Brother R Series

SPEEDIO :

R450Xd1/ R650Xd1

Brother's unique pallet changer "QT Table" that does not lift up, the newly developed CNC and the tool magazine that can store up to 40 tools will improve productivity at any workplace.

Highlights

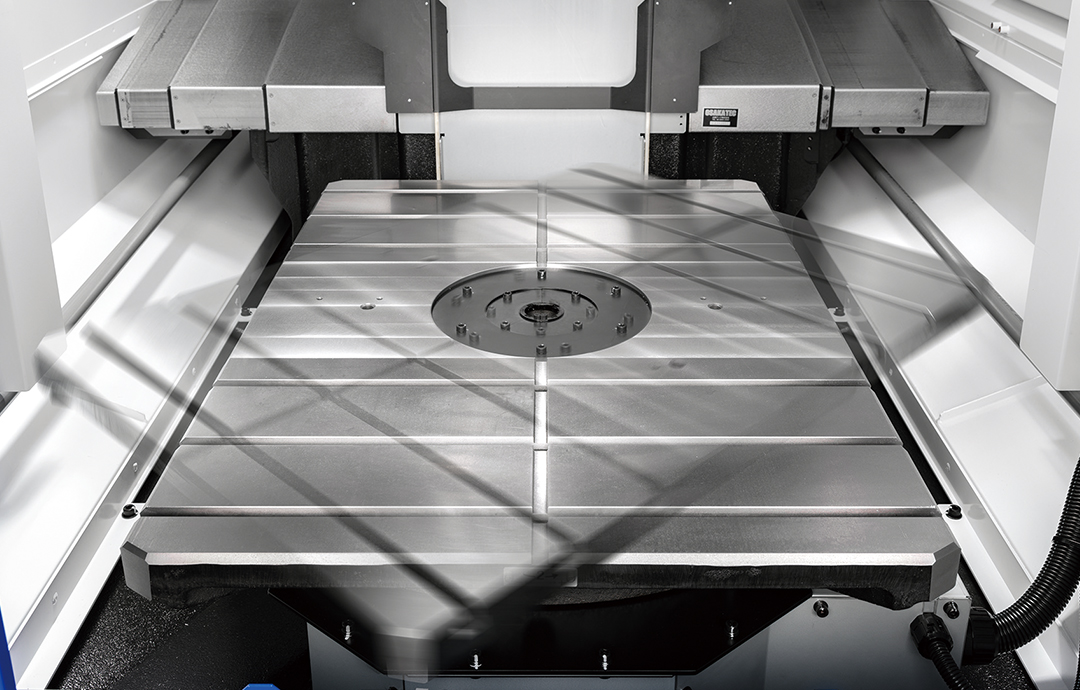

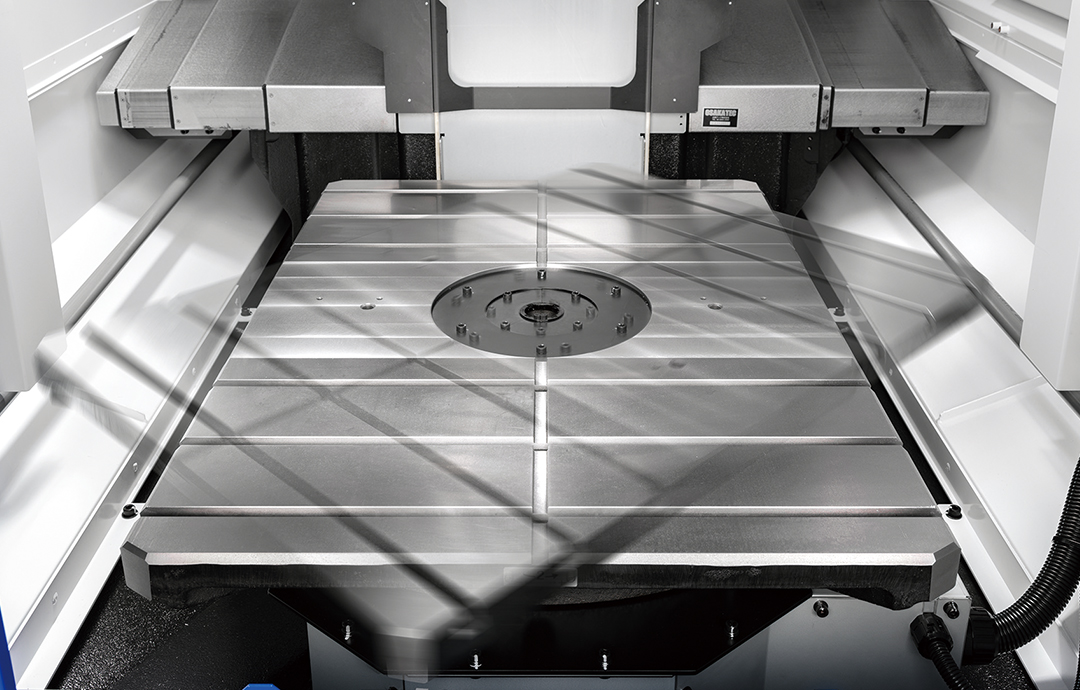

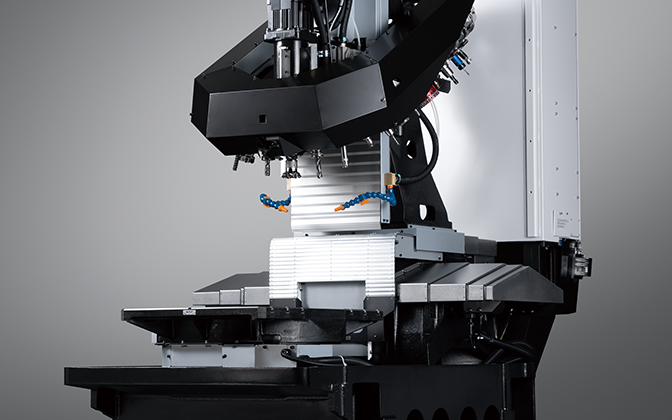

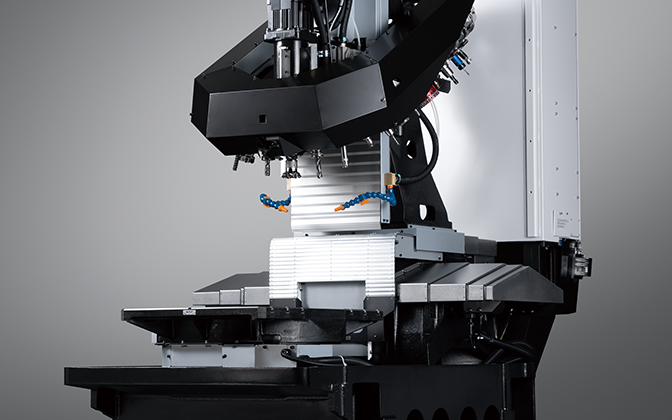

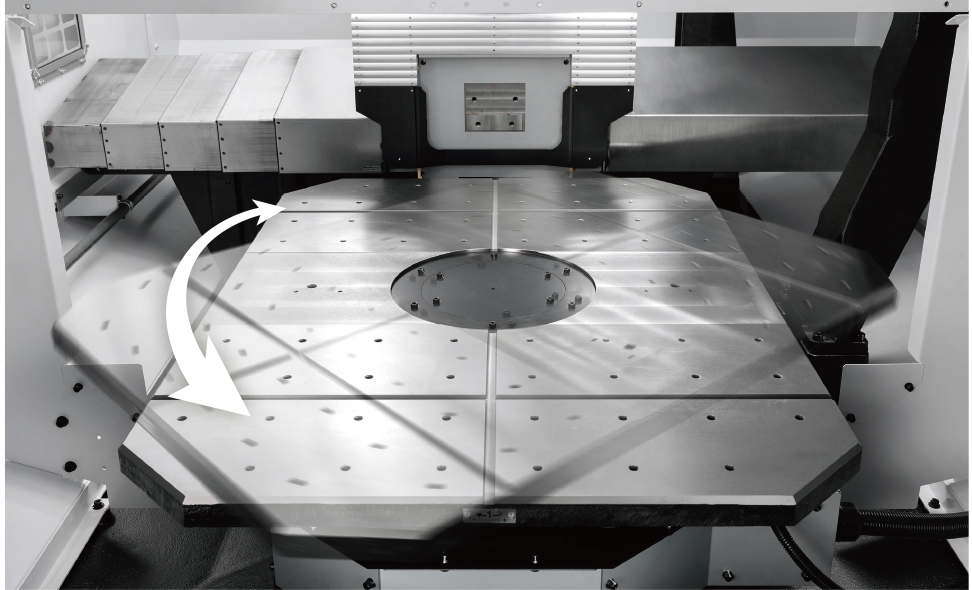

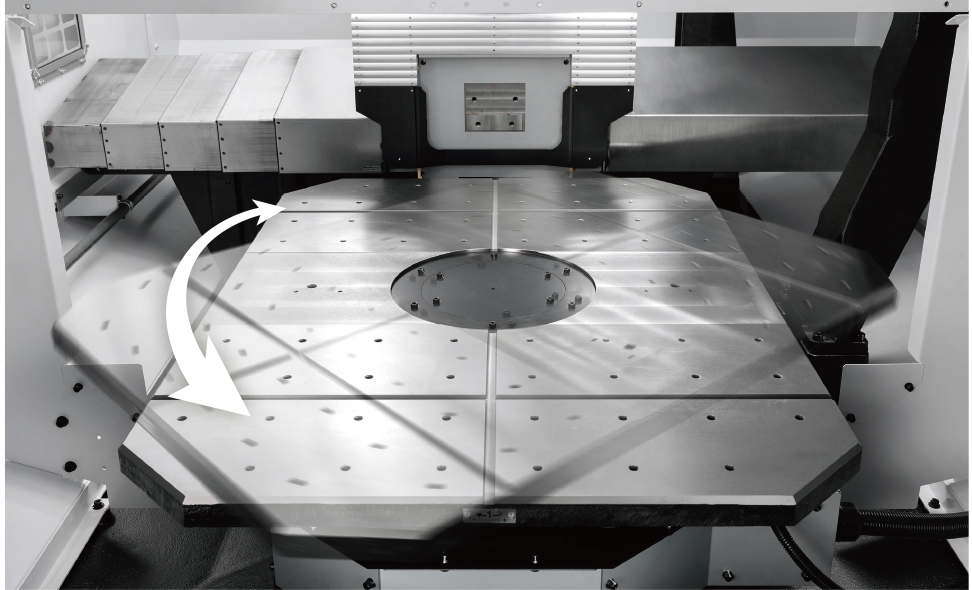

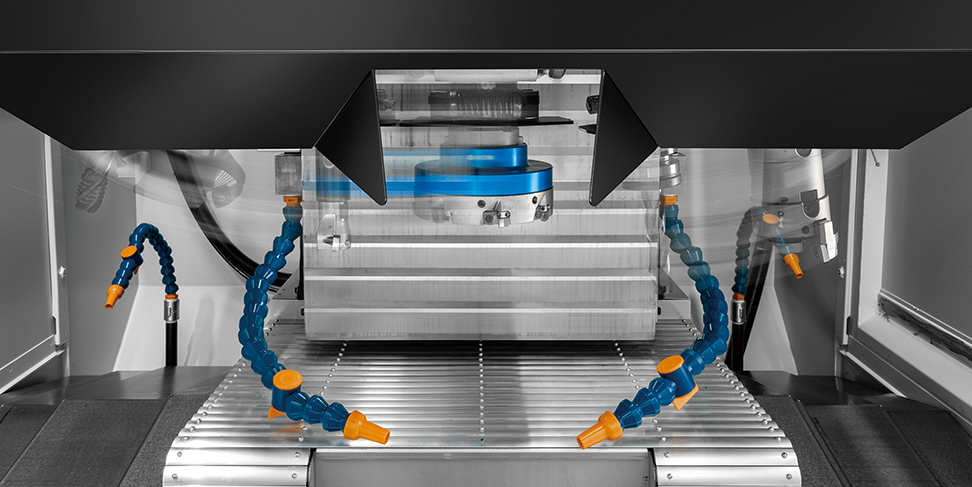

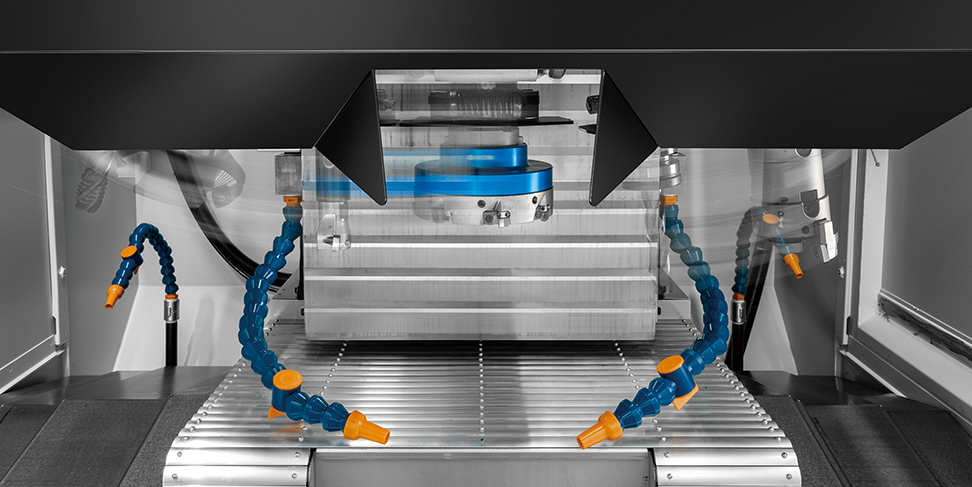

QT Table

Brother’s unique high-speed two-sided pallet changer “QT table”

combines a wide fixture area with high reliability, achieving high productivity through non-stop processing

