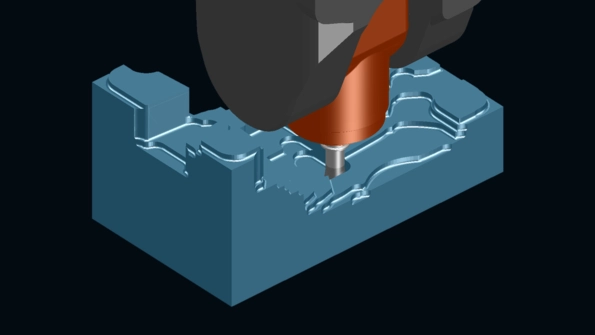

3D milling for roughing and finishing

The reliable and efficient path to premium surfaces

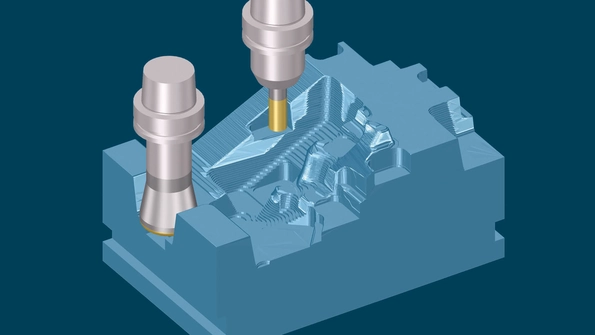

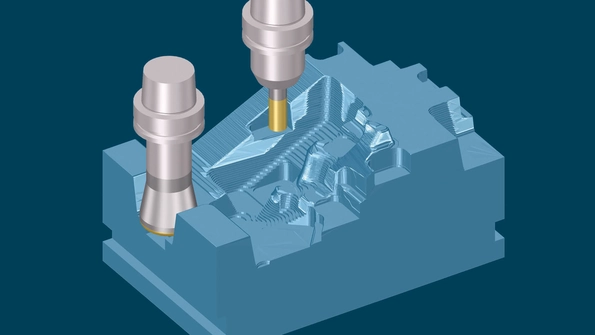

The 3D milling strategies can be used to create 3-axis and 3+2-axis NC programs for roughing, finishing and residual stock machining. You can prevent collisions during calculation. For example, the tool automatically avoids collisions or reduces areas at risk, depending on the application. In conjunction with the precise simulation technologies and harmonic slope-adjusted NC paths, optimal traverse paths are generated for the machine axes in 3D milling.

- Top performance – Make the best possible use of modern high-performance tools and benefit from maximum speed and tool life.

- User-friendly – Convenience with the combination of Tebis template technology and Tebis process libraries.

- High surface quality – Use Tebis to mill directly on surfaces and precisely control distribution of NC points.

