Brother M Series

SPEEDIO :

M200Xd1 / M300Xd1

Demonstrates high productivity in combined turning and machining and multi-sided machining.

New models with expanded machining areas have been added to the lineup.

The number of parts that can be used for process-intensive production has increased significantly.

M200Xd1 / M300Xd1 Product Introduction

M300Xd1 Seminar Video

(3 minutes 17 seconds)

(17 minutes 46 seconds)

M200Xd1 Seminar Video

(3 minutes 46 seconds)

(1 minute 36 seconds)

(1 min 08 sec)

(2 minutes 13 seconds)

Highlights

Mass production multitasking machine

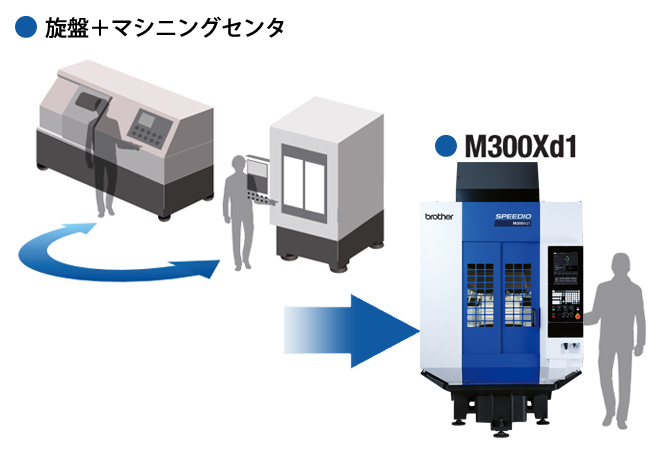

Process consolidation using mass-production multi-tasking machines

Processing Area

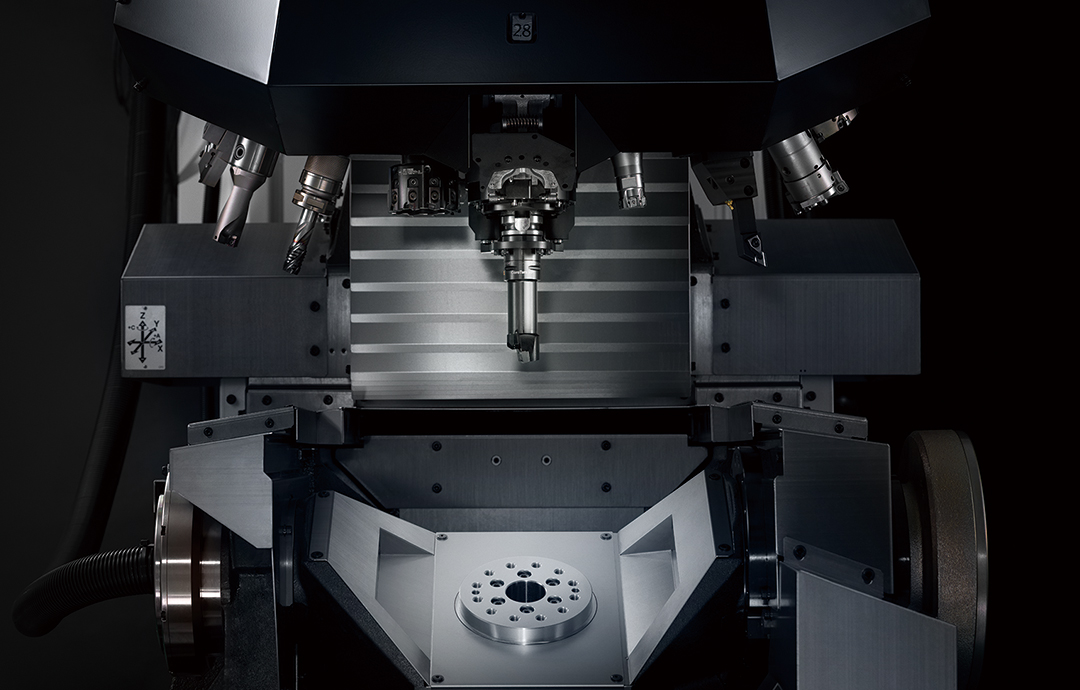

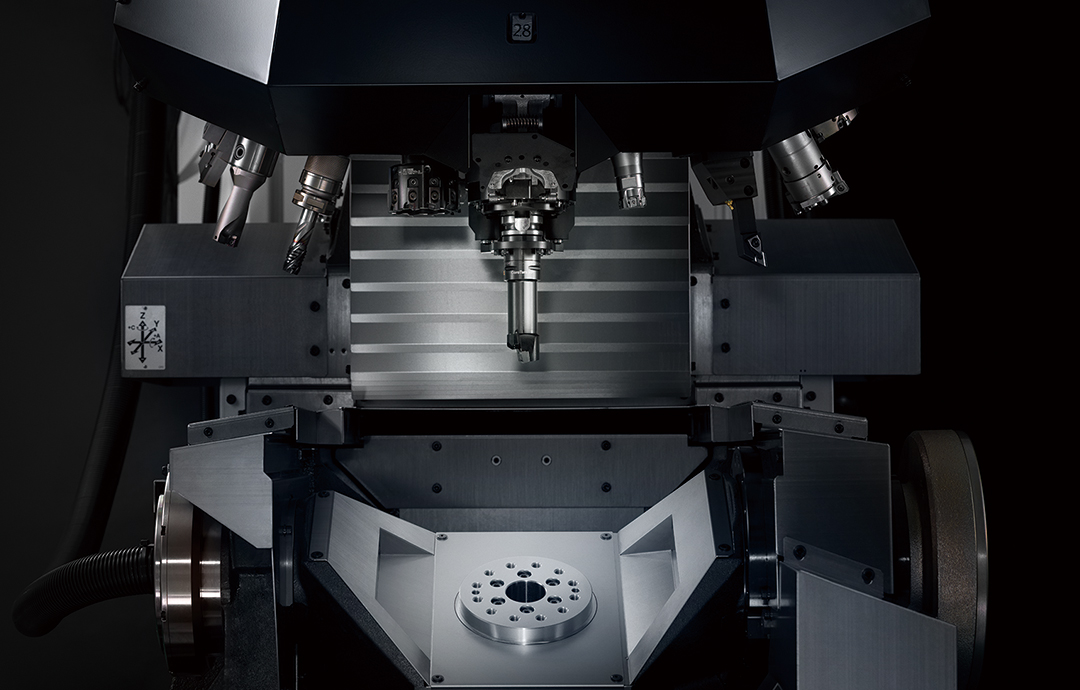

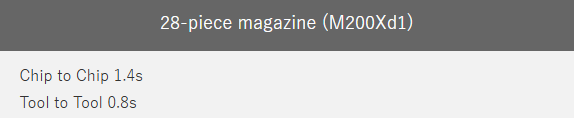

Combined with the 28-tool magazine, the number of workpieces that can be machined has been increased

