5-axis milling

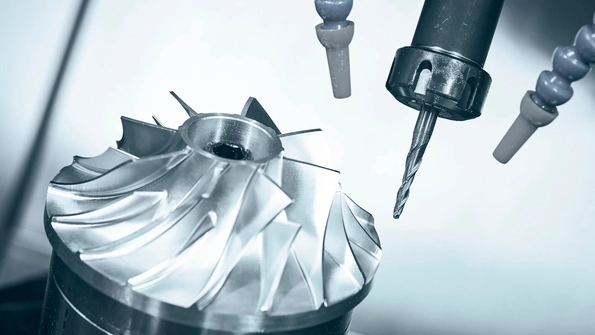

Easily, quickly and reliably manufacture 3D surfaces

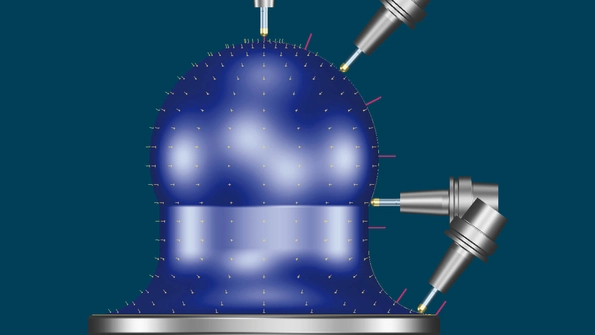

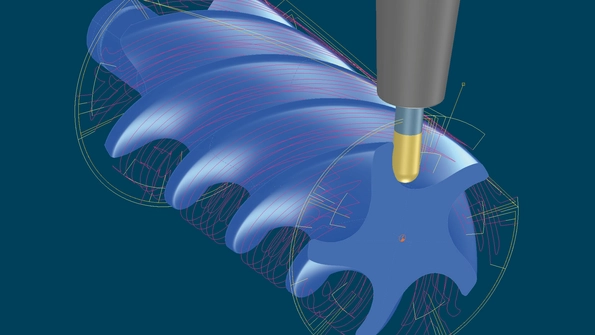

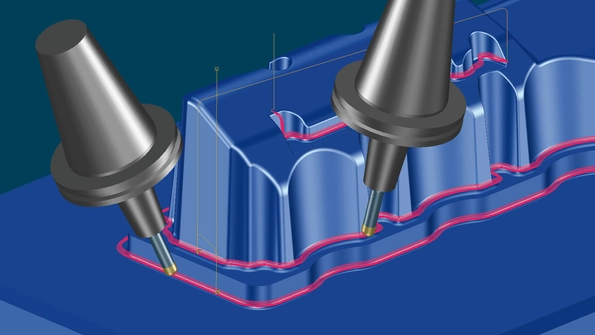

5-axis simultaneous milling quickly and efficiently produces high-quality surfaces unlike any other milling method. Tebis lets you use the full potential of your expensive high-performance machines: Collision-free programs can be easily planned and calculated for all multi-axis machining operations. Homogeneous toolpaths with low tool wear and checked for tilt direction are automatically generated.

- Simple – Integrated template technology • Functions for special manufacturing tasks • Mill between vectors • Interactively optimize tool tilt direction • All roughing and finishing strategies integrated

- Fast – Combine any machining types as desired • Optimal support for modern high-performance cutters • Machine multiple surfaces in a single pass without retracts

- Reliable – Completely collision-checked NC programs • For all milling machines including robots

Technical article

Multi-sided machining with positioned axes? Or do you prefer 5-axis simultaneous machining?

Whether a part is to be milled simultaneously on multiple sides with the positioned axis or by 5-axis simultaneous milling always depends on the specific machining task, the complexity of the part and the machine kinematics.

