Cavitation Abrasive Surface Finishing Technology

Features

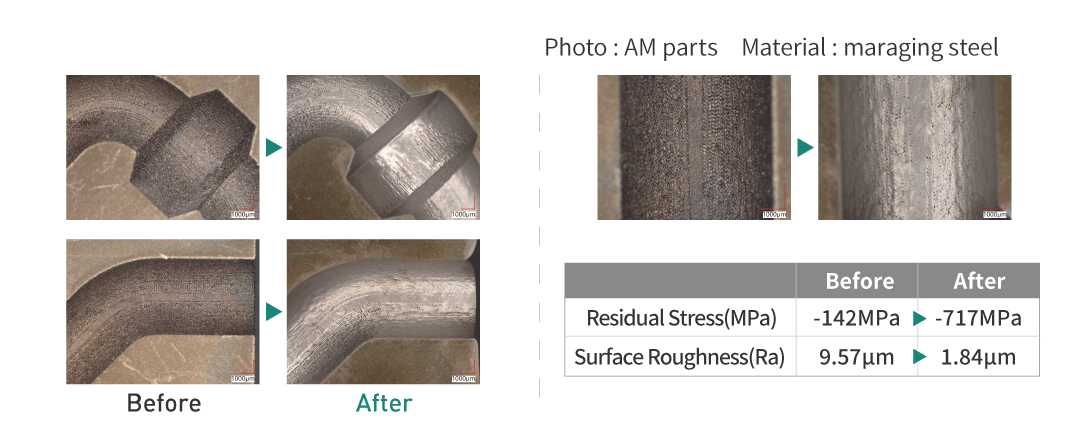

Removal of abnormal layers from metal additive manufacturing parts (AM parts)

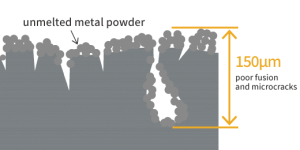

Metal additive manufacturing parts (AM parts) have abnormal layers, such as poor fusion and microcracks, that happen at positions approximately 150 μm from the surface during the manufacturing process.

If abnormal layers are present, there is a risk of component breakage and insufficient fatigue strength. Additionally, any remaining unmelted metal powder on the surface increases the frictional resistance of fluids.

With CASF, smoothing treatment can be performed to a position of approximately 200 μm below the surface.

By removing abnormal layers and unmelted metal powder, compressive stress can also be imparted, improving the fatigue strength of the component.

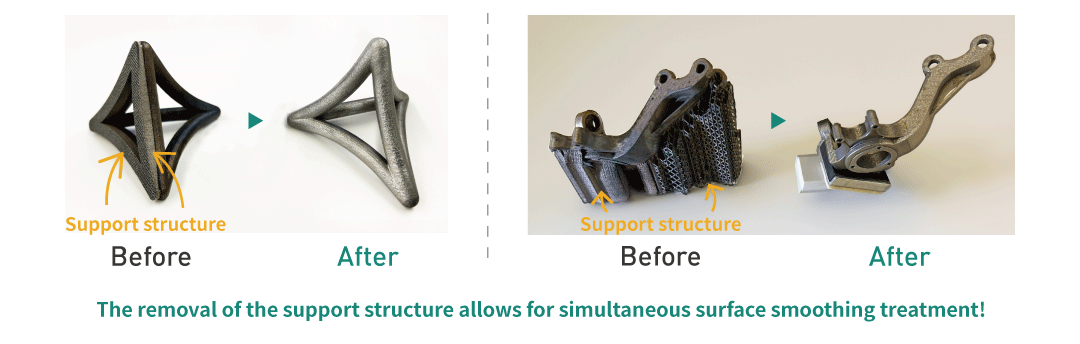

Remove the support structures from the metal additive manufacturing components (AM parts).

Conventionally, removal was often done manually, and post-removal polishing of the component surface was also necessary. However, with CASF, the removal of support structures and surface smoothing can be performed in a single pass.