Productivity

Processing Capability

and also features simultaneous 5-axis machining function

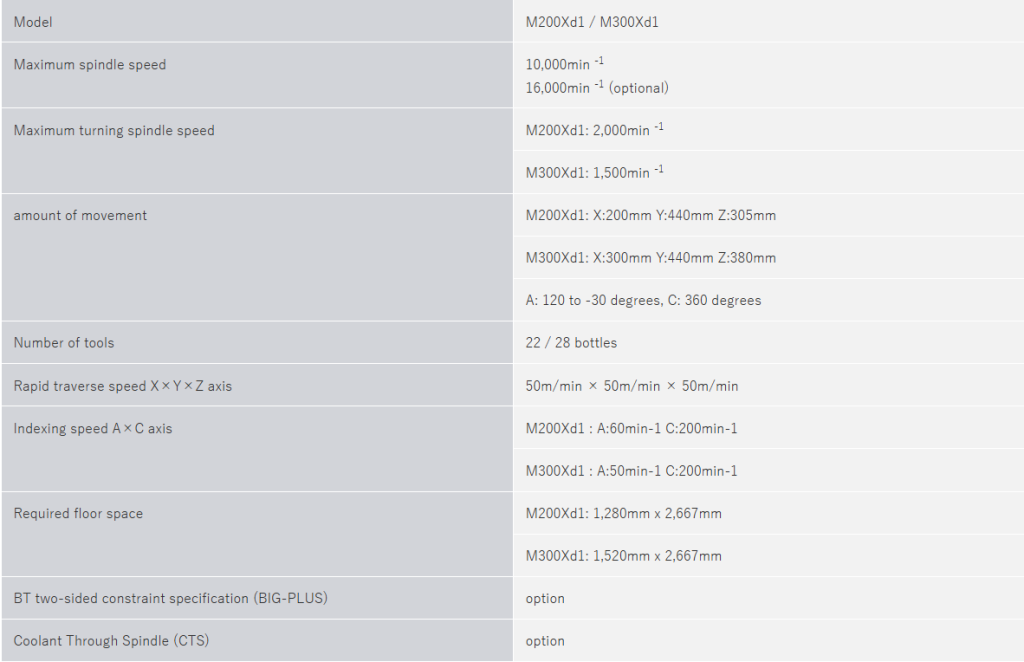

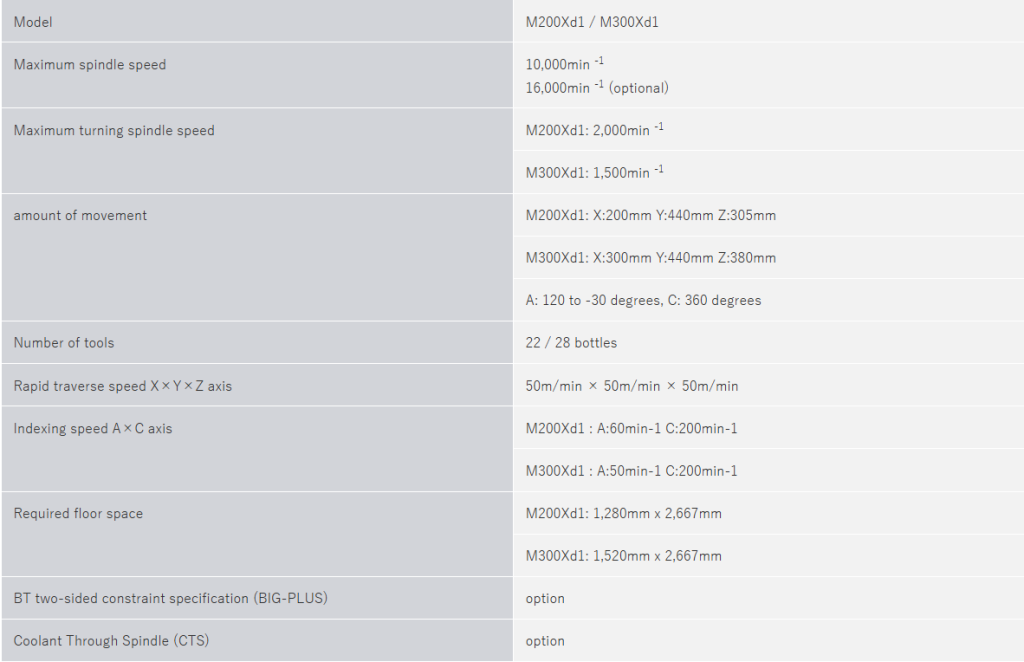

Specifications

Processing video

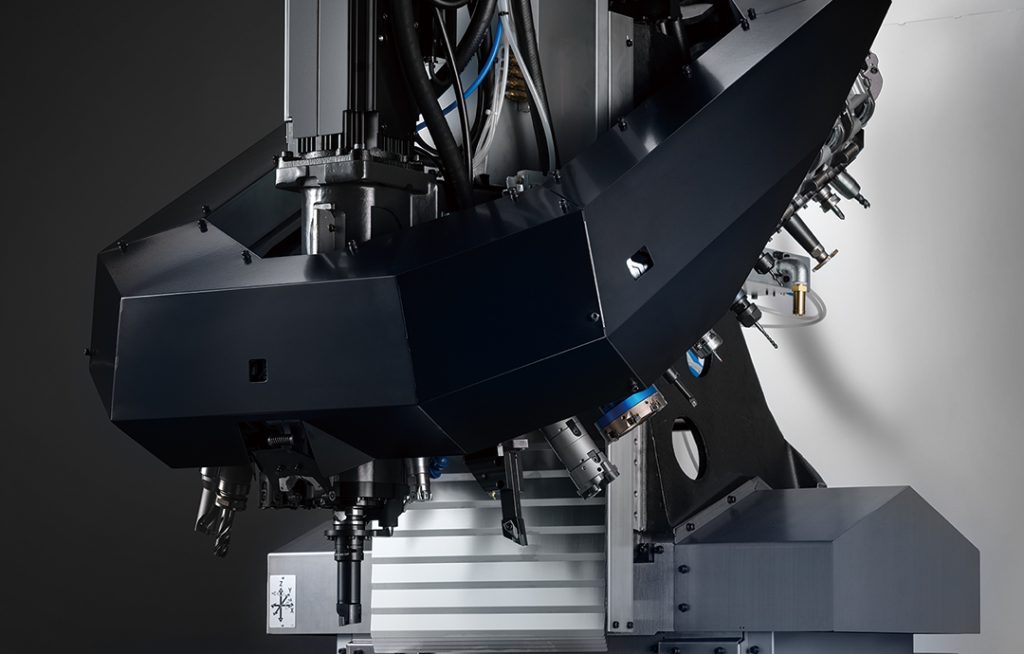

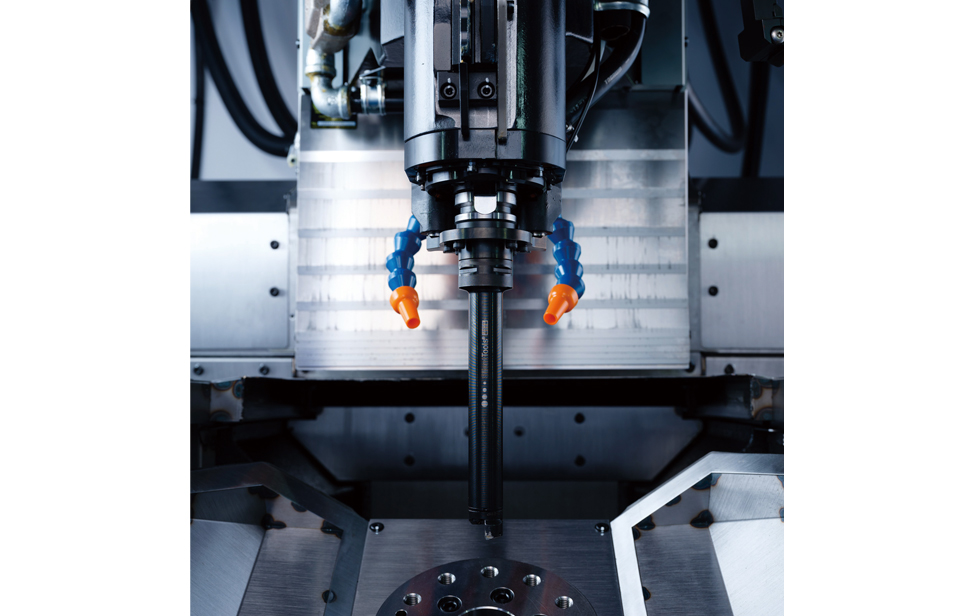

Mass production multitasking machine

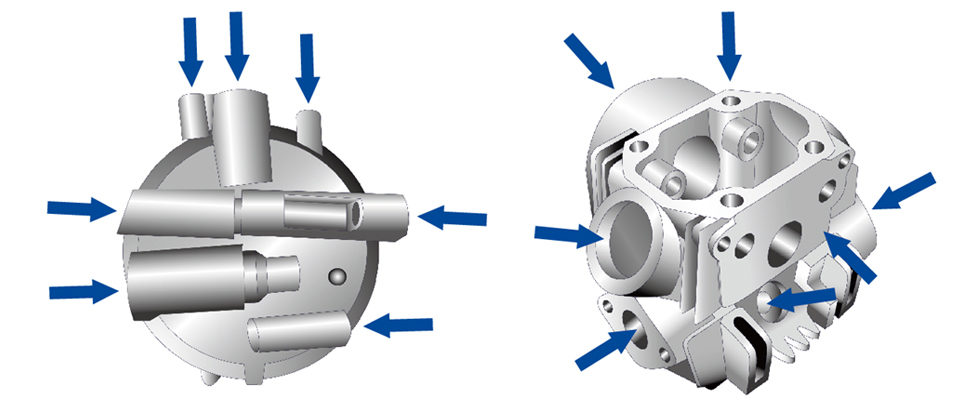

From jig-based composite machining to multi-sided machining

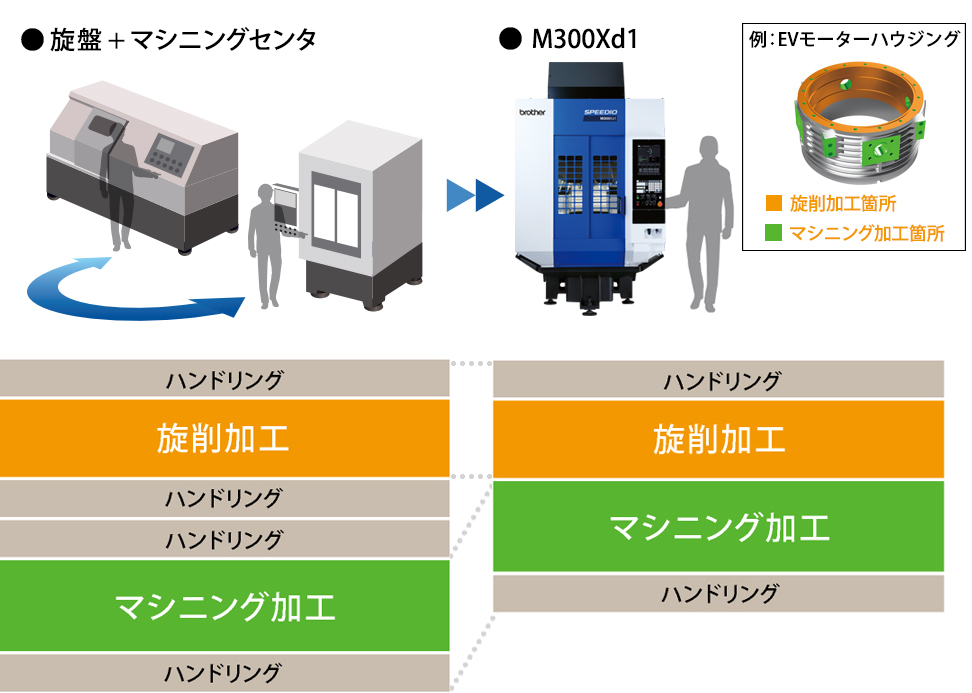

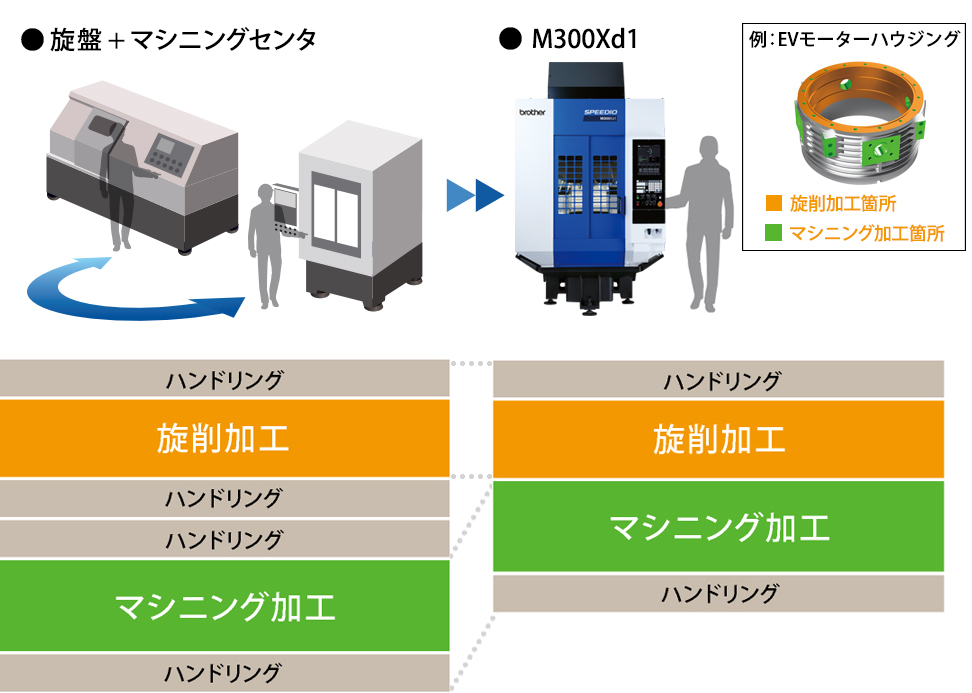

Process consolidation using mass-production composite machining centers

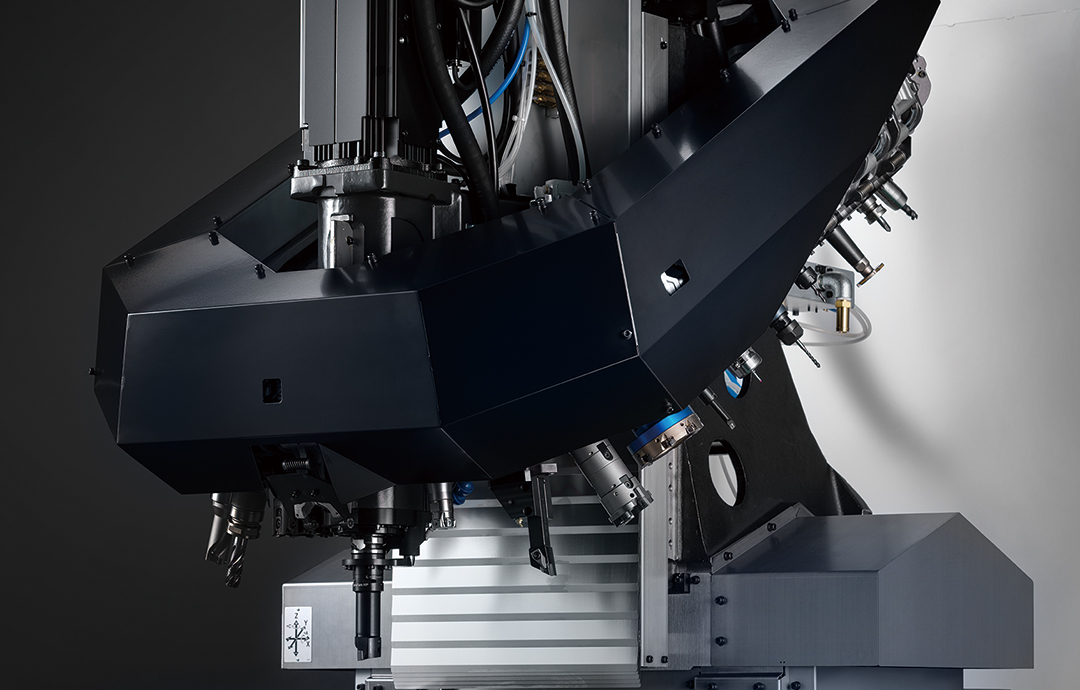

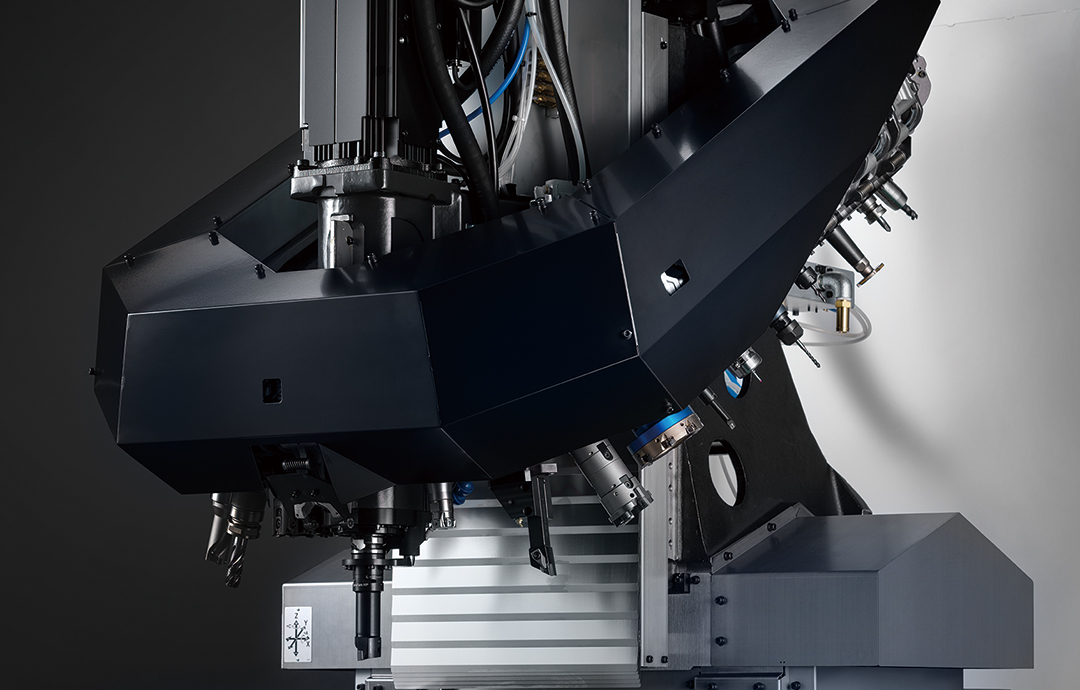

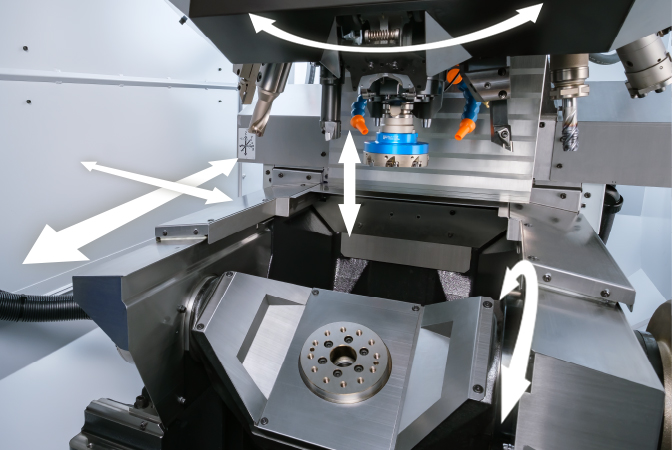

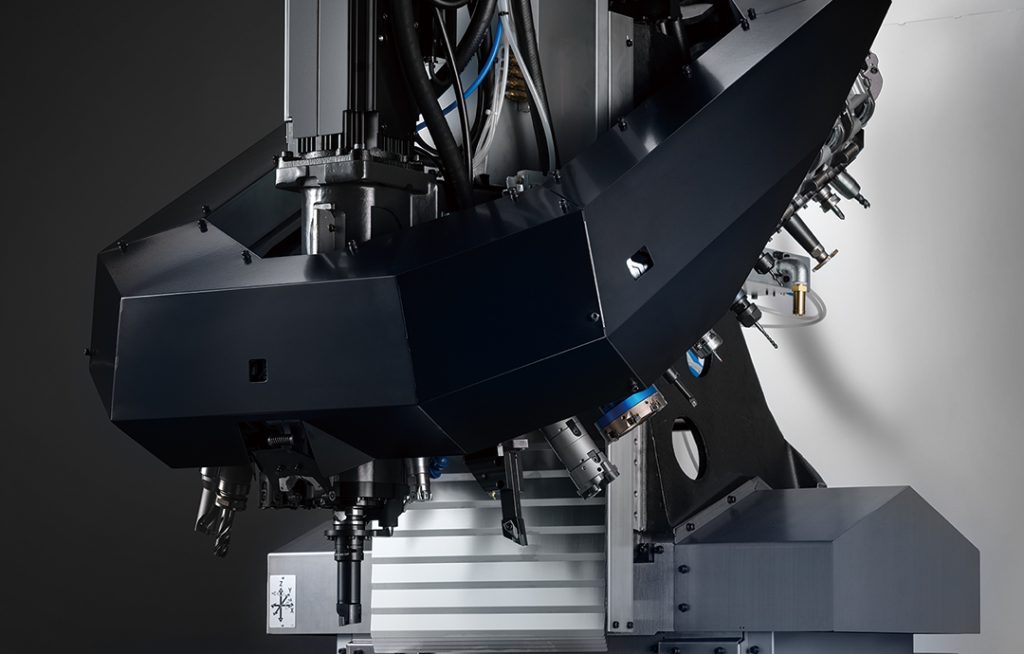

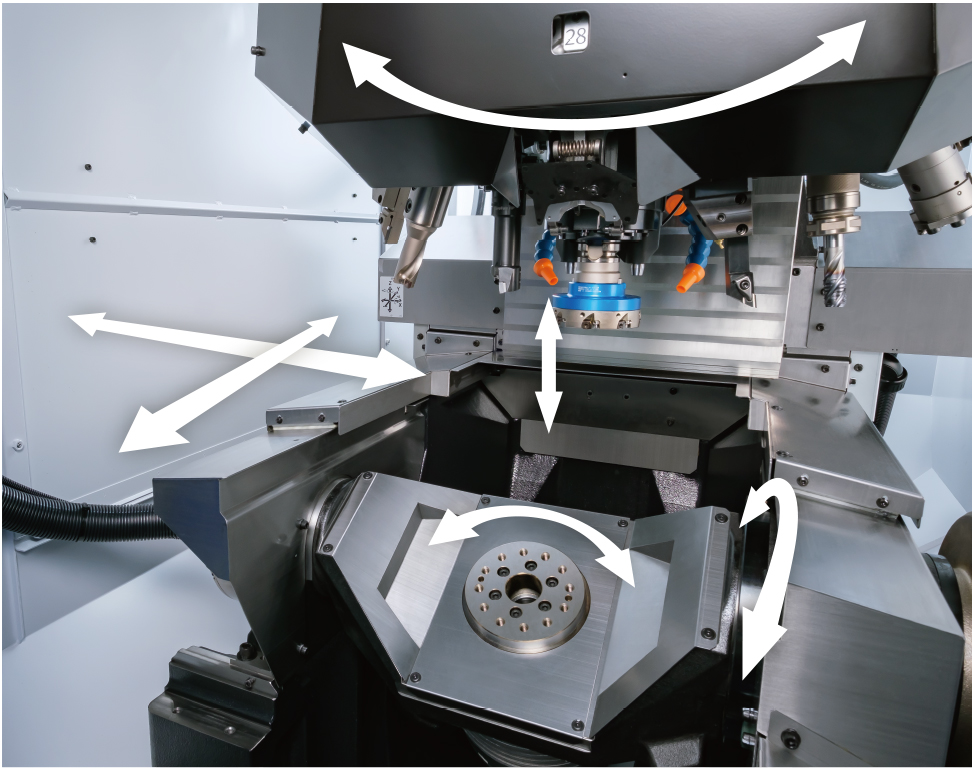

Equipped with a tilting rotary table with a turning spindle function, this single machine can handle everything

from combined turning and machining to multi-faceted machining .

Combined Processing

Turning and machining can be completed on one machine with one chuck.

There are various advantages to doing this as there is no longer any handling between the lathe and the machining.

Multi-faceted machining

Equipped with a tilting rotary table that allows high-speed indexing, it enables process integration through multi-sided machining, offering the same benefits as combined machining.

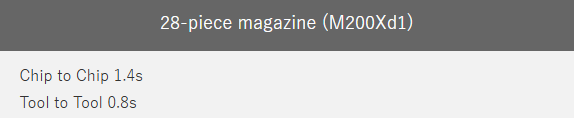

28 magazines

The newly developed turret magazine that can store 28 tools further promotes process integration through combined machining and multi-faceted machining.

