AutoForm Forming

AutoForm Forming offers you a portfolio of software products with a wide range of powerful features for the digital planning and validation of sheet metal processes and parts.

AutoForm-StampingAdviser

AutoForm-StampingAdviser

AutoForm-StampingAdviser enables you to quickly and easily evaluate part and process feasibility as well as determine blank shape, material utilization and blank cost. The software provides you with valuable feedback on key stamping quality issues, such as risks of splitting and excess thinning, potential for wrinkling and developed blank shape with its associated material costs.

In the simplest application, AutoForm-StampingAdviser is used for early feasibility evaluations based on part geometry alone, without considering tool geometry. For these analyses, the software allows you to modify the part and, when needed, automatically generate a blankholder surface and a schematic addendum. In a more advanced application, forming analyses and blank development are performed based on the draw-die 3D geometry created by AutoForm-DieDesigner. With a plausible die face, AutoForm-StampingAdviser quickly identifies potential formability issues and determines blank shape, material utilization and blank cost.

AutoForm-Explorer®

AutoForm-Explorer®

AutoForm-Explorer makes it very easy for you to quickly set up simulations and evaluate the most important result variables. If you are a process planner or process engineer, AutoForm-Explorer enables you to easily define and evaluate in detail a manufacturing process intended for sheet metal part production.

With AutoForm-Explorer, you can interpret results quickly and easily. Thanks to the semi-automatic issue identification feature, you can speed up the identification of stamping issues as well as the types of issues and their locations. By using synchronized multi-design views, you can track the progression of identified issues and quickly compare them. In addition, this software enables you to easily visualize surface imperfections through the digital stoning method.

Benefits

- Efficient simulation setup

- Issue identification and interpretation

- Assessment of process feasibility

- Quick evaluation of results

- Improved forming behavior of a stamped part

Key Features

- Easy workflow-based navigation concept

- Semi-automatic results evaluation

- Usage and management of company standards

- Visualization of surface imperfections – digital stoning

AutoForm-Sigma®

AutoForm-Sigma®

AutoForm-Sigma allows you to analyze and improve the robustness of sheet metal products and processes. The software gives you deep insight and transparency into the forming process in the early engineering stage. It enables you to identify which design parameters influence part quality and to what extent. It also supports you in determining appropriate correction measures during tryout and production. In addition, it identifies the correction measures which have no effect at all and those which offer a real chance of resolving the particular problem at hand.

With this information, you can easily identify critical areas in the part, the measures that can be taken to resolve these issues as well as the effect these measures will have on other areas. By analyzing process performance and, in particular, process capability, you can validate the stamping process, minimize part rejects and maximize production efficiency. With AutoForm-Sigma, you can achieve your desired quality targets through the most efficient and stable manufacturing process.

Benefits

- Systematic process improvement

- Stability and reliability of the forming process

- Robust manufacturing process

- Rejects of stamped parts reduced to minimum

- Correction loops and related costs reduced to minimum

Key Features

- Automatic variation of design parameters

- Identification of most dominant design parameter

- Determination of noise and variability of process parameters

- Determination of process capability

- Automatic multiple simulations

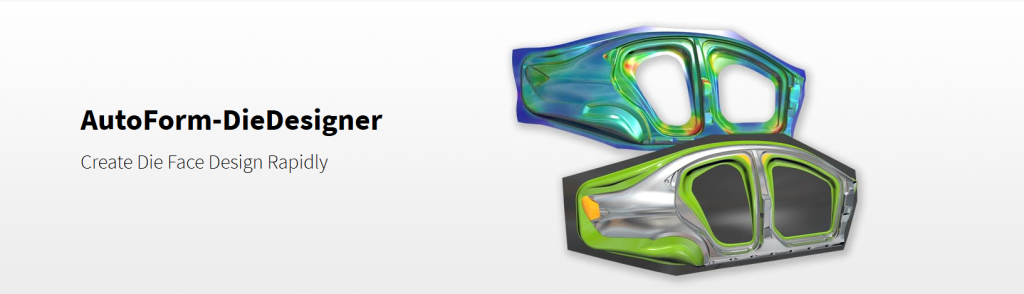

AutoForm-DieDesigner®

AutoForm-DieDesigner®

Whether you are a feasibility or process engineer, process planner or tool maker, AutoForm-DieDesigner enables you to rapidly create alternative die face designs for the complete sheet metal forming process. Once you have generated a die face design, the software uses it for the process simulations with AutoForm-FormingSolver. The results can be evaluated with AutoForm-Explorer. The full integration of die face design with simulation and results evaluation allows you to evaluate multiple, alternative process and tool concepts in a very short amount of time as well as select the best one with regard to feasibility, quality and cost.