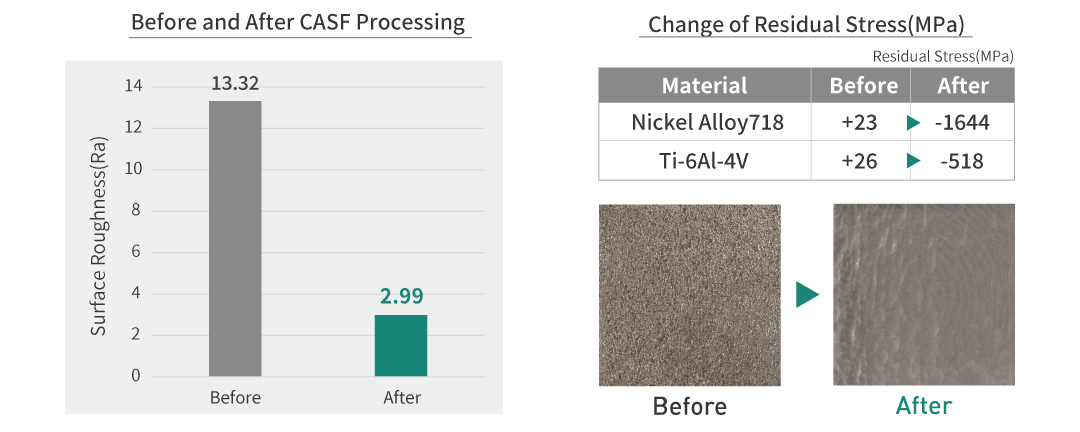

Improve surface roughness and fatigue strength

CASF process technology improves surface roughness , fatigue strength , and fatigue life by applying compressive stress.

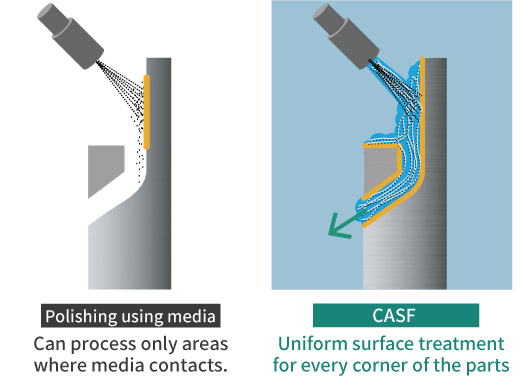

Can Reach Inside Diameter Surface

It is possible to reach inside diameter such as flow pipe.

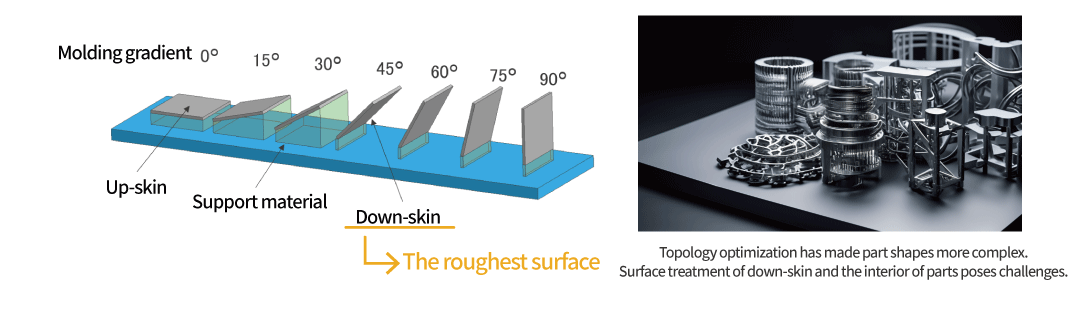

The surface roughness of down-skin is also improved uniformly.

In metal additive manufacturing (AM), the surface roughness varies significantly depending on the build angle.

Particularly, the down-skin at around 45° has the roughest surface, posing challenges due to difficult access and increased effort required in post-processing.

With CASF, fluids act on all corners of AM parts, allowing for uniform surface treatment in a single operation.

