Brother U Series

SPEEDIO :

U500Xd2

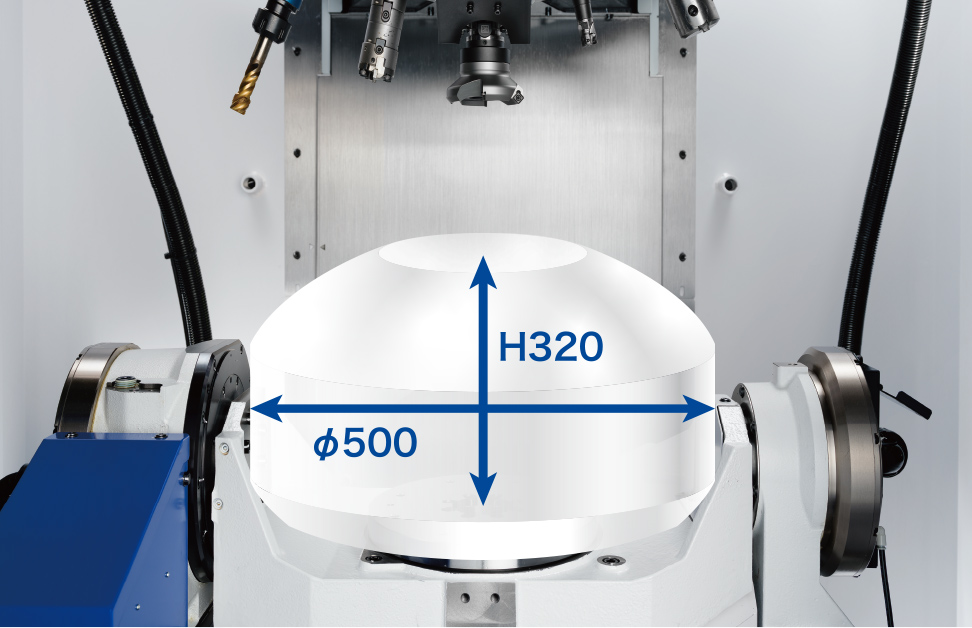

The tilting rotary table with a maximum jig area of ø500 is equipped as standard.

The increased travel of the Y/Z axes allows for a wider range of multi-sided machining.

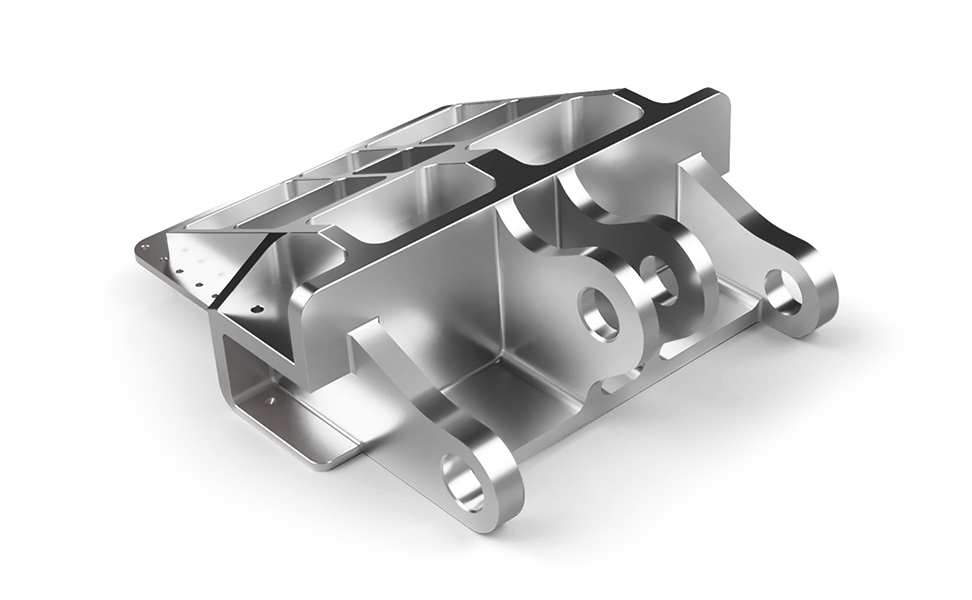

Processing Examples

Machine configuration

The tilting rotary table with a maximum fixture area of ø500 is standard equipment.

The increased Y/Z axis travel allows for a wider range of multi-sided machining.

Productivity

Relentless pursuit of high productivity

Reducing waste through optimized control of integrated mechanical and electrical development

Processing Capability

Highly rigid machine structure and highly efficient spindle motor support a wide range of machining

