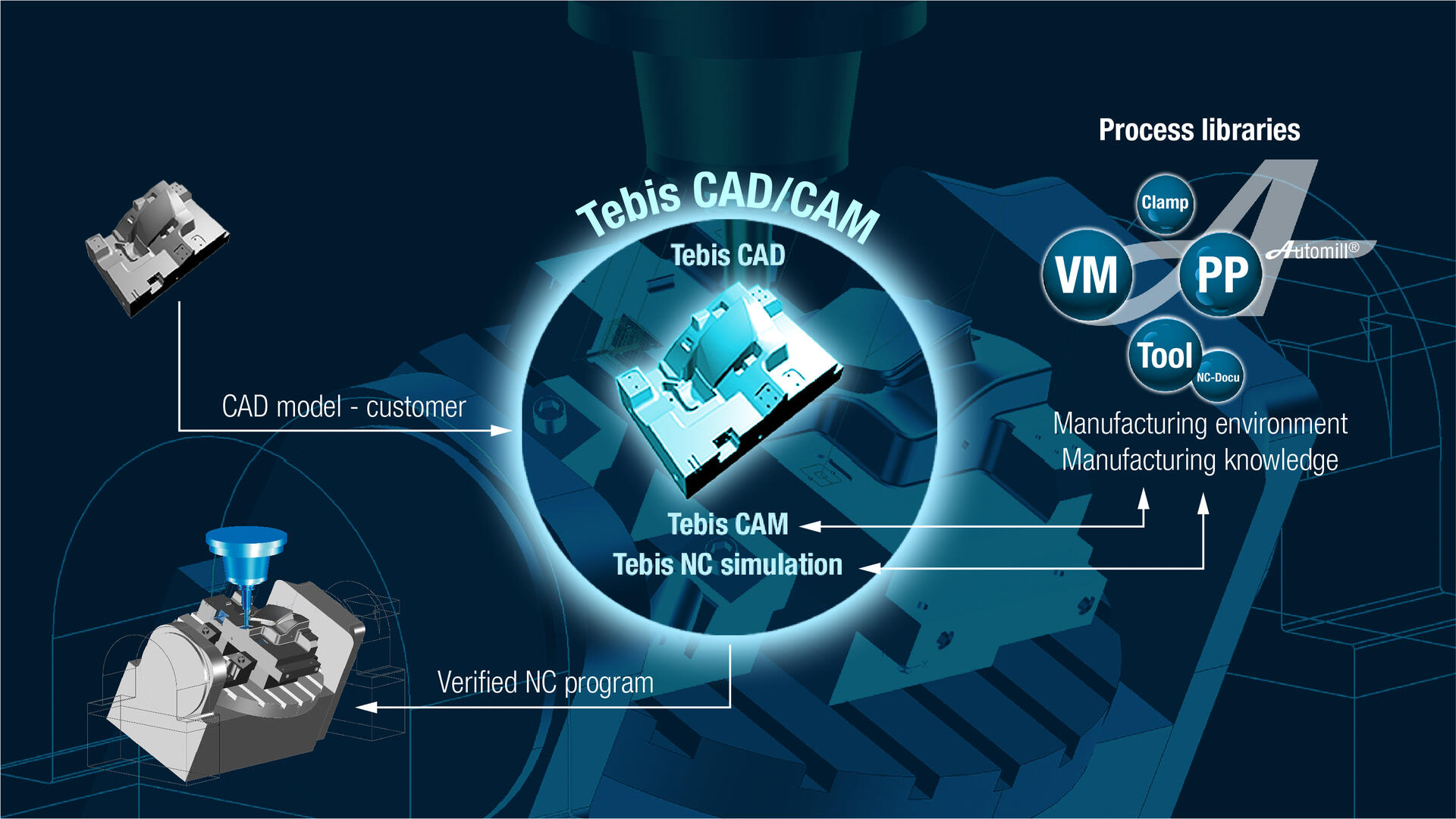

Intelligent Manufacturing with Tebis Automill®

Your expertise and your workshop mapped in Tebis process libraries

At the core is the intelligent part

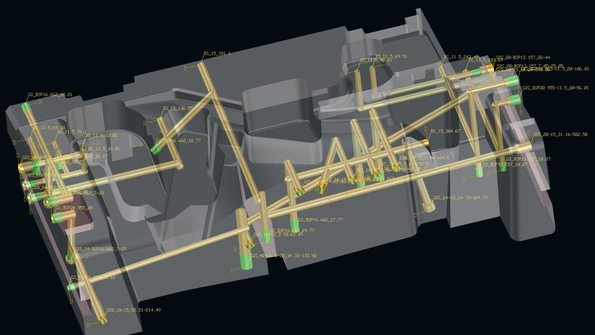

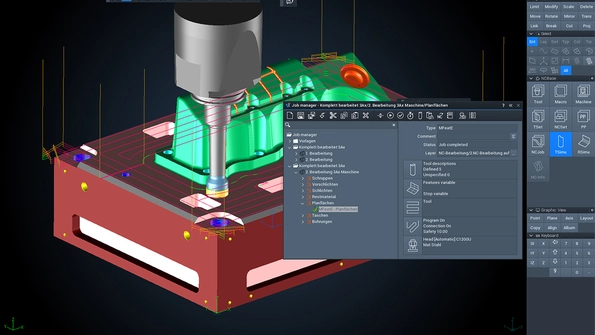

In Tebis CAD, the part is “intelligent” by virtue of your individual preparation work. Automated preparation instantly generates blanks, extensions, cover surfaces, guide curves and NC features. These are used by Tebis CAM.

Tebis CAM accesses process libraries containing your digitalized manufacturing environment and digitalized expertise and automatically calculates NC programs for 2.5D and 3D free-form geometry for milling, drilling, turning, turn-milling, wire and sinker EDM, laser hardening, laser cutting and laser weld cladding.

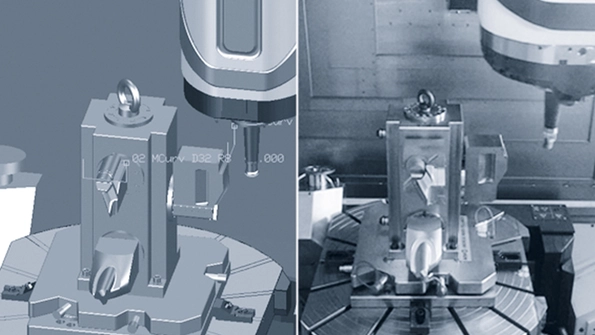

The integrated Tebis NC simulation generates verified NC programs in the control format

Your digital manufacturing expertise

NC programmers use their individual manufacturing knowledge stored in Tebis for standardized and automated work. Frequently used manufacturing sequences and methods are stored there as templates for manufacturing designers and NC programmers. Working with library objects and intelligent Job Managers reduces programming errors and turns proven methods into standards for all your personnel. This enables even inexperienced users to quickly create NC programs that meet your stringent requirements.

Your digital workshop

Tebis users work with process libraries that digitally represent their real manufacturing environment. The libraries contain geometric, kinematic and technical information on machines, their supplemental equipment, controls, tools and clamping devices. In the digitalized manufacturing environment, NC programmers can precisely define setups on the selected machines and tools, verify toolpaths and prevent collisions during calculation. This results in safe NC code for your manufacturing.

Tebis software services for your every need :

Digitalizing manufacturing knowledge

Access proven and optimized manufacturing knowledge

Digitalize your knowledge. Not in a spreadsheet, but right where your users can access it: in your Tebis installation. Use Automill® technology.

With our support. Our application engineers configure Tebis according to your requirements and integrate your proven and optimized manufacturing knowledge in process libraries. All authorized users can access the data at any time – quickly and repeatedly.

Your libraries can be protected for exclusive use in your company. They can be used at all Tebis workstations at your installation.

Before implementation, we evaluate your manufacturing processes and methods for frequently repeated work methods. These can be standardized using standards and templates in Tebis, significantly increasing your level of automation. Your employees can access the same information, from design to manufacturing, repeatedly and with no mixups.

You’ll minimize errors, make the best possible use of programming and machine capacities and increase your performance.