Productivity

Magazines with a wide variety of options

Overwhelmingly high productivity through integrated mechanical and electrical development

Processing Capability

Demonstrates a wide range of cutting power, from high-speed, high-efficiency machining to heavy-duty cutting

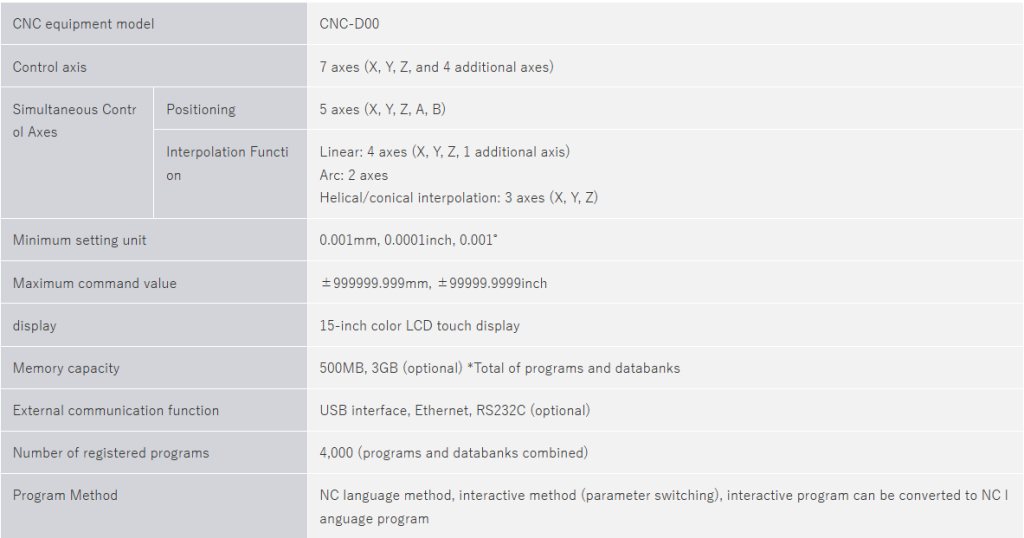

NC device

Equipped with the newly developed “CNC-D00” control device

Easy to use with a 15-inch touch panel LCD

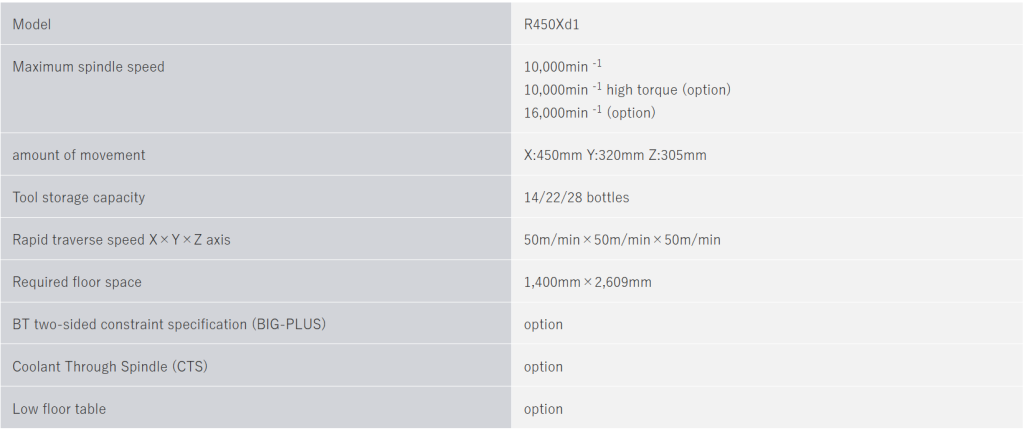

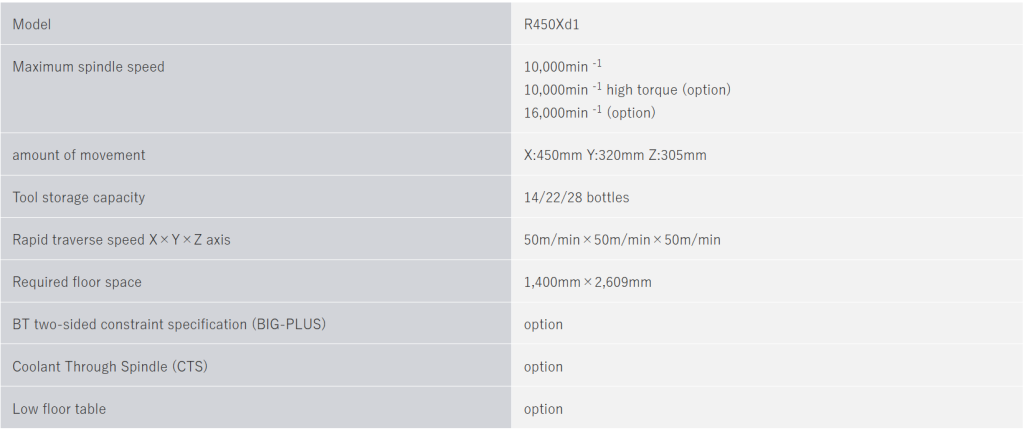

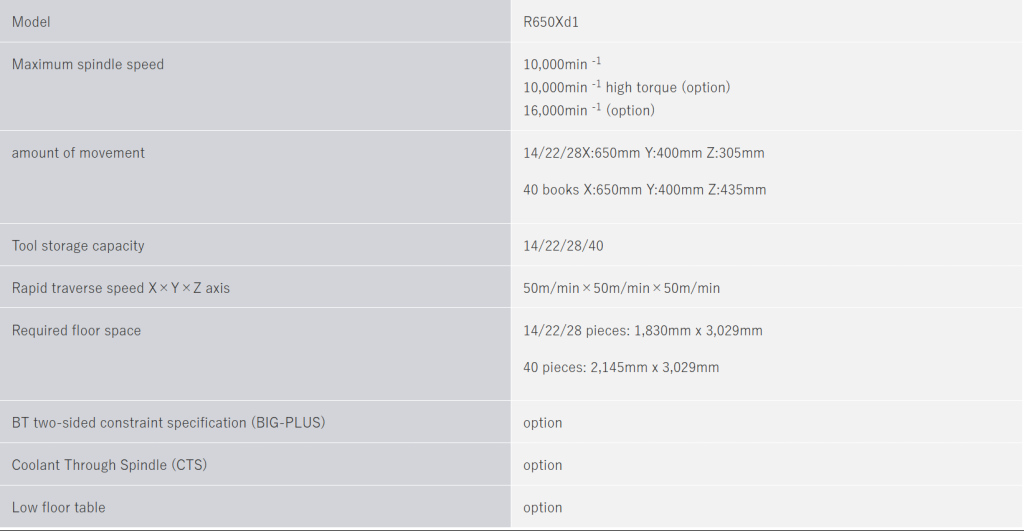

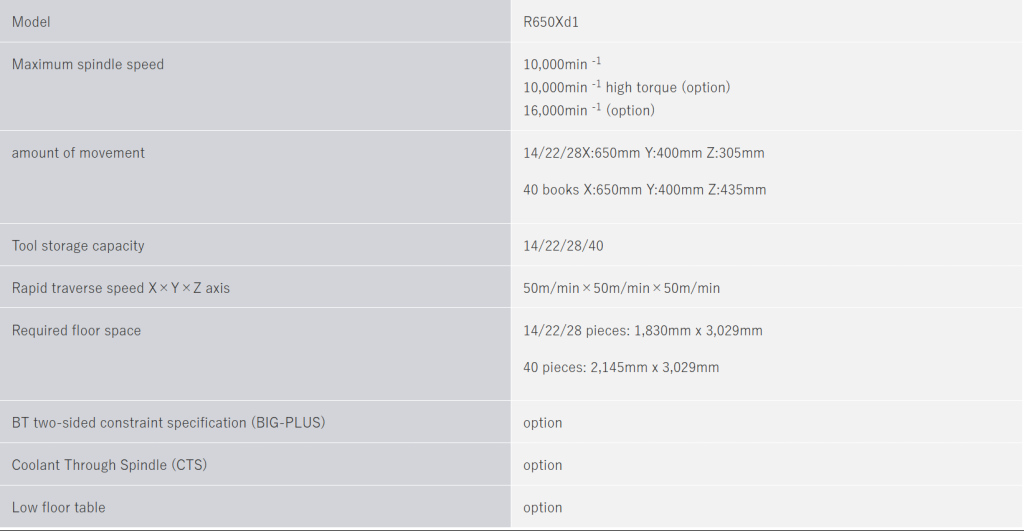

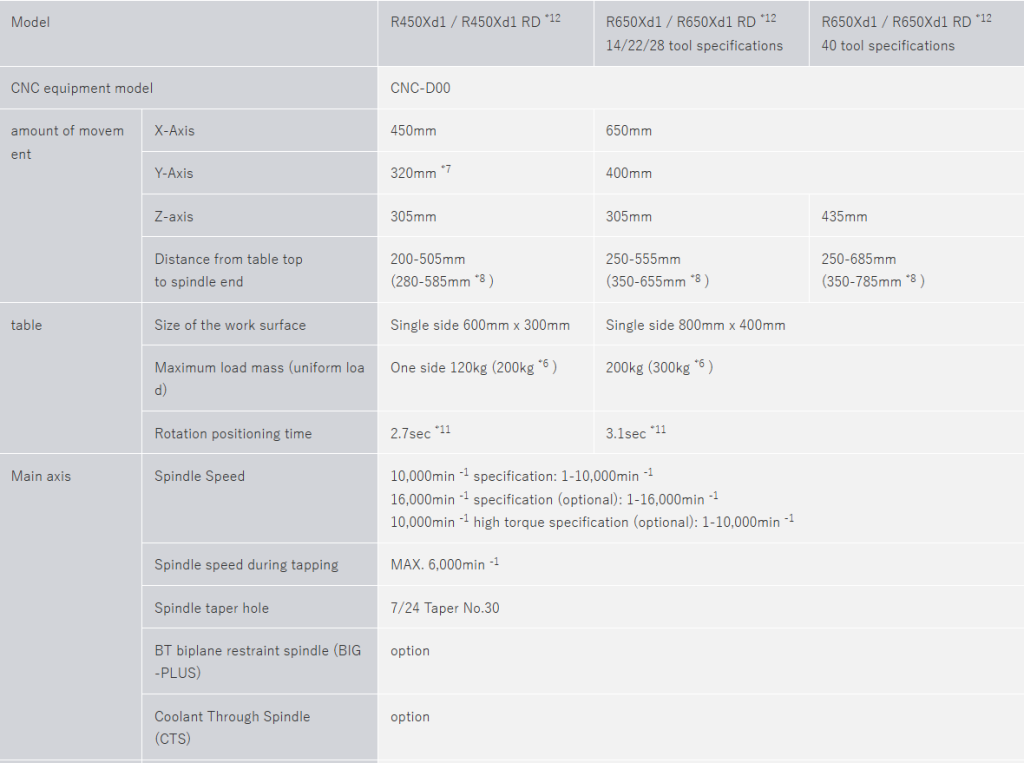

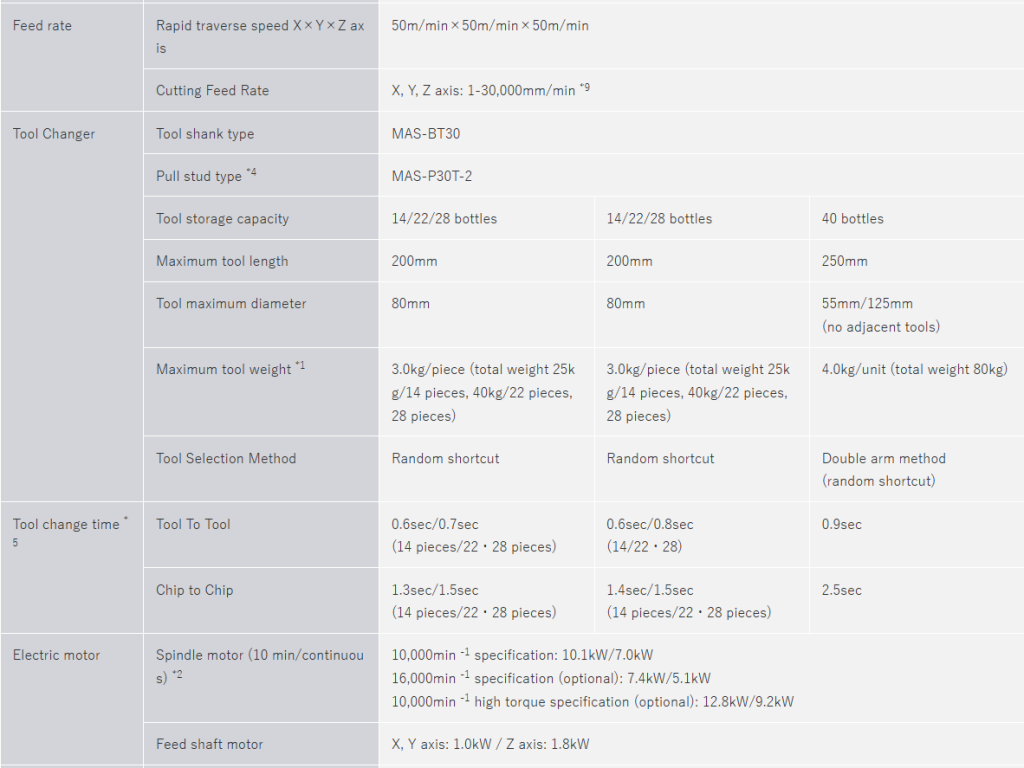

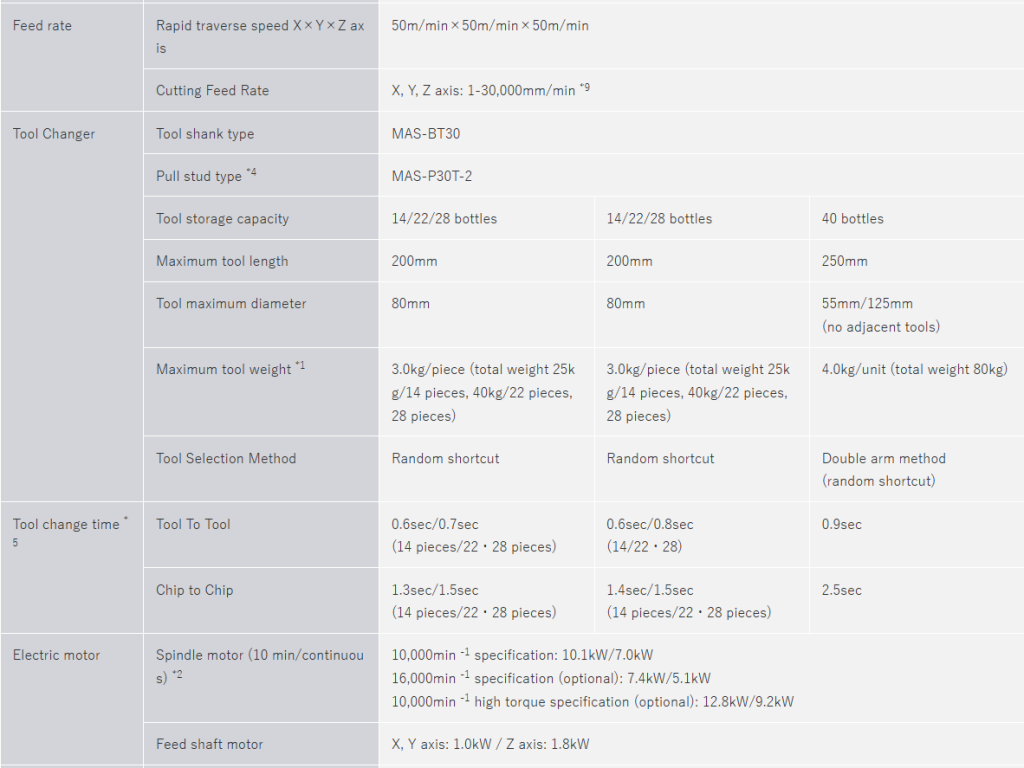

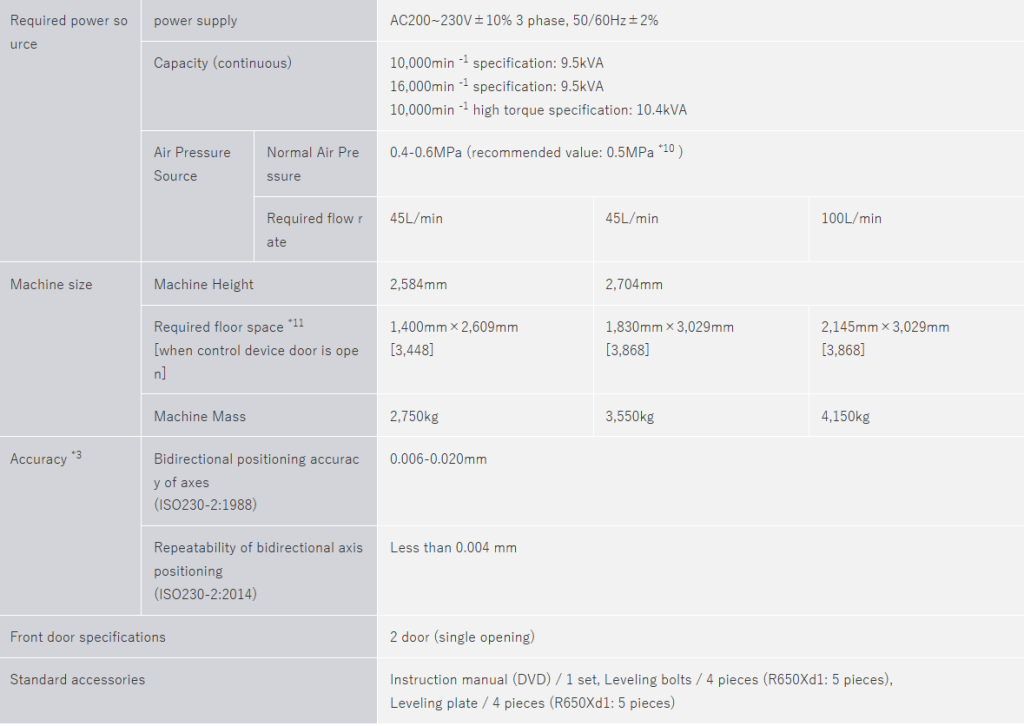

Specifications

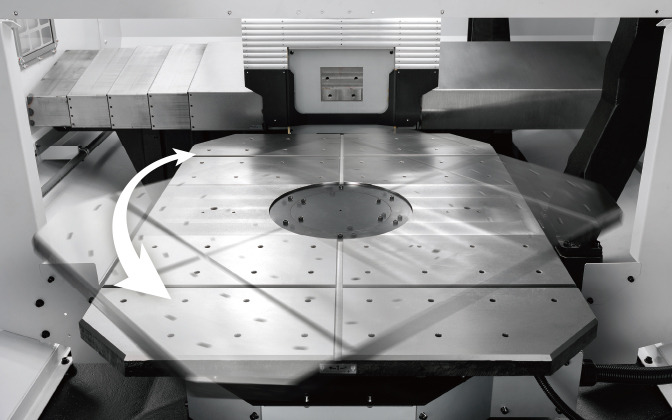

QT Table

