Brother Deburring Center Series

SPEEDIO :

DG-1

Realize mechanization of deburring work for die casting materials with variable variety and volume production

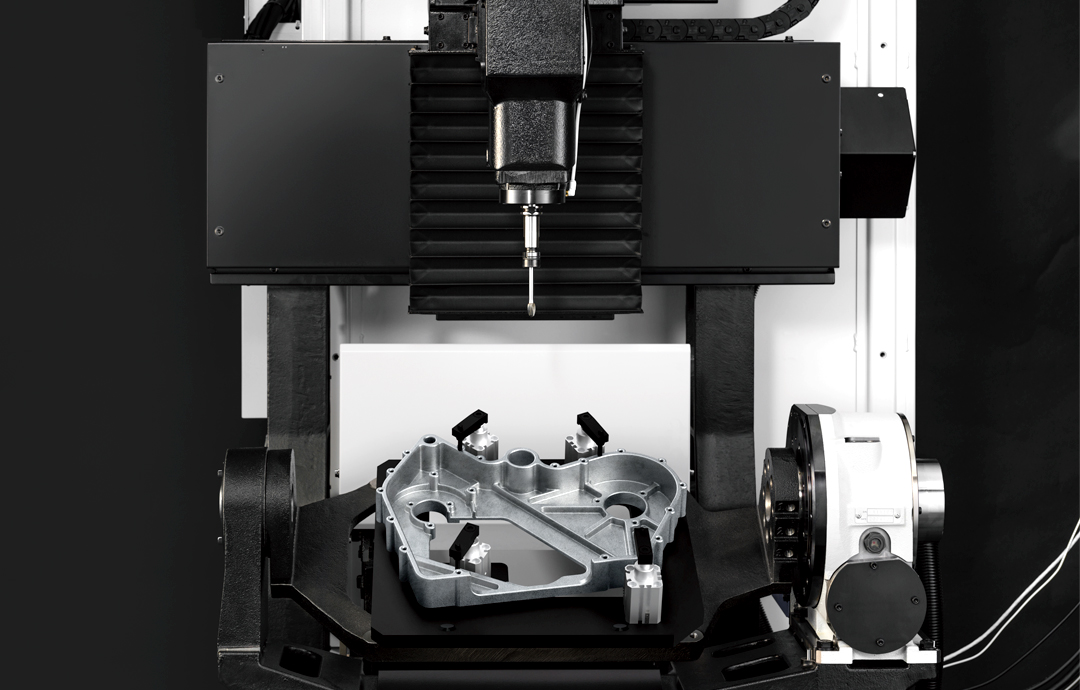

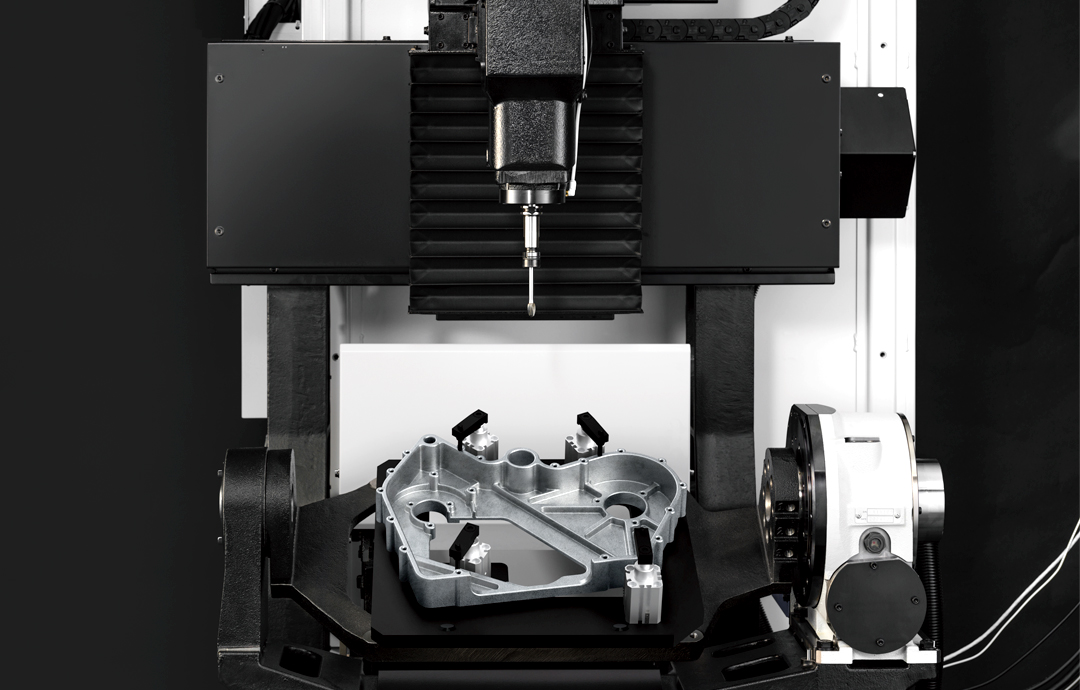

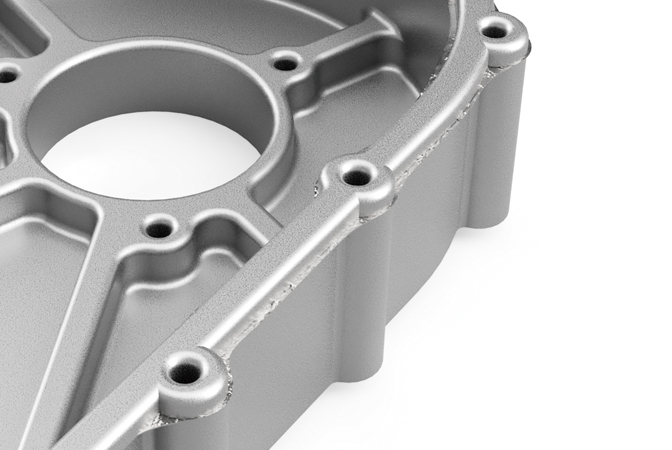

Processing Examples

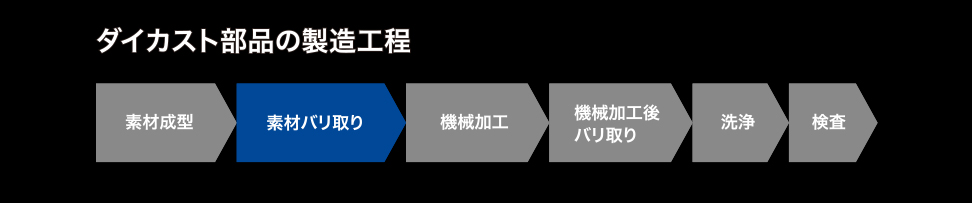

Target process and burrs

Targeted at the “material deburring” process in die-casting part manufacturing

Optimal machine configuration

Achieves high chip removal performance for handling a wide range of burrs and dry machining

Brother’s unique processing startup function

Simple operations such as teaching representative points and intuitive path correction greatly reduce the man-hours required for starting up machining.

