AutoForm ProgDie

AutoForm ProgDie allows progressive die makers to efficiently design, simulate, evaluate, validate and modify various strip layout concepts and then select the one that best suits their needs.

AutoForm-StampingAdviser

AutoForm-StampingAdviser

AutoForm-StampingAdviser enables you to design the optimal strip layout which is crucial for the cost efficient and precise manufacturing of a large number of parts with complex geometries. You can start with the part geometry and unfold it systematically by creating intermediate geometries until the part becomes flat.The software allows you to calculate the blank layout and to then quickly evaluate and compare different nesting options. In this way, you can efficiently identify the optimal strip layout, taking into consideration minimal material utilization. In addition, the software enables you to easily design carriers and complex webs.Benefits

- Prediction of potential blank shape and nesting

- Design of optimal strip layout with minimal material usage

Key Features

- Creation of 3D strip plan with an intuitive design interface

- Several strip layout options

- Rapid part geometry modification

AutoForm-Explorer®

AutoForm-Explorer®

AutoForm-Explorer makes it very easy for you to quickly set up simulations and evaluate the most important result variables. If you are a process planner or process engineer, AutoForm-Explorer enables you to easily define and evaluate in detail a progressive die stamping process.

With AutoForm-Explorer, you can interpret results quickly and easily. Thanks to the semi-automatic issue identification feature, you can speed up the identification of progressive die stamping issues as well as the types of issues and their locations. By using synchronized multi-design views, you can track the progression of identified issues and quickly compare them.

Benefits

- Efficient simulation setup

- Issue identification and interpretation

- Assessment of process feasibility

- Quick evaluation of results

- Easy web deformation analysis

Key Features

- Complete strip simulation for progressive die stamping

- Easy workflow-based navigation concept

- Semi-automatic results evaluation

- Usage and management of company standards

AutoForm-Sigma®

AutoForm-Sigma®

AutoForm-Sigma allows you to analyze and improve the robustness of the progressive die stamping process. The software gives you deep insight and transparency into the process in the early engineering stage. It enables you to identify which design parameters influence part quality and to what extent. It also supports you in determining appropriate correction measures during tryout and production. In addition, it identifies the correction measures which have no effect at all and those which offer a real chance of resolving the particular problem at hand.

With this information, you can easily identify critical areas in the part, the measures that can be taken to resolve these issues as well as the effect these measures will have on other areas. By analyzing process performance and, in particular, process capability, you can validate the progressive die stamping process, minimize part rejects and maximize production efficiency. With AutoForm-Sigma, you can achieve your desired quality targets through the most efficient and stable manufacturing process.

