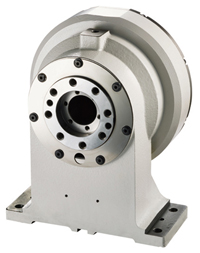

Rotary Table

SPEEDIO :

T-200A / T-200Ad

Features of the Rotary Table T-200A

Roller Gear Cam Mechanism

High precision

with no backlash

High productivity High productivity due to

the maximum rotation speed of 100 min -1

Long life,

minimal deterioration over time, and permanently maintains high accuracy

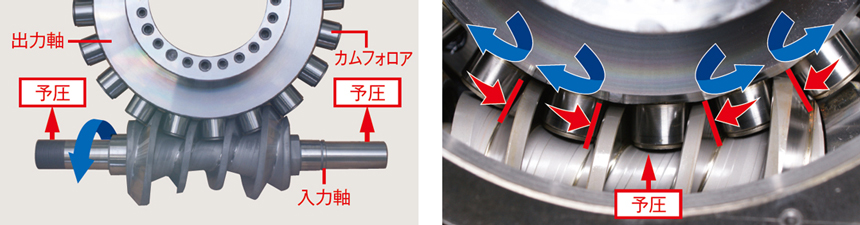

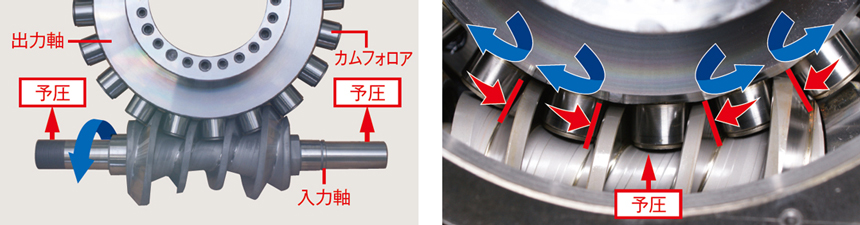

Roller Gear Cam Mechanism

The preload applied to the input and output shafts keeps the four cam followers in contact with the cam surfaces at all times, realizing no backlash and high rigidity. Furthermore, the rotating cam followers can transmit the motor torque efficiently, so they rotate with low torque, wear-free even with long-term use, and no adjustment is required.

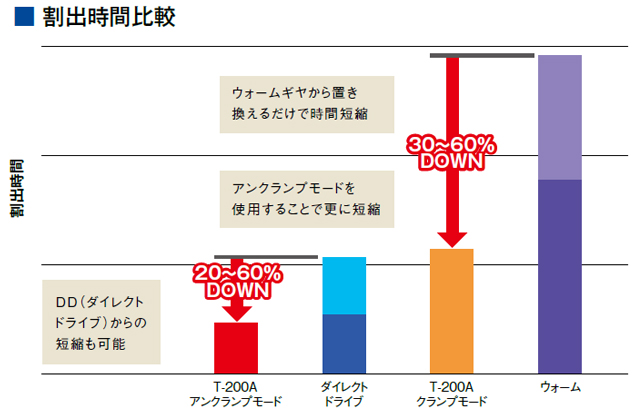

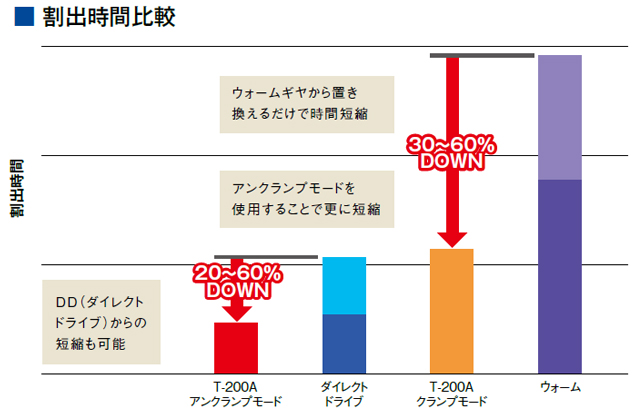

High Productivity

By combining a roller gear cam with an optimal motor, high acceleration and high rotation speed operation has been achieved. Also, depending on the processing load, processing can be performed by holding only with the motor torque without using a clamping mechanism.

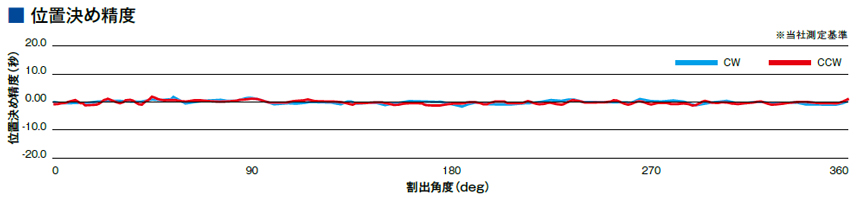

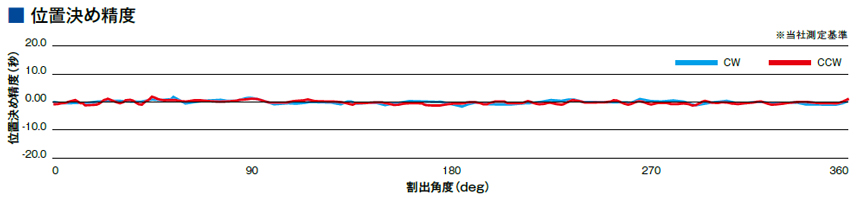

High accuracy

The preload given to the cam follower ensures that there is no backlash.

Even when the rotation direction is reversed, there is no adverse effect on the machined surface.

