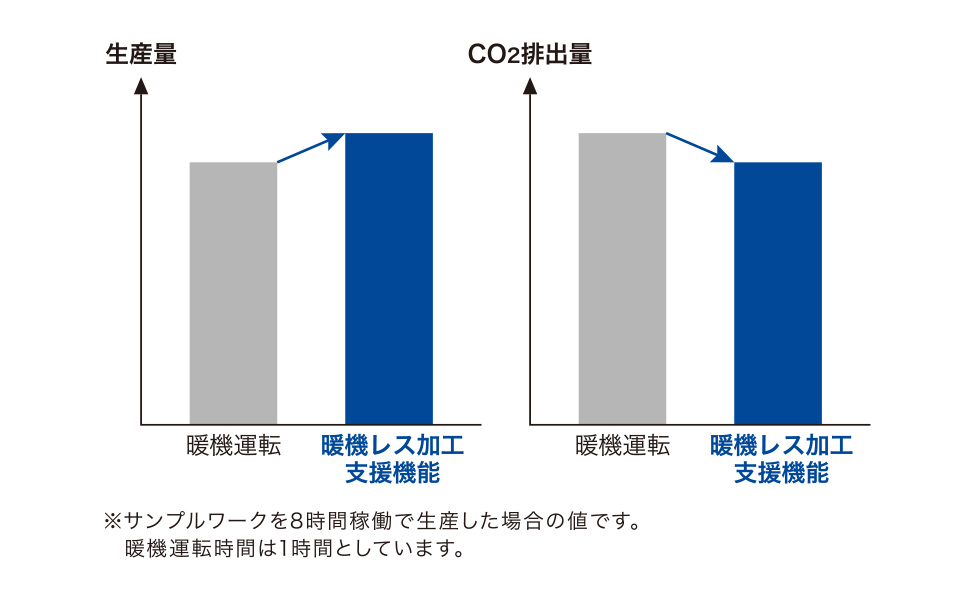

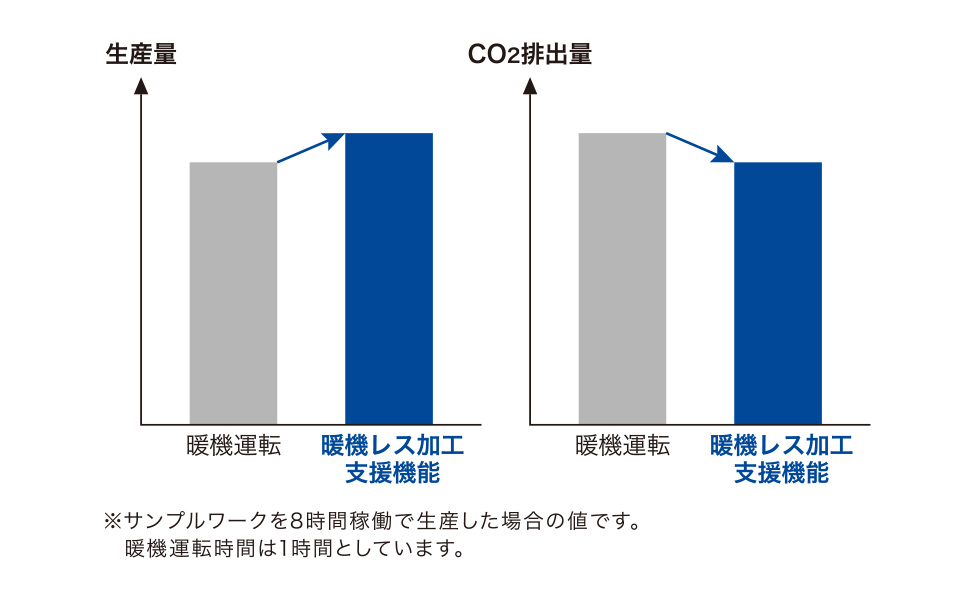

Warm-up-free processing support function

The load mass is estimated by moving the table, and the optimal values for XY-axis acceleration are set.

Processing Capability

A wide range of machining is possible with various spindle specifications and NC functions

We have a wide range of spindles that can be used in a variety of industries, from automobiles, semiconductors, and precision parts to IT-related equipment.

The NC device achieves high speed and high precision in 3D machining and simultaneous 5-axis machining .

* Simultaneous 5-axis machining function is only available on S300/500/700Xd2-5AX.

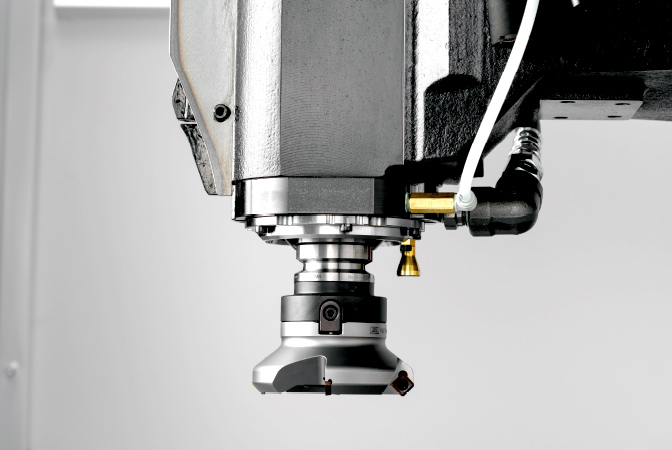

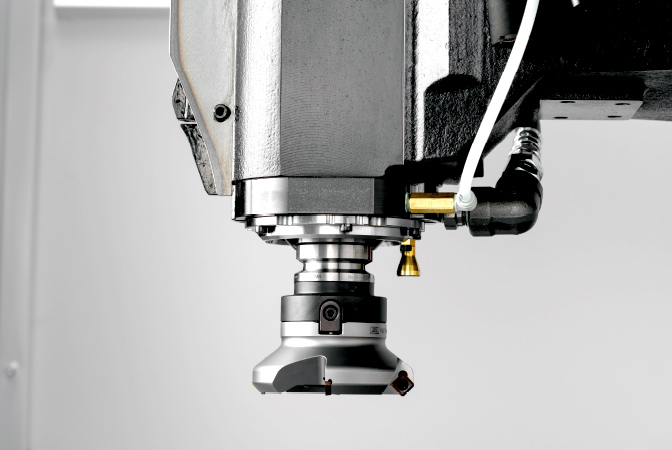

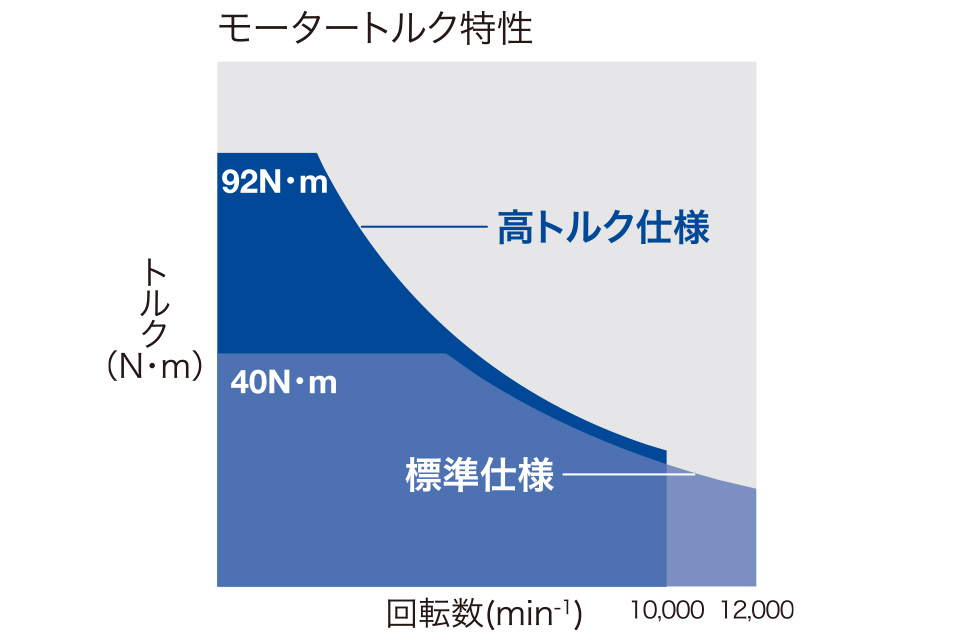

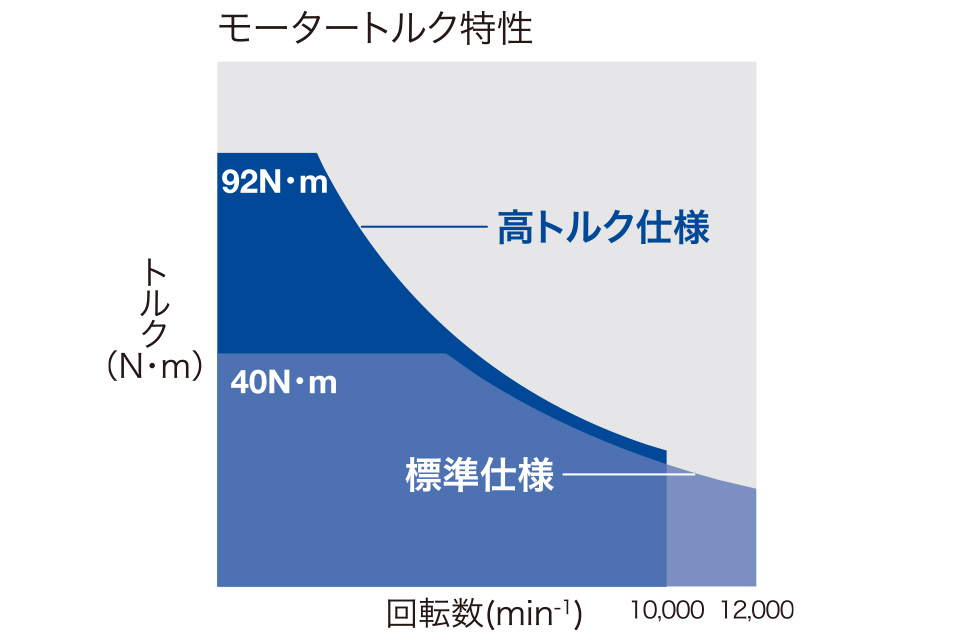

Newly developed 12,000min -1 high-efficiency spindle motor

The standard motor has been upgraded from the previous 10,000 min -1 to a newly developed 12,000 min -1

specification. It maintains the spindle torque in the medium to high speed rotation range, contributing to further shortening the machining time for high-speed, high-efficiency machining of aluminum and steel.

