Brother W Series

SPEEDIO

W1000Xd2

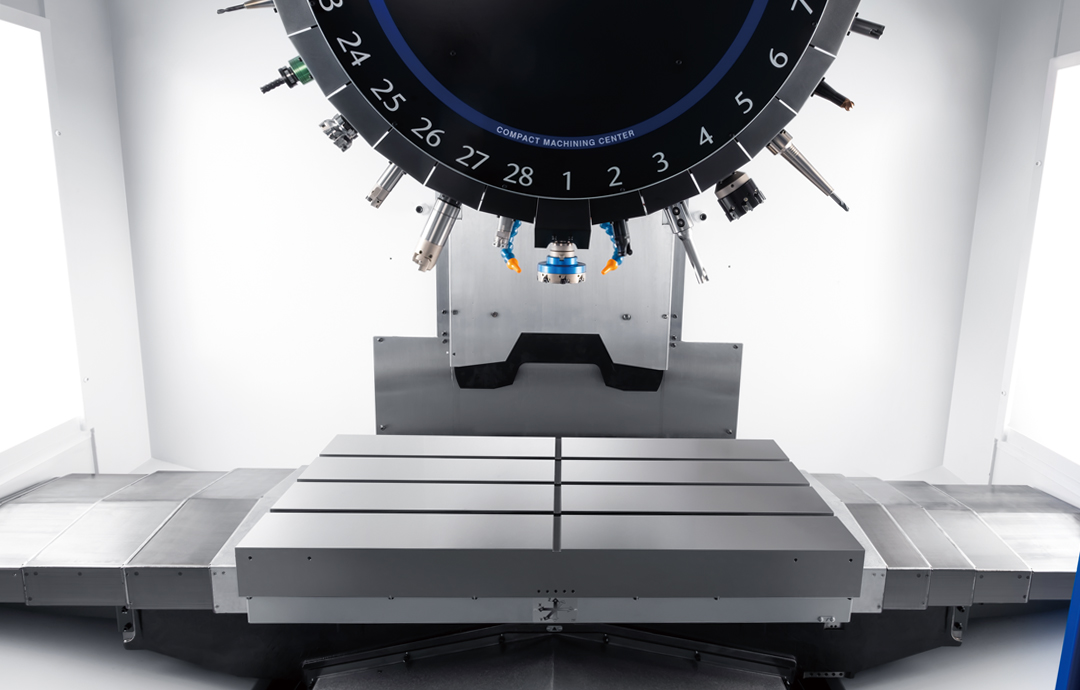

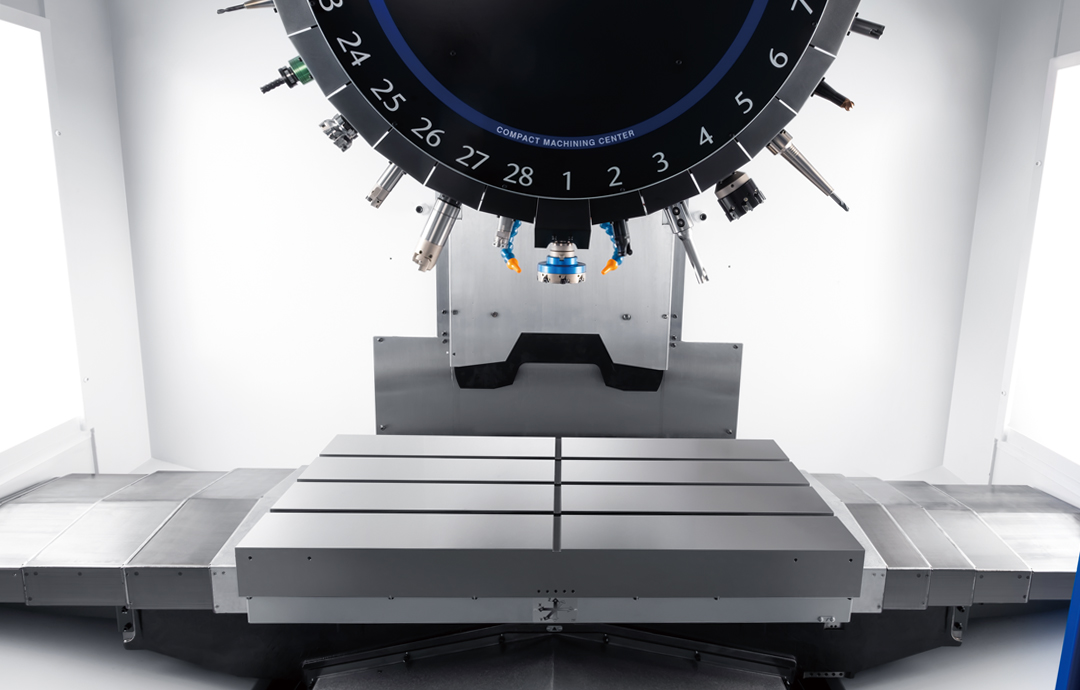

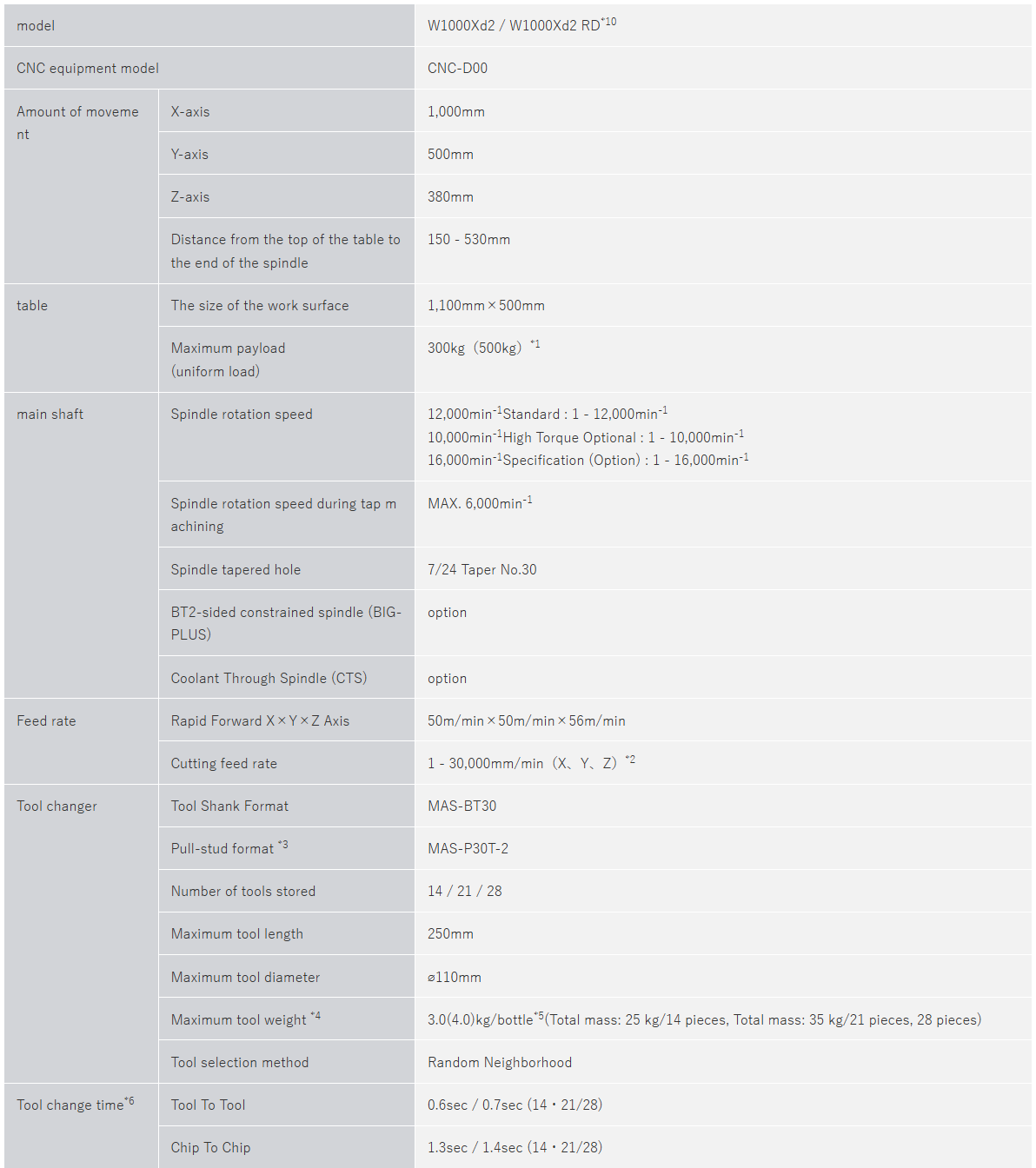

Equipped with a new 28-cylinder magazine, it promotes process consolidation of large workpieces. In addition, the maximum table loading capacity is 500 kg, and the Z-axis travel volume is expanded to support a wide variety of production systems.

Machining area

28 magazines, payload up to 500 kg, Z-axis travel expansion Further improvement of

the ability to handle large workpieces and high-mix low-volume workpieces

Productivity

Relentless pursuit of high productivity Reduction of waste through optimization control of integrated mechanical-electrical development

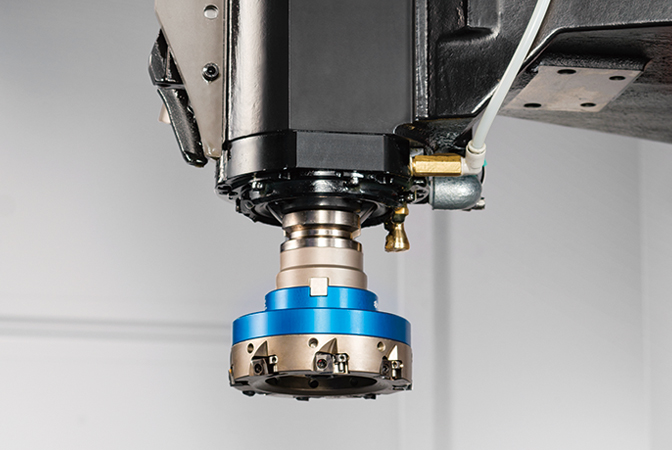

Processing Capability

High-efficiency spindle motor and high-rigidity mechanical structure support a wide range of processing

Operability

Equipped with a newly developed CNC-D00 control device that pursues ease of use, and also realizes accessibility that makes setup work easy

