Brother H Series

SPEEDIO

H550Xd1

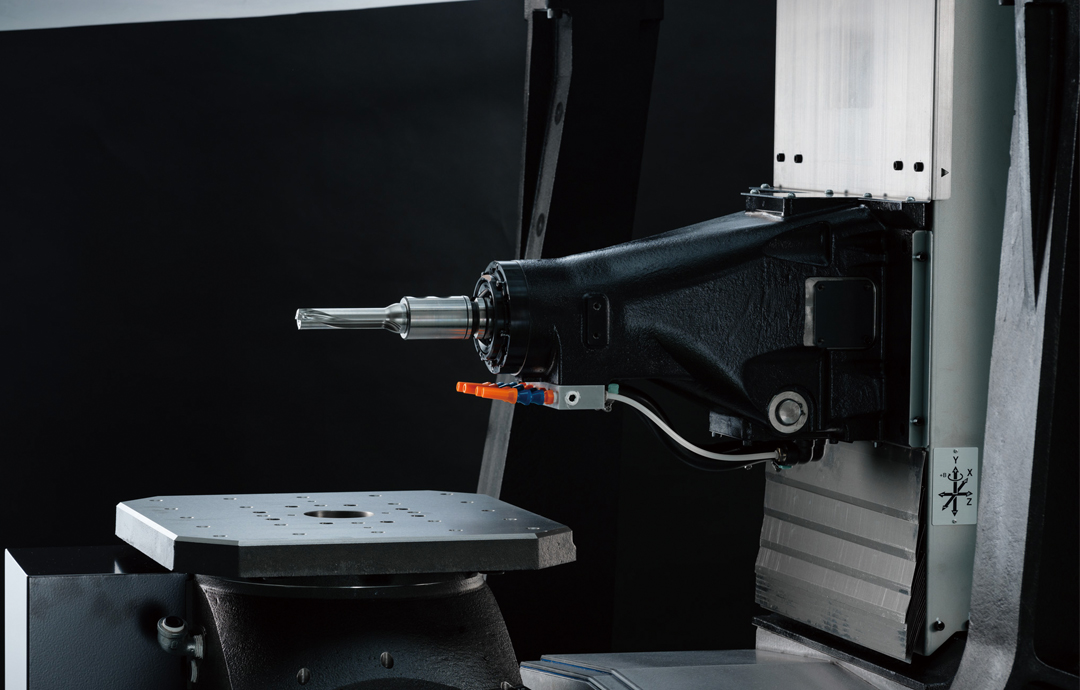

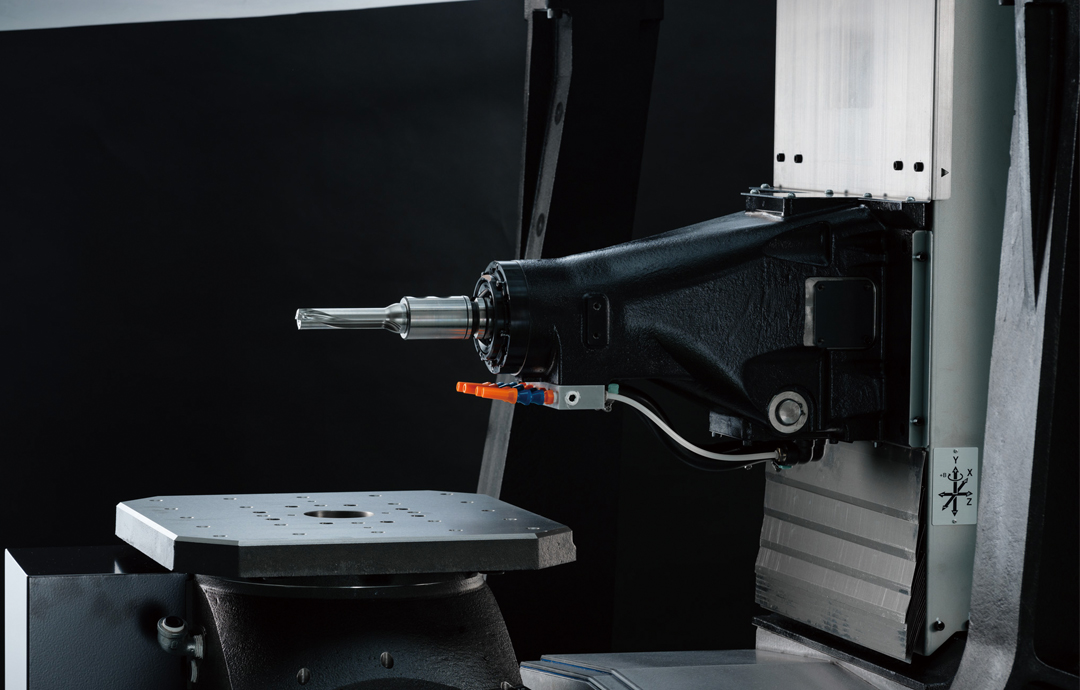

Birth of a horizontal machining center with a No. 30 spindle that demonstrates high productivity and excellent environmental performance

Machining area

28 magazines, payload up to 500 kg, Z-axis travel expansion Further improvement of

the ability to handle large workpieces and high-mix low-volume workpieces

Productivity

Relentless pursuit of high productivity by speeding up and optimizing integrated mechanical-electrical development

Processing Capability

High-efficiency spindle motor and optimal machine design provide high machining capacity

Operability

Equipped with a newly developed CNC-D00 control device that pursues ease of use, and pursues ease of setup and workpiece replacement work.