Achieving high productivity with the QT table that eliminates wasteful workpiece changing time

Brother’s unique high-speed two-sided pallet changer “QT table”combines a wide fixture area with high reliability, achieving high productivity through non-stop processing.

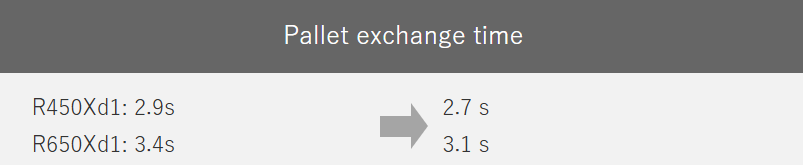

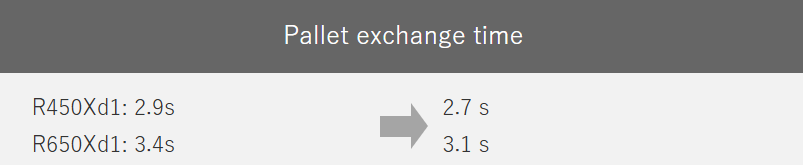

Fast pallet change

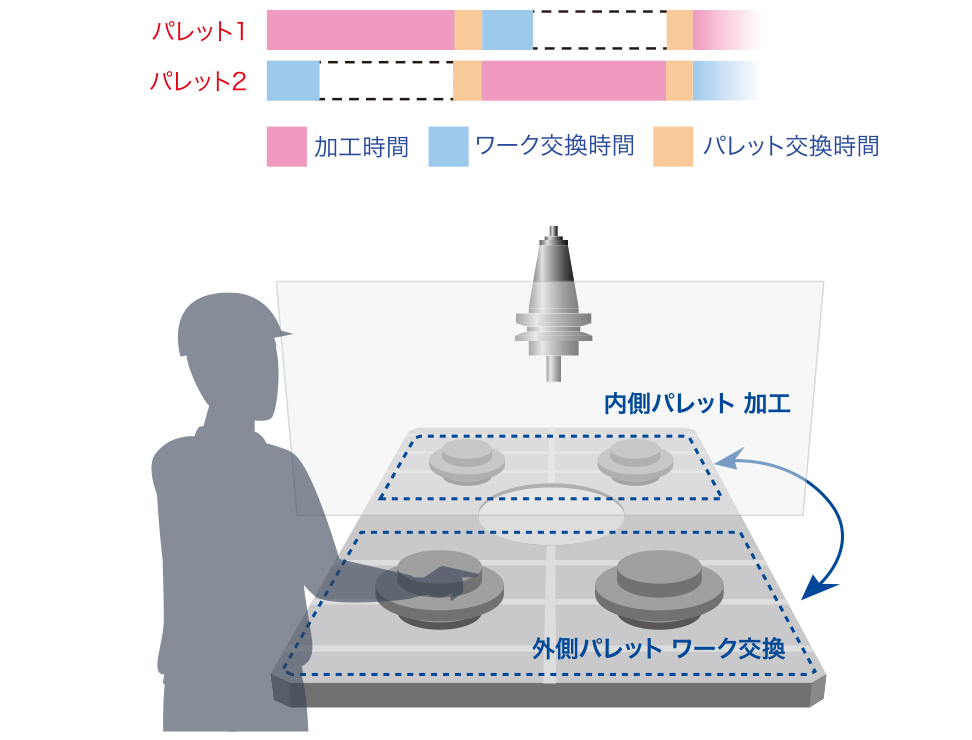

The QT (Quick Turn) table is a high-speed two-sided pallet changer with a turntable system. Optimized acceleration and deceleration control has made pallet changes even faster than before.

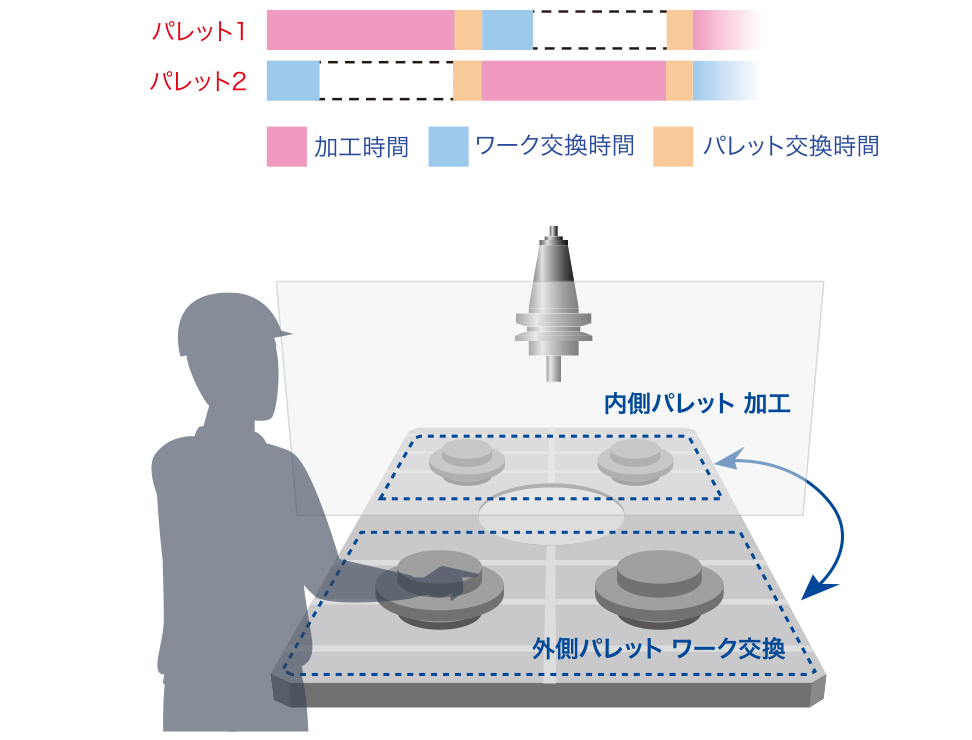

Non-stop processing

While processing with one side of the pallet, workpieces can be changed on the other side of the pallet. This eliminates the waste of workpiece changes and enables non-stop processing without the machine stopping.