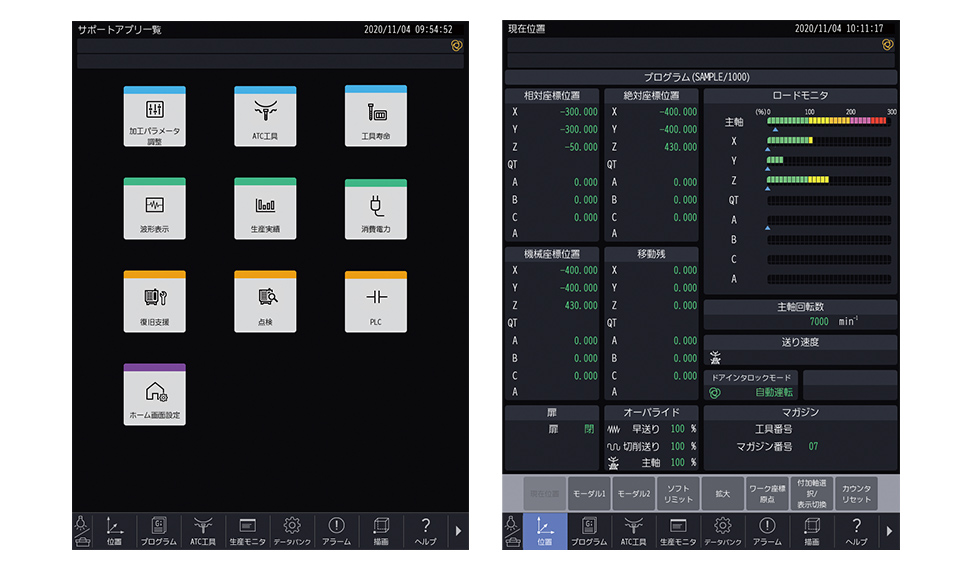

NC unit

Equipped with a “CNC-D00” control device

15-inch touch panel LCD for ease of use

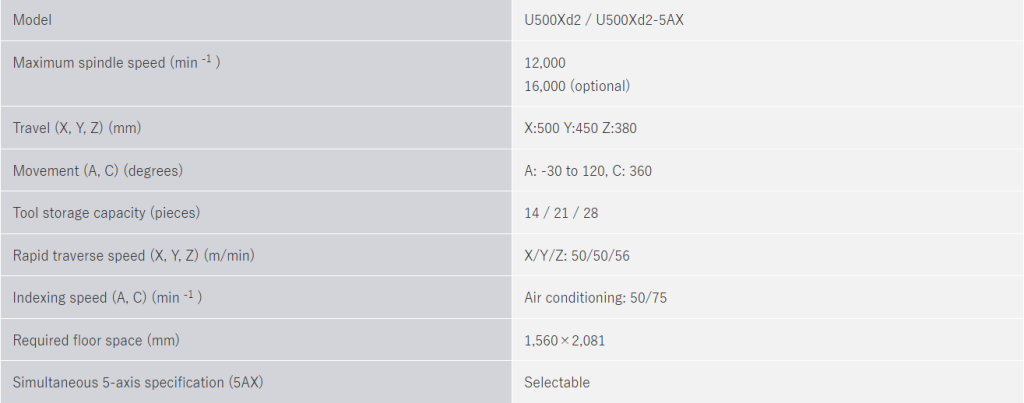

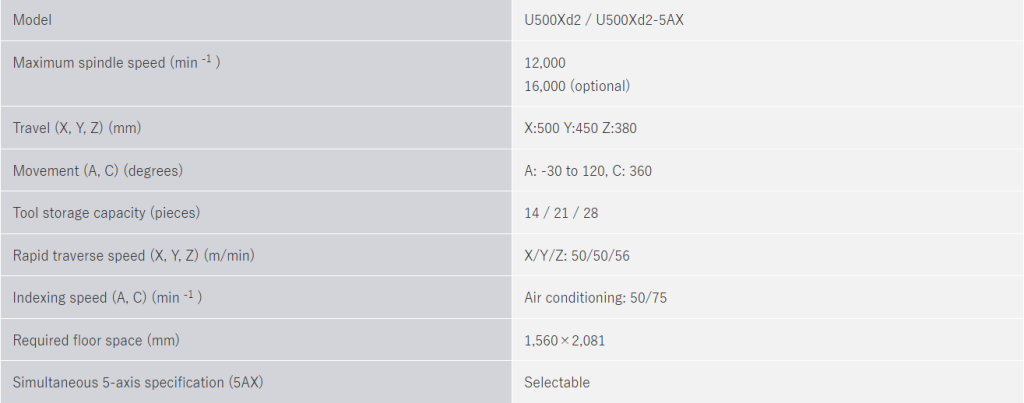

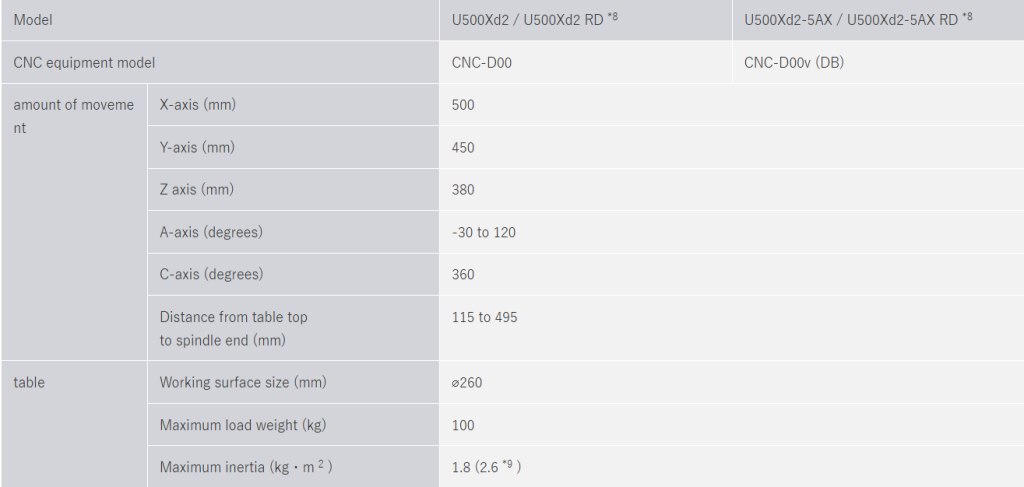

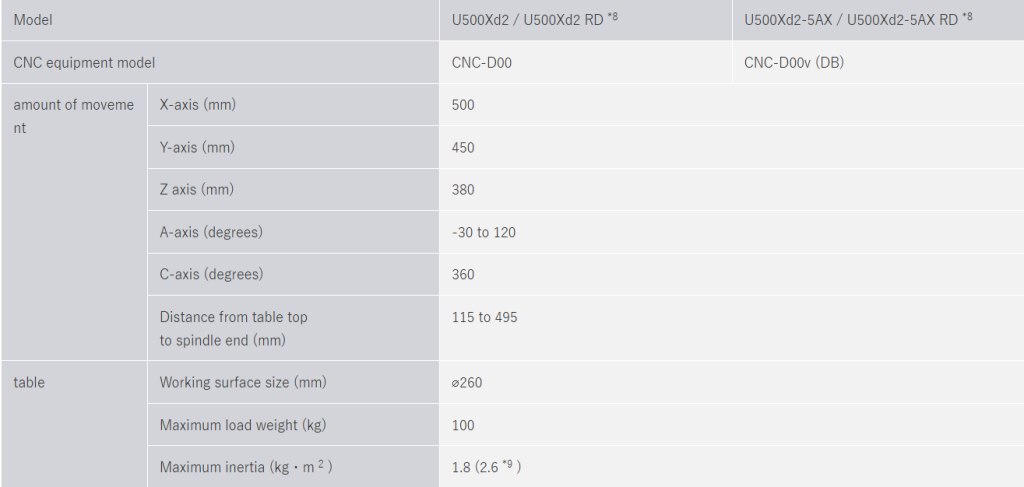

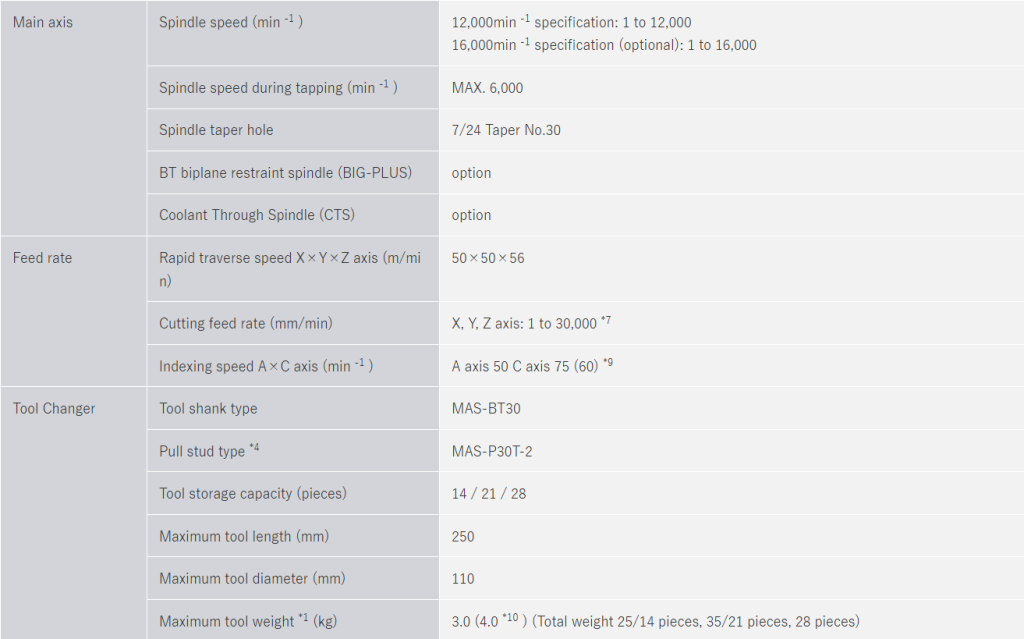

Specifications

Machine configuration

Equipped with a tilting rotary table with a jig area of ⌀500 Expanded

Y/Z axis travel allows for a wider range of multi-sided machining.

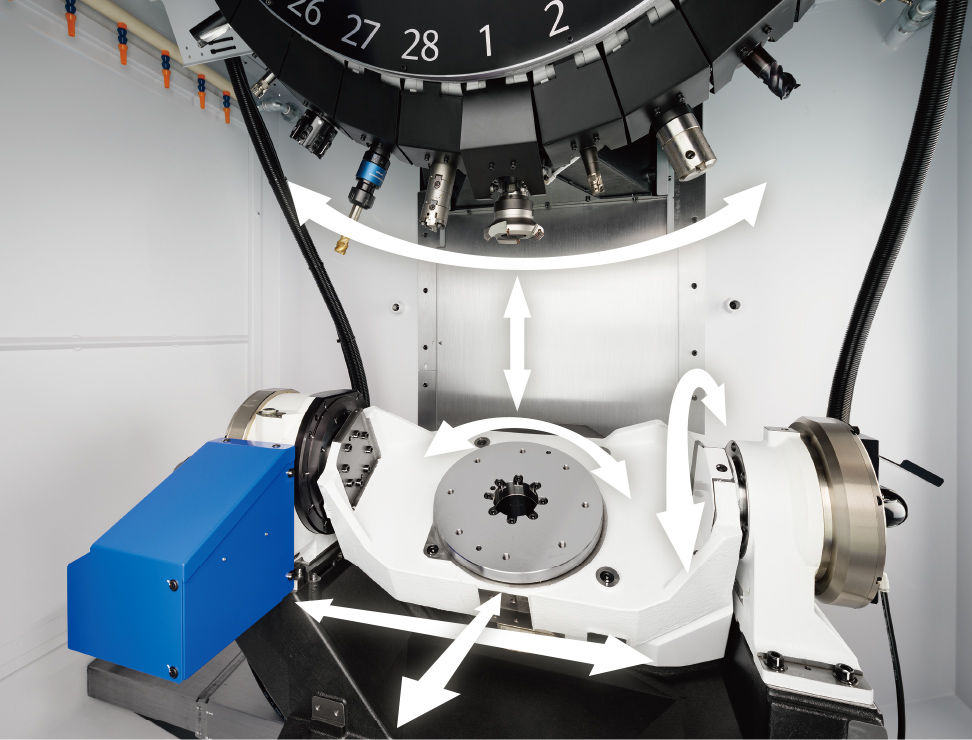

Equipped with a high-speed, high-precision tilting rotary table with a wide jig area as standard.

By expanding the Y/Z axis travel, the machine further accelerates process integration through one-clamp machining in conjunction with a magazine that can store up to 28 pieces.

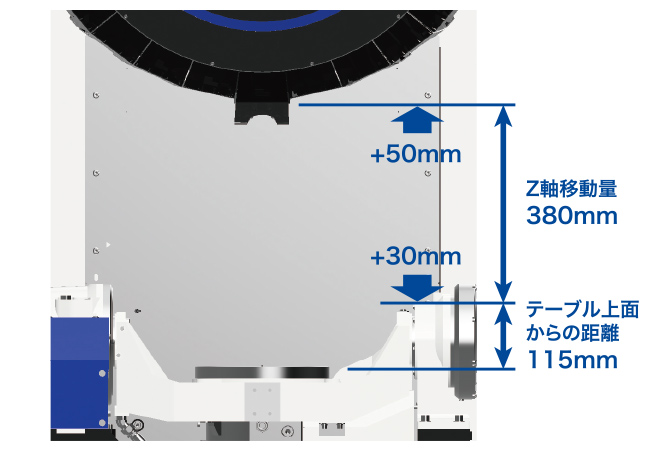

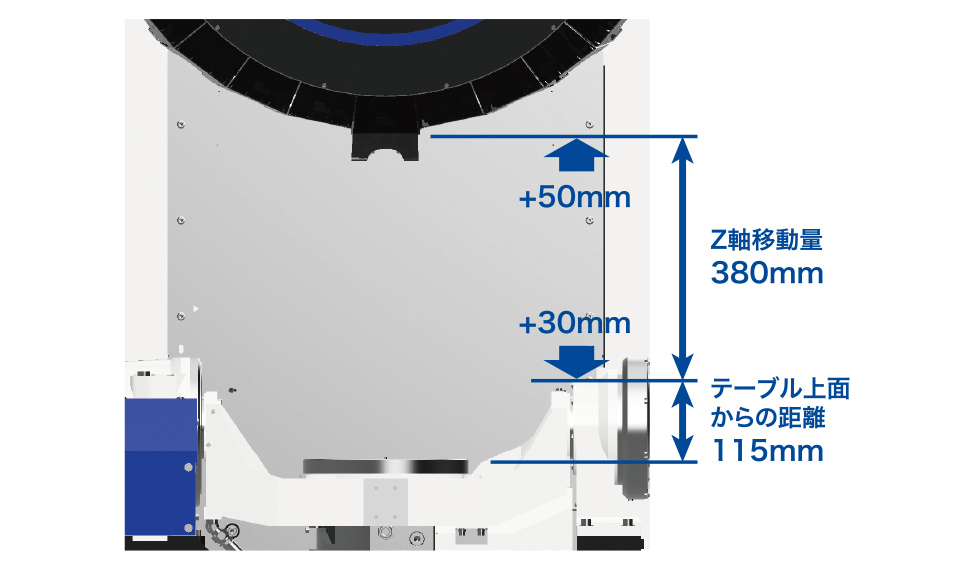

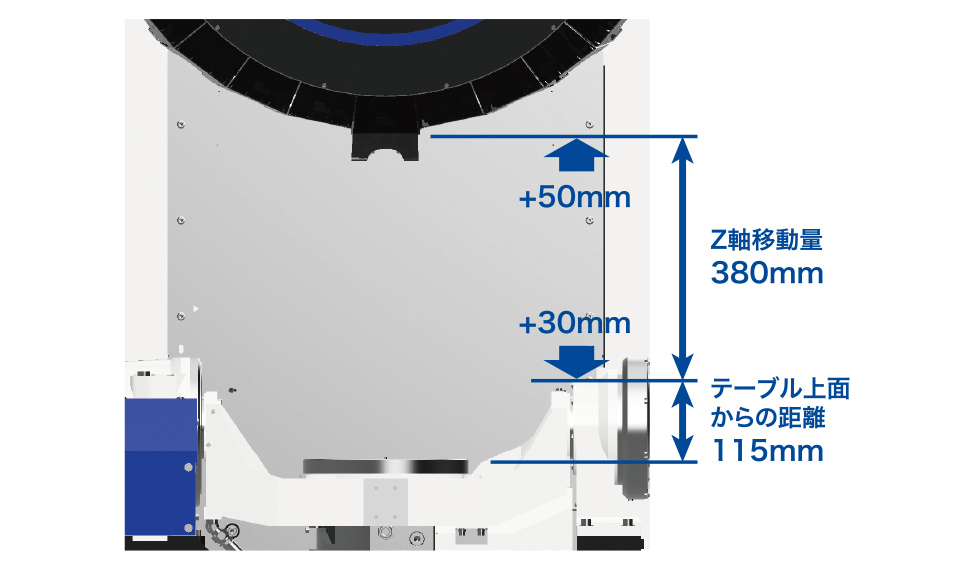

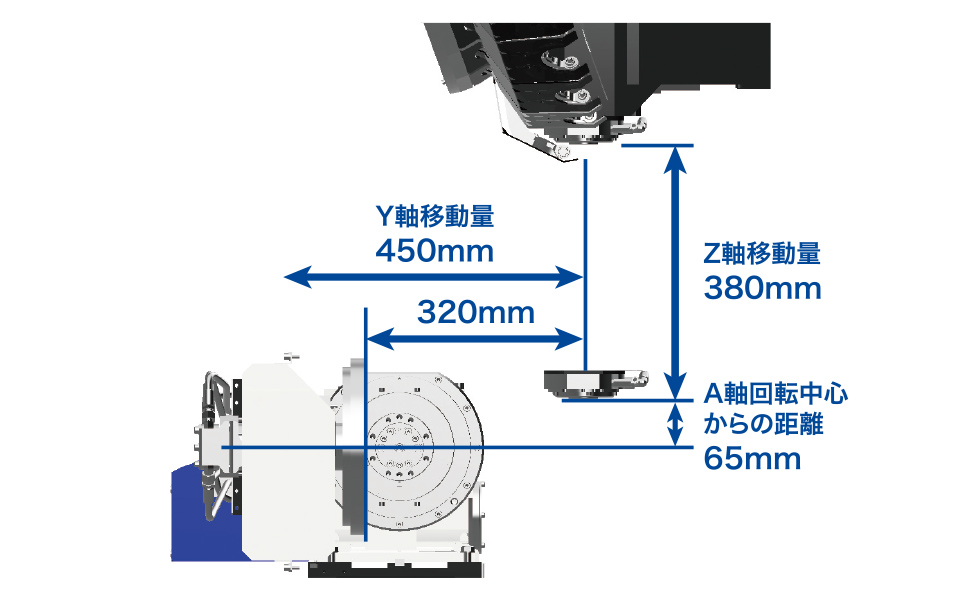

Increased Z-axis travel

By increasing the Z-axis travel and the vertical distance from the table top to the spindle end face, a wider machining area and improved tool accessibility in the Z-axis direction have been achieved.