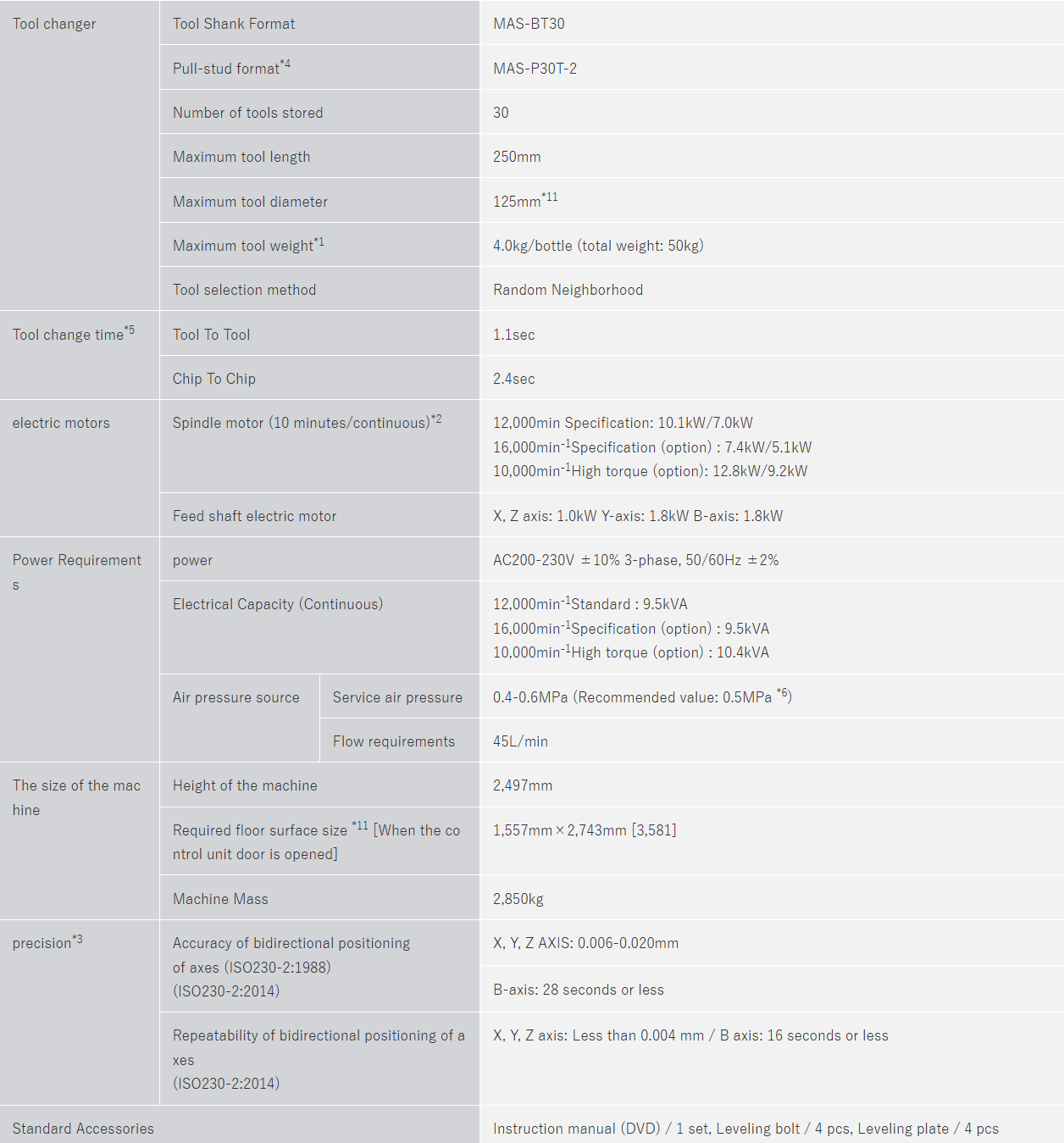

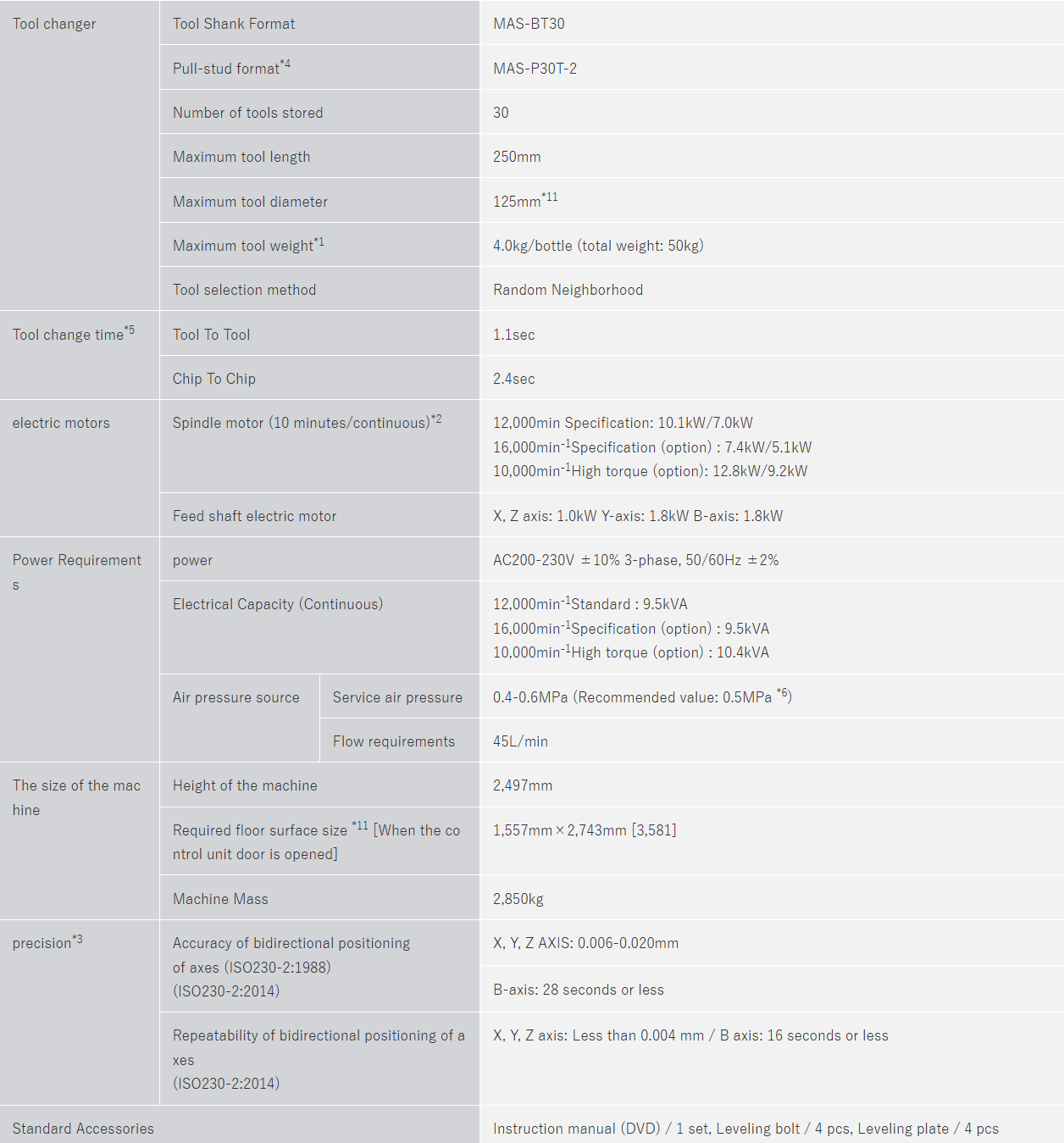

Specifications

| Model | H550Xd1 |

|---|---|

| Maximum spindle speed | 12,000min-1 16,000min-1 (Optional) 10,000 High Torque Min-1 (Optional) |

| Amount of movement | X:550mm Y:400mm Z:400mm B: 360 degrees |

| Number of tools | 30 |

| Rapid Forward X x Y x Z Axis | 50m/min x 56m/min x 56m/min |

| Indexing speed B-axis | 100min-1 |

| Required floor surface size | 1,557mm x 2,743mm |

| BT Two-Sided Restraint (BIG-PLUS) | option |

| Coolant Through Spindle (CTS) | option |

Features of Horizontal Machining Centers

High-productivity horizontal machining center for machining large and long workpieces

A high-productivity horizontal machining center with a 30-spindle with a large jig area and equipped with 30 magazines, a high-speed B-axis table, etc. We can realize the processing of large and long workpieces that are impossible with the conventional No. 30.

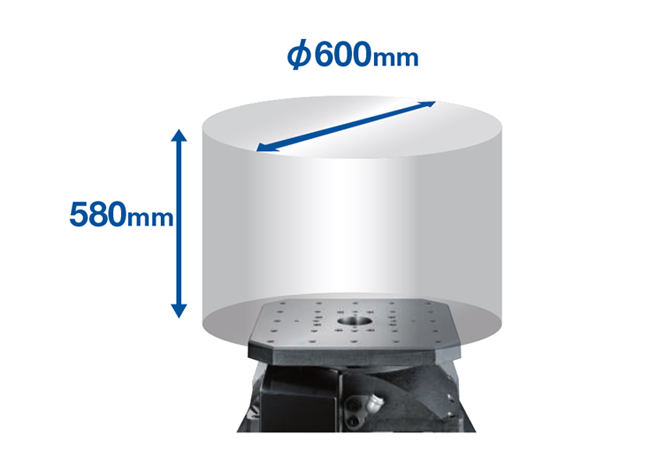

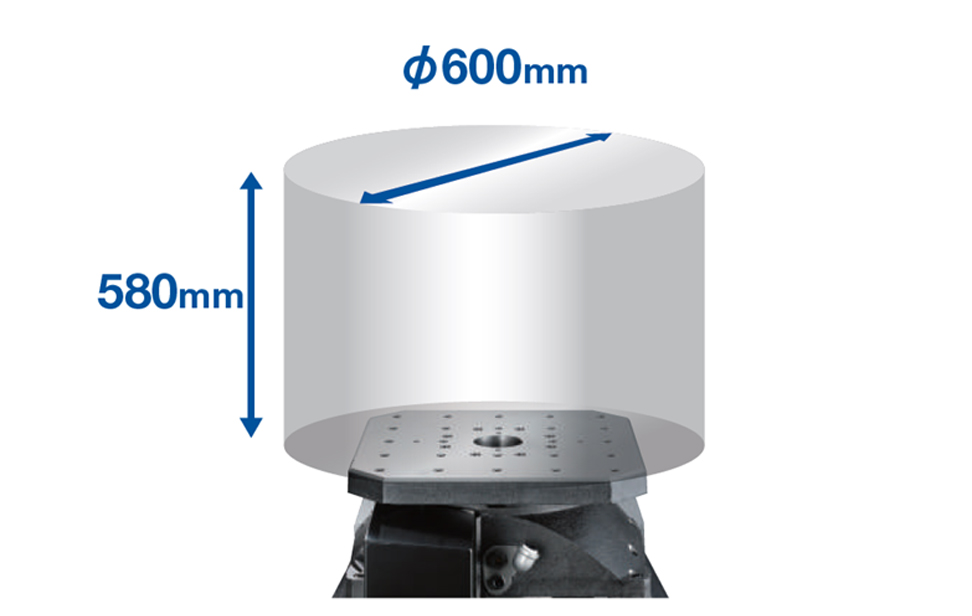

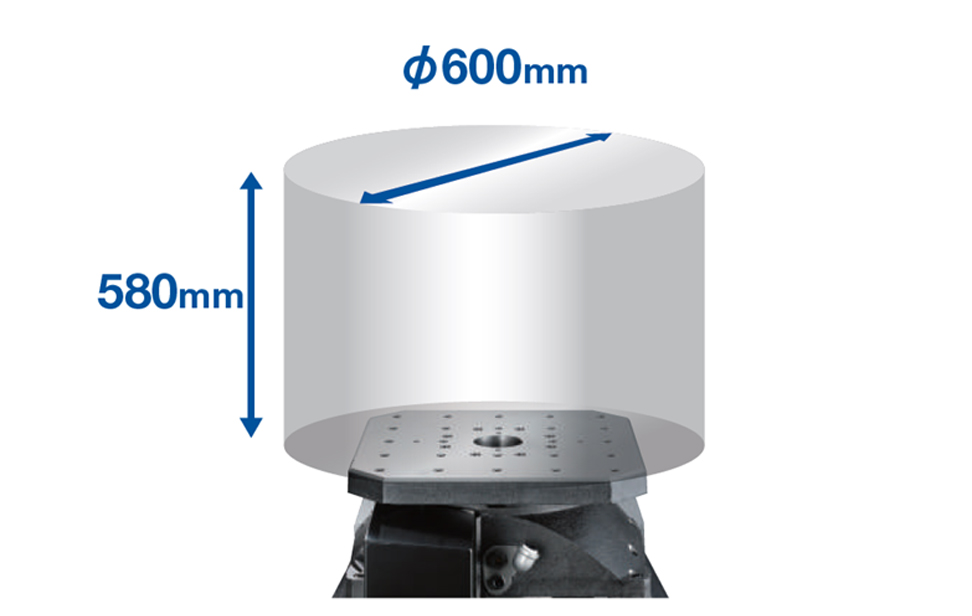

Jig area

⌀ 600X580 large fixture area is realized. *1

In addition, it can be expanded to ⌀800 by tool retract. *2

This makes it possible to mount large and long workpieces.