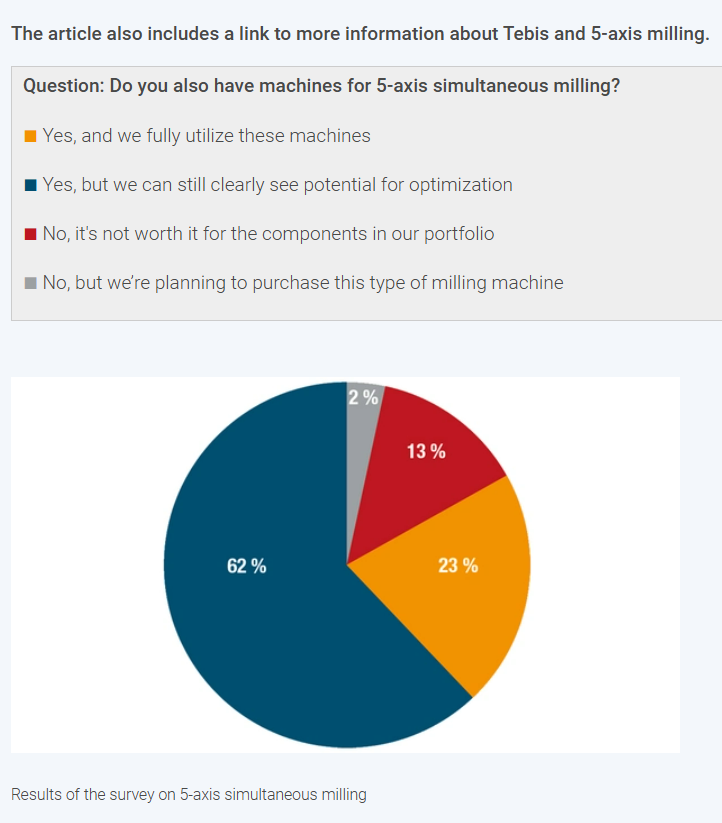

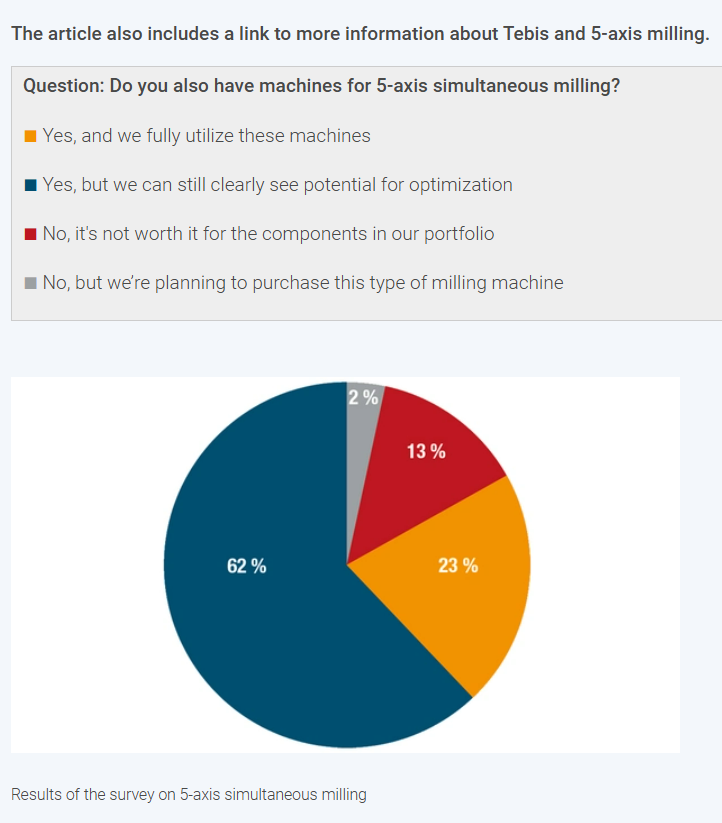

Are you still wondering whether machines for 5-axis simultaneous machining are even worthwhile for you? Or are you already using multi-axis machines and believe you can get still more out of your machines? Then you are not alone: According to a survey, 62 percent of those with multi-axis machines do not believe they are using the full potential of their machines.*

We have compared the advantages and disadvantages. Read our white paper.

I want to read the white paper

5-axis simultaneous milling – is it worth it?

Unlike any other milling method, high-quality surfaces are created quickly and efficiently with 5-axis simultaneous machining on modern high-performance machines.

However, many die, mold and machine manufacturers prefer to manufacture using fixed positionable axes. They tend to cast a more critical eye on multi-sided machining. Are these warranted concerns?

In the following article, Tebis Product Manager Helmut Vergin discusses the pros and cons of five-axis simultaneous milling – based in part on a survey of companies in the die and mold manufacturing industry.