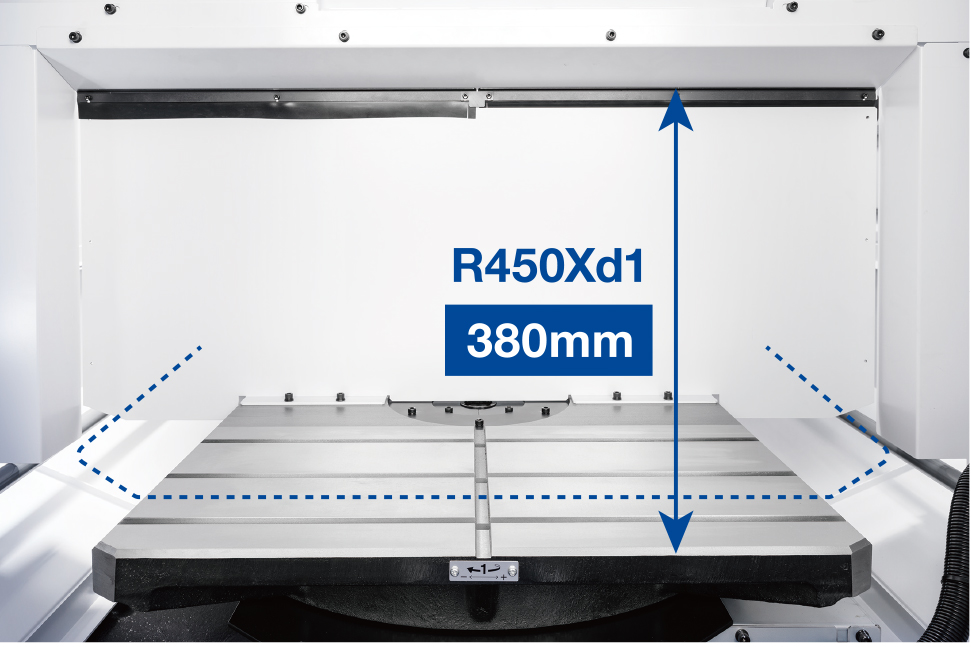

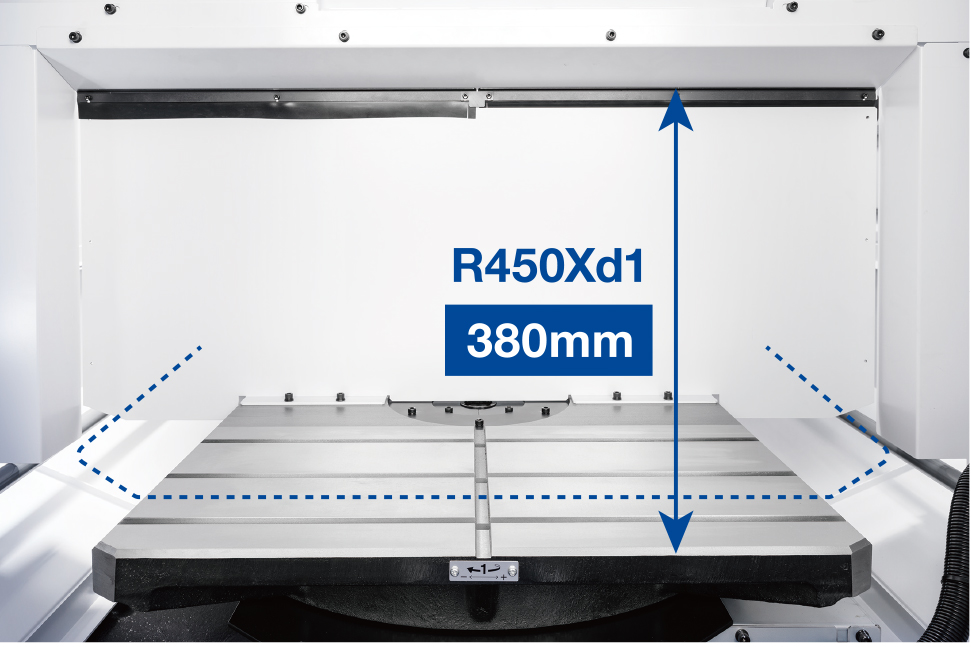

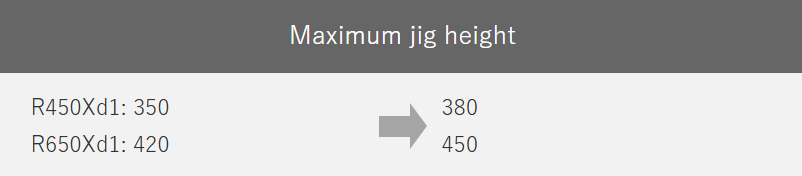

Large fixture area

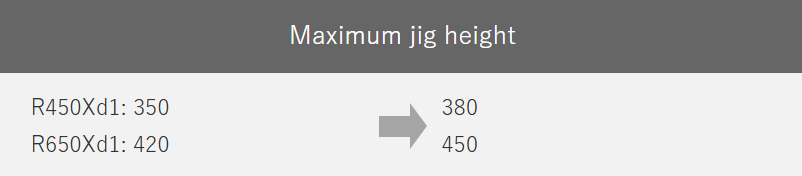

Jigs can be mounted outside the table as long as they are within the pallet’s turning diameter. The jig area can be further expanded by using options such as the low-floor table specification, which increases the jig height, and the enlarged turning diameter specification, which increases the jig area.

Productivity

Magazines with a wide variety of options

Overwhelmingly high productivity through integrated mechanical and electrical development

, such as simultaneous operation and faster and more optimized tool change operations,

it has achieved overwhelmingly high productivity.

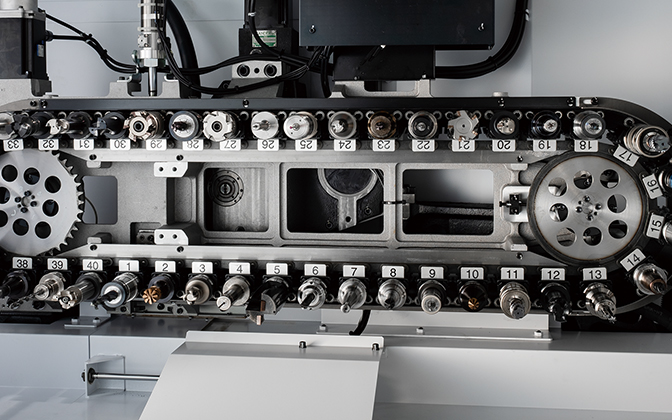

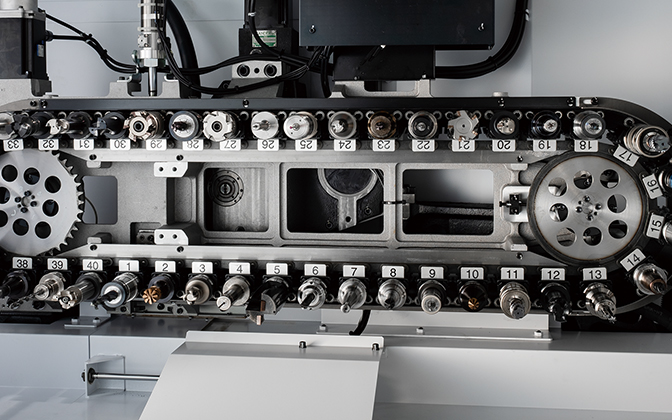

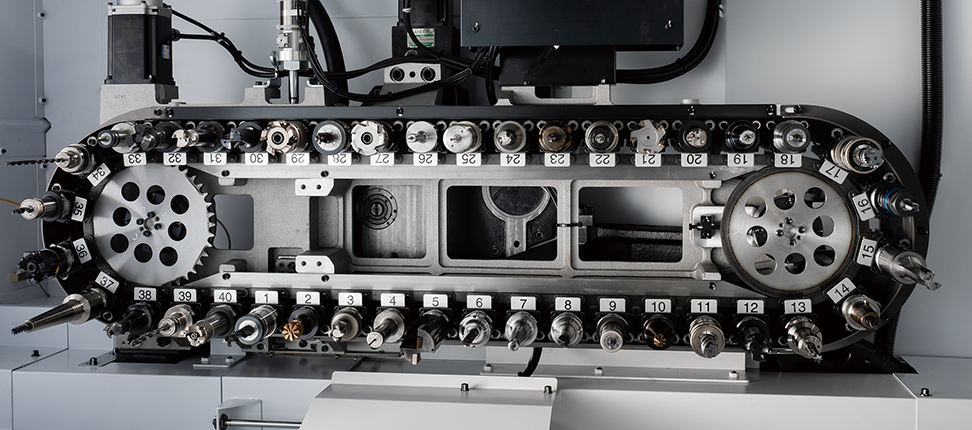

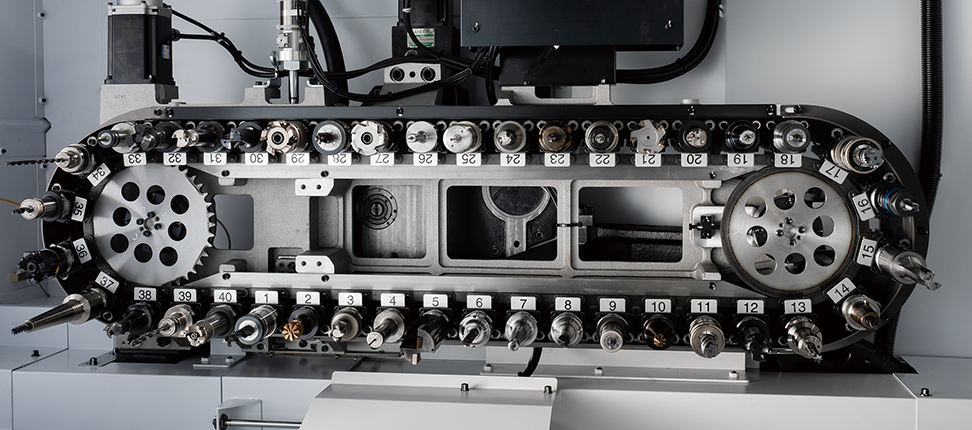

28 magazines

A compact turret-type 28-tool magazine has been newly developed, inheriting the high-speed tool change function,

enabling an expansion of the parts that can be machined and facilitating process integration.