*1. Interference areas occur depending on the tool length and tool diameter.

*2. It is necessary to retract the tool during B-axis rotation or to limit the tool length.

Space-saving

While having a large jig area and machining area, the machine width is 1557 mm and the depth is 2990 mm, which saves space.

*3. This is a numerical value that includes the coolant tank.

4. Comparison with No. 40 horizontal machining center with a similar stroke. *

| Installation space |

|---|

| 4.7 ㎡ * 3 |

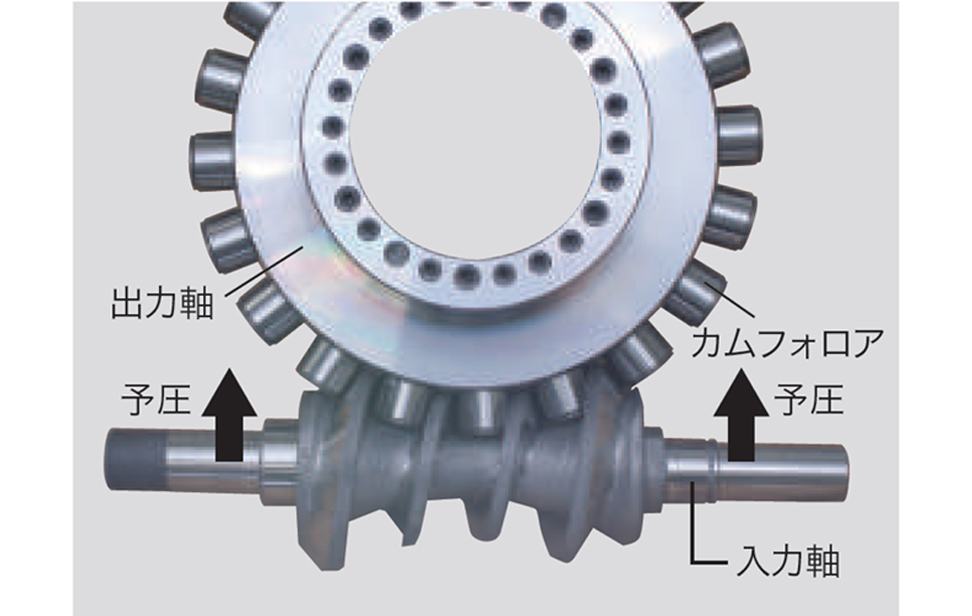

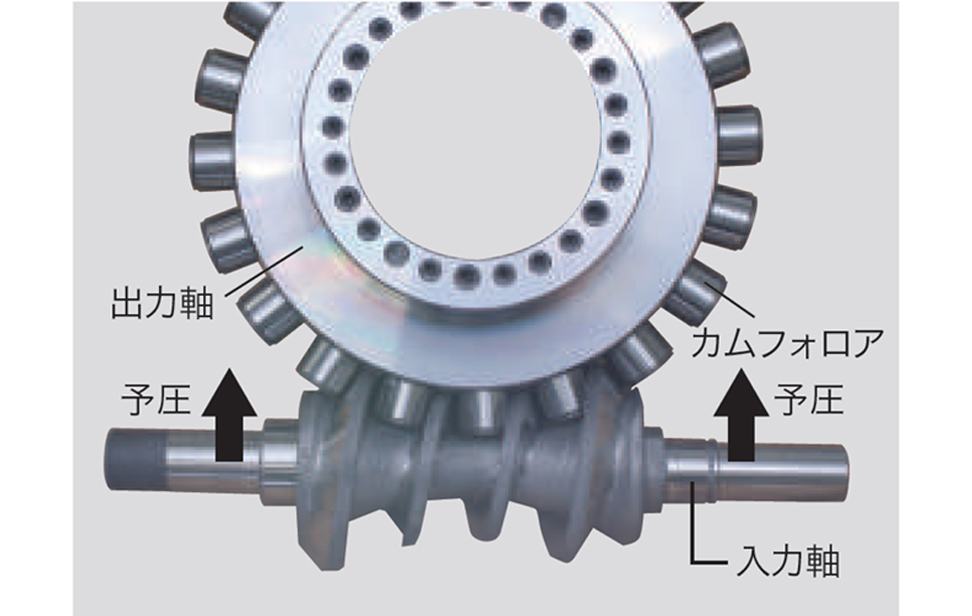

B-Axis Table

It is equipped with a B-axis table with a roller gear cam mechanism as standard, and the slewing speed is 100 min-1, which achieves high-speed operation.

The 400 x 400 mm table can have a load capacity of up to 400 kg. It is capable of handling heavy workpieces and jigs and is both high speed.