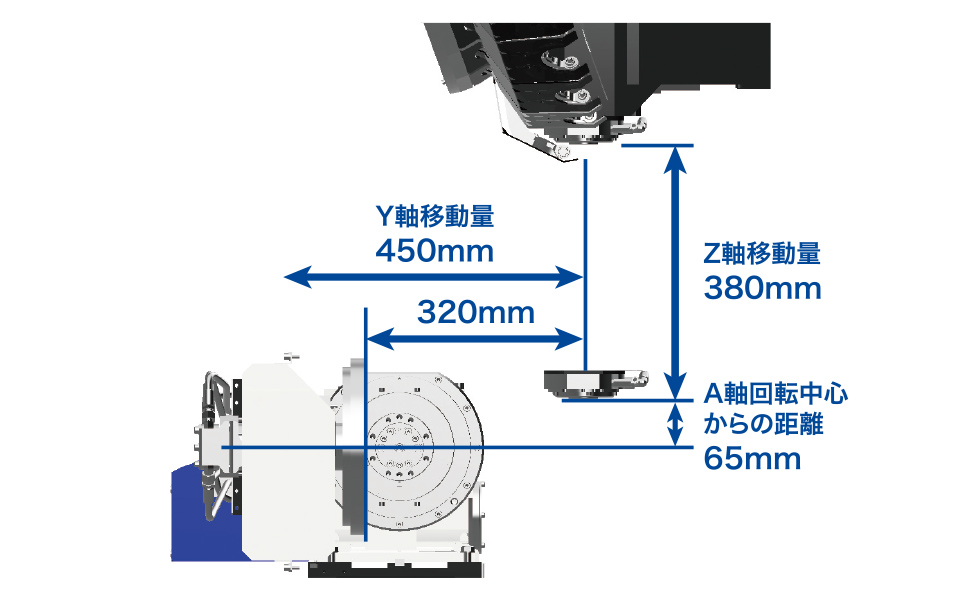

Increased Y-axis travel

By expanding the Y-axis travel and shifting the Y-axis travel range from the center of the tilt axis, the Y-axis travel amount when the A-axis is at 90° has been increased to 320 mm.

Tool accessibility has also been improved.

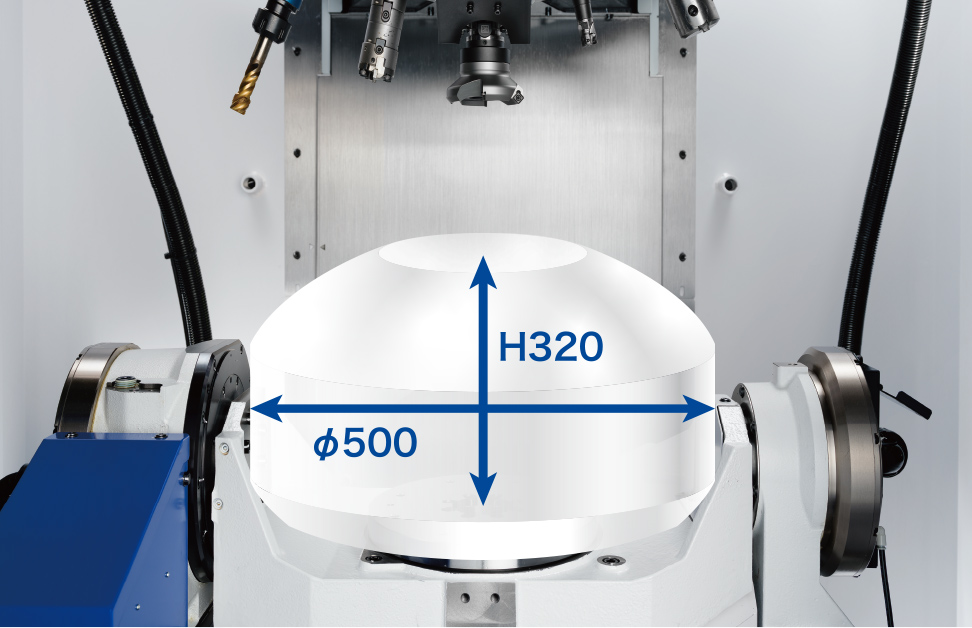

Expanded jig area

The increased Y/Z axis travel has realized a wide fixture area with a maximum of φ500 and height of 320,

enabling multi-sided machining of medium-sized workpieces.

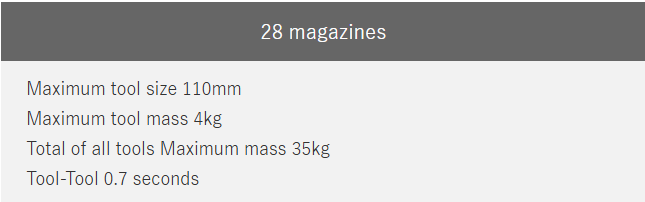

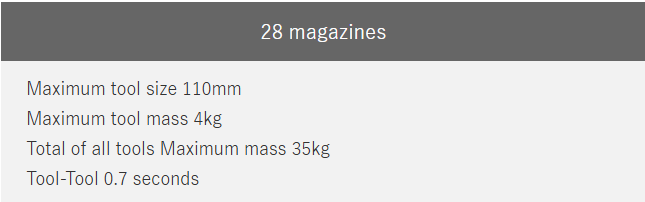

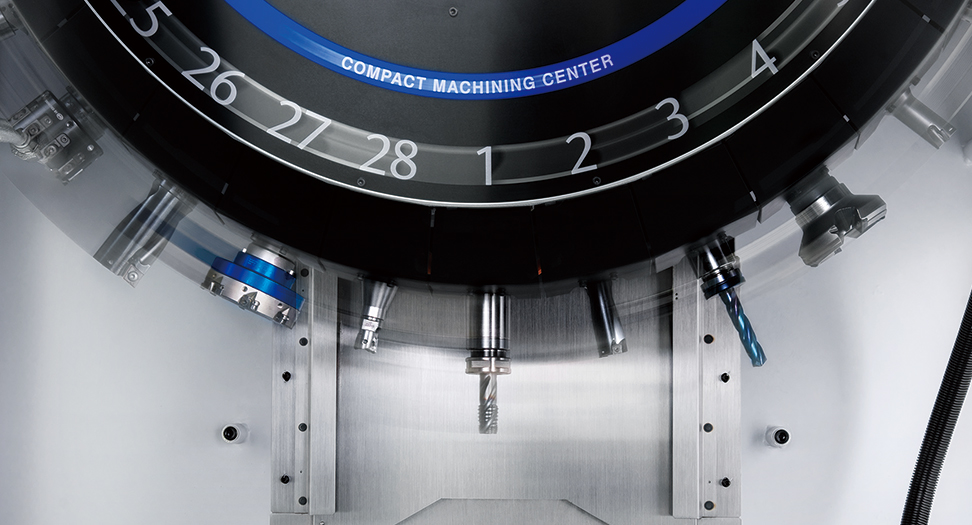

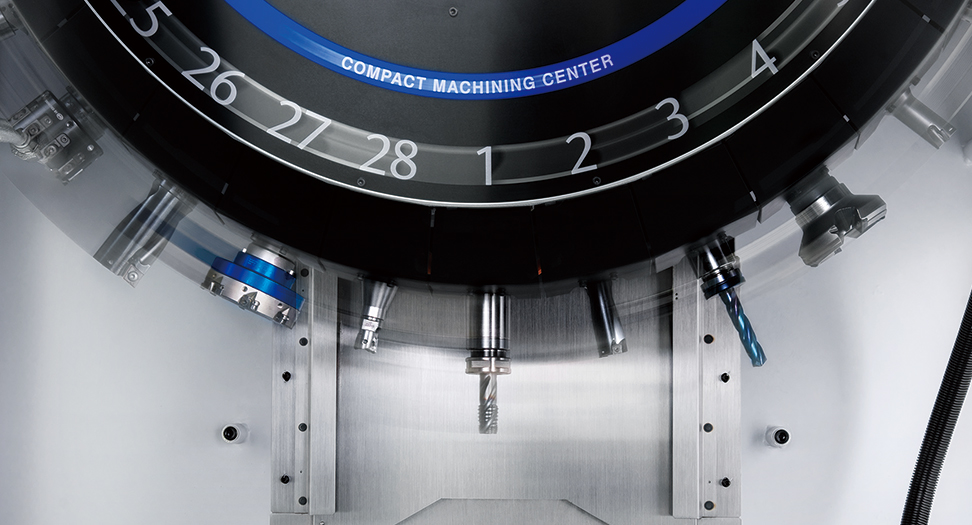

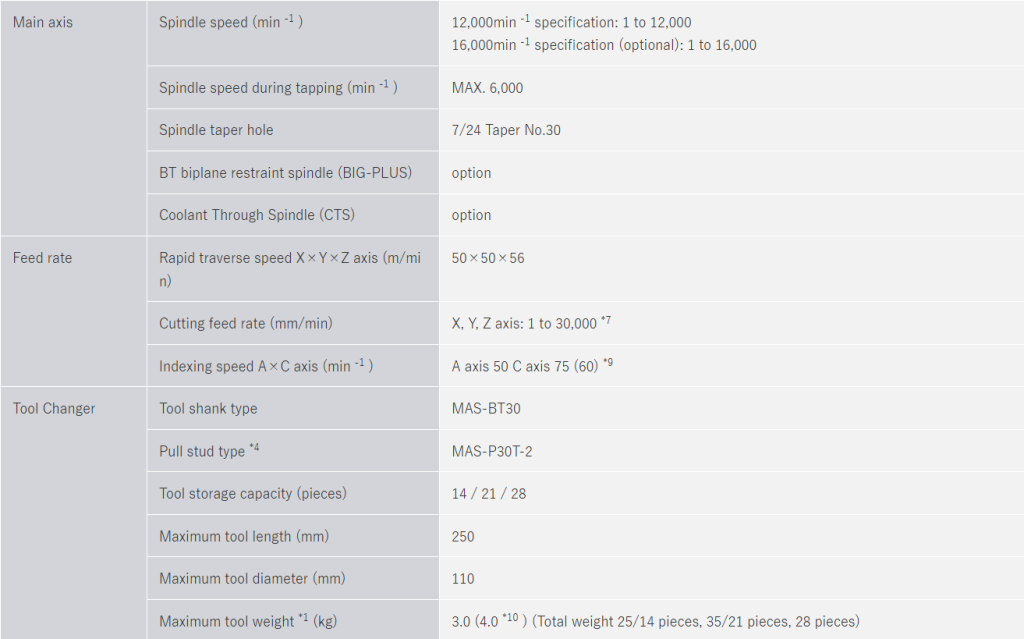

28 magazines

A compact drum-type magazine that allows for high-speed tool change.

You can choose from 14, 21, or 28 tool magazines.

The maximum tool weight can be up to 4kg.