*22 magazines are also available

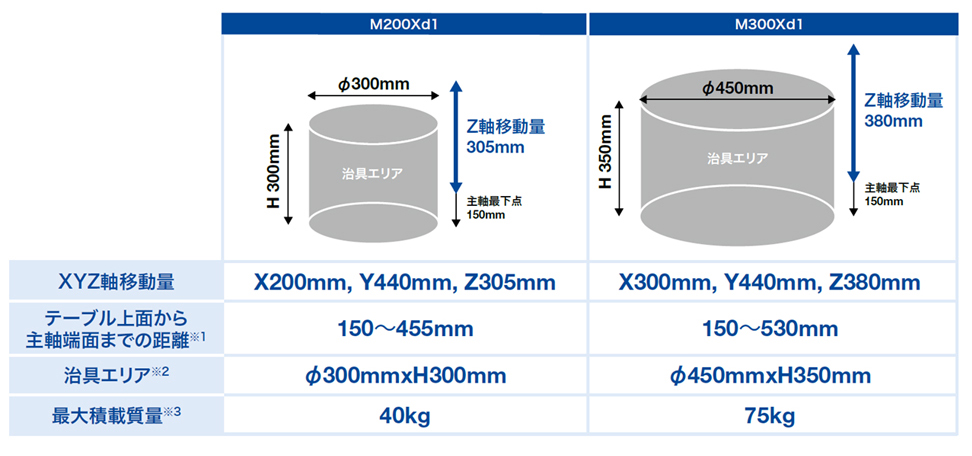

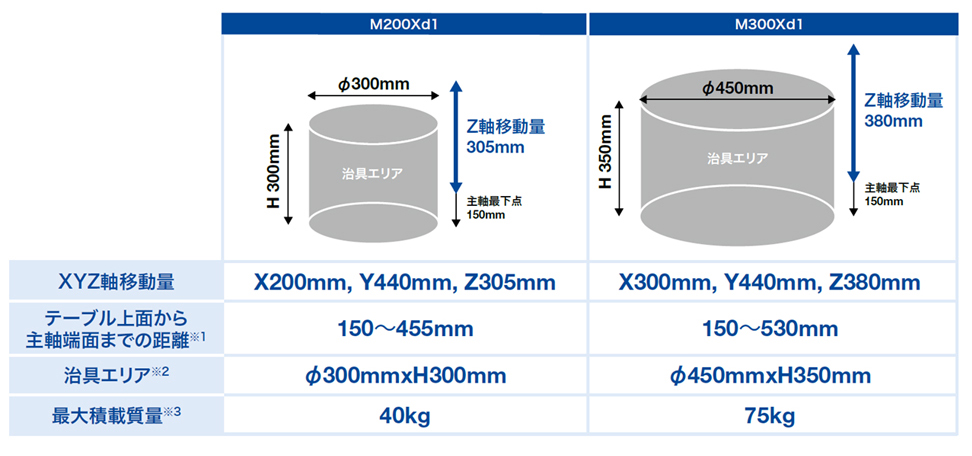

Processing Area

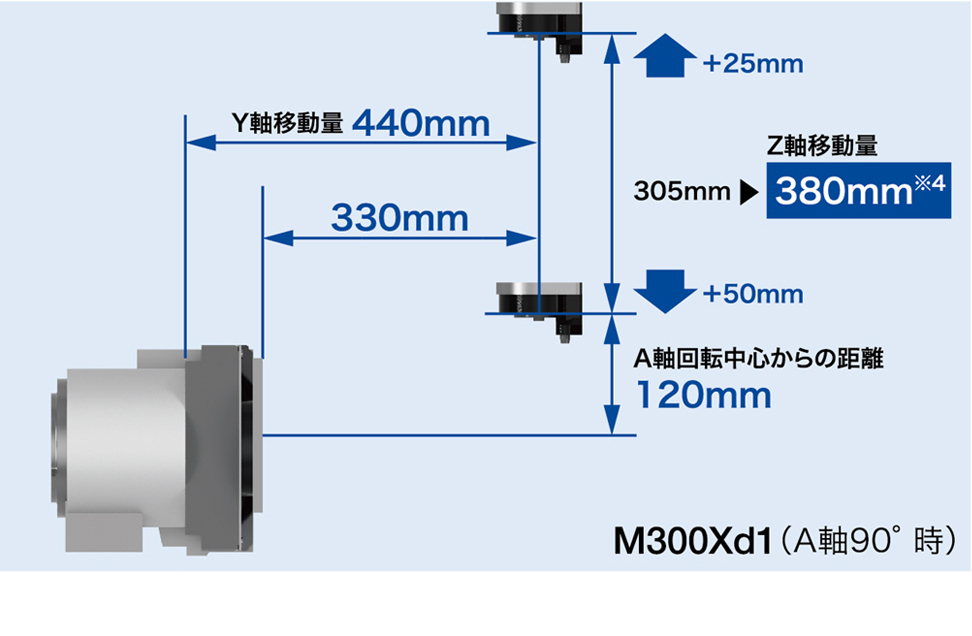

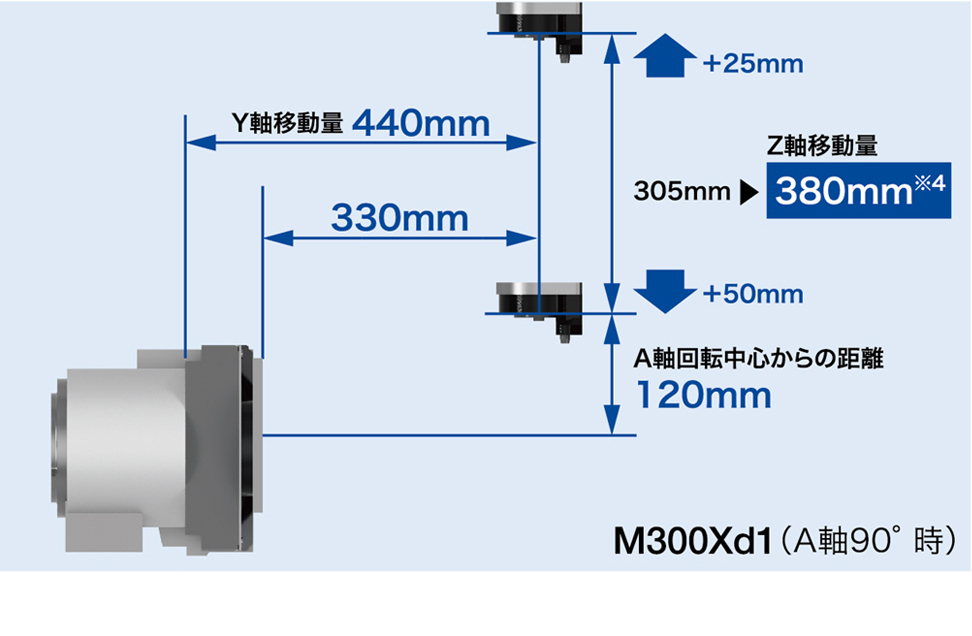

Expanded Z-axis travel and fixture area of M300Xd1

Combined with the 28-tool magazine, the number of workpieces that can be machined has been increased

the M200Xd1 is a compact machine focused on small parts, providing optimal machining for each part.

Large processing area

A wide jig area is secured, allowing flexibility in jig design and supporting a variety of machining workpieces. In particular, the M300Xd1 has an increased jig turning diameter of φ450, an increased Z-axis travel distance of 380mm, and an increased distance from the table top to the spindle end. This ensures a wide machining area in the Z-axis direction and improves tool accessibility.

*1 Value when A axis is at 0°.

*2 There is an interference area in the fixture area. Please refer to the table details.

*3 Maximum load weight on the table side.

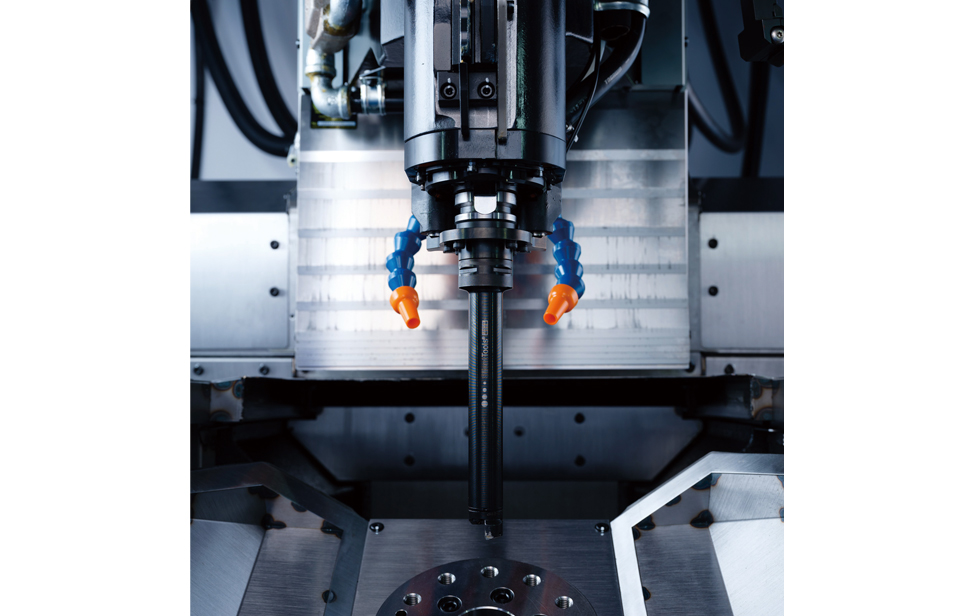

Increased maximum tool length

The mountable tool length has been expanded to 250 mm, enabling a wider variety of machining operations, including deep internal turning.

* If the tool length is 200 mm or more, depending on the jig height, there is a possibility that the jig may interfere with the magazine when it is rotated.

Improved tool accessibility when tilting the A-axis

Even when the A-axis is at 90°, sufficient Y-axis travel is ensured, and the increased Z-axis travel and maximum tool length improve tool accessibility.

*4 M200Xd1 is 305mm.

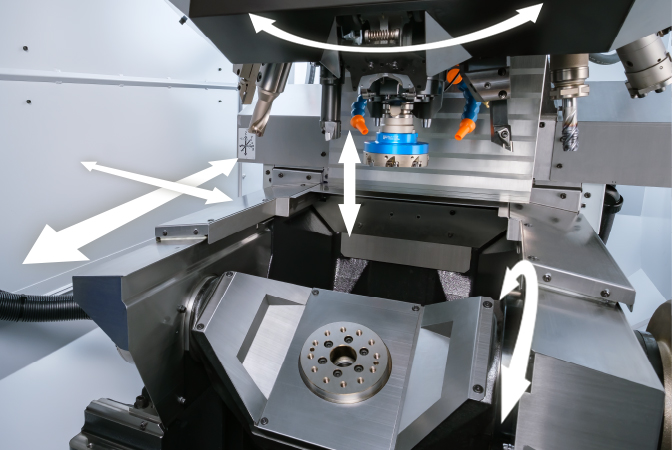

Productivity

Relentless pursuit of high productivity and

labor-saving through automation

Furthermore, the integrated loading device enables space-saving automated production, reducing manpower at the production site.