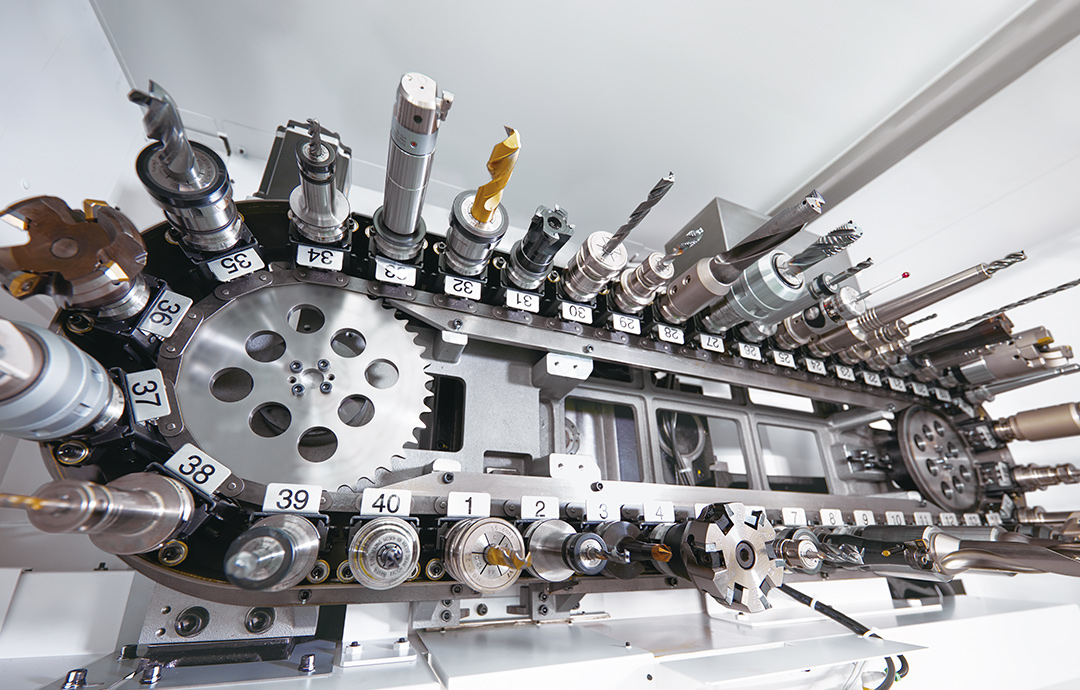

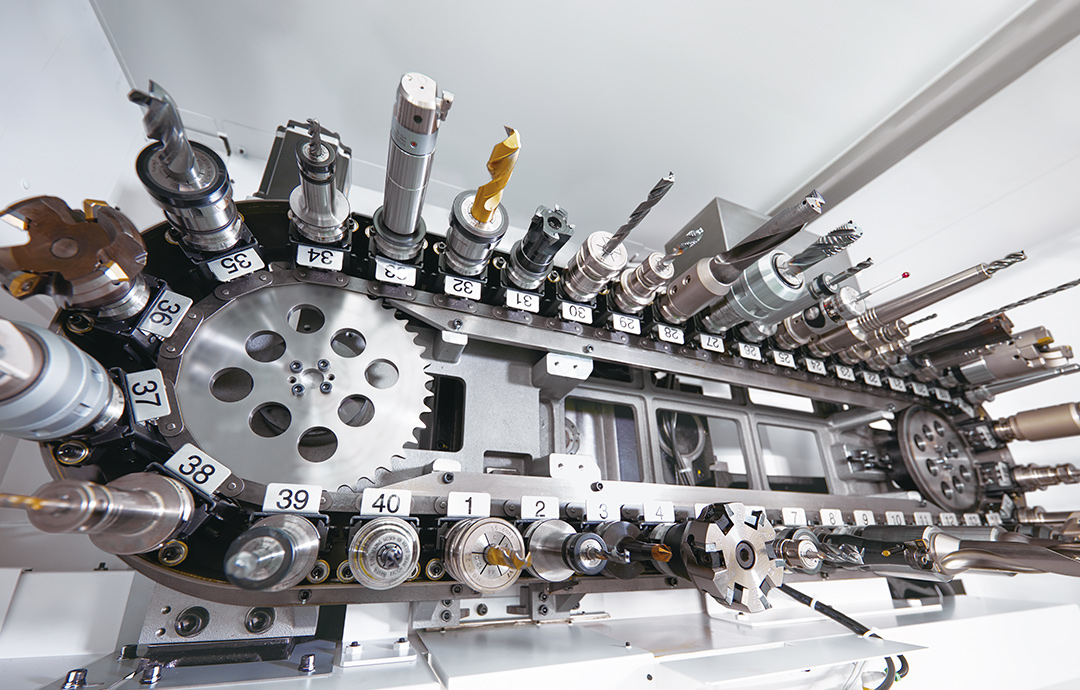

40 magazine (R650Xd1)

In addition to 14/22/28 magazines, it is equipped with a 40-magazine. Utilizing the two-sided pallet,

it promotes process integration and contributes to improved productivity.

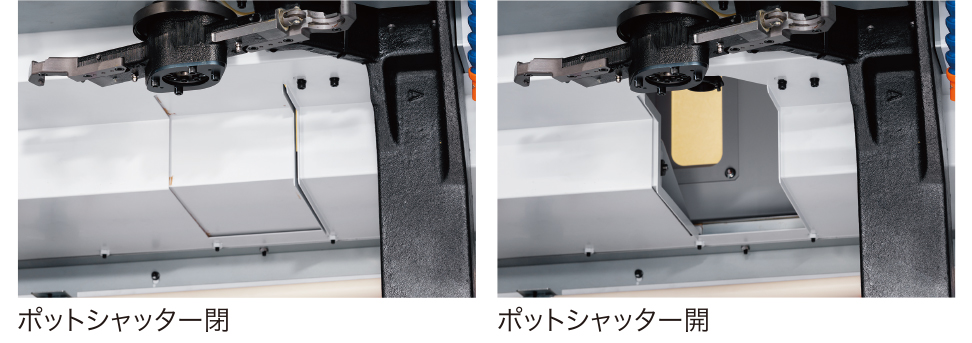

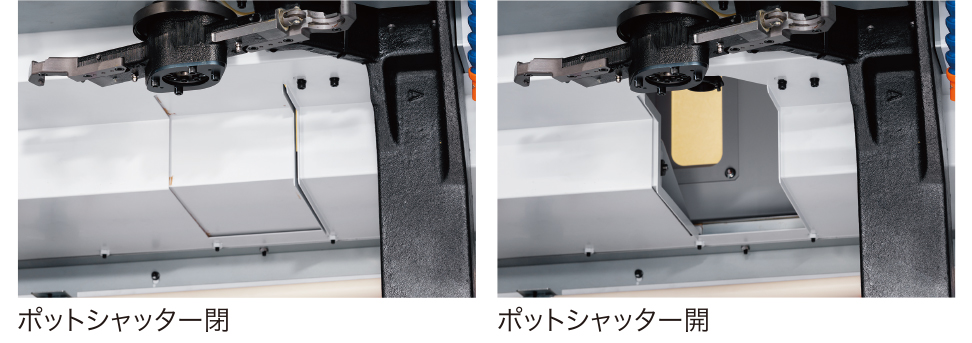

The 40-tool magazine has a shutter door separating the machining chamber and tool chamber,

preventing chips from entering the magazine.

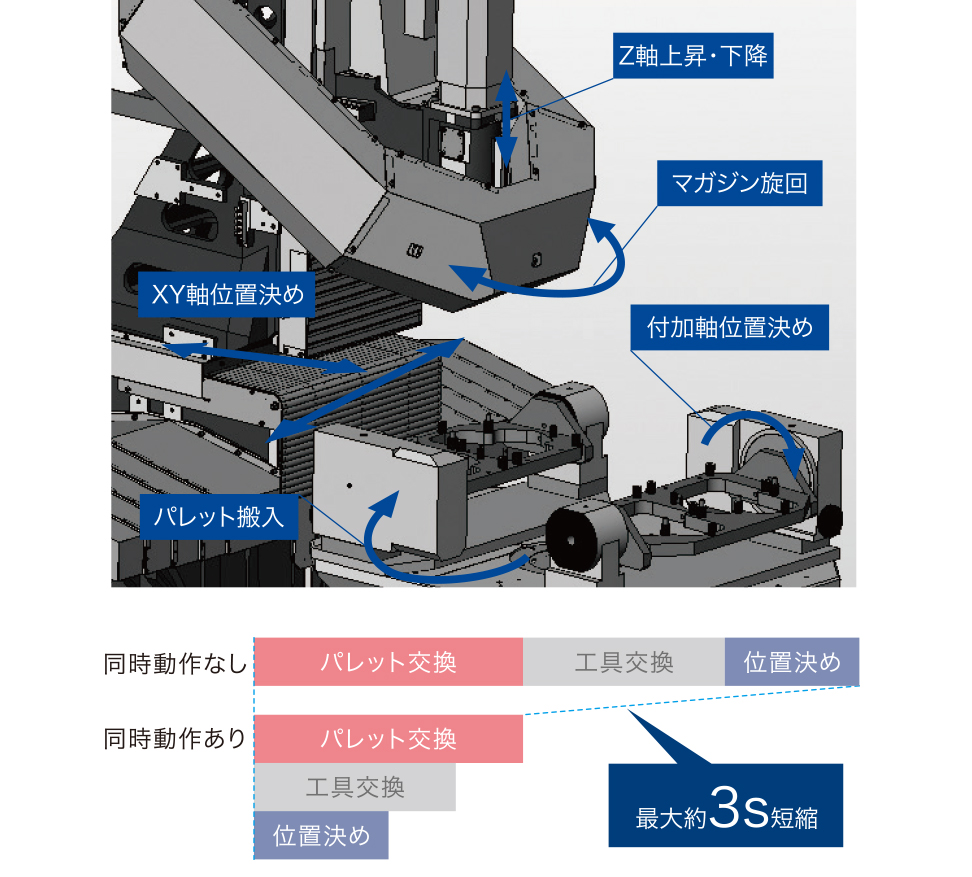

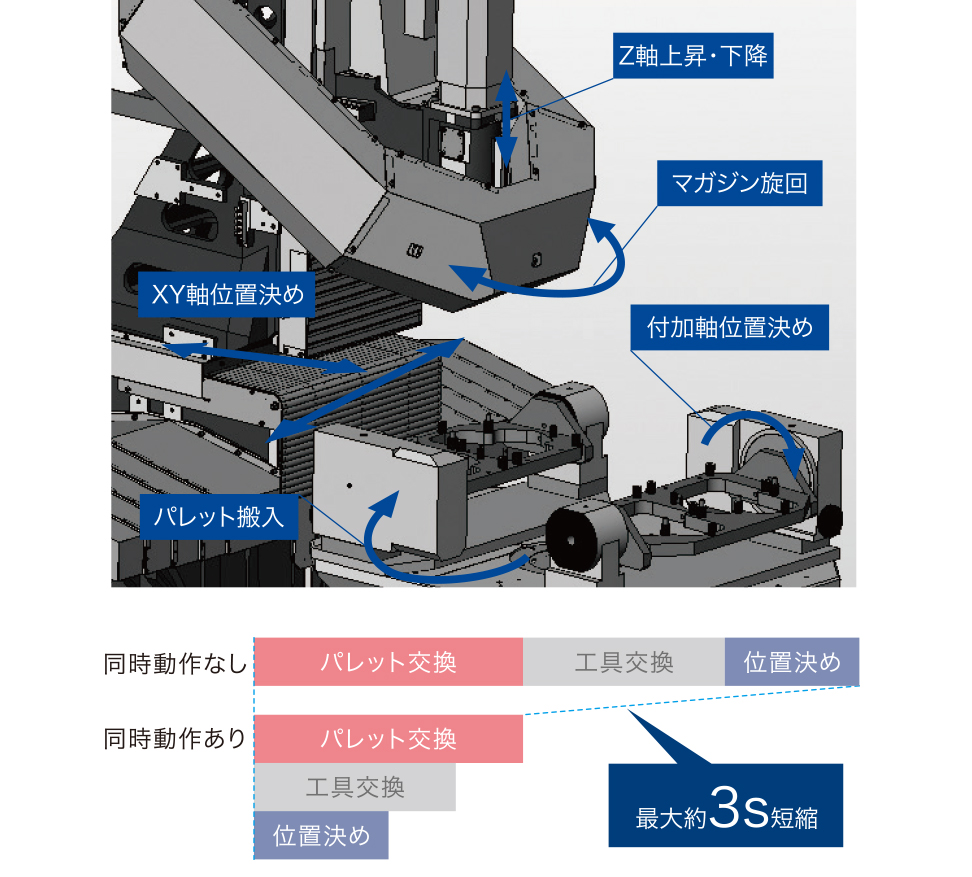

Simultaneous Operation

Equipped with simultaneous motion control that rotates the QT table and positions the XY and additional axes while changing tools . No time is wasted changing pallets.

