Cleverly combining turning and milling

Turn-milling, mill-turning or interpolation turning

Tebis CAD/CAM maximizes the efficiency of your manufacturing

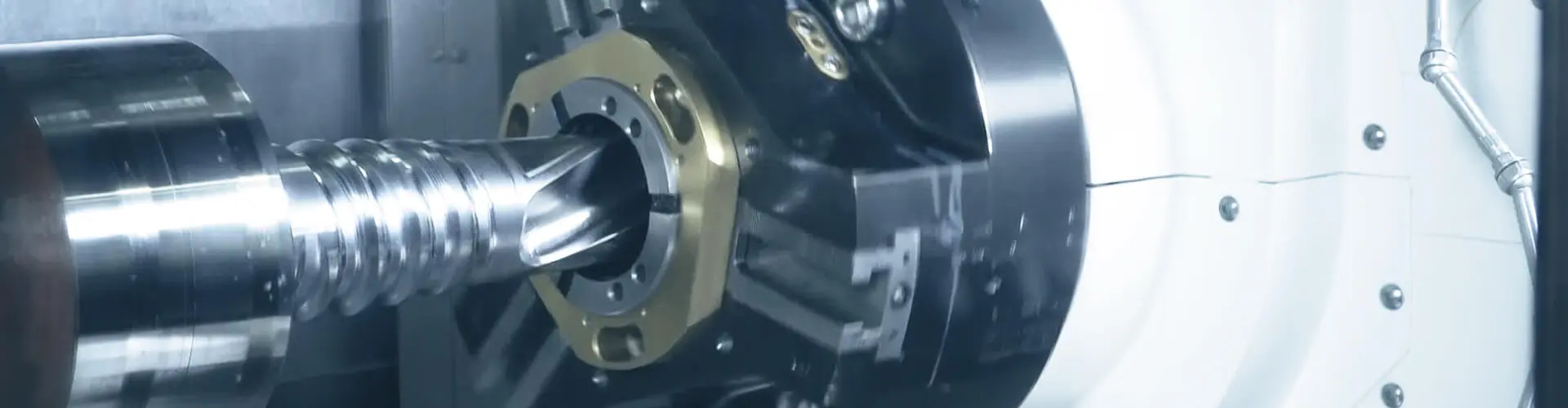

Combined turn-milling can be used to perform end-to-end turning and milling operations on a single machine without reclamping, resulting in high efficiency and reduced costs and throughput time. It also enables you to manufacture very complex and high-quality parts.

No wonder this versatile manufacturing method is growing in popularity throughout various industries, including. aerospace, energy, medical technology, automotive and semiconductor.

Don’t wait to offer extended range!

With Tebis, you only need one postprocessor for any combination of drilling, turning or milling.

In addition to turn-milling and mill-turning, Tebis also supports interpolation turning.

You can benefit from this modern manufacturing method while turning on milling machines.