Various functions

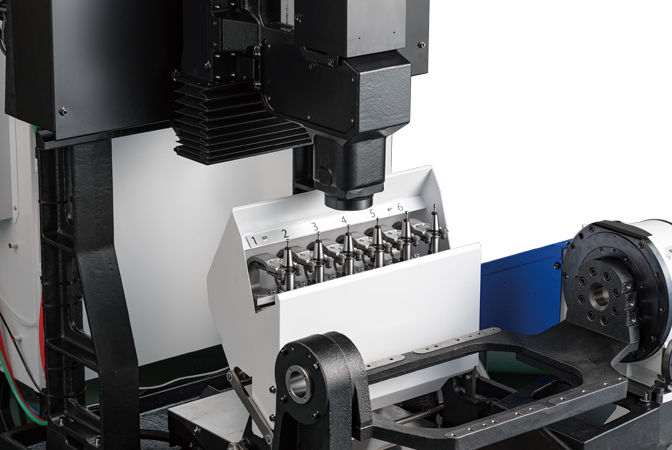

Equipped with a variety of functions, including pickup-type ATC

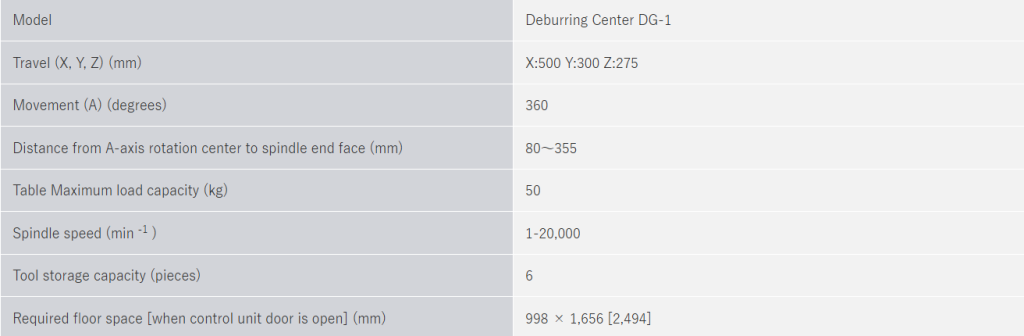

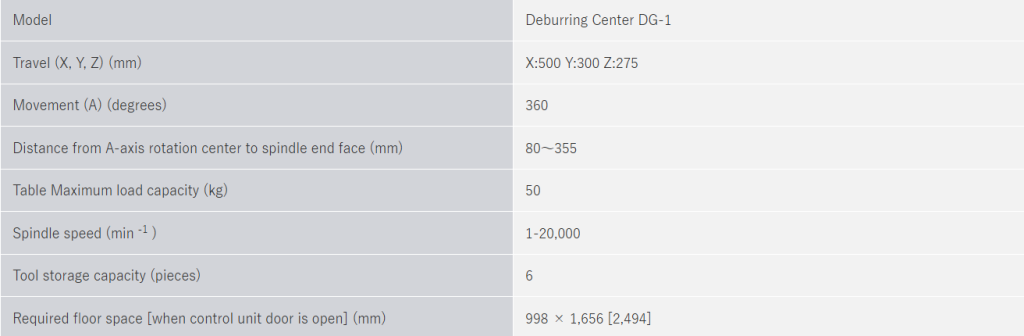

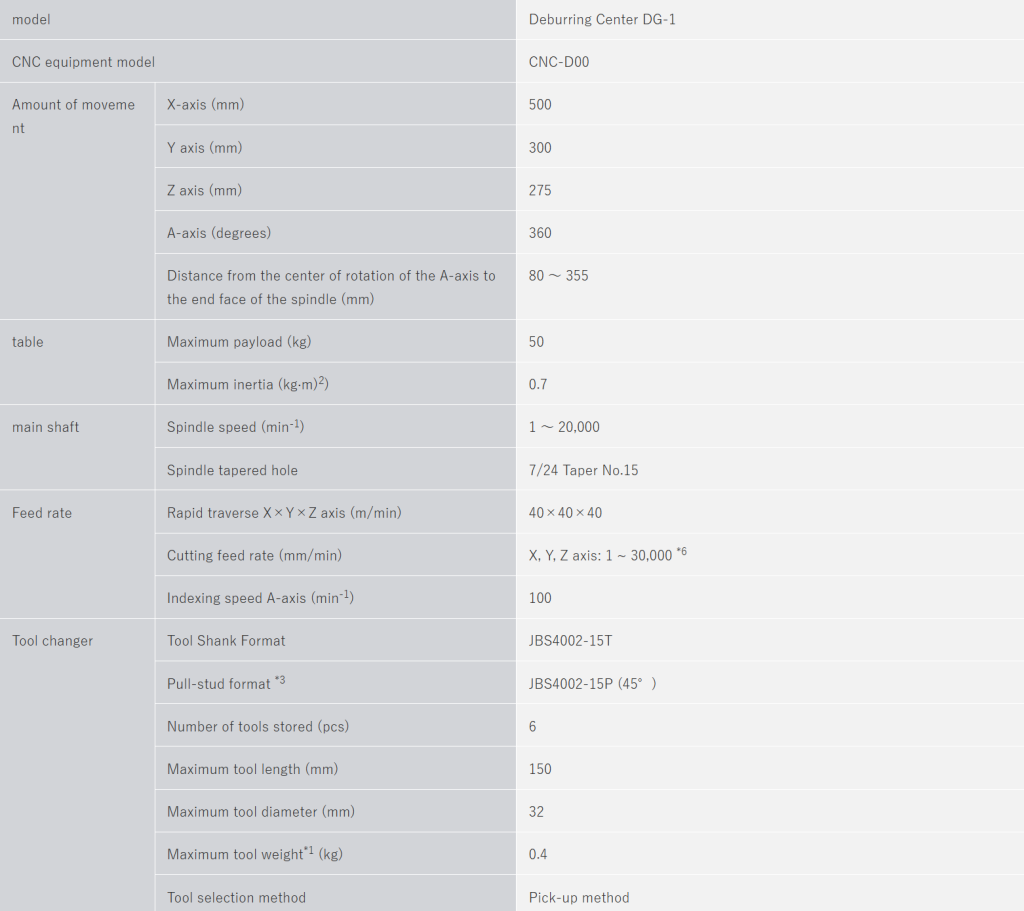

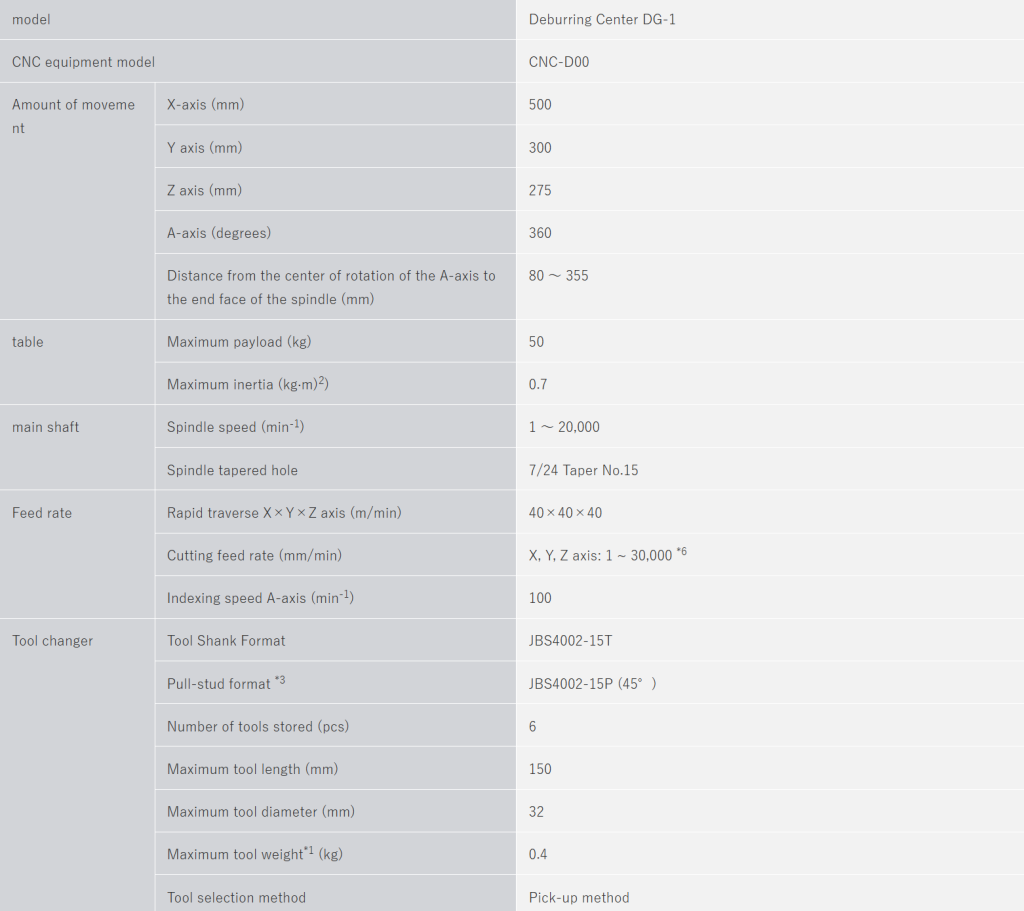

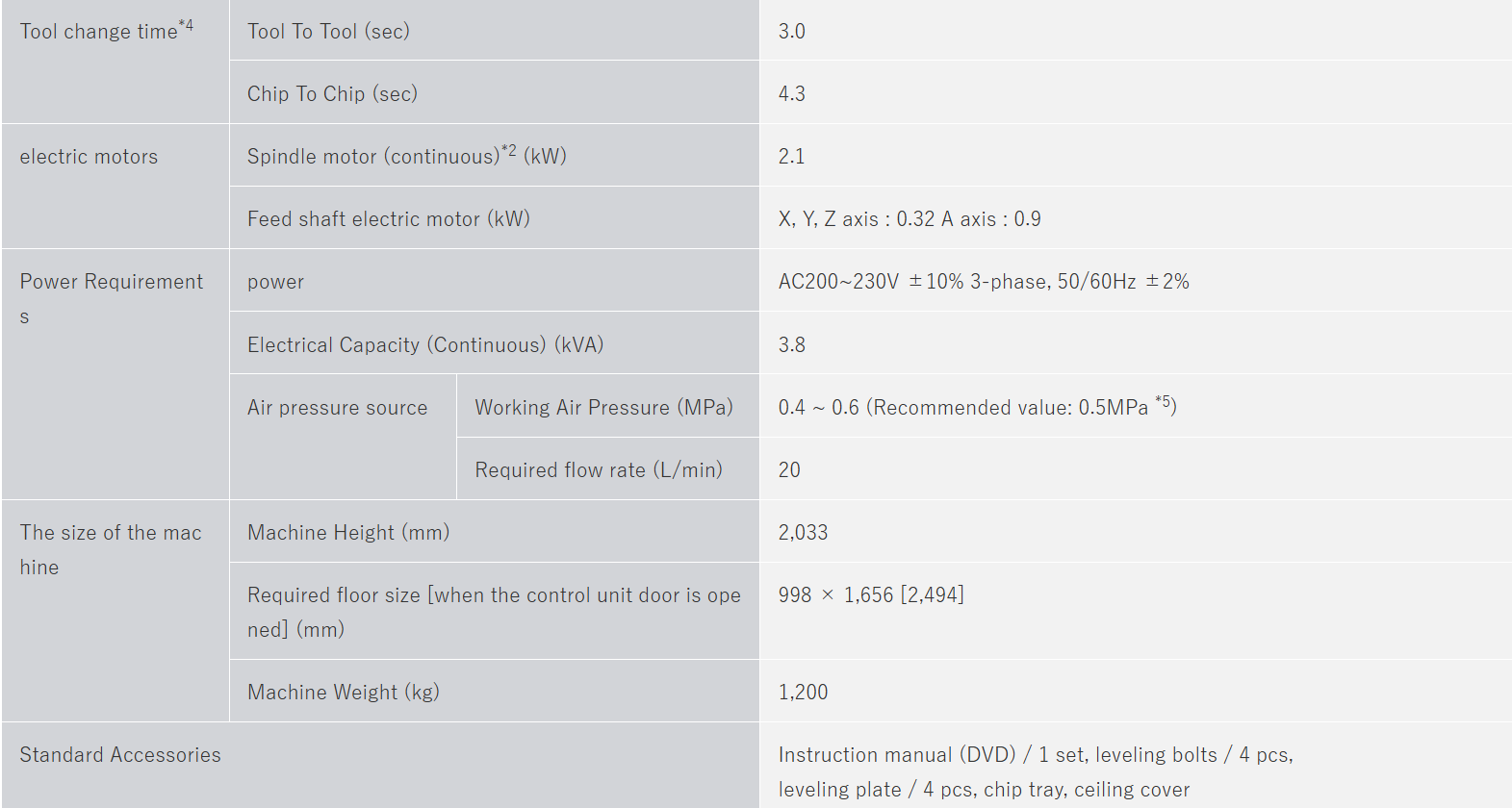

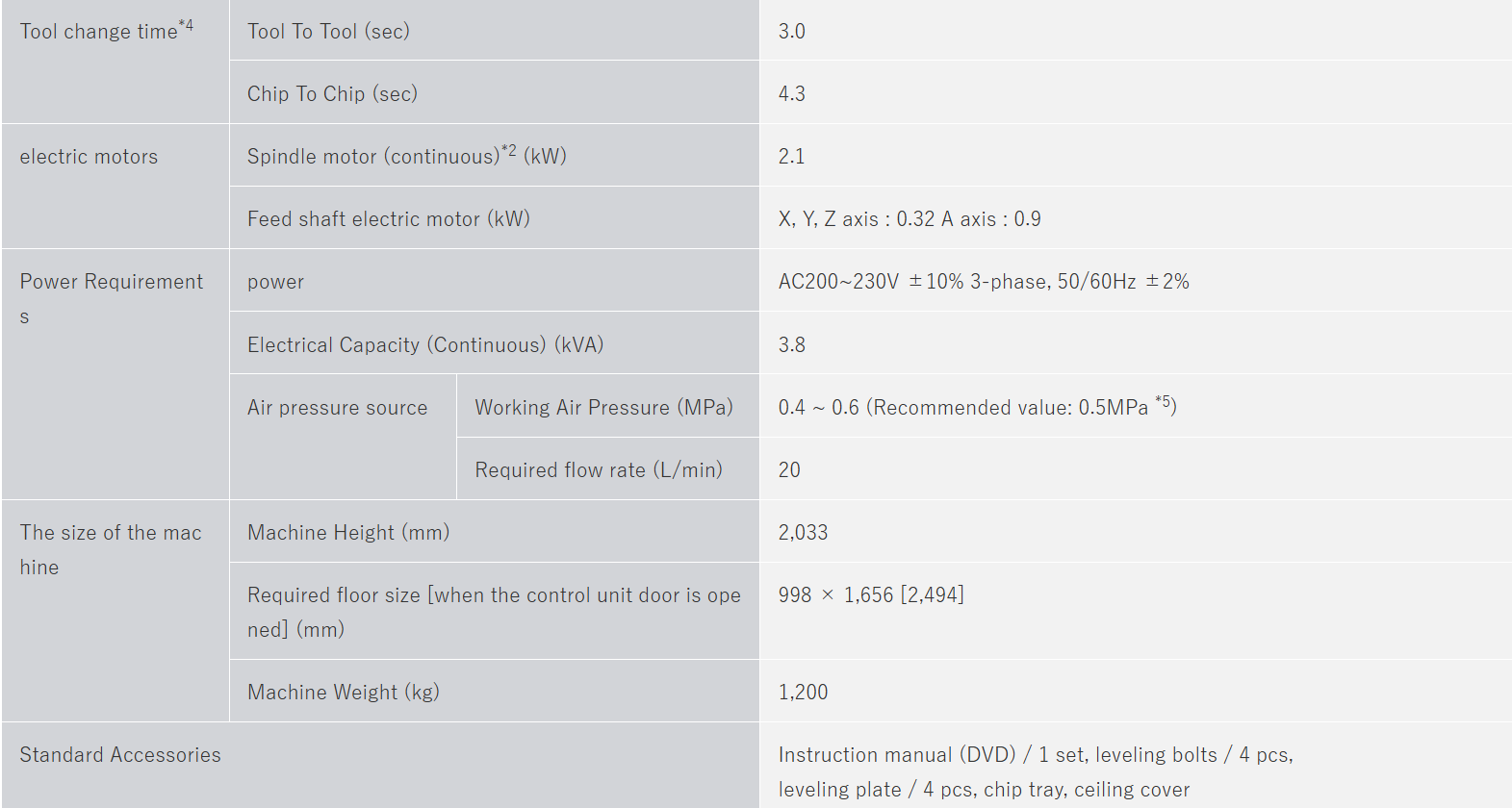

Specifications

Target process and burrs

Targeted at the “material deburring” process in die-casting part manufacturing

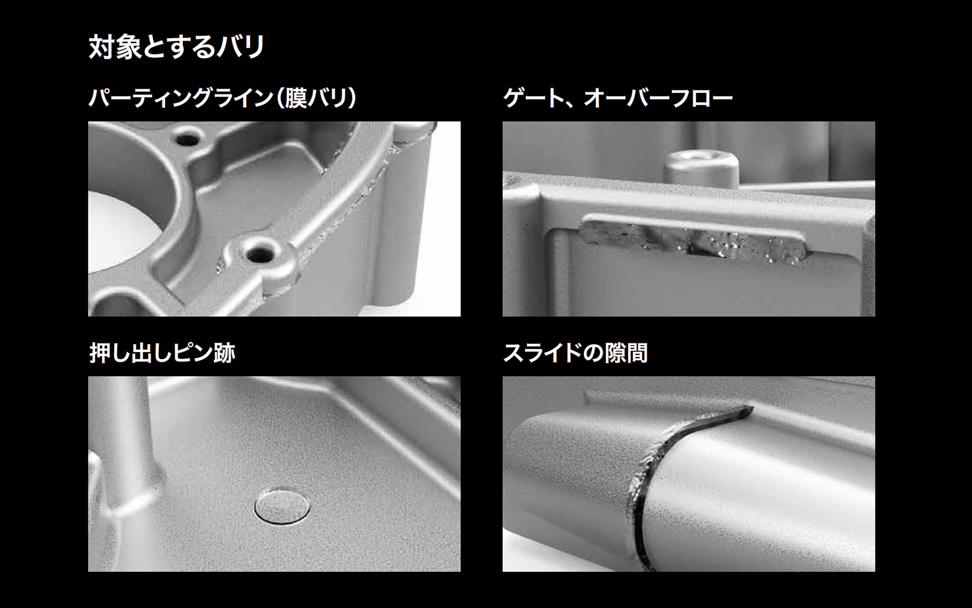

Target Bali

- Parting line (film burr)

- Gate, overflow

- Ejector pin marks

- Slide gap

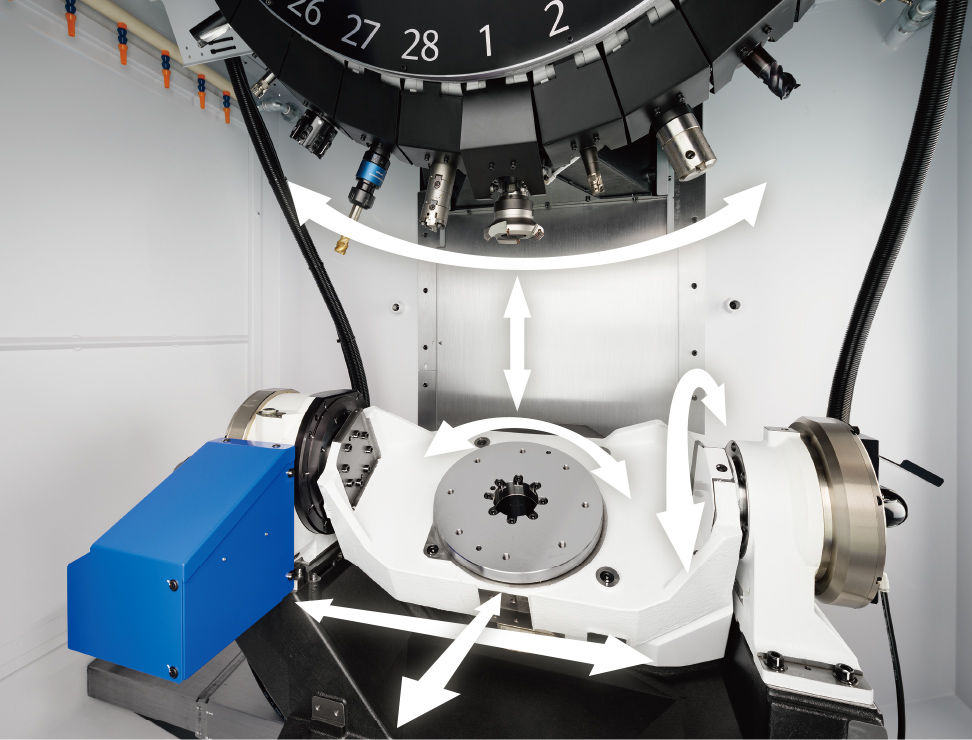

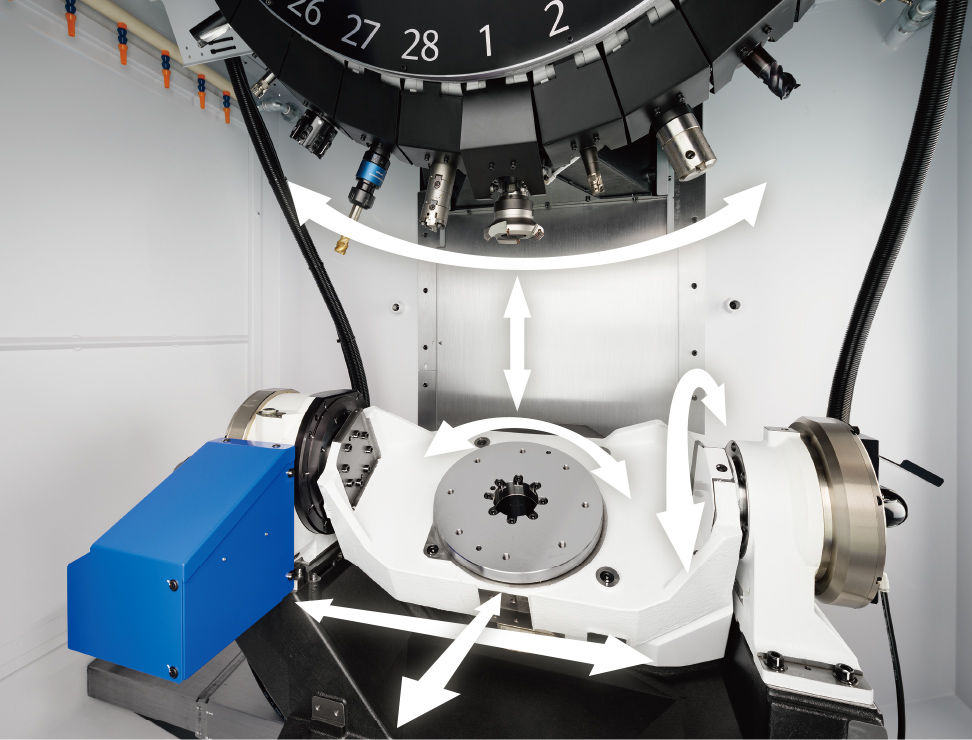

Optimal machine configuration

Brother’s unique features significantly improve the production efficiency of deburring processing