Simultaneous 5-axis functions for special manufacturing tasks

NC programming of milling paths for simultaneous 5-axis milling is easy to learn in Tebis: It largely corresponds to 3D programming. Tebis programmers who previously created 3-axis toolpaths also learn to program 5-axis milling programs very quickly.

Tebis contains multiple functions for programming toolpaths for simultaneous 5-axis milling. Each function is customized for special machining tasks and only contains those parameters that are actually needed.

- Milling curves: Face and side milling of curves

- Multi-axis engraving

- Roughing contours: 5-axis side milling roughing of planar and constant-curvature flank surfaces

- Finishing contours: 5-axis side milling finishing of planar and constant-curvature flank surfaces

- Roughing surfaces: Adaptive or contour-parallel roughing of free-form surfaces

- Finishing surfaces: HSC milling with ball cutters

- Face milling surfaces: HSC surface milling of simple and complex free-form surfaces with a lead angle

- Side milling surfaces: 5 axis milling of complex free-form surfaces

- Roughing pockets: Adaptive or contour-parallel roughing of free-form pockets

- Radial roughing: Roughing of rotational components

- Multi-axis deburring

Overview of the most important functions

5-axis simultaneous milling

A function for every manufacturing task

No unnecessary parameters, no protracted deliberation … Each function for 5-axis simultaneous milling is exactly customized for a specific machining task

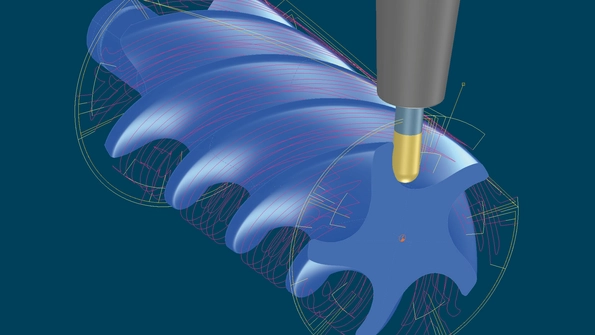

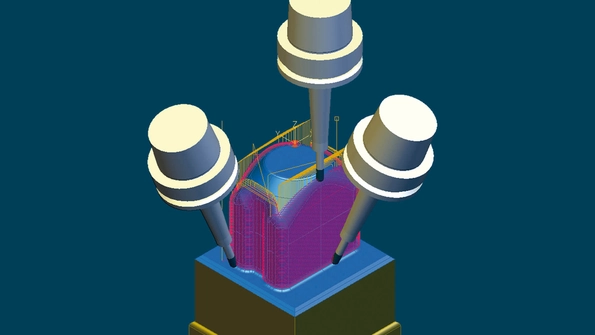

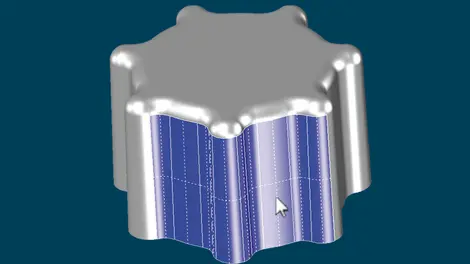

5-axis roughing

Tebis includes all functions for 5-axis simultaneous roughing, including the adaptive roughing strategies you need for roughing special geometries. A uniform stock allowance reduces machining time in subsequent finishing. 3-axis and 5-axis roughing operations can be easily combined, ensuring the greatest possible material removal.