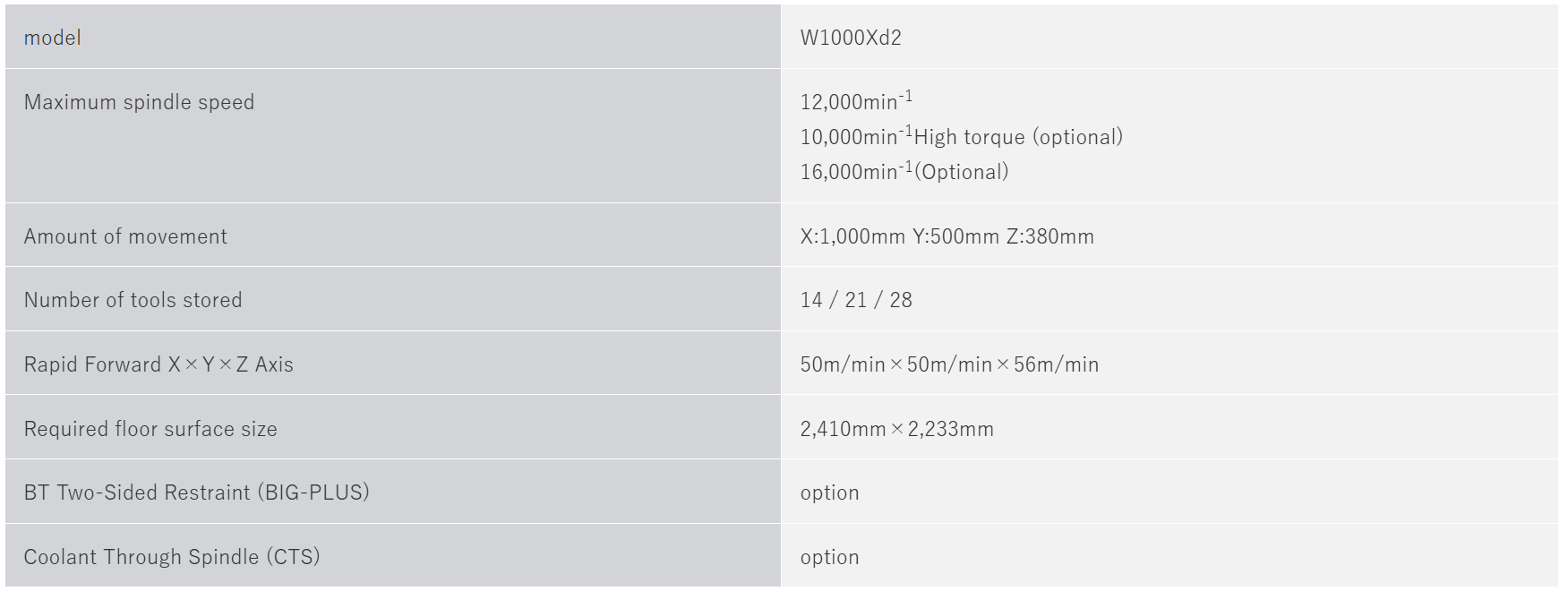

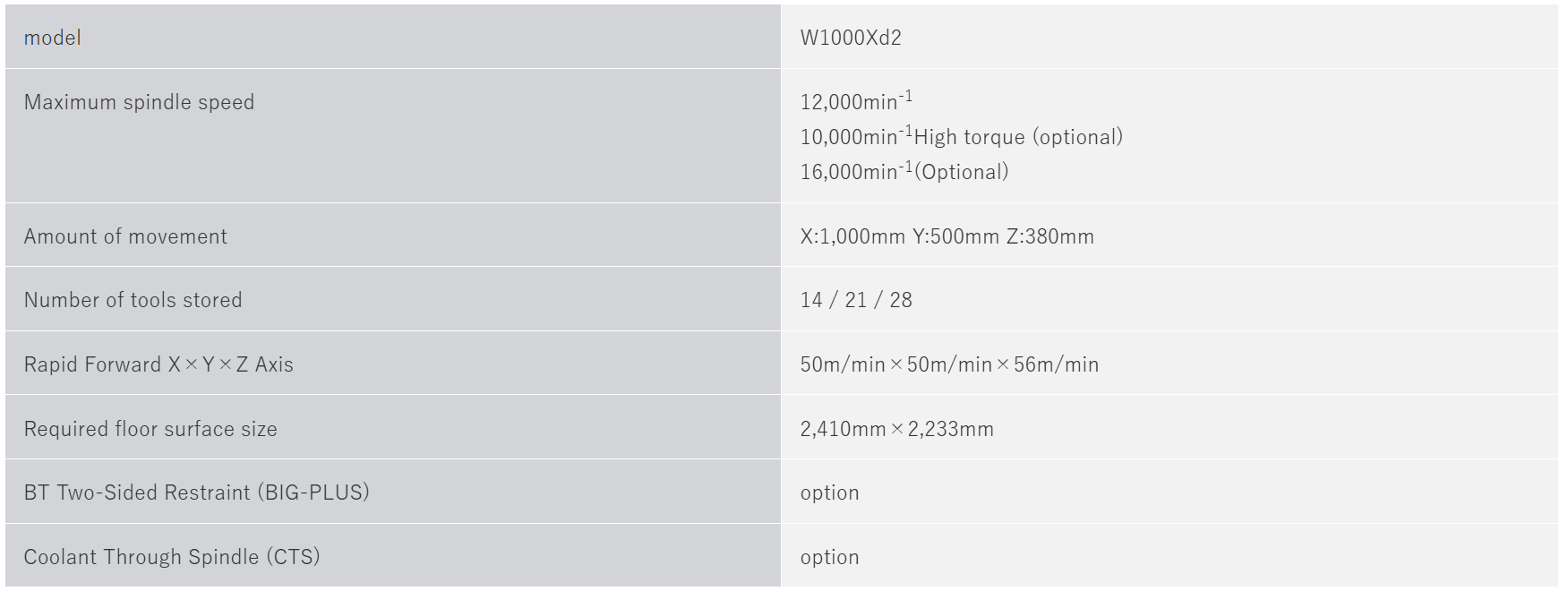

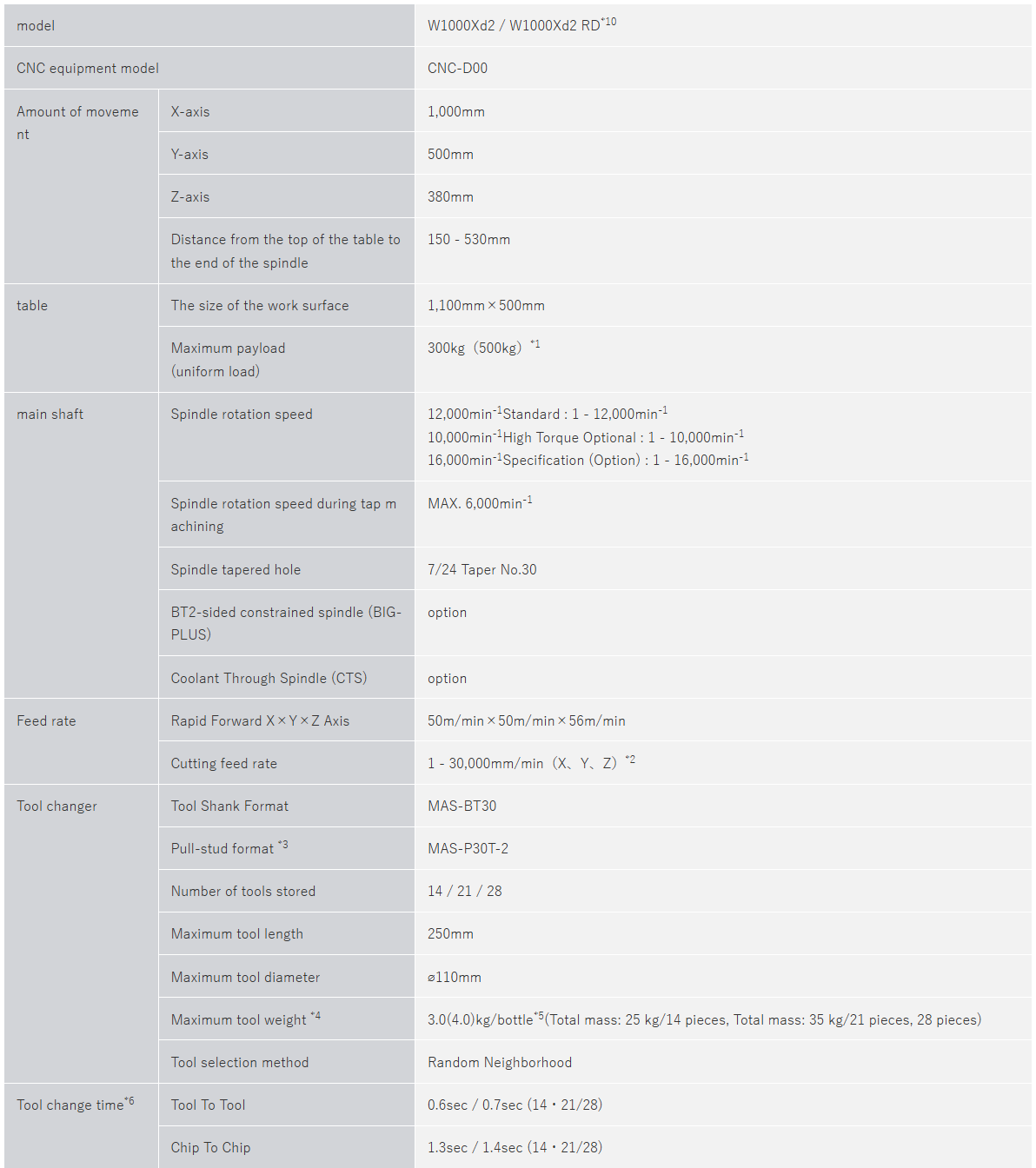

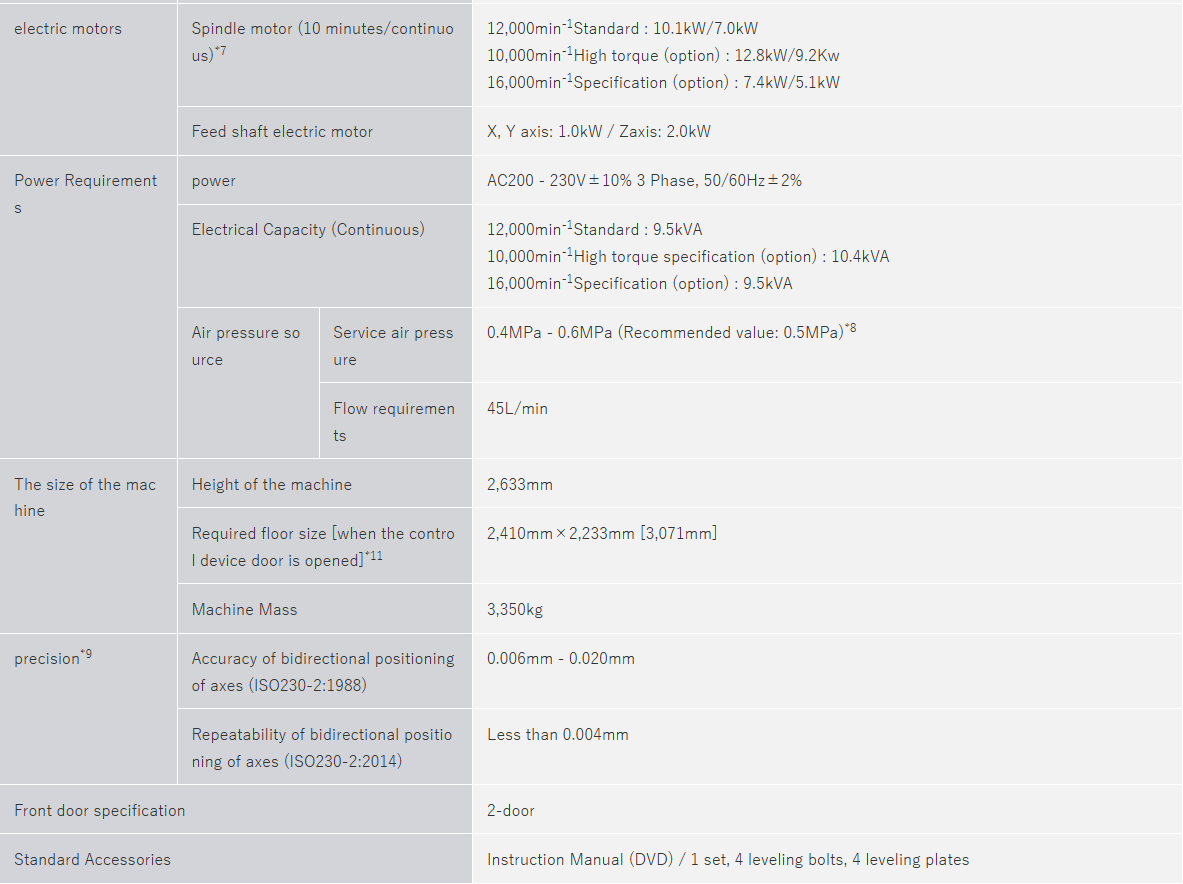

Specifications

Machining area

28 magazines, payload up to 500 kg, Z-axis travel expansion Further improvement of the ability to handle large workpieces and high-mix low-volume workpieces

In addition to the processing of large workpieces, the wide processing area responds to the ever-changing needs of the site, such as the processing of a large number of small parts, and the production of a wide variety of products in small quantities by placing a variety of jigs side by side, and increases the flexibility of the entire factory.