AutoForm-DieDesigner has a clear and logical structure which enables you to work step-by-step, from the import of CAD part geometry to the complete die face design. This software gives you an in-depth understanding, allowing you to validate the process layout as well as sheet behavior during multiple operations.

AutoForm-DieDesigner is based on a fully associatively linked model of the entire die layout, which allows you to easily modify the part geometry as well as intermediate operations. As soon as you have determined an optimal die face design, surfaces can be exported and processed further in any CAD system.

Benefits

- Generation of concept die faces

- Evaluation of multiple, alternative process concepts due to direct coupling with process simulation

- In-depth understanding and validation of the process layout

Key Features

- Generation of parametrized die face geometries for all operations

- Addendum creation based on specially adapted profiles

- Automatic development of flanges on the addendum surface

- Geometry modeling through morphing technology

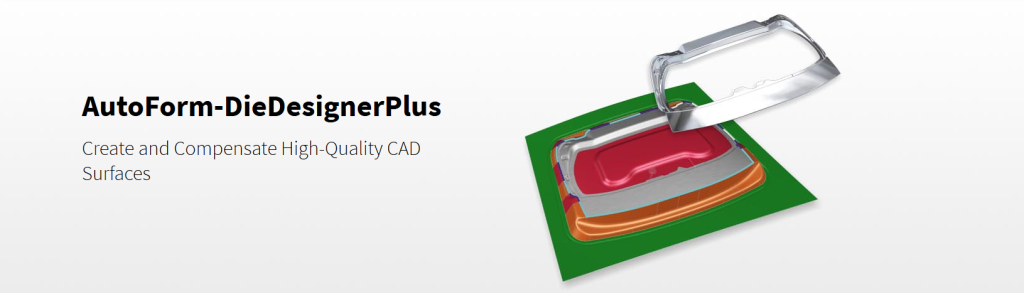

AutoForm-DieDesigner®Plus

AutoForm-DieDesigner®Plus

The creation and compensation of high-quality CAD surfaces for manufacturing has typically been carried out using external CAD software. Such software requires the user’s familiarity with its application, multiple importing and exporting of data from and to CAE software as well as the creation and potential integration of additional external documentation.

AutoForm-DieDesignerPlus provides a set of geometry creation features within the AutoForm user interface that are tailored to the need of engineers responsible for final CAD-quality surfaces. The software is best applied during the process design phase to facilitate the creation of high-quality CAD surfaces. Such surfaces are required for the final validation simulations and compensation of die surfaces, which will be exported afterwards for use in die manufacturing. With AutoForm-DieDesignerPlus, you can achieve a new level of efficiency in the process design phase.

Benefits

- Creation and compensation of high-quality CAD surfaces for manufacturing

- Efficient use of existing process plan information during process design

- Easy to use CAD surface creation within the AutoForm environment

Key Features

- Creation of parametrized die face geometries for stamping operations

- CAD-quality compensation of die surfaces

- Guided surface creation workflow for stamping process design

- Flexible modeling of any desired shape as a result of no predefined styles or profiles

- Automatic development of flanges onto process surfaces

AutoForm-Compensator

AutoForm-Compensator

AutoForm-Compensator allows you to automatically modify tooling surfaces based on precise springback calculation or measured springback data. With this software, you can easily define compensation regions, which are automatically adjusted using springback results. The compensated geometry can then be used for rapid and accurate tooling validation.

Die faces are compensated in the opposite direction of springback. This software enables you to modify either the entire tooling surface or only selected regions. Since different regions can be defined within the tool, you can systematically control compensation.