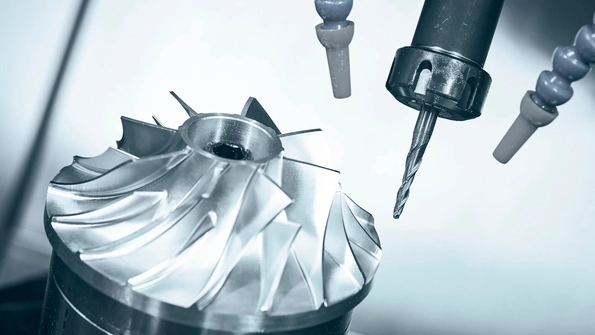

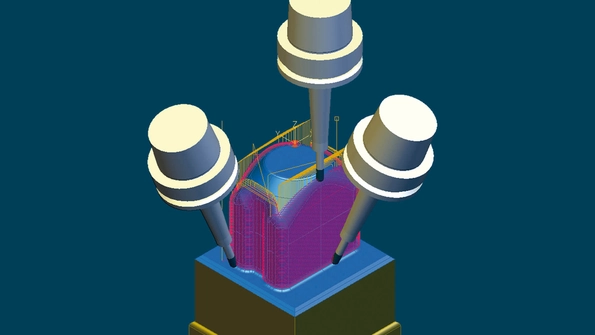

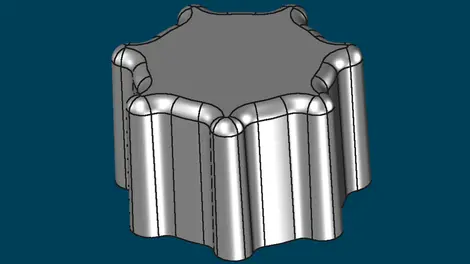

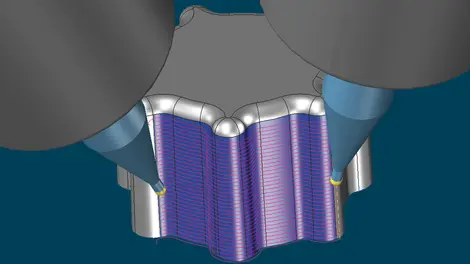

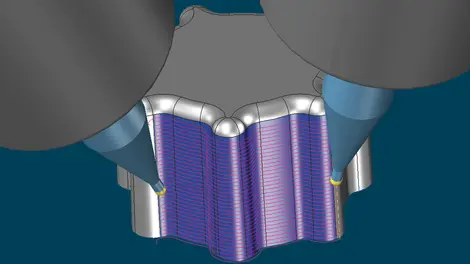

Roughing rotational parts

The “Radial roughing” function is ideal for fast NC programming and machining of 5-axis simultaneous toolpaths for roughing pocket and slot geometries in cylindrical and cone-shaped parts. The tool first roughs the part to the maximum possible depth with a low stepover and large downfeed in a single pass. It then machines the residual stock from bottom to top at a smaller cutting depth – precisely to the stock allowance. This procedure reduces tool wear and ensures a high material removal rate on the machine. The user can then program the final finishing operation very conveniently using a special function. Only the strategy is replaced: The system does the rest.

Roughing rotational parts with high infeed and finishing with low infeed in one operation.

Roughing pocket and slot geometries in rotational parts

Adaptive roughing

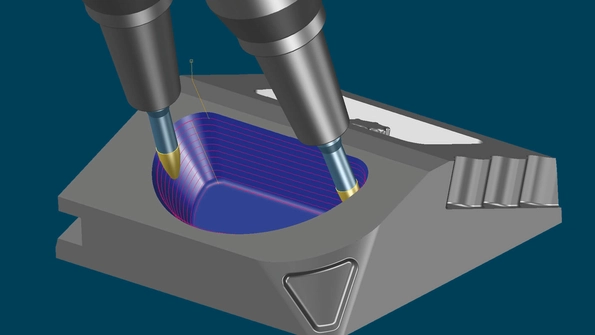

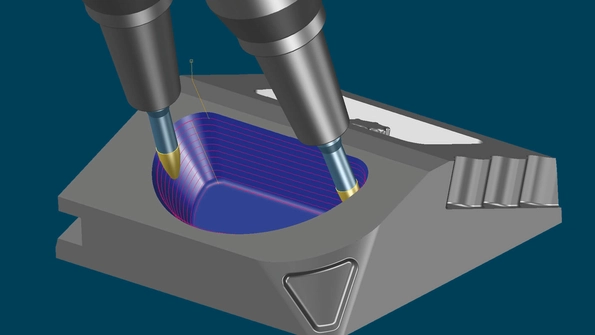

Ideal for fast 5-axis simultaneous machining of free-form surfaces and free-form pockets with HPC tools