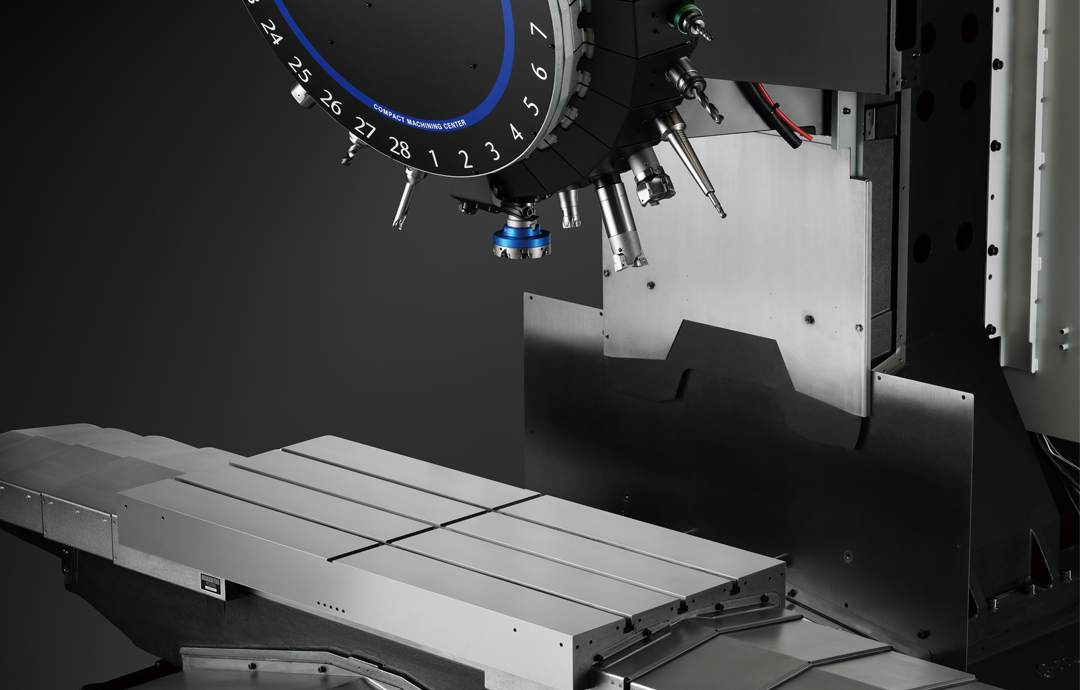

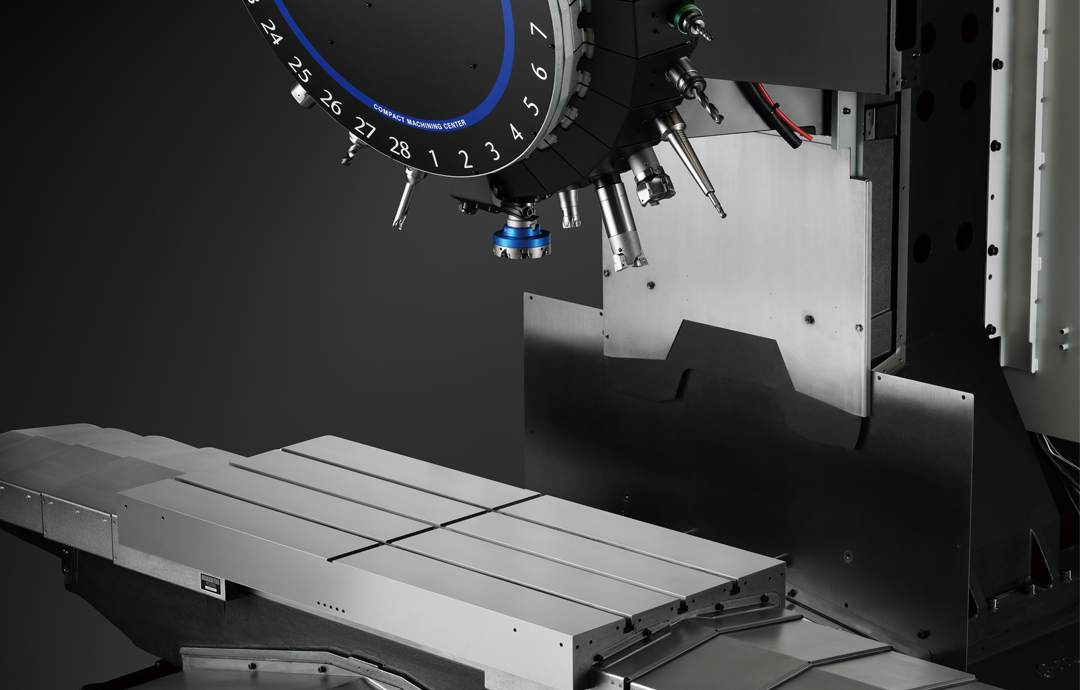

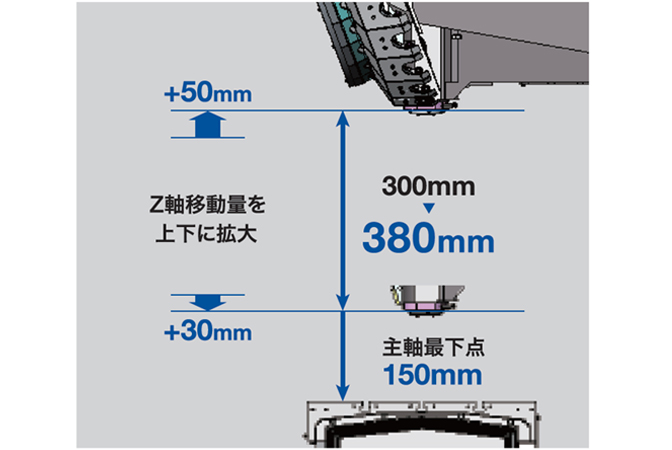

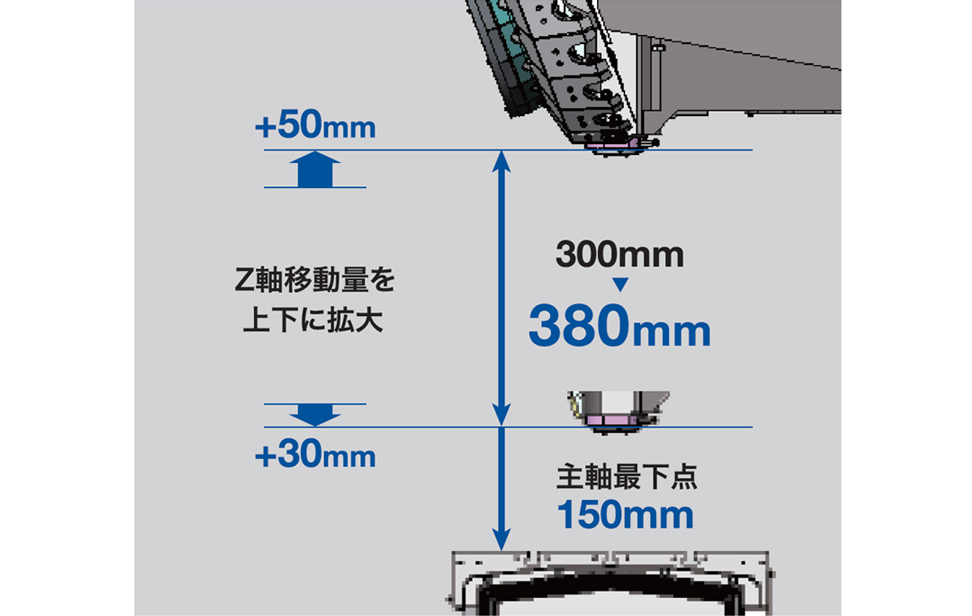

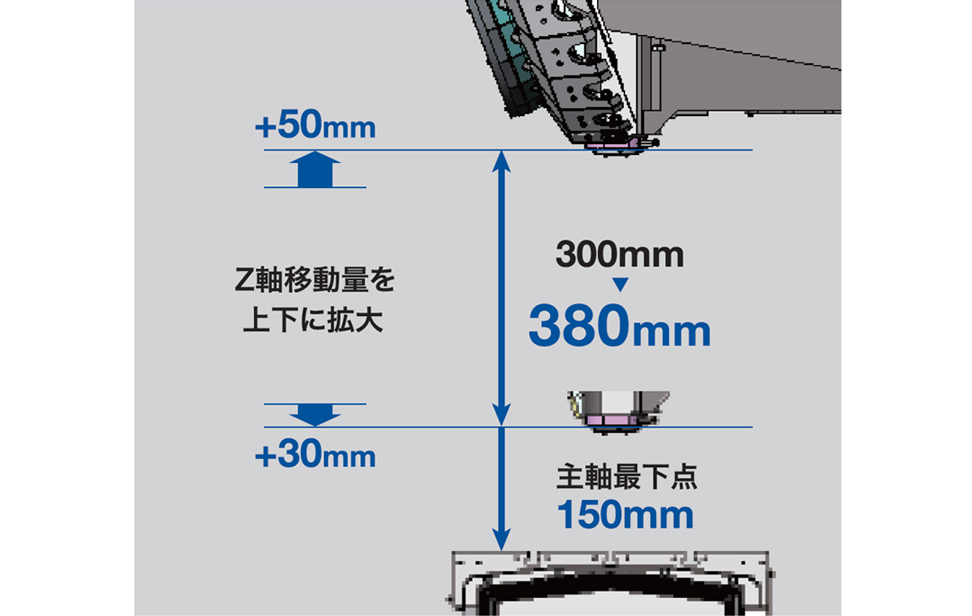

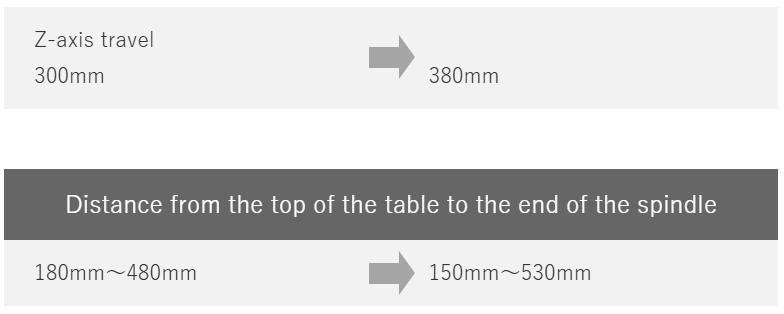

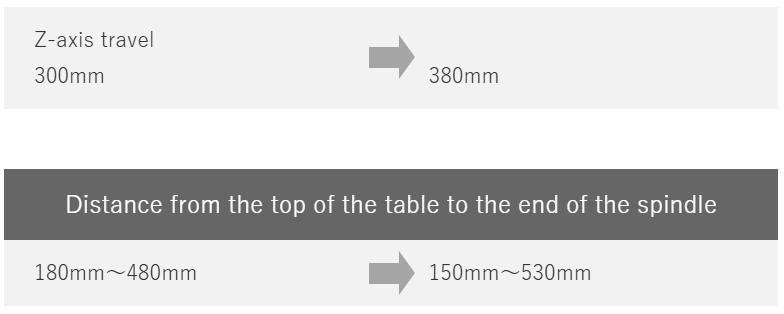

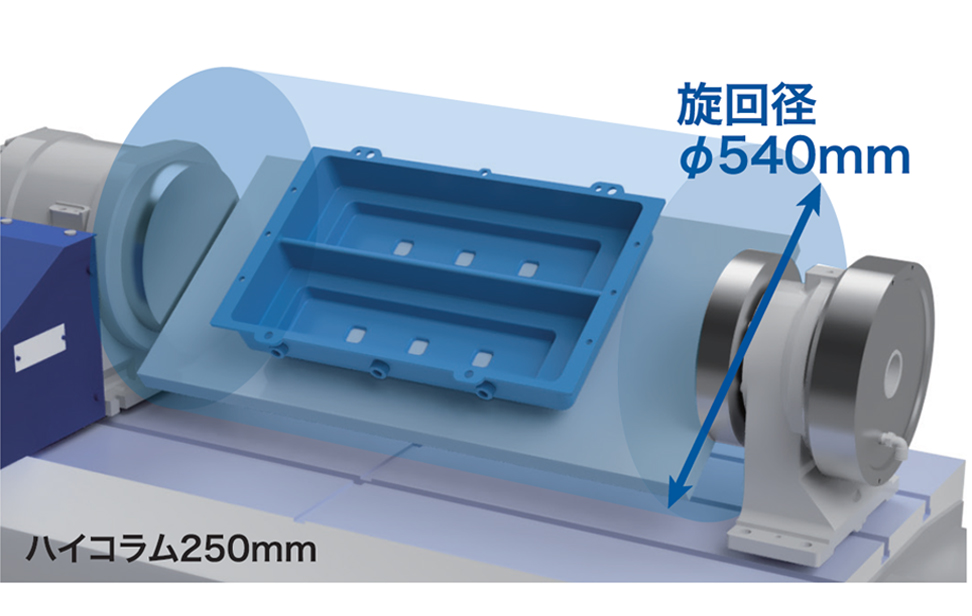

Increased Z-axis travel

By increasing the amount of travel in the Z-axis and increasing the distance from the top of the table to the end of the spindle up and down, a large machining area and improved tool accessibility in the Z-axis direction are achieved.

Increased table load

The maximum table load capacity has been increased to 500 kg. It expands the choice of jigs to support process consolidation and flexible fixture design.

Maximum payload: 500kg *

* Parameter settings need to be changed.

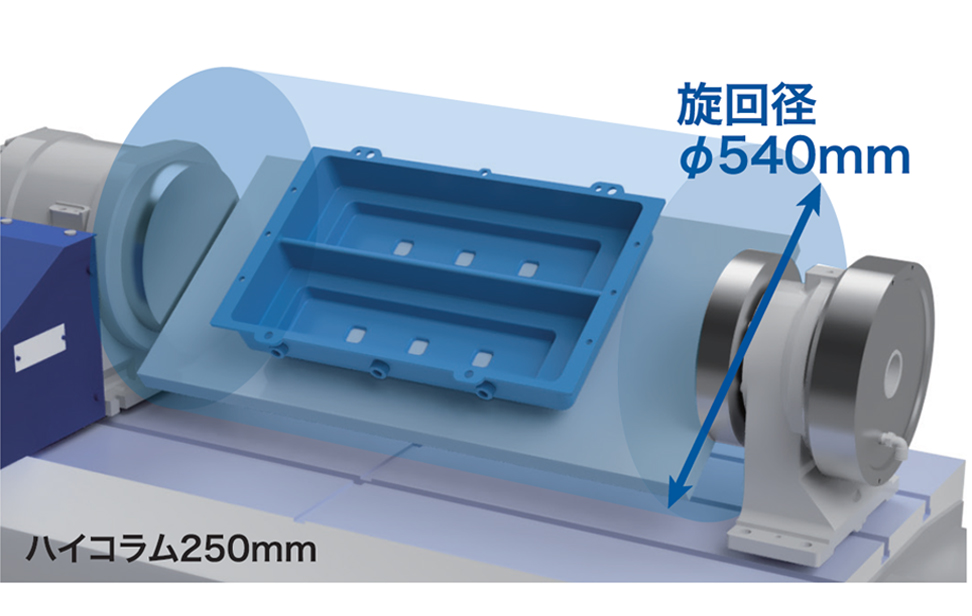

Large cradle jig can be mounted.

Depending on the application, high columns of 150, 250 and 350 mm are available. Multi-sided processing of large parts is possible with a cradle jig with a swivel diameter of 540 mm.