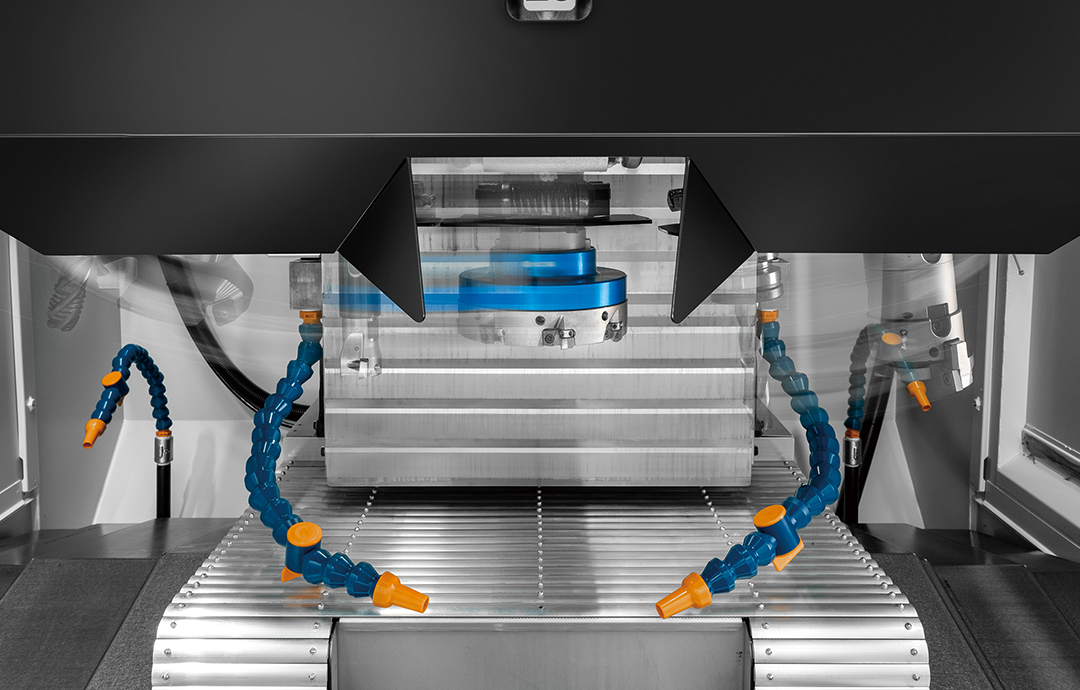

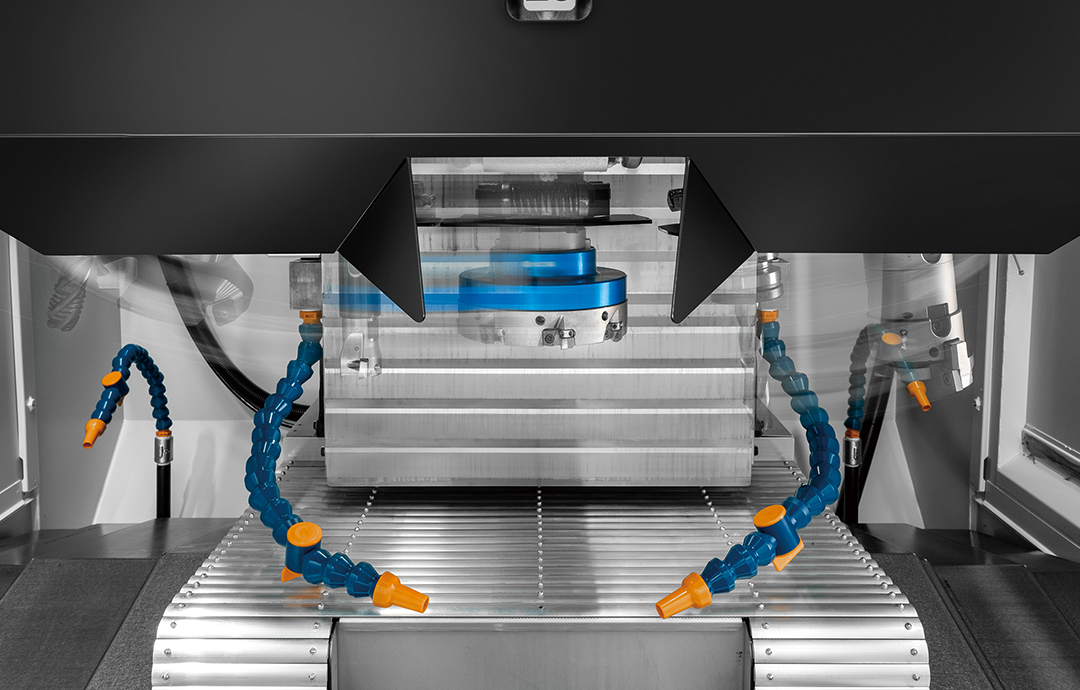

Processing Capability

Demonstrates a wide range of cutting power from high-speed, high-efficiency machining to heavy-duty cutting

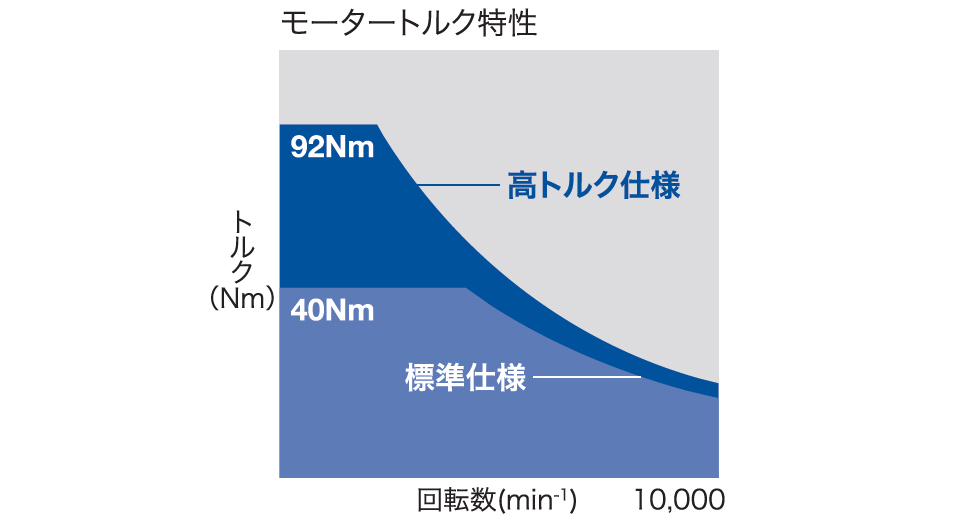

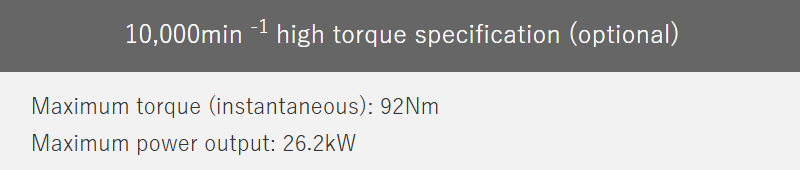

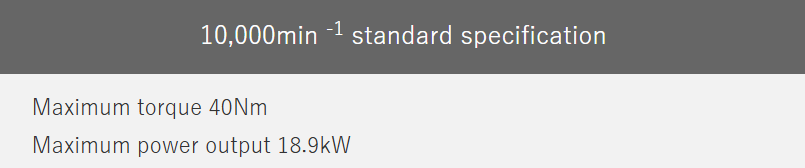

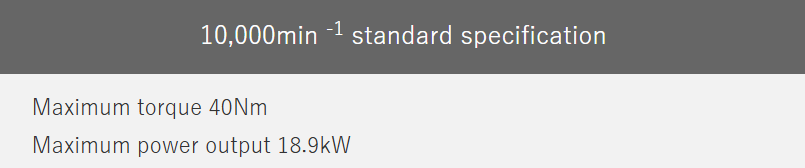

Our lineup of spindle motors features high mechanical rigidity andhigh torque thanks to their special design,

achieving stable machining and high machining capacity over a wide range.

From heavy cutting to high-speed, high-efficiency machining

The high torque spindle motor at medium and high speeds enables high-speed, highly efficient machining. Furthermore, the high torque specification (optional) significantly improves the torque at low speeds,

making it effective for heavy cutting of steel.

From heavy cutting to high-speed, high-efficiency machining

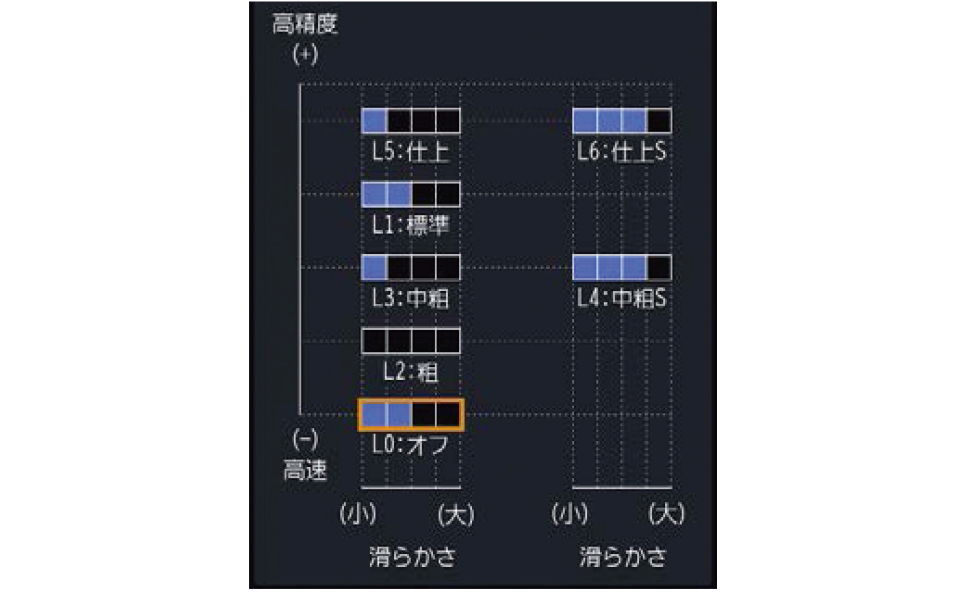

In addition to the highly responsive servo, the processing speed and resolution of the servo system have been greatly improved. The number of look-ahead blocks has been greatly increased, and the surface quality of the smooth path compensation function has been improved. Through the high performance of our unique 3D machining control, we have achieved high-speed, high-precision 3D machining.

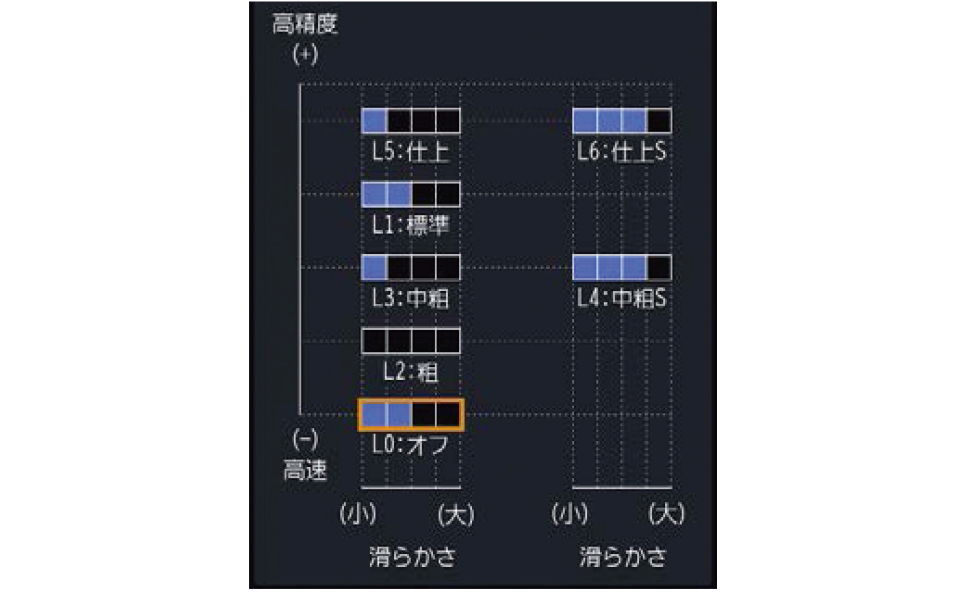

Easy setting of high-precision mode

The parameters for machining accuracy and surface quality can be adjusted with simple operations, making it easy to achieve high-quality machining.

High accuracy mode BI, 160 blocks look ahead

High accuracy mode BII (optional), 1000 blocks look ahead

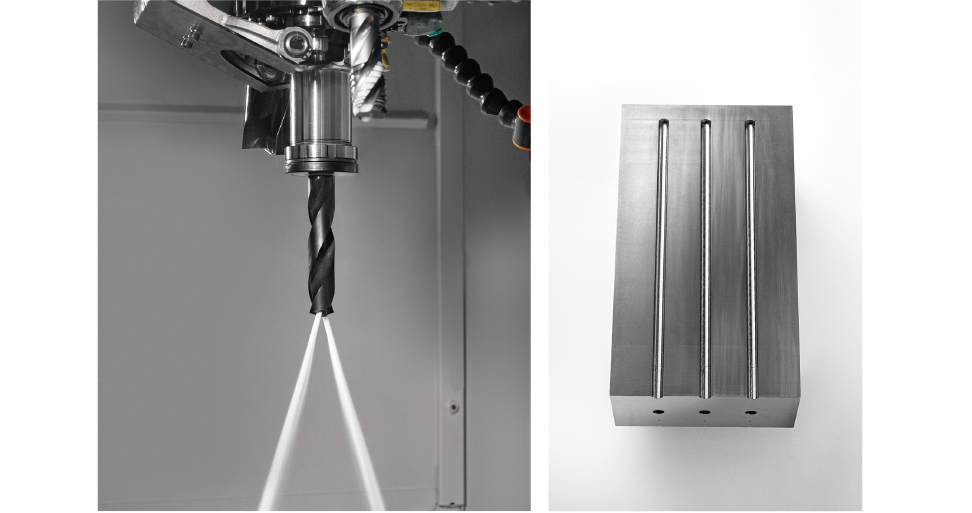

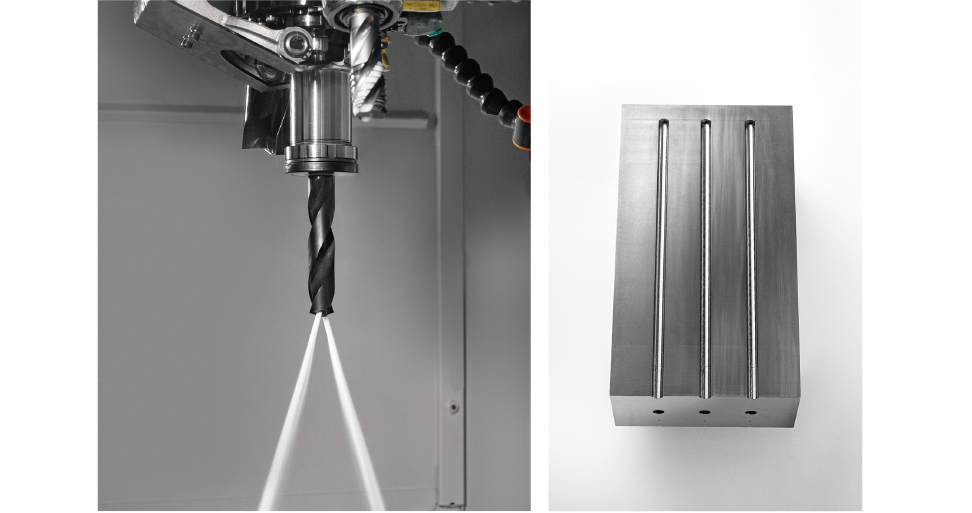

7MPa high pressure coolant through spindle (CTS) available (optional)

The coolant through spindle (CTS) is available with optional pressure resistance of 3MPa or 7MPa, which is effective for high speed drilling and deep hole processing.