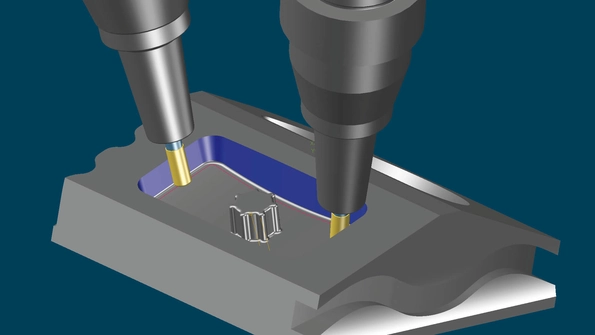

Adaptive 5-axis free-form surface roughing

Adaptive roughing of free-form pockets

5-axis roughing along a curve

Perform 5-axis simultaneous milling along any contours, accounting for part and protected surfaces. This method is suitable for scribing in model manufacturing, for example. Collisions can be avoided with automatic avoidance strategies or by specifically selecting the tool tilt direction. The required guide curves can be easily prepared with coordinated Tebis CAD functions. It is also possible to develop engraving paths directly on the part surface using special strategies.

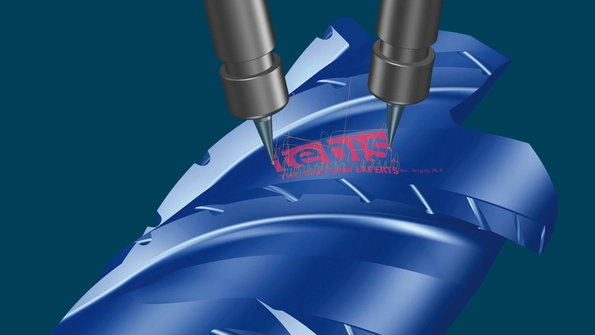

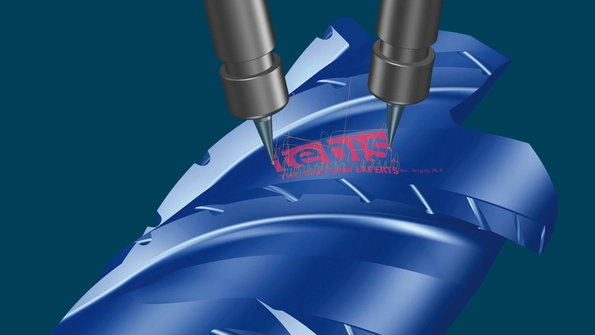

5-axis side milling

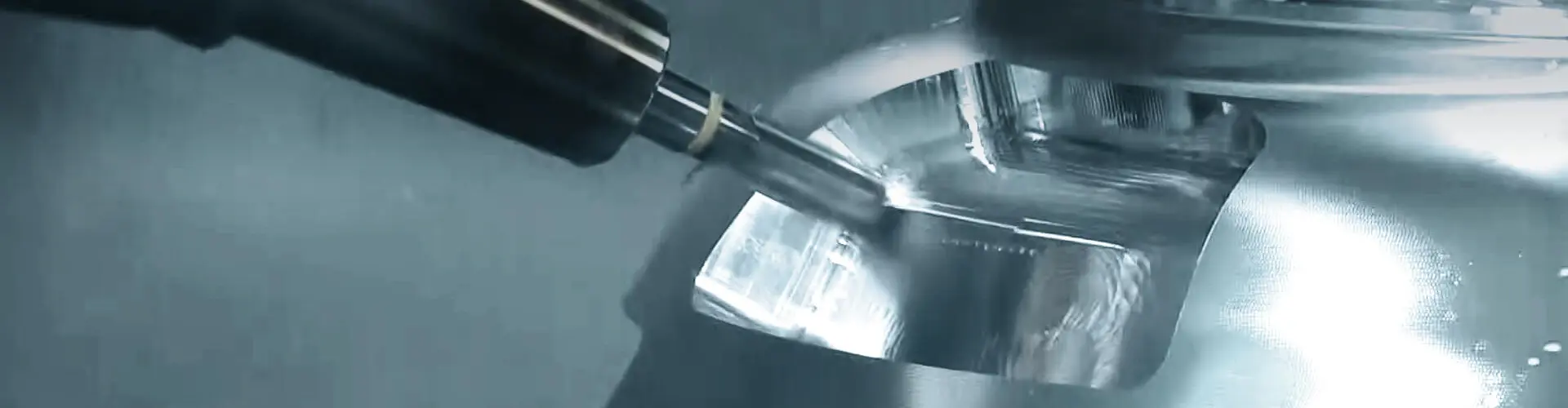

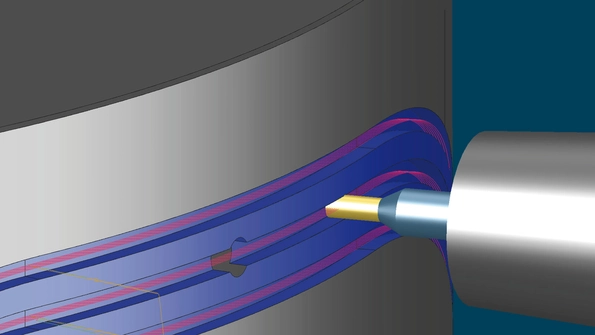

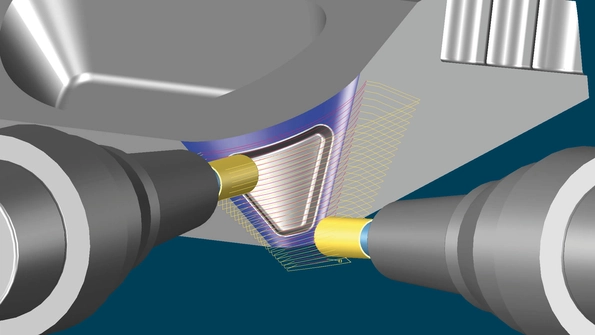

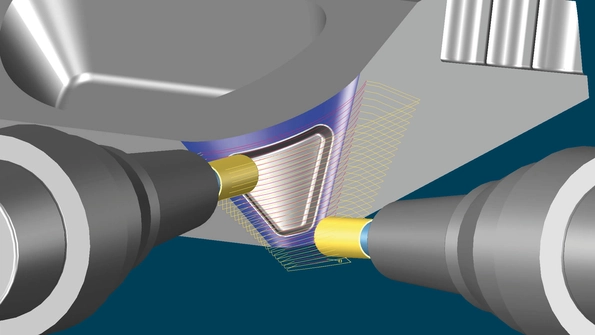