- 12,000min -1 standard specification

Maximum torque 40N・m

Maximum power output 18.9kW- High torque specification (optional)

Maximum torque 92N・m

Maximum power output 26.2kW

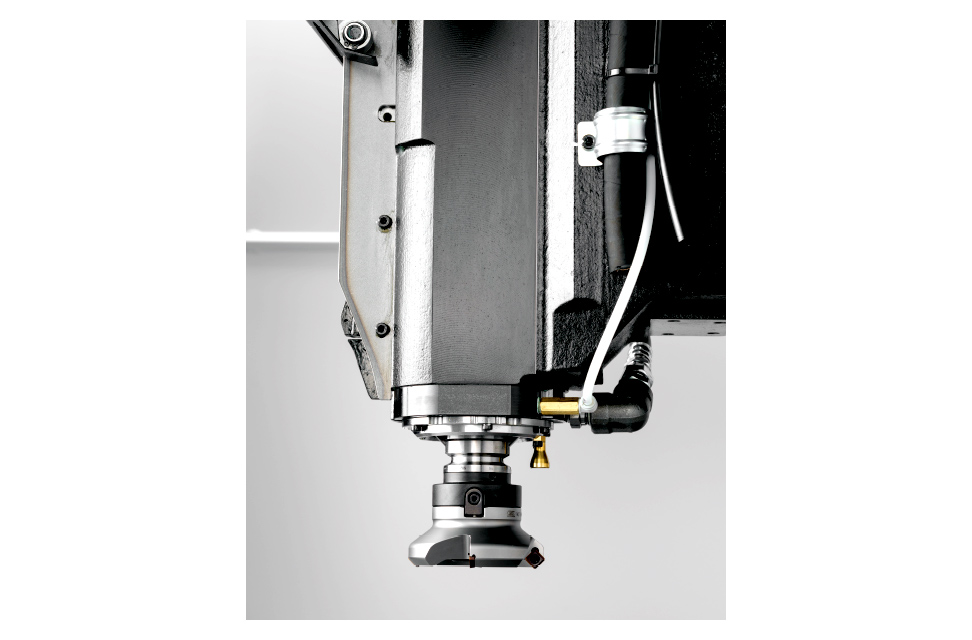

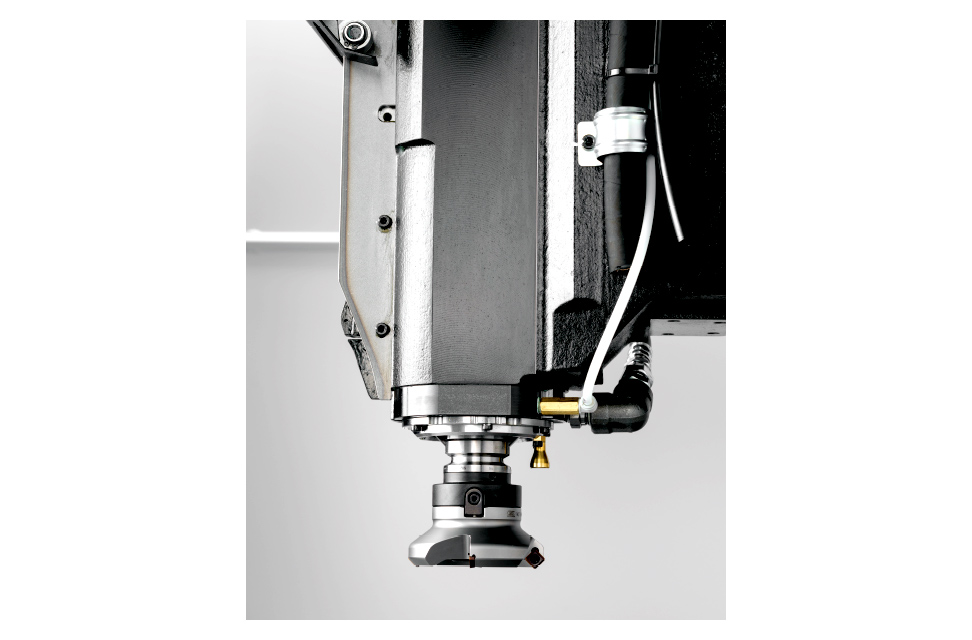

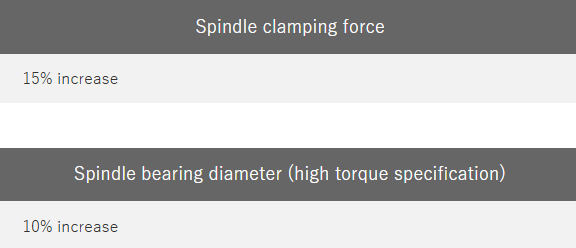

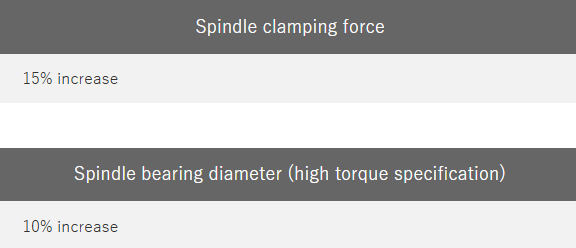

Improved spindle rigidity

The 10,000min -1 high torque specification (optional) has a larger spindle bearing diameter and increased rigidity,

making it effective for machining a wide range of workpieces, including heavy cutting of iron.

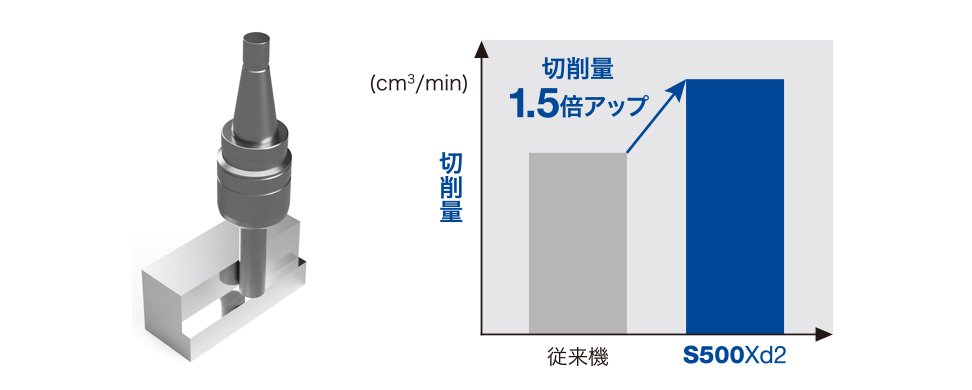

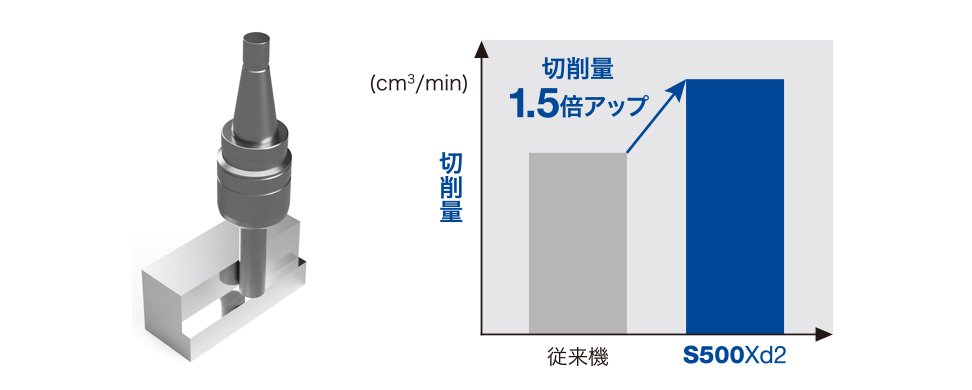

Side Machining

By improving the spindle rigidity, it is possible to improve the wall perpendicularity during side machining and increase the amount of cutting.

