Data and quality management software

ZEISS PiWeb

Transform quality data into meaningful results

Making truly informed decisions

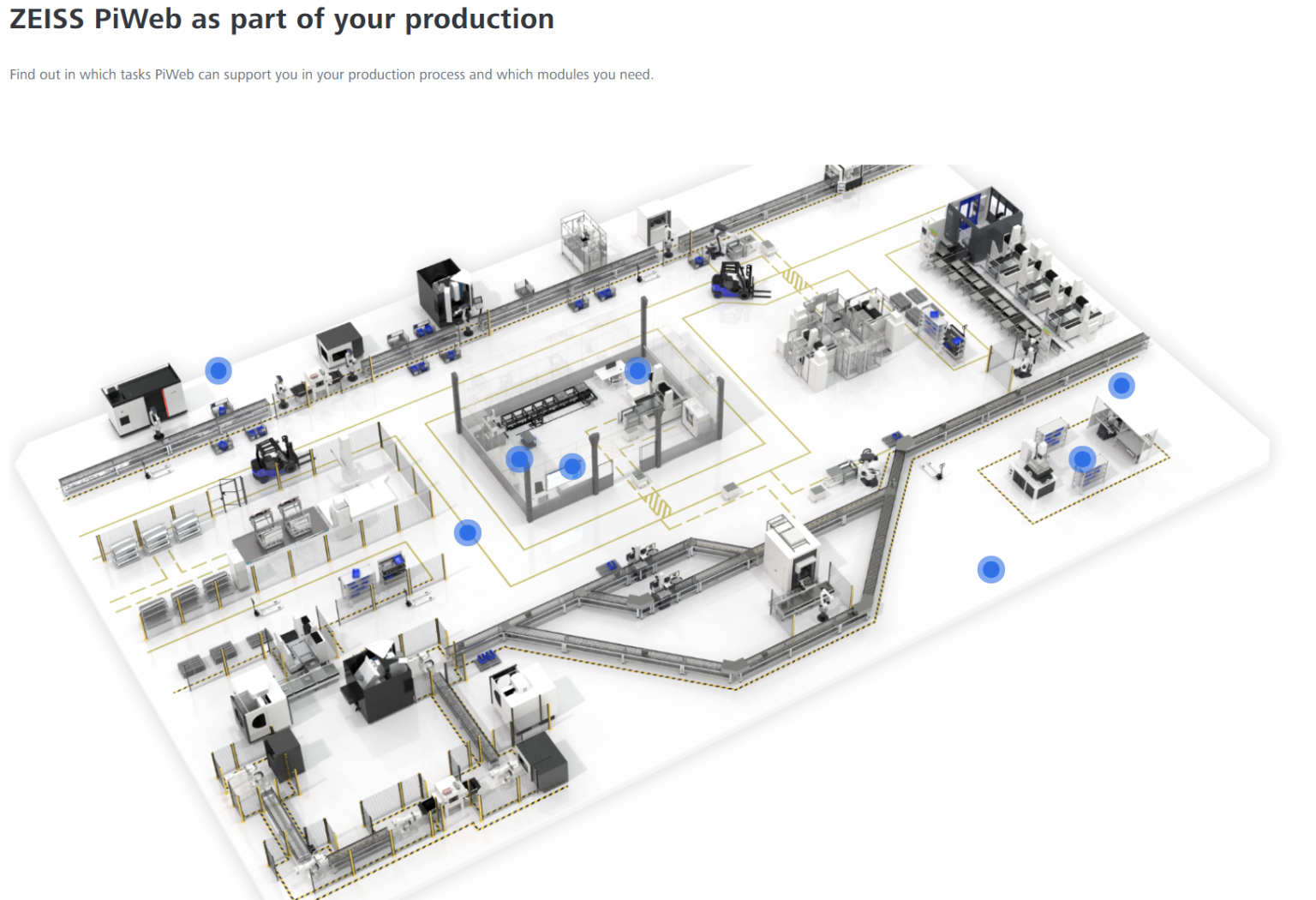

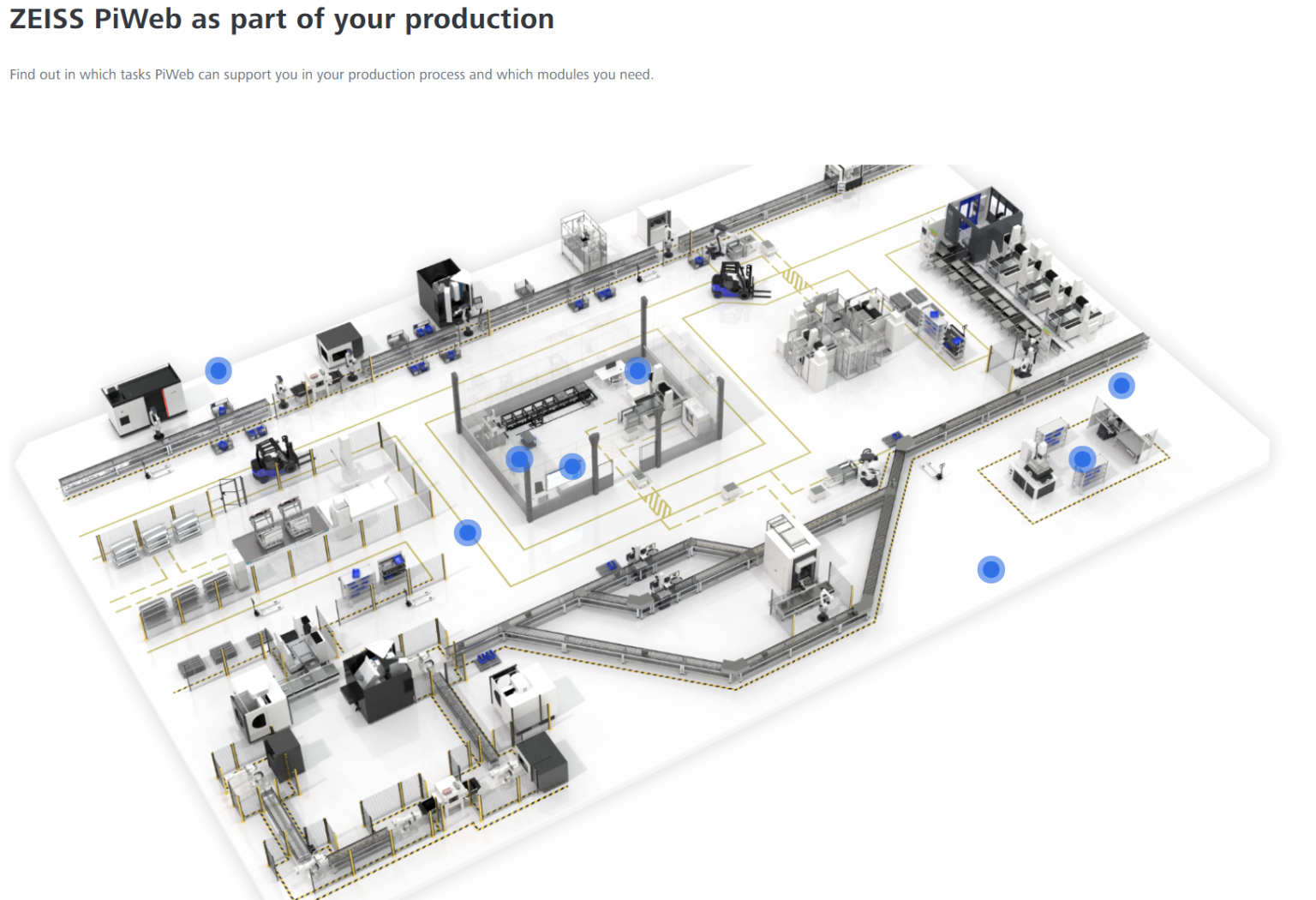

Industrial metrology is essential to deliver reliable product quality to your customers. Our ZEISS PiWeb reporting and quality data management software helps to connect measurement results coming from different measuring technologies to shop floor decisions. This way, you can efficiently track your production quality.

Use ZEISS PiWeb as an engineering tool for decision making – perform GR&R studies, control quality data management, work with manual data, create powerful statistics and profit from various ready-to-use standard report templates. Even for big data.

Making sense of your data

Regardless of what your reporting requirements are, ZEISS PiWeb has the tools to help you organize and visualize quality data exactly how you need it. From filtering and sorting your measurement data to creating your own reports from scratch. You can also benefit from many ready-to-use report templates.

