ZEISS PRISMO family

ZEISS PRISMO family

When precision matters most

Discover the ZEISS PRISMO family

Discover a new era of precision. ZEISS PRISMO has been one of the most precise CMMs on the market for over 30 years and achieves reliable and reproducible results with maximum accuracy. The coordinate measuring machines in the ZEISS PRISMO family offer the highest measuring speeds of all ZEISS CMMs and are suitable for use in a wide variety of environments. The ZEISS PRISMO family consists of four models. Their high quality and measuring accuracy increase the efficiency of your process. If you don’t want to compromise on precision when it comes to quality assurance, you’re in safe hands with the ZEISS PRISMO family. Because the rule here is: accuracy plus safety ensures productivity.

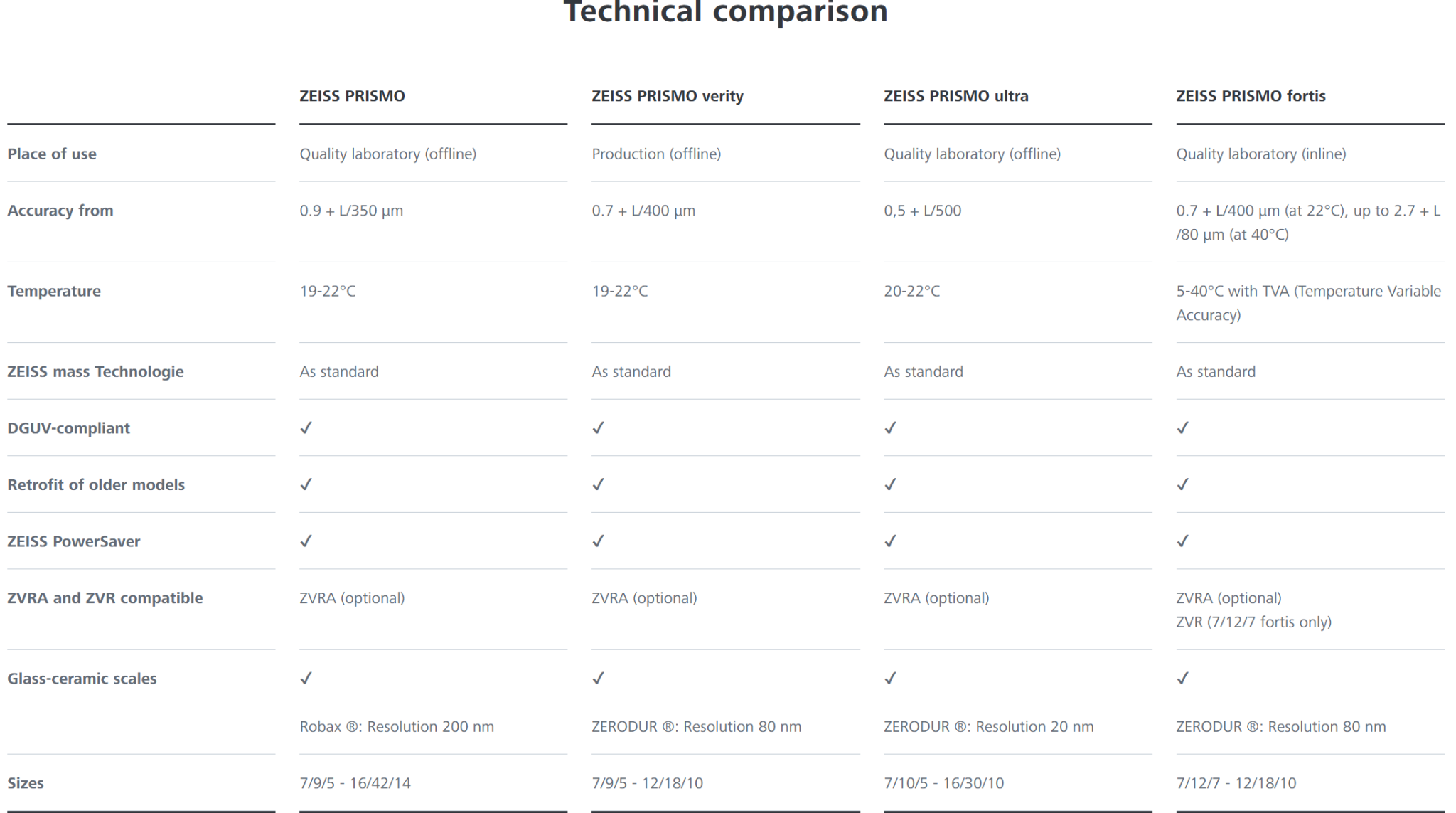

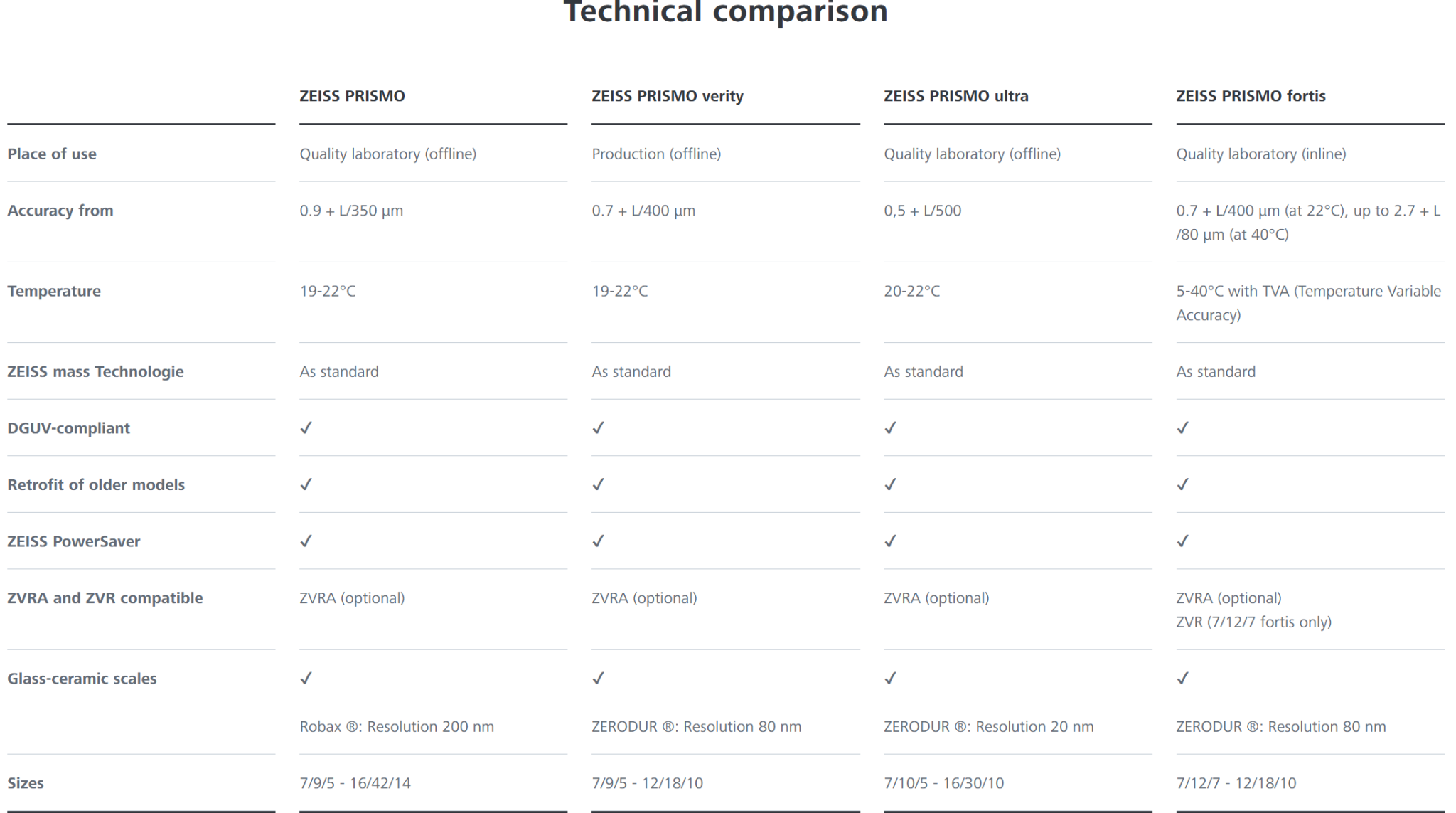

ZEISS PRISMO

The all-rounder

With a length measurement error from 0.9 + L/350 µm, ZEISS PRISMO is the flagship among ZEISS CMMs and offers maximum productivity and outstanding performance.

ZEISS PRISMO verity

The new standard

ZEISS PRISMO verity delivers results with a length measurement error from just 0.7 + L/400 µm and impresses with improved form measurement values.

ZEISS PRISMO ultra

Maximum precision in the PRISMO family

With a length measurement error of 0.5 + L/500 µm, ZEISS PRISMO ultra improves precision even further and is therefore particularly suitable for research and calibration tasks, as well as reference laboratories.

ZEISS PRISMO fortis

Precision in production environments

ZEISS PRISMO fortis is designed for use in production environments and offers maximum precision even at temperatures of up to 40°C.

ZEISS PRISMO sets new standards

More than just a facelift: The flagship family of coordinate measuring machines from ZEISS has been completely overhauled. With numerous upgrades, safety, economic and environmental efficiency, flexibility, ergonomics and, last but not least, productivity have reached a whole new level.

Increased safety

Safety laser scanner and DGUV certification

