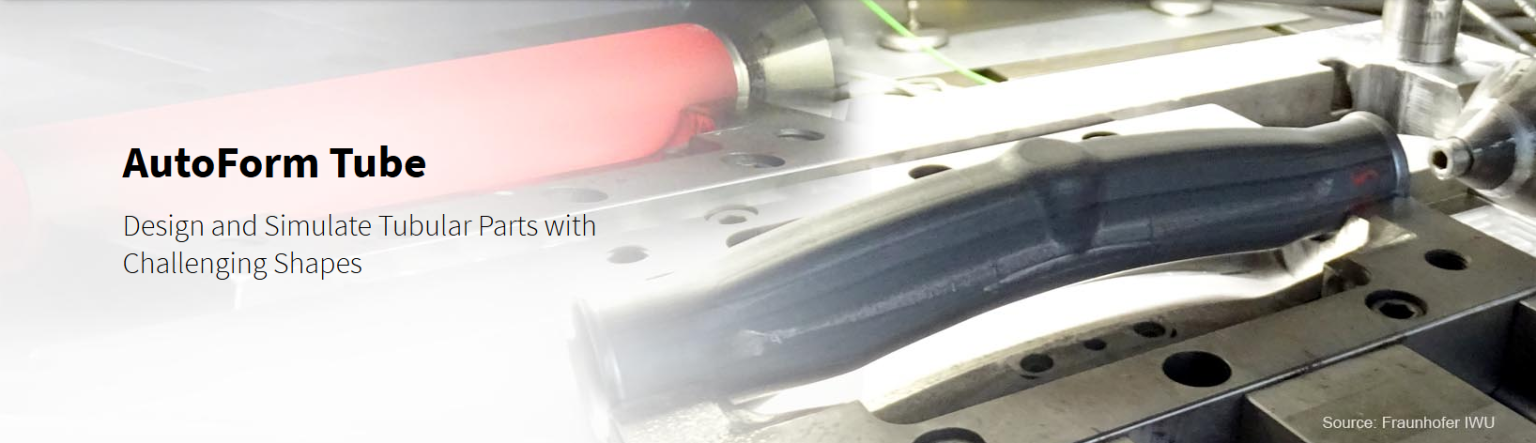

AutoForm Tube

With the AutoForm Tube solution, you can gain a comprehensive in-depth understanding of tube bending, forming, and hydroforming processes. AutoForm Tube is our software solution for the successful design and simulation of tubular parts.

AutoForm TubeXpert®

AutoForm TubeXpert®

AutoForm TubeXpert is an easy-to-use and highly intuitive software solution for rapid tool design and simulation of tube bending, forming, and hydroforming processes. The software enables you to meet the increasing demands regarding part complexity, part quality and advanced materials, such as advanced high-strength steels and aluminum, as well as the increasing complexity and variety of forming processes.

With AutoForm TubeXpert, you can carry out comprehensive virtual tryout analyses of the forming process of tubular parts including all process steps from bending and preforming to hydroforming, annealing and calibration, cutting and tube end forming. Both cold and hot tube forming can be addressed. In addition, the software enables you to perform accurate springback simulation after any of the forming process steps and automatically make the necessary adjustments to the tool geometry and process parameters in order to compensate the effects of springback. The full integration of AutoForm-Sigma technology in AutoForm TubeXpert enables you as a part designer, process engineer, or tool and die maker to systematically improve tool designs and process layouts as well as evaluate the robustness of the manufacturing process.

Benefits

- Rapid tool and process design for tubular parts

- Verification of multiple alternative concepts for quality and cost improvements

- In-depth understanding of entire forming process for tubular parts

- Shorter development time and reduced tooling, material, and production costs

- Improved process reliability for robust manufacturing

Key Features

- Rapid creation of all necessary tool designs and seamless process simulation of complete cold and hot tube forming processes

- Reliable and automatic identification of forming issues, such as splits, wrinkles or insufficient calibration

- Springback simulation after any forming operation and automatic tool modification for springback compensation

- Systematic process improvement and evaluation of process robustness for a reliable manufacturing process

- Implementation of company standards and automatic report generation

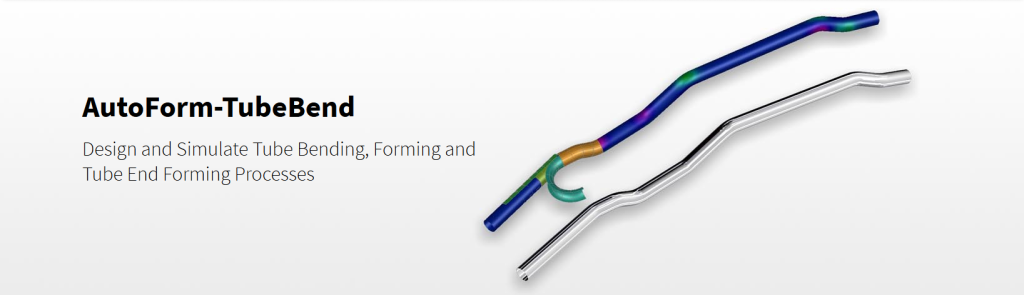

AutoForm-TubeBend

AutoForm-TubeBend

AutoForm-TubeBend is specially designed for the needs of tube bending companies and supports their standard processes, such as CNC rotary draw bending, press bending, and tube end forming. With AutoForm-TubeBend, you can successfully tackle all of the typical challenges you face during the tube bending and forming processes.

AutoForm-TubeBend allows for the rapid design and simulation of tube bending, forming, and tube end forming processes. The software allows you to carry out comprehensive virtual tryout analyses, including bending, preforming, calibration, cutting, and tube end forming. In addition, with AutoForm-TubeBend you can simulate the springback which may arise in the actual production process. Through the automatic springback compensation features, the necessary adjustments can be made to the tool geometry, bending line, and process parameters. Once the simulation results have been generated, you can initiate seamless data exchange to CAD software as well as tube bending or forming machines to carry out efficient production of tubular parts.

Benefits

- Rapid design and simulation of tubular parts

- Verification of multiple alternative concepts for quality and cost improvements

- In-depth understanding of tube bending, forming, and tube end forming processes

- Shorter development time and reduced tooling, material, and production costs

- Rapid springback compensation of tool geometries and bending lines

Key Features

- Quick generation of all necessary tool geometries without CAD knowledge and seamless process simulation

- Reliable identification of forming issues, such as splits, wrinkles, and other possible issues

- Springback simulation and automatic tool and bending line modification for springback compensation

- Seamless data exchange to CAD software as well as tube bending or forming machines

- Implementation of company standards and automatic report generation