Brother’s unique processing startup function significantly improves the production efficiency of deburring processing for variable-volume, variable-mix production, which is currently done manually, and enables mechanization.

Non-stop ATC

The deburring center is equipped with Brother’s unique processing startup function. Simple teaching operations, corrections, automatic path generation, etc. allow processing startup in a short time. The optimal machine configuration allows it to handle a wide range of burrs and has high chip removal performance for dry processing, promoting the mechanization of manual deburring processing.

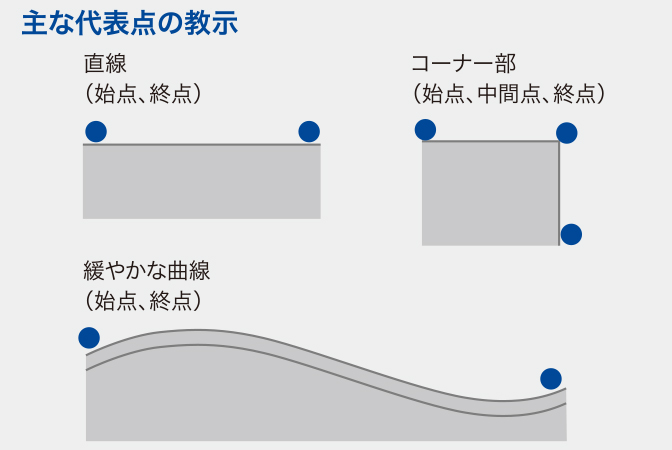

1. Realization of generating and correcting machining paths in a short time (Brother’s unique machining start-up function)