- Time savings – Achieve shorter programming, setup and machining times with templates

- Standardized – Use the same procedures across departments with no mixups

- Protected – Only accessible within your company

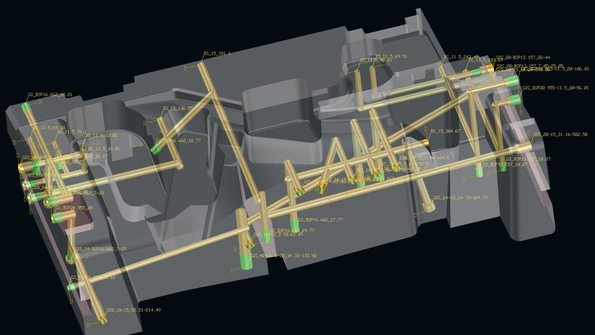

Filling the feature library

For design and manufacturing preparation

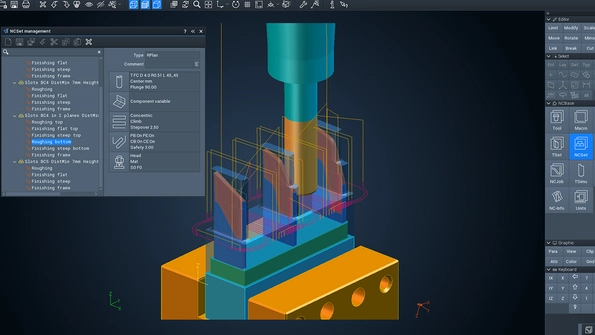

We store standardized geometry templates for parametric manufacturing objects like bores, fittings and pockets in your Tebis feature library and link them with suitable manufacturing sequences (NCSets).

You can also supplement your library objects yourself at any time.

Features are included in your CAD manufacturing files using the intelligent feature scanner and by manual insertion.

If parts contain NC features from the Tebis feature library, NC programming for these objects proceeds completely automatically.

Features for the example of deep holes

Filling the NCSet library

For NC automation

We integrate standardized manufacturing sequences into your NCSet library for all features and other frequently recurring manufacturing processes. NCSets consist of several NC calculation functions linked to each other with information on strategies, tools and calculation parameters. You can expand your NCSet library on your own at any time.

NC programming with NC sets is automatic. You save a lot of time

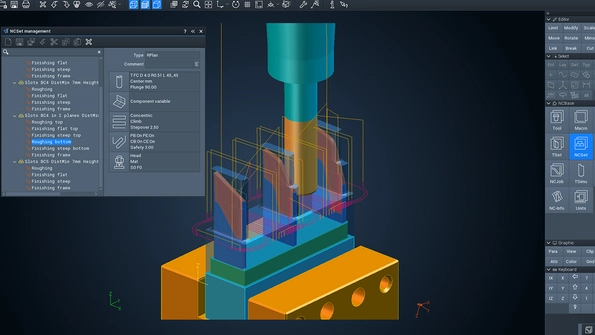

Store intelligent Job Managers

For the same and similar manufacturing tasks

We prepare templates for the same or similar manufacturing tasks with structures of any complexity. Your NC programmers use these intelligent templates and save significant time thanks to the automated functions. The NCJobs contained in the Job Managers automatically identify the geometry to be manufactured (AutoSelect) and use the information on tool use, strategies and cutting data stored in the templates.

This lets you complete even complex manufacturing tasks quickly, easily and reliably

NCJobs and Job Managers

Tebis lets us automate many processes, and users lose no time working with different files. These advantages are especially prominent when there are design changes.

Ryan Hotchkiss, Head of manufacturing at Integrity Tool and Mold, Canada

The benefits for your performance With digitalized manufacturing knowledge :