Material: A6061

Tool: φ16 end mill

Conditions: S3950min-1

F1550mm/min

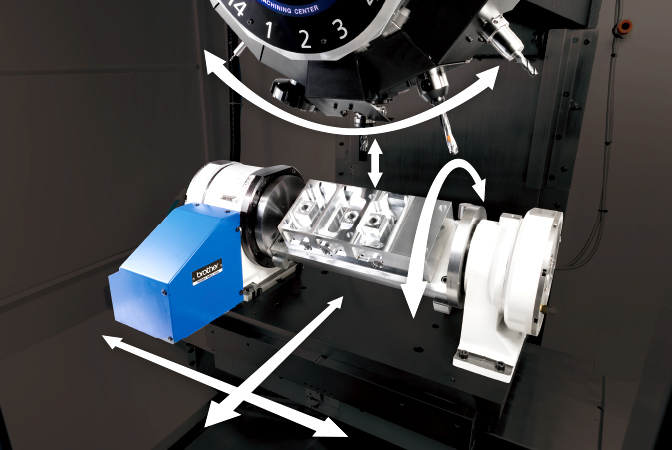

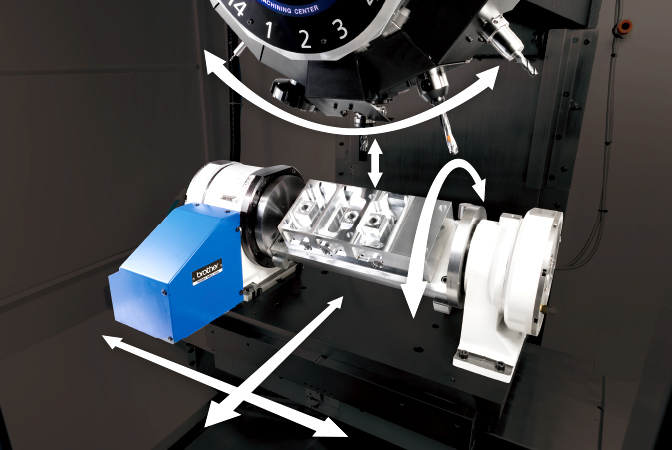

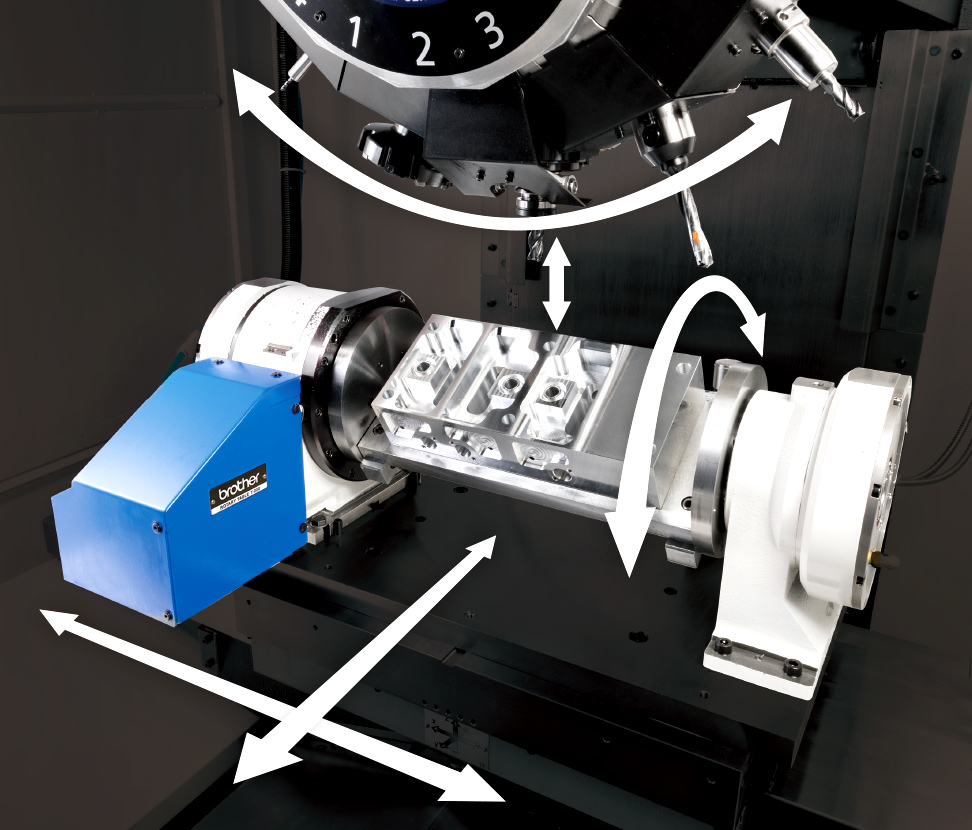

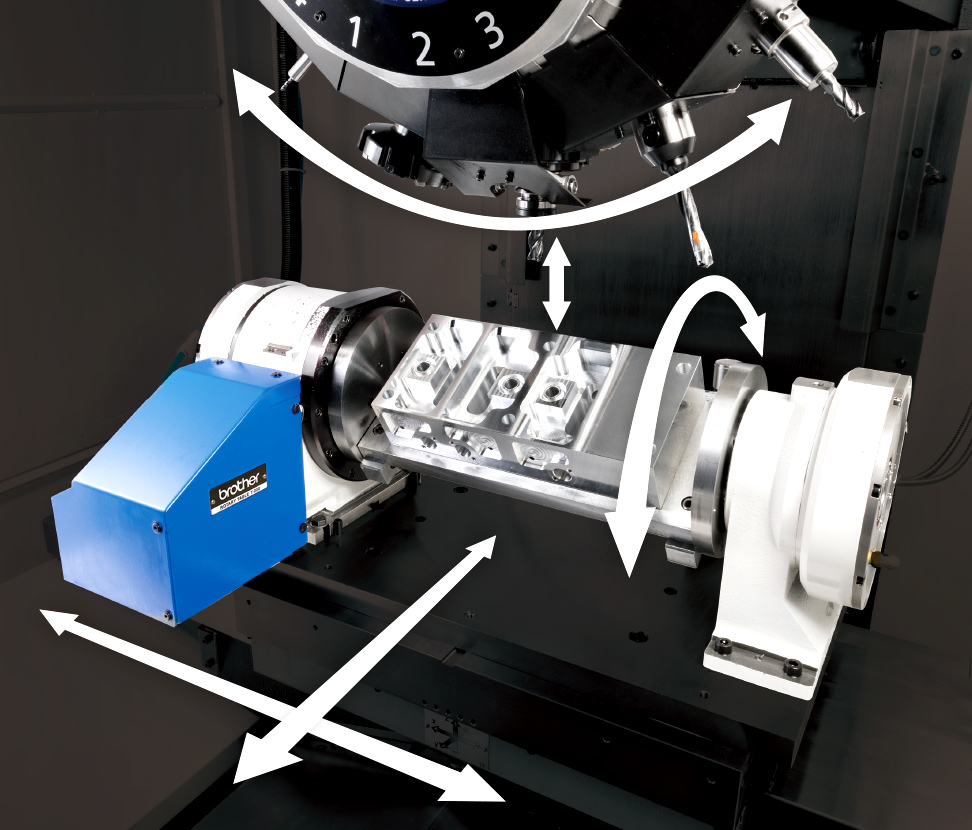

Simultaneous 5-axis machining

Equipped with a variety of functions including tool center point control and sub-micron command, it achieves high-speed, high-precision simultaneous 5-axis machining.

* The simultaneous 5-axis specification (5AX) does not allow switching to a dialogue language.

Tool center point control:

Equipped with tool center point control that changes the orientation of the tool relative to the workpiece during machining.

Simultaneous 5-axis machining is achieved through optimal acceleration/deceleration with up to 1,000 blocks of pre-reading.

Micro line processing speed

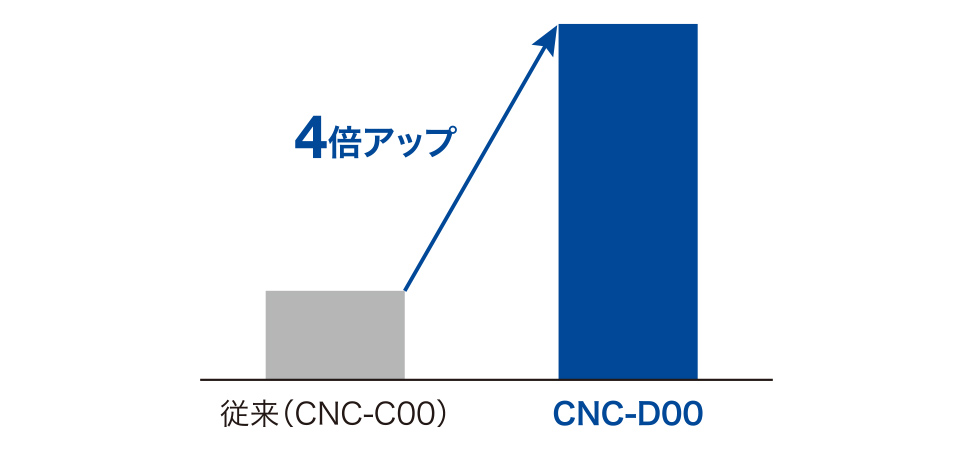

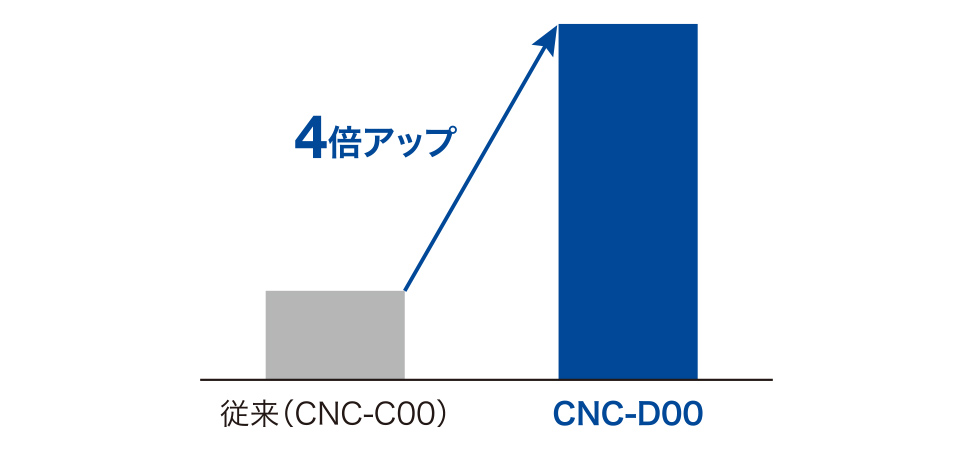

CPU capacity has been significantly improved, increasing the micro line processing speed to four times faster than before, enabling high-speed processing of CAM data with small tolerances

In addition to its compact size

, the unique acceleration/deceleration processing with predictive function makes the most of the machine’s performance (maximum speed and acceleration), enabling high-speed simultaneous 5-axis machining.