②Supports a wide range of deburring processes

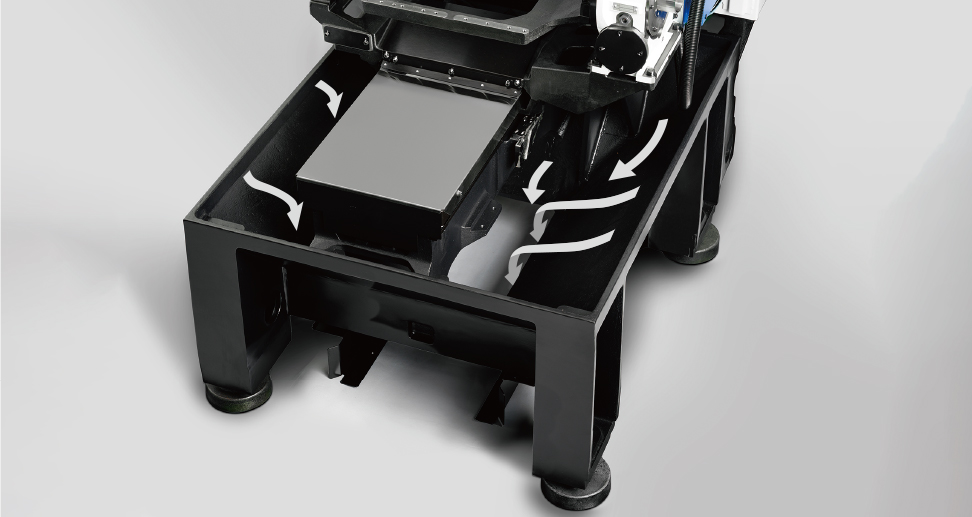

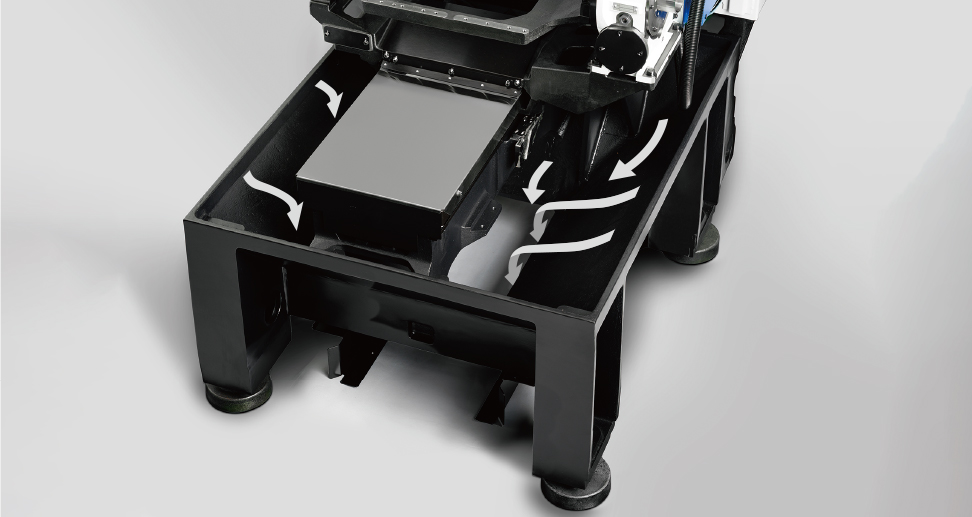

3. High chip removal performance for dry machining

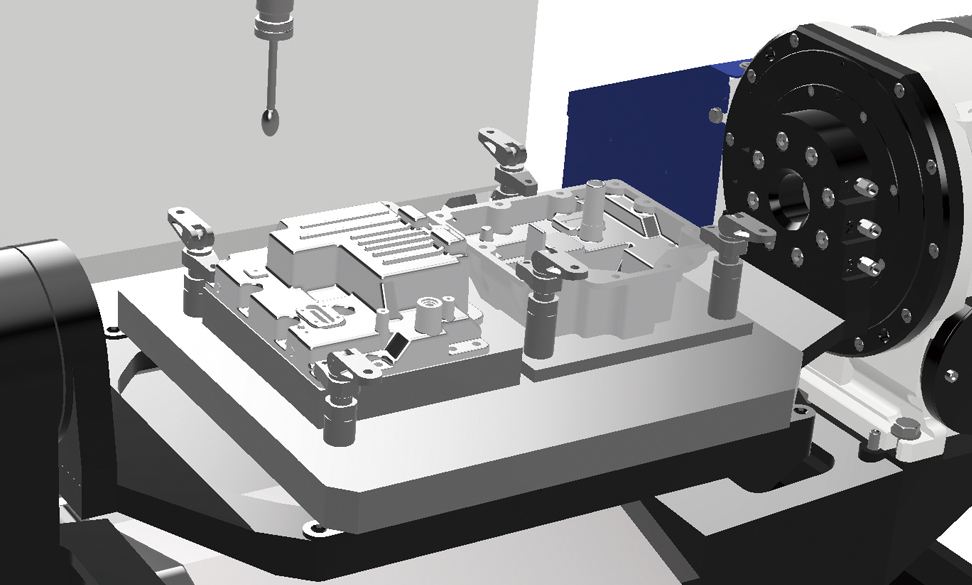

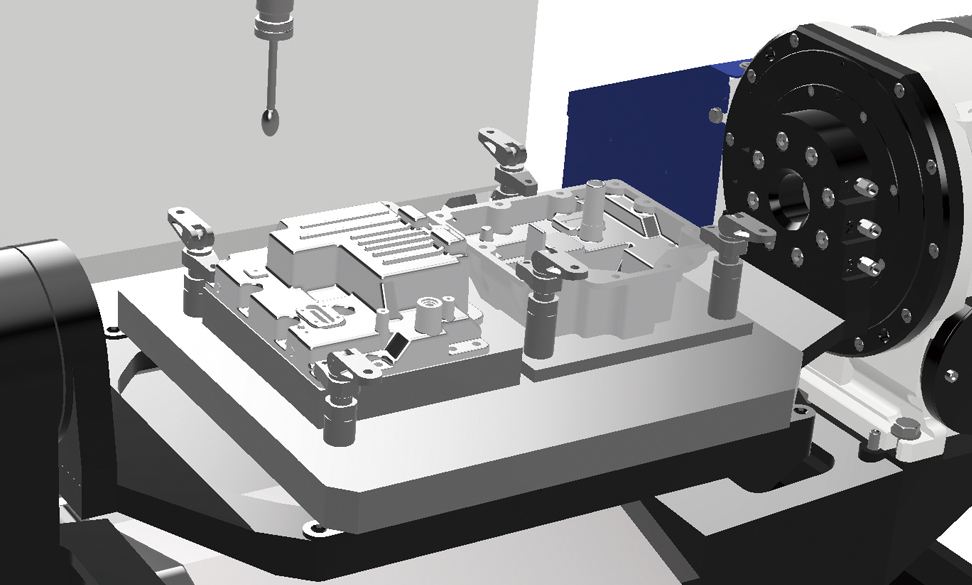

Fixture Area

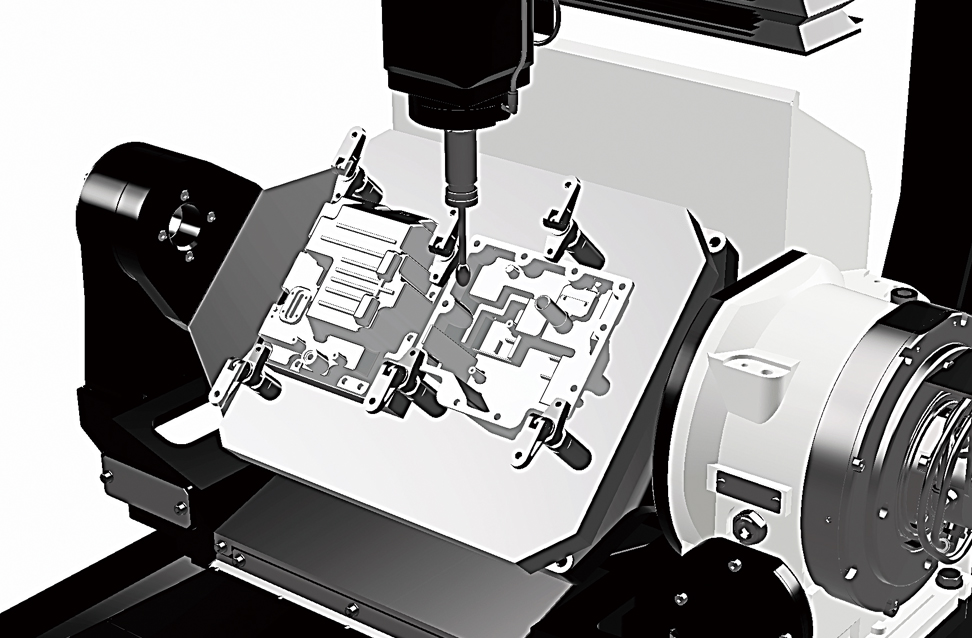

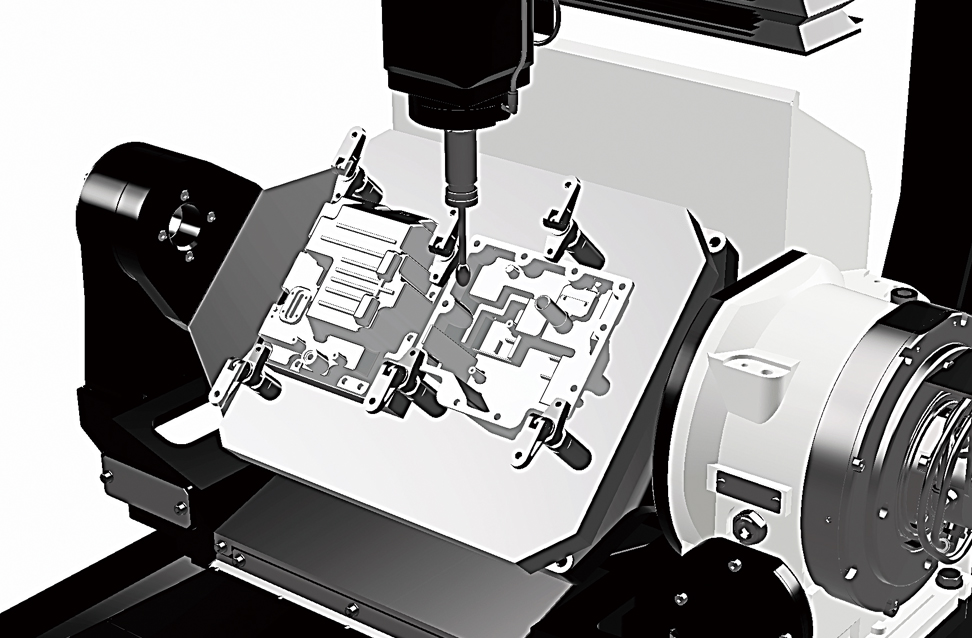

The 4-axis control is equipped with a tilt axis (A-axis) with a roller gear cam structure, and the wide fixture area allows for highly flexible fixture design. In addition, a fixture base (optional) is also available to configure a cradle fixture between the face plate and support of the tilt axis.

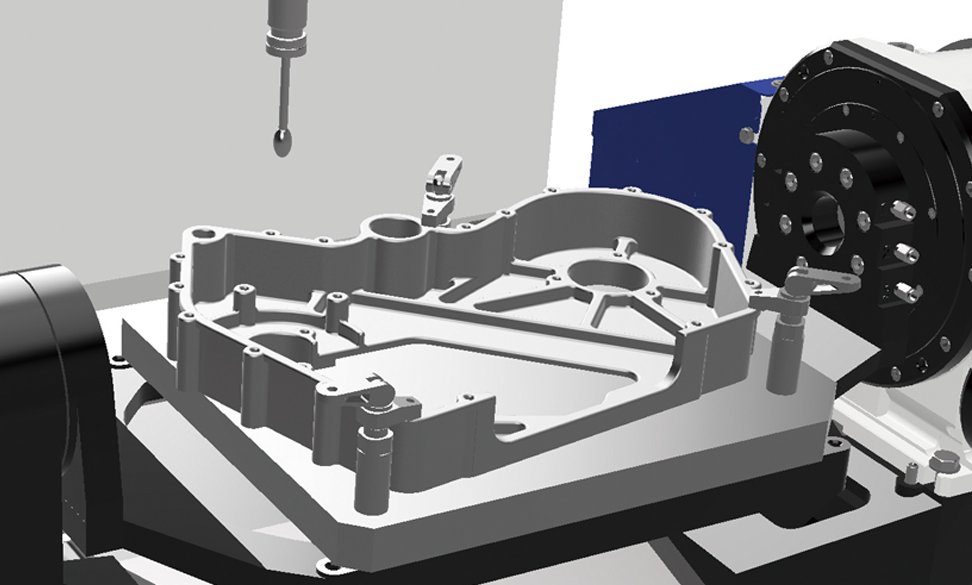

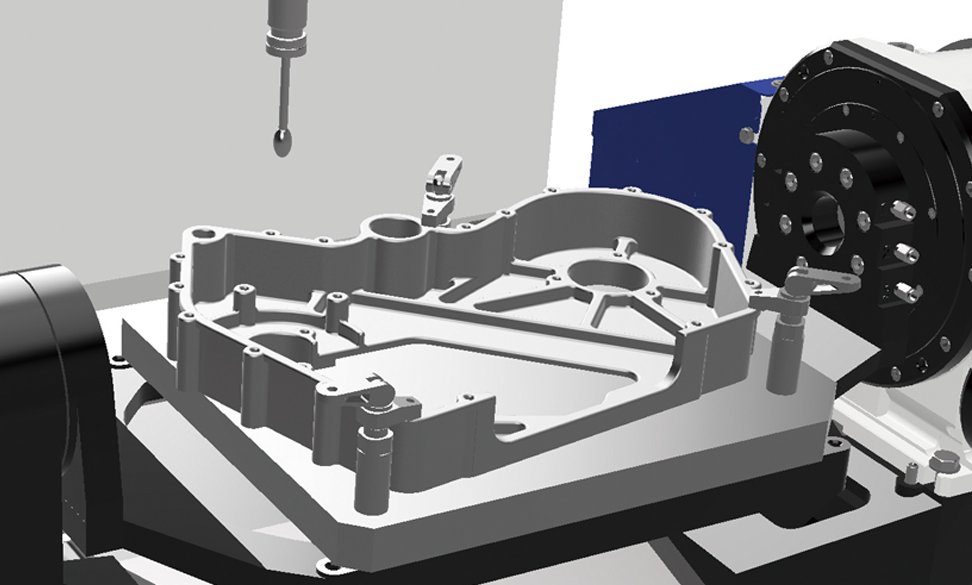

Jig mounting example

The lean machine configuration allows for great freedom in jig design, making it easy to mount everything from large workpieces to multi-cavity jigs.

Brother's unique processing startup function

Significant reduction in machining start-up man-hours. Simple machining path generation in a short time.