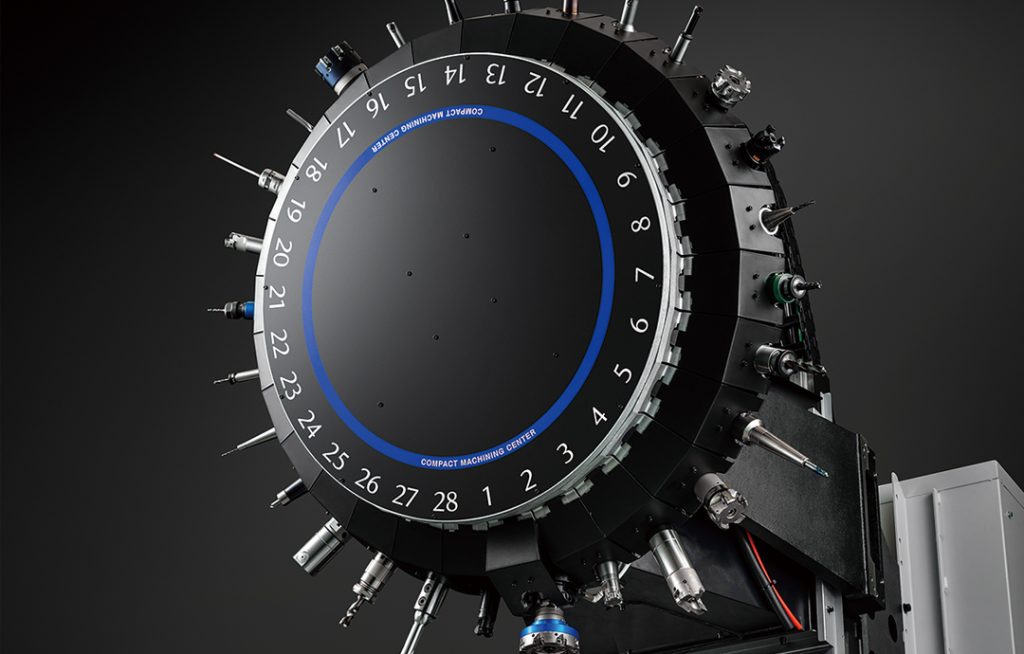

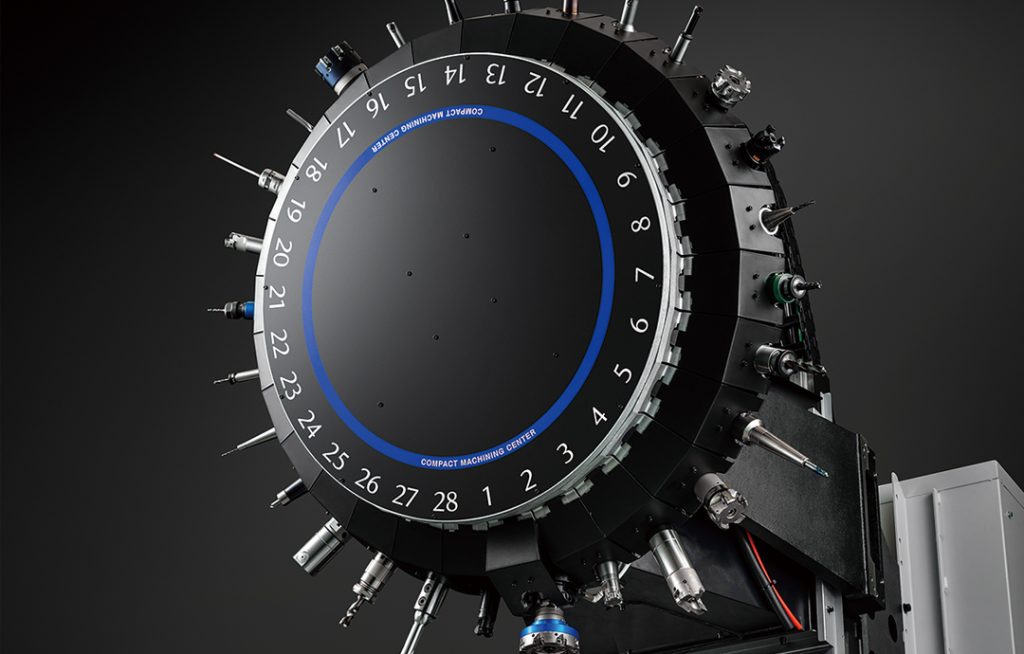

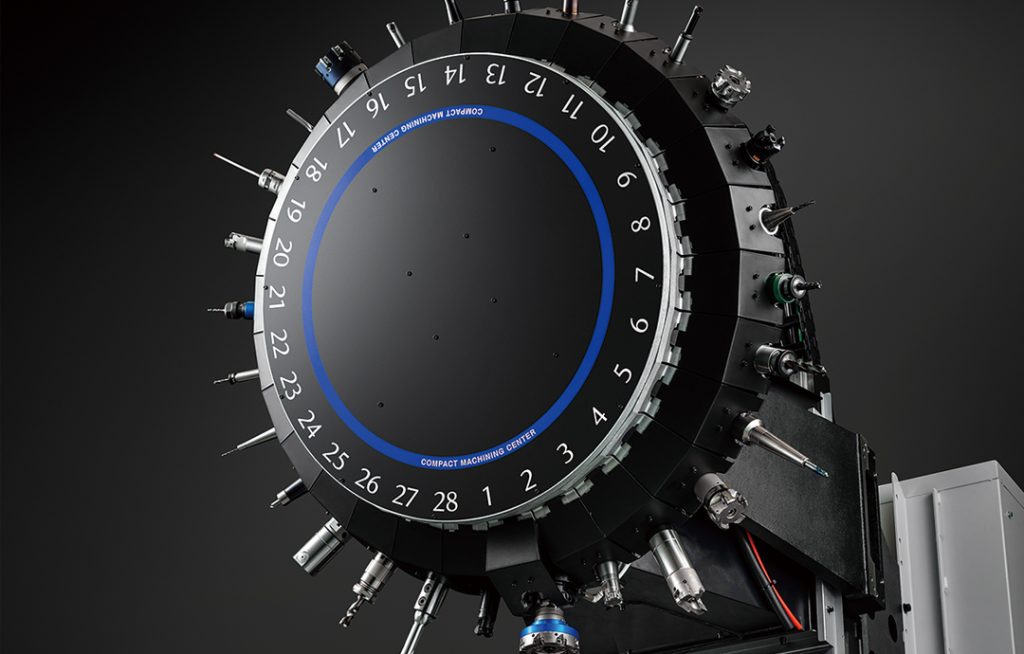

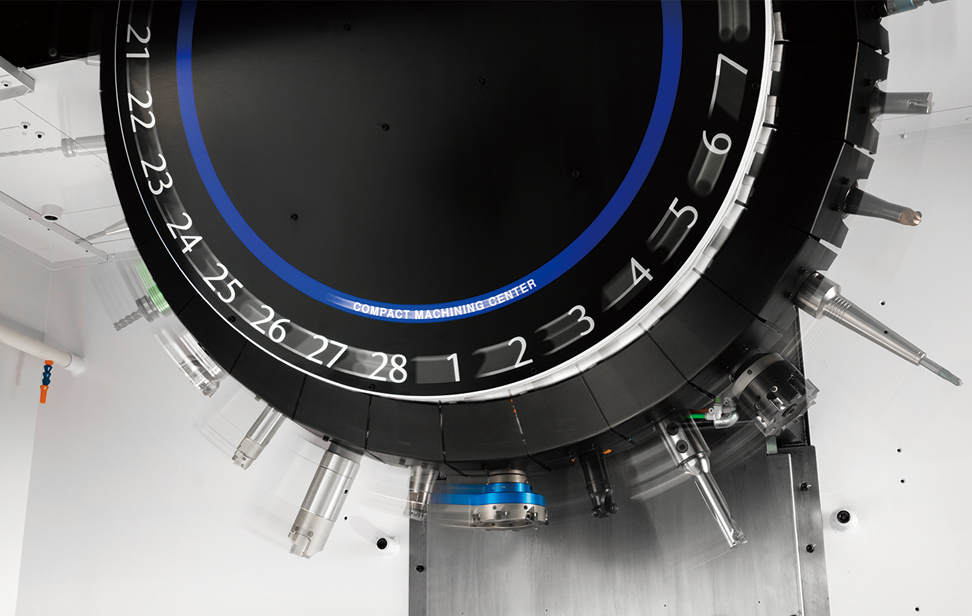

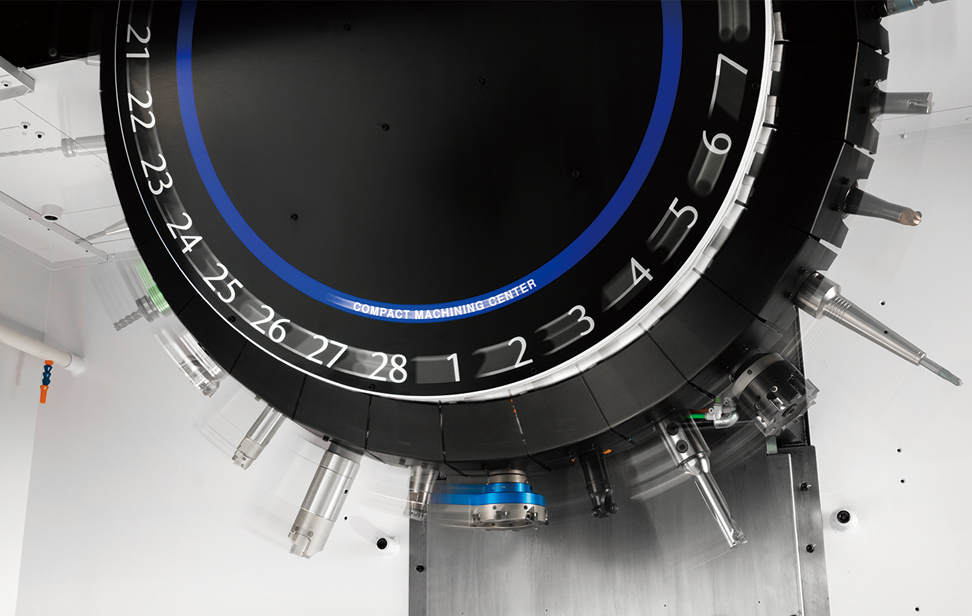

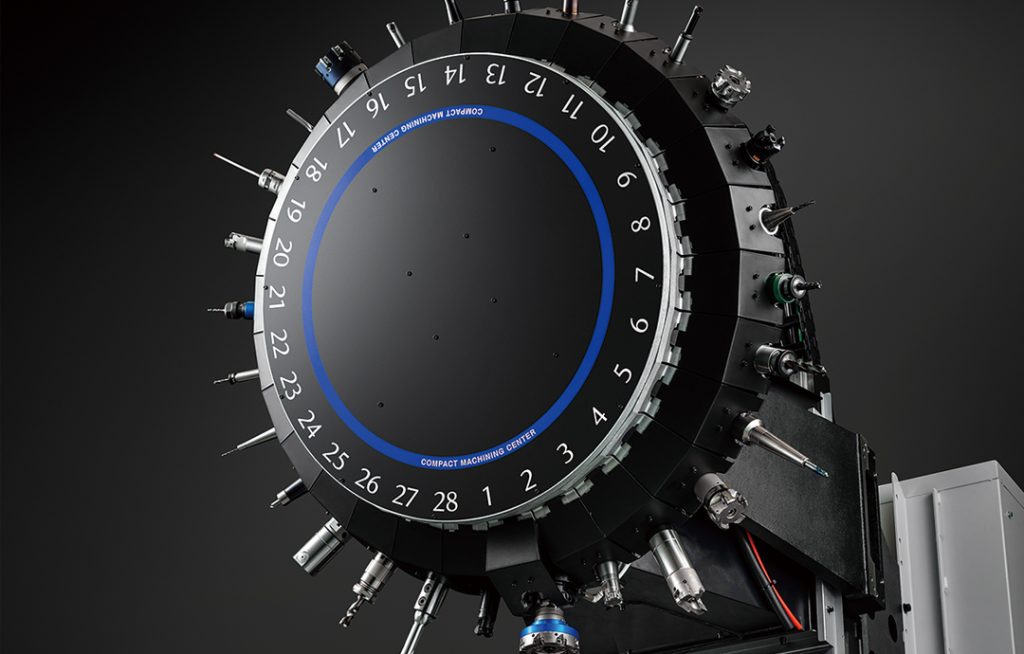

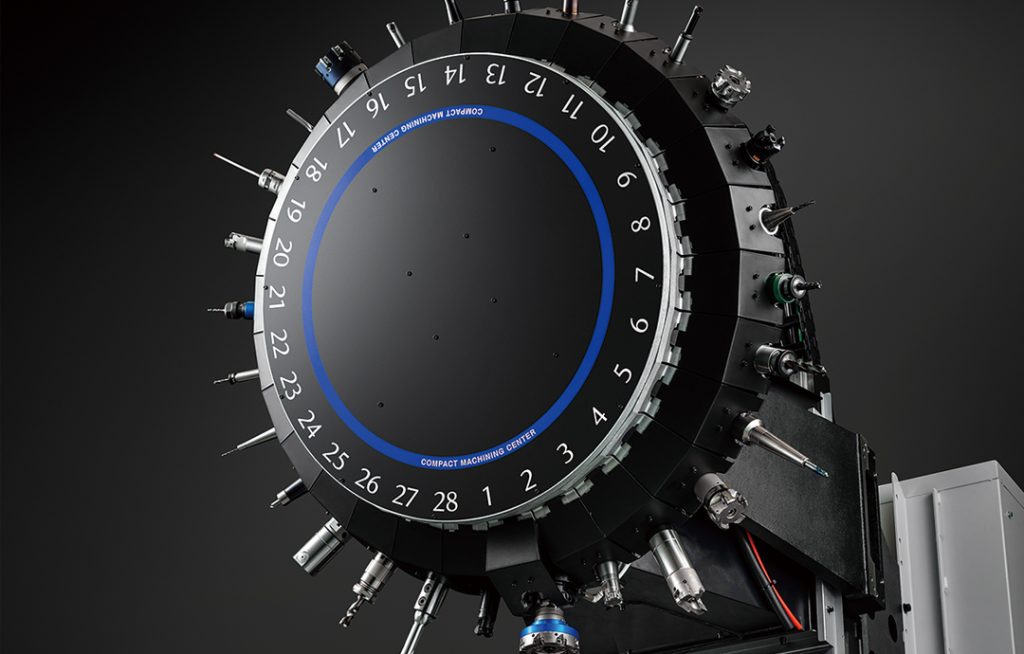

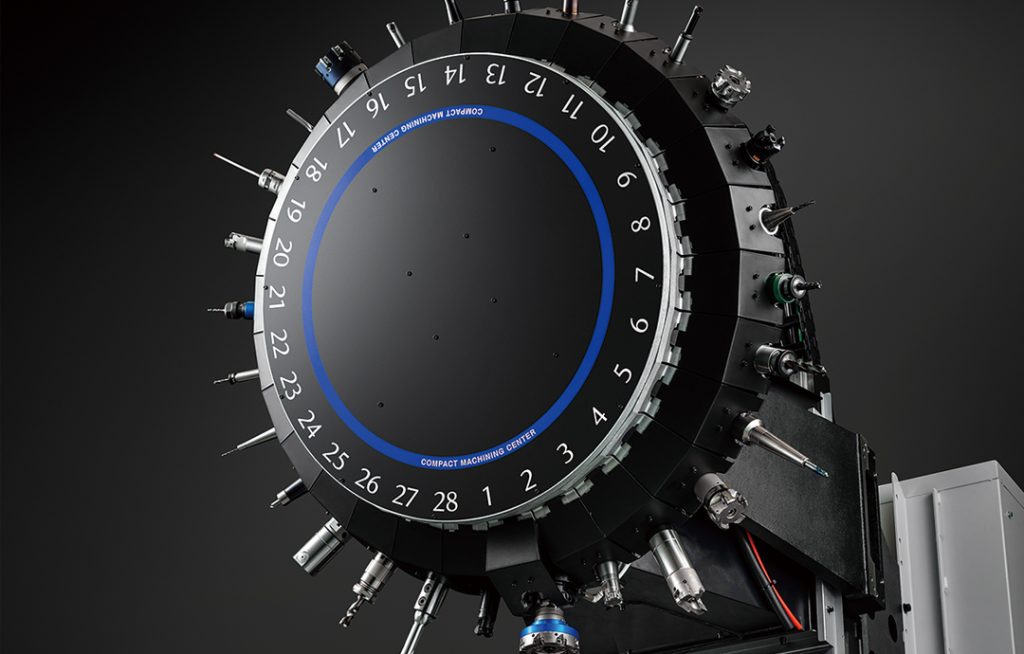

Equipped with 28 magazines

In addition to 14 and 21 magazines, it can be equipped with a drum-type 28-piece magazine that inherits high-speed tool changes. It can be used for all processing of large workpieces and high-mix, low-volume processing.

Maximum tool weight 4 kg

Productivity

Relentless pursuit of high productivity Reduction of waste through optimization control of integrated mechanical-electrical development

The light weight and low inertia of the No. 30 machine, as well as the in-house developed NC, maximize the performance of the machine and demonstrate high productivity.

Non-stop ATC

Spindle start/stop, Z-axis lifting, magazine operation is speeded up and optimized for fast tool change. Tools weighing up to 3 kg can be changed in the shortest possible time, and heavy tools weighing up to 4 kg can be changed with minimal time increase.

14/21 Magazine (Standard Tool) Chip-Chip 1.3s / Tool-Tool 0.6s

28 Magazine (Standard Tool) Chip-Chip 1.4s / Tool-Tool 0.7s

28 Magazine (Heavy Tools) Chip-Chip 1.4s / Tool-Tool 0.8s

Spindle start/stop, Z-axis lifting, magazine operation is speeded up and optimized for fast tool change. Tools weighing up to 3 kg can be changed in the shortest possible time, and heavy tools weighing up to 4 kg can be changed with minimal time increase.

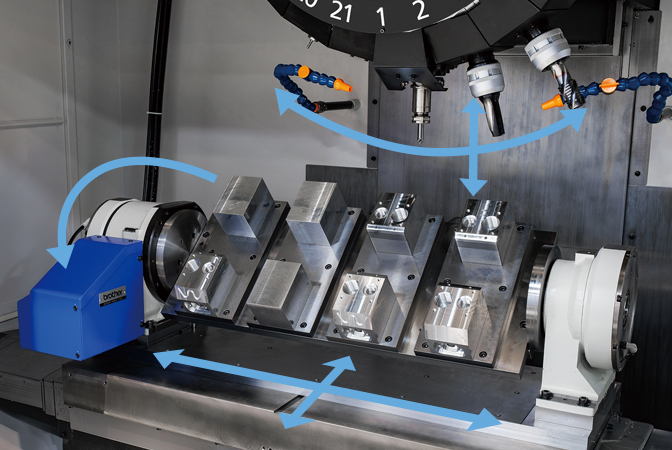

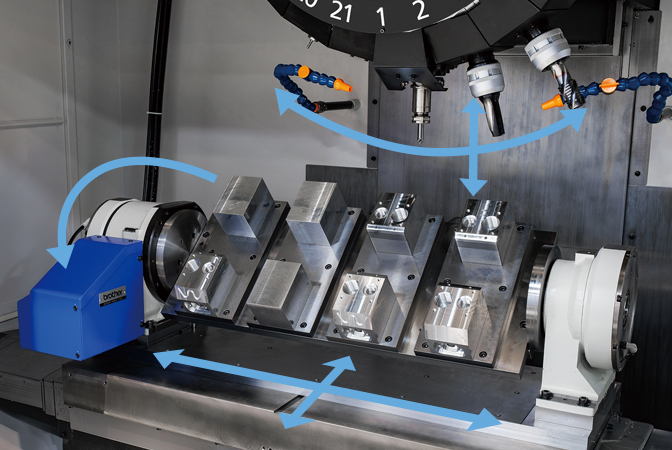

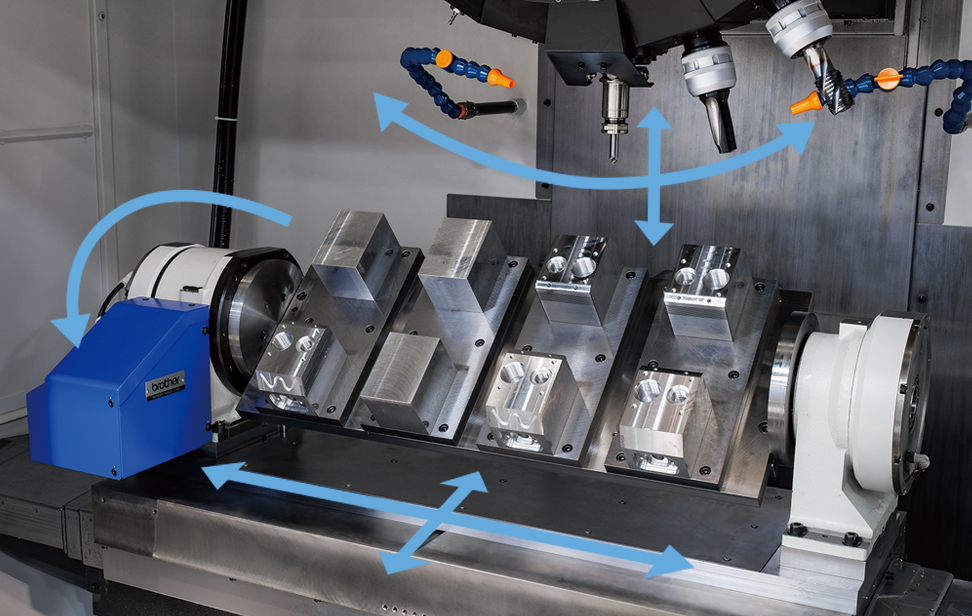

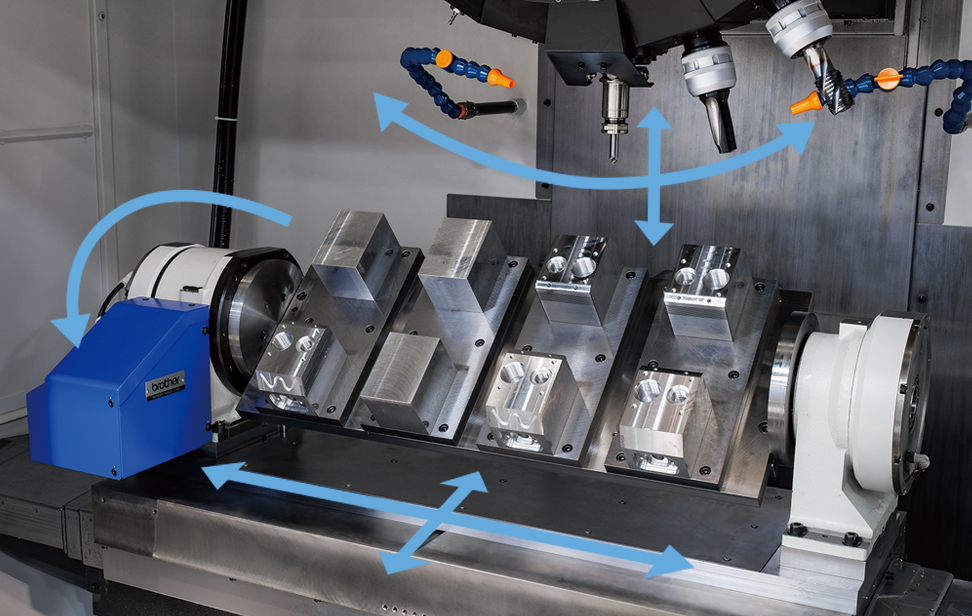

Simultaneous motion control

Simultaneous motion control Positioning of the XY axis and additional axes at the same time as the tool change reduces non-cutting time.

High acceleration and deceleration spindle

The low-inertia spindle and high-acceleration/deceleration spindle motor achieve high-speed start/stop of the spindle.