- Incorporate individual experience

- Transfer information between departments

- Reduce complexity and effort

- Save time and minimize errors

- Also suitable for less experienced employees

- Implement changes more easily

- Increase automation

- Get started in Industry 4.0

Digitalizing the manufacturing environment

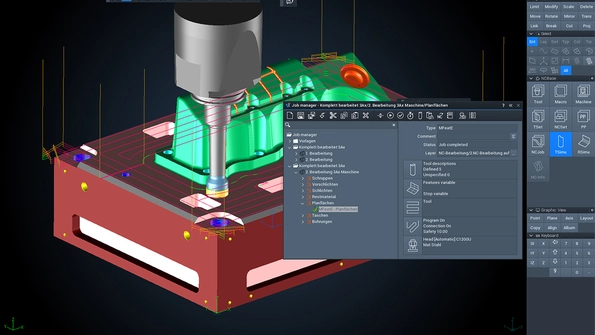

CAM manufacturing based on digital twins

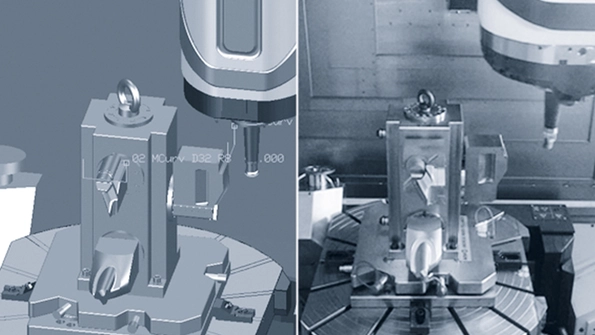

We digitally map your real manufacturing environment in your Tebis installation. It contains your tools and clamping devices with geometric and technical information. We also prepare virtual macahines based on your machinery with your detailed geometry and kinematics. The postprocessors we program for your controls access these details and generate reliable NC code.

Your libraries can be protected for exclusive use in your company. They can be used from all Tebis workstations at your installation.

NC programmers and machine operators work securely with automation in the digitalized environment. They unambiguously define the clamping positions and tools, simulate calculated toolpaths and check them for collisions.

We also develop individual templates for NC documentation for you.

- Precise – Work in virtual models with real data for geometry, kinematics and parameters

- Standardized – Use the same manufacturing information across departments with no mixups

- Reliable – Avoid collisions and errors from the beginning using simulation with detailed digital twins

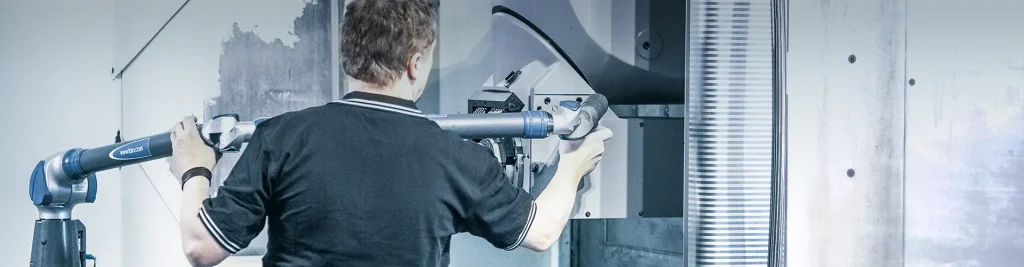

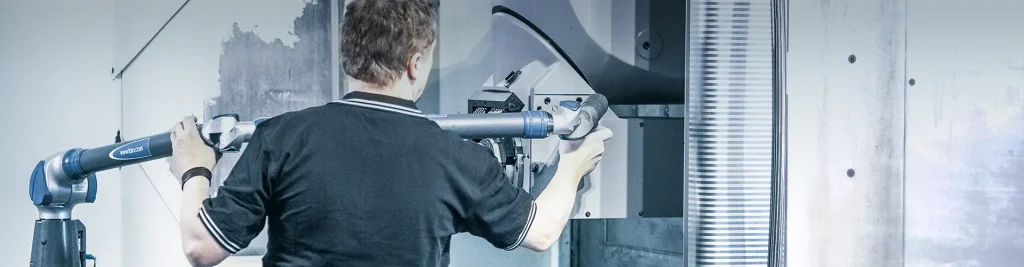

Virtual machines

We scan and measure your machines on-site and model them one-to-one in the Tebis programming environment.

Detailed digital twins of your actual machining centers and robots are generated from our inventory of catalog machines. The virtual model includes machine geometry, additional equipment, kinematics, limit switches, dynamic parameters for axes and drives and much more. We create every virtual machine model at your site individually.

A detailed digital twins allow you to work more precisely and efficiently in manufacturing.

A highly detailed model incorporating machine geometry, additional units, kinematics, limit switches, dynamic parameters for axes and drives and much more.

Machine digitalization on-site at the customer's location

With all geometric properties, tested and optimized cutting data and groups of tools in magazines

Virtual tools

Our implementation technicians work with you to generate your digital tool library.

The tool library represents your real tools with all their geometric and technical properties. Each tool therefore includes proven and optimized cutting data like feed rate and speed for each material.