Once the tooling geometry is compensated, it is automatically used as input for the next simulation. Final part geometry within the required tolerances is achieved with a minimum of correction loops.

Benefits

- Reliability of planning and process engineering

- Reduction of correction loops

- No risk of later changes due to springback

Key Features

- User-defined compensation regions

- Support for both free and clamped springback

- Automatic adjustment of tool geometry

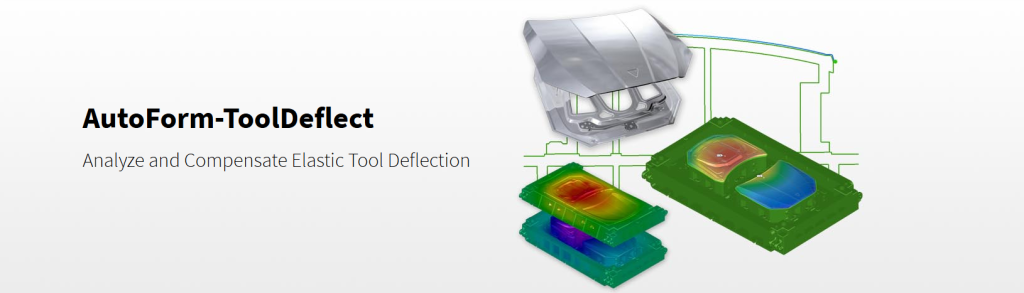

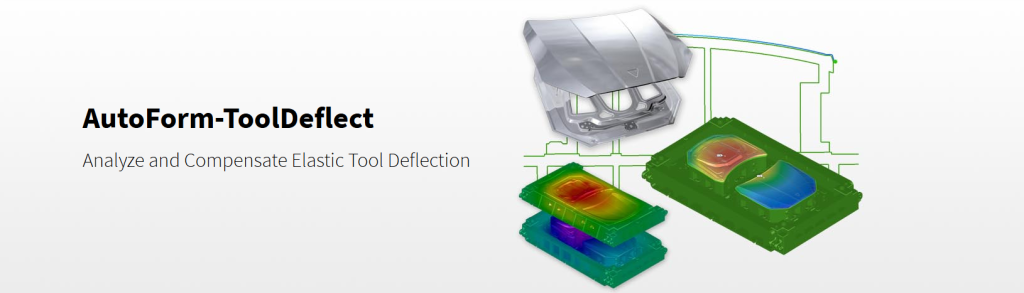

AutoForm-ToolDeflect

AutoForm-ToolDeflect

AutoForm-ToolDeflect allows for the efficient analysis and compensation of elastic tool deflection. With AutoForm-ToolDeflect, you can carry out the over-crowning process effectively and thereby significantly reduce the number of tryout loops.

AutoForm-ToolDeflect can be applied in the early process design phase when the final tool geometry is not yet available in CAD. You can quickly create initial tool design concepts based on part geometry only. By analyzing various alternative concept designs, you can select the most effective design for your tool.

The software can also be applied in the final validation phase by using already existing final tool geometry data in CAD. When the tool deflection has been calculated, you can carry out an over-crowning. The results you obtain from over-crowning can then be used for milling preparation.

Benefits

- Efficient compensation of elastic tool deflection (over-crowning)

- Effective application in the early process design phase as well as in the final validation phase

- Reduced number of tryout loops, rejects and press downtime in production

Key Features

- Analysis and evaluation of elastic tool deflection effects

- Tool substructure generator for creation of 3D solid tool concepts

- Press elasticity model generator to represent individual press conditions

AutoForm-AutoComp

AutoForm-AutoComp

With the increasing use of modern materials, such as high strength steels and aluminum, applying the most effective compensation strategy brings tangible benefits to users. AutoForm-AutoComp enables you to quickly evaluate and compare different compensation strategies and then select the one that is best suited to your needs.

With AutoForm-AutoComp, compensation loops are automatically carried out in the background. You can select the number of iterations, check their status and immediately visualize them on the screen. As a result, the final tool geometry and process setup can be defined efficiently ensuring part geometry within the required tolerances and with a minimum number of correction loops in physical tryout. This procedure results in improved planning reliability in die development, tool shop and tryout as well as minimized risk of later, costly changes to tooling or processes.