Spindle start/stop time: 0.15 s or less *

* High torque version

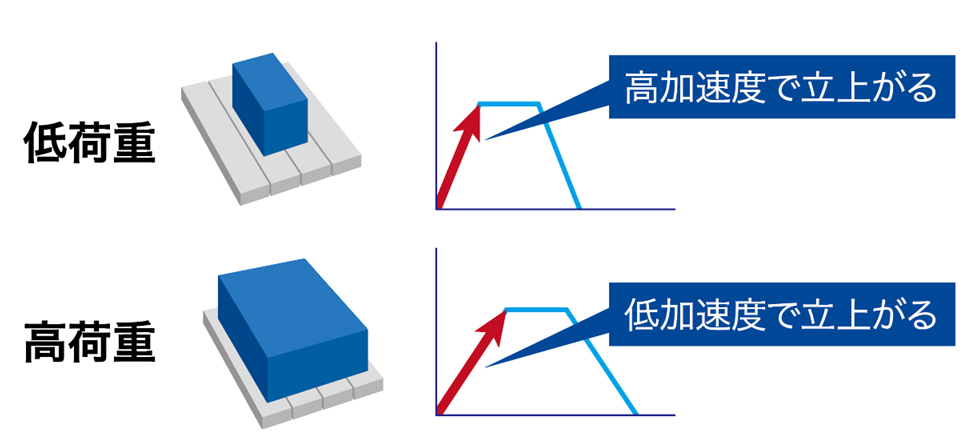

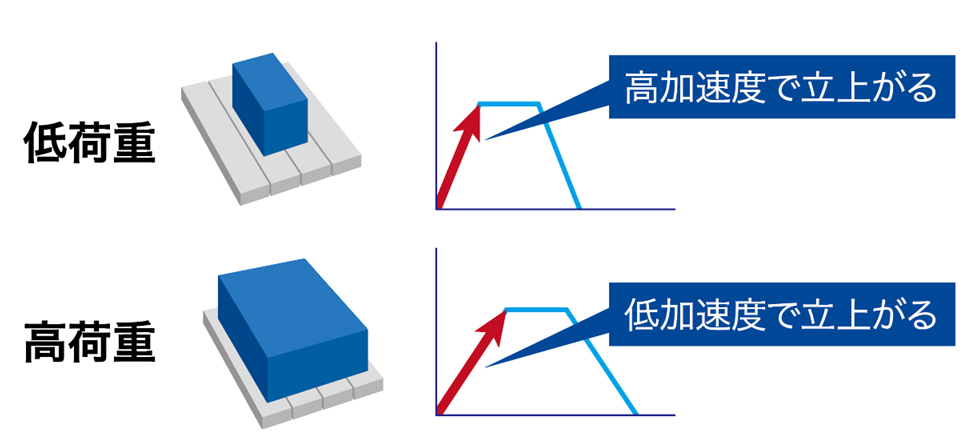

Optimal acceleration setting XY axis

The optimum acceleration setting function in the XY axis allows the optimum acceleration to be set according to the table load.

Machining Capacity

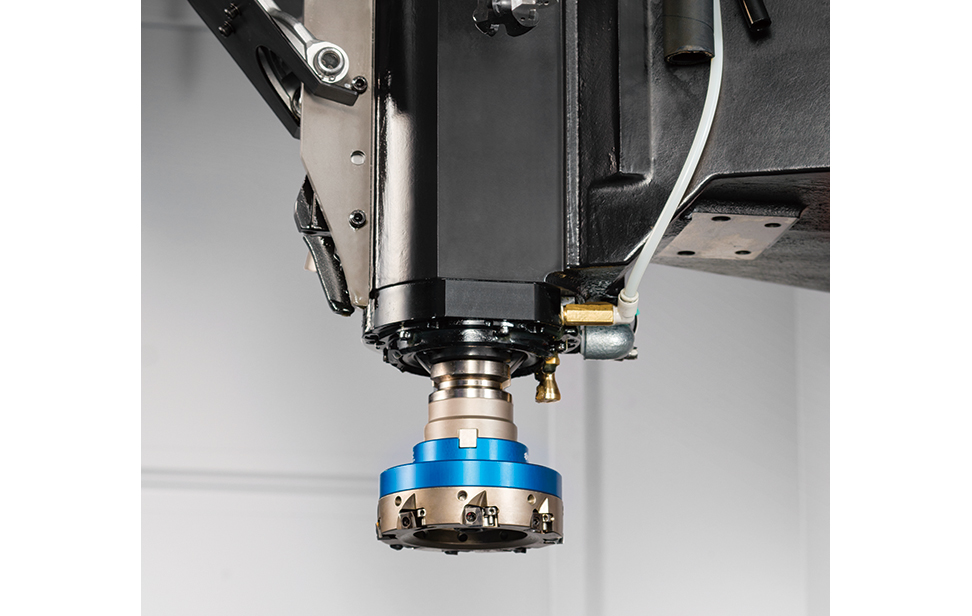

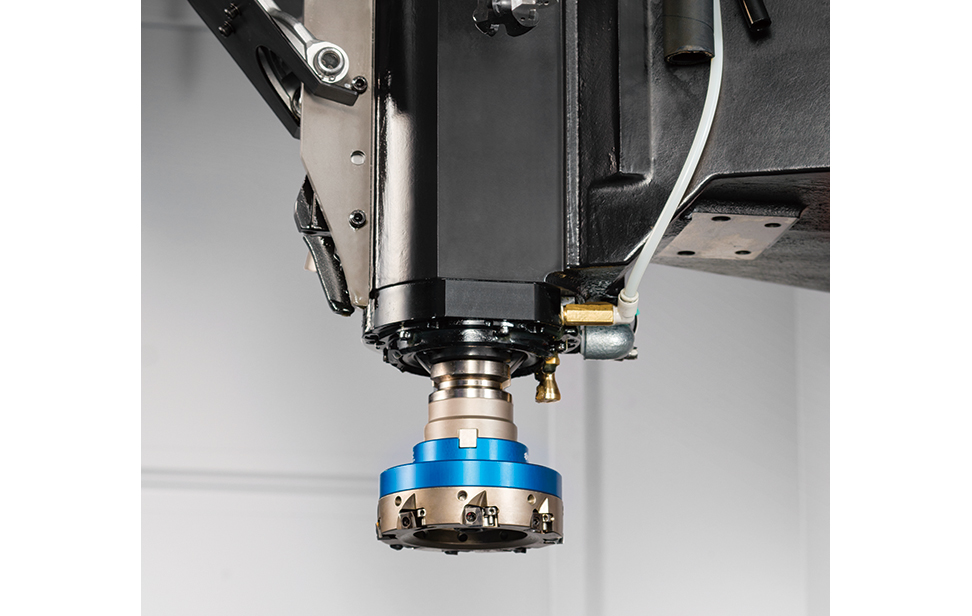

High-efficiency spindle motor and high-rigidity mechanical structure for a wide range of processing

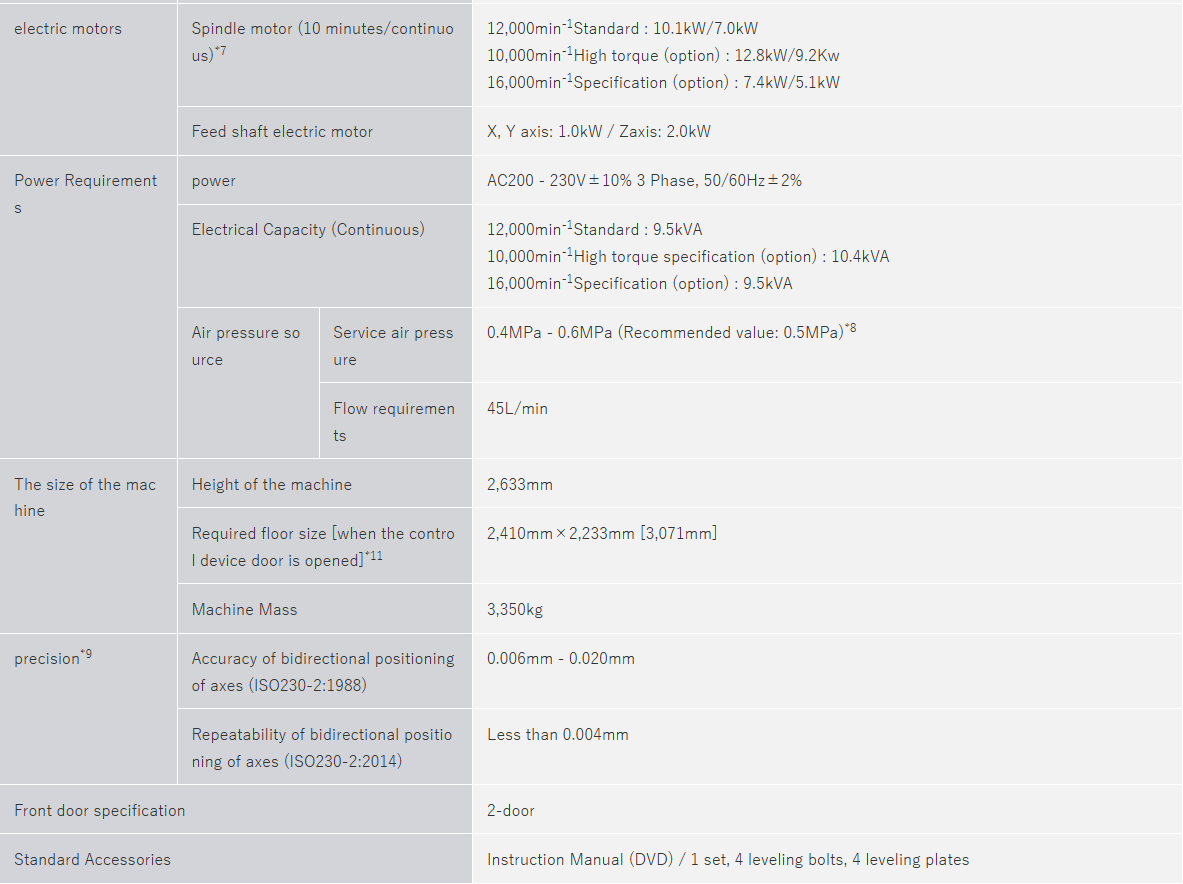

A lineup of spindle motors featuring high mechanical rigidity and high torque due to the special design of core parts such as bases, columns, and tables, achieves stable machining and high machining capacity over a wide area.

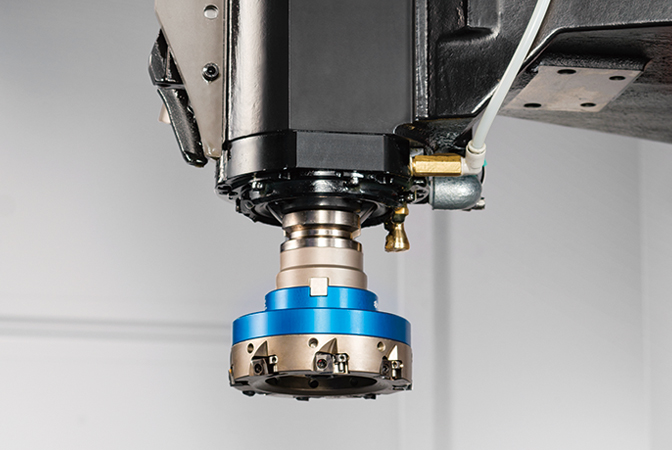

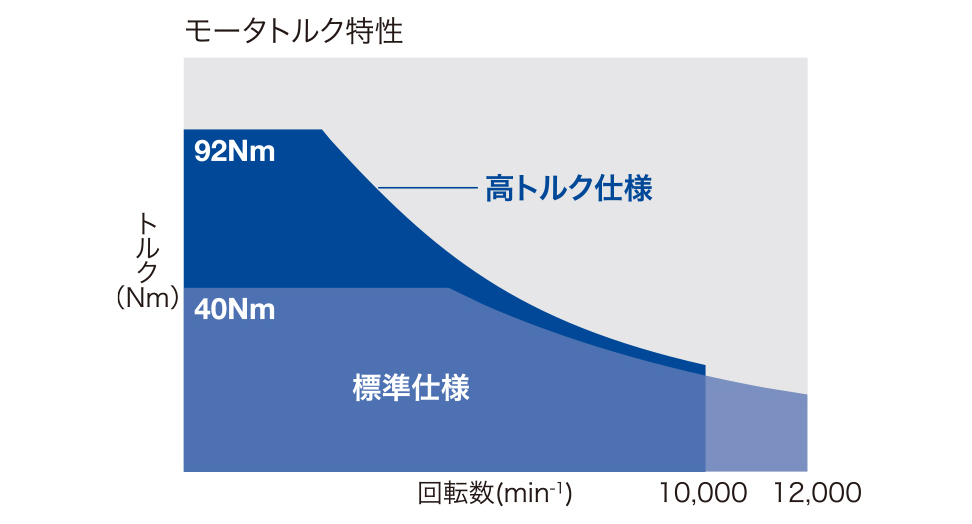

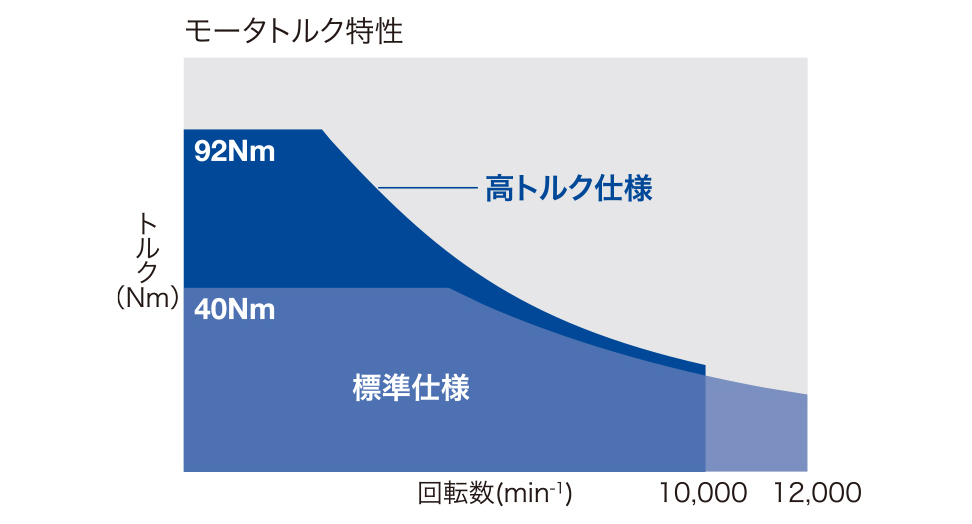

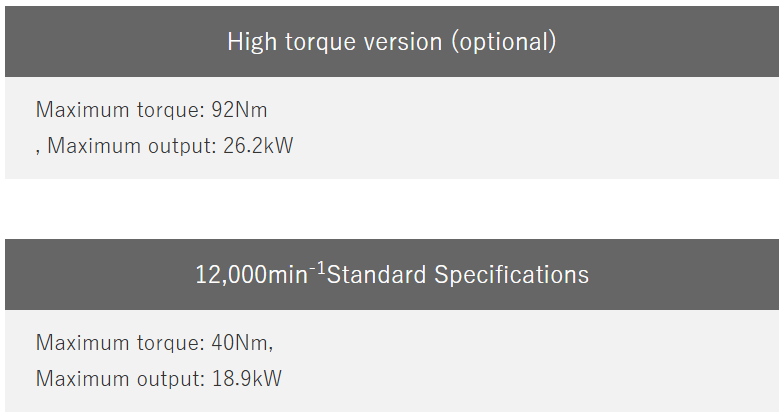

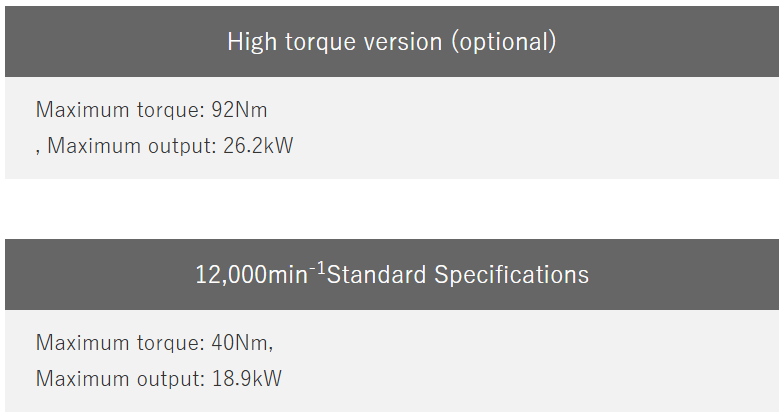

Newly developed 12,000min-1High-efficiency spindle motor

Standard specification motor 10,000 min-1Newly developed from 12,000min-1Specs have been upgraded to specifications. It maintains spindle torque in the medium-to-high-speed rotation range, contributing to further shortening of machining time for high-speed, high-efficiency machining of aluminum and steel.

