CAD software specialized for manufacturing

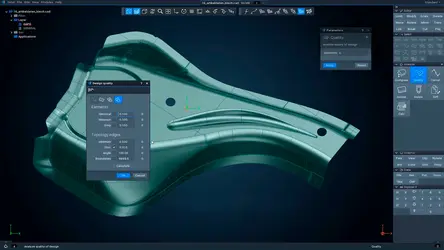

Creating, supplementing and modifying CAD models with Tebis

The time between order receipt and delivery deadlines in the manufacturing industry is consistently shortening. The CAD model is the digital template for the real part to be manufactured. High surface quality in the CAD model is a prerequisite forhigh quality in the finished components. Well-prepared CAD models also form the basis for automatable NC programming. All manufacturing preparation and design tasks can be highly automated with parametric/associative surface and solid technology. The entire component is automatically updated when element parameters are changed. Using Tebis templates is especially time-saving, in the CADenvironment: It can be used to standardize repetitive design activities in templates, such as for component variants or similar input data.

Tebis CAD software components provide a wide range of options for editing production-optimized design tasks in a variety of industries. These include:

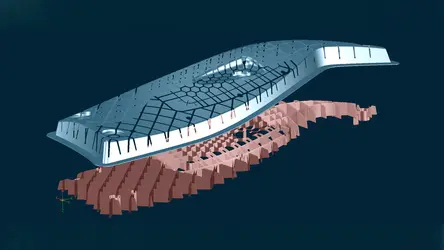

- Creation of CAD free-form surfaces, designing with points, curves and surfaces in 3D space combined with ruled geometry

- Reverse engineering for transforming the 3D scans of real parts in CAD surface models (digital CAD twin)

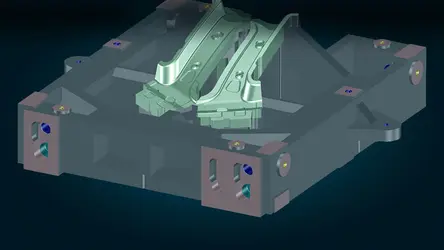

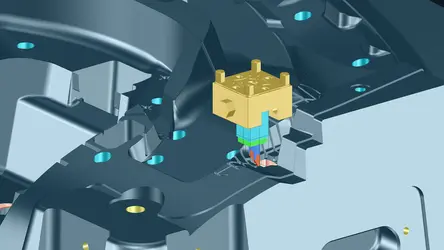

- Design preparation of existing CAD models for their NC manufacture on milling machines, lathes, laser cutting machines and additional methods

- Derivation of electrode geometry from the part geometry to be produced in mold manufacturing

- Creation of active surface geometry in sheet-metal draw-die manufacturing

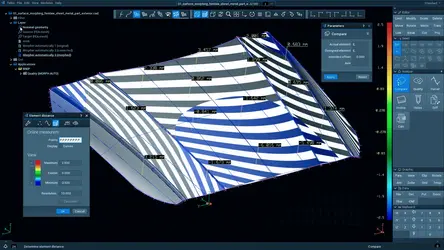

- Compensation of springback effects in sheet-metal parts in sheet-metal draw-die manufacturing

- Qualitative optimization of existing surface models