The most important strategies for 3D milling

- Direct 3D milling on surfaces

- End-to-end accounting for blanks

- Roughing in planes, protecting tools

- Automatic roughing of planar surfaces

- Equidistant 3D finishing

- Precise accounting for residual stock with material tracking

- Part-oriented curve milling

- Height-sorted fillet machining

- Automated machining of ribs and slots

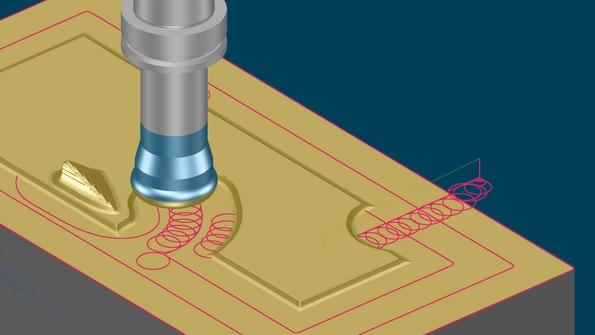

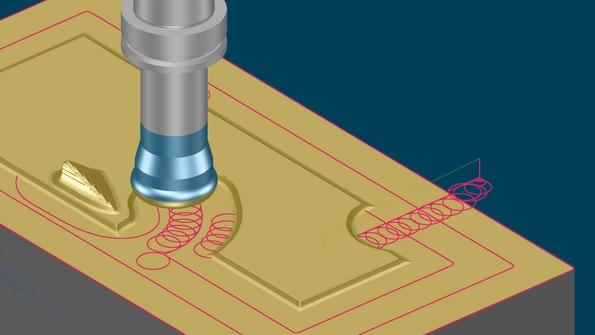

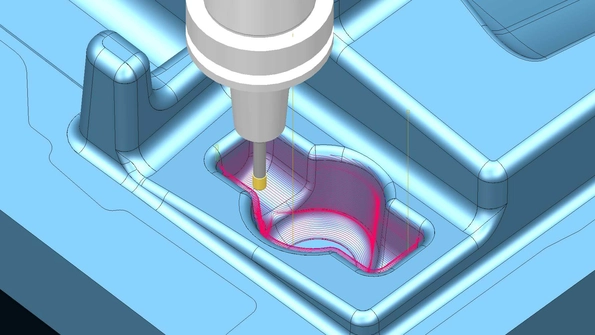

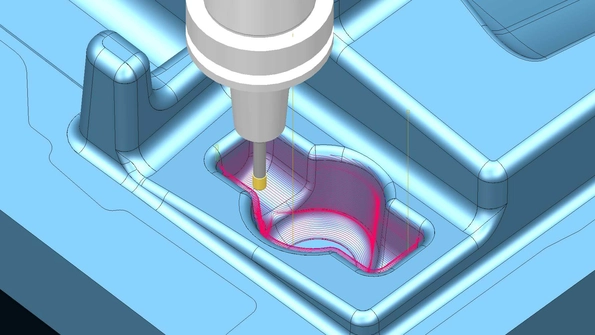

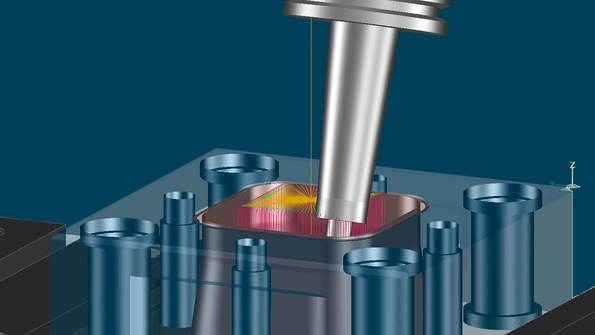

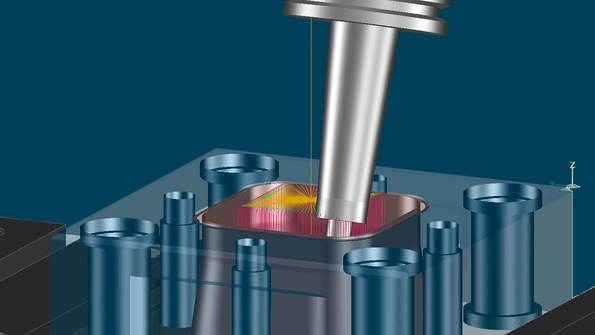

Prevent unnecessary idle travel during roughing

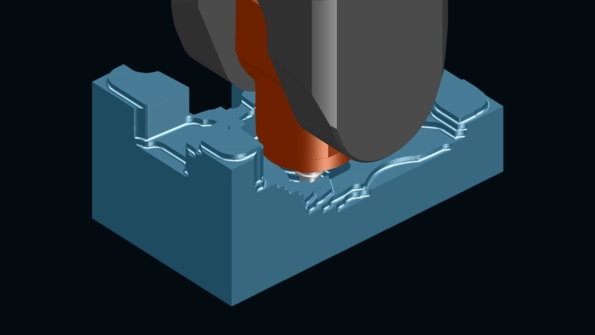

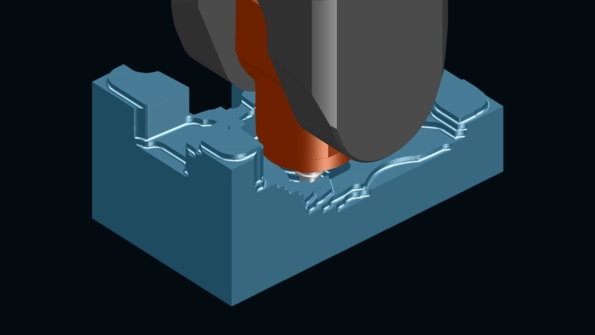

You can quickly and easily define any blanks. The material can be machined from different tilt directions..This significantly reduces computational effort.The blank is updated and passed on to the next machining operation – and the update is always performed using the actual cutter geometry. The system safely and reliably mills only where there is remaining material.

Tebis uses differentoptions for full-cut handling and full-cut avoidance in 3D milling: Depending on the situation, full-cut areas are machined trochoidally, or the path layout is automatically adapted to the geometry without full-cut machining. This is optimal for adaptive roughing with HPC cutters. All path layouts are also automatically smoothed – enabling further optimization of the feed rate.