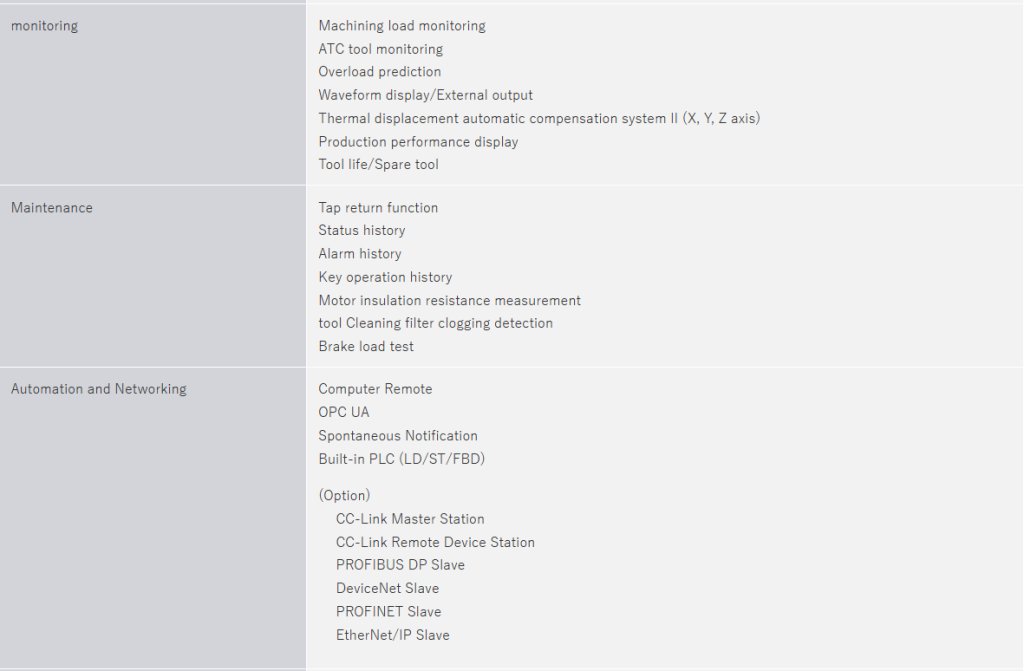

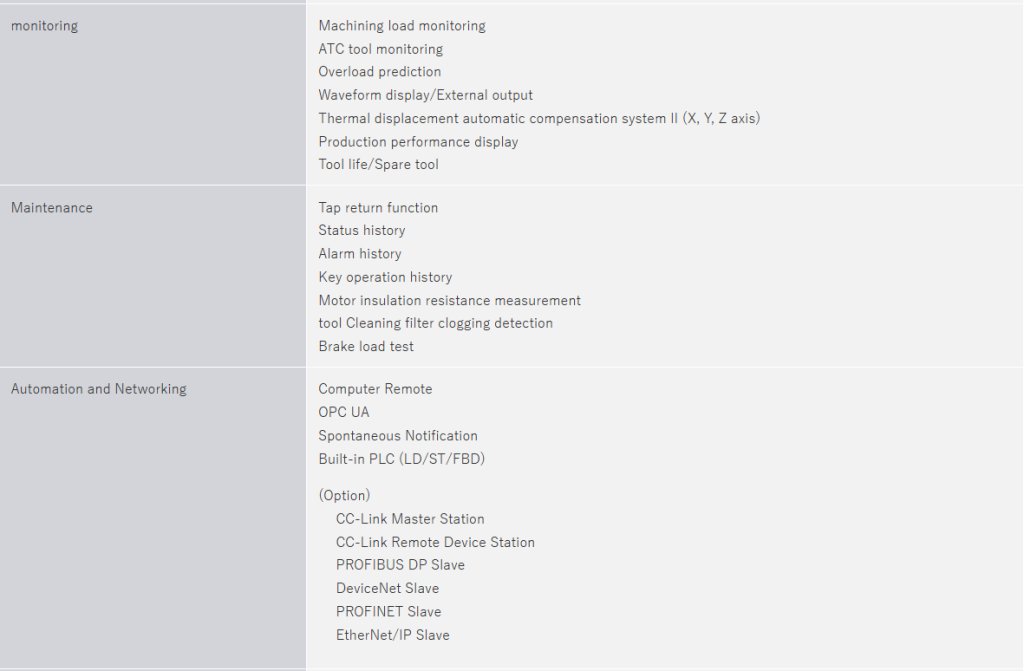

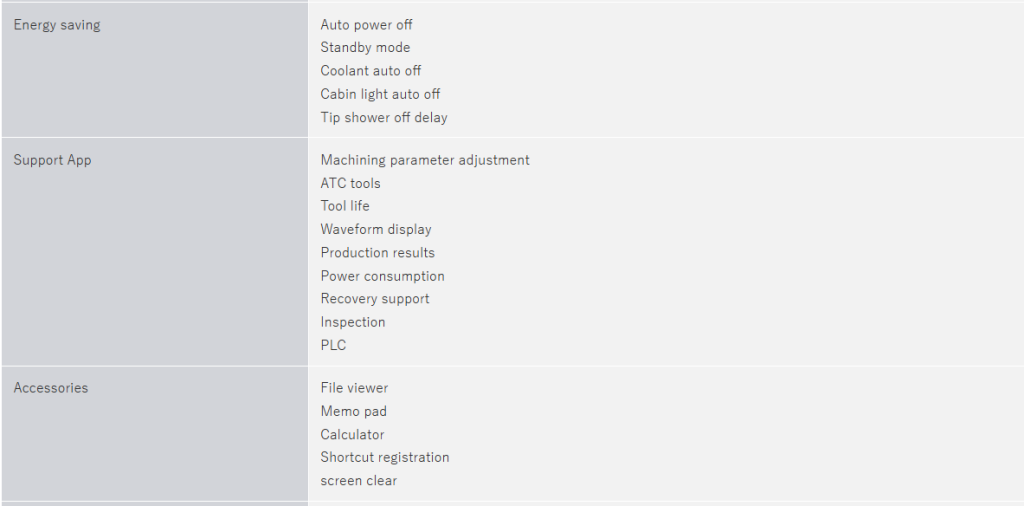

NC unit

Equipped with the newly developed “NC-D00 control device”

Pursuing ease of use with a 15-inch touch panel LCD

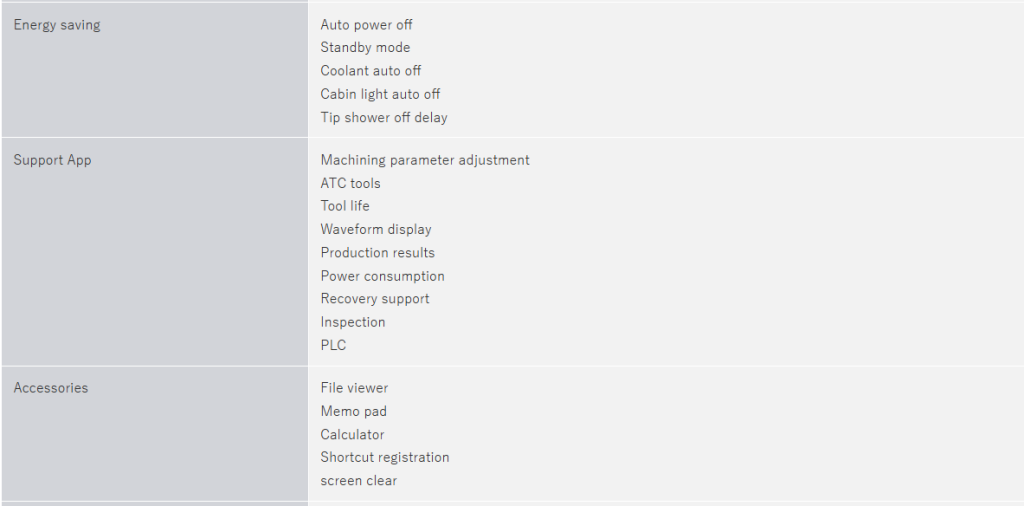

Functions related to setup and processing are consolidated to efficiently operate, visually display production and operating status, and quickly grasp the status. Work can be carried out efficiently in each process of setup, processing adjustment, production and recovery, contributing to improved work efficiency and operation rate.

New User Interface

New support apps have been developed that consolidate related functions and provide visual displays for improved ease of use and visibility. The app also comes equipped with convenient functions such as a calculator, memo pad, and file viewer, and operation via the conventional screen can now be easily achieved with the touch panel, greatly improving usability.