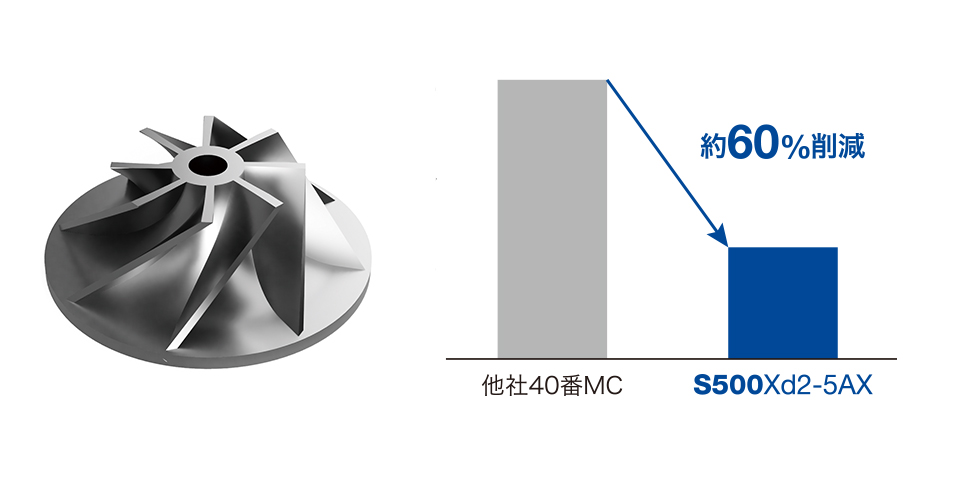

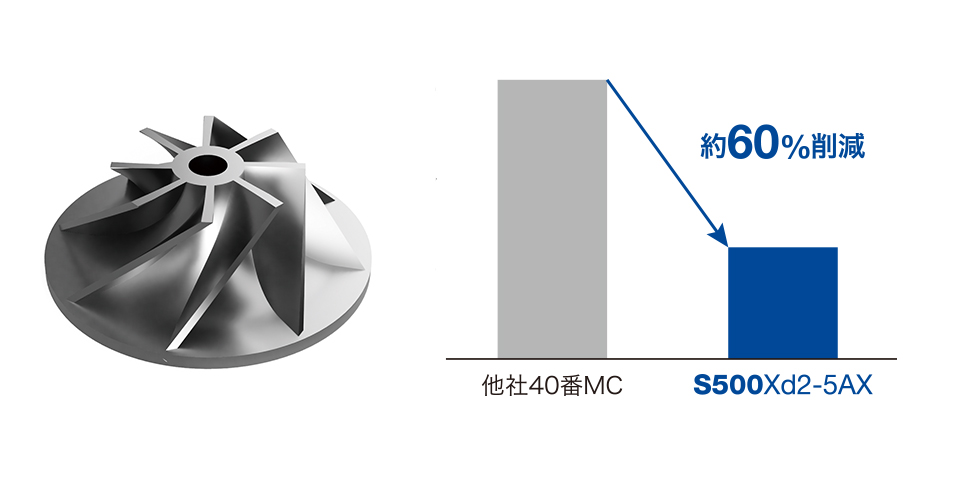

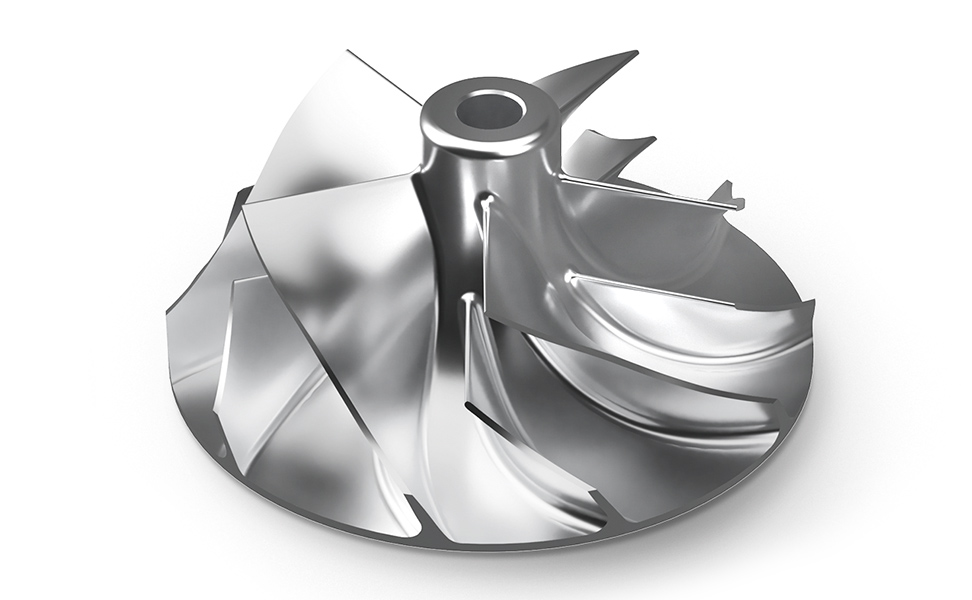

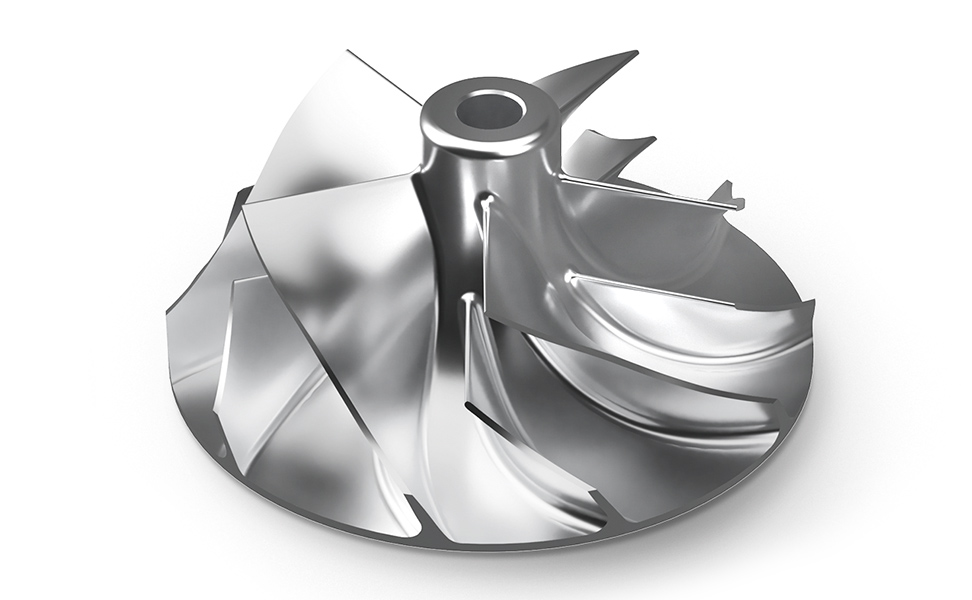

Comparison of cycle time with competitor’s No. 40 MC

Workpiece name: Impeller

Reliability

Reliability to maintain high productivity

Enhanced maintenance functions prevent equipment breakdowns, and cutting chip countermeasures reduce machining defects.

By not stopping the machine, high productivity at the production site is maintained.