DATA ANALYSIS

Powerful data analysis made easy

With ZEISS PiWeb you can analyze your measurement data very easily and quickly without being a software expert. The simple filtering, sorting and grouping options save you time and enable you to create tailored reports according to your needs.

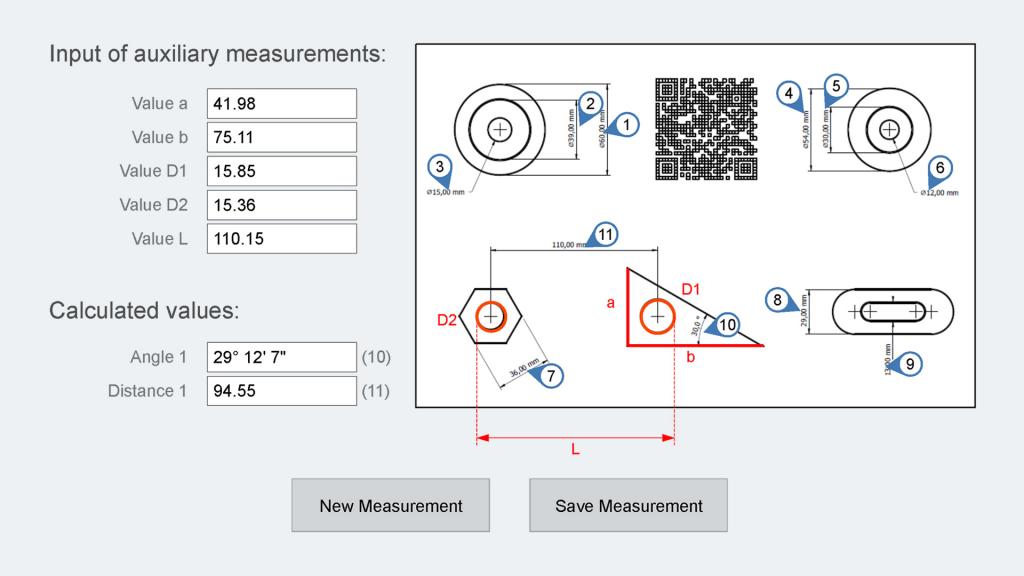

CUSTOM REPORTING

Tailored reports and custom solutions

ZEISS PiWeb is highly flexible and customizable in order to get the best results, tailored to your specific requirements. You can easily digitize manual processes such as data entry, customer reporting requirements, first article inspection and many more. Create your report exactly how you need it.

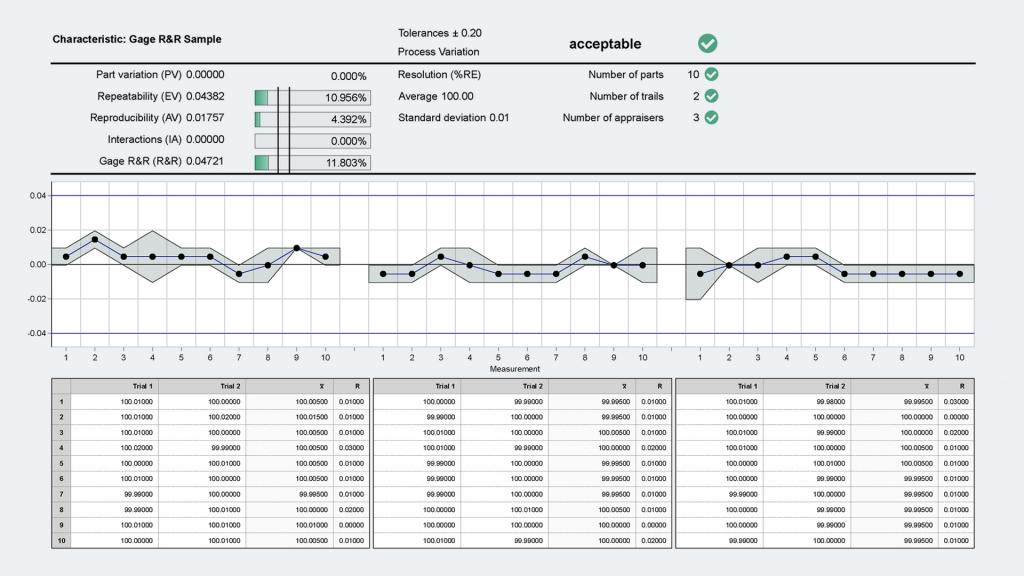

POWERFUL STATISTICS

Better results with powerful statistics

Track your production quality on all levels. Statistics made with ZEISS PiWeb provide information about the quality of measuring systems and measurement results as well as the production process itself: perform GR&R studies, report machine capability or create statistical overviews of your manufacturing process.