Turn-milling

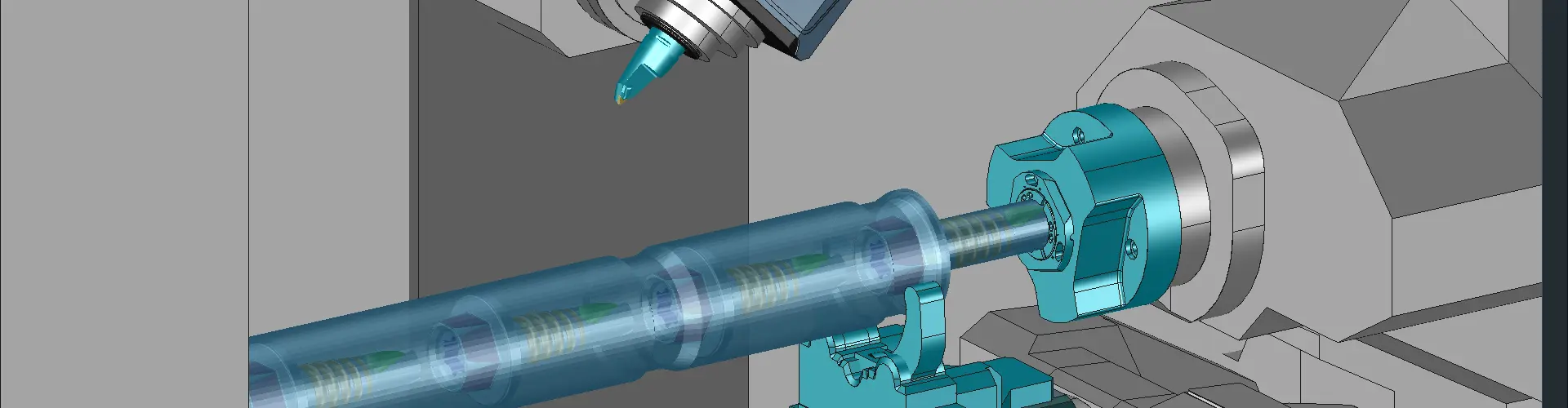

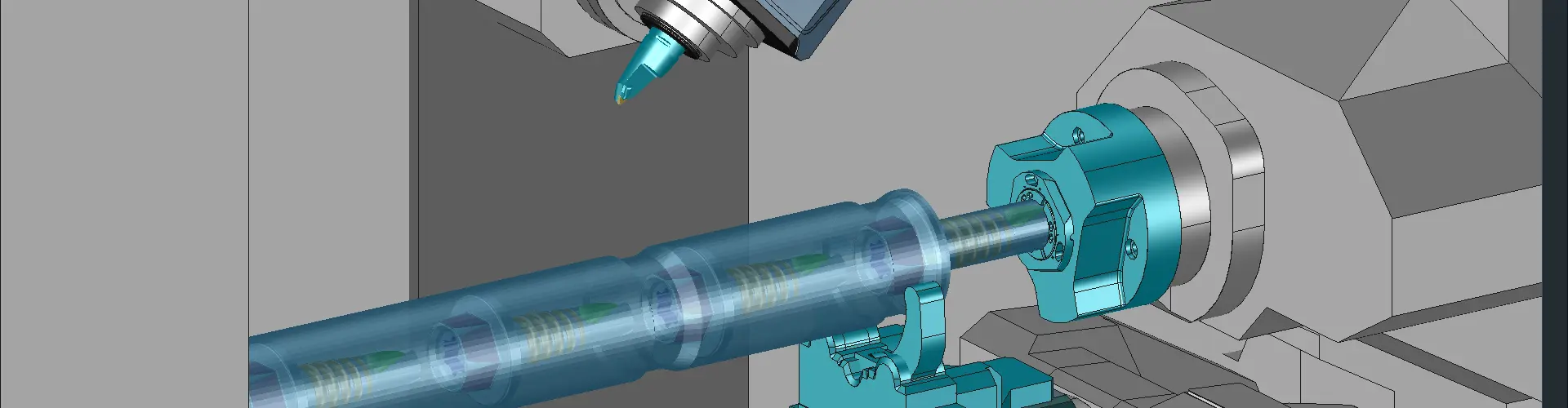

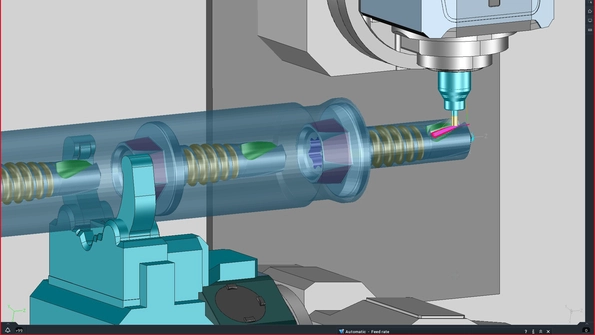

For automated manufacturing on complex machining centers

Tebis gives you full control over your machines, including all positioning movements. This enables reduced personnel and automated manufacturing without the machine operator having to intervene.

With Tebis, CAM programmers program end-to-end in a single application, with the same user interface – for both turning and milling. After brief training, they’re ready to go.

Tebis also allows for extensive strategies to achieve ideal results in every machining task. In roughing, the focus is on high cutting performance, while finishing emphasizes a high surface quality.

Mill-turning

For safe end-to-end manufacturing of complex parts

You always see the big picture with the Tebis Job Manager when machining highly complex parts, even with many different machining operations. If necessary, you can interactively intervene.

Because you’re already accessing the machine and tools used in the virtual CAD/CAM environment in Tebis, only collision-free NC programs are sent to the machine.

To get even more automation and process safety with direct measurement on the machine, check the setup position and blank before machining as well as the manufacturing results after machining.

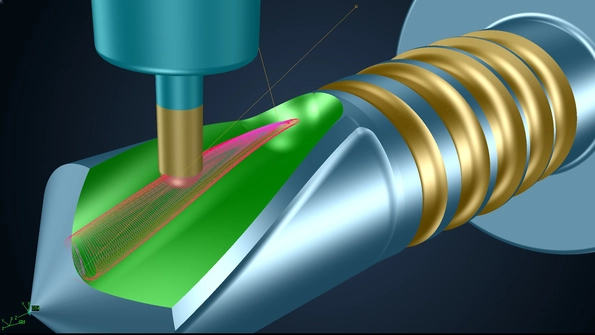

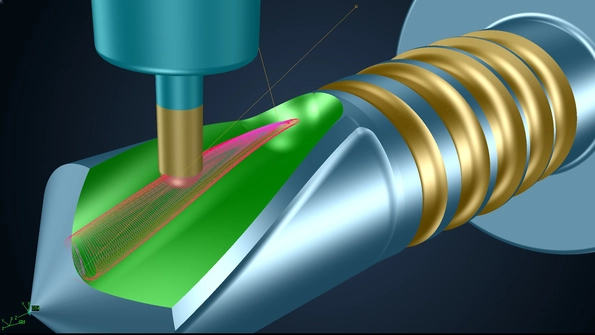

Interpolation turning

For cost-effective and efficient manufacturing of symmetrical part areas on all machines with position-controlled spindles

This new manufacturing method is the hottest trend, and with good reason: It enables turning on all machines, including milling machines, with a position-controlled spindle. This approach is particularly suitable for parts with only a few rotationally symmetrical elements (e.g., more milling than turning, but with high efficiency). It can all be done cost effectively, on one machine, up to 80% faster and fully supported by Tebis.