Benefits

- Easy evaluation and comparison of different compensation strategies

- Adoption of the most effective compensation strategy

- Minimized risk of later costly changes to tooling or process

Key Features

- Compensation loops carried out in the background

- Automatic control of the tool surface consistency

- Visualization of different strategies all at once on the screen

AutoForm-CostEstimator

AutoForm-CostEstimator

AutoForm-CostEstimator is designed for OEMs and tooling suppliers to estimate tooling costs early on in the planning and bidding phases. With this software, each part detail which has an impact on tooling costs is automatically associated to a production step. With just a few mouse clicks, AutoForm-CostEstimator calculates tooling costs based on the defined production sequence. As a result, this software enables you to systematically evaluate alternative production concepts and rapidly identify the most cost-effective one.

The automatic detection of part geometry features and the costing engine embedded in AutoForm-CostEstimator provide you with the ideal replacement for conventional Excel-based worksheets and tedious, manual calculations. With AutoForm-CostEstimator, you can produce tooling cost estimates much more consistently, reliably and rapidly, based on CAD part data and the stamping process.

Benefits

- Measurement of cost impact of alternate stamping processes on tooling costs

- Estimation of tooling costs based on CAD part data and stamping process

- Generation of reliable cost estimates in minutes

Key Features

- Full graphic-based 3D approach using CAD part geometry

- Automatic detection of part geometry features

- Intelligent costing engine for stamping operations

AutoForm-DieAdviser®

AutoForm-DieAdviser®

AutoForm-DieAdviser allows you to determine the optimal tool layout and the most efficient wear protection concept based on AutoForm-FormingSolver simulation results. With this software, you can define the durability of tool materials, hardening and tool coating, taking into account the production quantity and press stroke rate.

By using AutoForm-Die Adviser, you can gain new insights into both improving tool layout early in the product development process and providing longer lasting and lower cost tooling. In particular, if you work in the fields of tool design and stamping, AutoForm-DieAdviser enables you to meet today’s challenging requirements such as those posed by the introduction of new materials like ultra-high-strength steels as well as the demand for higher press stroke rates and lower lubricant consumption.

Benefits

- Definition of the optimal tool layout (potentially segmented tools)

- Cost-effective wear protection concept based on production volumes

- Lower lubricant consumption

- Better performance and durability of the tool

Key Features

- Identification of areas with intensive tool wear

- Differentiation of sheet materials and part types

- Wear protection concepts that combine the appropriate tool material, hardening and tool coating

AutoForm-FormingSolver

AutoForm-FormingSolver

AutoForm-FormingSolver enables you to rapidly and accurately simulate the sheet metal forming processes, including drawing and secondary operations as well as springback and hemming. Once you have obtained simulation results with AutoForm-FormingSolver, you can then visualize them with AutoForm-Explorer, which provides you with in-depth information about all aspects of the forming process. With AutoForm-FormingSolver, you can simulate stamping processes involving line or transfer dies as well as progressive dies.

AutoForm-FormingSolver optimally supports the engineering process during all its phases. You can use AutoForm-FormingSolver to quickly obtain simulation results during an early, conceptual development phase and also to generate very precise results during the final validation phase.

AutoForm-FormingSolver provides results for one simulation at a time, i.e. the solver results describe one deterministic result of a forming process as only a single set of input parameters is selected for the simulation. However, AutoForm-FormingSolver is also capable of running a stochastic analysis using the AutoForm-Sigma functionality. During these simulations, design or noise parameters are varied while maintaining the focus on the quality targets set for the stamping part as well as on the robustness of the stamping.

Furthermore, you can enhance the functionality of AutoForm-FormingSolver using AutoForm-Thermo Plug-In for thermal analyses, AutoForm-PhaseChange Plug-In for phase transformation analyses of MnB-grade steels and TriboForm Plug-In for refining the tribological model used for the simulation.