Efficiently machine planar areas

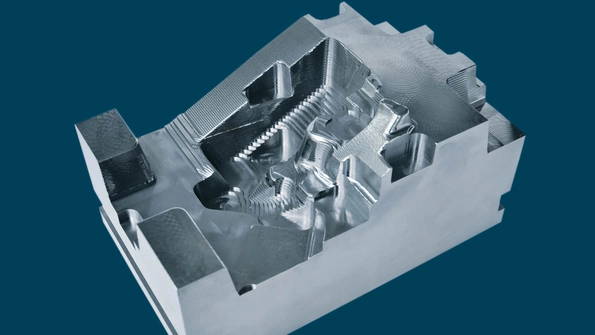

Finishing for the best surface quality

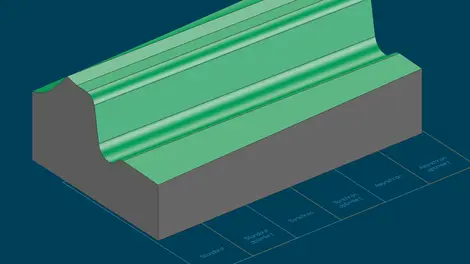

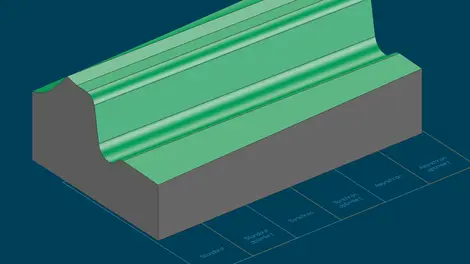

Tebis strategies for optimized 3D stepoverensure uniform stepover on the surface in 3D milling of both flat and steep areas. The part is automatically subdivided in slope ranges that can each be machined using special strategies and tools – the best prerequisite for automated NC programming in conjunction with Tebis template technology.

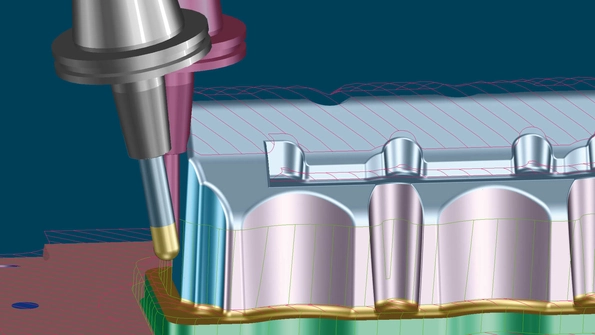

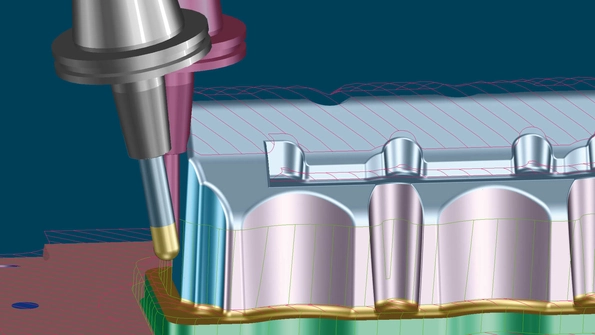

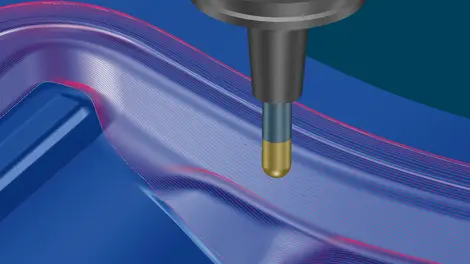

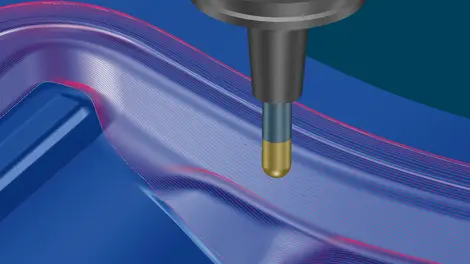

High-quality toolpaths: HSC point distributionoptimally positions the NC points on the surface. You can influence the point distribution so that the output toolpaths precisely match your machine control. An additional benefit: You can mill directly on surfaces without needing a faceted substitute model.

Precisely determine milling areas: In Tebis, the contour of the virtual tool matches exactly with that of the actual tool used. You can therefore optimally use the potential of your HFC cutters even for prefinishing.

Optimized 3D stepover for 3D milling

HSC point distribution...