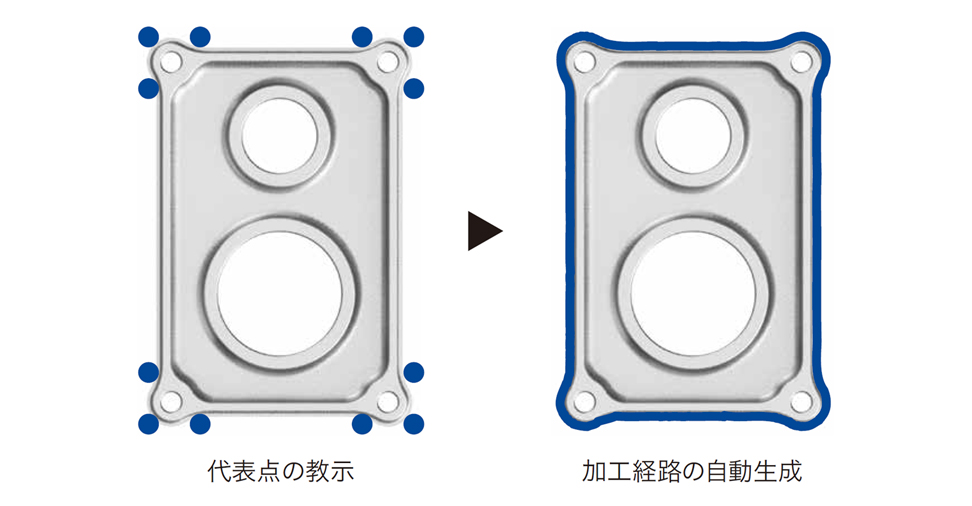

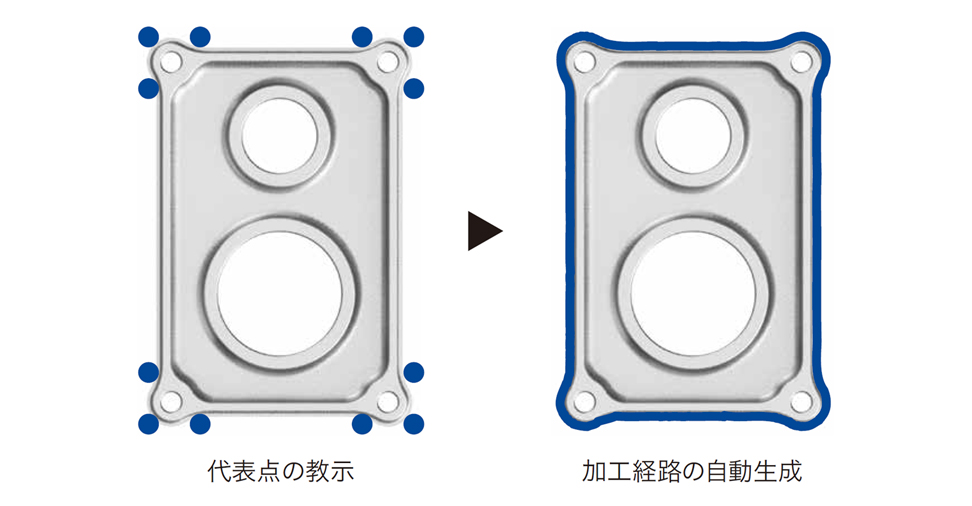

It is equipped with Brother’s unique machining startup functions, such as simple operations such as teaching representative points and intuitive path correction, automatic machining path generation, automatic program conversion, etc.

The short machining startup time enables the mechanization of deburring processing for variable-volume production, which is currently done manually.

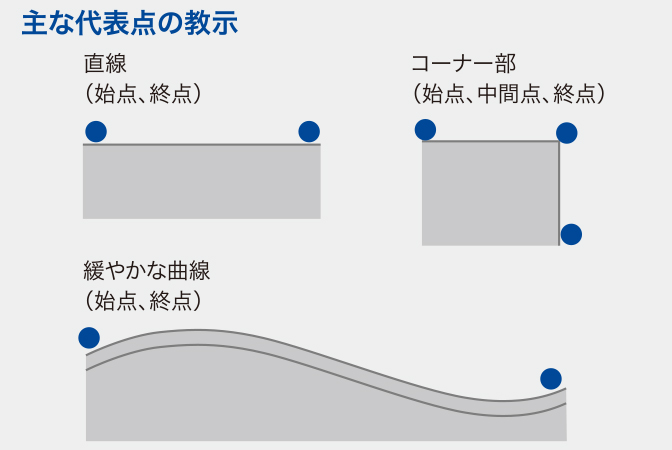

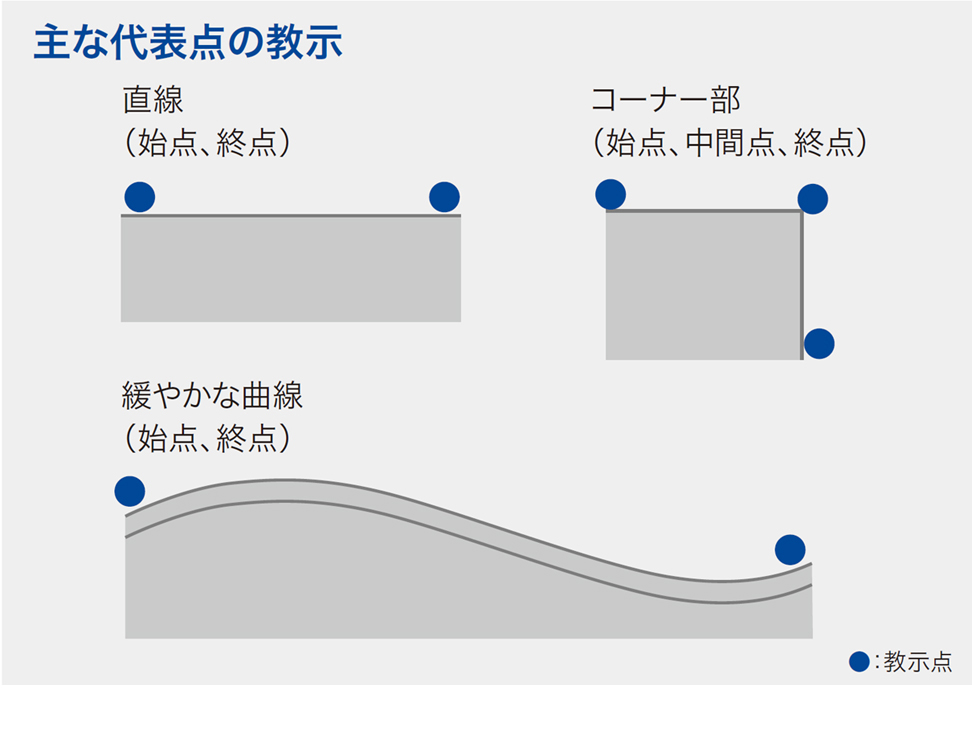

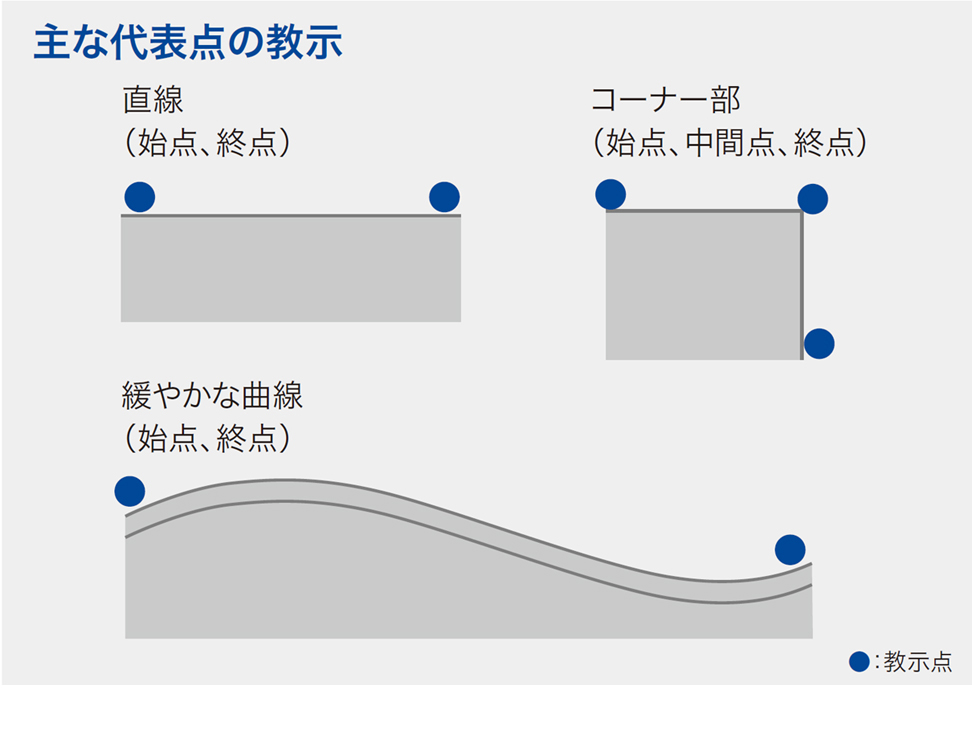

STEP 1: Teaching representative points

The tool is placed against the master workpiece * and representative points are taught. Compared to a robot, there are fewer teaching points, and there is no need to define straight lines or arcs. For gentle curves, the machining path can be automatically generated by teaching only the start and end points.

* Please prepare a non-deburred master workpiece.

Teaching controller (optional)

The movement direction and speed can be intuitively controlled, improving the efficiency of teaching representative points.