ZEISS PRISMO has safety laser scanners that not only fully detect every corner but also trigger an automatic speed reduction as soon as they detect movement or hazards in the safety zone.

In addition, every ZEISS PRISMO coordinate measuring machine is officially certified by the internationally recognized German Social Accident Insurance (DGUV). This voluntary certification is unique among CMM providers. Additional innovations have been introduced to comply with DGUV guidelines, such as the adjustable side panels. By reducing the distance between the moving parts to less than 4 mm, the crushing hazard is reduced.

Maximum productivity

Speed and optional ZEISS VAST Rotary Table Axis

The new safety laser scanners are equipped with a function for automatic speed reduction and thus enable significantly faster measurement than before – while reliably maintaining high safety standards.

The speed is also increased by the ZVRA option for defining the rotary table axis. Axis definition on a rotary table no longer takes 60 seconds, but only 15 seconds – thanks to continuous measurement using the special ZEISS VAST Rotary Table Axis (ZVRA) option.

Improved ergonomics

Control panel holder, switch arrangement and slim design

Ergonomics have also been optimized as part of the new ZEISS PRISMO family. The new control panel holder allows the control panel to be conveniently stored when not in use.

For even easier operation and monitoring, most of the switches are no longer located on the controller, but directly on the control panel.

The new cover at the front significantly reduces the distance between the operator and the measuring volume compared to the previous model – which can protect employees, especially when loading heavy workpieces.

Increased flexibility

Free choice of sensor and extended size selection

With the new ZEISS C99m controller, ZEISS PRISMO now supports both ZEISS ROTOS (roughness sensor) and ZEISS LineScan (optical sensor), thus increasing operational flexibility.

The range of sizes has also been extended. The usual ZEISS PRISMO sizes from 7/9/5 to 16/42/10 are still available. The standard version now also comes in three new sizes: 16/24/14, 16/30/14 and 16/42/14.