Preparing CAD models for manufacturing

Fast and easy to modify

Precise preparation of the CAD models is the basic prerequisite for almost completely automated NC programming. Manufacturing preparation can also be quickly performed, mostly with a high degree of automation. Tebis also offers highly convenient functions for interactive intervention: for example, to close complex recesses. Processes can be more easily planned with extensive options for part analysis.

- High data quality – Resulting high manufacturing quality and short manufacturing times

- High efficiency – Standardized and automated NC programming is possible

- Always ready – Fast learning curve for employees during NC programming

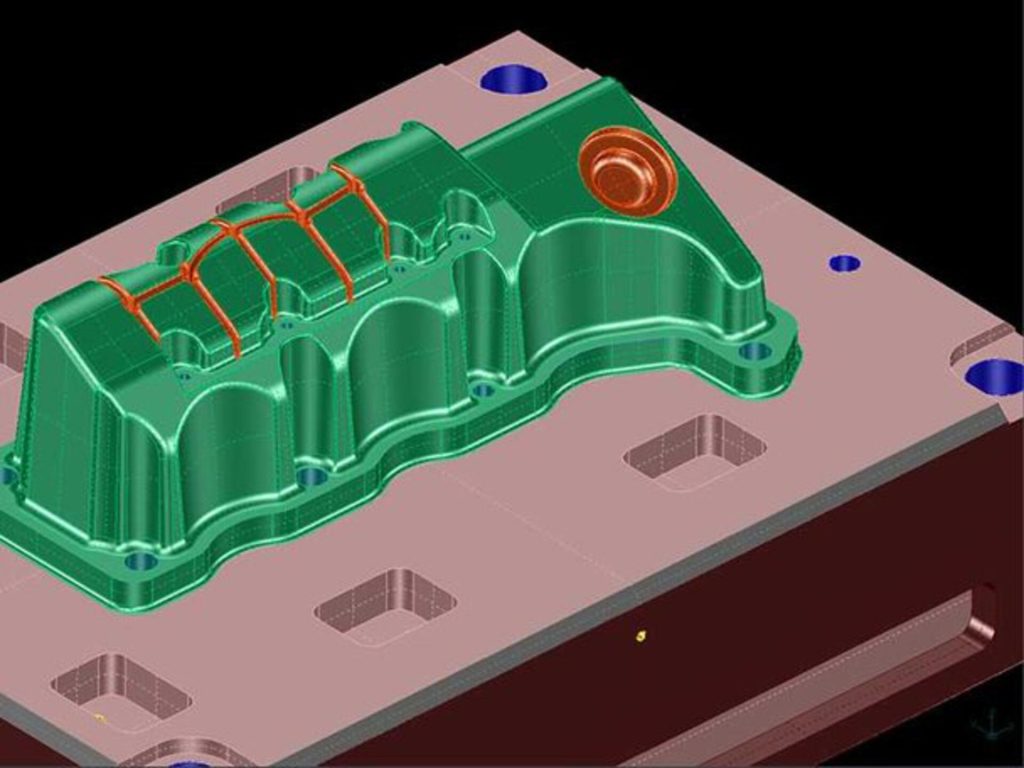

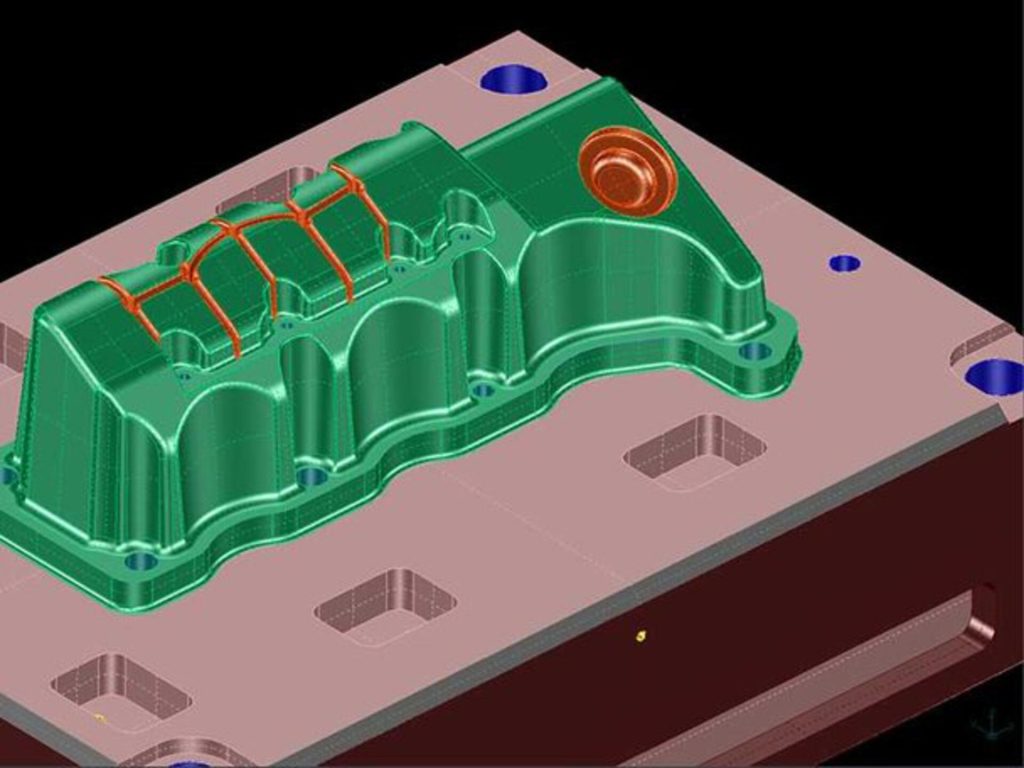

Automated data preparation with CAD templates

You still remain highly flexible: Changes like selecting a different clamping system can be controlled directly and conveniently with the user parameters in the object tree. Parameters like the length, radius or direction of elements can also be modified with the click of a mouse.

Straight to CAM programming with automated CAD templates

Automatically adjust auxiliary geometries and finished parts for a smaller, similar model.

One template for any part: Easily modified data preparation that’s optimal for manufacturing.