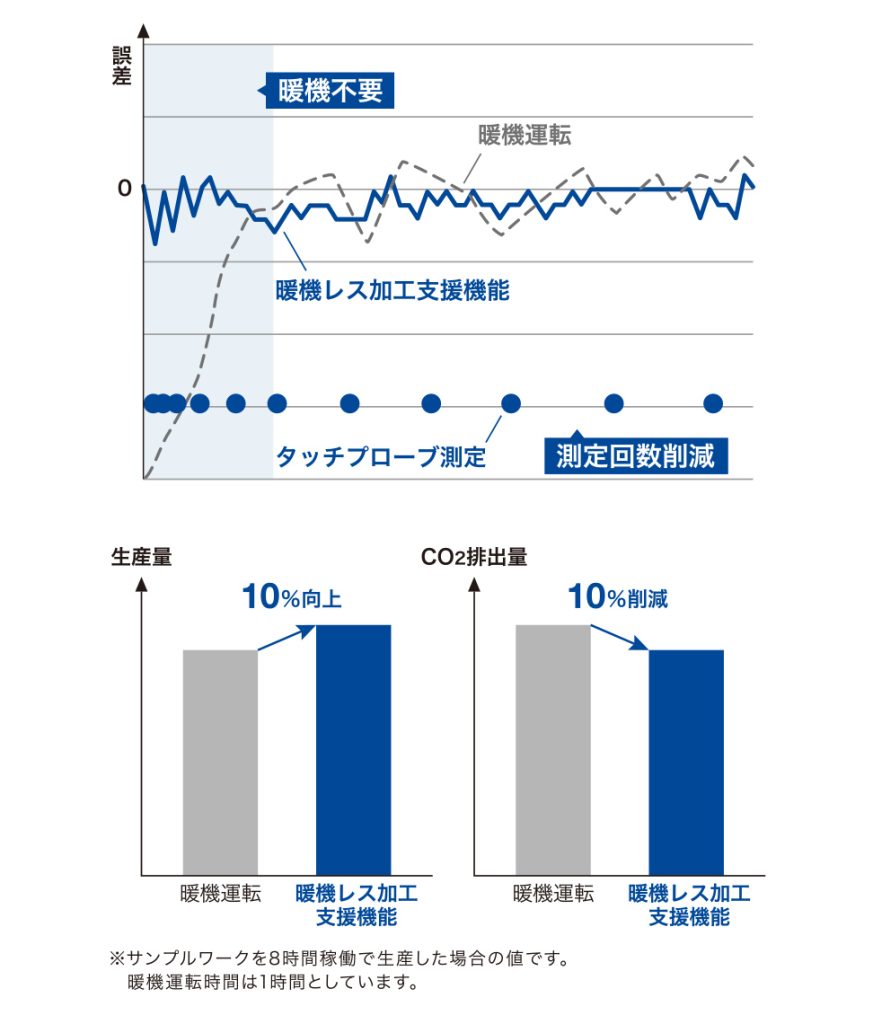

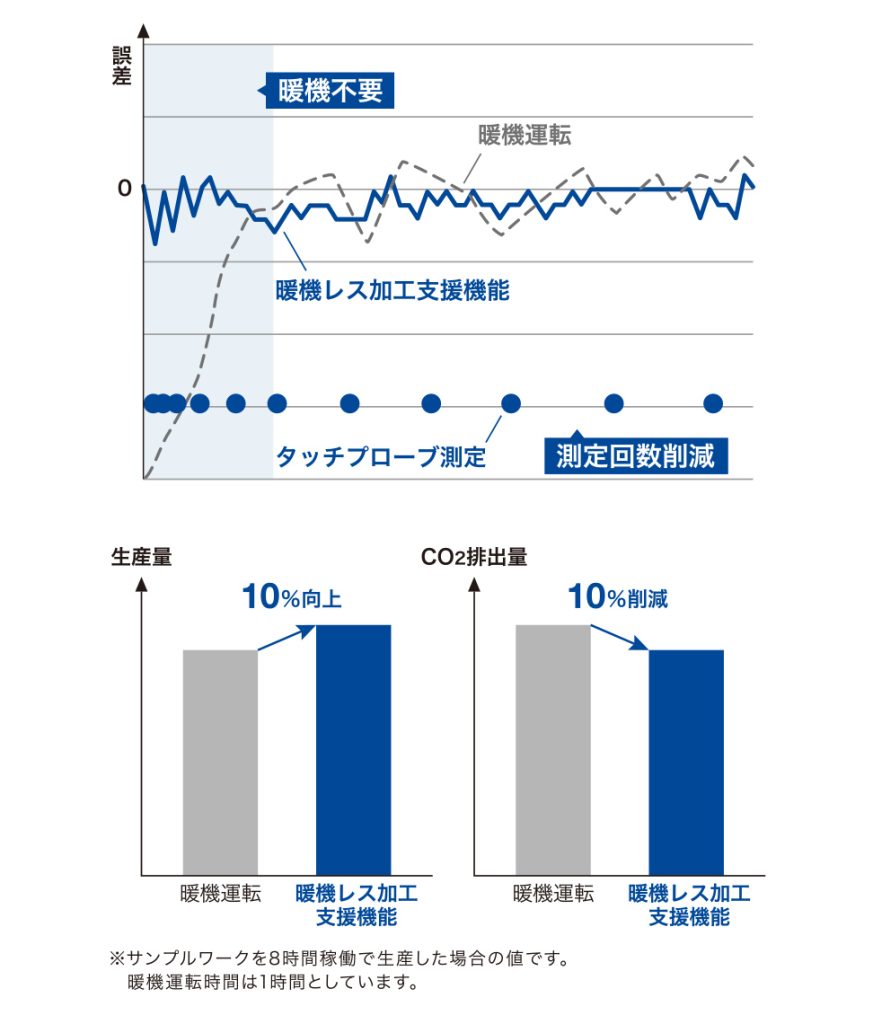

Warm-up-free processing support function

It is equipped with a unique measurement processing function that thins out the actual measurements of the touch probe according to the magnitude of the displacement. This

eliminates the need for warm-up operation, minimizes the impact on productivity, and achieves high-precision machining.

STEP 2 Automatic generation of machining paths

The standard motor has been upgraded from the previous 10,000 min -1 to a newly developed 12,000 min -1

. It maintains the spindle torque in the medium to high speed rotation range, contributing to further shortening the machining time for high-speed, high-efficiency machining of aluminum and steel.

Machining path generation operation

The machining path is automatically generated by rotating the tool based on the taught representative points and repeatedly contacting the master workpiece.

Simultaneous 5-axis machining (U500Xd2-5AX)

It is equipped with various functions including tool center point control and sub-micron command.

Combined with the backlash-less tilting rotary table, it achieves high-speed, high-precision simultaneous 5-axis machining.

* The simultaneous 5-axis model (5AX) cannot switch to a dialogue language.

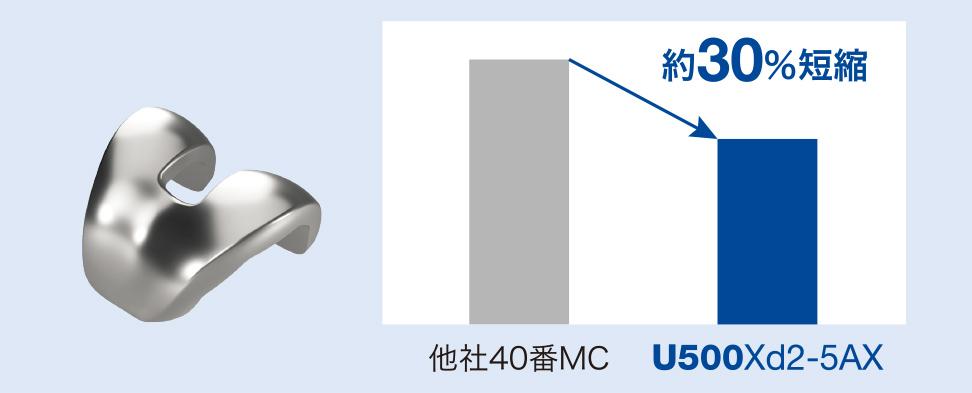

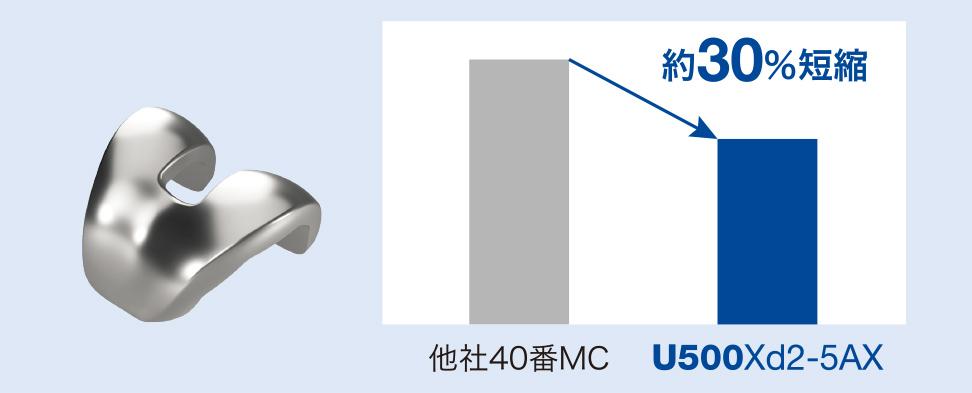

Productivity improvement

In addition to the compact size of the No. 30, the unique acceleration/deceleration processing with look-ahead allows for maximum use of the machine’s performance (maximum speed and acceleration), achieving high-speed simultaneous 5-axis machining.