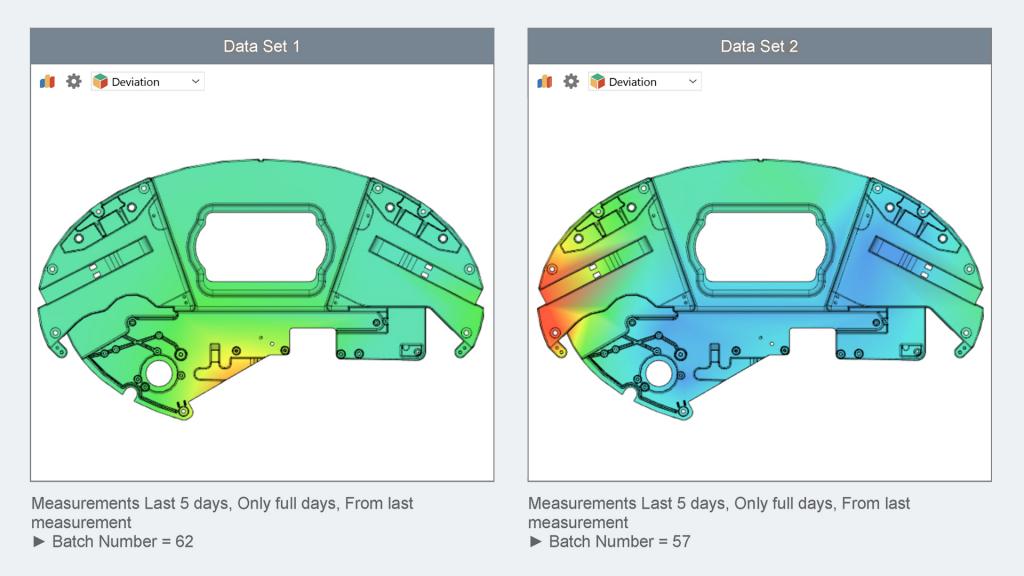

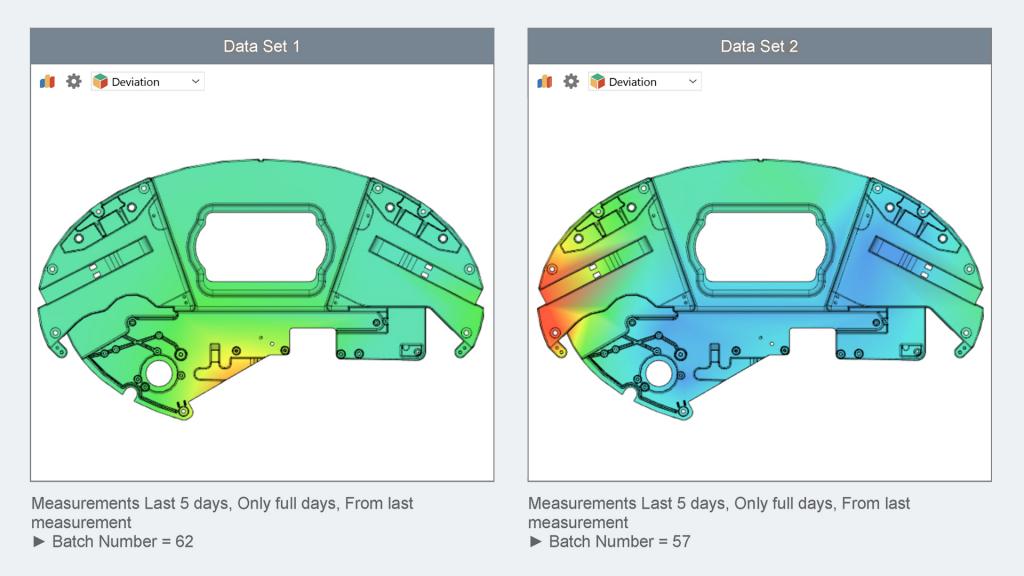

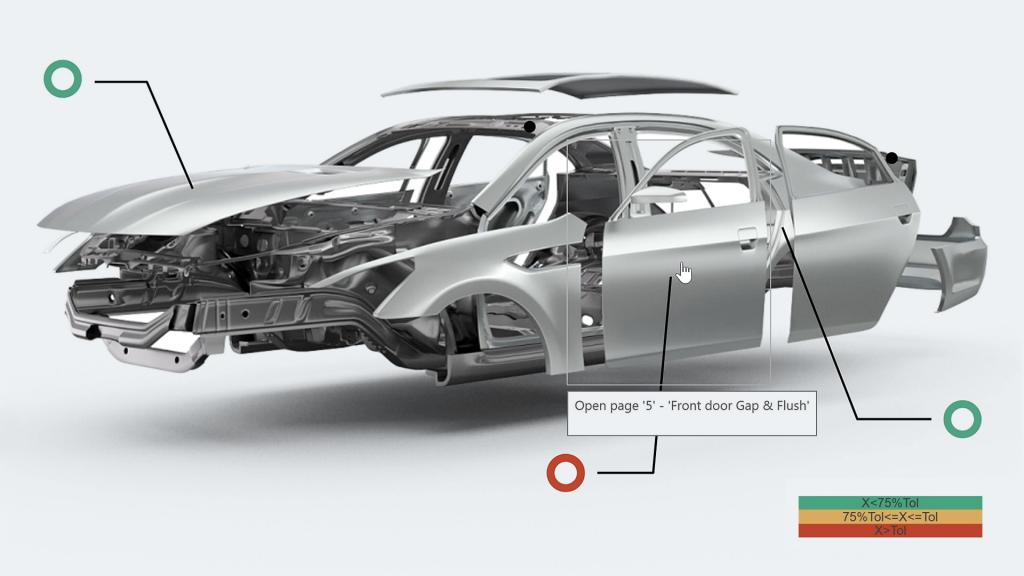

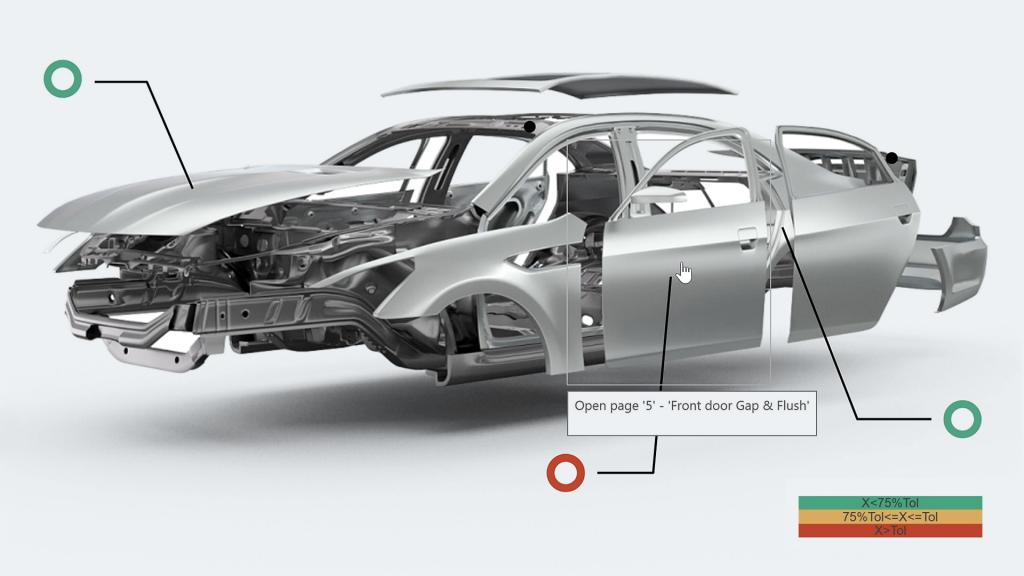

INTERACTIVE REPORTS

Fast decision-making in quality assurance

Static reports such as PDFs are often not enough to make timely and confident decisions. With ZEISS PiWeb, there are endless possibilities to interact with real-time data. Learn how you can always easily find the information you need.

ZEISS PiWeb is a modular software

ZEISS PiWeb is composed of various modules that can be used depending on the task. This makes the software flexible and individually configurable. Find out which modules are suitable for your application.

ZEISS Smart Services

Transform machine data into uptime

In the age of Industry 4.0, connectivity is key. Unlock the full potential of your ZEISS measuring solutions – and maximize their capability – with ZEISS Smart Services, our digitally enhanced service options. Benefit from greater machine availability, safety of measurement processes and higher productivity.

- Real-time monitoring and analysis of important data

- Central overview of the key performance indicators

- Plan measurement processes and react quickly and specifically to critical situations