| B-axis traverse speed |

|---|

| 100min-1 |

| Payload |

| Up to 400kg |

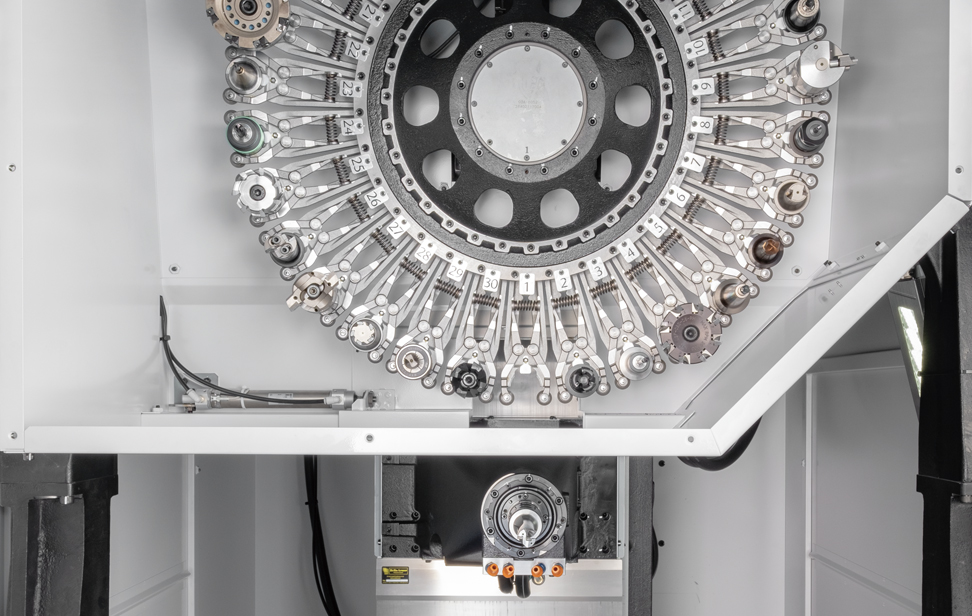

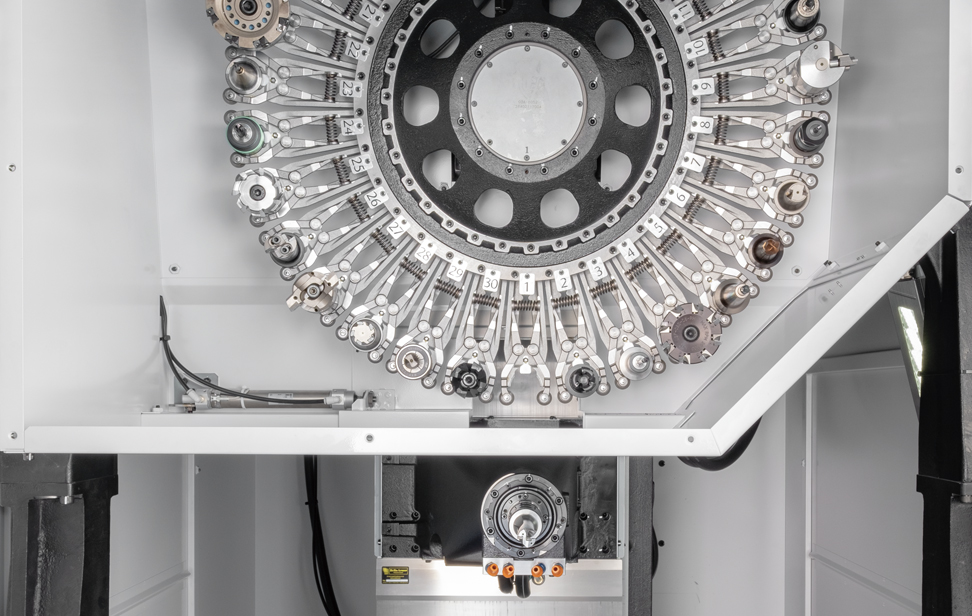

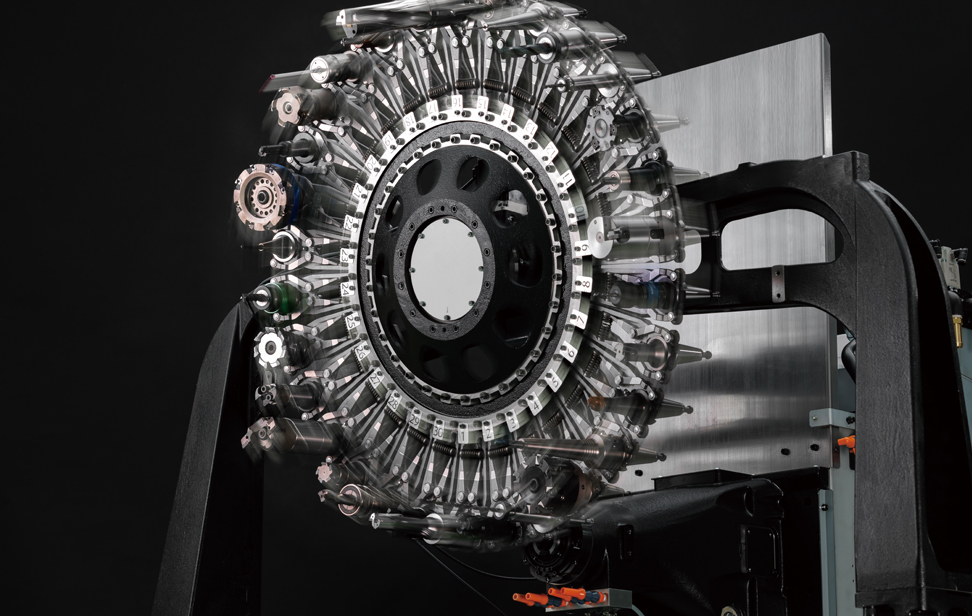

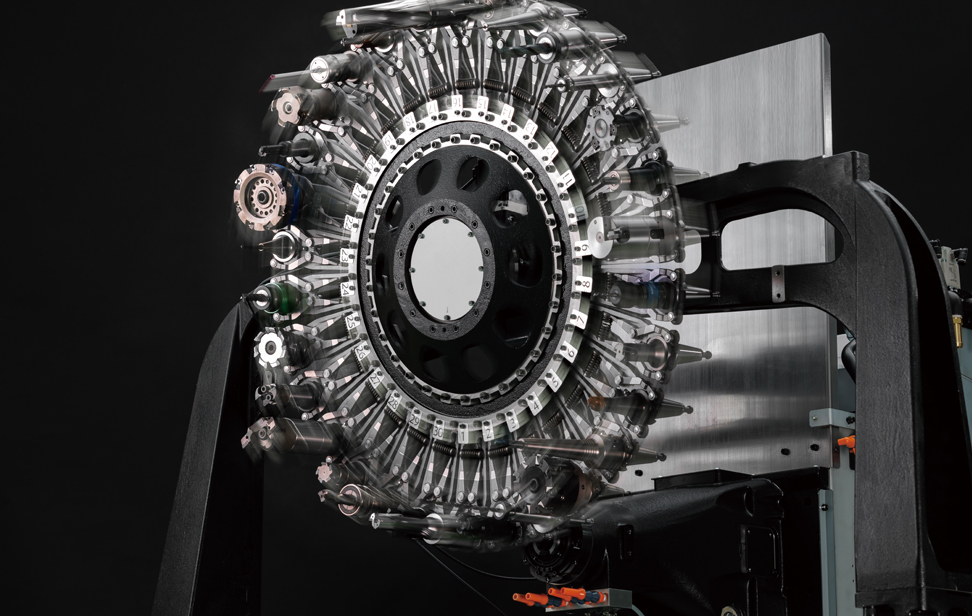

30 Books Magazine

It is equipped with a newly developed direct ATC 30-piece magazine. The maximum tool length is 250 mm, the maximum tool diameter is 125 mm, and the maximum tool weight is 4 kg, and it can be used for various machining such as long workpieces.

Maximum tool length: 250mm,

Maximum tool diameter: 125mm *5

Maximum tool weight 4 kg

Productivity

Relentless pursuit of high productivity by speeding up and optimizing integrated mechanical-electrical development

It achieves overwhelmingly high productivity by taking advantage of the strengths of integrated mechanical-electrical development, such as high acceleration and deceleration spindles, high-speed and optimization of tool change operations, and inertia estimation function.

High acceleration and deceleration spindle

The low-inertia spindle and high-acceleration/deceleration spindle motors enable high-speed start/stop of the spindle.

| Spindle start/stop time |

|---|

| 0.15s or less *1 |

*1. This is the value of the high torque specification

High-speed tool change

Taking advantage of the strengths of integrated mechanical-electrical development, we have achieved high-speed tool change with high acceleration and deceleration and optimal operation.

| Tool change time |

|---|

| Tool – Tool: 1.1s Chip – Chip: 2.4s |

High-speed B-axis table

The B-axis table uses a roller gear cam mechanism to achieve both durability and high speed. High-speed indexing is achieved with a maximum rotation speed of 100 min-1.

By performing the tool change operation and the B-axis indexing at the same time, the wasted time is further reduced.

In addition, depending on the processing load, it is possible to process only by holding the motor torque without using a clamping mechanism.

| B-axis table indexing time *2 |

|---|

| 0 → 90°: 1.0s 0 → 180°: 1.1s |

*2 Values in standard inertia mode.

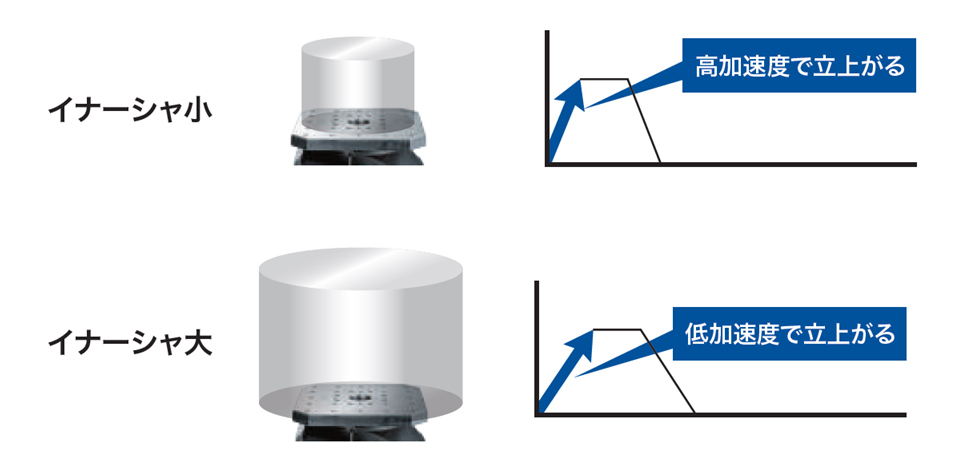

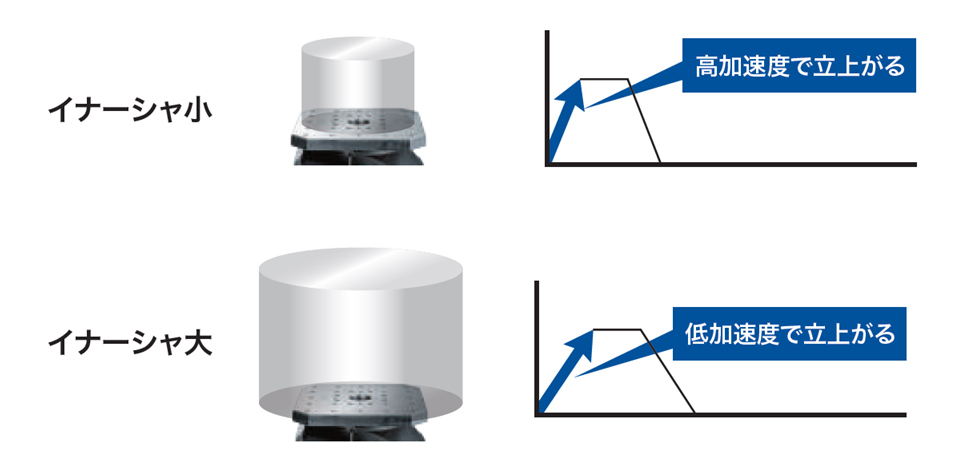

Inertia estimation function for B-axis tables

It is equipped with an inertia estimation function that estimates the inertia of the jig mounted on the B-axis table. Depending on the magnitude of the inertia, the optimum acceleration can be achieved, which can improve productivity.*3

*3. Parameter settings need to be changed

Machining Capacity

High-efficiency spindle motor and optimal machine design provide high machining capacity

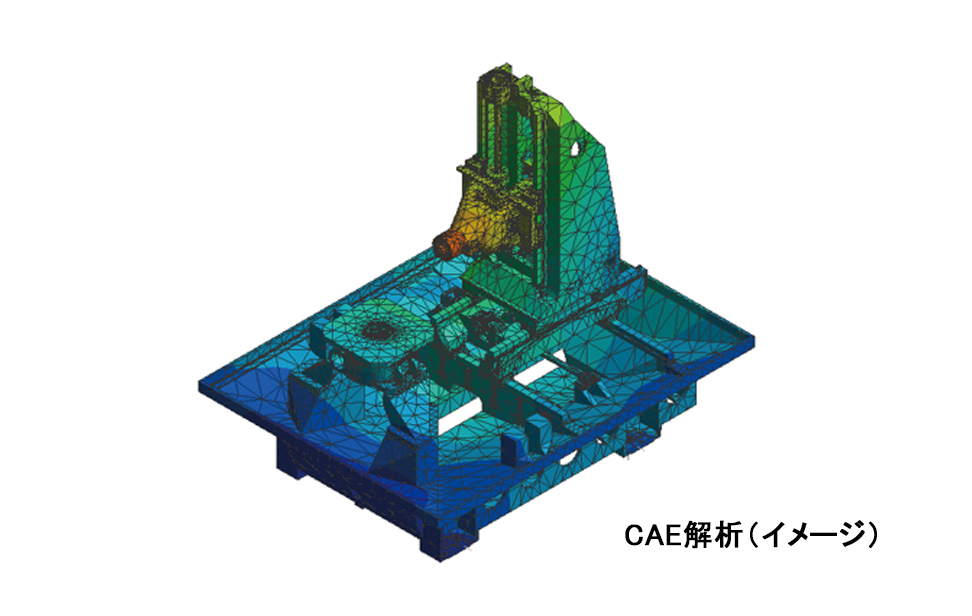

In addition to being equipped with a high-efficiency, high-output spindle motor such as a newly developed 12,000 min-1 standard spindle motor and a newly developed high-rigidity spindle, we are working to achieve both high-speed performance and mechanical rigidity using the CAE analysis technology cultivated by SPEEDIO.