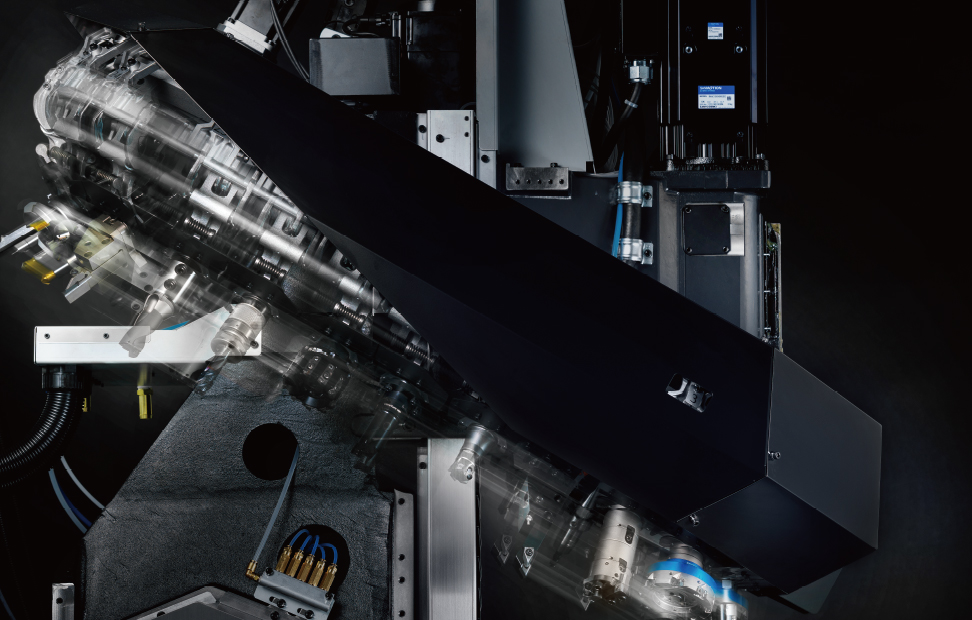

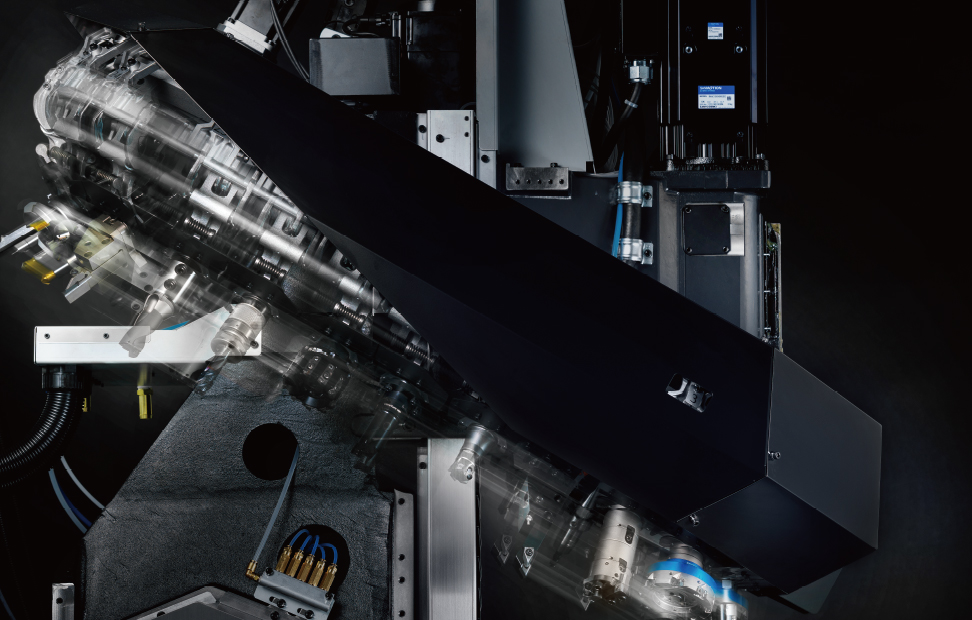

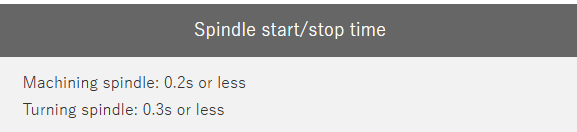

Non-stop ATC

High-speed tool changes are achieved by accelerating and optimizing spindle start/stop, Z-axis lift, and magazine operation

Simultaneous Operation

By performing tool change and positioning of the XY and AC axes at the same time, unnecessary time is reduced.

High acceleration/deceleration spindle

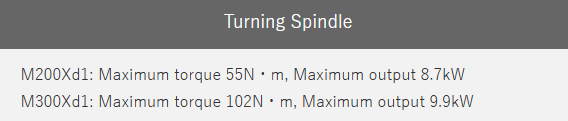

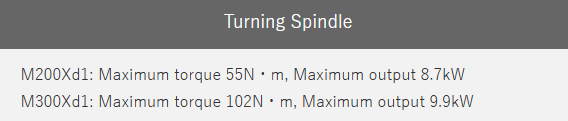

The low inertia spindle and high acceleration/deceleration spindle motor enable high-speed start/stop of the spindle. The turning spindle also uses a DD motor, achieving high acceleration/deceleration.

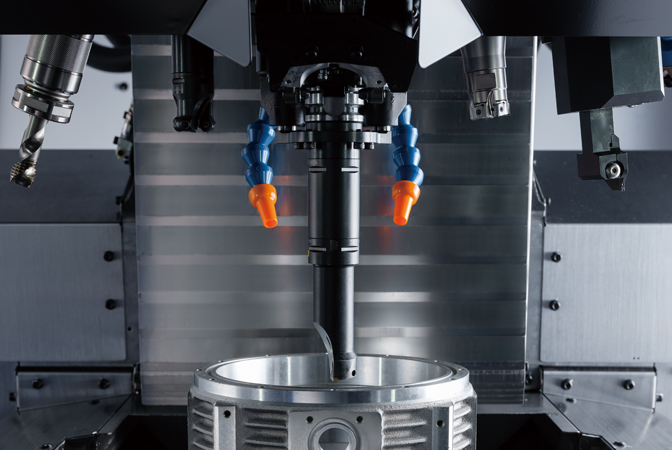

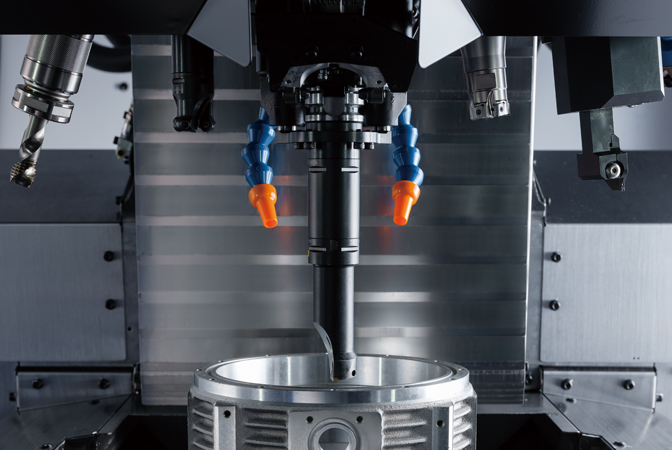

Processing Capability

Demonstrates high machining capabilities from machining to turning,

and also features simultaneous 5-axis machining function

The machining spindle and turning spindle are equipped with high-power motors, and the tilting rotary table has a high clamping force, providing high machining capabilities in combined machining and multi-sided machining. The

new tool center point control function also supports simultaneous 5-axis machining.

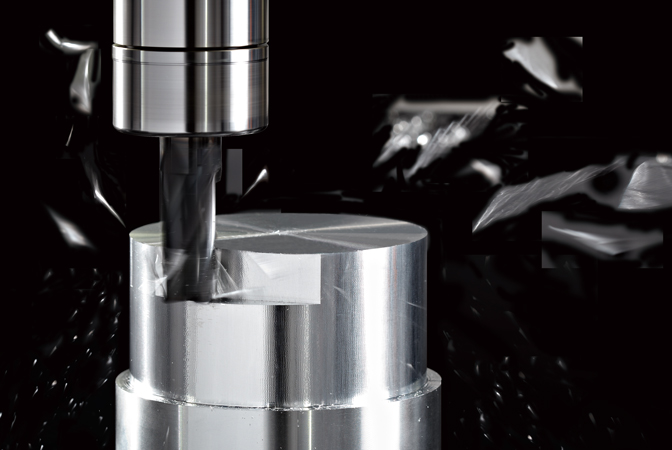

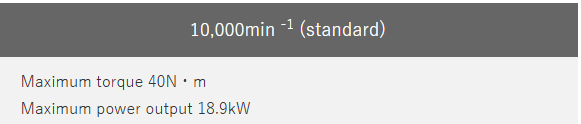

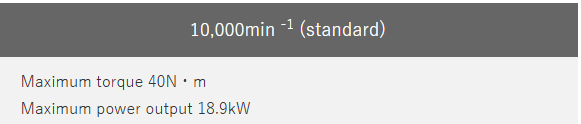

Machining

The high spindle torque in the medium to high speed rotation range makes it effective for high-speed, high-efficiency machining of aluminum and steel.

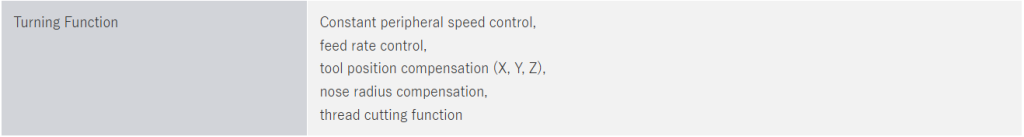

Turning

A high-power turning spindle with a maximum speed of 2,000 min -1 (M200Xd1) and turning tools held by a double plunger lock method ensure efficient machining.

C-axis clamp

The C-axis has a high clamping force, which allows for higher cutting conditions to be set in machining that places a load in the rotational direction, improving production efficiency.