Productivity

Relentless pursuit of high productivity

Reducing waste through optimized control of integrated mechanical and electrical development

The pursuit of high acceleration and high response through integrated mechanical and electrical development, and optimal motion control by the “CNC-D00” control device, maximizes the machine’s performance and delivers high productivity.

Non-stop ATC

Non-stop ATC

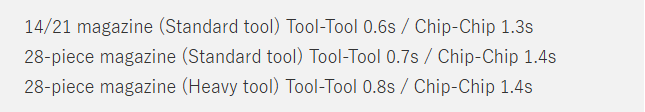

High-speed tool change is achieved by accelerating and optimizing spindle start/stop, Z-axis lift, and magazine operation. Tools up to 3 kg can be changed in the shortest time, and heavy tools up to 4 kg can be changed with minimal increase in time.

Simultaneous Operation

By changing tools and positioning the XY and AC axes at the same time, wasted time is reduced.

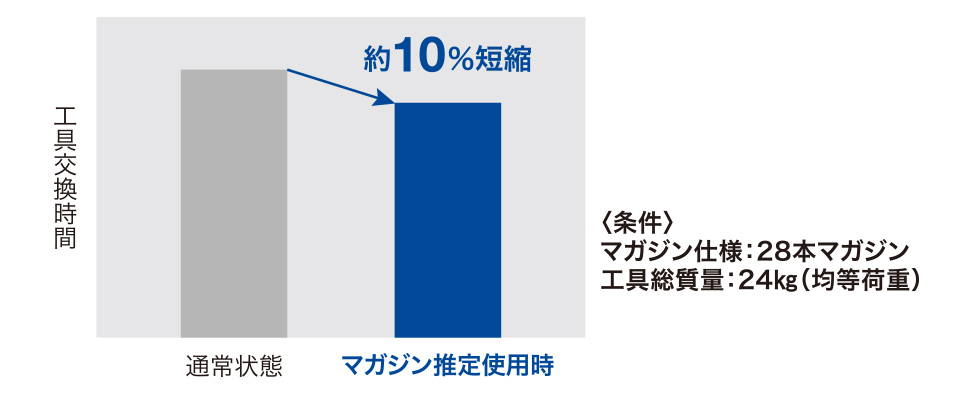

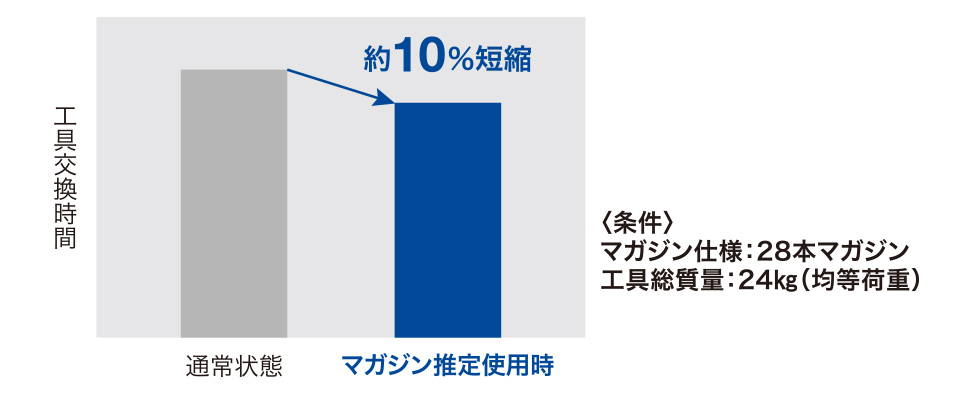

Magazine loading condition estimation

The inertia and unbalanced load of the tools loaded in the magazine are estimated, and the optimum acceleration value for the magazine axis is set.It also has a function that automatically updates to the optimum acceleration by estimating even during program operation.

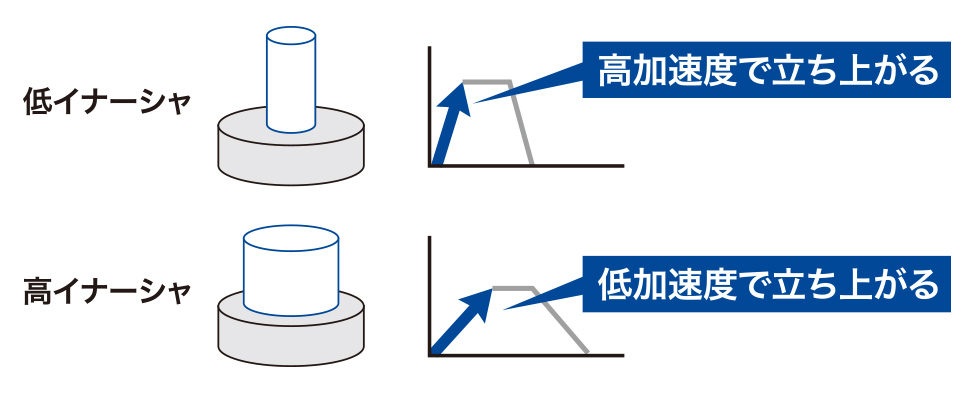

AC axis indexing speed optimization

Based on the AC axis inertia estimation, the AC axis ramps up to the index speed with optimal acceleration.

Improved automatic door opening and closing speed

Improved automatic door opening and closing speed enables significant reduction in setup time.

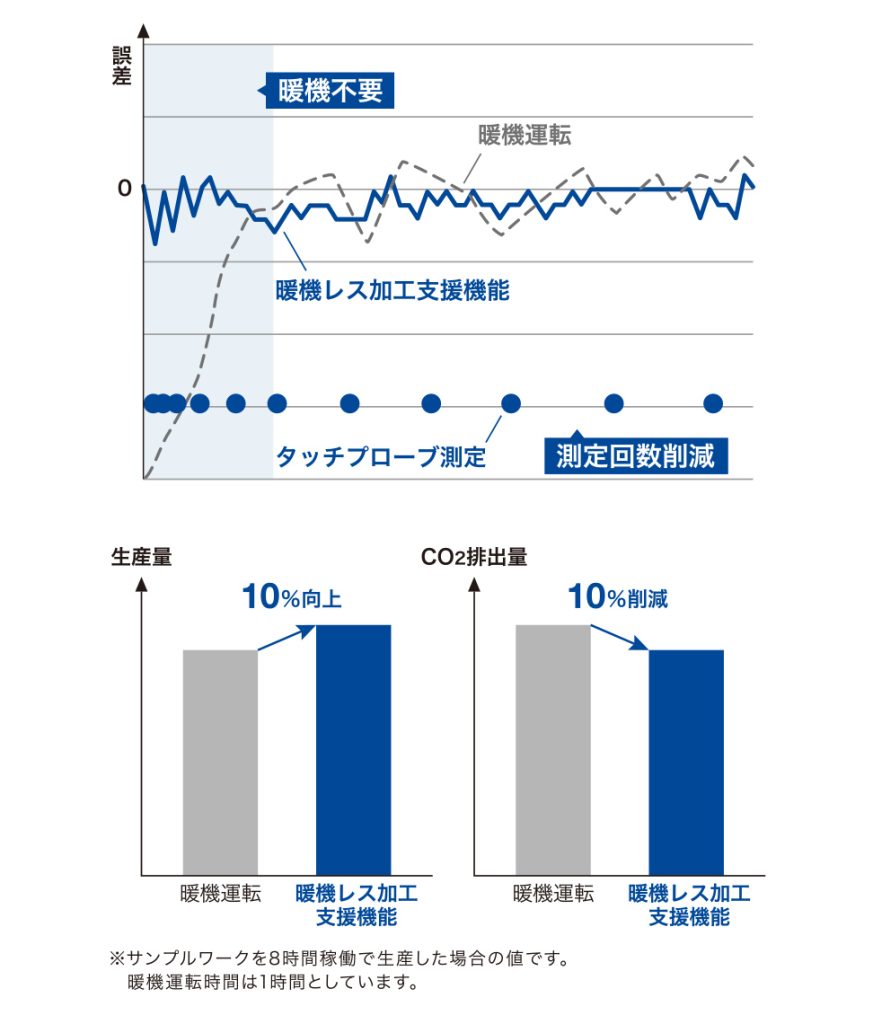

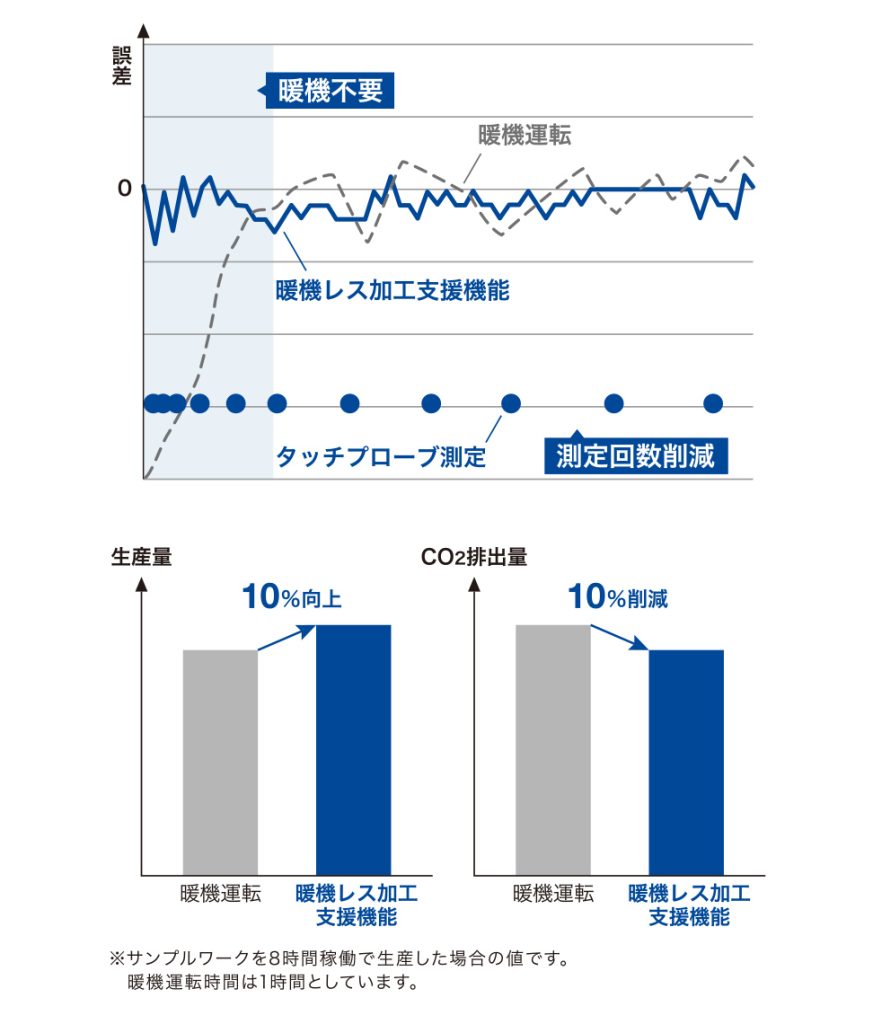

Warm-up-free processing support function

It is equipped with a unique measurement processing function that thins out the actual measurements of the touch probe according to the magnitude of the displacement. This

eliminates the need for warm-up operation, minimizes the impact on productivity, and achieves high-precision machining.

Processing Capability

Highly rigid machine structure and highly efficient spindle motor support a wide range of machining

Equipped with a highly efficient spindle motor that exerts sufficient torque from low to high speeds in a highly reliable mechanical structure,

it realizes highly efficient machining in various industries such as automobiles, general machinery, medical care, and aircraft.