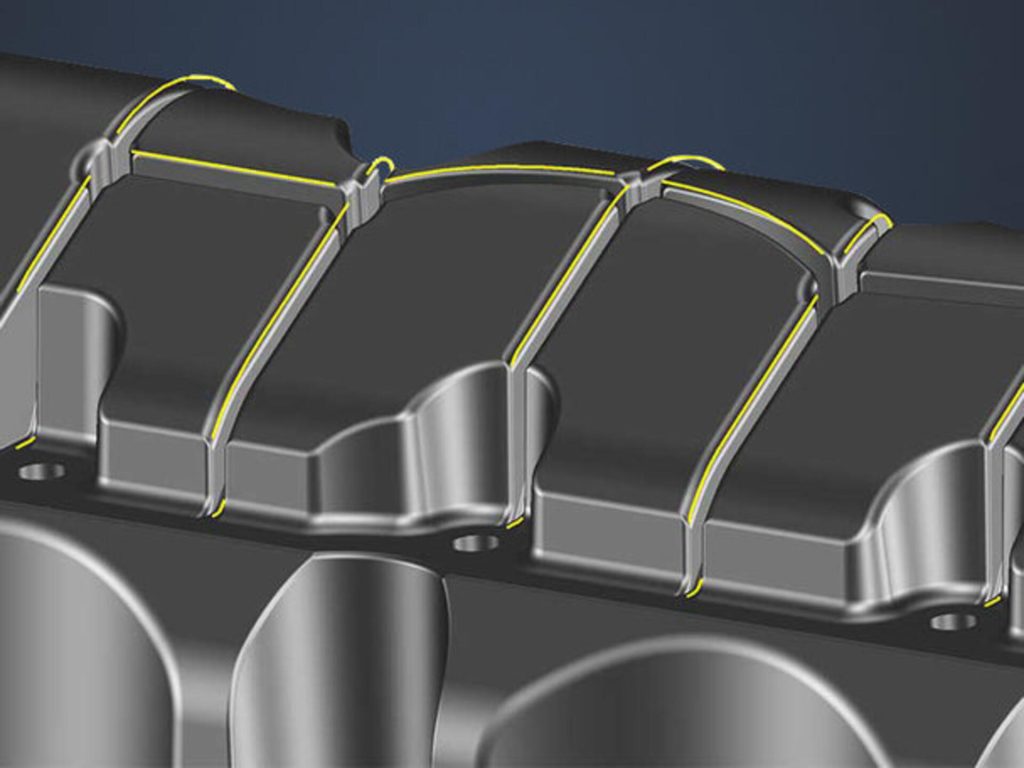

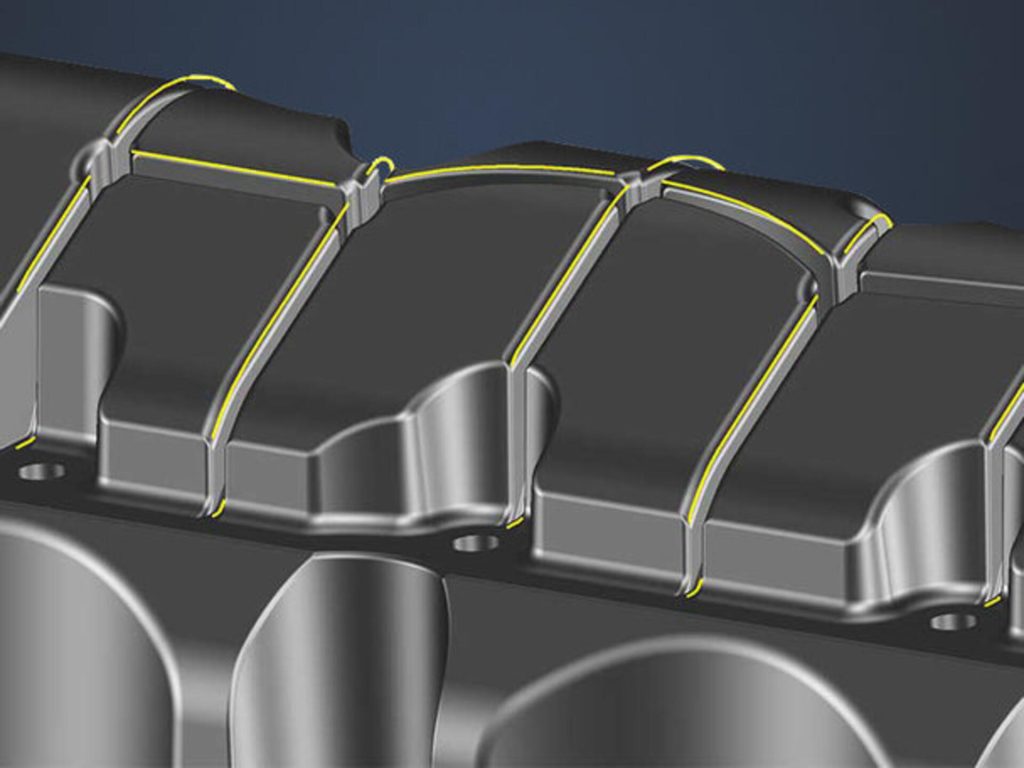

Design functions for the NC programmer

Sometimes the NC programmer has to intervene interactively during data preparation: for example, to generate complex fill surfaces and extension surfaces or area and center curves. It may also be necessary to first design the geometry of the blank. These tasks can be quickly and easily performed with Tebis. Parts can also be simplified and split for a better overview.