Benefits and Key Features

- Simulation of line and progressive die stamping

- Rapid and accurate simulation of deep drawing, restriking, trimming and flanging operations as well as hemming

- Accurate springback simulation

- Deep insight into all stamping process operations

- Rapid verification of new process concepts for quality and cost improvements

- Reduced computing time by taking advantage of SMP or MPP parallel processing technology

- Enhancement options to include thermal effects, phase transformations as well as tribological refinement

Optional :

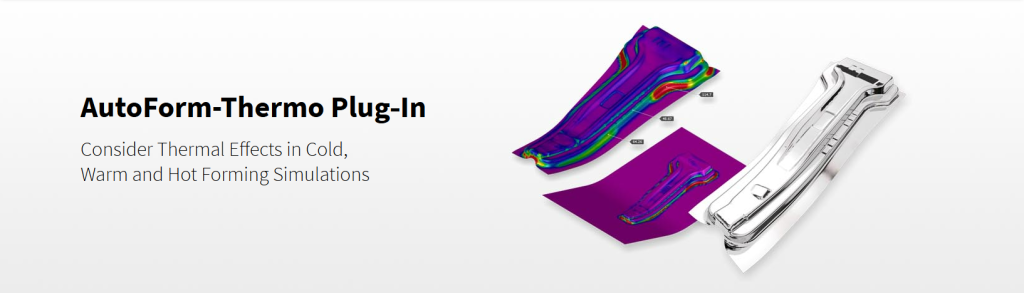

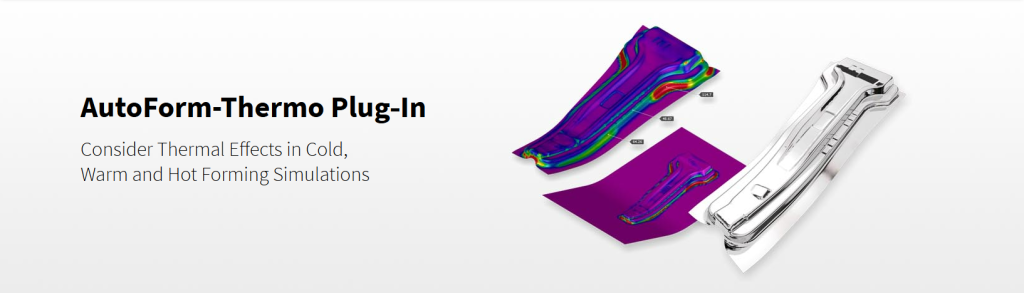

AutoForm-Thermo Plug‑In

AutoForm-Thermo Plug‑In is used in connection with AutoForm-FormingSolver to consider general thermal effects in cold, warm and hot forming simulations. With this plug‑In, you can take thermal behavior into account while examining part and process feasibility, optimizing forming and production process parameters and conducting final validation analyses as long as there are no phase transformation effects to be considered. Taking temperature into account leads to increased accuracy of simulation results for both warm and hot forming of many automotive light metals such as aluminum alloys. Furthermore, you can also analyze the effects of real forming tool temperatures as well as temperature effects on the tribological system, and subsequently on the forming results.

AutoForm-Thermo Plug‑In enables AutoForm-FormingSolver to handle coupled solutions of the mechanical and thermal finite element equations for all of the warm and hot forming process operations, including heating, transport and cooling. You can define tool surface temperatures to be constant or evenly distributed, mapped as temperature fields obtained from external computations or internally computed as the result of tool temperature control using cooling channels.

You can use AutoForm-Thermo Plug‑In together with AutoForm-Sigma to analyze the impact of design and noise variables on hot forming processes. Moreover, when used with TriboForm Solver Plug‑In, you can simulate the effect of temperature on the tribology system.

With AutoForm-PhaseChange Plug‑In, the functionality of AutoForm-FormingSolver and AutoForm-Thermo Plug‑In can be further extended into the area of phase transformation simulation of Manganese-Boron Steels.