It also supports simultaneous 5-axis machining with the newly equipped tool center point control . *

This function is only available for the U500Xd1-5AX.

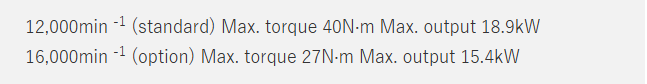

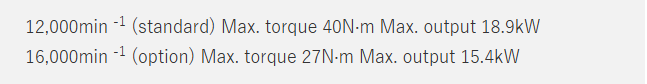

Newly developed 12,000min -1 high-efficiency spindle motor

The standard motor has been upgraded from the previous 10,000 min -1 to a newly developed 12,000 min -1

. It maintains the spindle torque in the medium to high speed rotation range, contributing to further shortening the machining time for high-speed, high-efficiency machining of aluminum and steel.

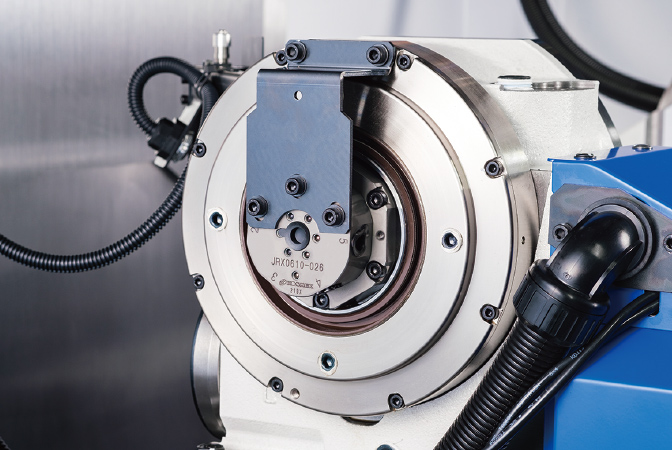

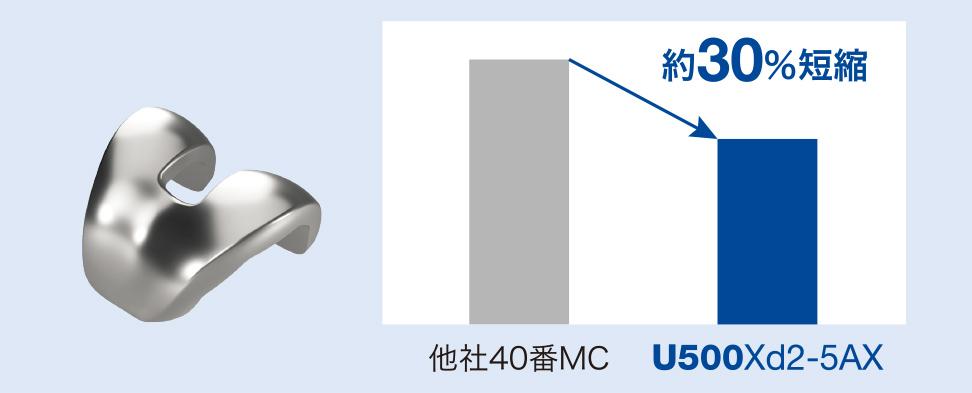

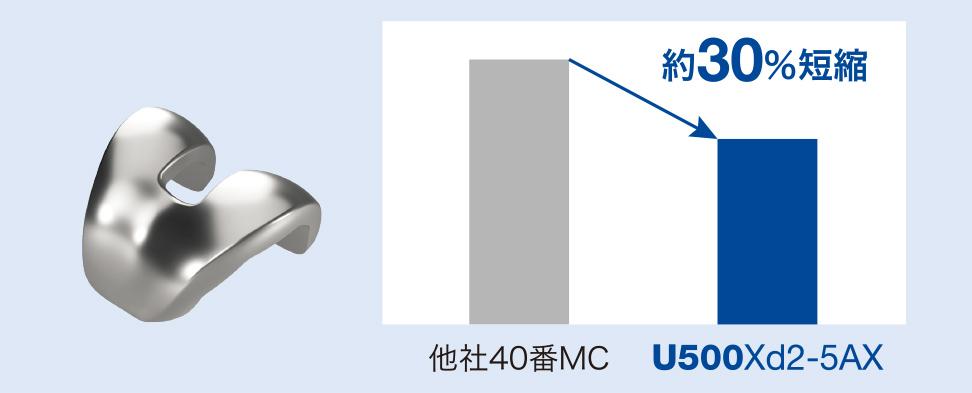

Simultaneous 5-axis machining (U500Xd2-5AX)

It is equipped with various functions including tool center point control and sub-micron command.

Combined with the backlash-less tilting rotary table, it achieves high-speed, high-precision simultaneous 5-axis machining.

* The simultaneous 5-axis model (5AX) cannot switch to a dialogue language.

Productivity improvement

In addition to the compact size of the No. 30, the unique acceleration/deceleration processing with look-ahead allows for maximum use of the machine’s performance (maximum speed and acceleration), achieving high-speed simultaneous 5-axis machining.

Comparison of cycle times with other companies’ No. 40 MCs Workpiece

name: Knee joint

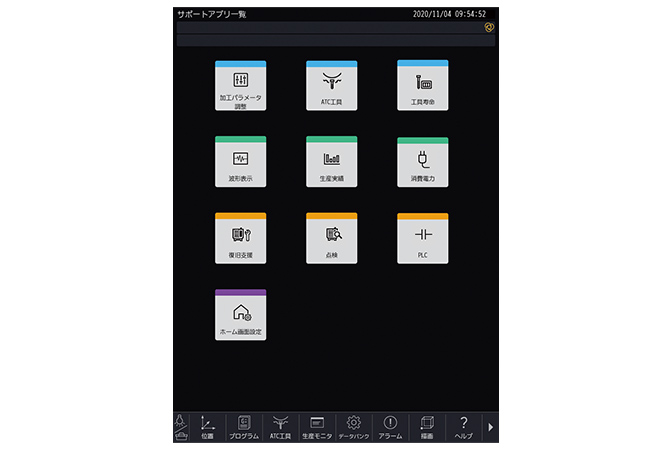

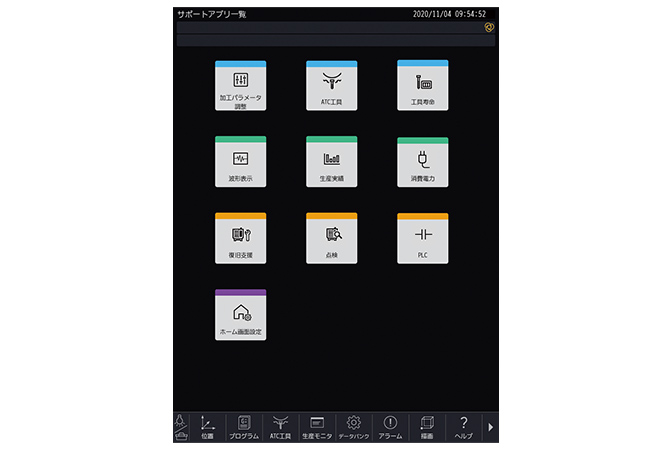

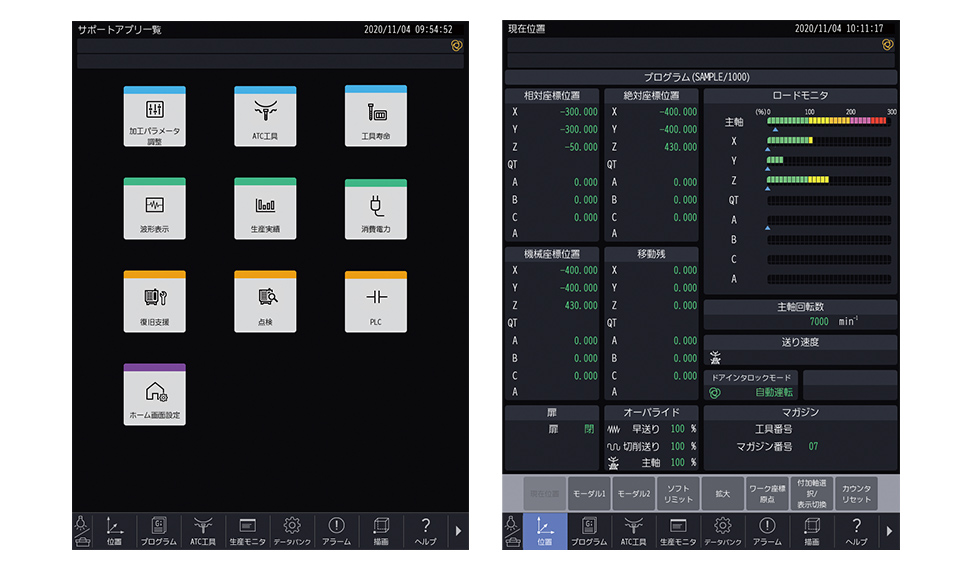

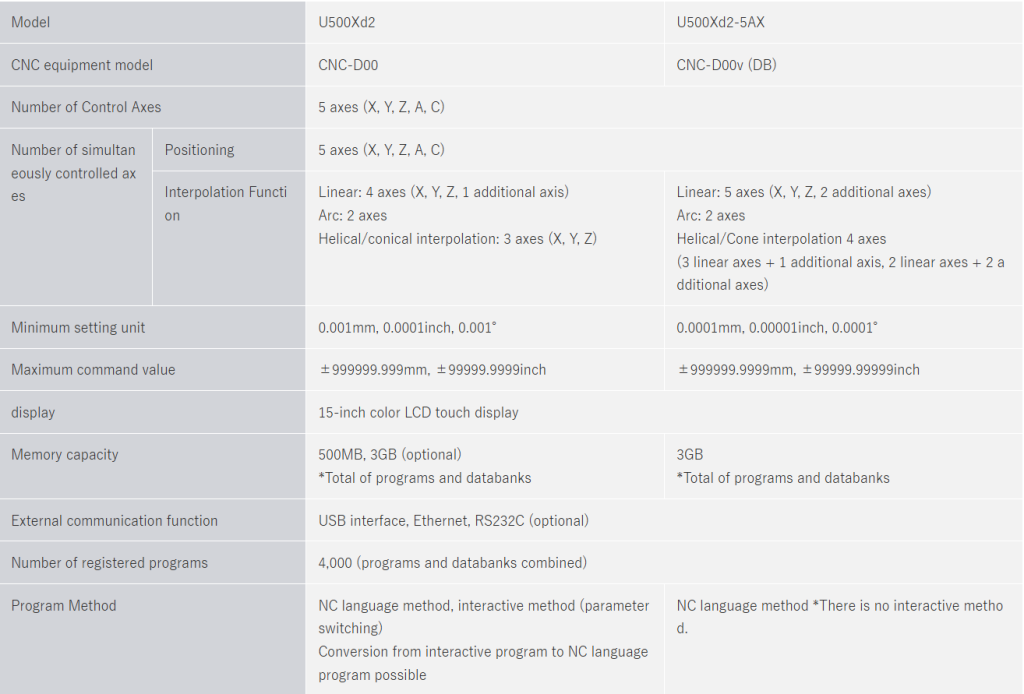

NC unit

Equipped with a “CNC-D00” control device

15-inch touch panel LCD for ease of use

The app function and vertical touch panel screen allow intuitive operation.

Functions related to setup and processing are consolidated to efficiently operate, visually display production and operation status, and allow for quick understanding. Work can be carried out efficiently in each process of setup, processing adjustment, production and recovery, contributing to improved work efficiency and operation rate.