Create complex fill surfaces

Less time required: Create complex fill surfaces

Quickly complete the following tasks: Generate fill surfaces and support curves

Extend surfaces

Create guide curves

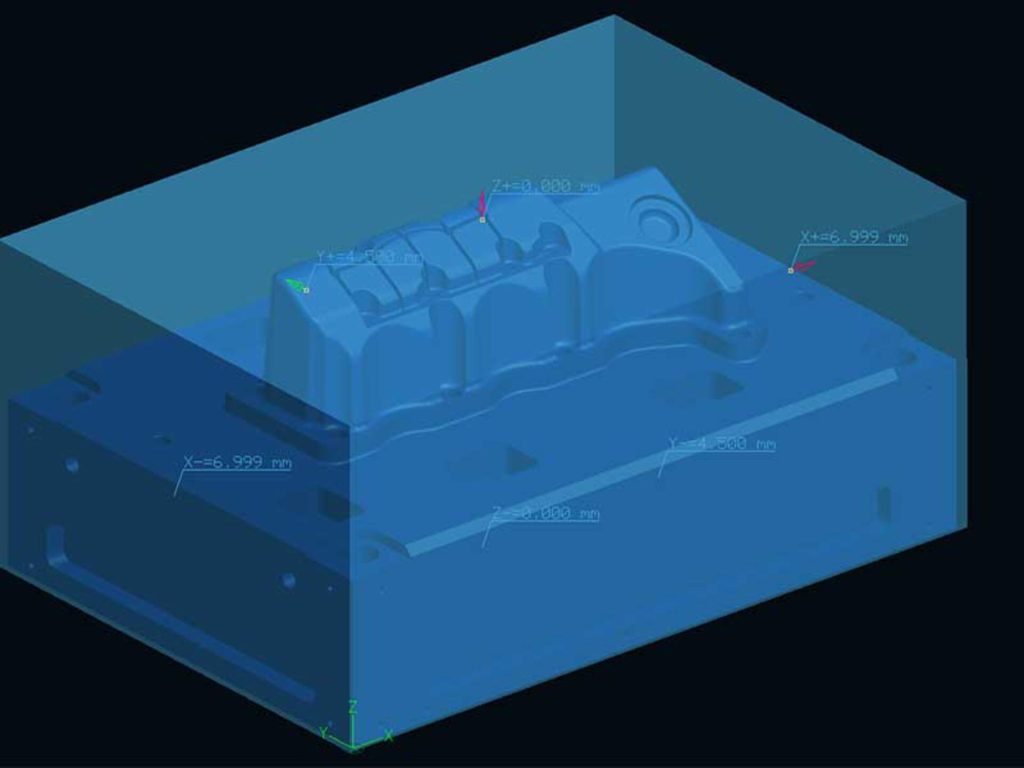

Design blanks

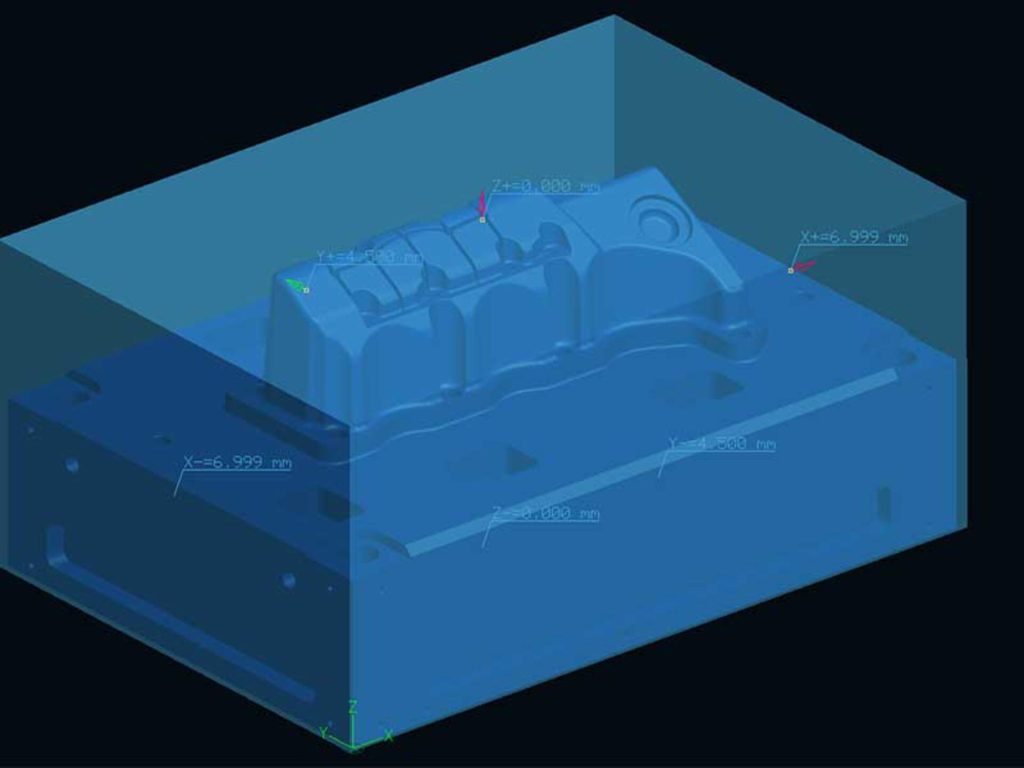

Tebis offers several automatic design functions for defining blanks:

- With a part envelope

- With a casting allowance

- As a layered blank

- As a 6-sided blank

- With an extruded profile

Analyzing geometry

Tebis offers extensive functions for analyzing geometry:

- Calculate lengths, surfaces and volumes for costing and ordering materials

- Determine dimensions like coordinates, length, radius, distance and angle

- Real-time intersection functions through the part

- Compare two versions to detect changes

- Detect and identify bores

- Detect planar surfaces: for example, for defining tool lengths

- Detect and identify roundings

- Compare two manufacturing stages to determine the remaining material to be removed

- Detect geometric steep areas and undercuts to define appropriate milling directions

- Detect surfaces with quality features that haven’t been complied with, including gaps, high segmentation, and overlapping surfaces