Benefits

- Systematic process improvement

- Stability and reliability of the progressive die stamping process

- Robust manufacturing process

- Rejects of stamped parts reduced to minimum

- Correction loops and related costs reduced to minimum

Key Features

- Automatic variation of design parameters

- Identification of the most dominant design parameters

- Determination of noise and variability of process parameters

- Determination of process capability

- Automatic multiple simulations

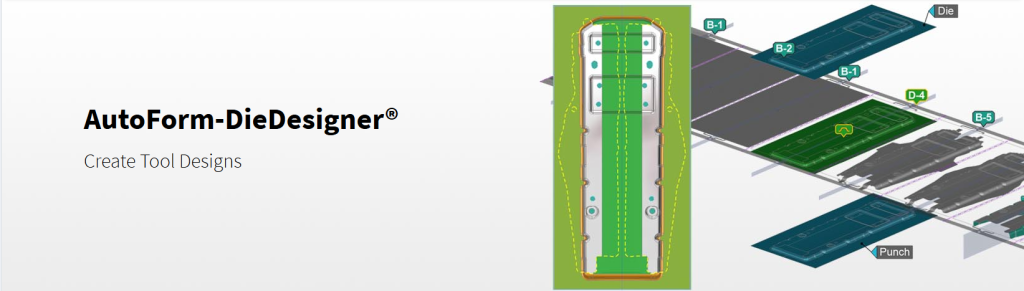

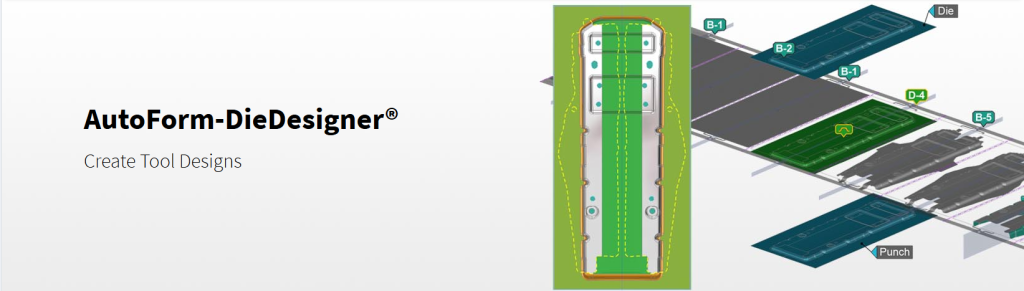

AutoForm-DieDesigner®

AutoForm-DieDesigner®

AutoForm-DieDesigner enables you to rapidly create alternative strip layout and die face designs for progressive die stamping. Once you have generated a strip layout and die face designs, the software uses them for the process simulations with AutoForm-FormingSolver. The results can be evaluated with AutoForm-Explorer. The full integration of strip layout and die face designs with simulation and results evaluation allows you to evaluate multiple, alternative process and tool concepts in a very short amount of time as well as select the best one with regard to feasibility, quality and cost.

AutoForm-DieDesigner has a clear and logical structure which enables you to work step-by-step, from the import of CAD part geometry to the complete strip layout and die face designs. This software gives you an in-depth understanding, allowing you to validate the process layout as well as strip behavior during multiple operations.

AutoForm-DieDesigner is based on a fully associatively linked model of the entire die layout, which allows you to easily modify the part geometry as well as intermediate operations. As soon as you have determined an optimal strip layout and die face designs, surfaces can be exported and processed further in any CAD system.

Benefits

- Generation of detailed strip layout and die faces

- Evaluation of multiple, alternative process concepts due to direct coupling with process simulation