We also represent groups of tools in machine magazines and tool cabinets every detail.

With the resulting transparency of the existing tools, the tools available in each magazine can be preferentially selected for NC programming. Calculated NC programs contain the optimized cutting data for each operation

Virtual machine units

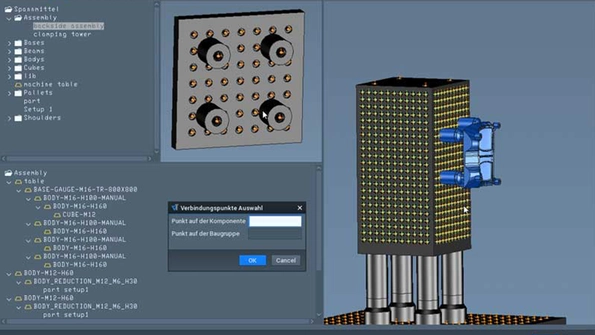

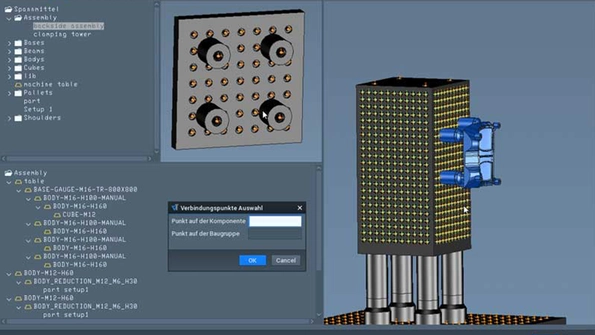

Our specialists also create a separate library for modeling your machine units in your Tebis installation. The digital representations ensure better handling and reliability.

In the central unit library, you can conveniently manage equipment like jaw chucks, steady rests and tips as well as machine tables, attachments and partitions (see video). In the central unit library, you can assemble the components to form complete units and equip the machine with all units in the Job Manager.

With all geometric and technical properties

Clamping device library: This contains all devices for securing workpieces so that the precise clamping position is set up in the CAD/CAM model.

Virtual clamping devices

Our implementation technicians work with you to generate your digital tool library.

The tool library represents your real tools with all their geometric and technical properties. Each tool therefore includes proven and optimized cutting data like feed rate and speed for each material.

We also represent groups of tools in machine magazines and tool cabinets every detail.

With the resulting transparency of the existing tools, the tools available in each magazine can be preferentially selected for NC programming. Calculated NC programs contain the optimized cutting data for each operation

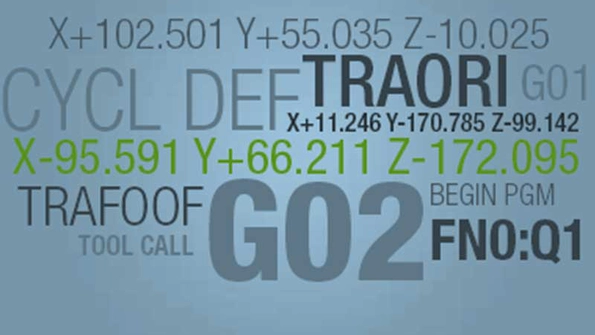

Postprocessors

Our Tebis implementation technicians use the catalog inventory of postprocessors to program individual postprocessors according to your requirements.

You may need a specific postprocessor depending on the type and complexity of your machines. When you export your NC programs in the control format, these postprocessors access information from the virtual machines. This combination makes your machining operations more reliable.

We prepare various postprocessors for milling (with two performance levels) turning, laser cutting, turning/milling and for robots, including those with more than five axes. We create each individual postprocessor at your location.

Configured for your controls and the special aspects of your machine

NC documentation

Our digital templates for NC documentation let you seamlessly register important information in the shop for the NC programs. Our specialists use proven templates and adapt them to your requirements.

We set up a variety of output formats: On-screen overview, XML format, PDF file and for hard-copy printout.

Better overview and clear structure thanks to digital documentation

Our Specialists

With our large teams of qualified implementation specialists, the consulting coverage we offer for our customers is unparalleled. As highly experienced and reliable partners, they work passionately to ensure that all Tebis installations are optimally set up and all processes fine-tuned