Benefits

- Realistic simulation of thermal effects in sheet metal forming processes (cold, warm and hot forming)

- More realistic modelling of temperature dependent friction behavior in conjunction with the TriboForm Plug‑In

- Simulation of the quenching process for Manganese-Boron Steels using AutoForm-PhaseChange Plug‑In

Key Features

- Rapid simulation of thermal behavior in sheet metal forming processes

- Fully coupled thermo-mechanical simulations without consideration of phase dependent material properties

- Graphic display of simulation results, i.e. temperature changes and distribution in part and tool, final part properties such as thickness distribution, strain-stress distribution and springback

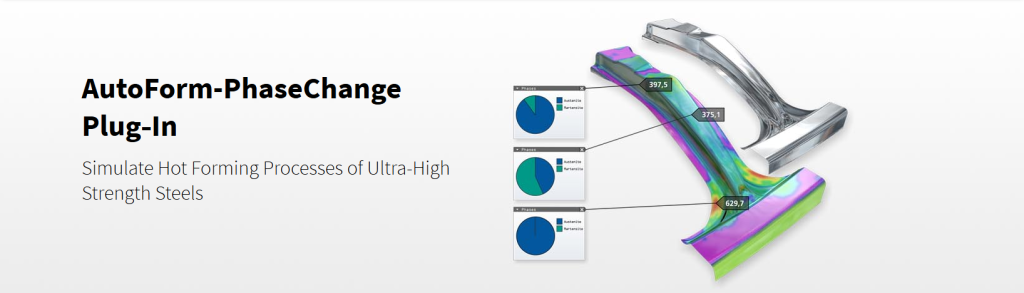

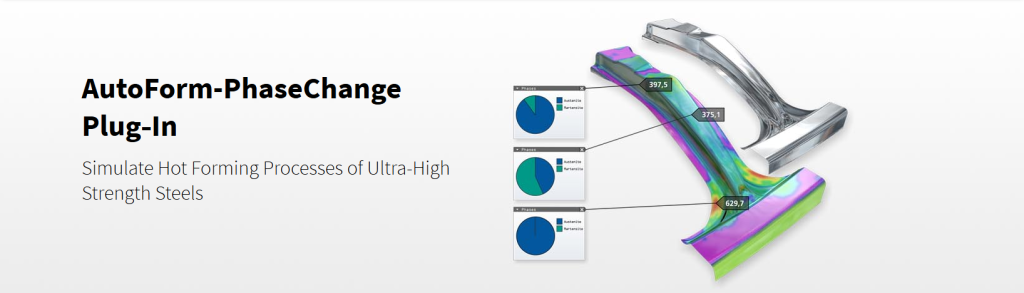

AutoForm-PhaseChange Plug-In

AutoForm-PhaseChange Plug-In in combination with AutoForm-Thermo Plug-In enables you to realistically simulate the hot forming processes of ultra-high strength steels. These processes have become very important for the automotive industry in order to meet specific requirements regarding a higher level of crash safety and a reduction of overall weight. With this plug-in, you can engineer components with high strength, challenging geometrical complexity and minimized springback effects in much shorter time and at lower cost.

AutoForm-PhaseChange Plug‑In supports direct and indirect hot forming, which are both followed by the quenching and cooling processes. This innovative software takes into account phase transformation during quenching and thermal distortion after cooling. In addition, AutoForm-PhaseChange Plug‑In allows you to calculate the final part properties, such as the thickness distribution, strain-stress distributions as well as the distribution and local percentages of different material phases, such as austenite, ferrite, pearlite, bainite and martensite, including the resulting hardness distribution.

AutoForm-PhaseChange Plug‑In allows you to gain better insight into the effects of phase transformation as well as have better control over the resulting mechanical properties of the hot-formed part. With this plug-in, you can also simulate the tailored tempering process, thus enabling the engineering of stamped parts with targeted local strength properties. Based on the results of AutoForm-PhaseChange Plug‑In, you can improve crash simulation accuracy by taking the real strength distribution of the hot-formed component into account.