- In-depth understanding and validation of the process layout

Key Features

- Generation of parametrized die face geometries for all operations

- Addendum creation based on specially adapted profiles

- Automatic development of flanges on the addendum surface

- Geometry modeling through morphing technology

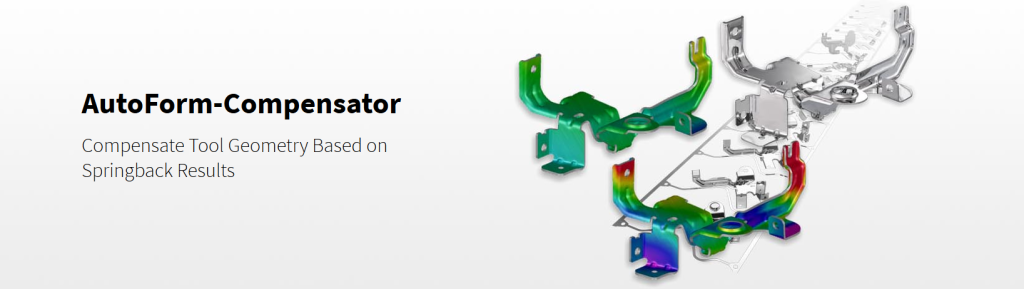

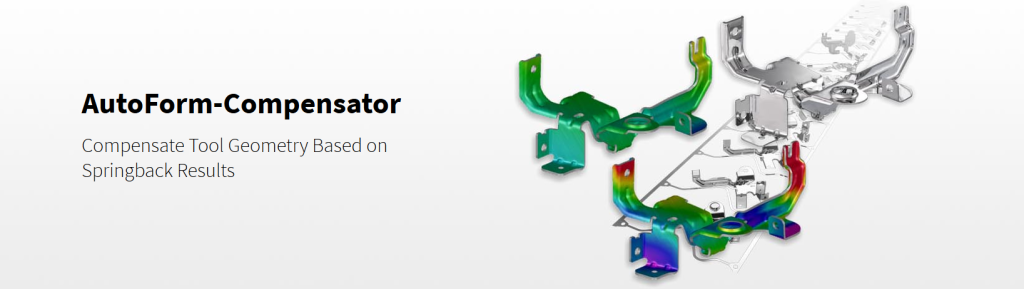

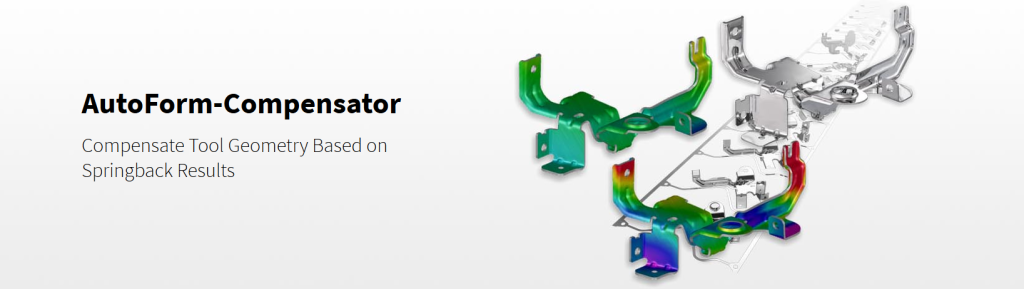

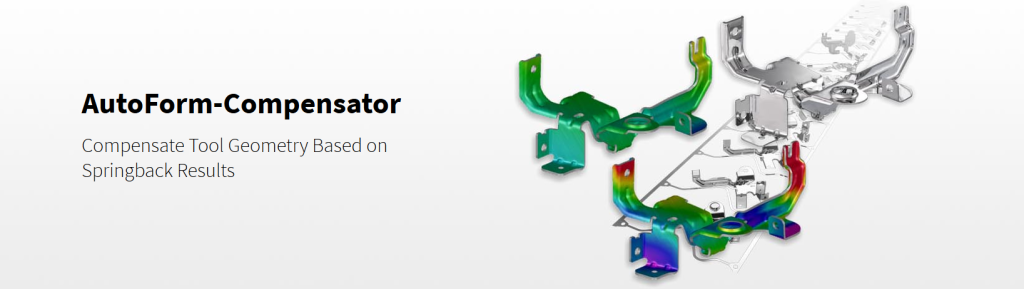

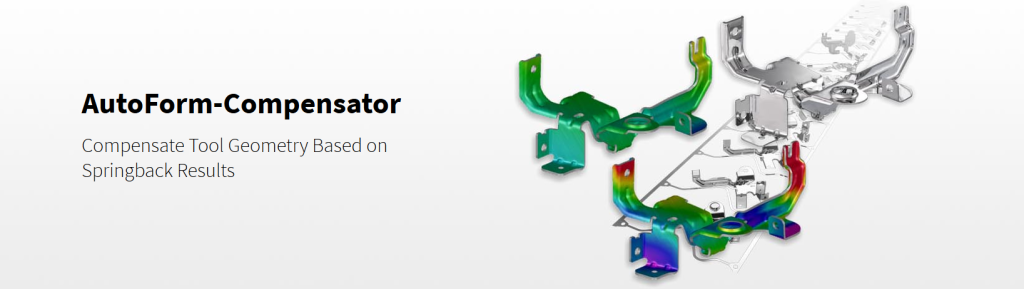

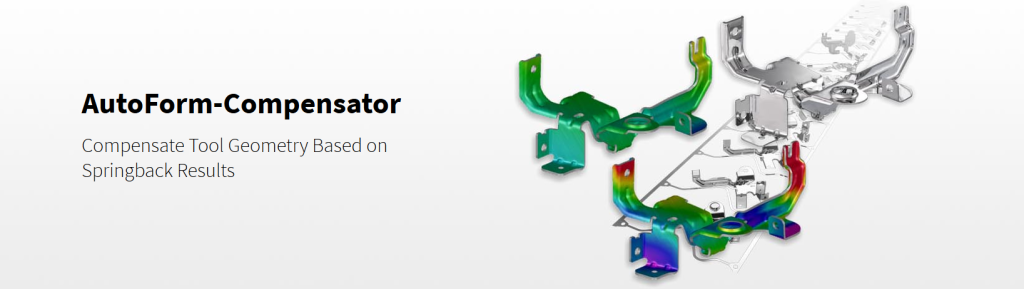

AutoForm-Compensator

AutoForm-Compensator

AutoForm-Compensator allows you to automatically modify tooling surfaces based on precise springback calculation or measured springback data. With this software, you can easily define compensation regions, which are automatically adjusted using springback results. The compensated geometry can then be used for rapid and accurate tooling validation.

Die faces are compensated in the opposite direction of springback. This software enables you to modify either the entire tooling surface or only selected regions. Since different regions can be defined within the tool, you can systematically control compensation.

Once the tooling geometry is compensated, it is automatically used as input for the next simulation. Final part geometry within the required tolerances is achieved with a minimum of correction loops.

Benefits

- Reliability of planning and process engineering

- Reduction of correction loops

- No risk of later changes due to springback

Key Features

- User-defined compensation regions

- Support for both free and clamped springback

- Automatic adjustment of tool geometry

AutoForm-FormingSolver

AutoForm-FormingSolver

AutoForm-FormingSolver enables you to rapidly and accurately simulate the progressive die stamping process, including drawing and secondary operations as well as springback. Once you have obtained simulation results with AutoForm-FormingSolver, you can then visualize them with AutoForm-Explorer, which provides you with in-depth information about all aspects of the progressive die stamping process.

AutoForm-FormingSolver optimally supports the engineering process during all its phases. You can use AutoForm-FormingSolver to quickly obtain simulation results during an early, conceptual development phase and also to generate very precise results during the final validation phase.