Combined with a B-axis table with 7MPa high-pressure coolant and high clamping torque, it demonstrates high machining capacity.

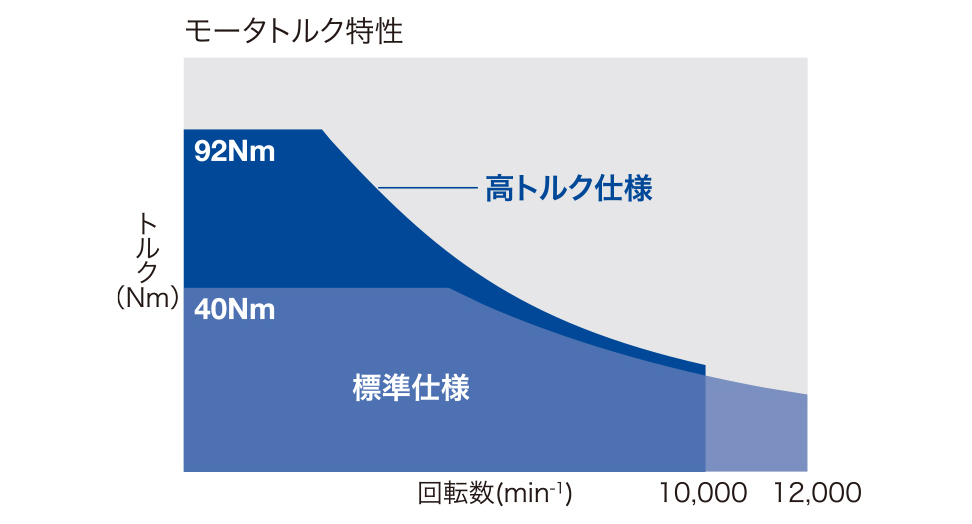

High-efficiency spindle motor

Newly developed 12,000min-1Specifications (standard) and maximum torque of 92 N·m in 10,000 min-1 It is equipped with a high-efficiency spindle motor such as a high-torque version (optional). The high spindle torque in the medium-to-high-speed rotation range makes it effective for high-speed, high-efficiency construction of aluminum and steel.

| 12,000min-1 (Standard) |

|---|

| Maximum torque: 40Nm, Maximum output: 18.9kW |

| 10,000min-1 High Torque (Optional) |

|---|

| Maximum torque: 92Nm, Maximum output: 26.2kW |

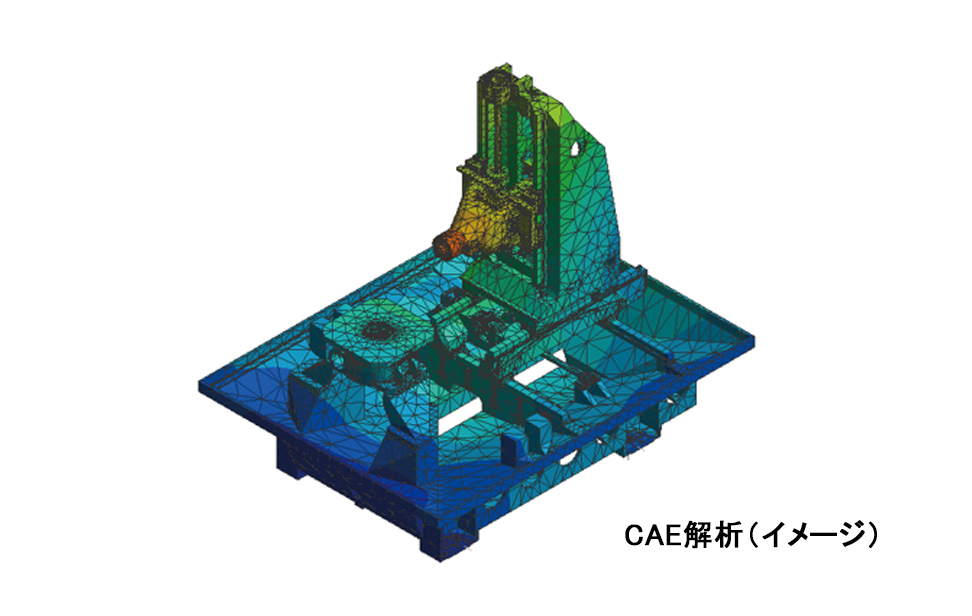

Optimal mechanical design and high rigidity spindle

We are achieving both high-speed performance and mechanical rigidity by optimizing the shape of the casting by making full use of CAE analysis. The newly developed spindle has a higher clamping force than the conventional SPEEDIO, and the spindle with high torque has the largest bearing diameter in the SPEEDIO. As a result, it exhibits high machining capability from high-efficiency machining to heavy-duty machining.