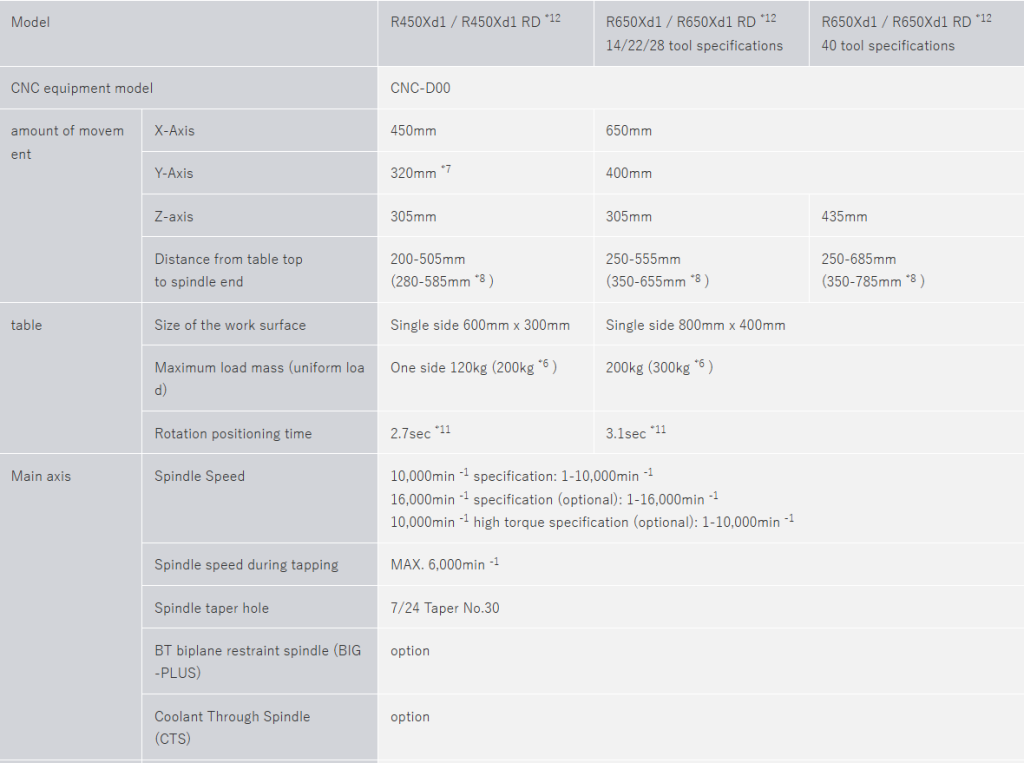

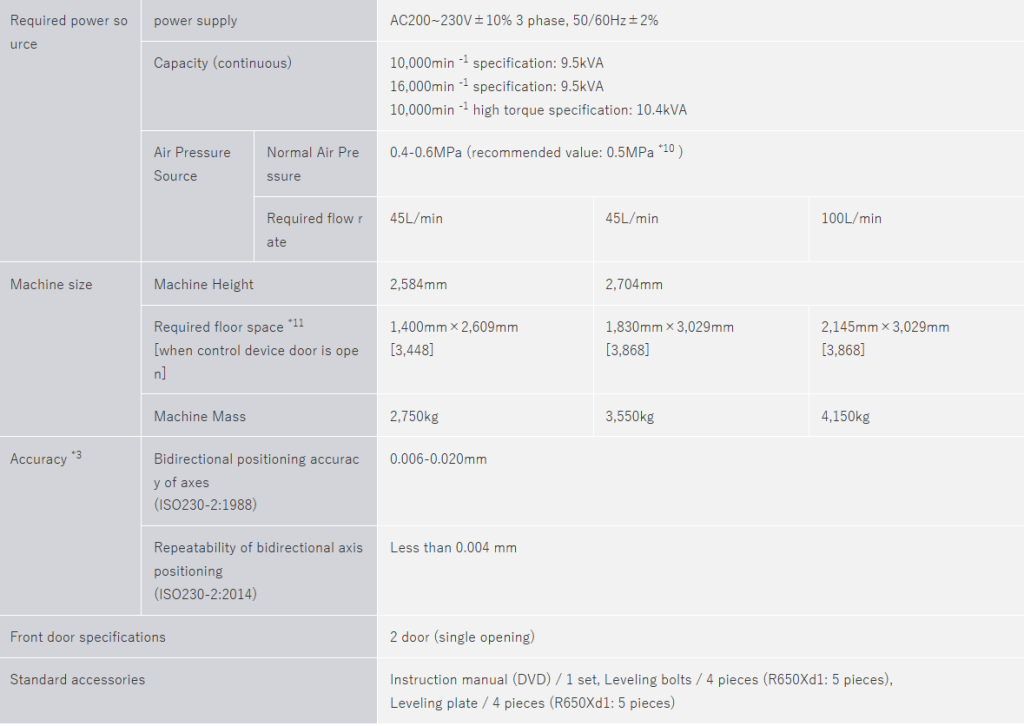

Mechanical Specifications

*1 The maximum weight of a tool varies depending on its shape, center of gravity, etc., so please consider this value as a reference only.

*2 The spindle motor output varies depending on the rotation speed.

*3 The measurement method is based on ISO and Brother standards. Please contact us for details.

*4 The pull studs for CTS are Brother specifications.

*5 The tool change time measurement method is based on JIS standard B6336-9 and MAS011-1987.

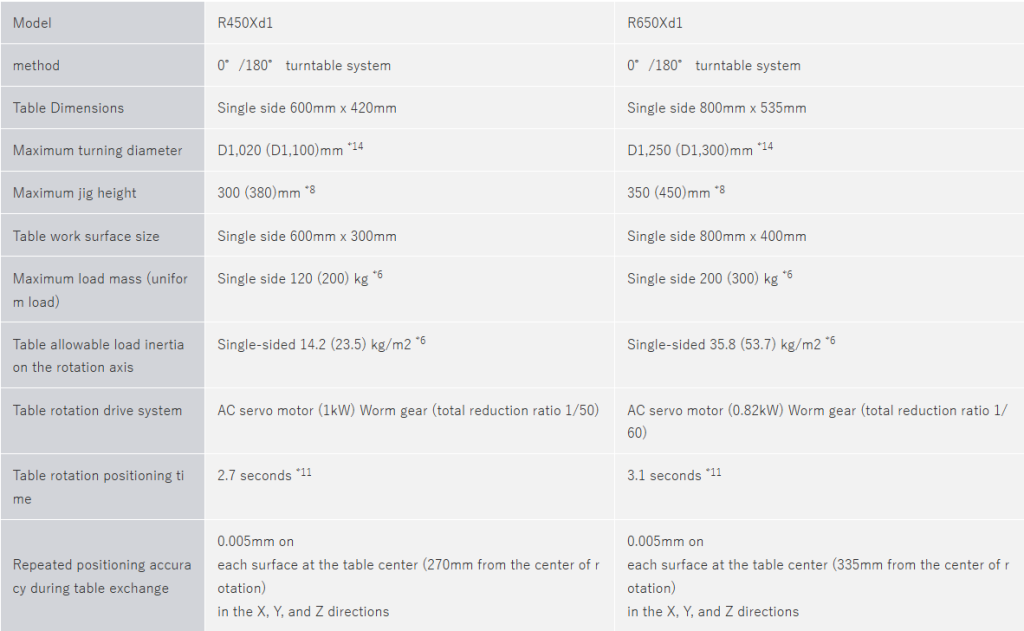

*6 By changing the parameters, it is possible to support up to 200kg for the R450Xd1 and 300kg for the R650Xd1 (one side). Please contact us for details.

*7 When using a hydraulic rotary joint, the Y-axis travel distance is 290 mm.

*8 This is the value when a low-floor table is selected.

*9 This is the value when using high precision mode B.

*10 The normal air pressure will vary depending on the machine specifications, processing program contents, and usage of peripheral devices, so please set a pressure higher than the recommended value.

*11 Values when load mass is R450Xd1: 120kg, R650Xd1: 200kg (one side).

*12 Depending on the destination, a relocation detection device may be required. Models equipped with a relocation detection device have “RD” at the end of their model names.

*13 This value does not include the coolant tank and chip conveyor.

*14 This is the value when the Enlarged Turning Diameter (optional) is selected.

QT table specifications

* The QT table is a turntable type two-sided pallet changer.

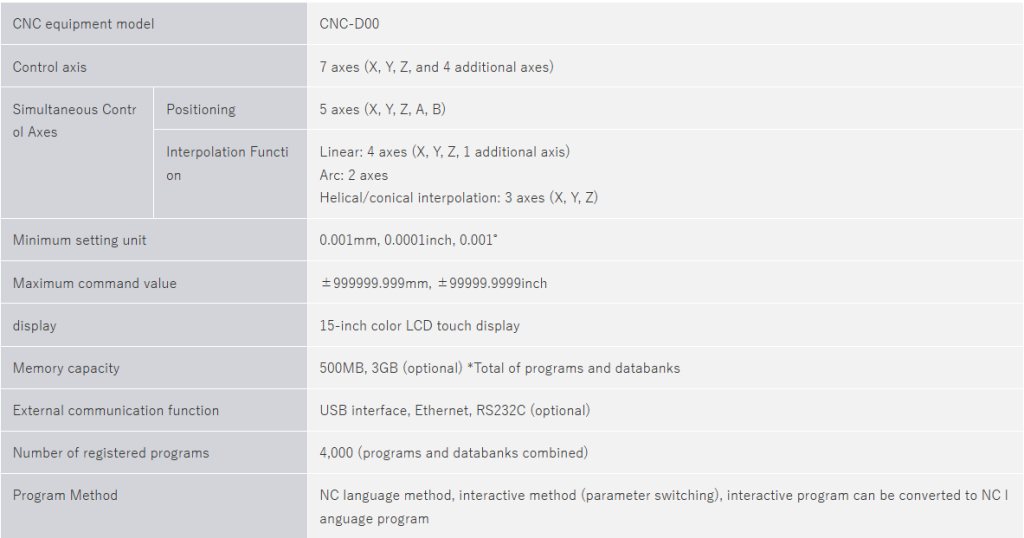

NC unit specifications

* “Number of controlled axes” and “Number of simultaneously controlled axes” are the maximum numbers of axes and vary depending on the destination and specifications.

* Ethernet is a registered trademark of XEROX Corporation in the United States

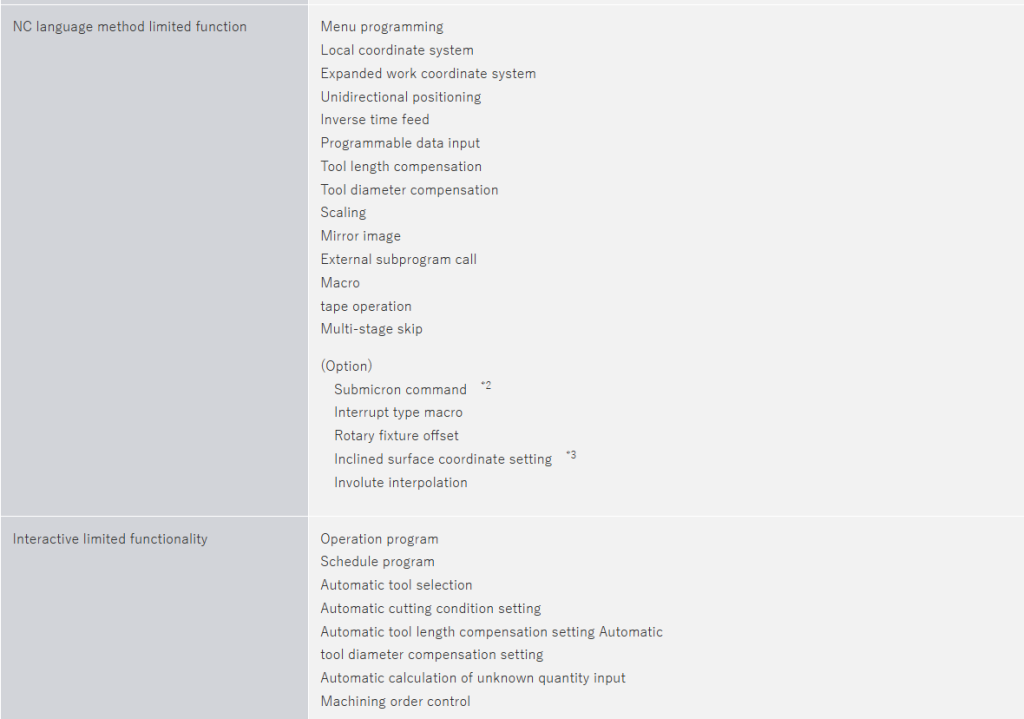

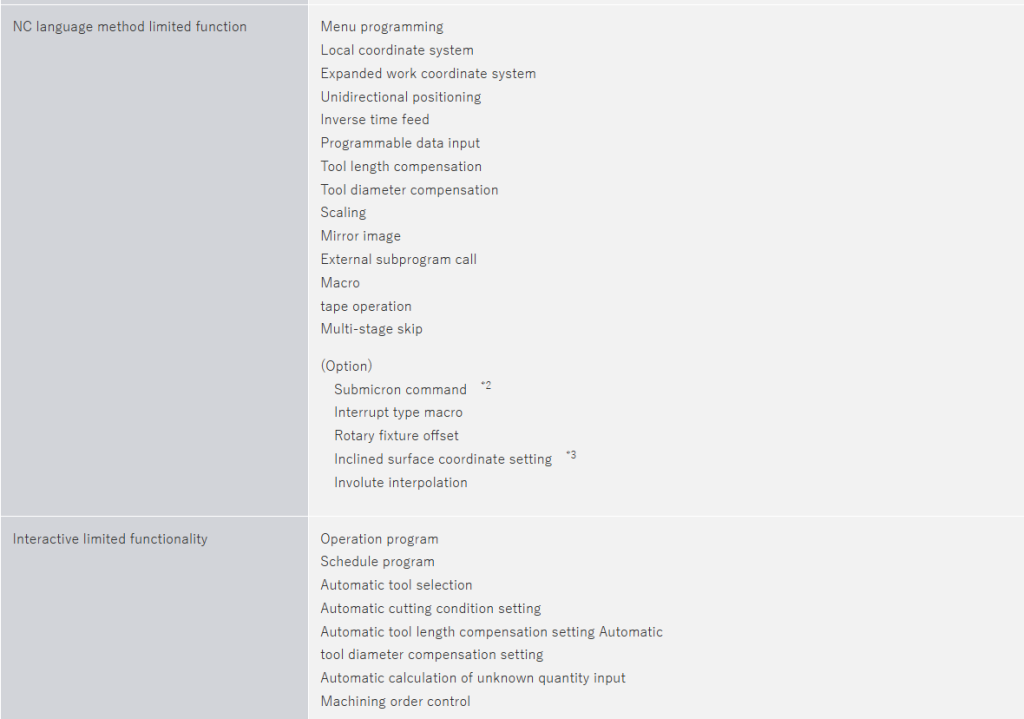

NC Function

*1 Please prepare your own measuring equipment.

*2 When a submicron command is selected, switching to an interactive program is not possible.

*3 There are limitations to the axis configuration

Processing Examples

Precision Equipment

| Part Name | Watch Plate |

|---|---|

| Material | brass |

| Part Name | L-bracket |

|---|---|

| Material | SUS316L |

Value

| Part Name | Gas Control Valve |

|---|---|

| Material | SUS316L |

| Part Name | L-bracket |

|---|---|

| Material | SUS316L |

Car

| Part Name | Aluminum wheels |

|---|---|

| Material | Aluminum alloy |

| Part Name | ABS valve housing |

|---|---|

| Material | Aluminum alloy |

| Part Name | Brake calipers |

|---|---|

| Material | cast iron |