AutoForm-FormingSolver provides results for one simulation at a time, i.e. the solver results describe one deterministic result of a forming process as only a single set of input parameters is selected for the simulation. However, AutoForm-FormingSolver is also capable of running a stochastic analysis using the AutoForm-Sigma functionality. During these simulations, design or noise parameters are varied while maintaining the focus on the quality targets set for the stamping part as well as on the robustness of the progressive die stamping process.

Benefits and Key Features

- Full strip simulation for progressive die stamping

- Rapid and accurate simulation of deep drawing, restriking, trimming and flanging operations

- Accurate springback simulation

- Rapid verification of new process concepts for quality and cost improvements

- Reduced computing time by taking advantage of SMP or MPP parallel processing technology

- Option to include enhanced tribological refinement

AutoForm-Trim

AutoForm-Trim

AutoForm-Trim in combination with AutoForm-FormingSolver is an essential tool for the determination of optimum trim lines. The trim line is optimized to ensure that the desired shape and dimensions of the part boundary are obtained at the end of the operations following the trimming operation.

Benefits

- Determination of optimum trim line and blank outline

- Time and costs savings due to simultaneous development of trim and draw die

Key Features

- Automatic calculation of multiple blank outlines

- Calculation of customer-specified segments of blank or cut outline

- Simultaneous determination of all cut-out lines for several cutting operations

TriboForm Plug-In

TriboForm Plug-In

The TriboForm software allows you to quickly simulate the effects of tool coatings, lubricants, material surface characteristics or new sheet materials on friction and ultimately on product quality. Through a more realistic consideration of tribological effects, a new level of simulation accuracy can be achieved. TriboForm’s products complement AutoForm’s product portfolio.

TriboForm Plug-In enables the direct integration of TriboForm results into AutoForm simulations. This allows you to account for realistic friction conditions during the progressive die simulation and evaluate its effect on product quality.

Benefits

- Accurate representation of complex tribological phenomena

- Simulation, visualization and evaluation of friction and lubrication conditions

- Improved simulation accuracy

- Savings on expensive tool modifications during tryout or production

- Easy integration in AutoForm