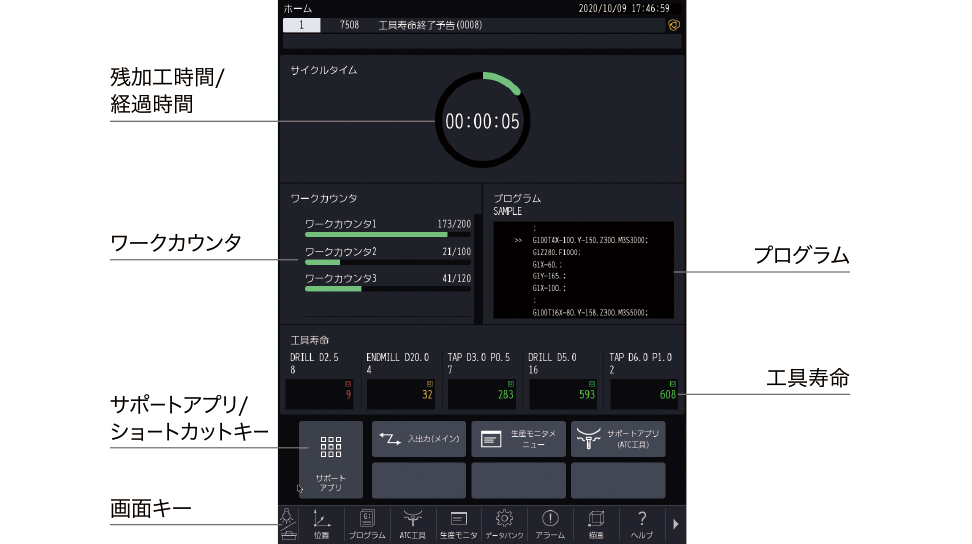

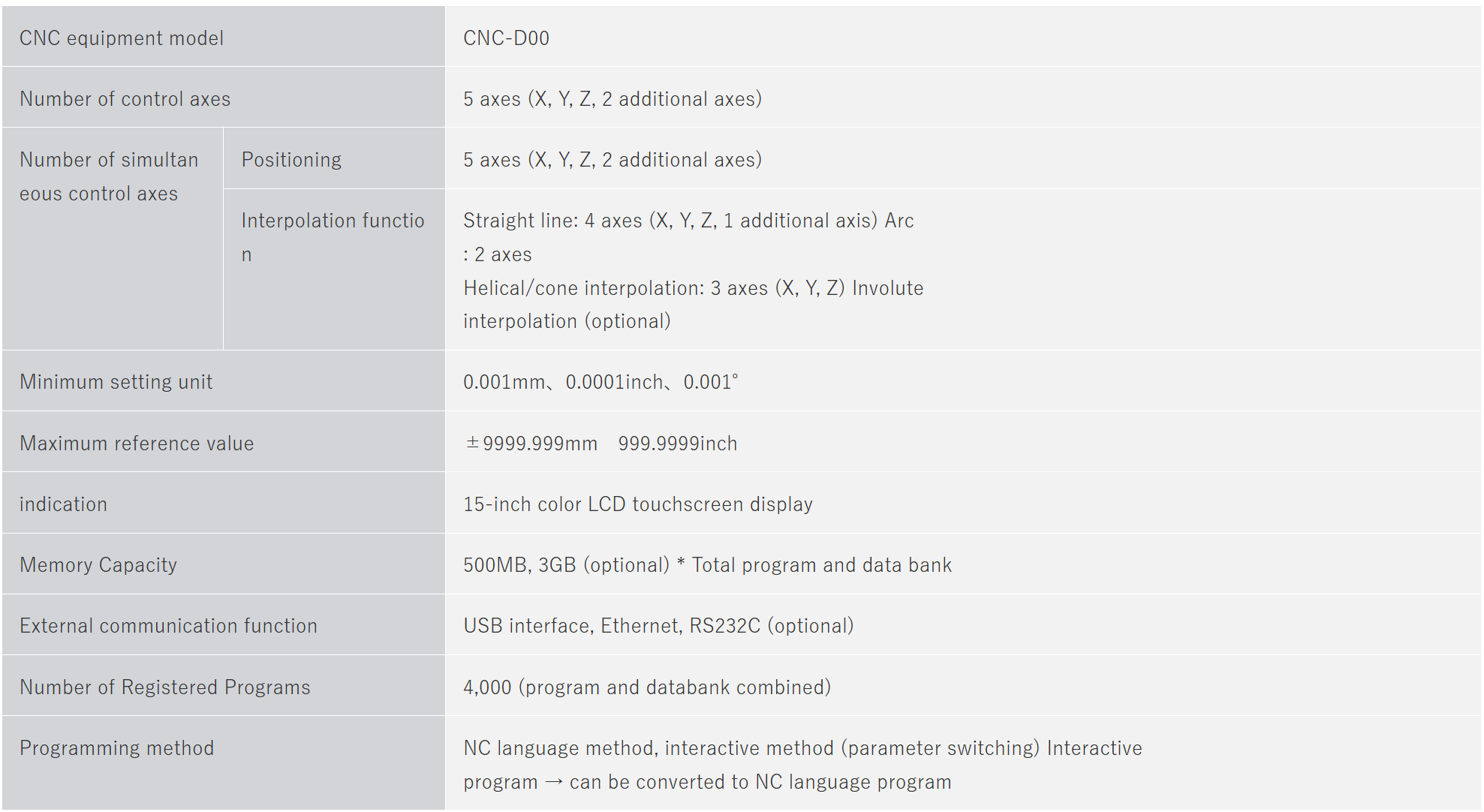

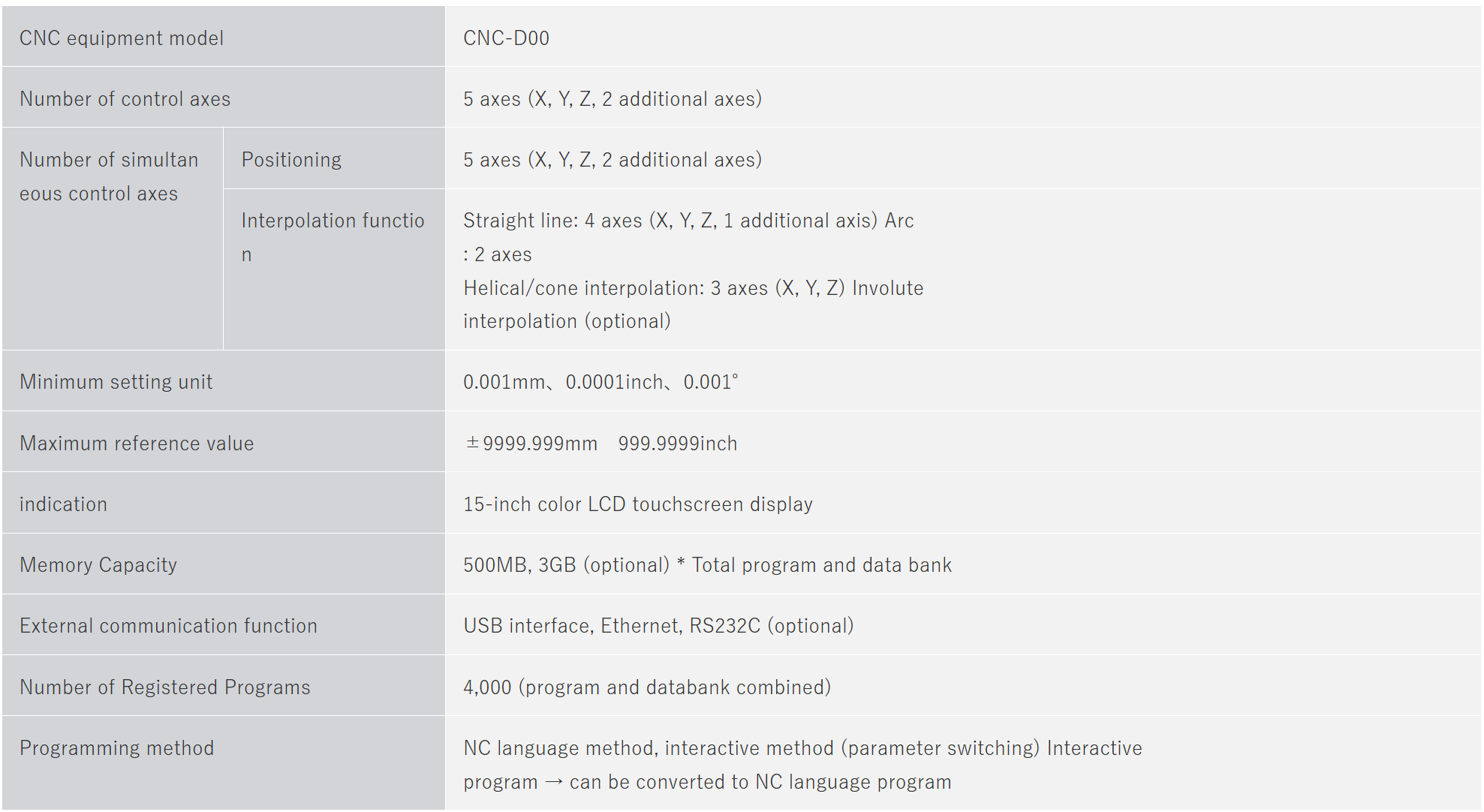

Operability

Equipped with a newly developed CNC-D00 control device that pursues ease of use, and pursues ease of setup and workpiece replacement work.

Intuitive operation is realized with a new app function and a 15-inch LCD screen with a vertical touch panel.

In the setup, processing adjustment, production, and recovery processes, it is possible to proceed with lean work, contributing to improved work efficiency and utilization rate.

Workability is improved by placing an operation panel on the side of the machine.

Home screen

Centralize information necessary for production, such as work counters and tool life. In addition, shortcut keys allow you to transition to frequent screens with a single touch.

New user interface

A new support app has been established that consolidates related functions and improves operability and visibility through visual display, and is equipped with convenient functions such as a calculator, notepad, and file viewer, and the operation on the conventional screen is easy with a touch panel, greatly improving usability.

*1 The maximum mass of the tool varies depending on the shape, center of gravity, etc., so it should be considered as a reference value only.

*2 The output of the spindle motor varies depending on the rotation speed.

*3 The measurement method is based on ISO and Brother standards. Please contact us for details.

*4 The pull studs for CTS are Brother specifications.

*5 The tool change time measurement method is based on JIS standards B6336-9 and MAS011-1987.

*6 The normal air pressure fluctuates depending on the machine specifications, processing program contents, and the usage of peripheral equipment, so please set the pressure above the recommended value.

*7 This value is used when high-precision mode B is used.

*8 Depending on the destination, it is necessary to install a relocation detection device. Specifications equipped with a relocation detection device have “RD” at the end of the model name.

*9 Coolant tanks and chip conveyors are not included.

*10 The value of the high inertia mode. Parameter changes are required.

*11 When attaching adjacent tools, the sum of diameters with adjacent tools must be within 130 mm.

*12 When designing a jig, it is necessary to pay attention to the maximum inertia.