User Interface

The device is equipped with support apps that consolidate related functions and provide a visual display for improved ease of use and visibility, as well as other convenient functions such as a calculator, memo pad and file viewer.

Operation via the conventional screen is also easy with the touch panel, making the device much easier to use.

Accessibility and workability

Accessibility has been improved to enable workers to carry out setup work such as workpiece replacement in a comfortable posture.

*1 The maximum weight of a tool varies depending on its shape, center of gravity, etc., so please consider this value as a reference only.

*2 The spindle motor output varies depending on the rotation speed.

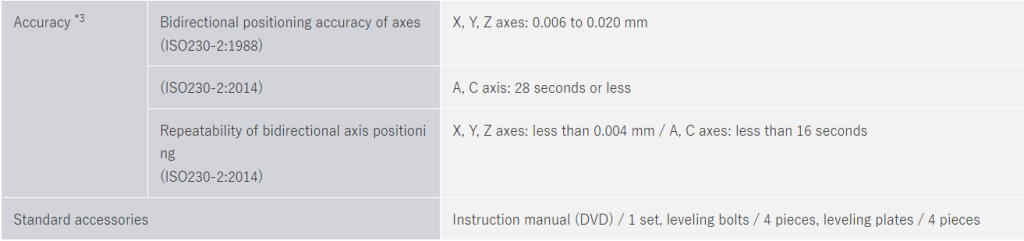

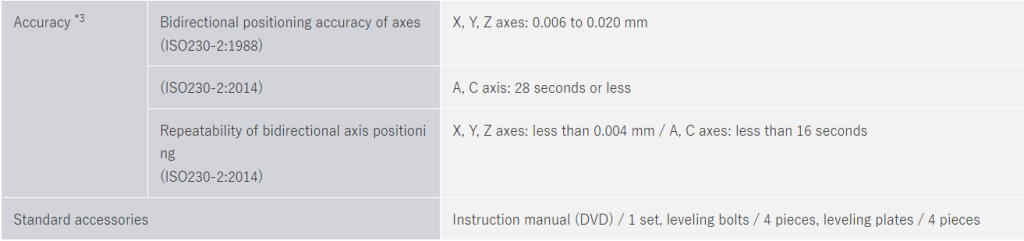

*3 The measurement method is based on ISO and Brother standards. Please contact us for details.

*4 The pull studs for CTS are Brother specifications.

*5 The tool change time measurement method is based on JIS standard B6336-9 and MAS011-1987.

*6 The normal air pressure will vary depending on the machine specifications, processing program contents, and usage of peripheral devices, so please set a pressure higher than the recommended value.

*7 These are the values when using high precision mode B.

*8 Depending on the destination, a relocation detection device may be required. Models equipped with a relocation detection device have “RD” at the end of their model names.

*9 High inertia mode value. Parameter setting needs to be changed.

*10 Parameter settings need to be changed. (Tool indexing time will change.)

*11 The value does not include the coolant tank.