You can manufacture all forms of blank surfaces under ideal cutting conditions and reduce machining time with optimal downfeed: This allows material to be removed in layers with smaller lateral stepover, protecting the tool. A special advantage for 5-axis milling using circle-segment cutters with barrel geometry: Tool tilt direction is precisely adapted to the geometry.

Machining flanks with barrel cutters ...

... and with flat cutters

5-axis simultaneous machining of flank faces with barrel cutters

5-axis face milling

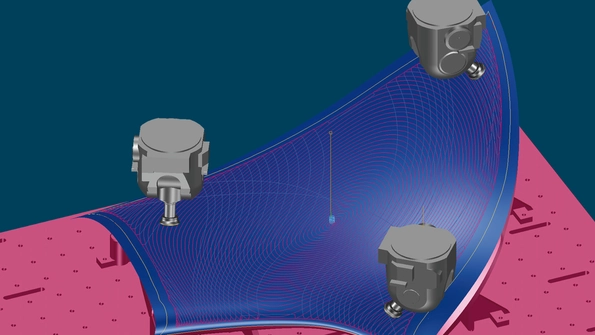

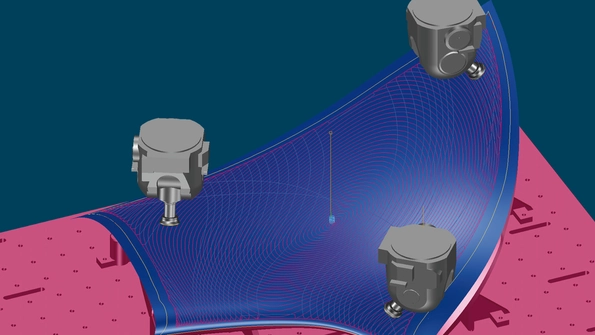

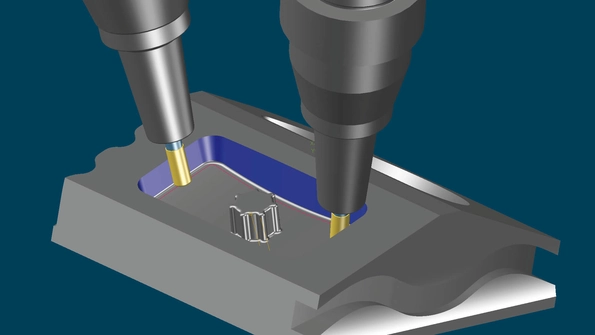

Automated multi-axis deburring

Tebis lets you machine sharp part edges using ball cutters or tapered cutters with automated multi-axis deburring. The tilt direction is automatically determined; the tool automatically avoids shank and holder collisions. Complex 5-axis machining operations can be optimally prepared using special preparation functions.