Benefits

- Realistic simulation of hot forming and quenching processes

- Stamped parts with challenging geometrical complexity and minimized springback effects

- Stamped parts engineered with targeted local strength properties

- Improved crash simulation accuracy

Key Features

- Rapid simulation of direct and indirect hot forming processes

- Fully coupled thermo-mechanical simulations with consideration of phase dependent material properties

- Phase transformation during quenching and thermal distortion after cooling

- Support of innovative tailored tempering process

- Graphic display of final part properties, such as thickness distribution, strain-stress distribution as well as distribution and percentage of different material phases and the resulting hardness

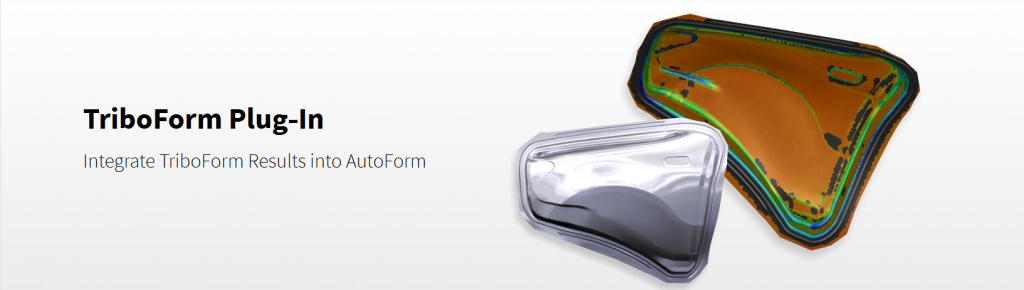

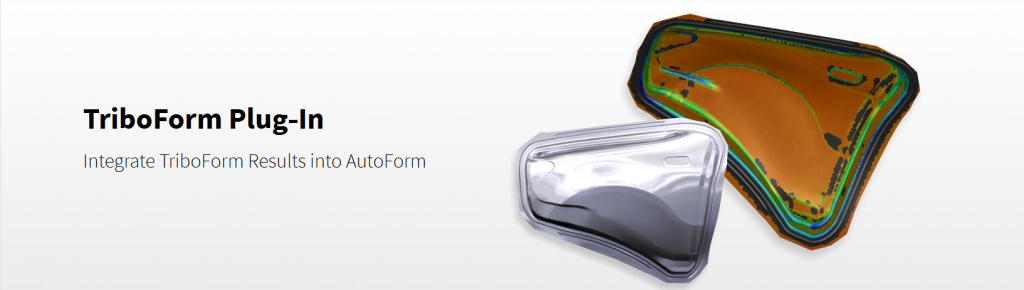

TriboForm Plug-In

The TriboForm software allows you to quickly simulate the effects of tool coatings, lubricants, material surface characteristics or new sheet materials on friction and ultimately on product quality. Through a more realistic consideration of tribological effects, a new level of simulation accuracy can be achieved. TriboForm’s products complement AutoForm’s product portfolio.

TriboForm Plug-In enables the direct integration of TriboForm results into AutoForm simulations. This allows you to account for realistic friction conditions during the forming simulation and evaluate its effect on product quality.

TriboForm Plug-In in combination with AutoForm-Thermo Plug-In enables you to accurately account for temperature effects on the tribological conditions. This allows a more accurate description of friction conditions, increasing the accuracy of the forming simulation.

Benefits

- Accurate representation of complex tribological phenomena

- Simulation, visualization and evaluation of friction and lubrication conditions

- Improved simulation accuracy in forming simulations

- Savings on expensive tool modifications during tryout or production

- Easy integration in AutoForm

AutoForm-Trim

AutoForm-Trim

AutoForm-Trim in combination with AutoForm-FormingSolver is an essential tool for the determination of blank outlines and for the tryout of trimming dies used to find the optimum trim line. This software enables you to design trimming tools simultaneously with the draw die.

Optimum trim line is necessary for the multi-operation stamping process. The trim line is optimized to ensure that the desired shape and dimensions of the part boundary are obtained at the end of the operations following the trimming operation.

Optimum blank outline is necessary for near-net-shape manufacturing (crash forming). The blank outline is optimized to ensure that the desired shape and dimensions of the part boundary are obtained at the end of the crash forming process.

Benefits

- Determination of optimum trim line and blank outline

- Time and costs savings due to simultaneous development of trim and draw die

- Reduced laser-trim tryout time for complex parts

Key Features

- Automatic determination of blank outline for near-net-shape manufacturing

- Automatic calculation of multiple blank outlines

- Calculation of customer-specified segments of blank or cut outline

- Simultaneous determination of all cut-out lines for several cutting operations