Simultaneous 5-axis machining

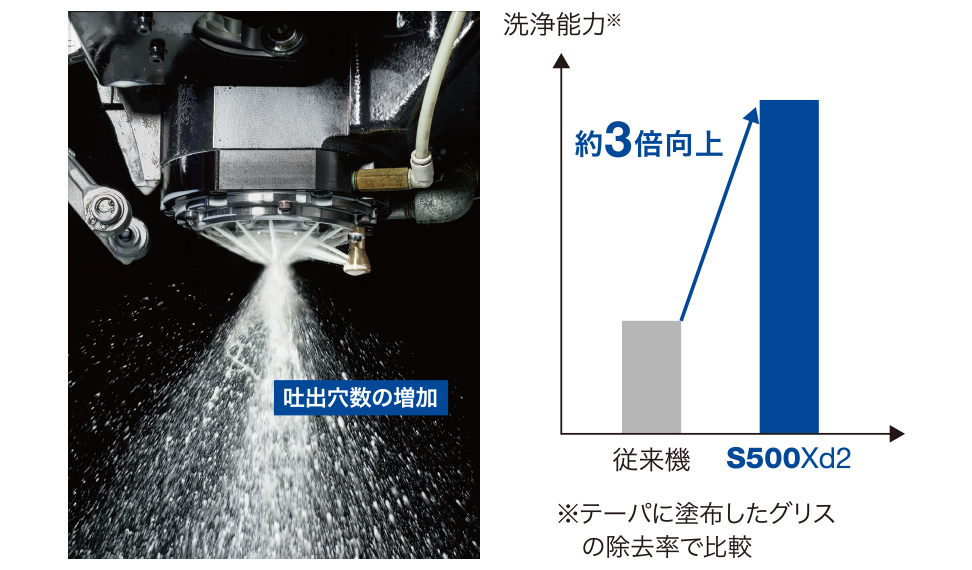

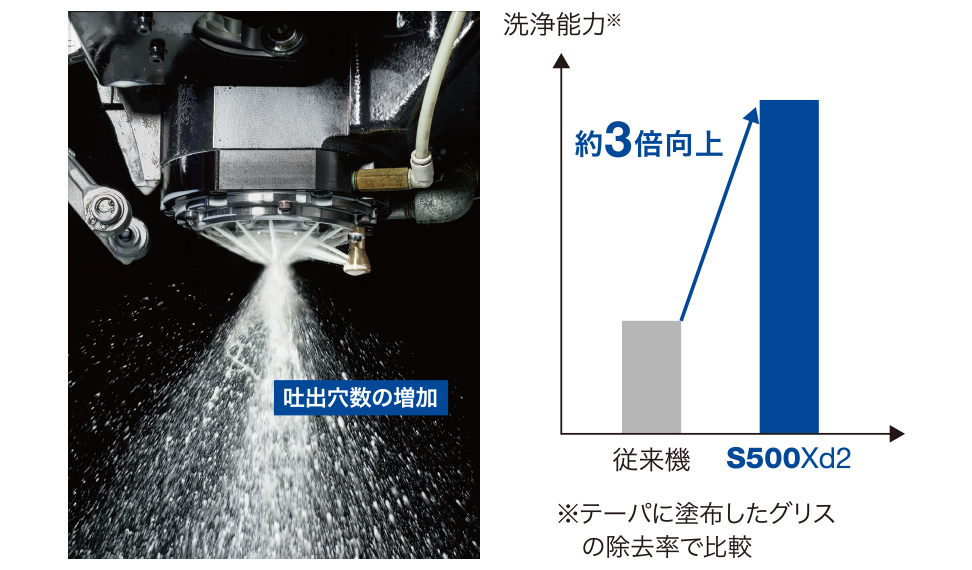

The number of holes in the outlet and the angle of the outlet have been optimized to significantly increase the discharge flow rate. This has resulted in a three-fold improvement in cleaning capacity compared to previous models.

When CTS is selected, the tool cleaning fluid is discharged from the CTS pump, reducing the amount of air consumed compared to the air-assisted type.

* If CTS is not selected, air-assisted tool cleaning will be used.

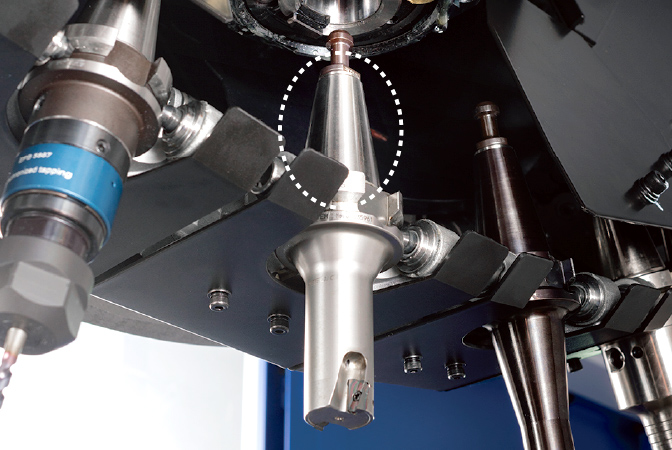

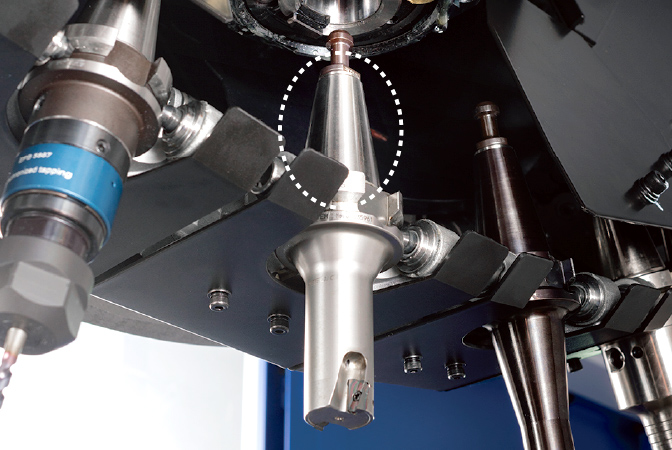

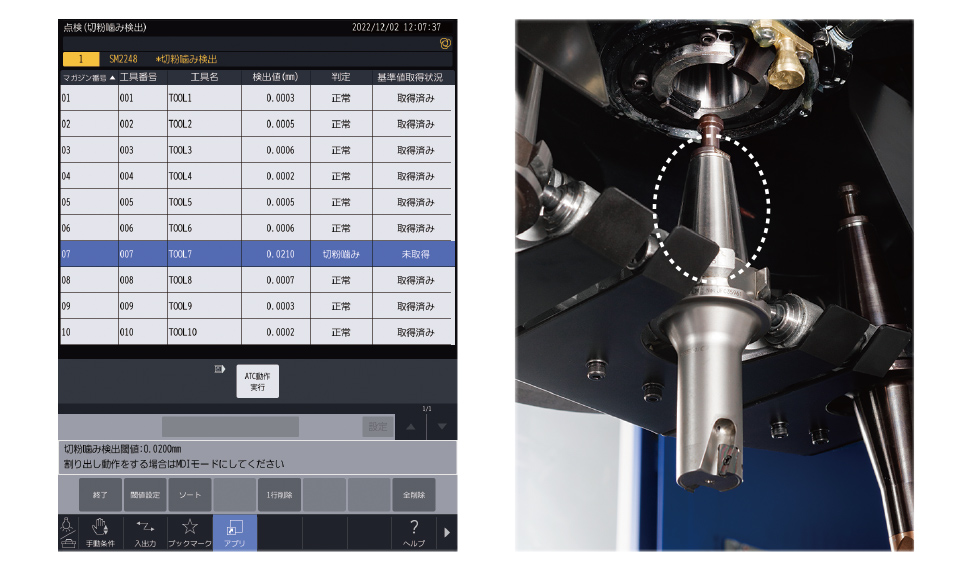

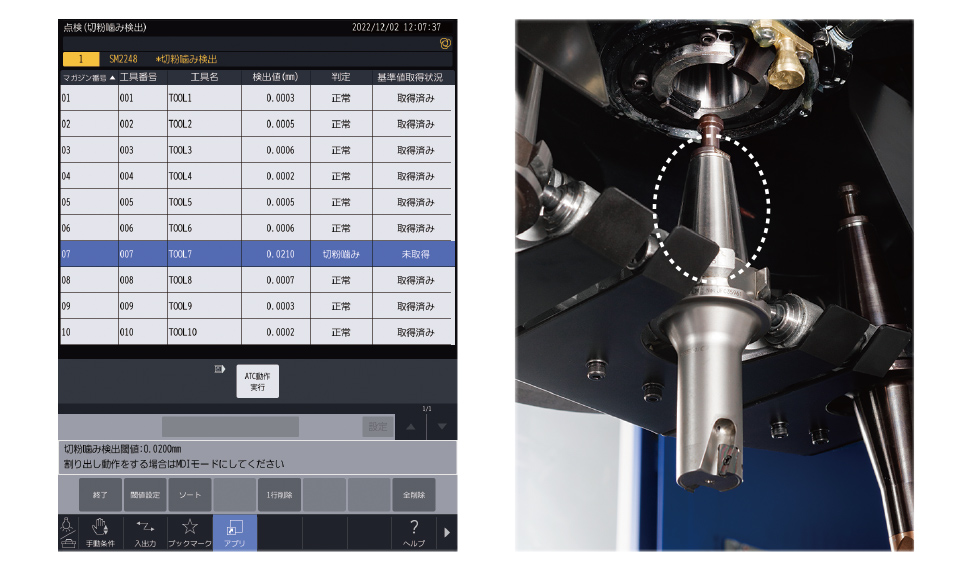

Chip jamming detection function

When changing tools, the sensorless detection of chips caught between the spindle and holder is performed. By detecting sudden chips caught during tool change, it prevents defective products from being produced.

Mechanical Specifications

| Model | S300Xd2 S300Xd2 RD *9 S300Xd2-5AX S300Xd2-5AX RD *9 | S500Xd2 S500Xd2 RD *9 S500Xd2-5AX S500Xd2-5AX RD *9 | S700Xd2 S700Xd2 RD *9 S700Xd2-5AX S700Xd2-5AX RD *9 | ||||

|---|---|---|---|---|---|---|---|

| CNC equipment model | 《S300Xd2/S500Xd2/S700Xd2》 CNC-D00 《S300Xd2/S500Xd2/S700Xd2-5AX》 CNC-D00v (DB) | ||||||

| amount of movement | X-axis (mm) | 300 | 500 | 700 | |||

| Y-axis (mm) | 450 | ||||||

| Z axis (mm) | 300 | 300 | 380 | 300 | 380 | ||

| Distance from table top to spindle end (mm) | 180 to 480 | 180 to 480 | 150 to 530 | 180 to 480 | 150 to 530 | ||

| table | Working surface size (mm) | 600×450 | 800×450 | ||||

| Maximum load (even load) (kg) | 250 (300 *6 ) | 250 (400 *6 ) | |||||

| Main axis | Spindle speed (min -1 ) | 12,000min -1 specifications: 1 to 12,000 16,000min -1 specifications (optional): 1 to 16,000 10,000min -1 high torque specifications (optional): 1 to 10,000 27,000min -1 specifications (optional): 1 to 27,000 (Z-axis 380mm specifications cannot be selected.) | |||||