- Analyze curvatures to evaluate surface quality

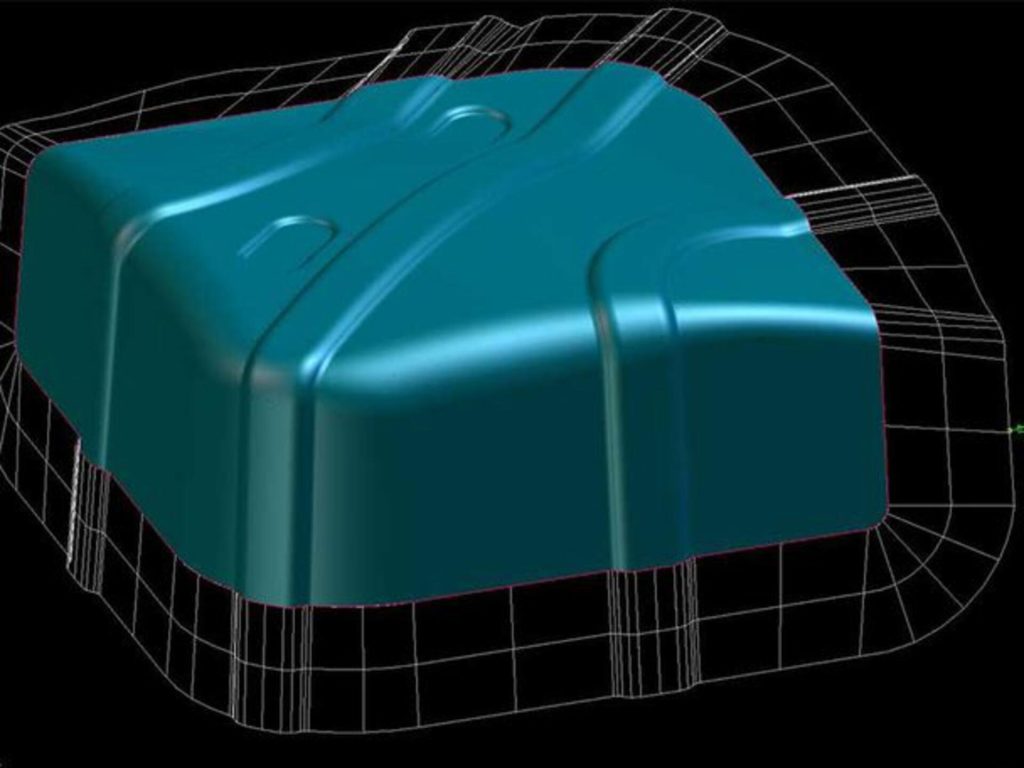

Analysis functions for the example of a part from mold manufacturing

- Determine dimensions

- Analyze roundings

- Detect undercuts

- Detect planar surfaces

- Detect bores

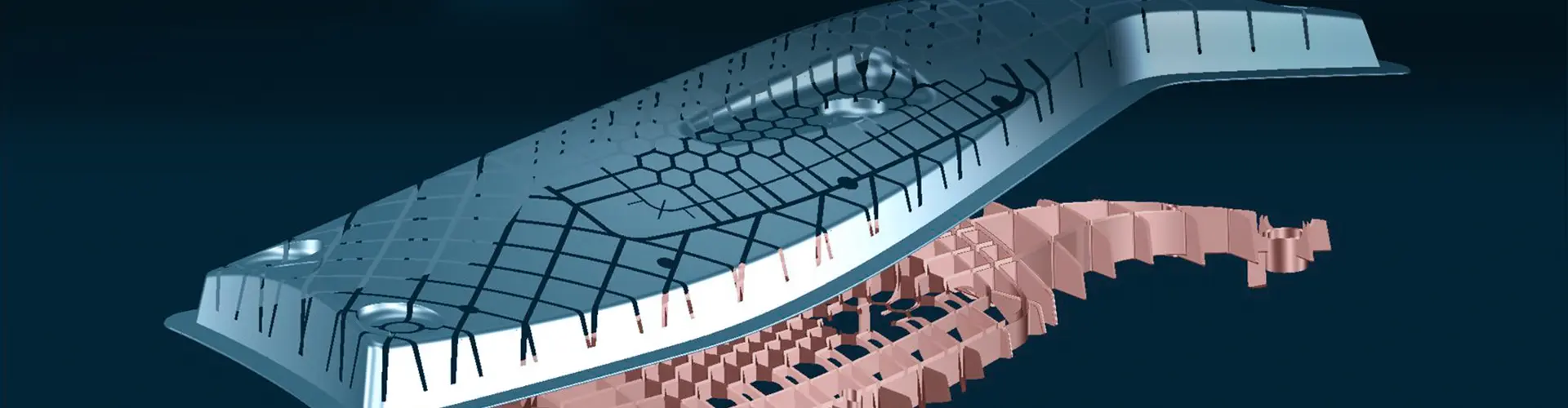

Analysis functions for the example of a sheet metal die

- Determine dimensions

- Analyze planar surfaces and roundings

- Determine steepness relative to Z-axis

- Detect bores

- Real-time intersection function

- Analyze material thickness

- Compare part versions