Example: machine manufacturing

Example: Mold manufacturing

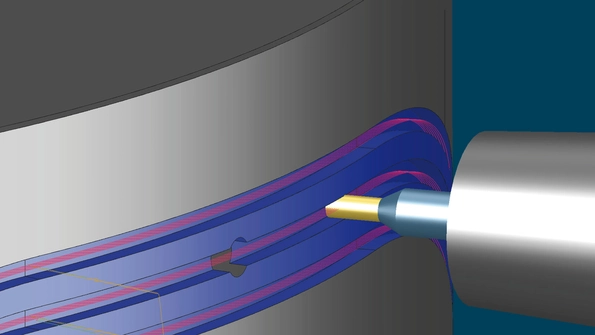

5-axis simultaneous machining grows out of 3+2-axis machining

In 5-axis simultaneous avoidance milling, you can generate 3+2-axis NC programs with no specific tilt angle for individual milling areas with no extra effort. Subsequent conversion to programs for simultaneous 5-axis milling is automatic. The tool tilt angle is optimized in this process, taking machine kinematics into account.

Avoidance milling is especially suitable for collision avoidance: Collisions of the tool holder with the part are already detected during calculation and are automatically avoided with simultaneous 5-axis milling. This enables outstanding machining of electrodes and parts with deep cavities, for example, with short tools.

However, you can also implement this functionality with good results in other areas besides collision avoidance. In specific part areas – such as for free-form surfaces in the visible area where machining requires frequent reorientation – machining with fixed tilt angles often negatively affects surface quality due to unfavorable cutting conditions. An expedient solution is to compensate this with dynamic 5-axis tool movements.

If desired, you can decide at the end whether to remove residual stock by 3+2-axis machining with the positioned axes, by simultaneous 5-axis machining or by 3-axis indexed machining. Tebis performs high-precision calculation of the remaining residual stock. Depending on the machining situation, you can interactively position the tool using the positoned axes or enable the fully automatic calculation of toolpaths for simultaneous 5-axis milling.

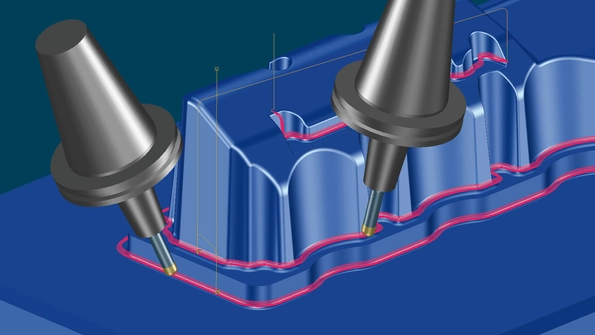

Machining multiple surfaces in a single pass without retracts?

With direct surface selection, multiple surfaces can be machined in a single pass with no additional design effort

Select multiple surfaces ...

... with no additional design effort ...

… and perform 5-axis simultaneous machining

5-axis simultaneous machining of multiple surfaces in a single pass without retracts

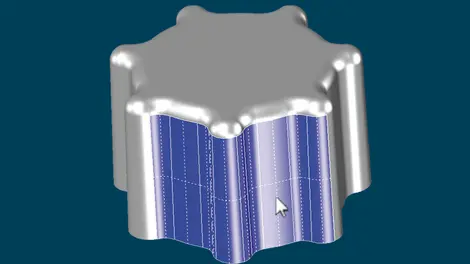

5-axis milling between vectors

Specify any vectors between which the parties to be milled. The selected vectors determine the movement of the tool. If desired, you can optimize tool movement during programming: Check the tilt direction with the integrated tilt direction preview and adjust it interactively.