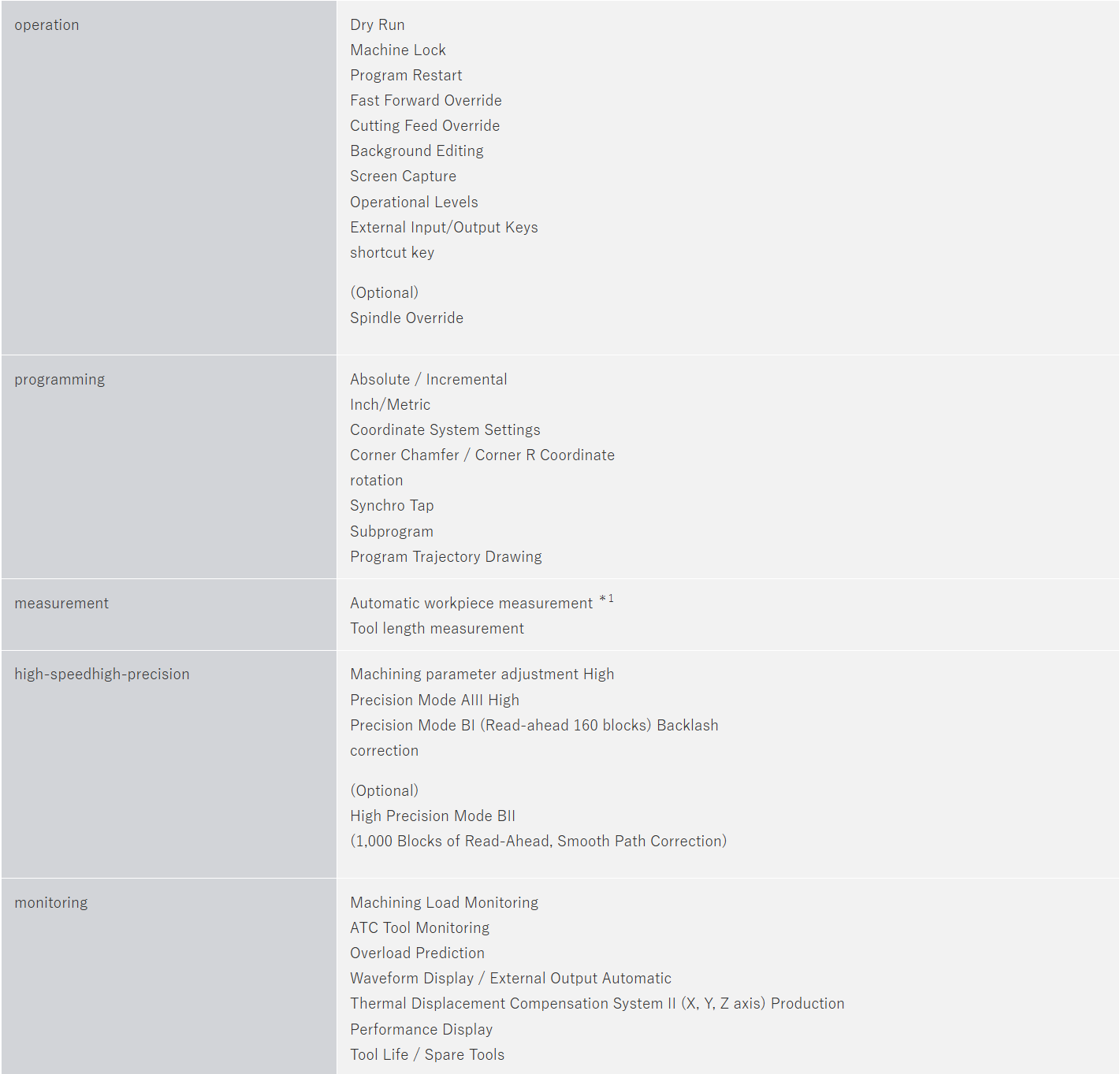

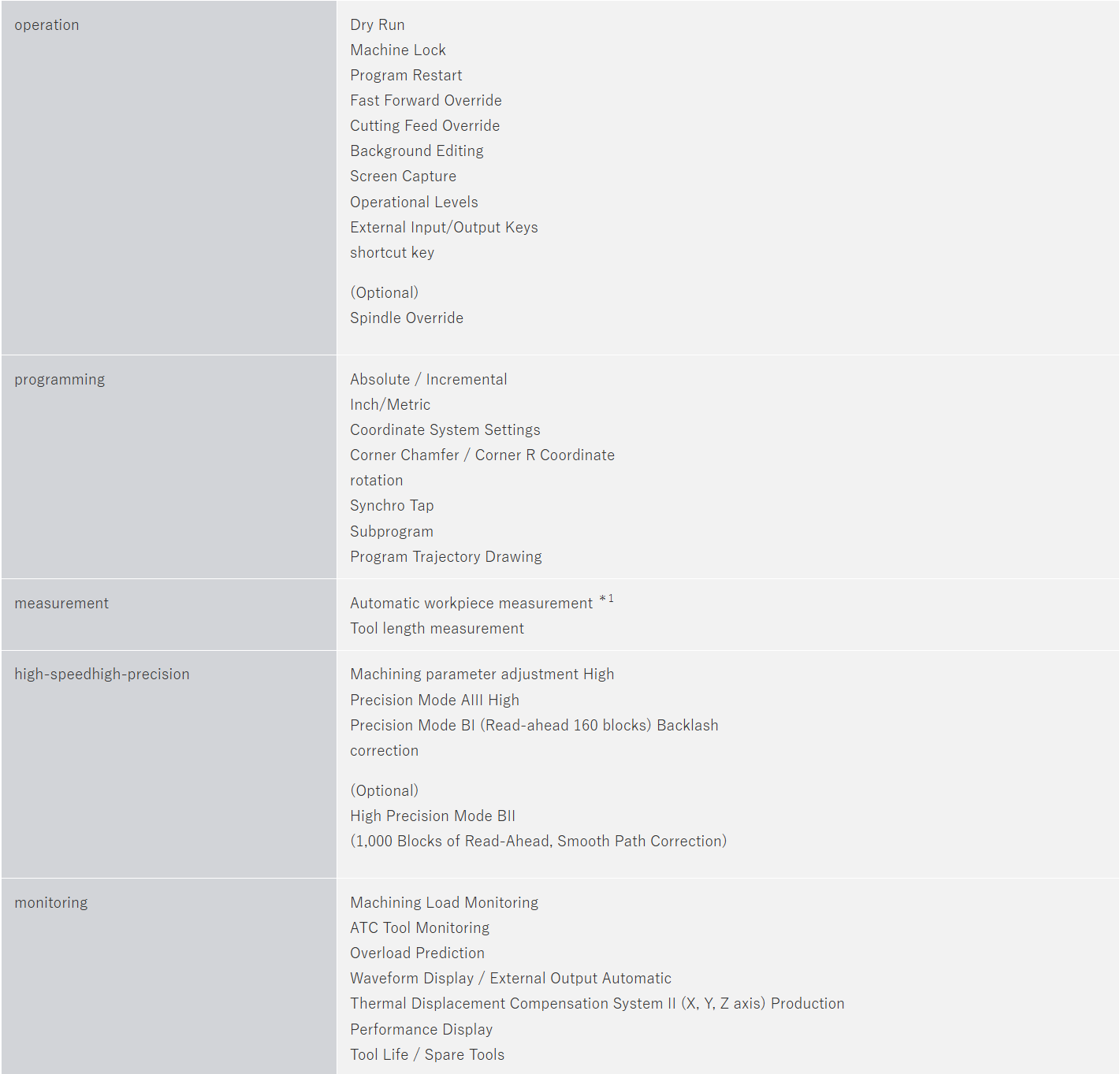

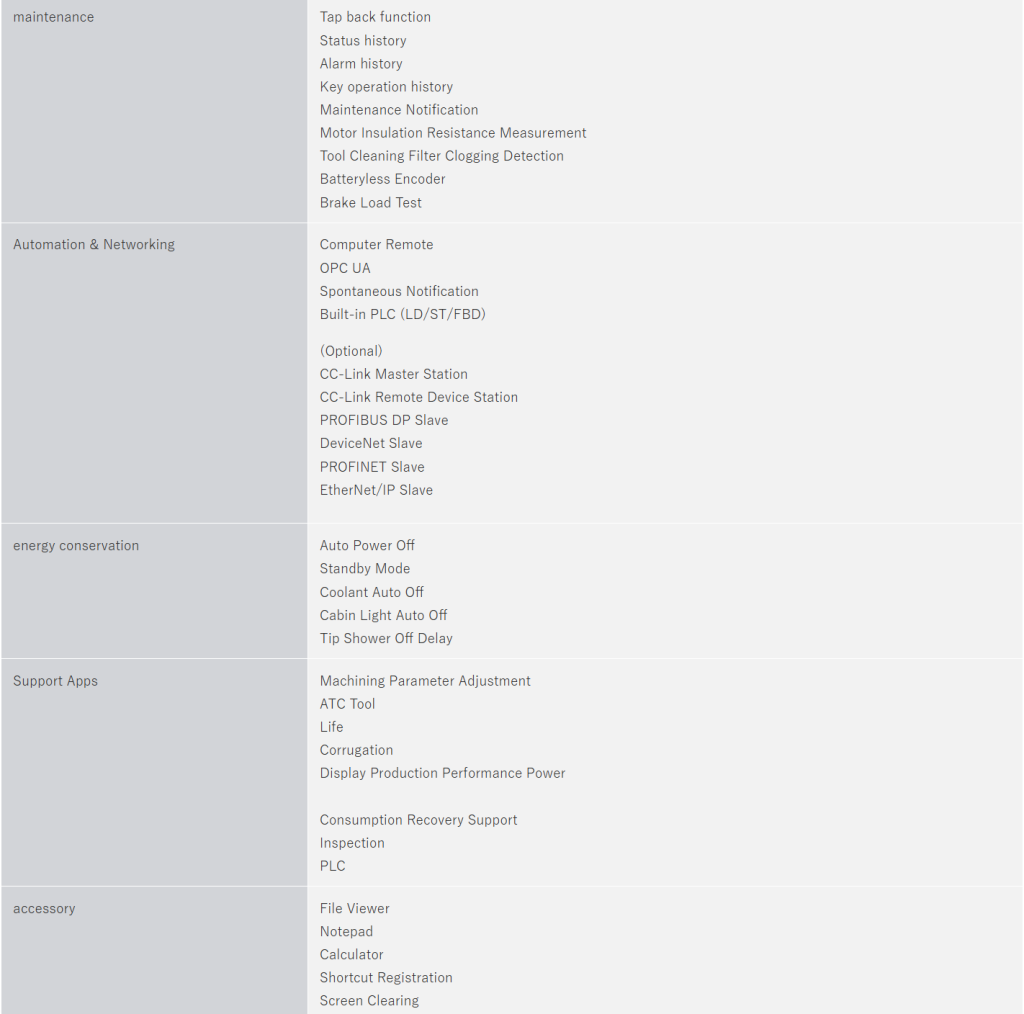

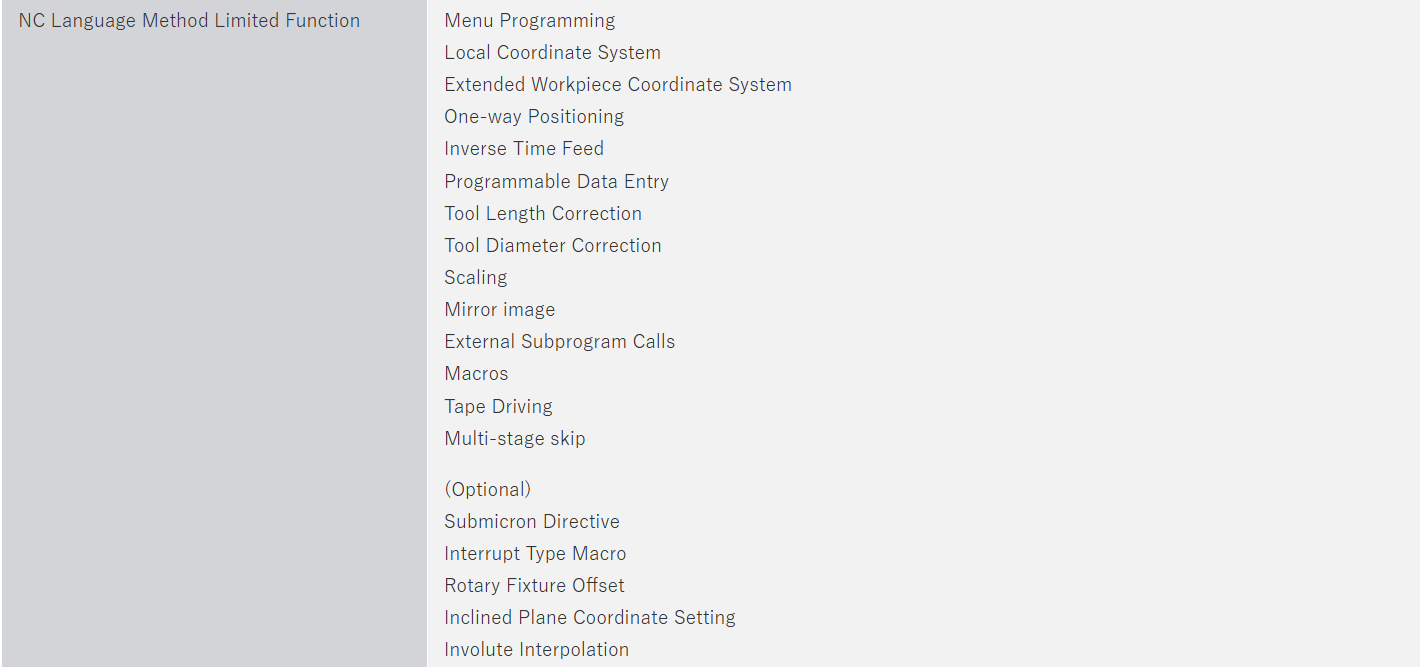

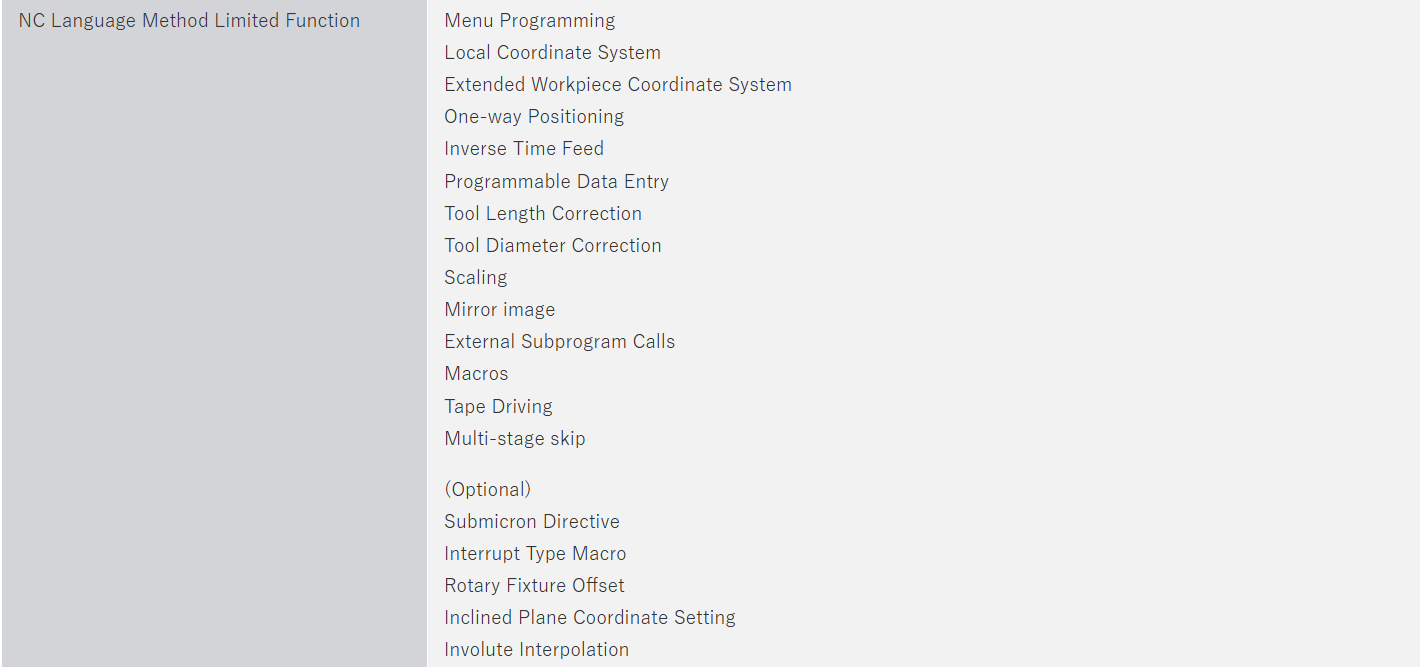

NC Specifications

* “Number of control axes” and “Number of simultaneous control axes” are the maximum number of axes, and vary depending on the destination and specifications.

* ETHERNET IS A REGISTERED TRADEMARK OF XEROX IN THE UNITED STATES.

NC function

*1 Please prepare your own measuring equipment.

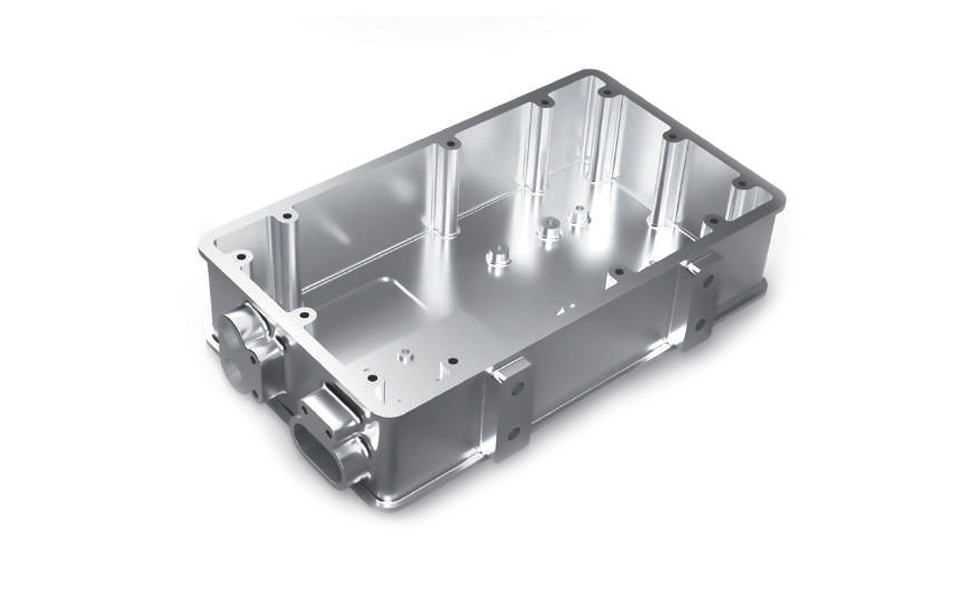