...controlled for your specific machine

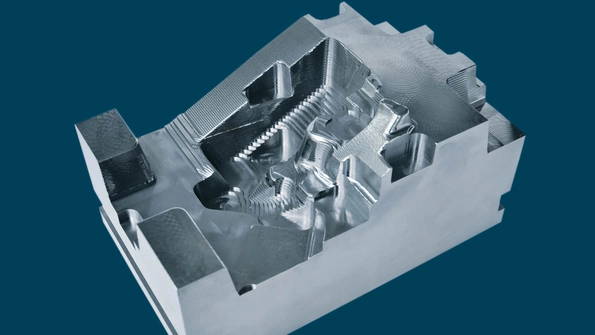

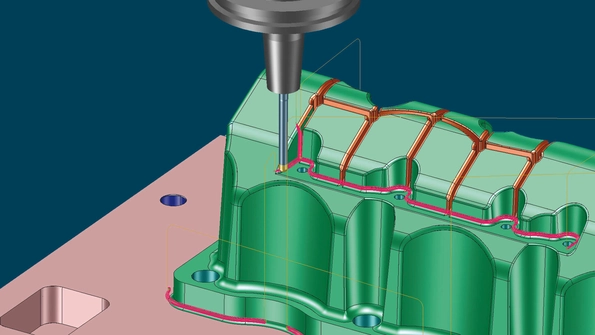

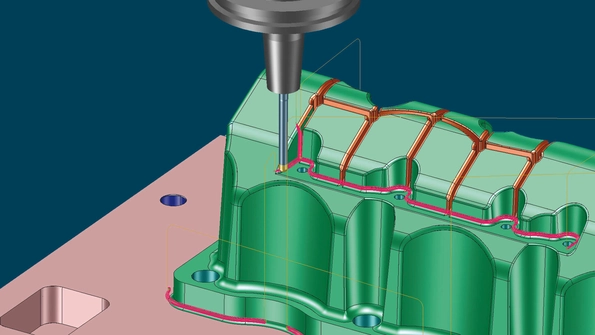

Path and height-oriented residual stock machining

Depending on the task, special residual stock machining strategies are available for 3D milling, such as for fillets or complex cavities. Path and height-oriented NC programs reduce machine run times. You also benefit from precise calculation of the milling areas in residual stock machining.

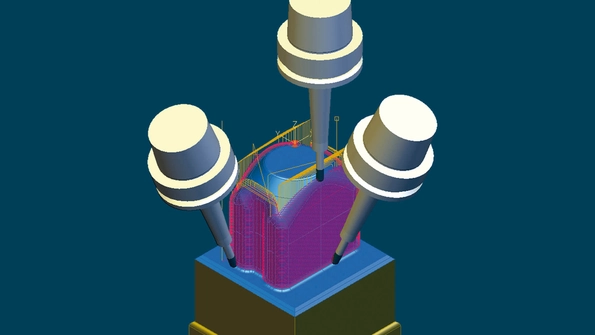

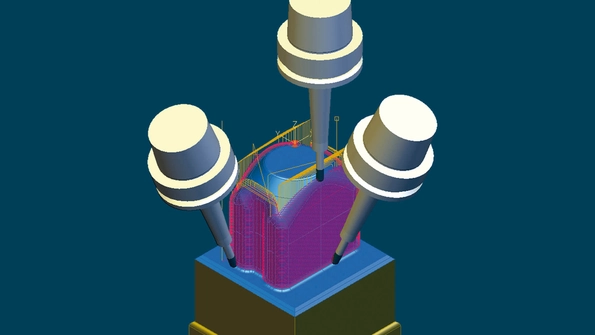

Machine undercuts in a single setup

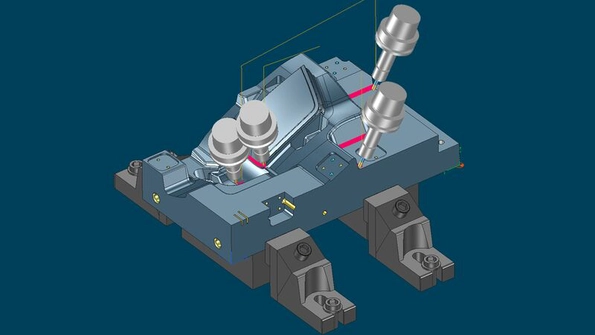

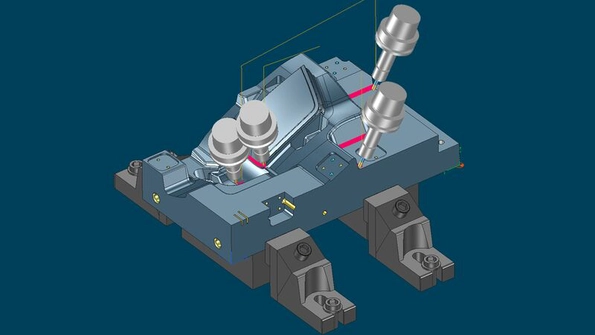

Quickly create collision-checked NC programs

Tebis detects potential collisions automatically during NC calculation. The wide range of collision avoidance solutions are optimized for specific situations.

Area reduction accounting for the real head geometry

5-axis simultaneous avoidance milling

Indexed residual stock programs can also be calculated fully automatically. This reduces machining times on the machine and achieves better surface quality.

Great flexibility through interactive interface

An additional benefit: The tilt direction can be adjusted interactively, enabling you to remain flexible despite the high degree of automation