Improved spindle stiffness

10,000min-1The high-torque version (optional) has a new spindle bearing diameter to increase rigidity. It is effective in machining a wide range of workpieces, including heavy cutting of iron.

7MPa High Pressure Coolant Through Spindle (CTS) available (optional)

The coolant-through spindle (CTS) can be selected from 3 MPa and 7 MPa as options. It is effective for high-speed drilling and deep hole drilling.

Operability

Equipped with

a newly developed CNC-D00 control device that pursues ease of use, and also realizes accessibility that makes setup work easy

Intuitive operation is realized with a new app function and a 15-inch LCD screen with a vertical touch panel.

In the setup, processing adjustment, production, and recovery processes, it is possible to proceed with lean work, contributing to improved work efficiency and utilization rate.

The accessibility to the machine is increased so that setup work such as workpiece replacement can be performed smoothly.

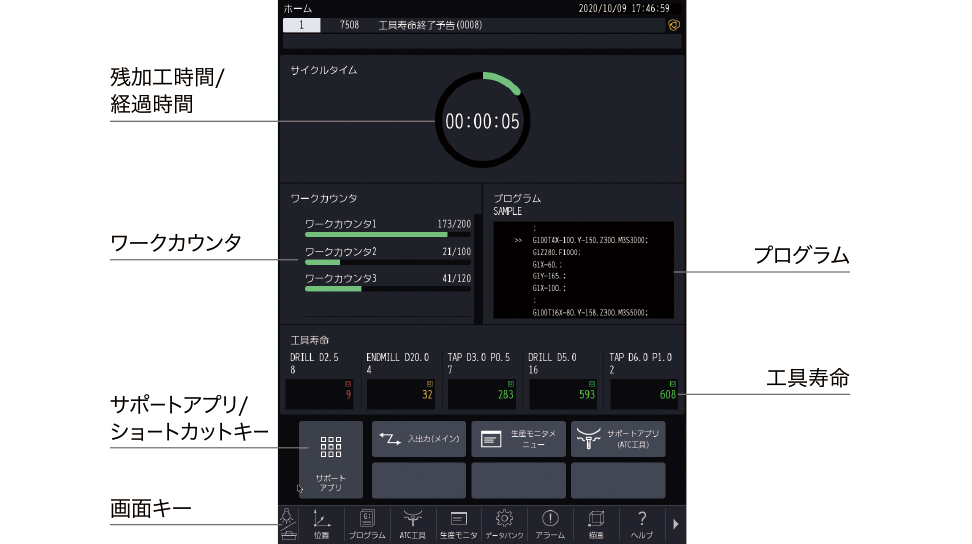

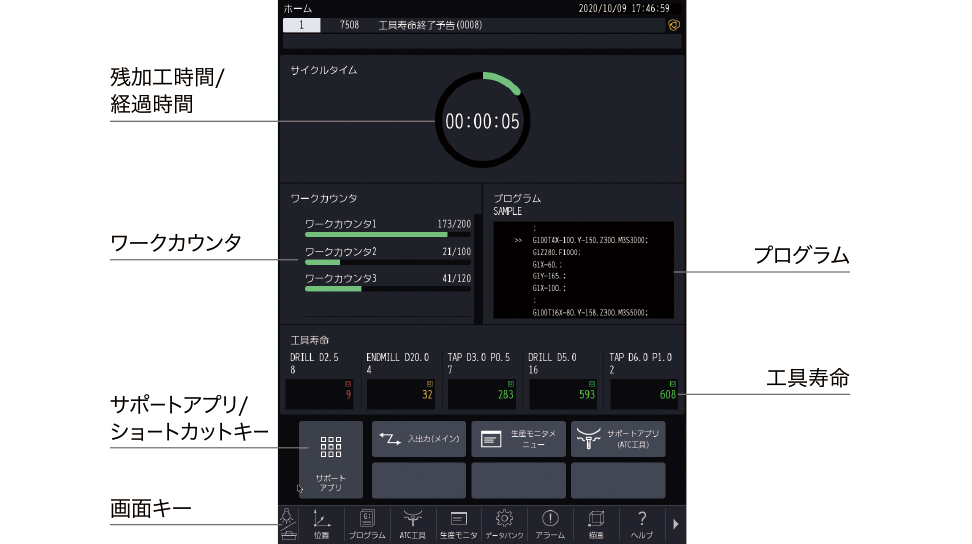

Home screen

Centralize information necessary for production, such as work counters and tool life. In addition, shortcut keys allow you to transition to frequent screens with a single touch.

New user interface

A new support app has been established that consolidates related functions and improves operability and visibility through visual display, and is equipped with convenient functions such as a calculator, notepad, and file viewer, and the operation on the conventional screen is easy with a touch panel, greatly improving usability.

*1 You need to change the parameter settings. (The table movement time will be changed.) )

*2 This value is used when high-precision mode B is used.

*3 CTS pull studs are Brother specifications.

*4 The maximum mass of the tool varies depending on the shape, center of gravity, etc., so please consider it as a reference value only.

*5 You need to change the parameter settings. (The indexing time of the tool will change.) )

*6 The tool change measurement method is based on JIS standards B6336-9 and MAS011-1987.

*7 The output of the spindle motor varies depending on the rotation speed.

*8 The normal air pressure fluctuates depending on the machine specifications, processing program contents, and the use of peripheral equipment, so please set the pressure above the recommended value.

*9 The measurement method is based on ISO and Brother standards. Please contact us for details.

*10 Depending on the destination, it is necessary to install a relocation detection device. If a relocation detection device is installed, “RD” will be added to the end of the model name.

*11 The value does not include the coolant tank.