Comparison of cycle times with other companies’ No. 40 MCs Workpiece

name: Knee joint

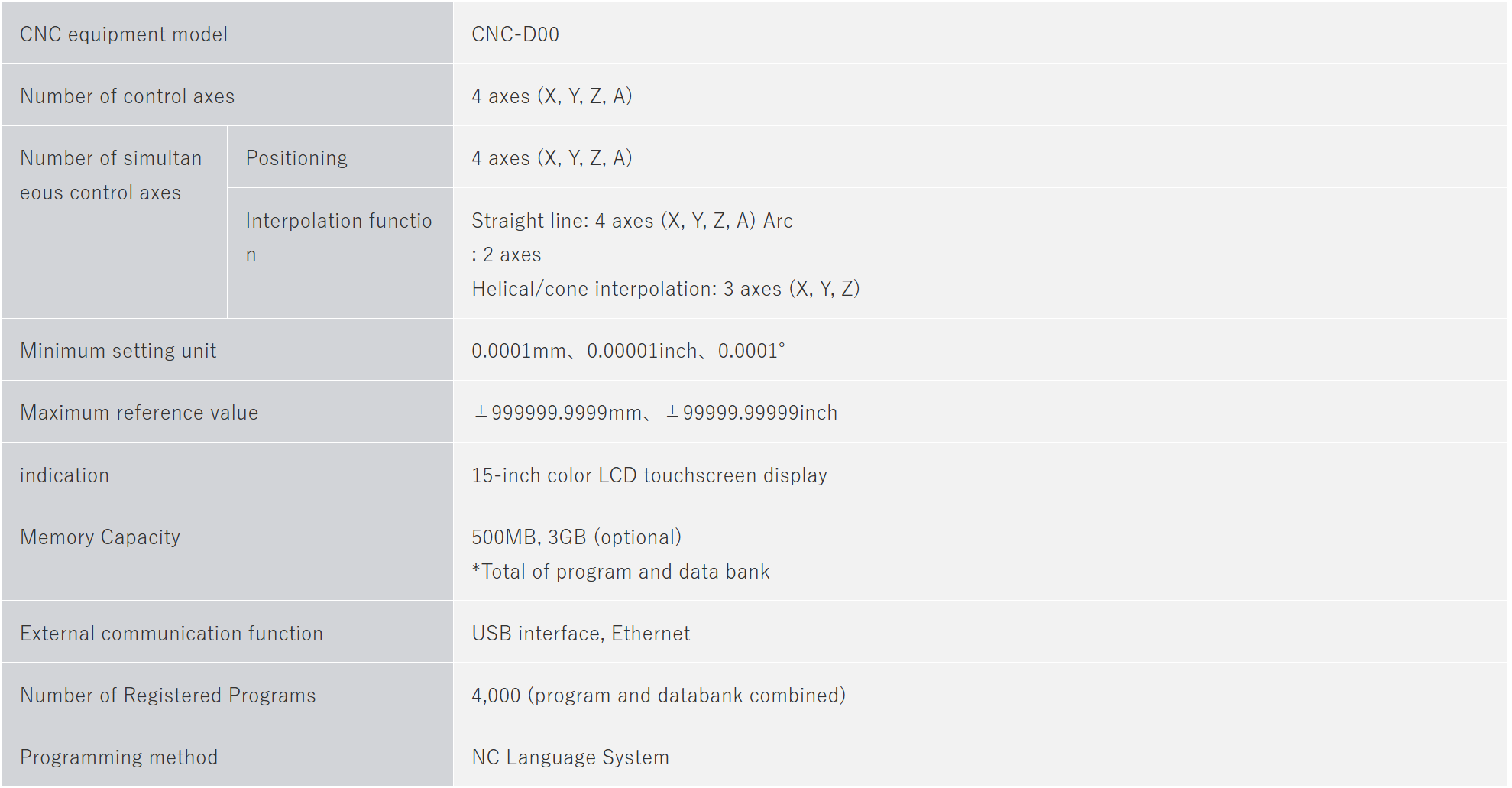

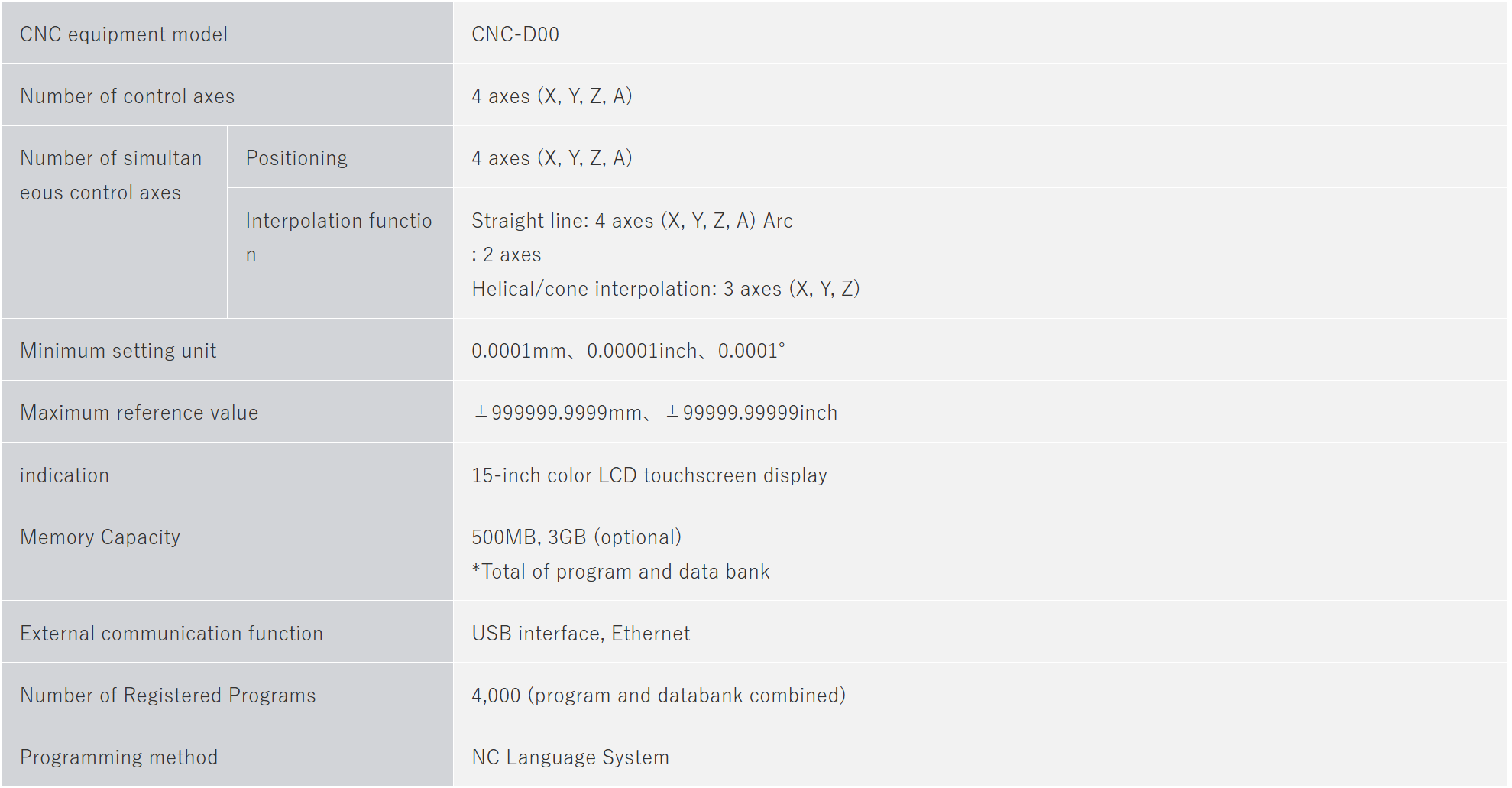

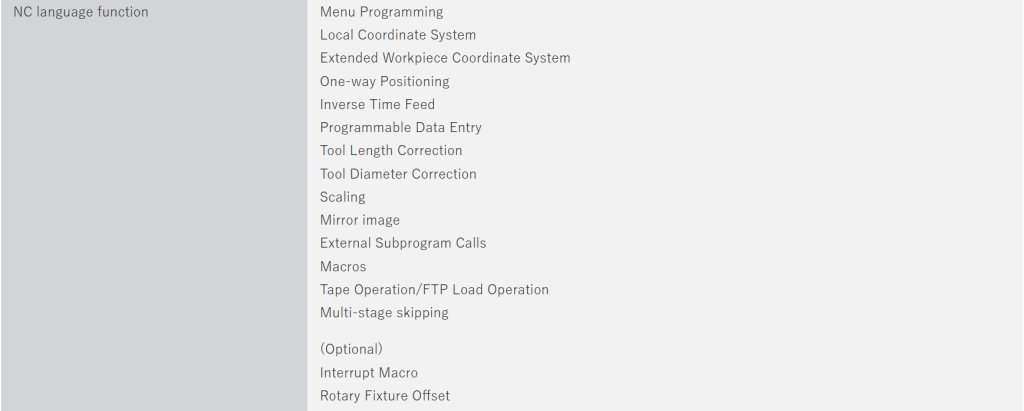

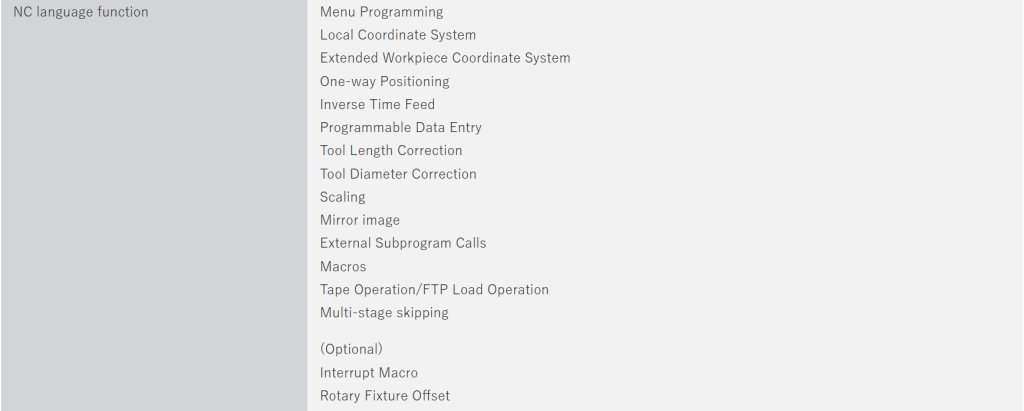

NC unit

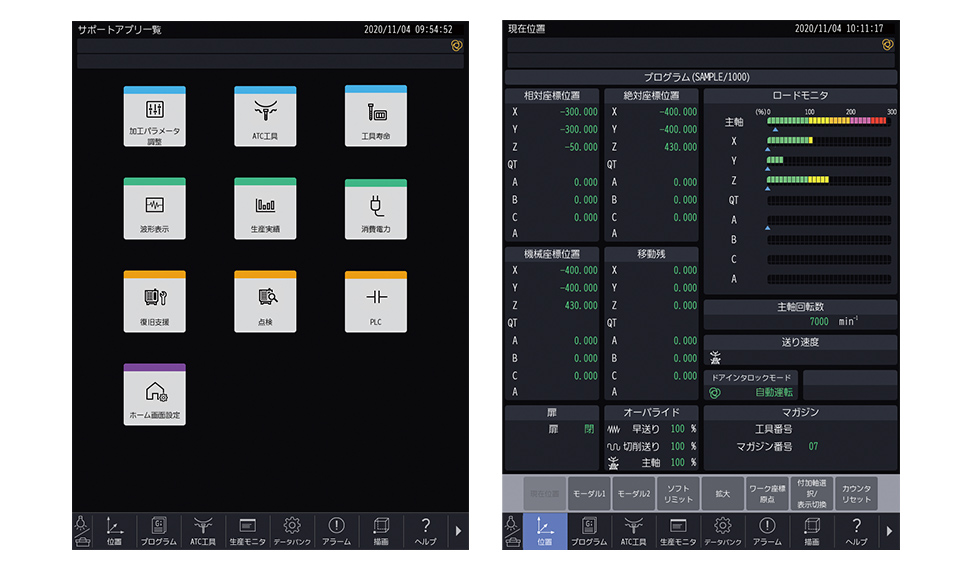

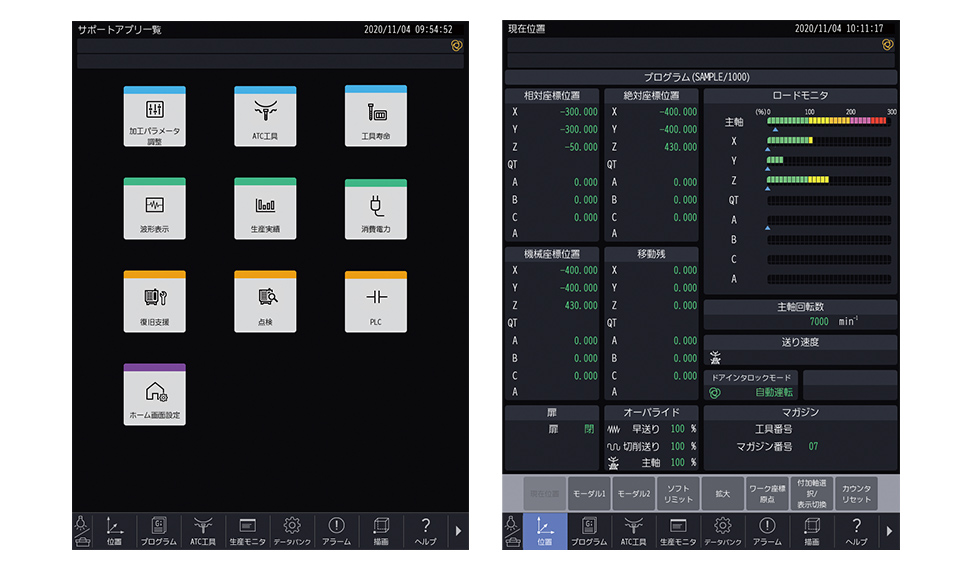

Equipped with a “CNC-D00” control device

15-inch touch panel LCD for ease of use

The app function and vertical touch panel screen allow intuitive operation.

Functions related to setup and processing are consolidated to efficiently operate, visually display production and operation status, and allow for quick understanding. Work can be carried out efficiently in each process of setup, processing adjustment, production and recovery, contributing to improved work efficiency and operation rate.