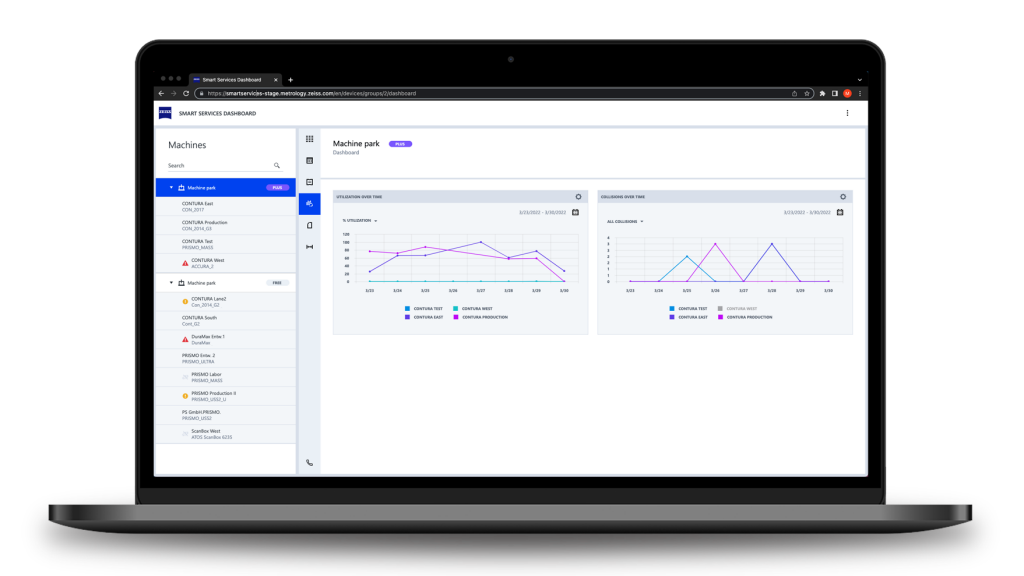

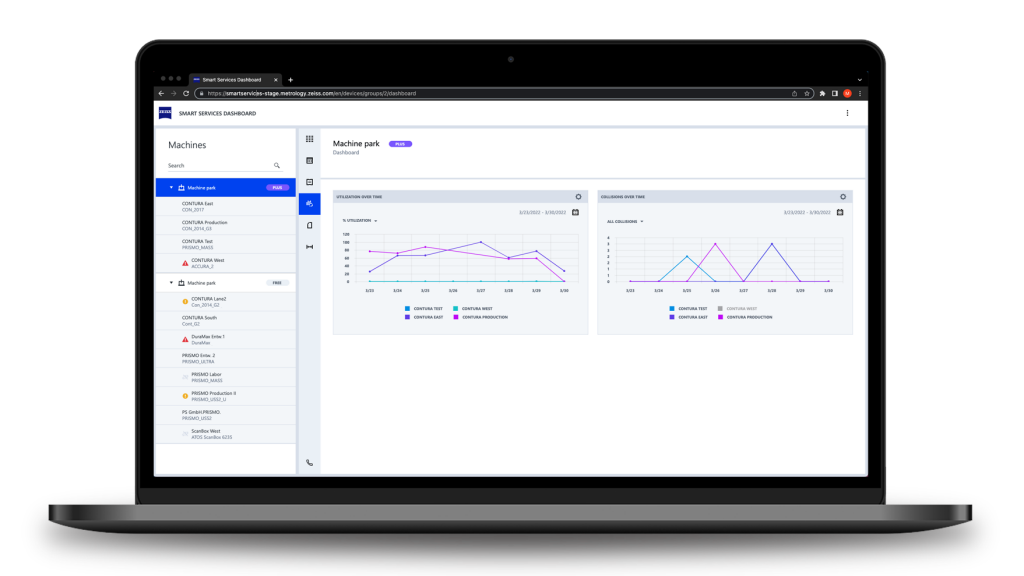

ZEISS Smart Services Dashboard

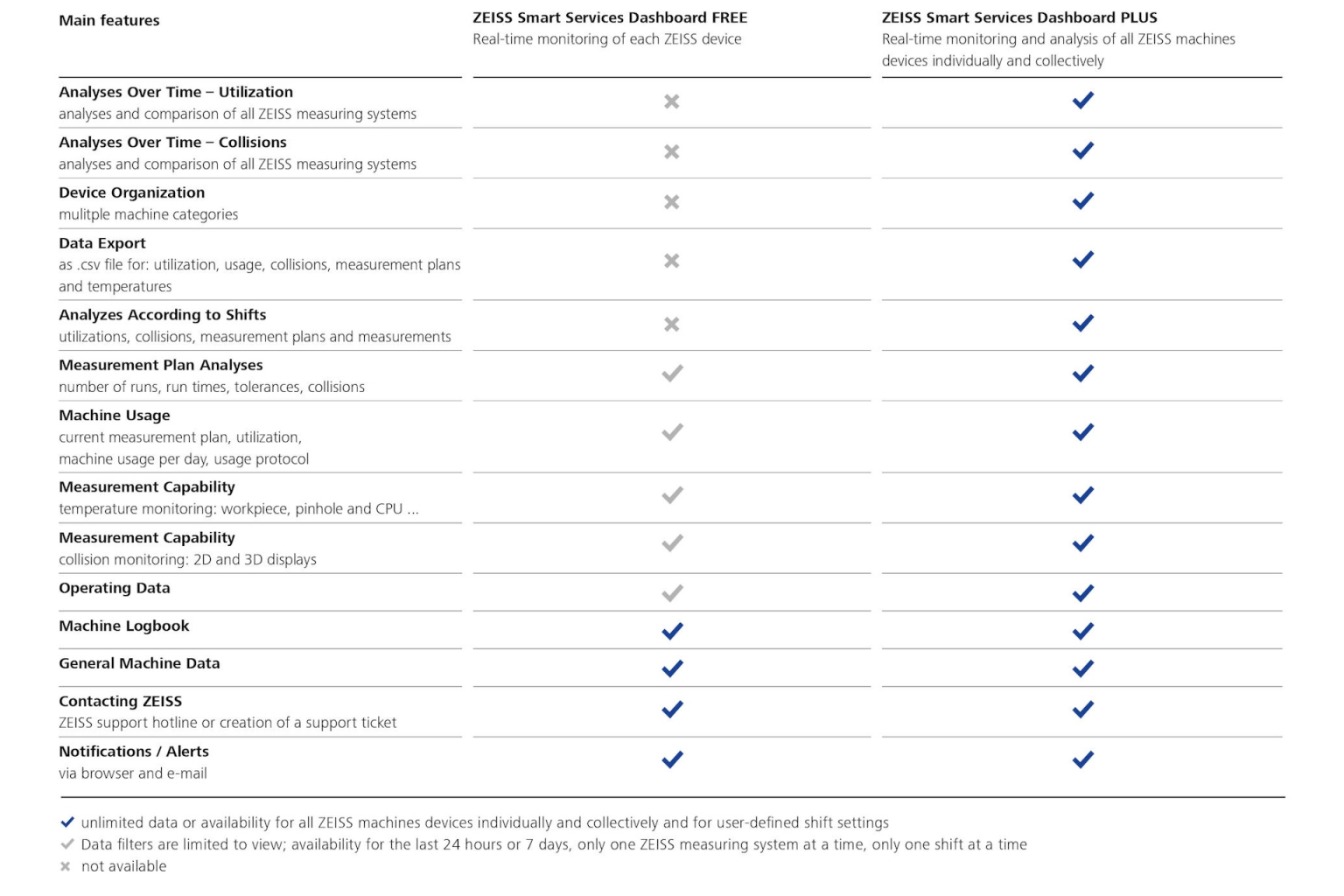

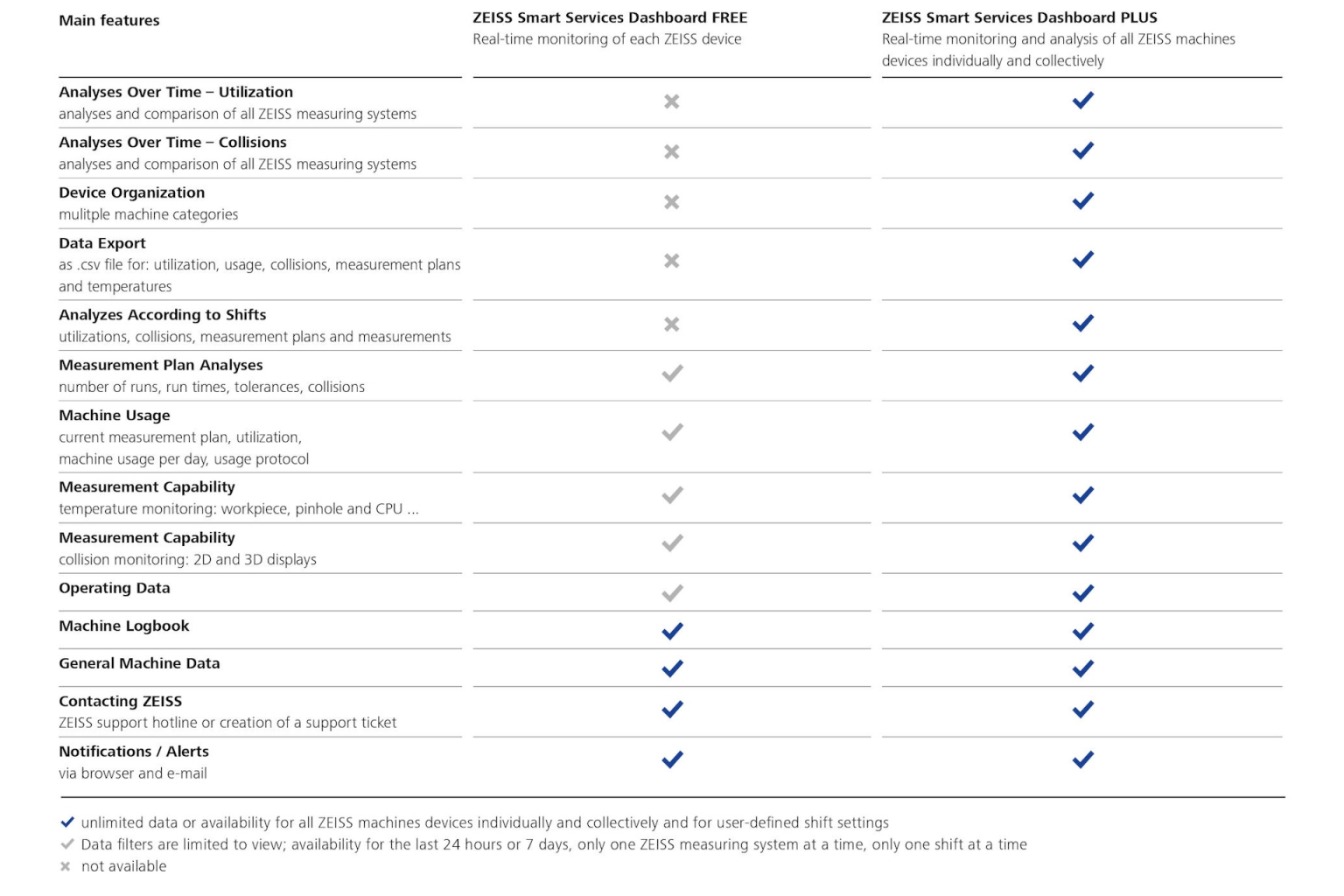

FREE vs. PLUS version

In addition for the ZEISS Smart Services Dashboard FREE, ZEISS offers a ZEISS Smart Services Dashboard PLUS. With the PLUS version, the machine data can not only be monitored in real-time, but