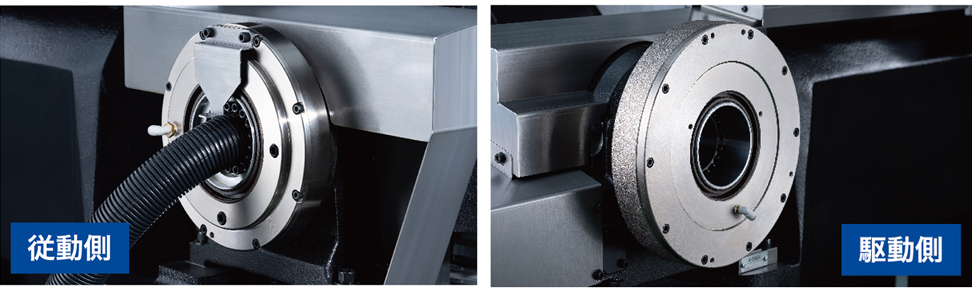

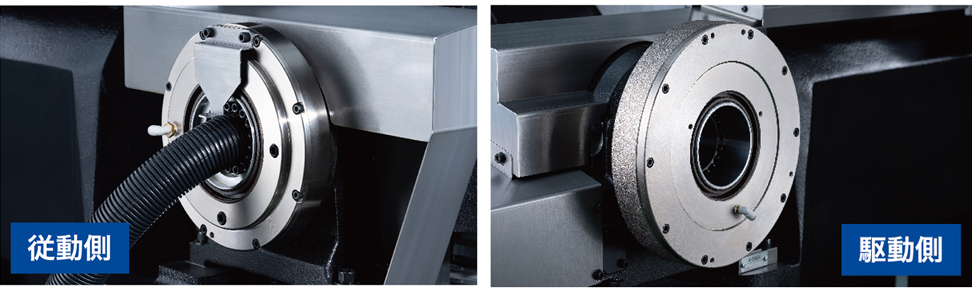

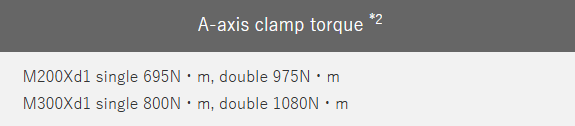

A-axis clamp (optional)

The mechanical + servo clamping system provides high machining capabilities in heavy-duty machining, and also realizes stable machining in turning, improving machining accuracy. A double type with clamping mechanisms on both the left and right sides has also been added, providing even higher machining capabilities.

A-axis clamp (double) *1

Operability

Equipped with the newly developed “CNC-D00” control device that pursues ease of use.

Also achieves easy access for setup work.

New app functions and a vertically-mounted 15-inch touch panel LCD screen enable intuitive operation. This

allows for efficient work in each process of setup, processing adjustment, production, and recovery, contributing to improved work efficiency and operating rates

. The machine is also easier to access, allowing for smooth setup work such as workpiece replacement

New User Interface

New support apps have been developed that consolidate related functions and provide visual displays for improved ease of use and visibility. The device is equipped with convenient functions such as a calculator, memo pad, and file viewer, and operation via the conventional screen is also easy with the touch panel, making the device much easier to use.

Accessibility and workability

The jig and workpiece can be tilted toward the operator, improving accessibility so that the operator can carry out setup work such as workpiece replacement in a comfortable posture

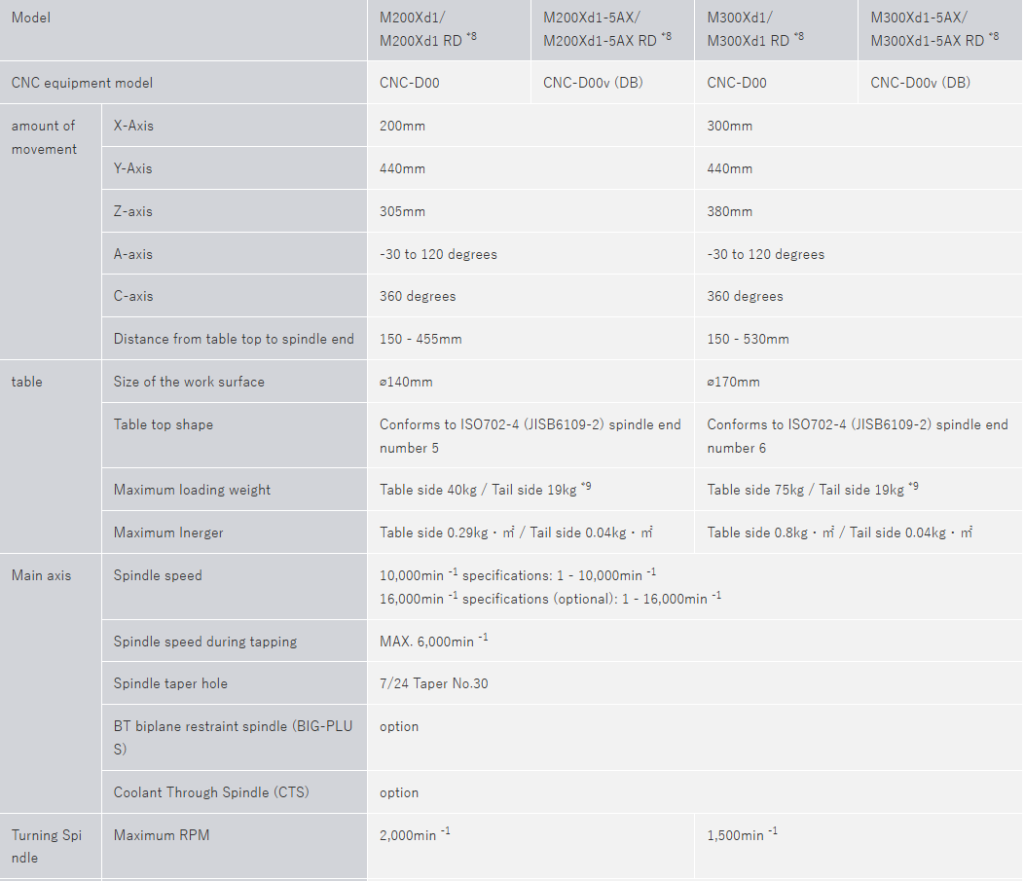

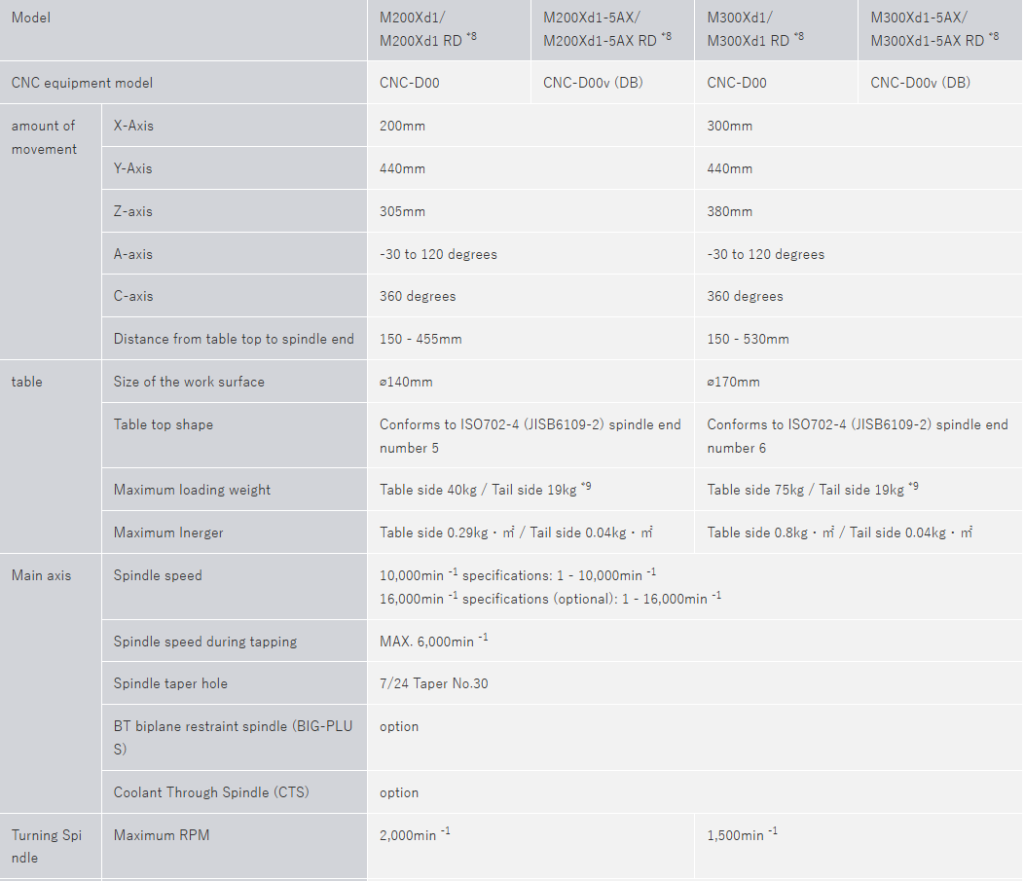

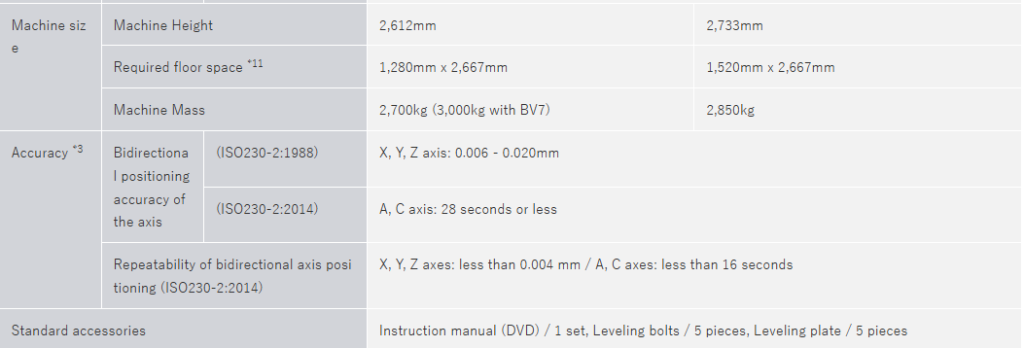

Mechanical Specifications

- *1The maximum weight of a tool varies depending on its shape, center of gravity, etc., so please consider this value as a reference only.

- *2The spindle motor output varies depending on the rotation speed.

- *3The measurement method is based on ISO and Brother standards. Please contact us for details.

- *4The pull studs for CTS are Brother specifications.

- *5The tool change time measurement method is based on JIS standard B6336-9 and MAS011-1987.

- *6The normal air pressure will vary depending on the machine specifications, processing program contents, and usage of peripheral devices, so please set a pressure higher than the recommended value.

- *7These are the values when using high precision mode B and tool center point control.

- *8Depending on the destination, a relocation detection device may be required. Models equipped with a relocation detection device have “RD” at the end of their model names.

- *9The load mass on the tail side is 13kg for the rotating part and 6kg for the fixed part.

- *10The 28-tool magazine does not allow turning tools to be mounted side-by-side.

- *11This value does not include the coolant tank and chip conveyor.

- *12If the tool length is 200 mm or more, depending on the jig height, there is a possibility that the jig may interfere with the magazine when it is rotated.