| Spindle speed during tapping (min -1 ) | MAX. 6,000 (27,000min -1 specification: MAX. 8,000) | ||||||

| Spindle taper hole | 7/24 Taper No.30 | ||||||

| BT biplane restraint spindle (BIG-PLUS) | option | ||||||

| Coolant Through Spindle (CTS) | Option ( CTS cannot be selected for the 27,000 min -1 specification.) | ||||||

| Feed rate | Rapid traverse speed X×Y×Z axis (m/min) | 50×50×56 | |||||

| Cutting feed rate (mm/min) | X, Y, Z axis: 1 to 30,000 *7 | ||||||

| Tool Changer | Tool shank type | MAS-BT30 | |||||

| Pull stud type *4 | MAS-P30T-2 | ||||||

| Tool storage capacity (pieces) | 14 / 21 | 14 / 21 / 28 | |||||

| Maximum tool length (mm) | 160 (21 pieces), 250 (14 pieces) | 250 | |||||

| Maximum tool diameter (mm) | 110 | ||||||

| Maximum tool weight *1 (kg) | 3.0 (4.0 *10 ) (Total weight 25/14 pieces, 35/21 pieces, 28 pieces) | ||||||

| Tool Selection Method | Random shortcut | ||||||

| Tool change time *5 | Tool To Tool (sec) | 0.6/ 0.7 (14, 21/ 28) | |||||

| Chip to chip (sec) | Z-axis 300mm specification: 1.2/ 1.3 (14, 21/ 28) Z-axis 380mm specification: 1.3/ 1.4 (14, 21/ 28) | ||||||

| Electric motor | Spindle motor (10 min/continuous) *2 (kW) | 12,000min -1 spec: 10.1/7.0 16,000min -1 spec (optional): 7.4/5.1 10,000min -1 high torque spec (optional): 12.8/9.2 27,000min -1 spec (optional): 8.9/6.3 | |||||

| Feed shaft motor (kW) | X, Y axis: 1.0 / Z axis: 2.0 | ||||||

| Required power source | power supply | AC200~230V ±10% 3 phase, 50/60Hz ±2% | |||||

| Electrical capacity (continuous) (kVA) | 12,000min -1 spec: 9.5 16,000min -1 (option) spec: 9.5 10,000min -1 (option) High torque spec: 10.4 27,000min -1 (option) spec: 9.5 | ||||||

| Air Pressure Source | Normal air pressure (MPa) | 0.4 to 0.6 (recommended value: 0.5MPa *8 ) | |||||

| Required flow rate (L/min) | 40 (27,000min -1 spec: 115) | ||||||

| Machine size | Machine Height (mm) | Z-axis 300mm specification: 2,529, Z-axis 380mm specification: 2,568 | |||||

| Required floor space *11 [when control device door is open] (mm) | 1,080×2,161 [2,999] | 1,560×2,081 [2,919] | 2,050×2,081 [2,919] | ||||

| Machine mass [When equipped with BV7-870Ad] (kg) | 2,350 [2,650] | 2,400 [2,700] | 2,550 | ||||

| Accuracy *3 | Bidirectional positioning accuracy of the axis (ISO230-2:1988) (mm) | 0.006 to 0.020 | |||||

| Repeatability of bidirectional axis positioning (ISO230-2:2014) (mm) | Less than 0.004 | ||||||

| Front door specifications | 2 door | ||||||

| Standard accessories | Instruction manual (DVD) / 1 set, leveling bolts / 4 pieces, leveling plates / 4 pieces | ||||||

- *1The maximum weight of a tool varies depending on its shape, center of gravity, etc., so please use this value as a reference only.

- *2The spindle motor output varies depending on the rotation speed.

- *3The measurement method is based on ISO and Brother standards. Please contact us for details.

- *4The pull studs for CTS are Brother specifications.

- *5The tool change time measurement method is based on JIS standard B6336-9 and MAS011-1987.

- *6Parameter adjustment is required. (Acceleration adjustment and positioning speed will also change according to the weight.)

- *7This is the value when using high precision mode B.

- *8The normal air pressure will vary depending on the machine specifications, processing program contents, and usage of peripheral devices, so please set a pressure higher than the recommended value.

- *9Depending on the destination, a relocation detection device may be required. Models equipped with a relocation detection device have “RD” at the end of their model names.

- *10Parameter settings need to be changed. (The tool indexing time will change.) Also, the 27,000min -1 specification cannot accommodate a maximum tool mass of 4.0kg.

- *11The value does not include the coolant tank.

NC Specifications

| Model | S300Xd2/S500Xd2/S700Xd2 | |

|---|---|---|

| CNC equipment model | CNC-D00 | |

| Number of Control Axes | 5 axes (X, Y, Z, and 2 additional axes) | |

| Simultaneous Control Axes | Positioning | 5 axes (X, Y, Z, and 2 additional axes) |

| Interpolation Function | Linear: 4 axes (X, Y, Z, 1 additional axis) Arc: 2 axes Helical/conical interpolation: 3 axes (X, Y, Z) | |

| Minimum setting unit | 0.001mm, 0.0001inch, 0.001° | |

| Maximum command value | ±999999.999mm, ±99999.9999inch | |

| display | 15-inch color LCD touch display | |

| Memory capacity | 500MB, 3GB (optional) *Total of programs and databanks | |

| External communication function | USB interface, Ethernet, RS232C (optional) | |

| Number of registered programs | 4,000 (programs and databanks combined) | |

| Program Method | NC language method, interactive method (parameter switching) Conversion from interactive program to NC language program possible | |

| Model | S300Xd2-5AX/S500Xd2-5AX/S700Xd2-5AX | |

|---|---|---|

| CNC equipment model | CNC-D00v (DB) | |

| Number of Control Axes | 5 axes (X, Y, Z, and 2 additional axes) | |

| Simultaneous Control Axes | Positioning | 5 axes (X, Y, Z, and 2 additional axes) |

| Interpolation Function | Linear: 5 axes (X, Y, Z, 2 additional axes) Arc: 2 axes Helical/conical interpolation: 4 axes (3 linear axes + 1 additional axis, 2 linear axes + 2 additional axes) | |

| Minimum setting unit | 0.0001mm, 0.00001inch, 0.0001° | |

| Maximum command value | ±999999.9999mm, ±99999.99999inch | |

| display | 15-inch color LCD touch display | |

| Memory capacity | 3GB *Total of programs and databanks | |

| External communication function | USB interface, Ethernet, RS232C (optional) | |

| Number of registered programs | 4,000 (programs and databanks combined) | |

| Program Method | NC language method *There is no interactive method | |

- *“Number of controlled axes” and “Number of simultaneously controlled axes” are the maximum numbers of axes and vary depending on the destination and specifications.

- *Ethernet is a registered trademark of XEROX Corporation in the United States.

NC Function

| operation | Dry run Machine lock Program restart Fast forward override Cutting feed override Background edit Screen capture Operation level External input signal key Shortcut key (Optional) |

|---|---|

| programming | Absolute/Incremental Inch/Metric Coordinate System Setting Corner Chamfering/Corner R Coordinate Rotation Synchronous Tap Subprogram Program Path Drawing |

| measurement | Automatic workpiece measurement *1 Tool length measurement |

| High speed and high accuracy | Machining parameter adjustment High precision mode AIII High precision mode BI (Look-ahead 160 blocks) Backlash compensation Tool tip point control *3 *4 (Look-ahead 1,000 blocks) (Optional) |

| monitoring | Machining load monitoring ATC tool monitoring Overload prediction Waveform display/External output Thermal displacement automatic compensation system II (X, Y, Z axis) Production performance display Tool life/spare tool Chip jamming detection function |

| Maintenance | Tap return function Status history Alarm history Key operation history Maintenance notification Motor insulation resistance measurement tool Cleaning filter clogging detection Battery-less encoder Brake Load test |

| Automation and Networking | Computer Remote OPC UA Spontaneous Notification Built-in PLC (LD/ST/FBD) (Option) |

| Energy saving | Auto power off Standby mode Coolant auto off Cabin light auto off Tip shower off Delay tip shower Energy saving operation Energy saving mode |

| Support App | Machining parameter adjustment ATC tool Tool life Waveform display Production record Power consumption Recovery support Inspection PLC Warm-up-less machining support function |

| Accessories | File viewer Memo pad Calculator Shortcut registration screen clear |

| NC language method limited function | Menu programming Local coordinate system Expanded work coordinate system Unidirectional positioning Inverse time feed Programmable data input Tool length compensation Tool diameter compensation Scaling Mirror image External subprogram call Macro Tape operation/FTP load operation Multi-stage skip (Optional) |

| Interactive limited functionality | Operation program Schedule program Automatic tool selection Automatic cutting condition setting Automatic tool length compensation setting Automatic tool diameter compensation setting Automatic calculation of unknown quantity input Machining order control |

- *1Please prepare your own measuring equipment.

- *2When a submicron command is selected, switching to an interactive program is not possible.

- *3There are limitations to the axis configuration.

- *4This function is only available on S300Xd2-5AX/S500Xd2-5AX/S700Xd2-5AX.

- *5It is standard equipment on the S300Xd2-5AX/S500Xd2-5AX/S700Xd2-5AX.

- *6The S300Xd2-5AX/S500Xd2-5AX/S700Xd2-5AX does not have an interactive mode.