also analyzed thanks to unlimited data display and additional functions.

ZEISS Smart Services Dashboard feature highlights

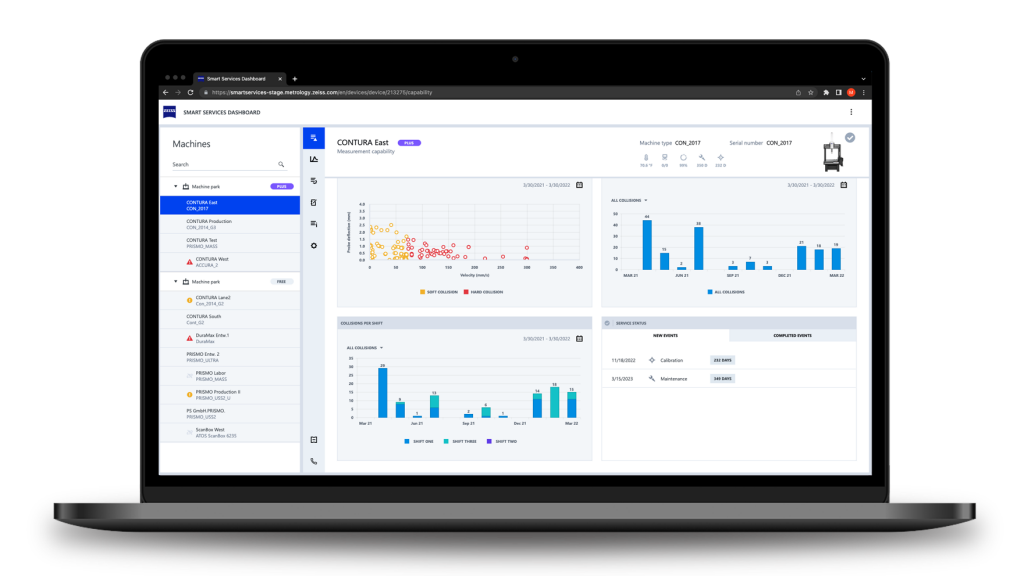

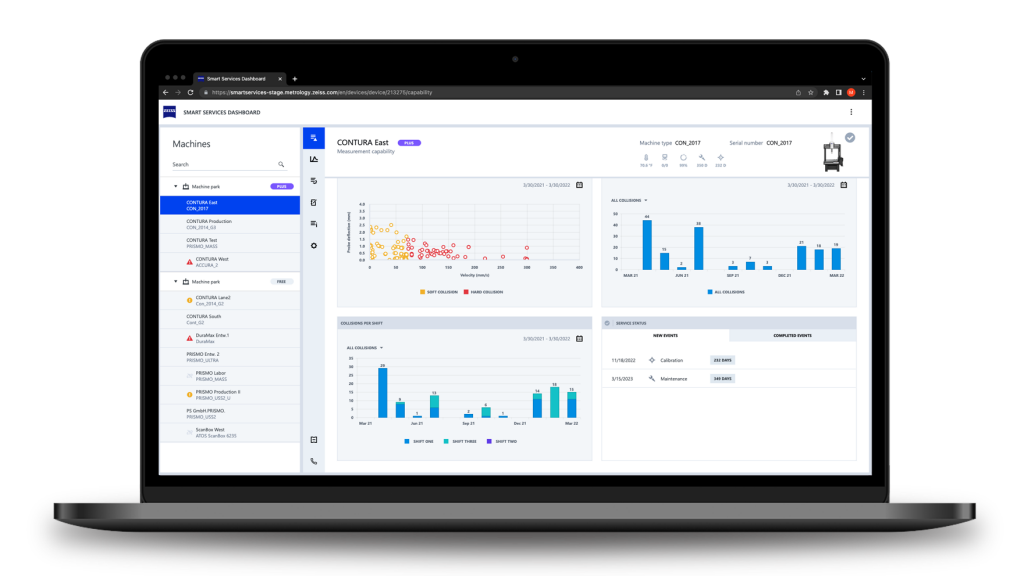

Multiple machine analyzes

If your company owns several ZEISS measuring machines, the multiple machine analyzes function offers clear monitoring with regard to collision and utilisation information of all of your ZEISS machines so that you can compare them. In this way, users receive meaningful information regarding the utilisation and measuring capability of individual machines in order to be able to make appropriate adjustments and optimization measures. For example, measurement processes can be transferred, service work can be scheduled or potential sources of error can be recognized in good time and then eliminated.