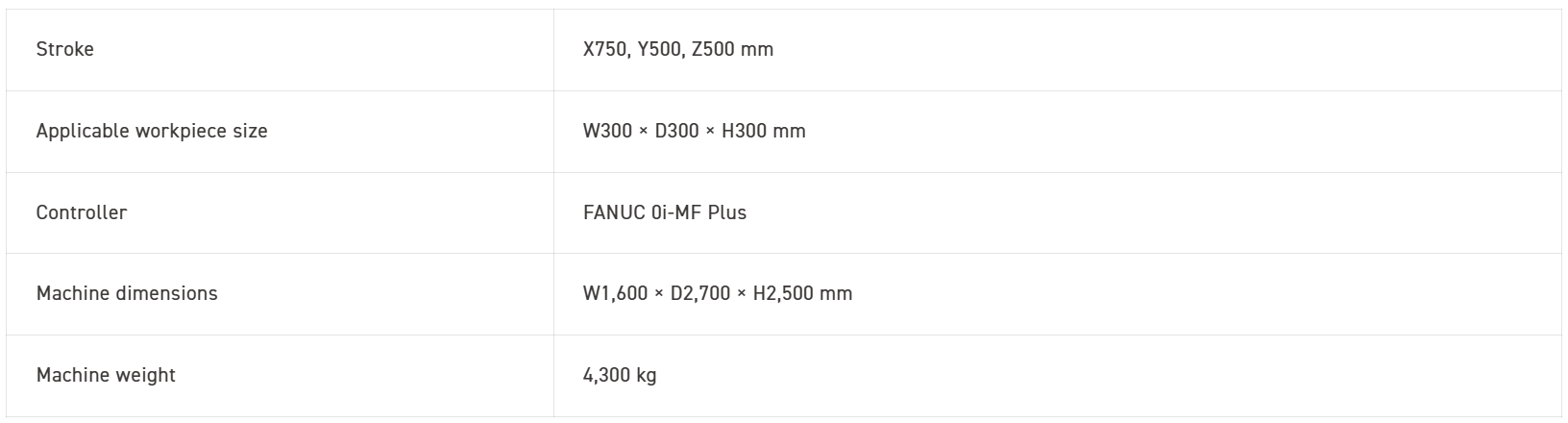

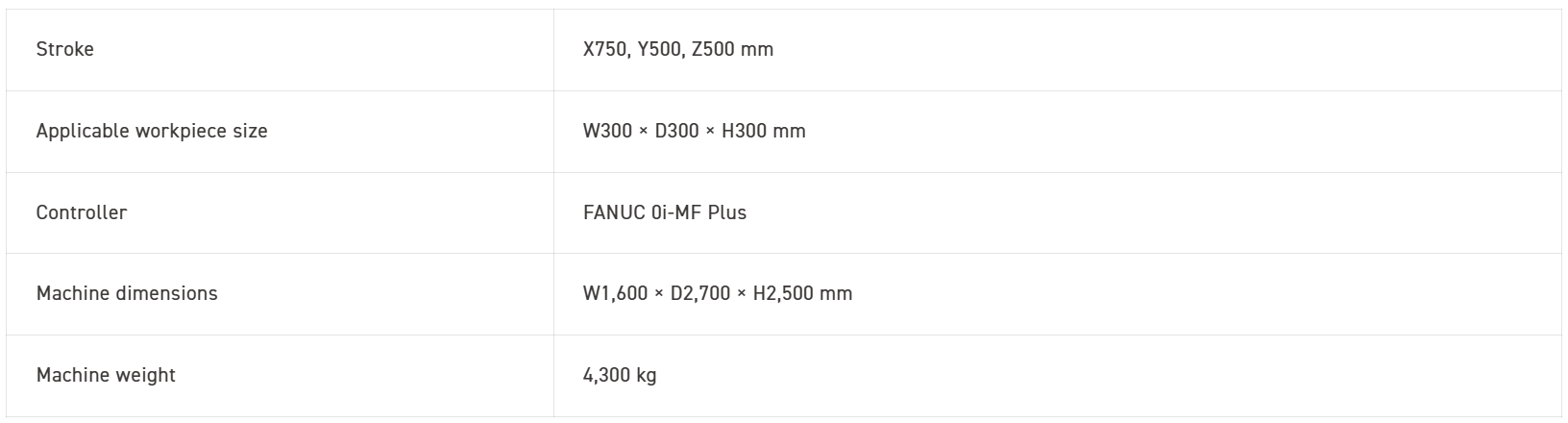

CASF Main Specifications