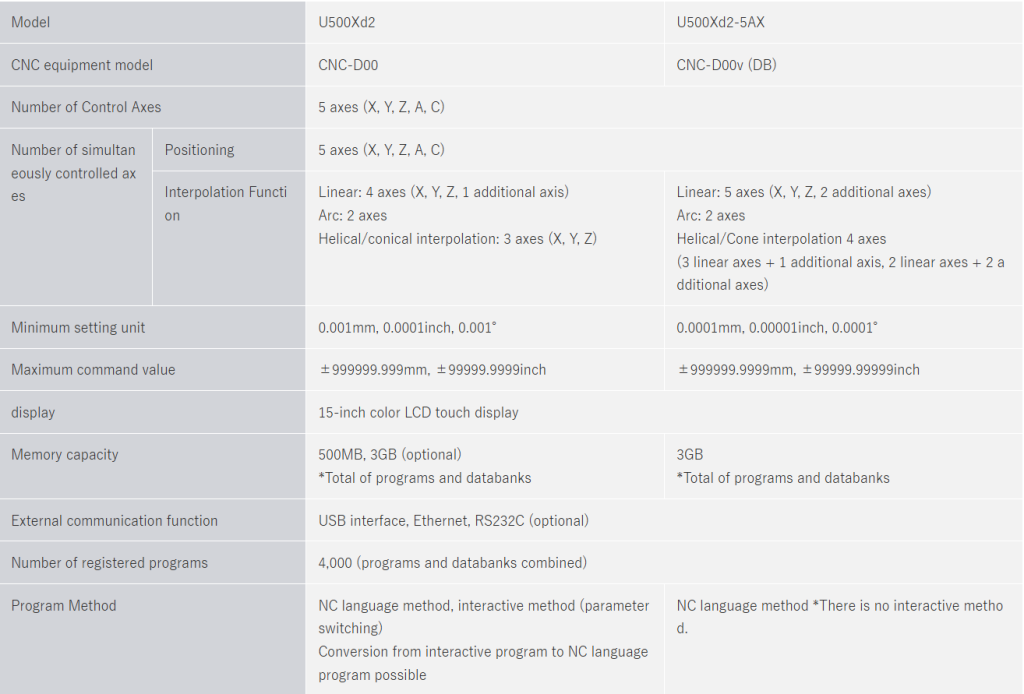

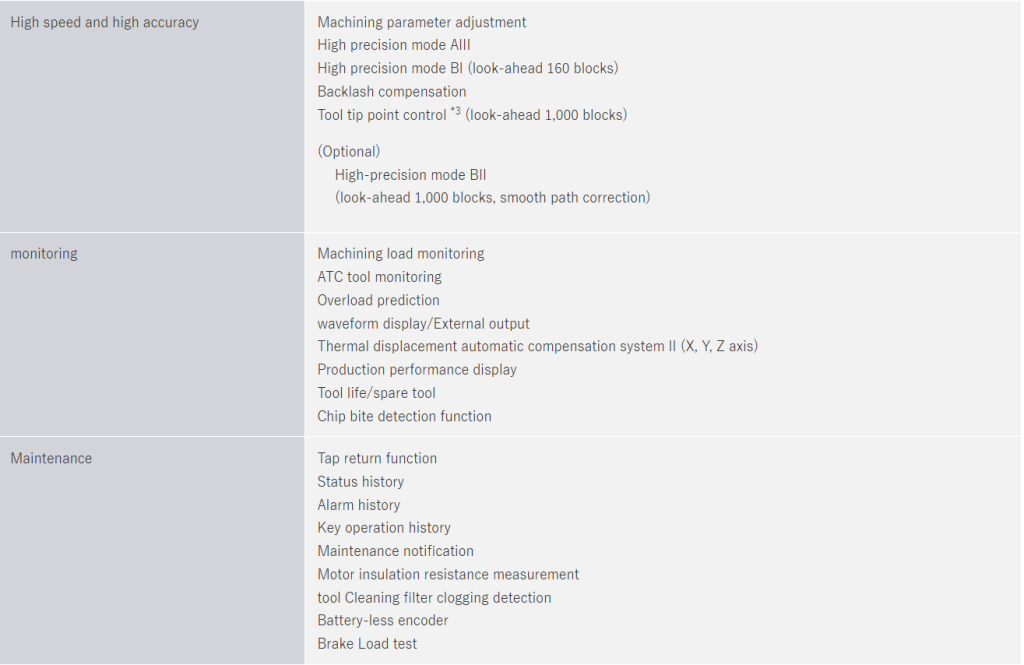

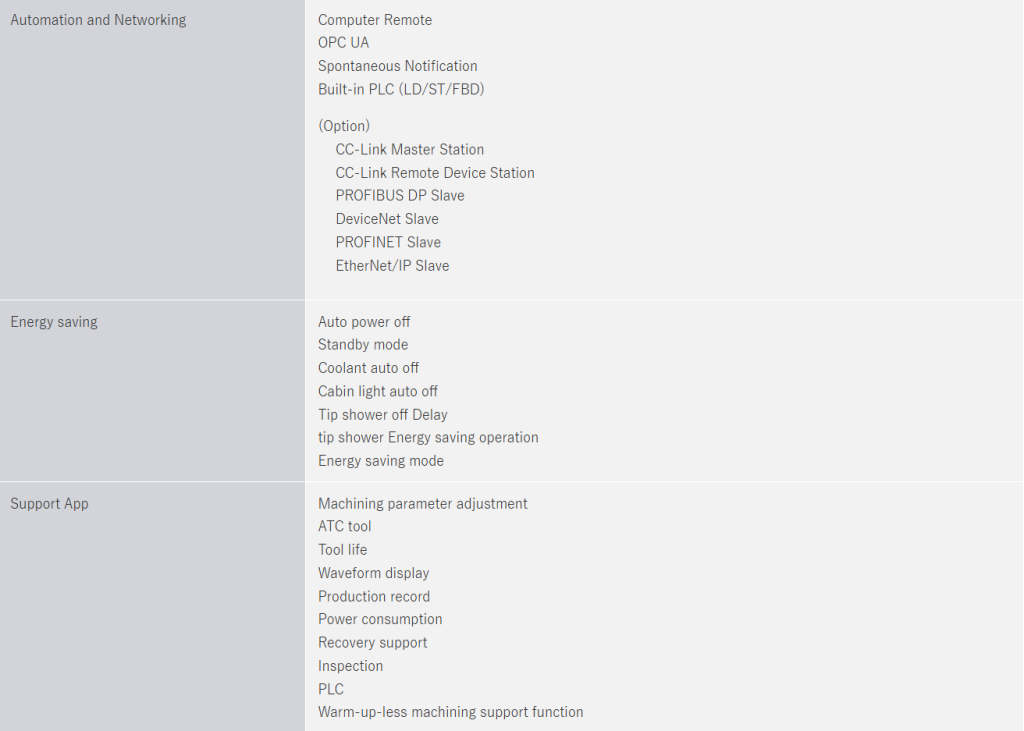

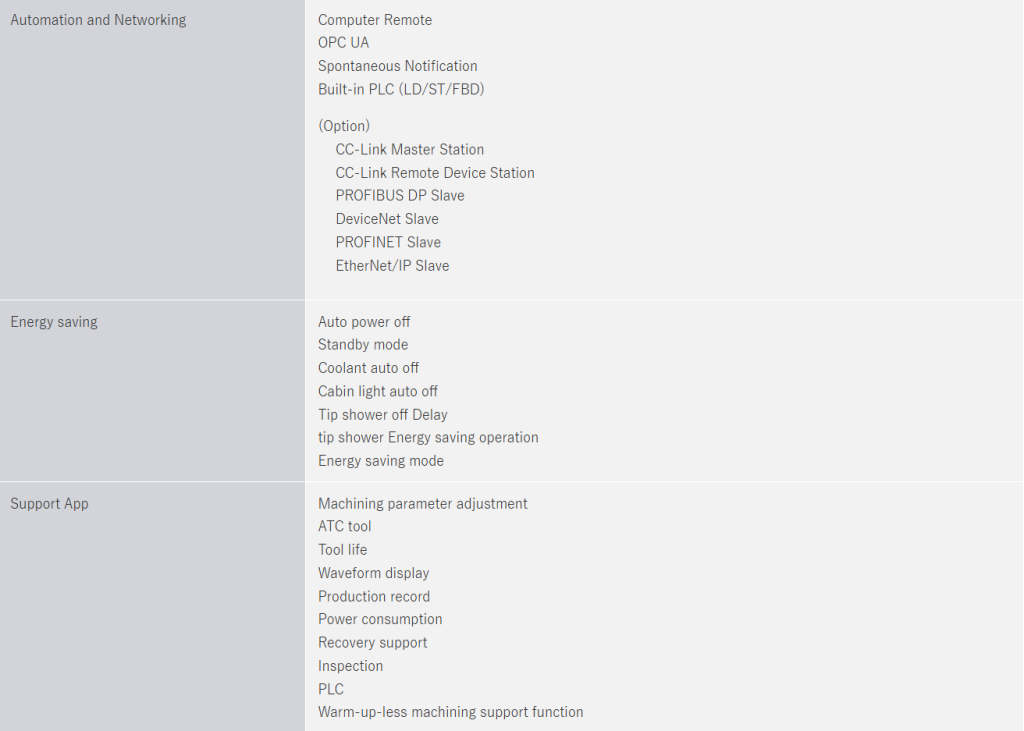

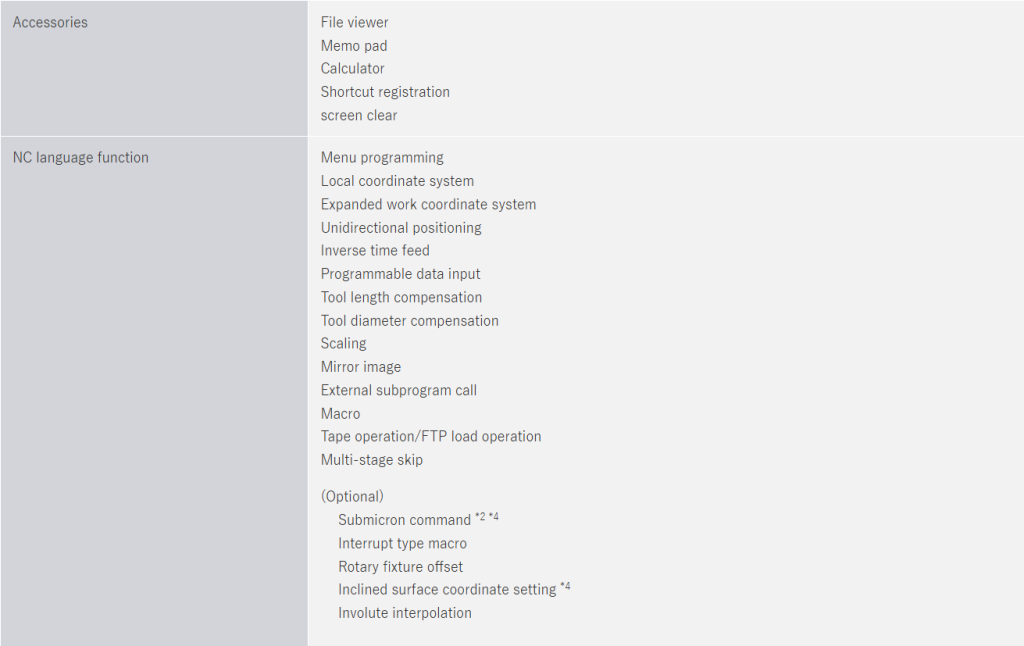

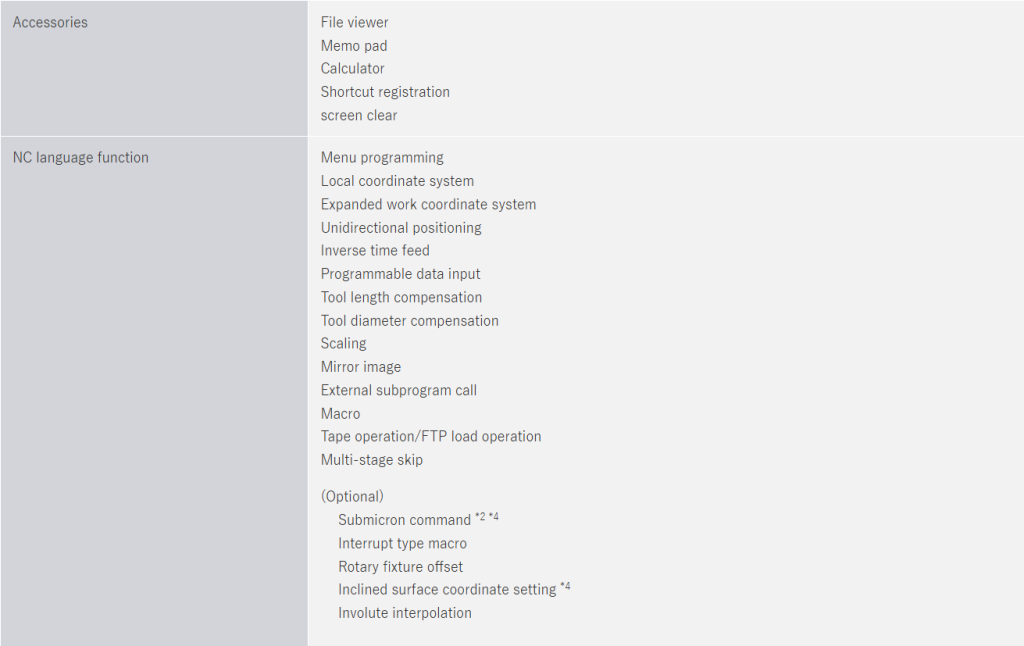

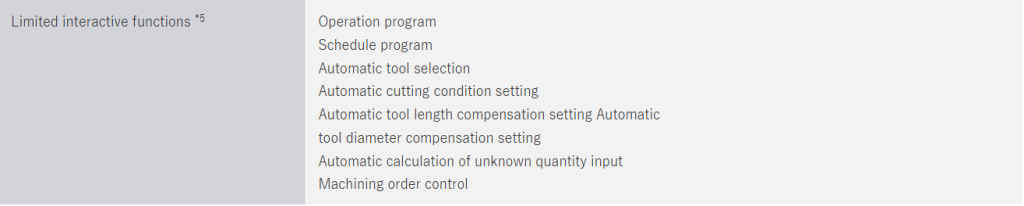

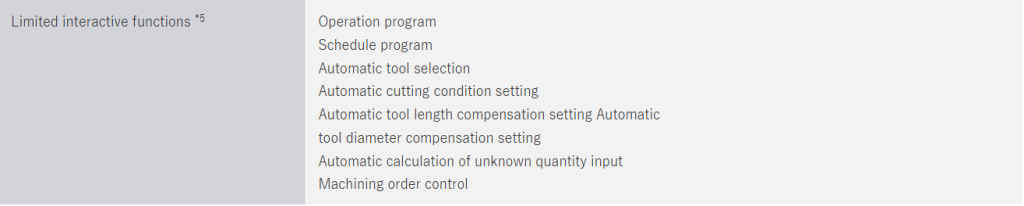

NC specifications

* “Number of controlled axes” and “Number of simultaneously controlled axes” are the maximum numbers of axes and vary depending on the destination and specifications.

* Ethernet is a registered trademark of XEROX Corporation in the United States.

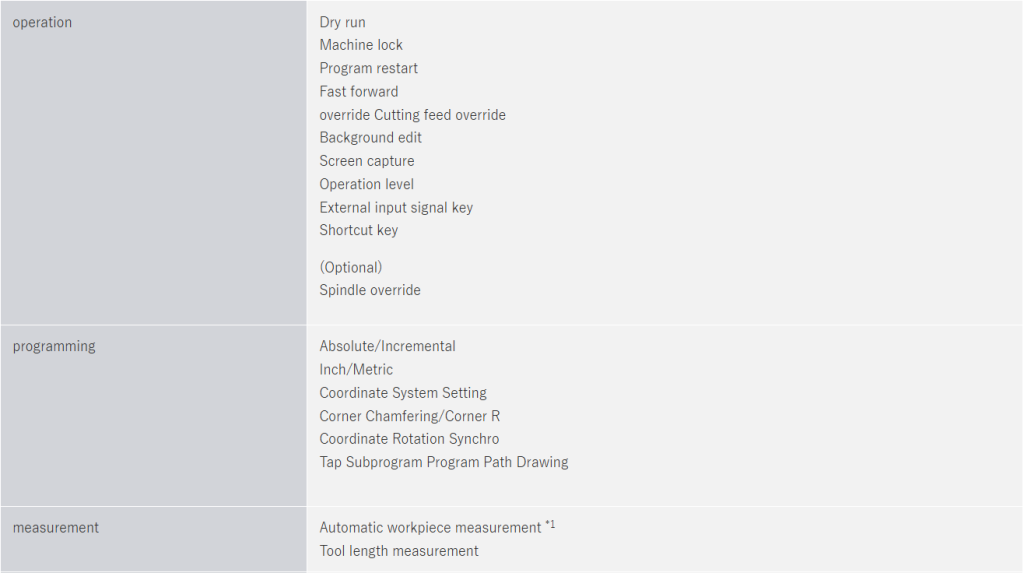

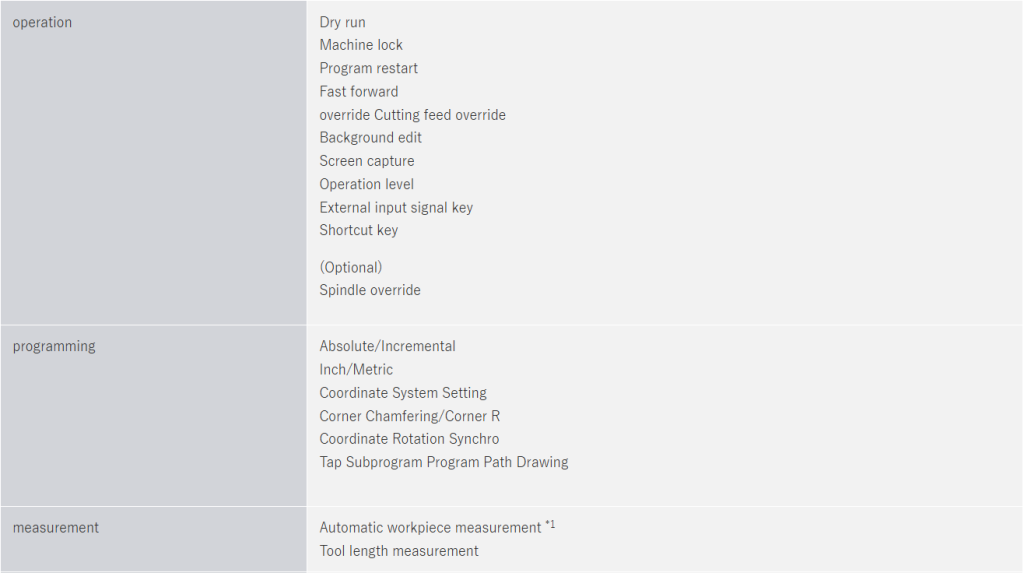

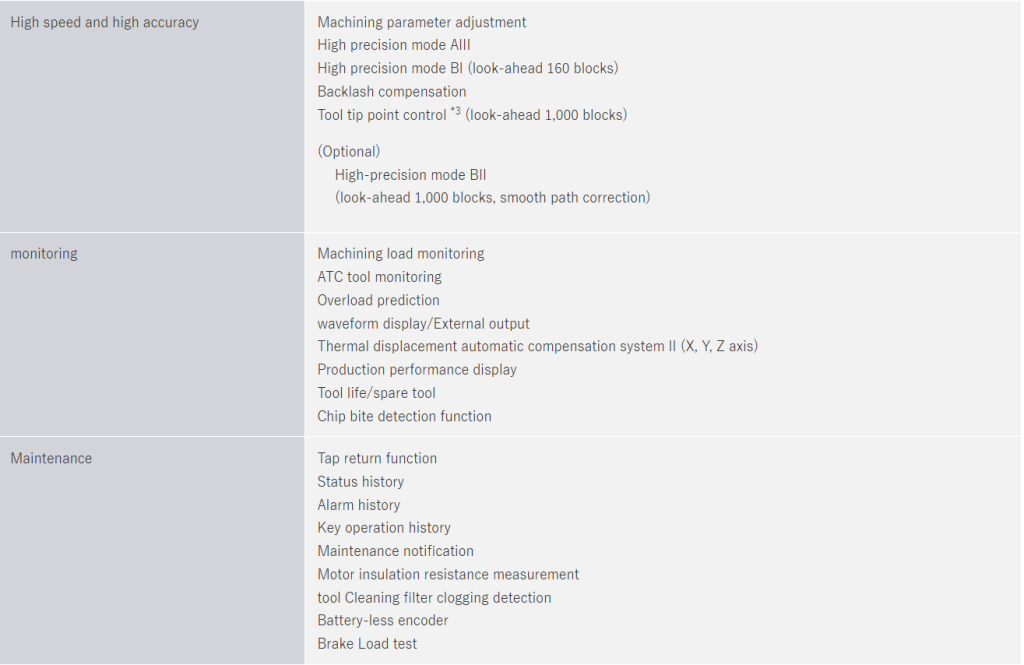

NC Function

*1 Please prepare your own measuring equipment.