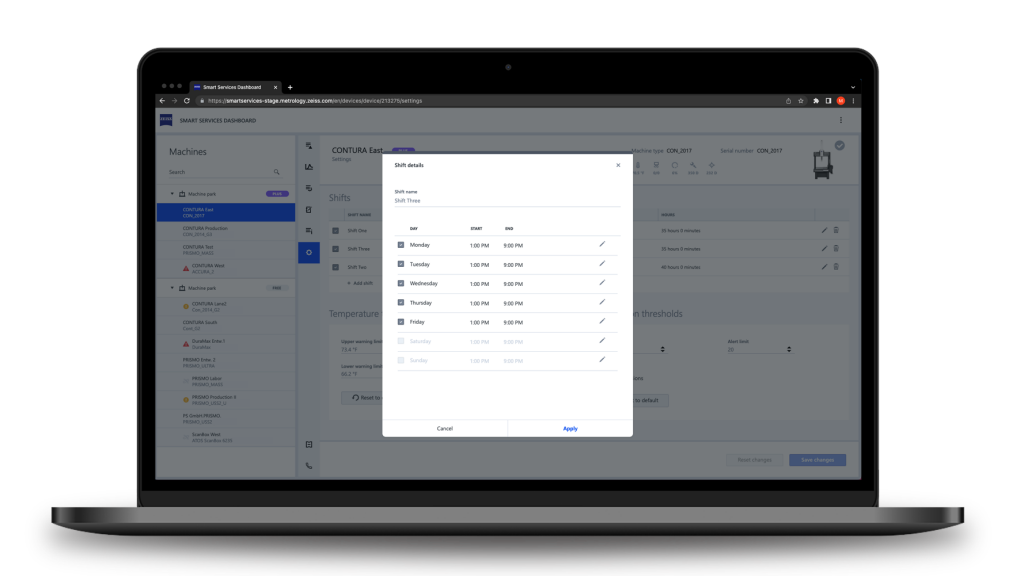

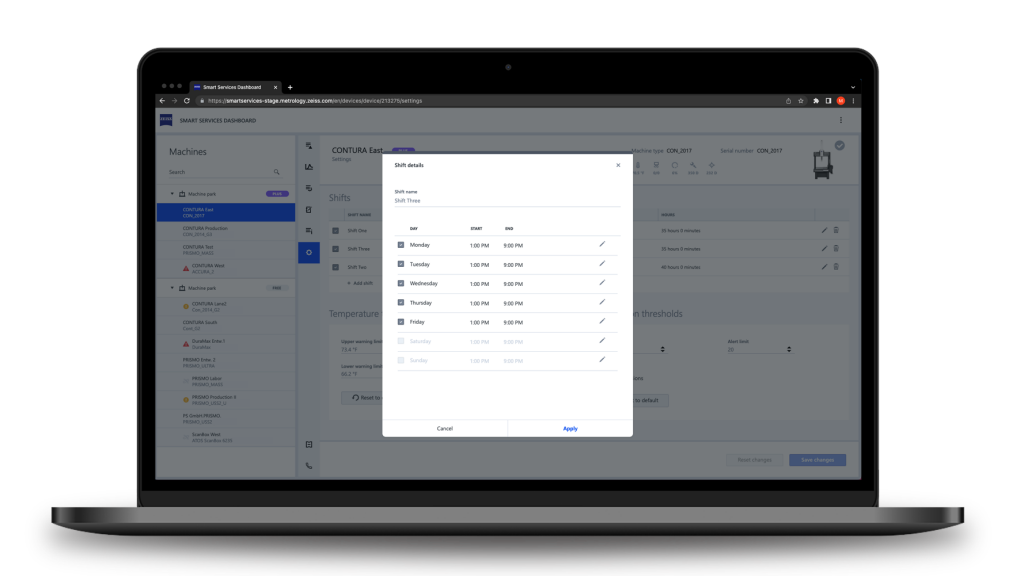

Shift analyzes

Evaluate your data based on defined shift times. Data patterns and critical conditions become visible through precise filtering. Save your own shift times and evaluate the data based on them with the new ZEISS Smart Services Dashboard PLUS. Through precise filtering of the data patterns and critical conditions become visible. Machine utilization, collisions as well as availability and productivity become transparent. This makes it easy for example to identify shift-specific sources of problems and to solve them quickly.

No time limitation

With the ZEISS Smart Services Dashboard PLUS, you can view and retrieve all data from the time of machine installation or dashboard activation – over the entire time life cycle of the measuring machine. Unlimited data recording and storage enables you to perform professional and customised analyses of various kinds. In addition, continuous process control is achieved, which is of great advantage during audits and thus supports your quality management.