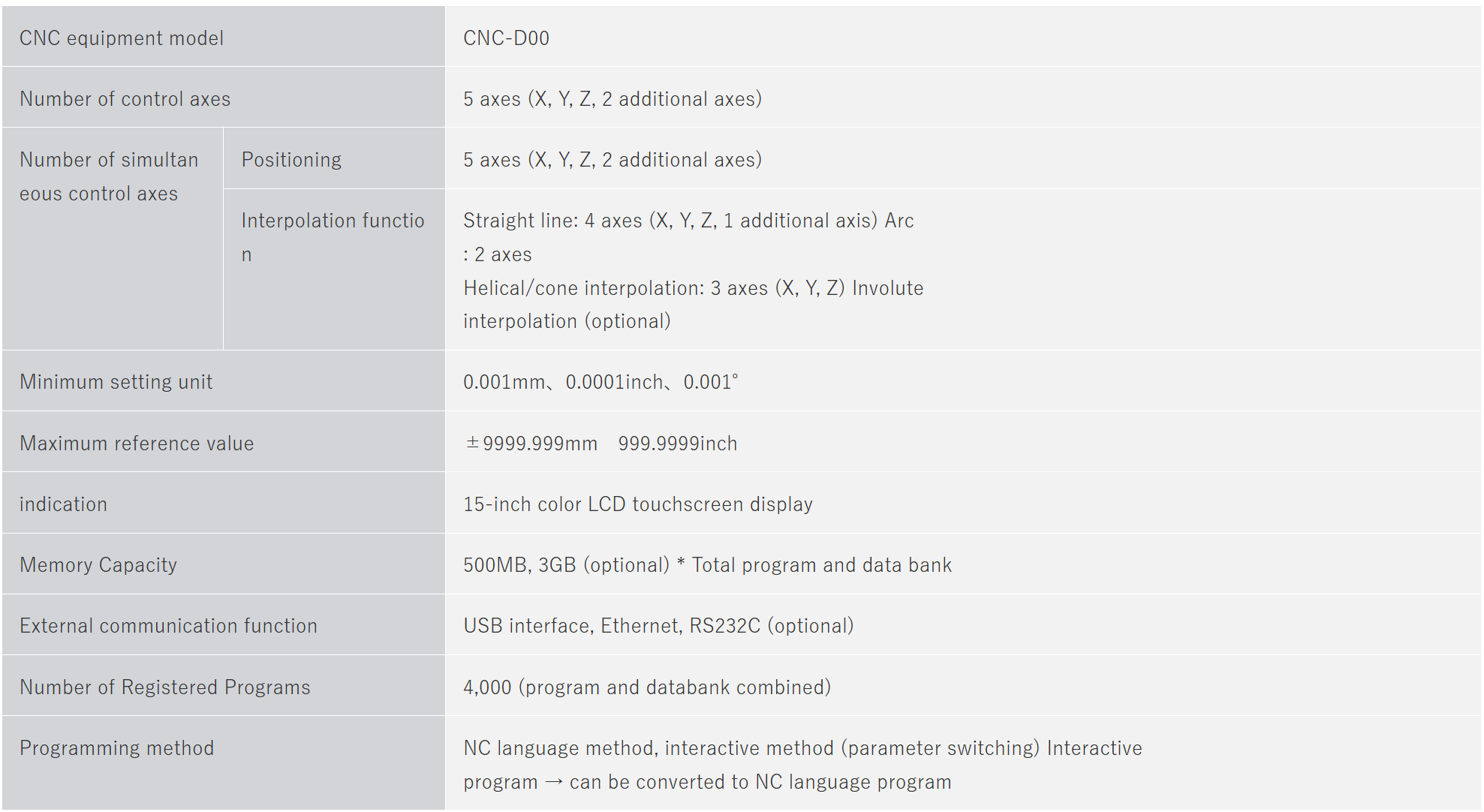

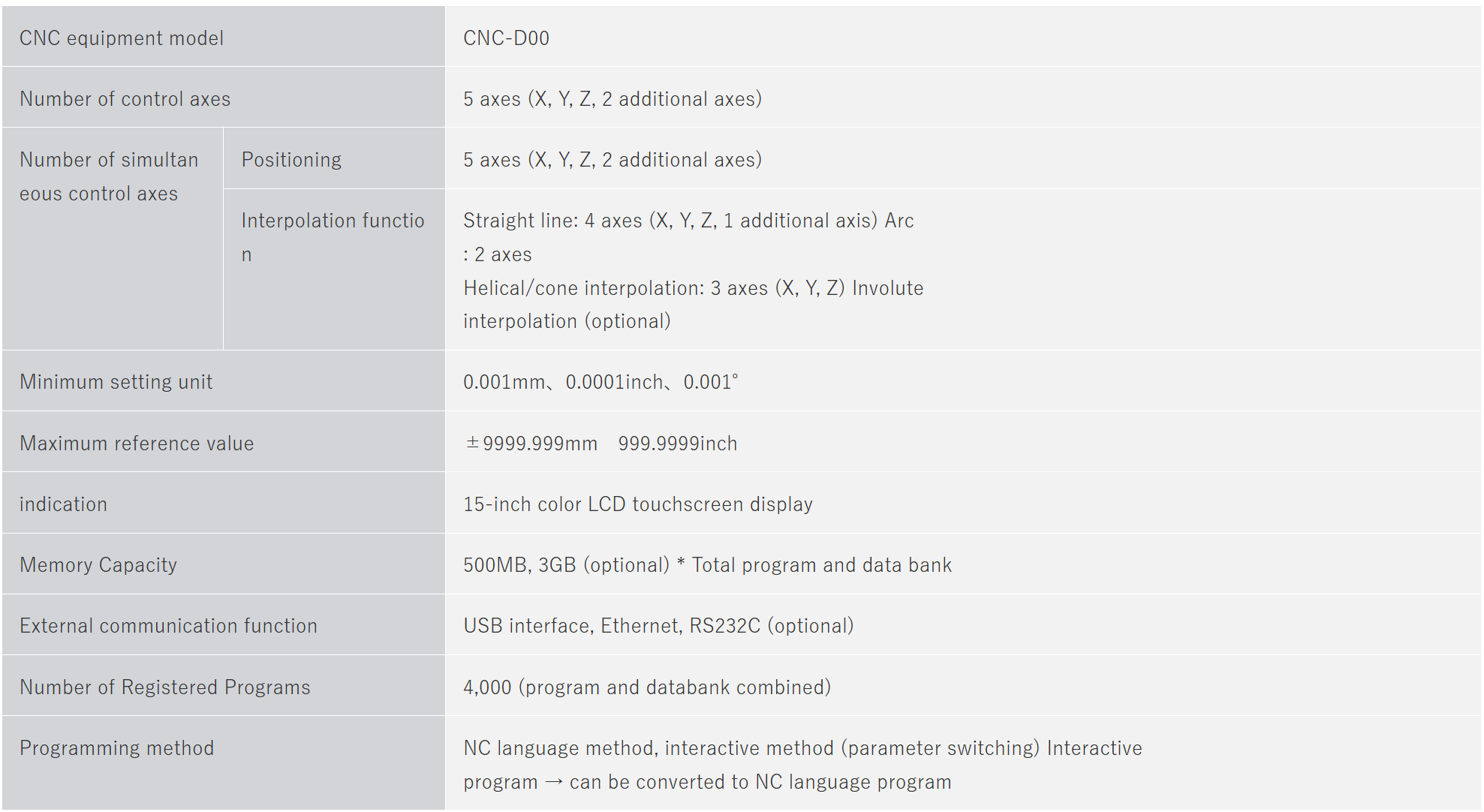

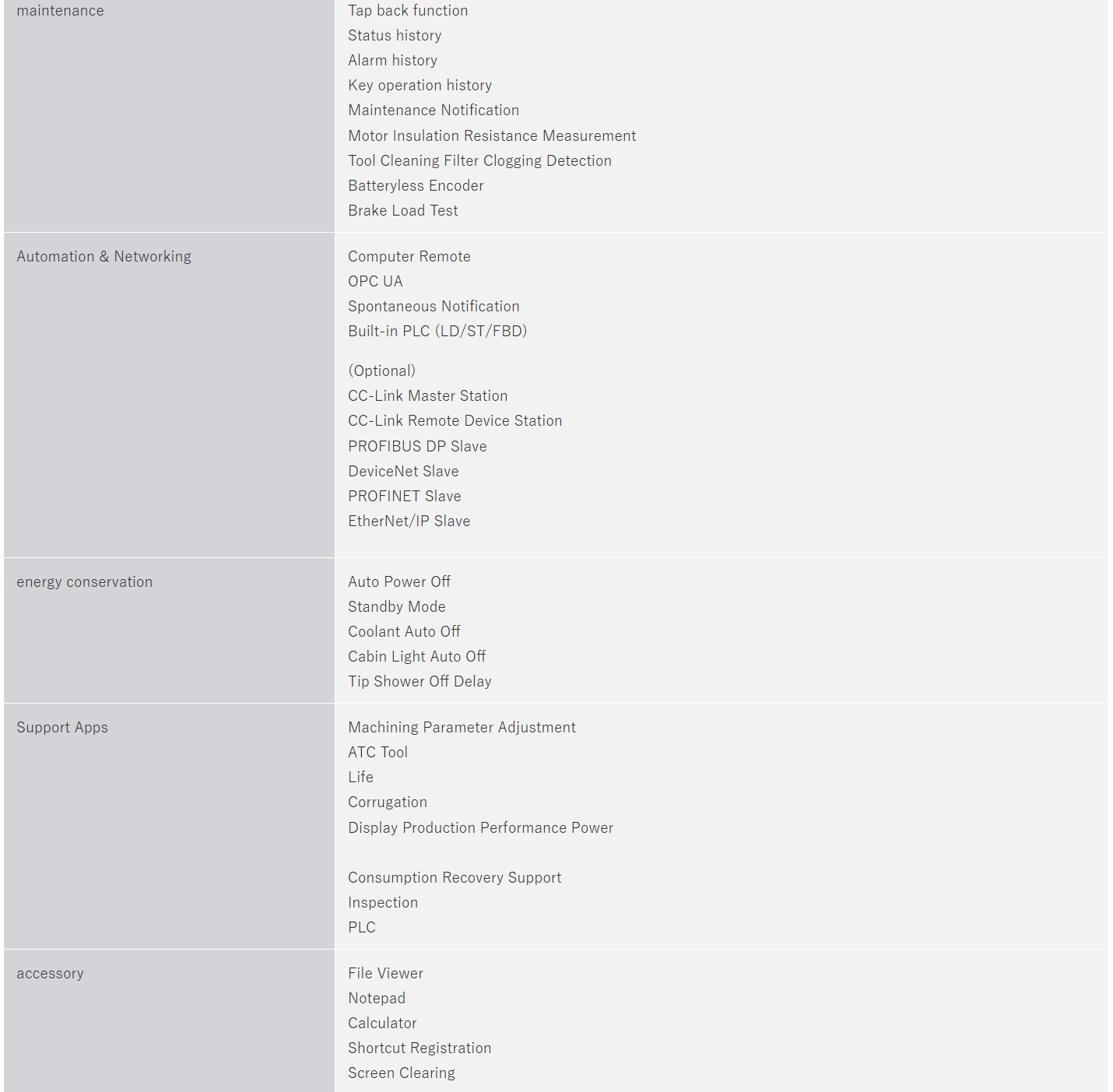

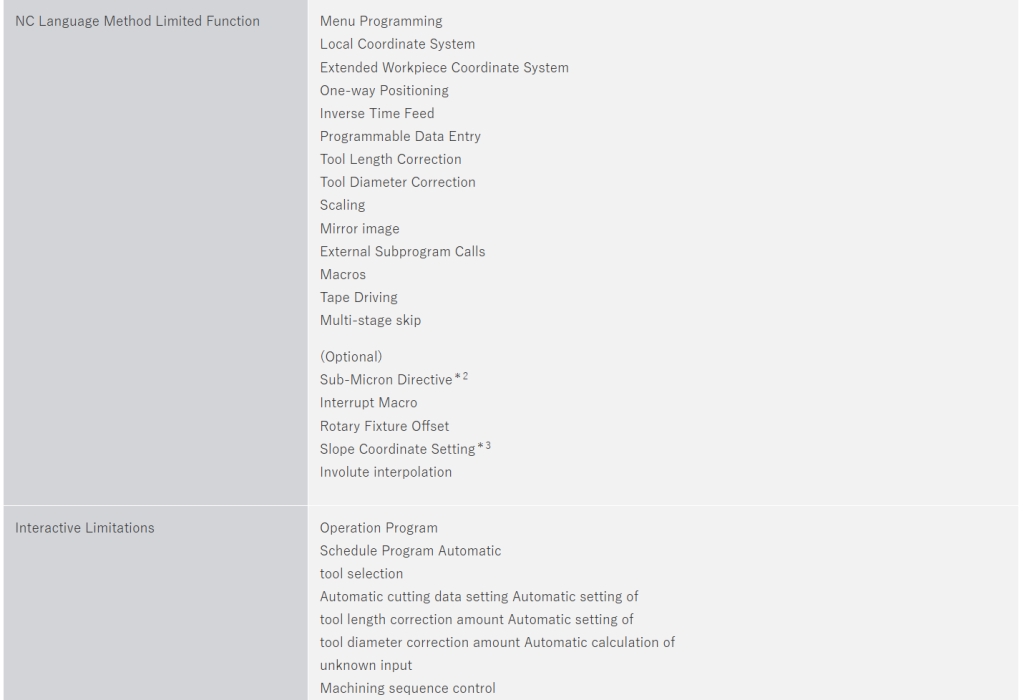

NC Specifications

* “Number of control axes” and “Number of simultaneous control axes” are the maximum number of axes, and vary depending on the destination and specifications.

* ETHERNET IS A REGISTERED TRADEMARK OF XEROX IN THE UNITED STATES.

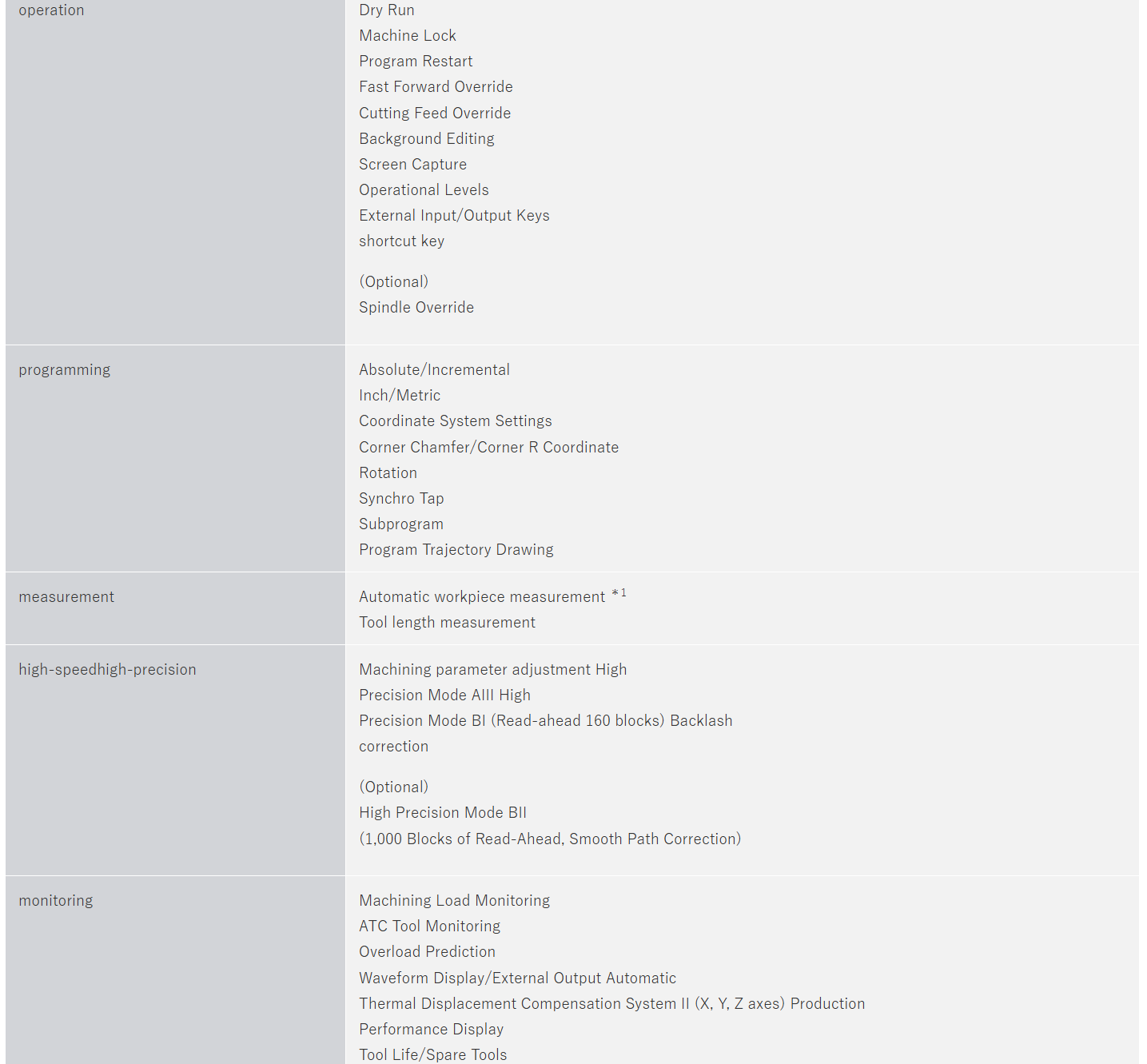

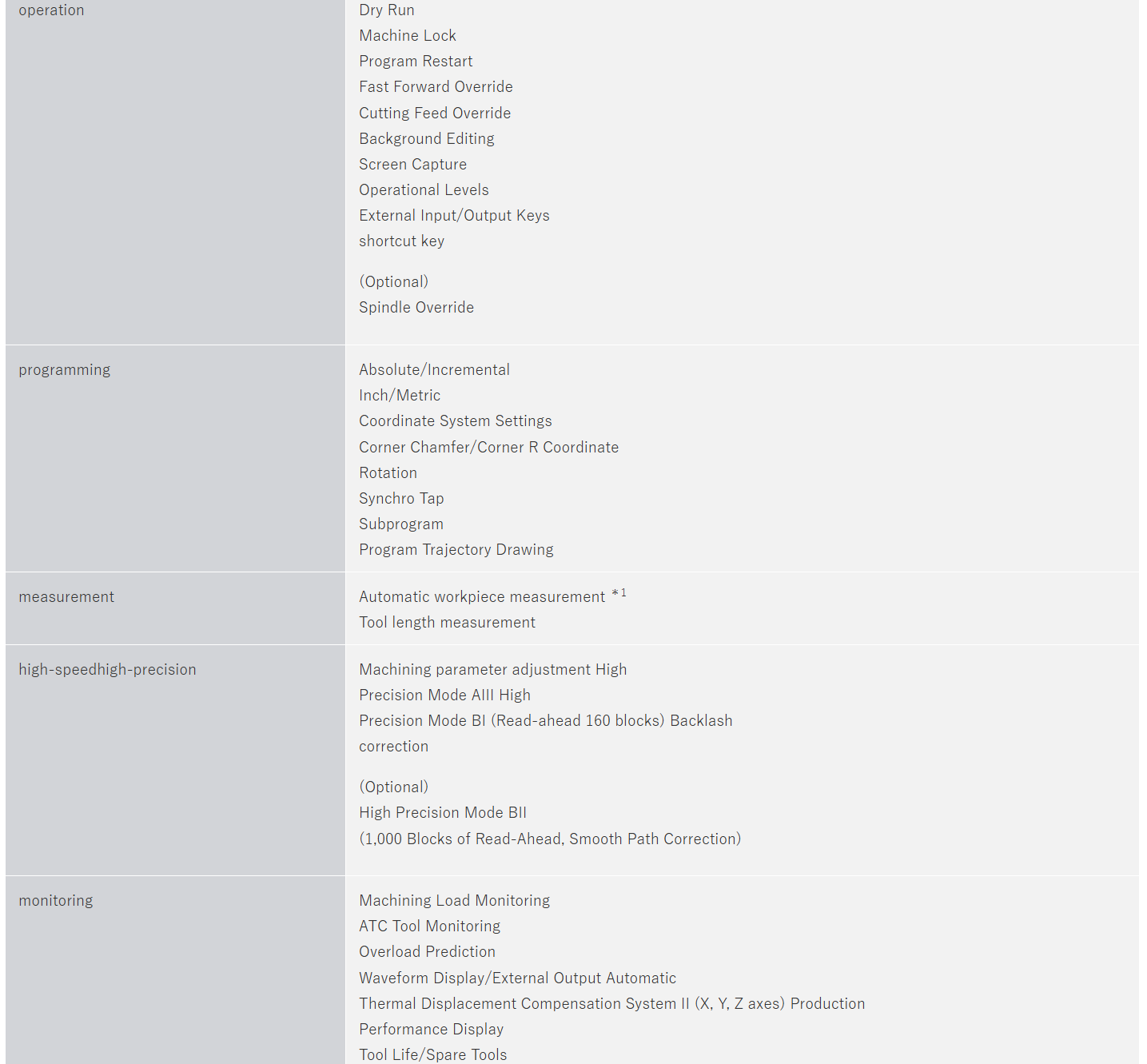

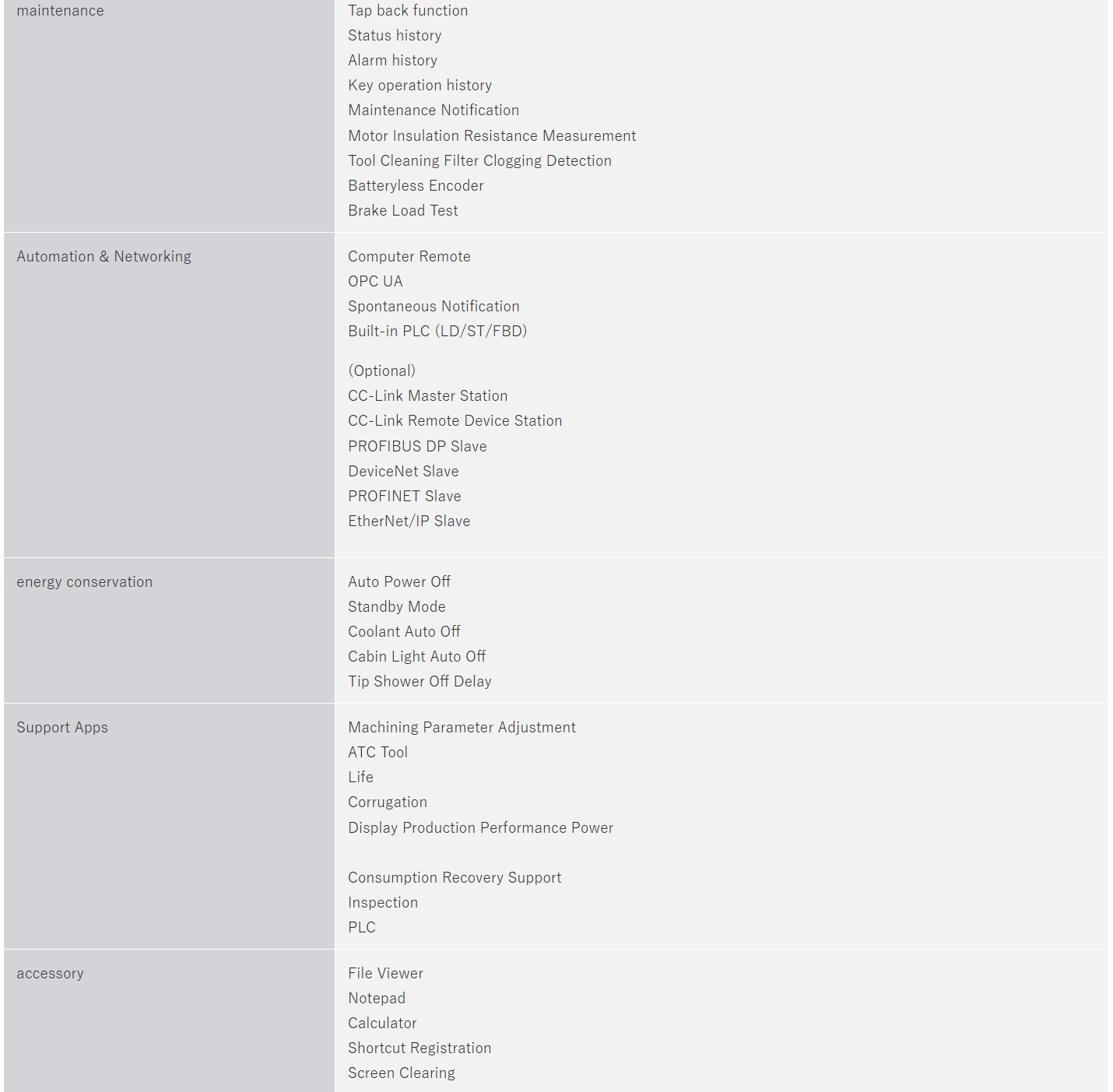

NC function

*1 Please prepare the measuring equipment yourself.