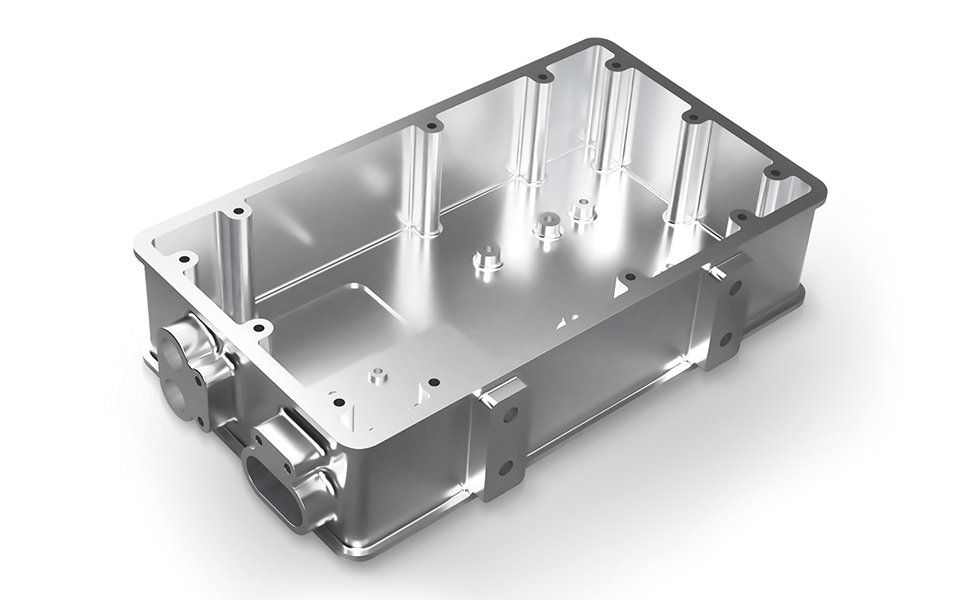

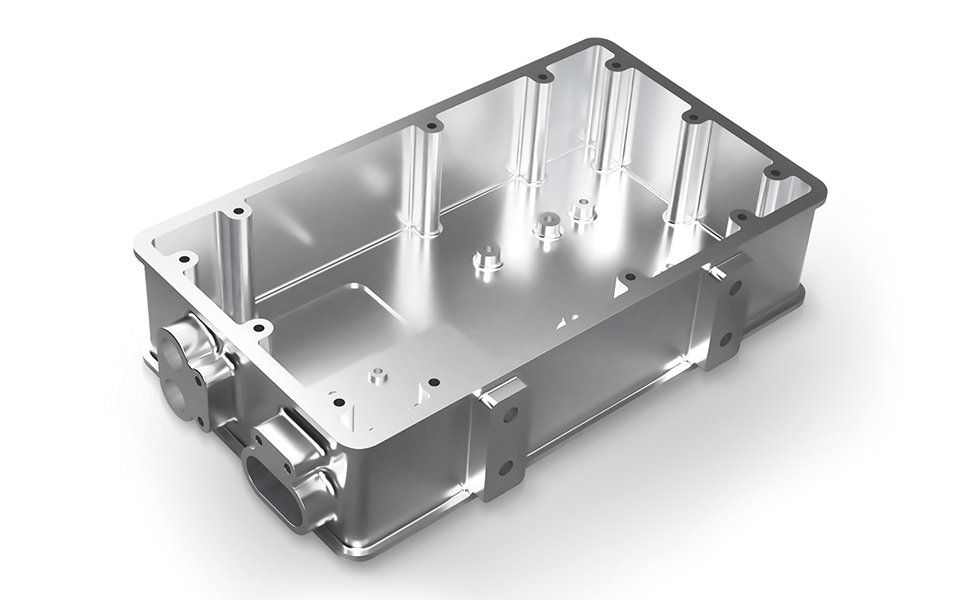

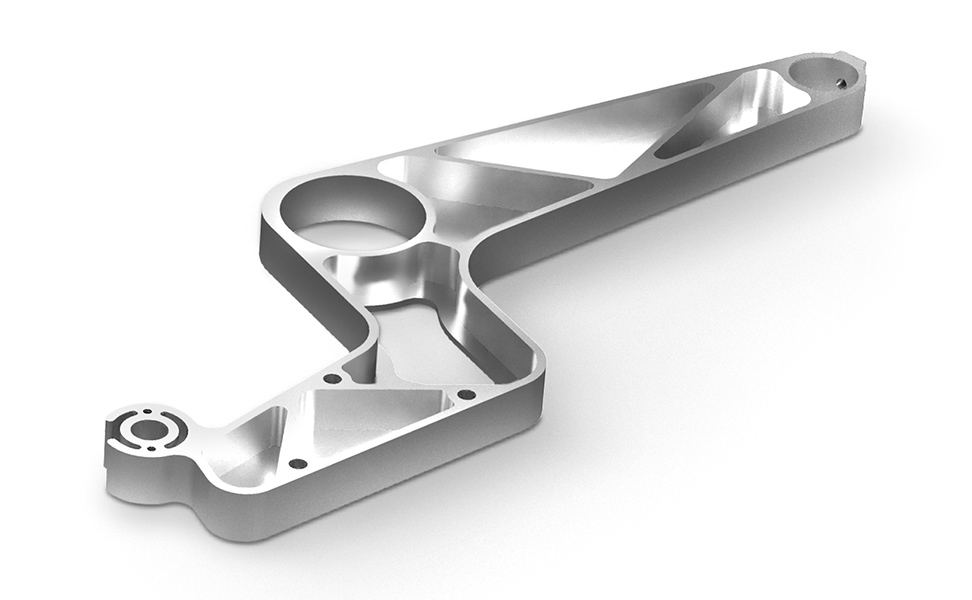

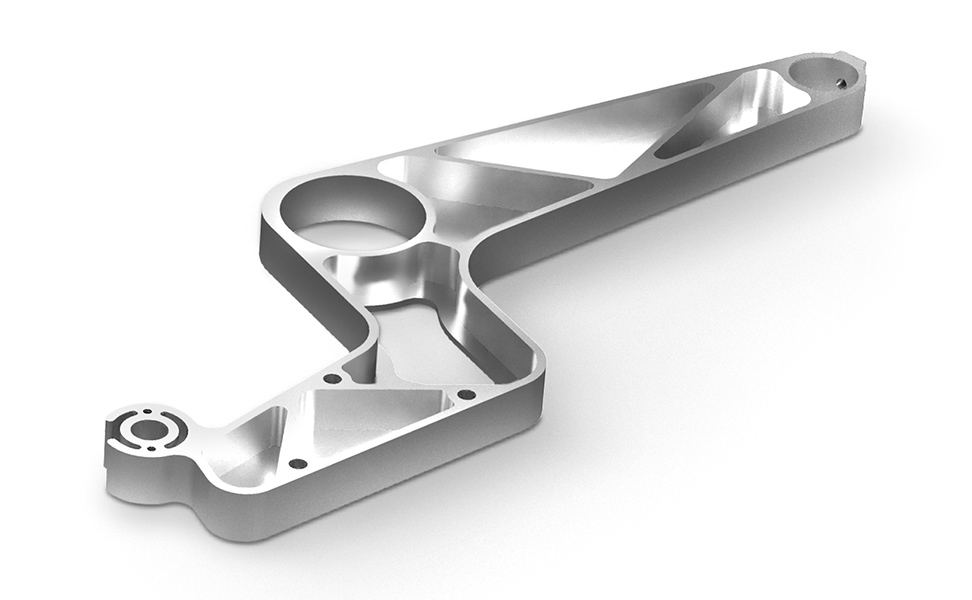

Processing Examples

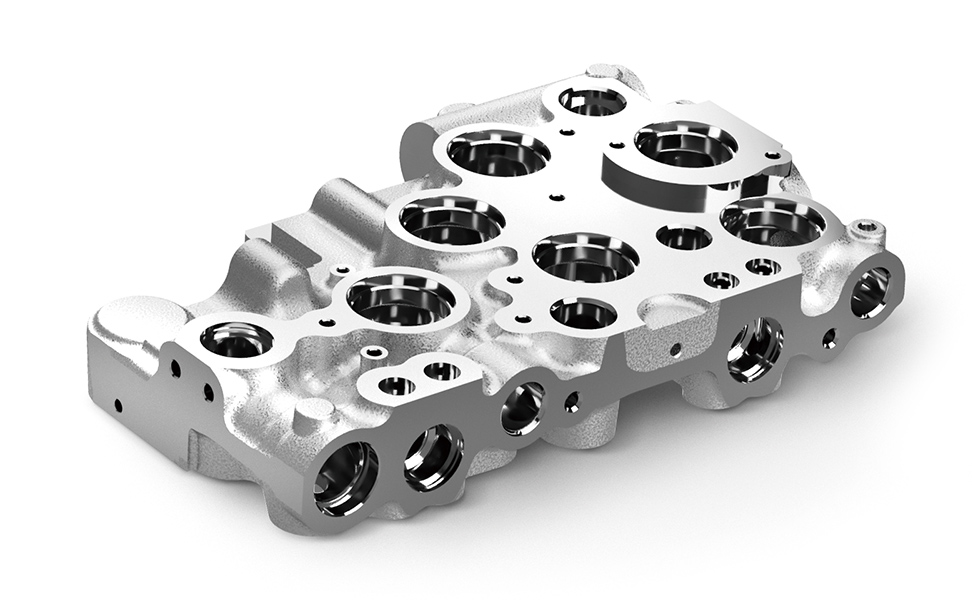

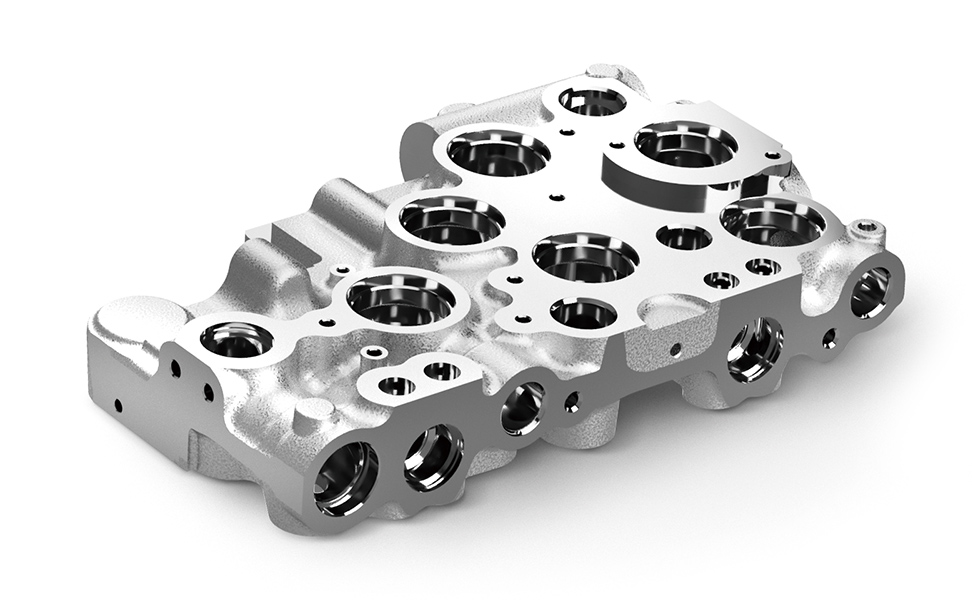

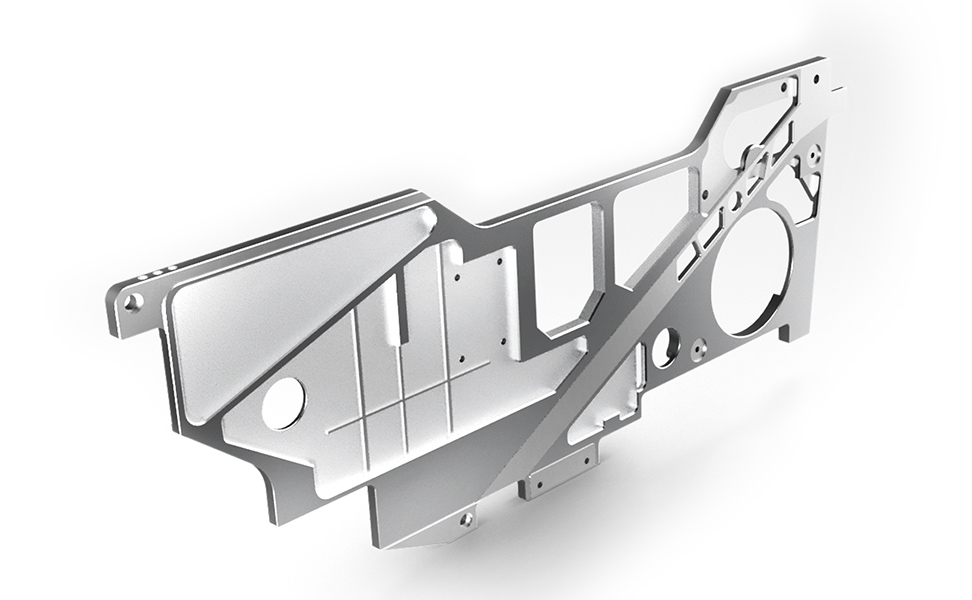

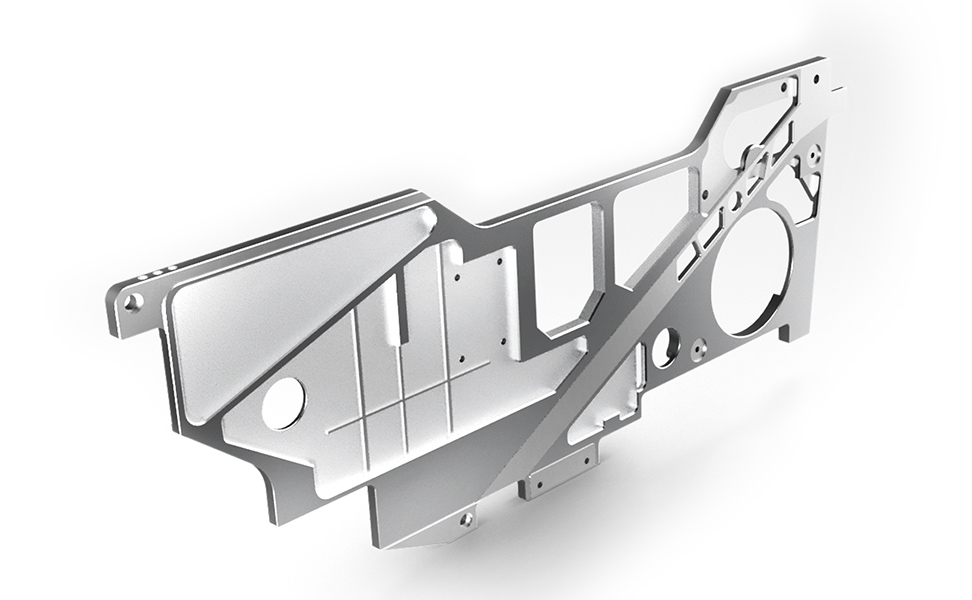

Car

| Part Name | Inverter Case |

|---|---|

| Material | Aluminum alloy |

| Part Name | Impeller |