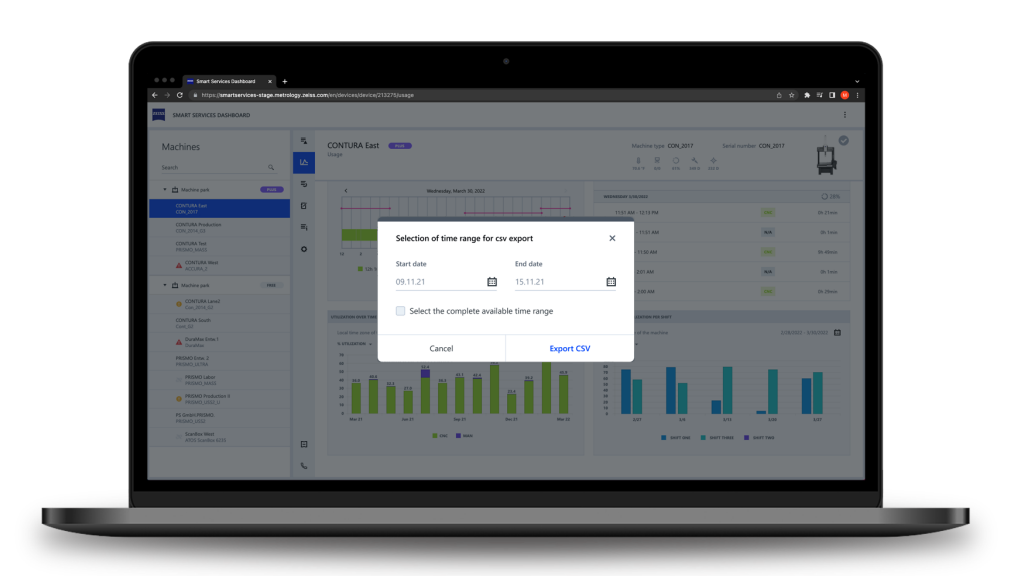

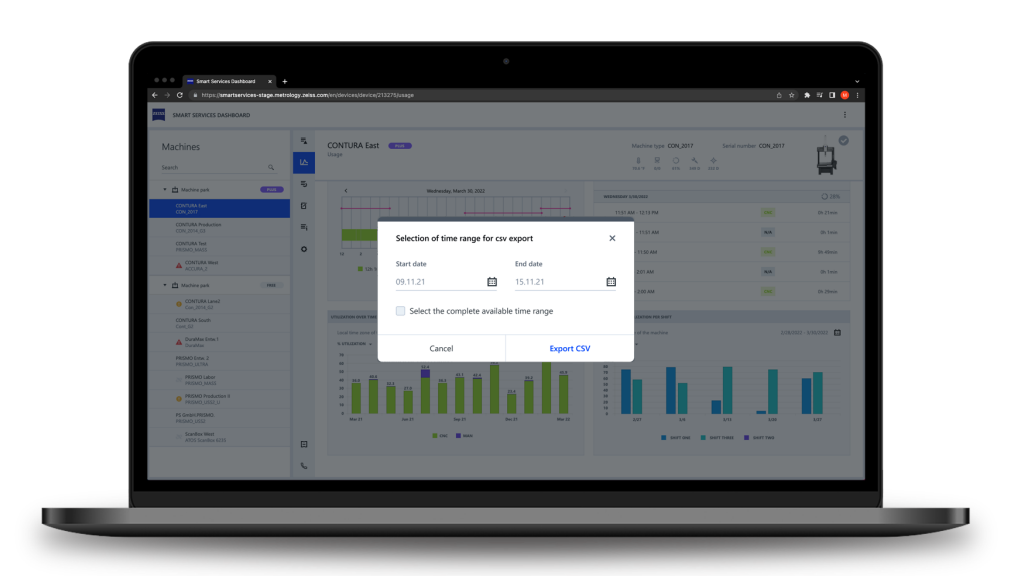

Data export

Would you like to perform further analyses and need the data from the ZEISS Smart Services Dashboard PLUS? The new export function allows you easily to download a wide range of machine data in csv format. In this way, you can easily filter the data that is valuable and interesting to you and carry out user-specific analyses and evaluations in relation to utilization, usage, collisions, measurement plans or temperatures on the corresponding database.

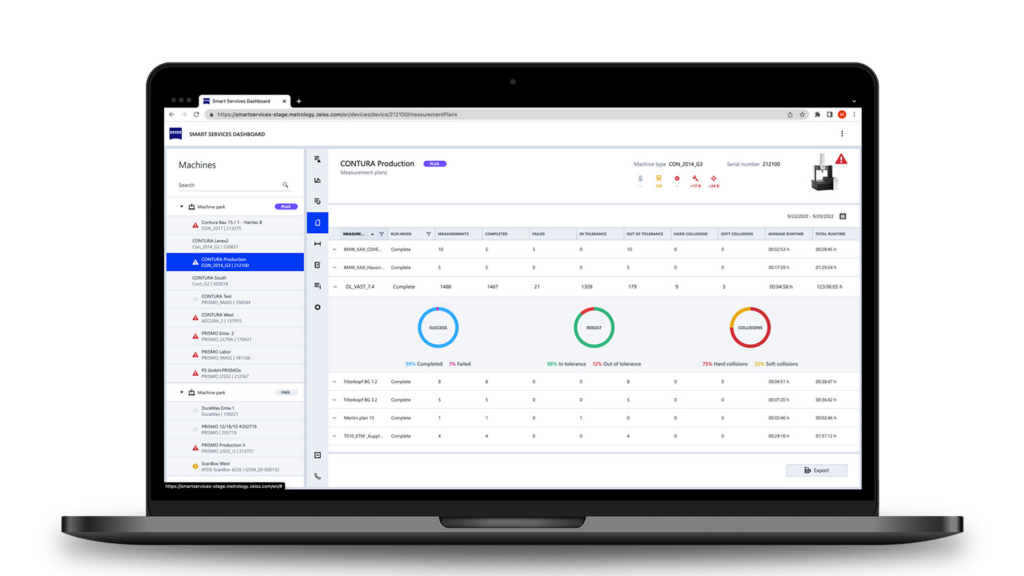

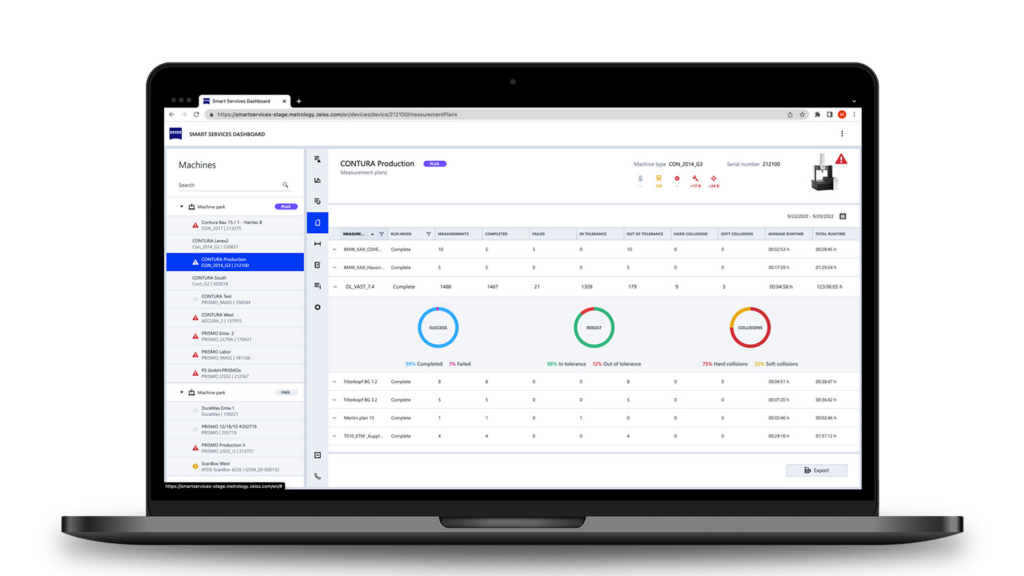

Monitor & analyze measurement plans

The functions provide you the transparency of all your measurement plans performed on your ZEISS machine devices individually and collectively, including number of runs, running times, completed & failed, in/out of tolerances and number of collisions. This enables a very simple root cause analysis of measurements with collisions and/or out of tolerances, needed to implement process improvements. In addition, you can increase your flexibility of with respect to parts being measured on different machines.