*2 When the submicron command is selected, it is not possible to switch to the interactive program.

*3 There are restrictions on axis configurations.

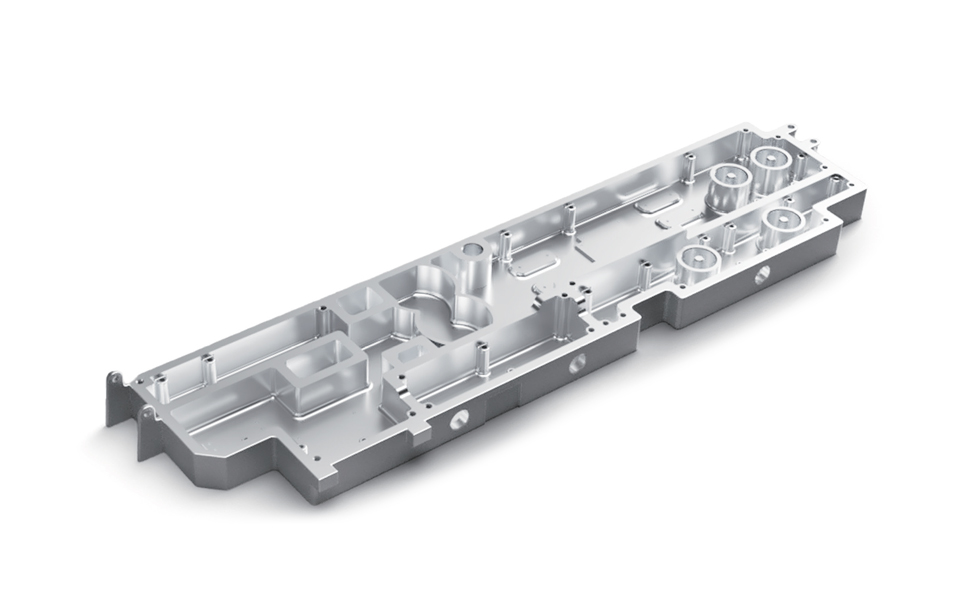

Processing example

Car

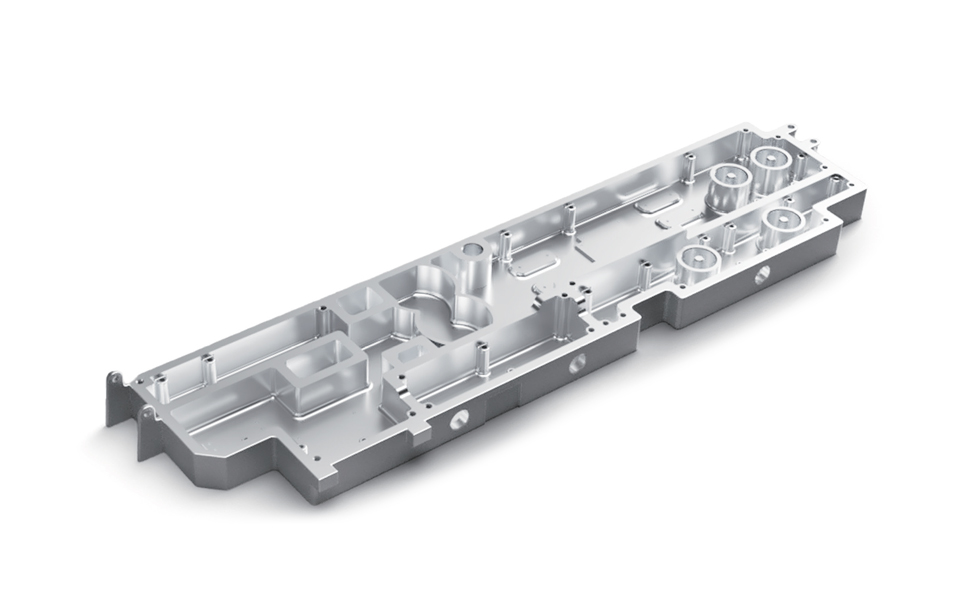

| Names of parts | Battery Control Box |

|---|---|

| material | Aluminum alloy |

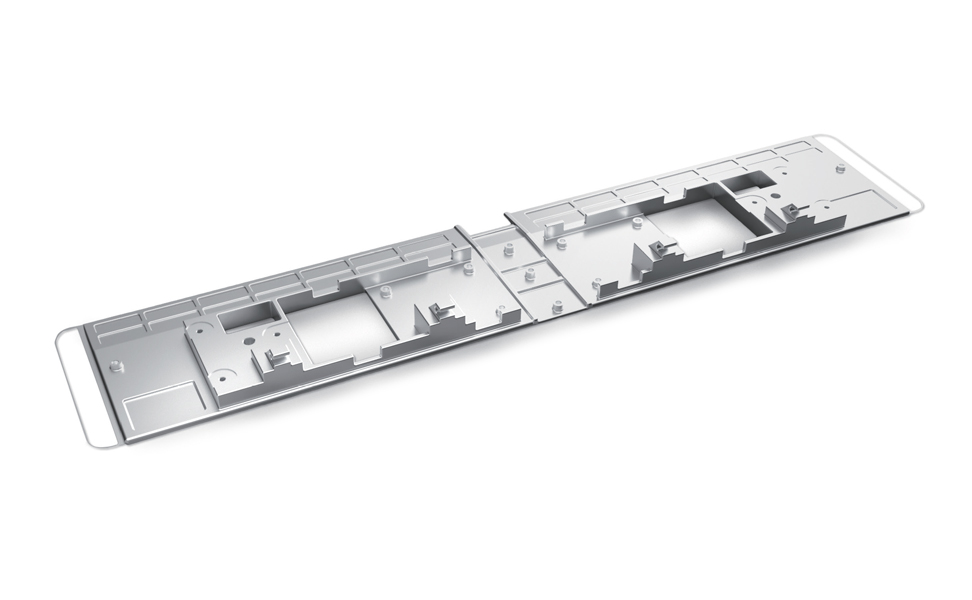

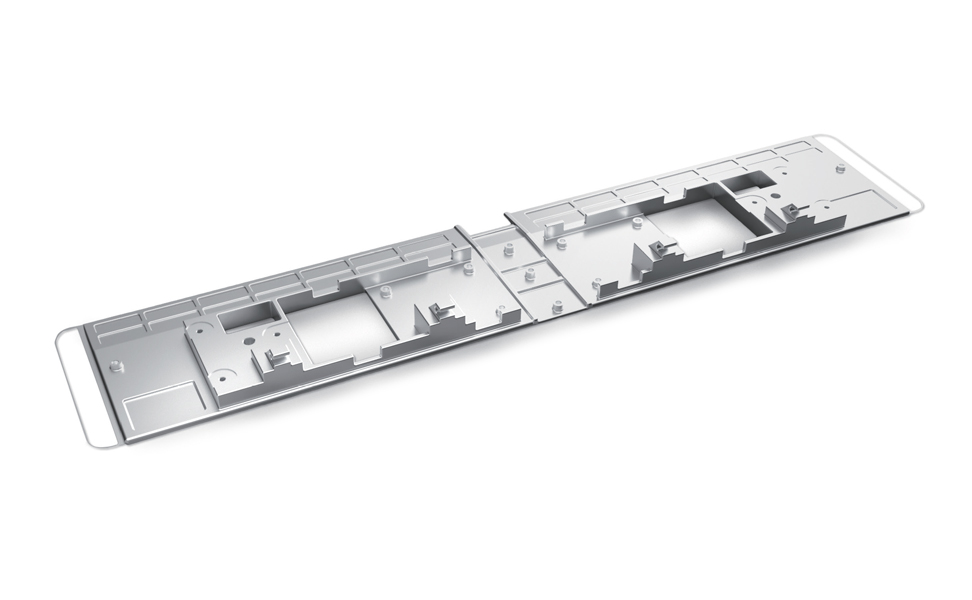

| Part Name | Instrument panel |

|---|---|

| Material | Aluminum Alloy |

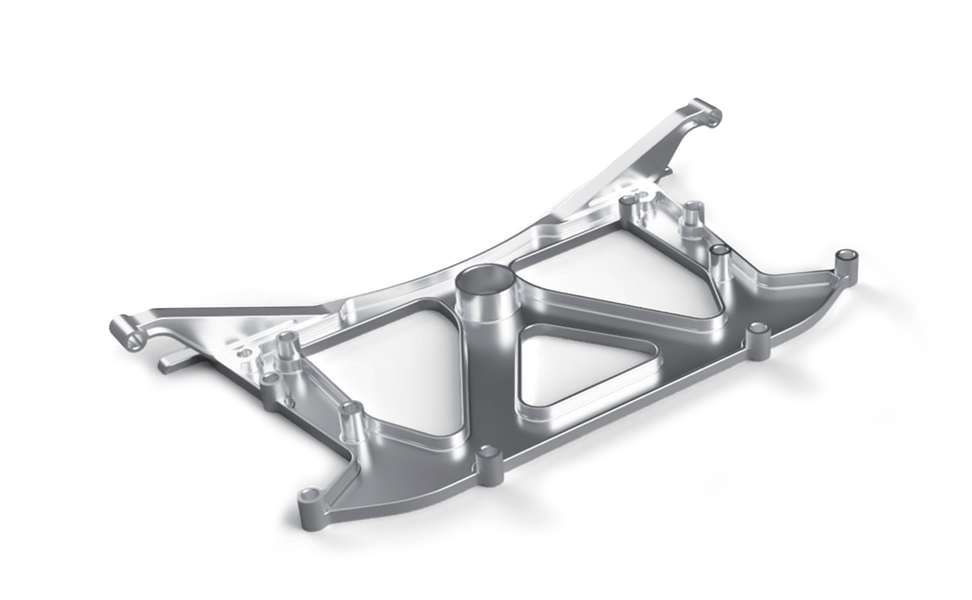

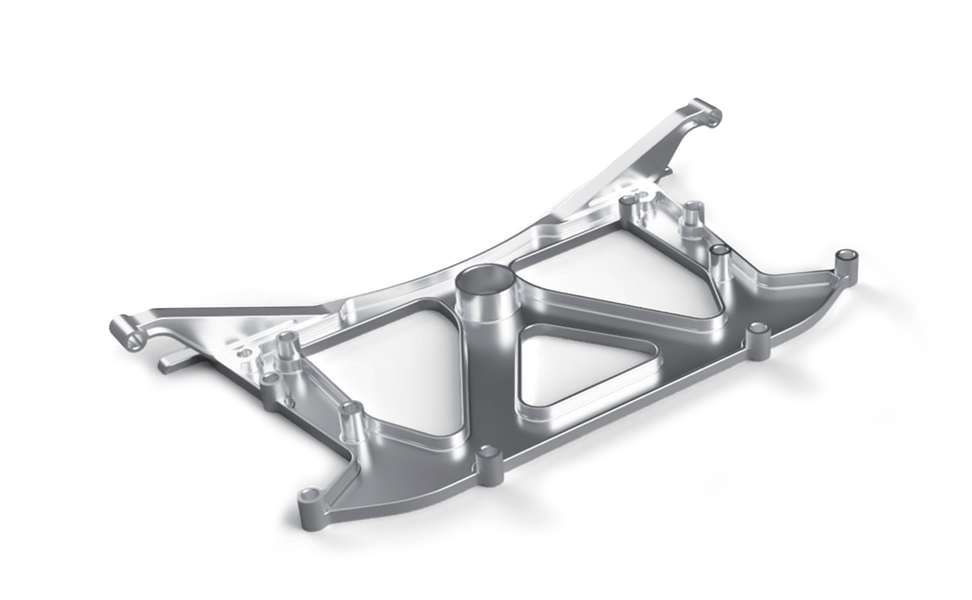

| Part Name | EV Frame |

|---|---|

| Material | Aluminum Alloy |

Semiconductor

| Names of parts | Shower Plate |

|---|---|

| material | Aluminum Alloy |

Car

| Names of parts | Frame Parts |

|---|---|

| material | Aluminum alloy |

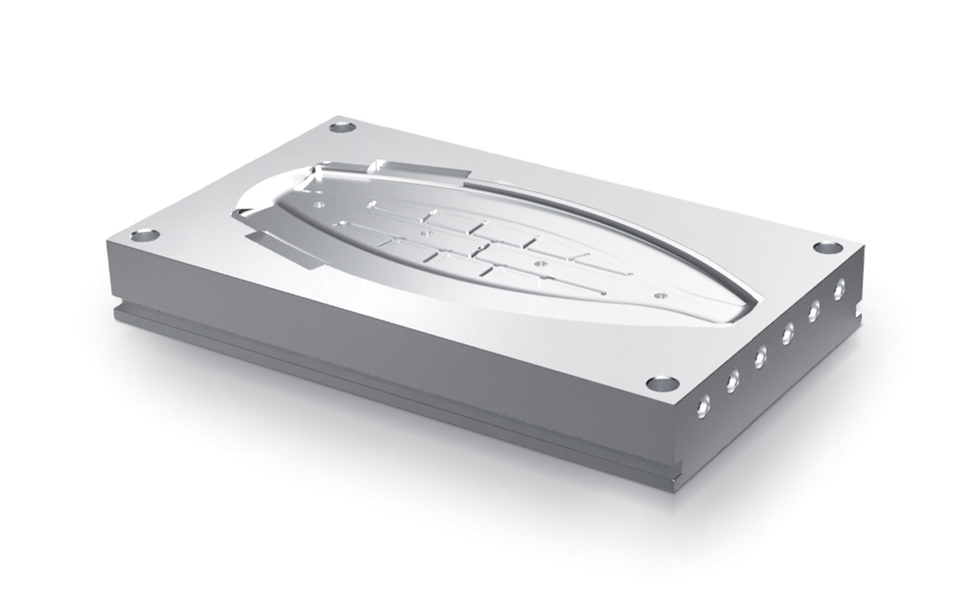

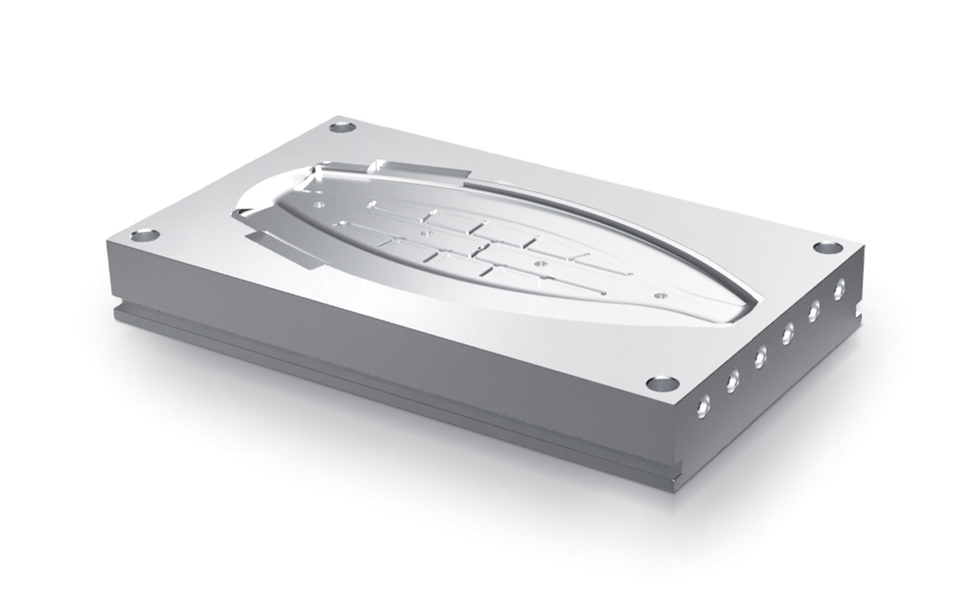

| Part Name | Mold Parts |

|---|---|

| Material | Alloy tool steel |