*2 When a submicron command is selected, switching to an interactive program is not possible.

*3 This feature is only available on U500Xd2-5AX.

*4 It comes standard on the U500Xd2-5AX.

*5 The U500Xd2-5AX does not have an interactive mode.

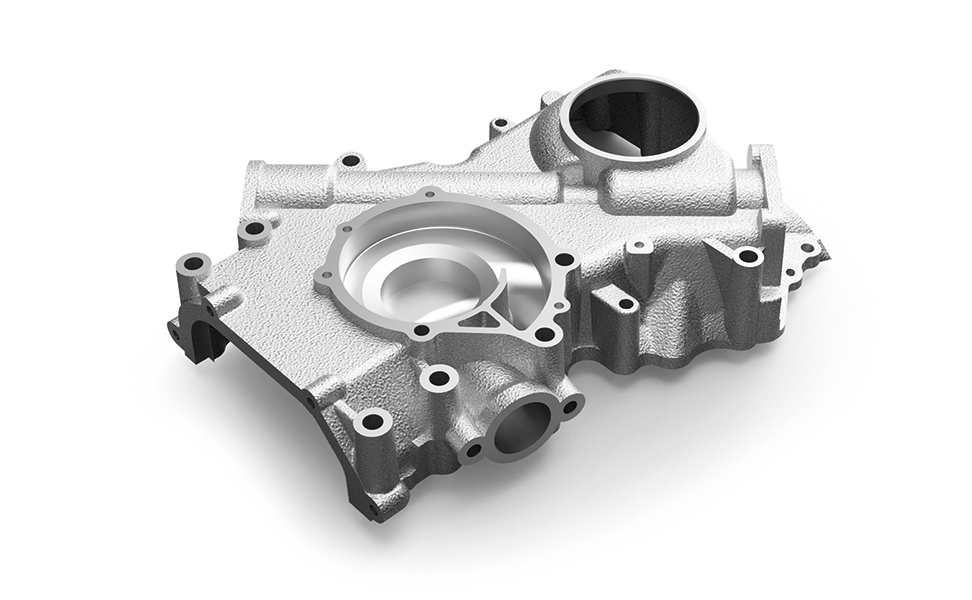

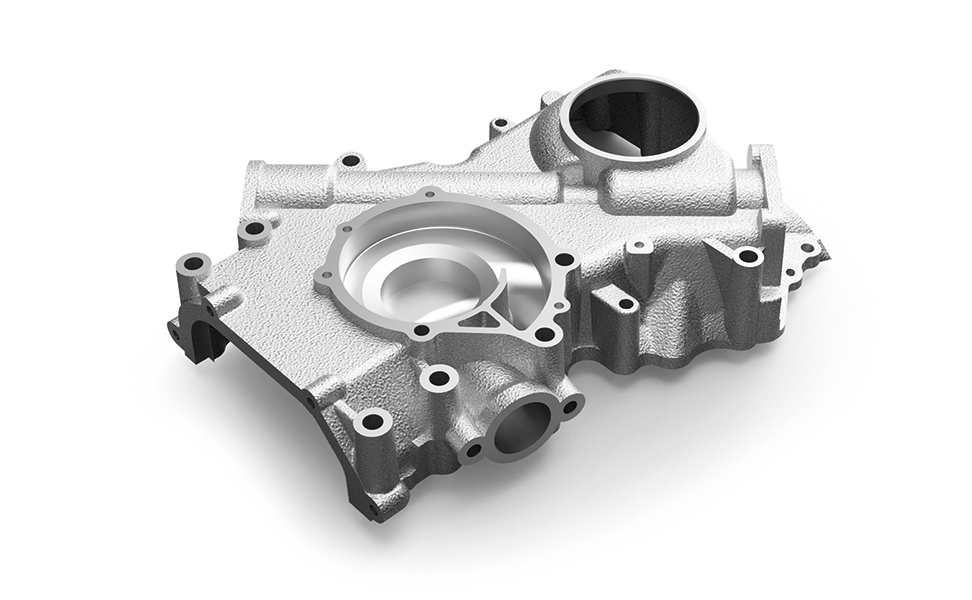

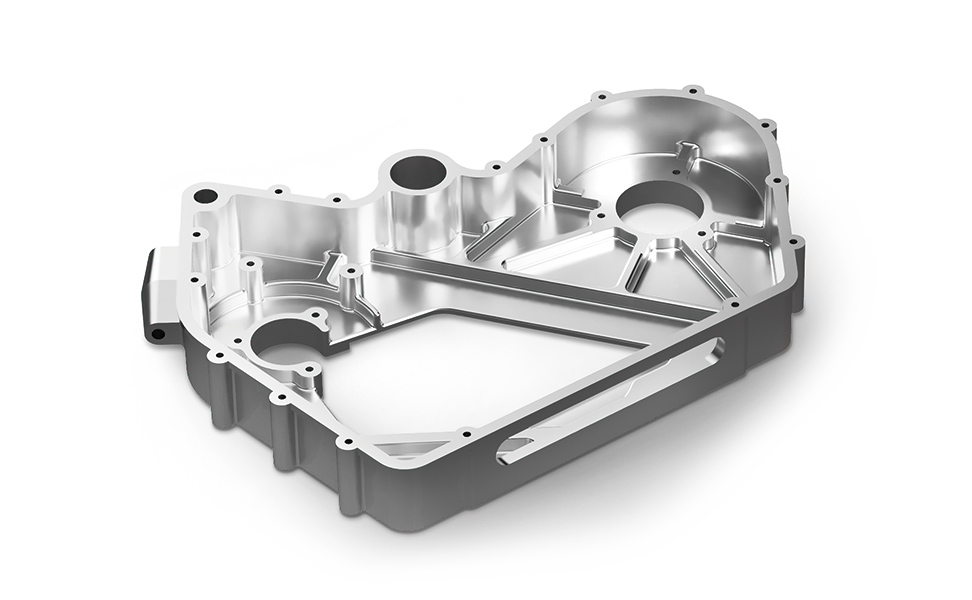

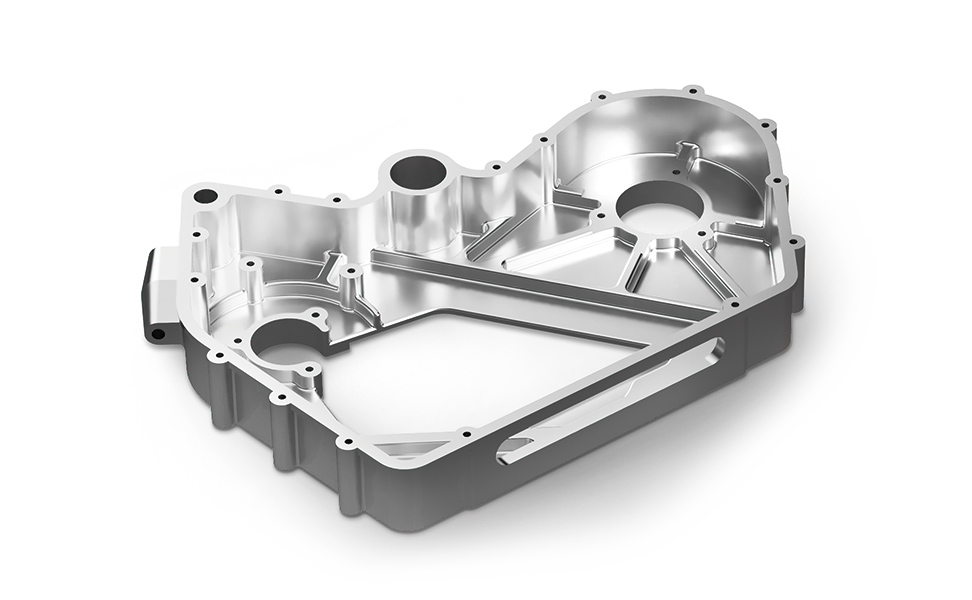

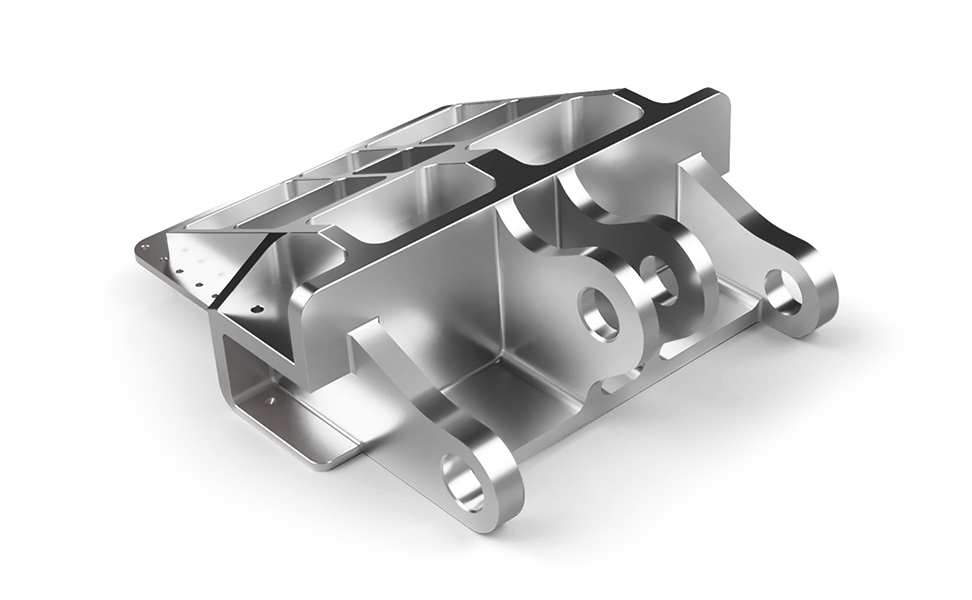

Processing Examples

Car

| Part Name | EV Gearbox Housing |

|---|---|

| Material | Aluminum alloy |

| Part Name | Gear case cover |

|---|---|

| Material | Aluminum alloy |

| Part Name | EV Gearbox Housing |

|---|---|

| Material | Aluminum alloy |

aircraft

| Part Name | Aircraft Parts |

|---|---|

| Material | Aluminum alloy |

| Part Name | Turbine blades |

|---|---|

| Material | Titanium Alloy |

medical care

| Part Name | Bone Plate |

|---|---|

| Material | Ti-6Al-4V |