Would you like to learn more?

It’s showtime, baby!

Tebis has worked with its partners to create a series of exclusive parts. The team is especially proud of the screw created with DMG MORI – a part that used a CAD/CAM application for end-to-end programming of turning and milling.

The hard facts

Actual machining took just 4.5 hours and generated a significant quantity of chips with the steel block losing 85% of its initial weight of 100 kg. The dimensions of the finished screw were 200 x 400 mm and was machined in material C45 1.0503 on an NTX3000/3000 using a total of 11 tools.

The most spectacular feats

Transferring the part from the main spindle to the sub spindle is one of the classic challenges in turning. And the combination of turning and milling machines is gaining popularity in the industry, for several good reasons. It offers extensive options, up to and including fully automated 6-sided machining. The part can then be manufactured without manual re-clamping, which reduces throughput time. In addition, the operator’s workload is decreased and additional setup time is eliminated. However, turn-milling machines are also highly complex. The prerequisite for a safe and smooth process is a CAD/CAM application with full control over the machine that includes all positioning movements and automated transfer from the main spindle to the sub spindle.

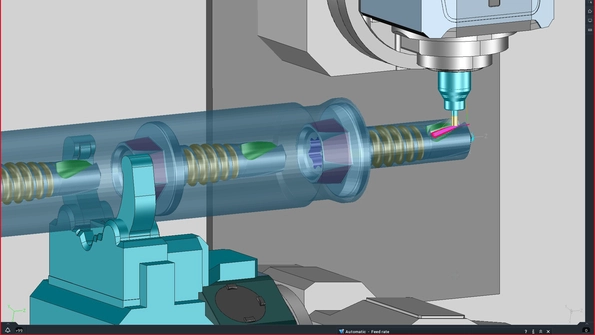

Tebis excelled here with flexibility and automation. Use of the steady rest can be automatically programmed in the CAM system, so it was possible to simulate this workflow step for the screw and control the steady rest as needed. Positioning, opening and closing of the steady rest and synchronous movement to the sub spindle were all fully automatic; the steady rest didn’t need to be manually set.

Roughing and finishing including radial machining were also quickly, easily and safely performed in Tebis. The software ensured optimal machine dynamics and specifically detected residual stock areas in fillets, corner blendings and cavities, automatically splitting these areas. All this was accomplished with no user intervention.

The highlights in preparing this showpiece included the use of high-performance milling functions from the CAD/CAM system. Because the part features several special geometries, a special roughing cycle designed for shell machining was used for simultaneous milling of the helix with a toroidal tool. This enabled highly efficient use of the tool by moving it offset from the axis of rotation.

A key advantage of automated manufacturing comes from the machine operator’s work time being largely decoupled from the operating time of the machine. In the case of this showpiece, the machine operator only had to set up the tools and press the start button before machining.

The actual work was done in advance in offline programming – Tebis simulator technology brought safety and speed together. From the start, the screw was planned end-to-end using so-called “digital twins.” These are precise representations of all tools, units like the steady rest, machine and other components, including geometric data and storage of information (e.g., kinematic properties of the machine, tool cutting data for different materials in the tool libraries).

Tebis can fully control all machine operations

The stunt double: The digital twin

Tebis defines the digital twin as the representation of all existing manufacturing resources and processes in the software. The prerequisites for comprehensive and realistic work with the digital twin require, among other things, that the machines, tools and clamping devices are recorded in all essential detail and the data are continuously maintained. Because the simulation can realistically anticipate reality only if all relevant parameters are reported.

In Tebis, the simulator is fully integrated in the CAD/CAM environment. As a result, the user can perform a valid simulation and collision check at any time in NC programming before post-processing. The most efficient solution is to ultimately check the toolpaths for collisions in the CAM environment and make any necessary corrections before NC output. Most importantly, this procedure is extremely safe, ensuring the best conditions for reduced-personnel and unattended manufacturing (e.g., weekends). As we know, this can only happen if you confirm all machines can continue operating without interruption.

And the award goes to: Every part!

Automation is now a must, in many cases even for lot size 1. And of course, this applies not to just stylish showpieces for tradeshows, but daily production. This is the only way we can convert big investment in precise, high-performance machines into competitive hourly rates. Machining with no operator intervention requires high process stability and corresponding process safety, which is necessary throughout the process, in every operation and at every point in time.