Support table

We provide the support table required for the cradle jig.

Clamp torque

330N・m

*: When clamp specification is selected

Rotary joint for main body

6P: Hydraulic/pneumatic (with center through port)

*: Please contact us separately regarding the rotary joint on the support table side.

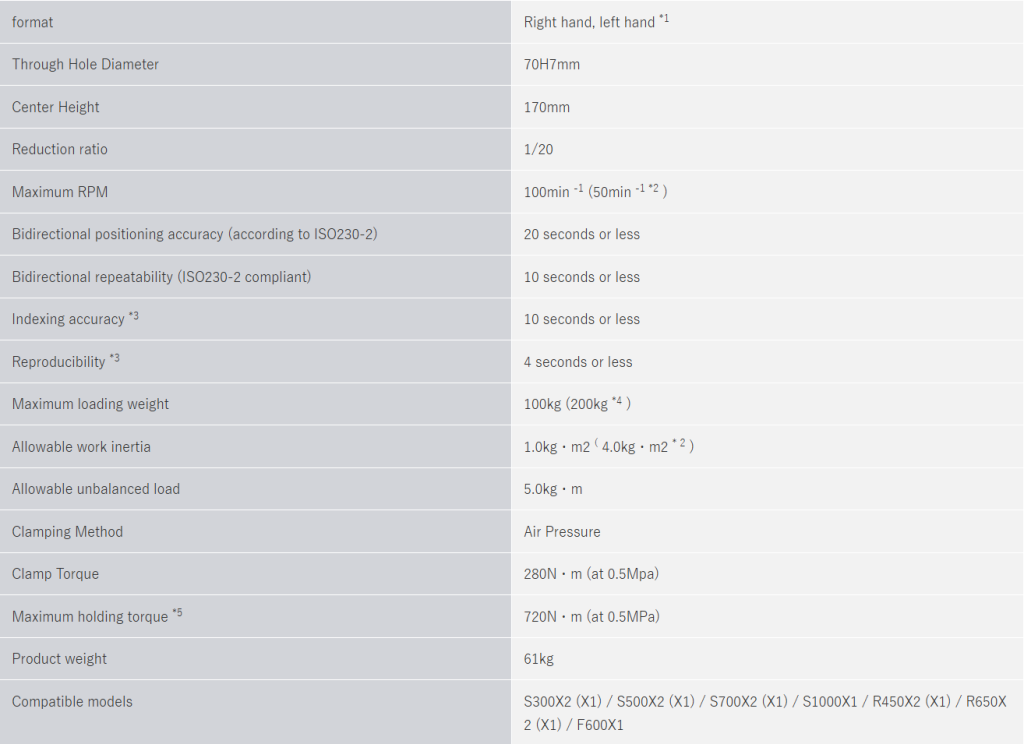

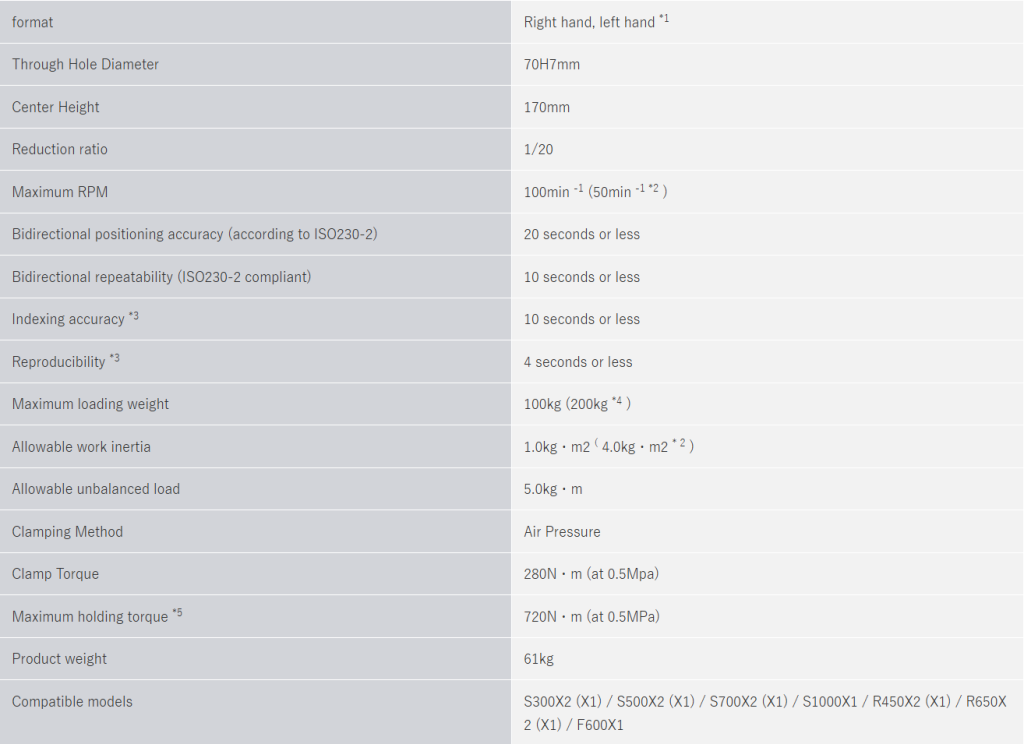

specification

*1: The R450X2(X1) and R650X2(X1) are only available in right-handed mode.

*2: In high inertia mode. You can change the parameters to high inertia mode.

*3: Our measurement standards.

*4: When using the support table.

*5: The value added to the clamp torque by the servo.