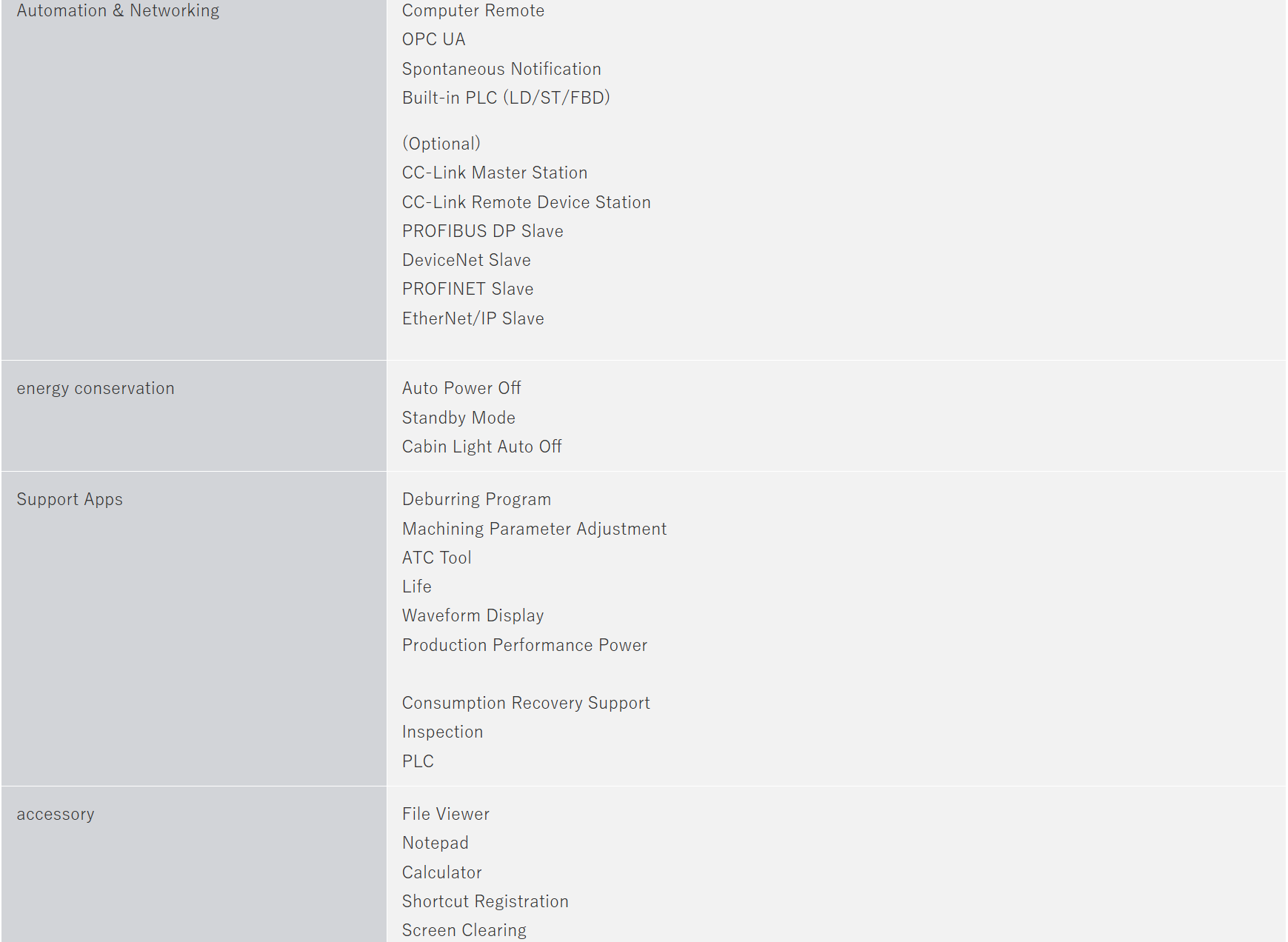

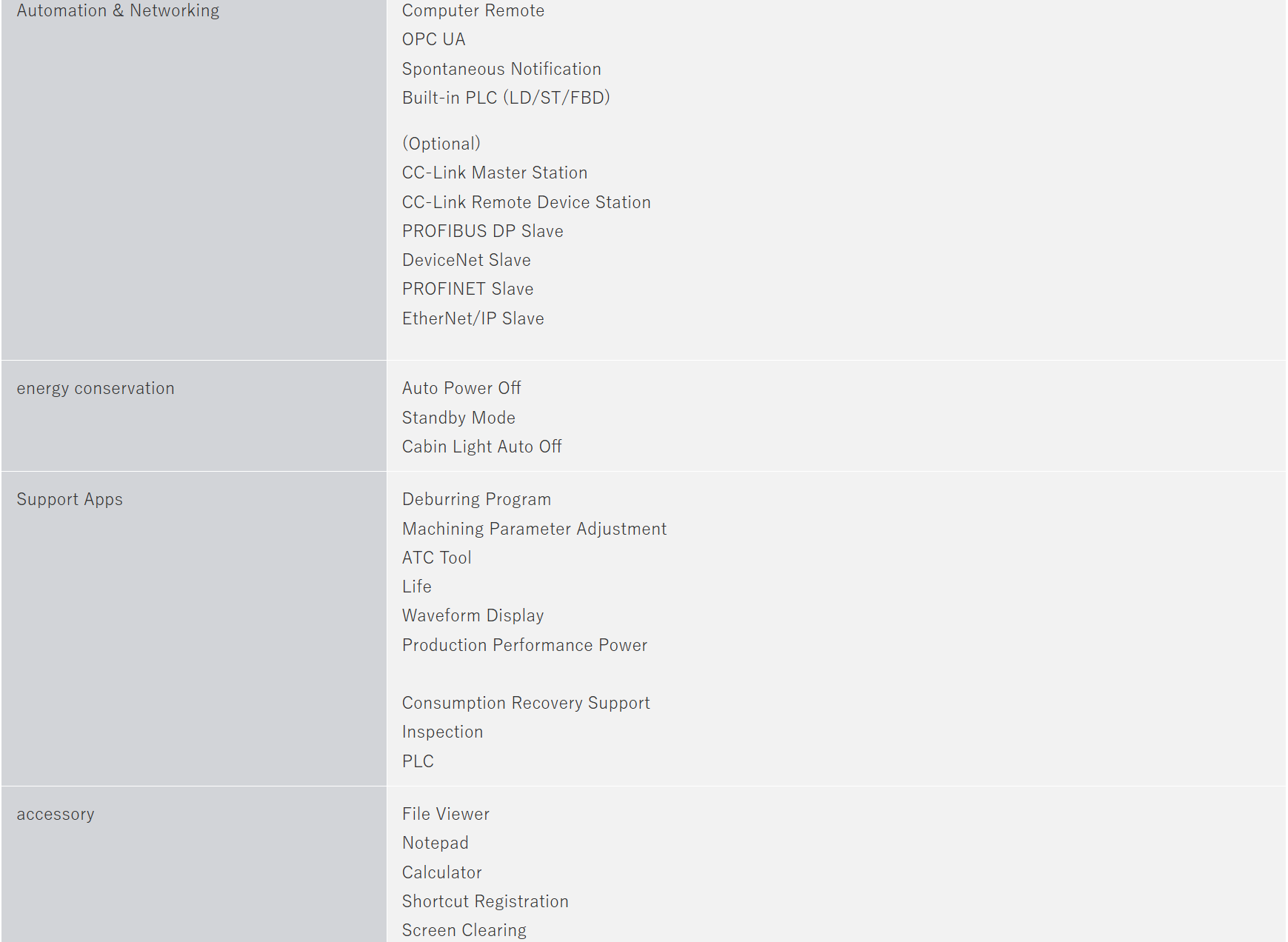

User Interface

The device is equipped with support apps that consolidate related functions and provide a visual display for improved ease of use and visibility, as well as other convenient functions such as a calculator, memo pad and file viewer.

Operation via the conventional screen is also easy with the touch panel, making the device much easier to use.

Accessibility and workability

Accessibility has been improved to enable workers to carry out setup work such as workpiece replacement in a comfortable posture.

**1 The maximum mass of the tool varies depending on the shape, center of gravity, etc., so please consider it as a reference value only.

*2 The output of the spindle motor varies depending on the rotation speed.

*3 The pull stud will be a Brother specification.

*4 The tool change time measurement method is based on JIS standards B6336-9 and MAS011-1987.

*5The normal air pressure fluctuates depending on the machine specifications, processing program contents, and the usage of peripheral equipment, so please set the pressure above the recommended value.

*6 This value is based on the use of high-precision mode B and tool tip point control.

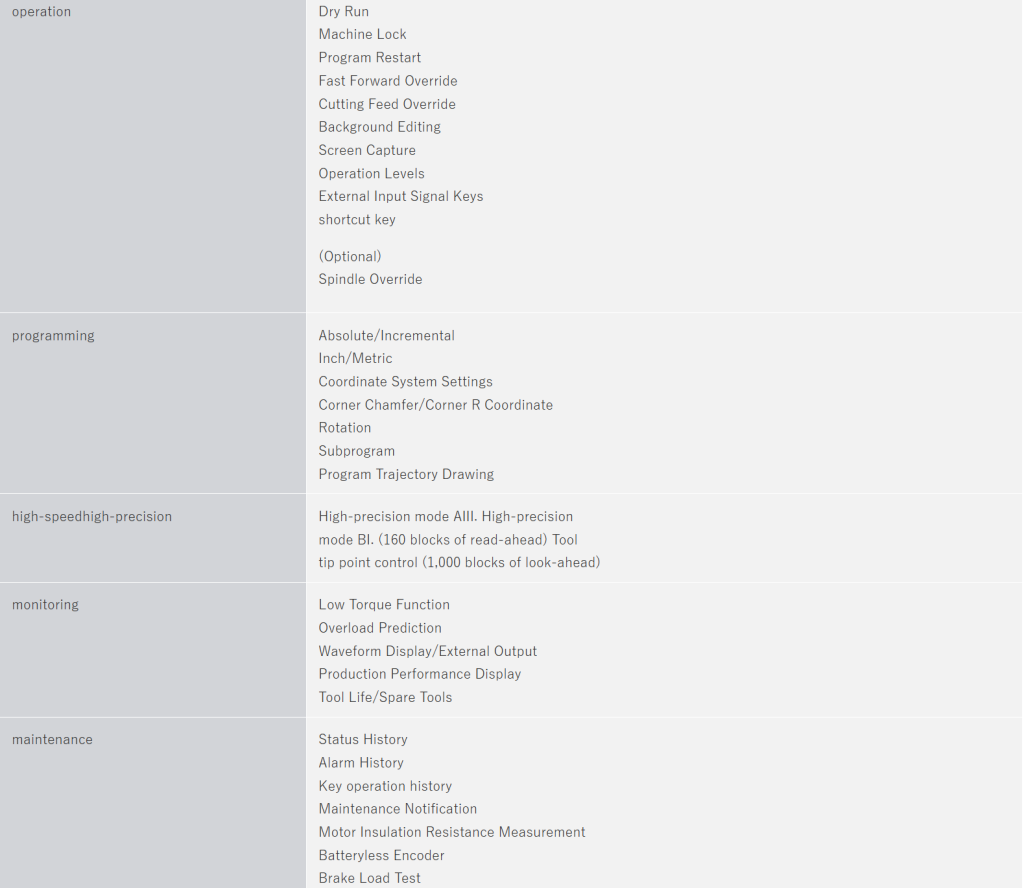

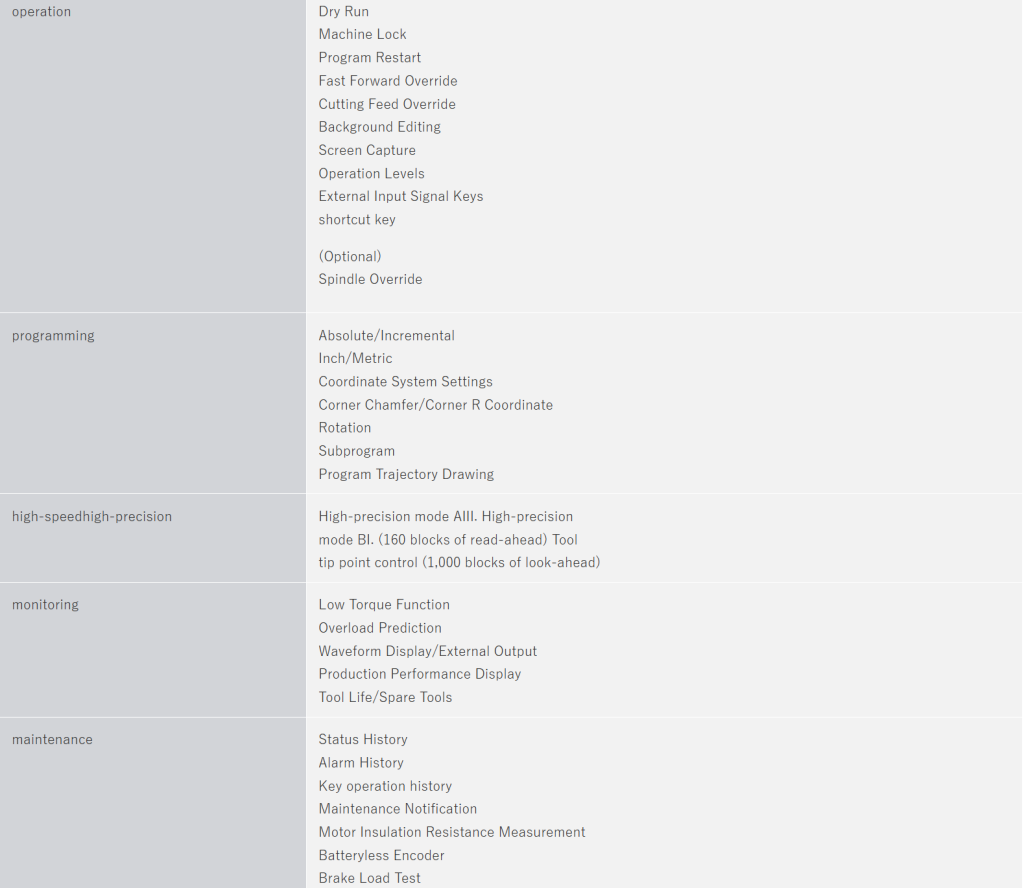

NC specifications

* “Number of control axes” and “Number of simultaneous control axes” are the maximum number of axes.

* ETHERNET IS A REGISTERED TRADEMARK OF XEROX IN THE UNITED STATES.* Ethernet is a registered trademark of XEROX Corporation in the United States.

NC Function

*1 Please prepare your own measuring equipment.