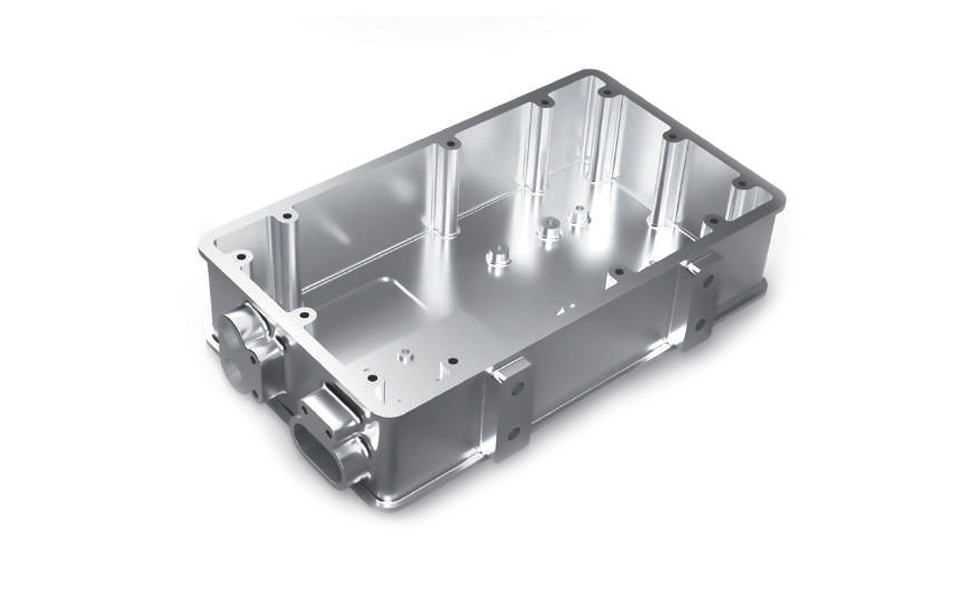

Processing example

Car

| Names of parts | EV Gearbox Housing |

|---|---|

| material | Aluminum alloy |

| Part Name | EV Gear Case |

|---|---|

| Material | Aluminum Alloy |

| Part Name | EV Inverter Case |

|---|---|

| Material | Aluminum Alloy |

| Part Name | Battery Case |

|---|---|

| Material | Aluminum Alloy |

| Part Name | Aluminum Wheels |

|---|---|

| Material | Aluminum Alloy |

| Part Name | ABS Valve Housing |

|---|---|

| Material | Aluminum Alloy |

| Part Name | Steering Rack Housing |

|---|---|

| Material | Aluminum Alloy |