|---|---|

| Material | Aluminum alloy |

| Part Name | Large valve for thermal management |

|---|---|

| Material | Aluminum alloy |

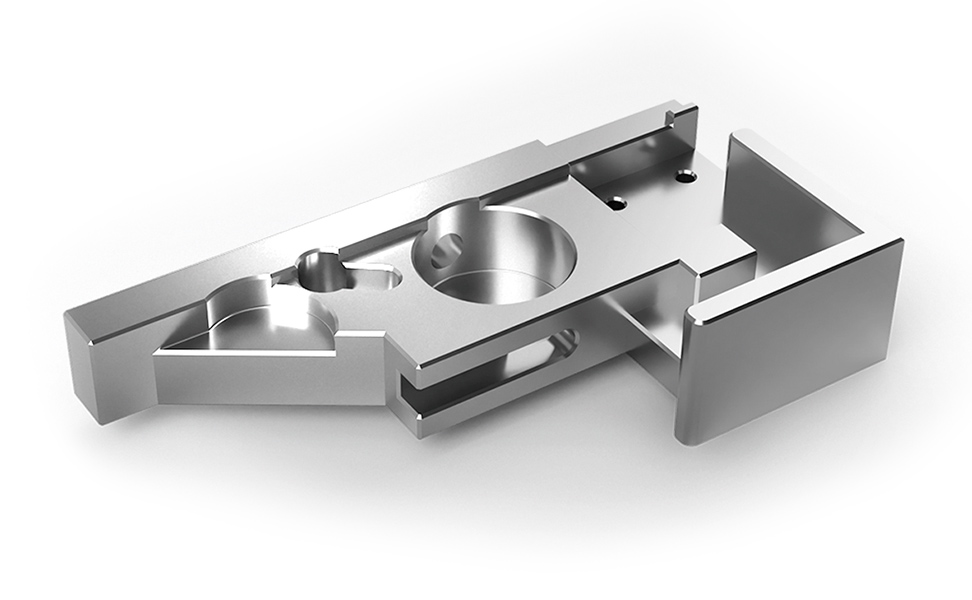

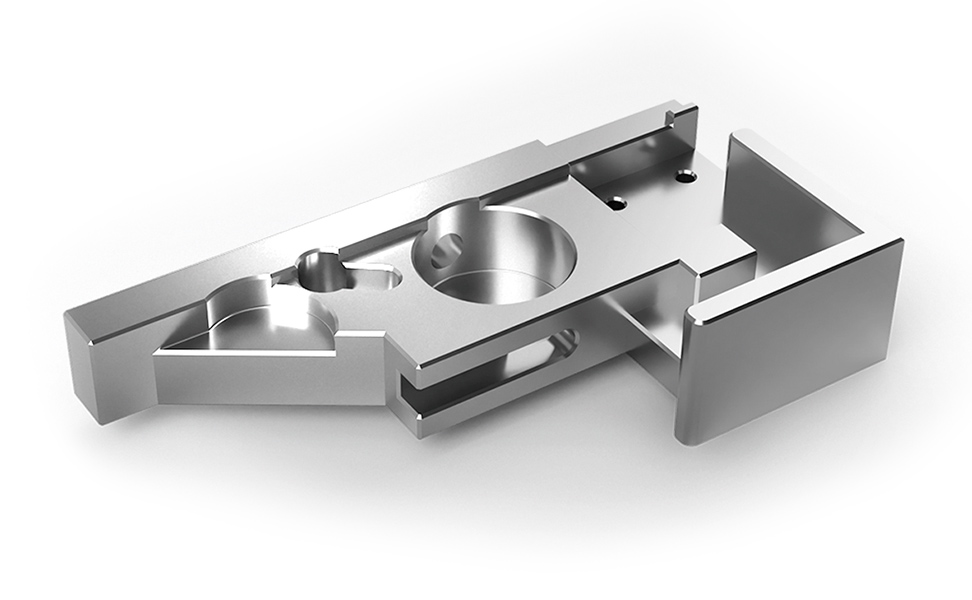

Semiconductor

| Part Name | Feeder Frame |

|---|---|

| Material | Aluminum alloy |

| Part Name | Support bracket |

|---|---|

| Material | SUS316L |

Aircraft

| Part Name | Seat parts |

|---|---|

| Material | Aluminum alloy |