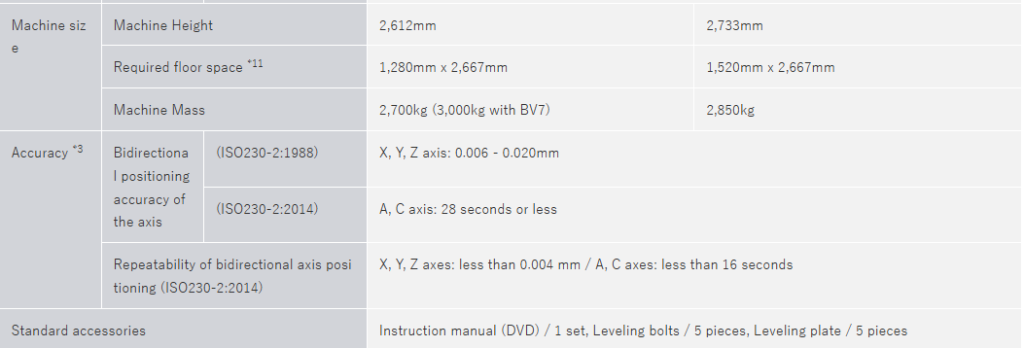

Mechanical Specifications

- *“Number of controlled axes” and “Number of simultaneously controlled axes” are the maximum numbers of axes and vary depending on the destination and specifications.

- *Ethernet is a registered trademark of XEROX Corporation in the United States.

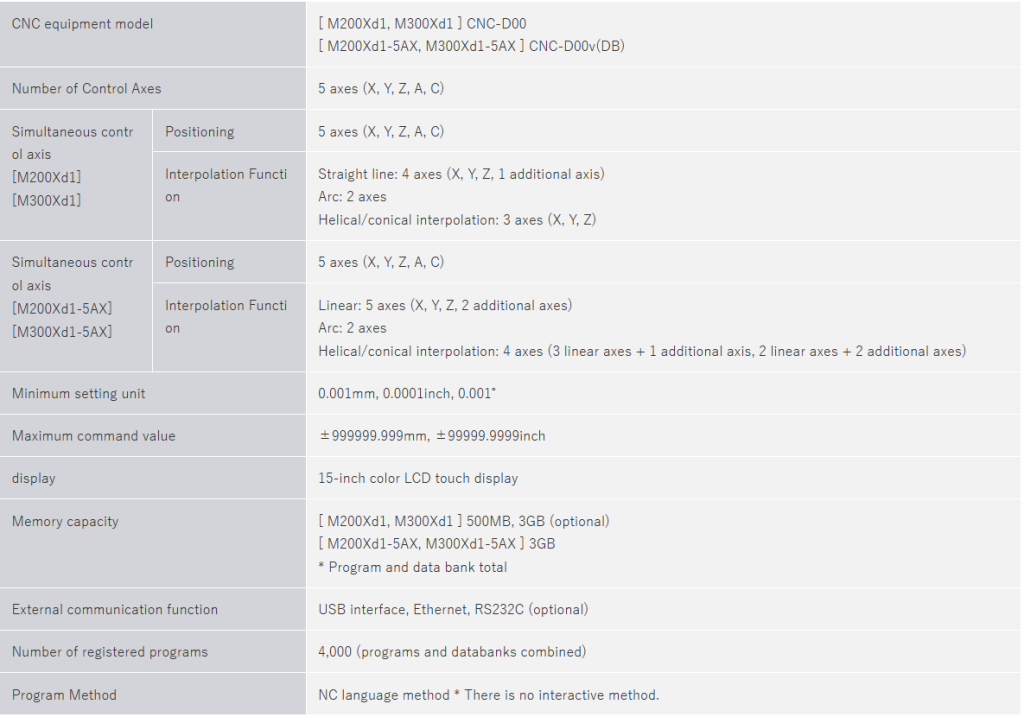

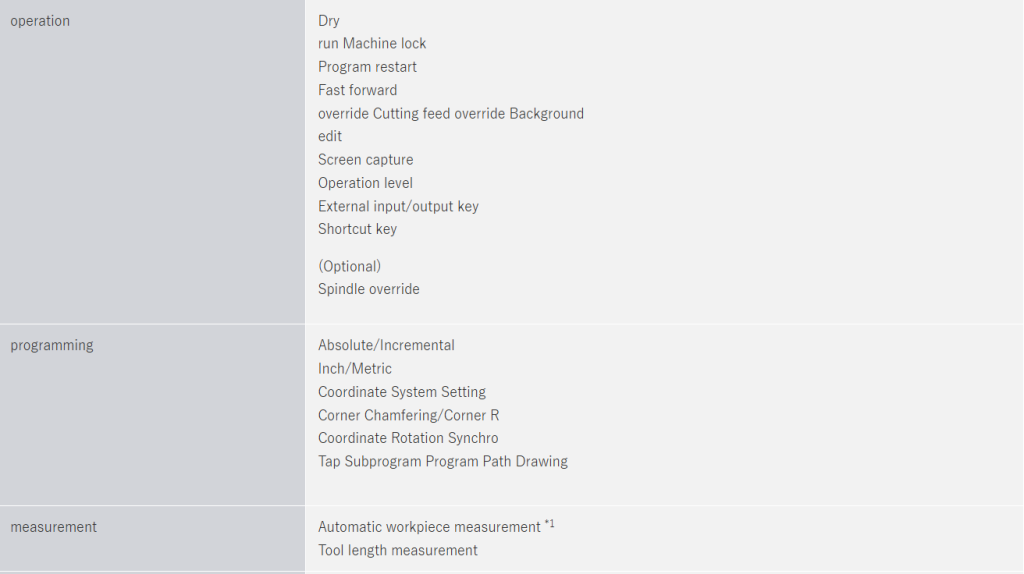

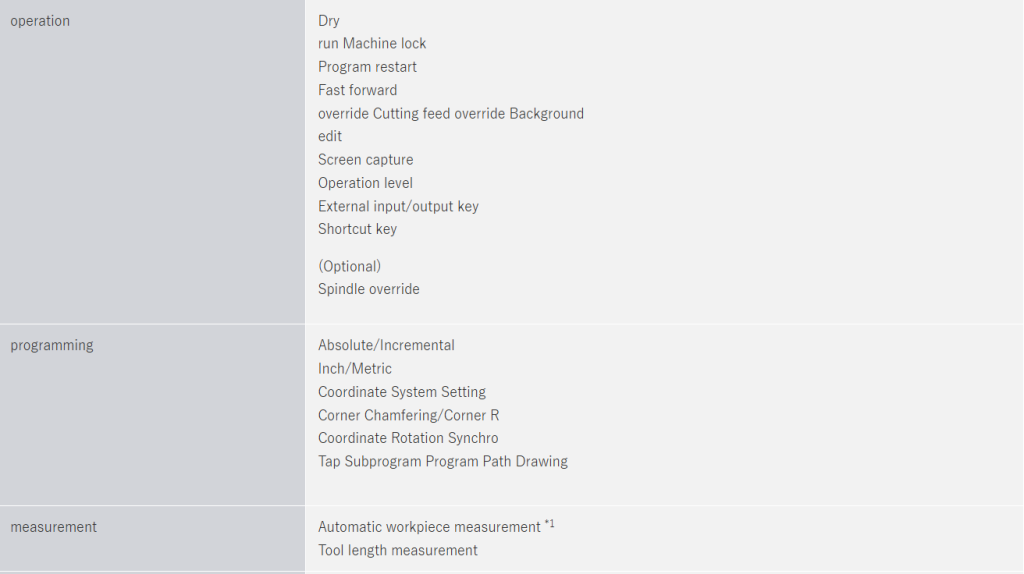

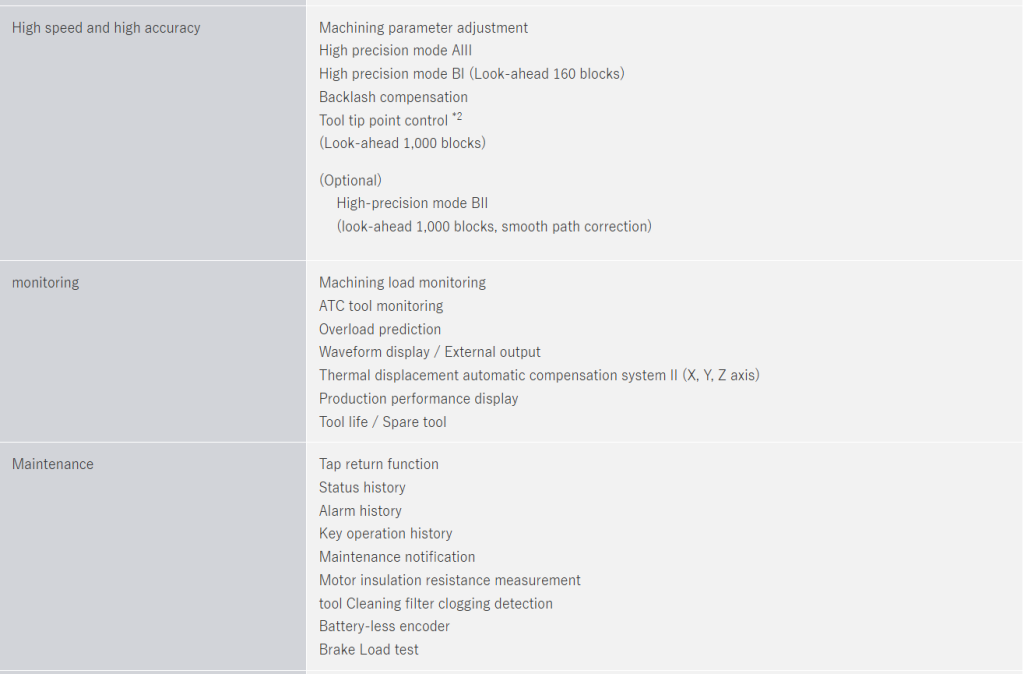

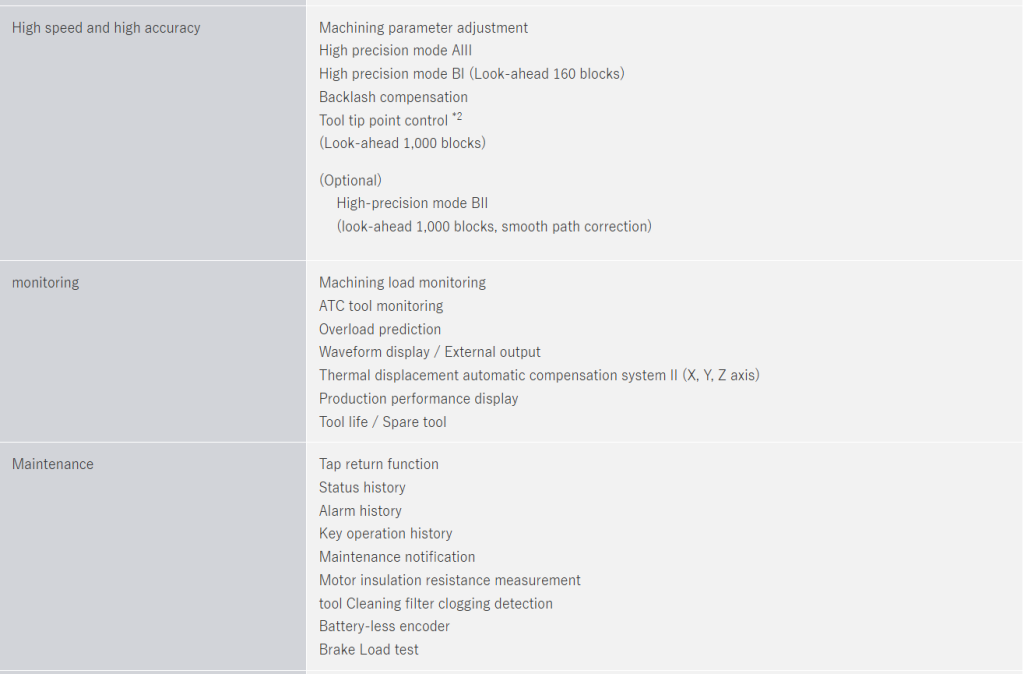

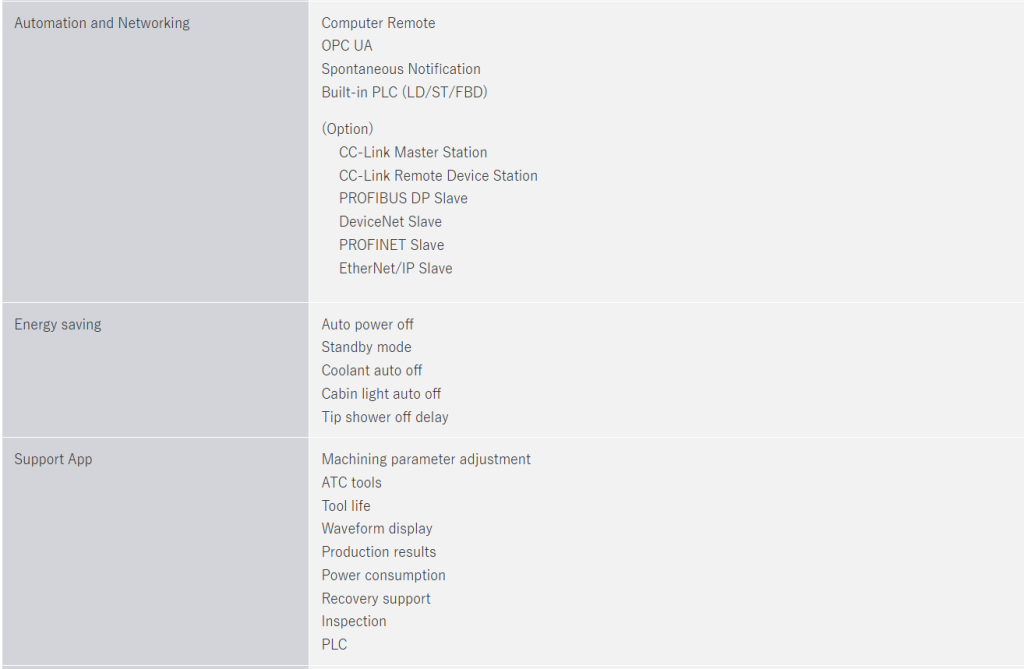

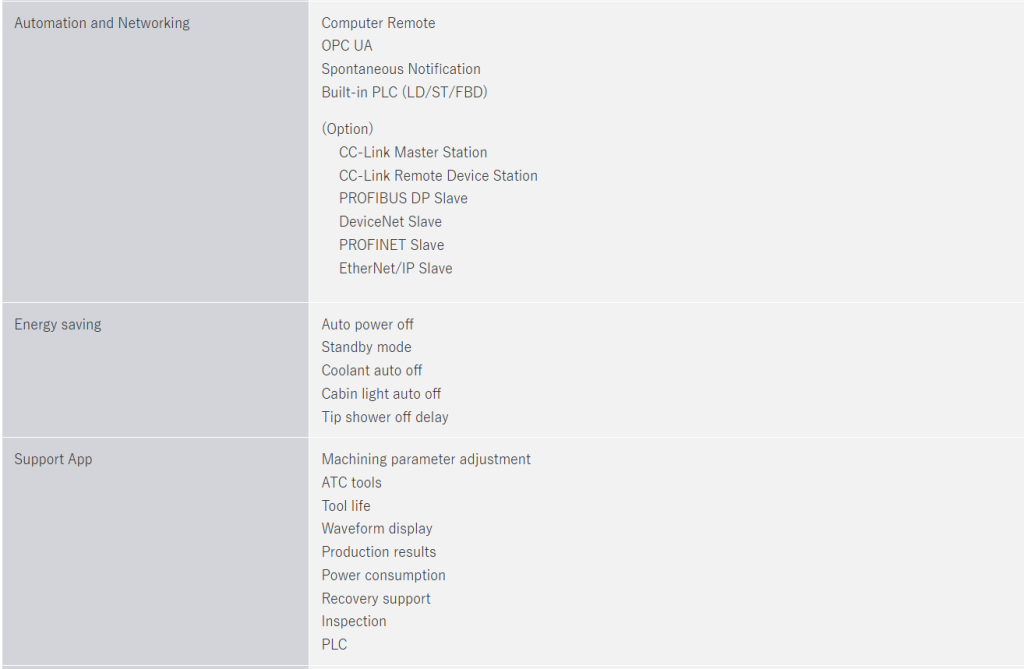

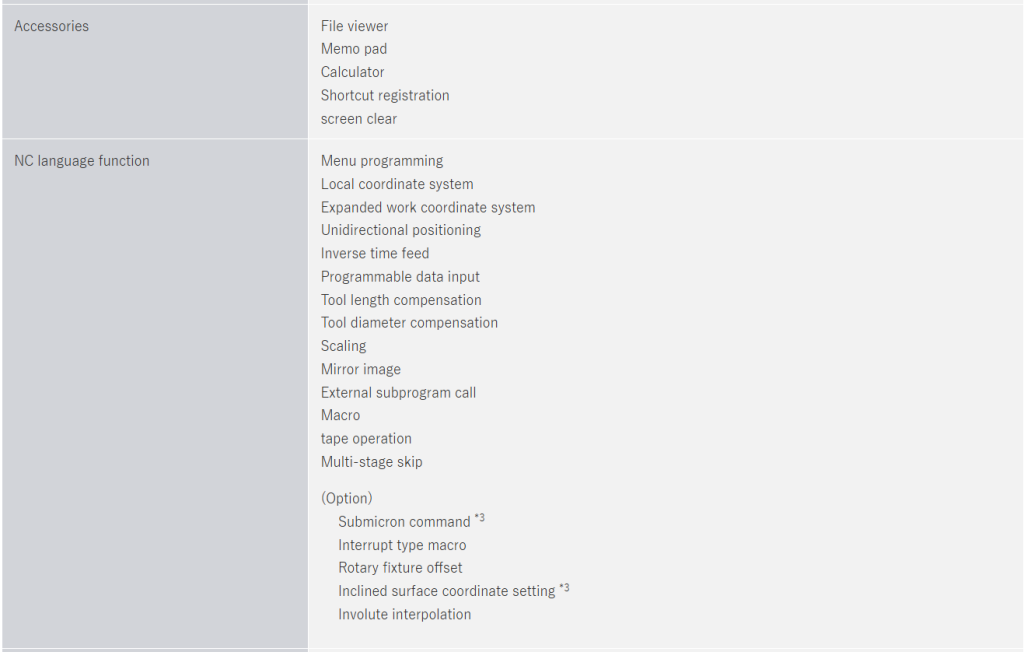

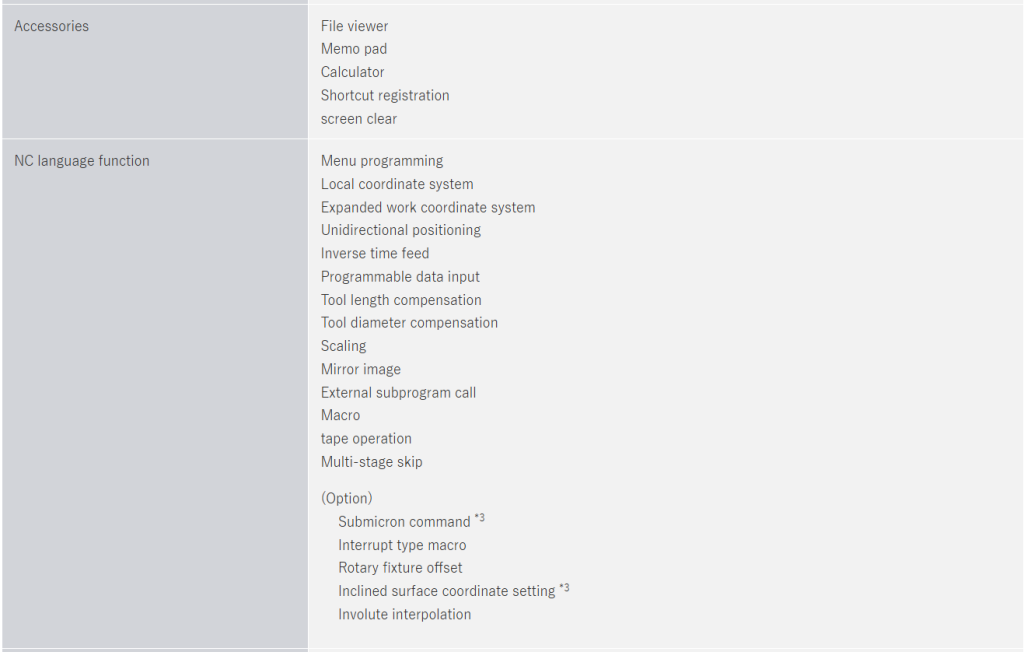

NC Function

*1Customers must provide their own measuring equipment.

*2This feature is only available on M200Xd1-5AX and M300Xd1-5AX.

*3It is standard equipment on the M200Xd1-5AX and M300Xd1-5AX.

Processing Examples

Car

| Part Name | Electric water pump housing |

|---|---|

| Material | Aluminum alloy |

| Part Name | Scroll Compressor Parts |

|---|---|

| Material | Aluminum alloy |

| Part Name | EV motor case |

|---|---|

| Material | Aluminum alloy |

medical care

| Part Name | Artificial knee joint |

|---|---|

| Material | Ti-6Al-4V |

| Part Name | Hip joint acetabulum |

|---|---|

| Material | Ti-6Al-4V |

| Part Name | EV motor case |

|---|---|

| Material | Ti-6Al-4V |

medical care

| Part Name | High Pressure Regulator |

|---|---|

| Material | SUS630 |

| Part Name | Gas Cylinder Valve |

|---|---|

| Material | brass |

| Part Name | Watch Case |

|---|---|

| Material | SUS316L |