Metrology and inspection software

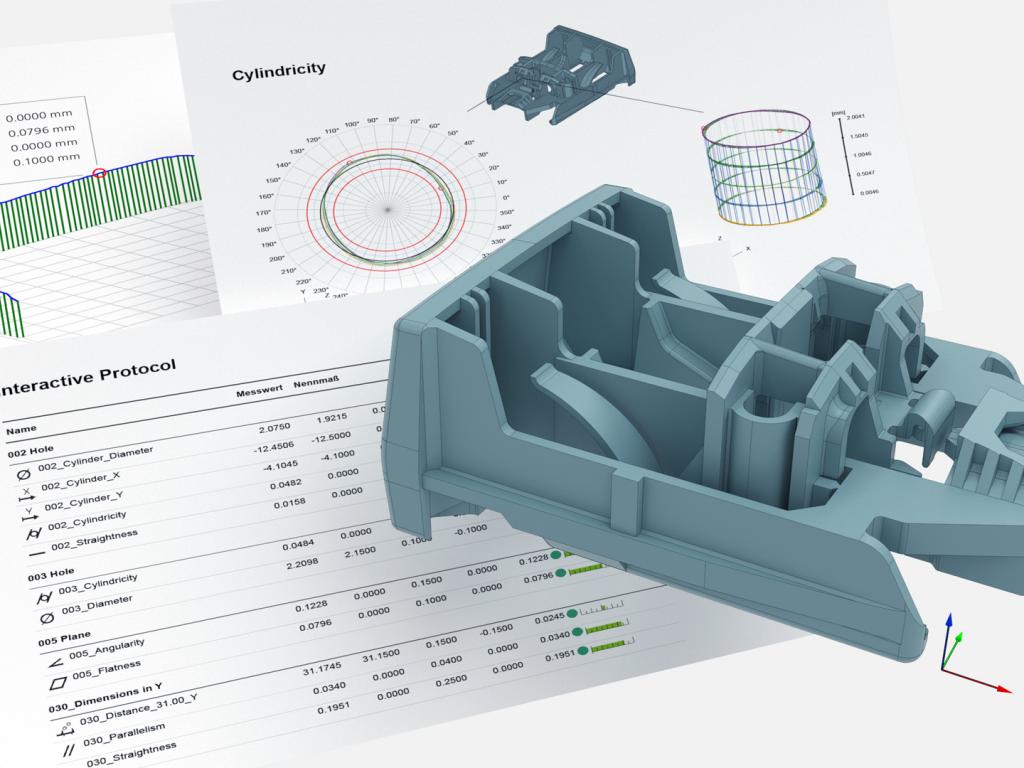

ZEISS CALYPSO

The direct path to meaningful results

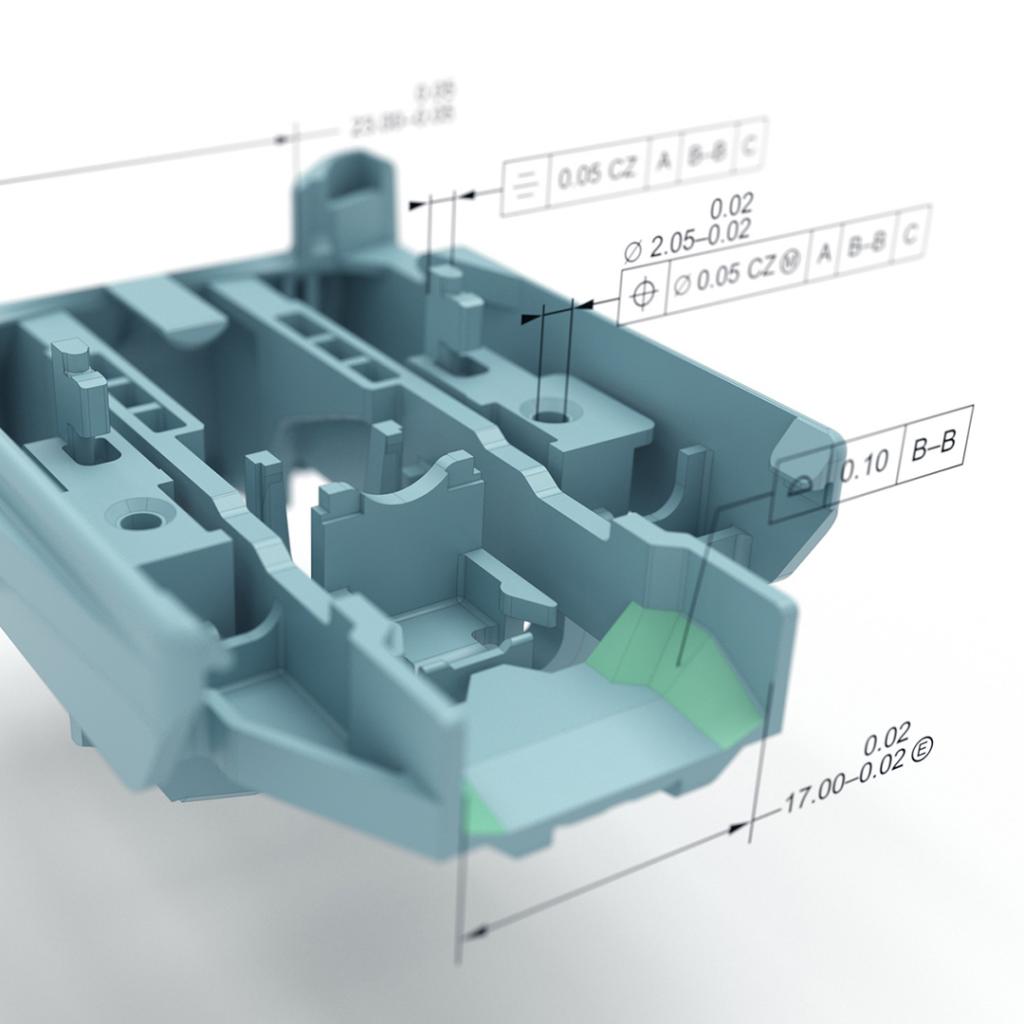

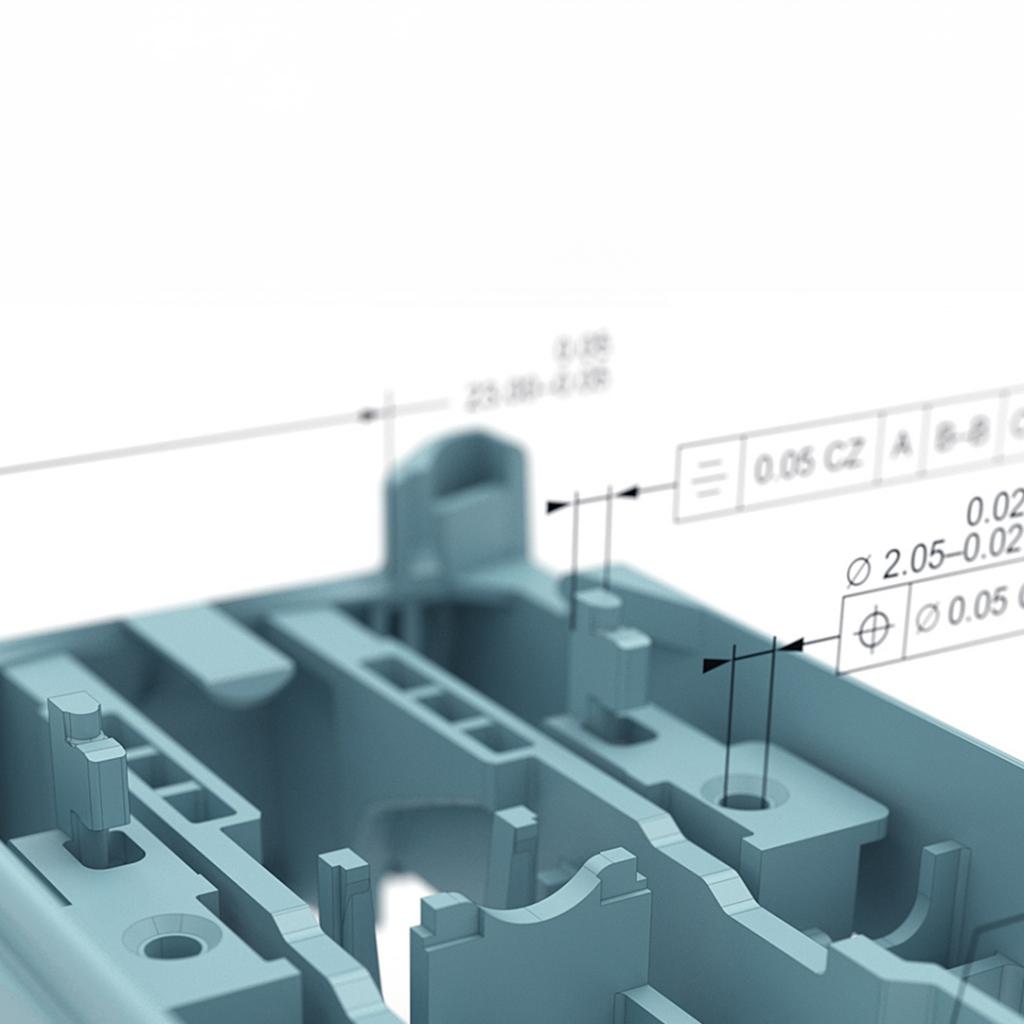

Your software for coordinate measuring machines: ZEISS CALYPSO measures geometrical elements simply, quickly and reliably. Just click the desired features to configure inspection plans. Combined with ZEISS measuring systems and sensors, you will have a powerful one-stop system. The software will also adjust to your demands: Due to numerous optional add-ons, ZEISS CALYPSO also offers the right tools for special requirements.

The software delivers the results

Combined with ZEISS CALYPSO, the ZEISS coordinate measuring machines tap their full potential. Optimize your quality control: The software supports you before, during and after the measurement. Measure and analyze your workpieces with all sorts of different functions and get the best out of your coordinate measuring machine.

Adjust ZEISS CALYPSO to your needs

ZEISS CALYPSO software options

ZEISS provides numerous software options to customize ZEISS CALYPSO for special applications and measuring tasks. Do you want to measure curve-related features? Or simply create inspection plans offline? Or carry out a surface analysis of non-standardized 3D geometries? Why not use one or more options? You can purchase any option on top of ZEISS CALYPSO to adjust the software to your individual measuring requirements.

Discover more

ZEISS CALYPSO software options

Expand your software easily

ZEISS CALYPSO is your universal software for dimensional metrology and measures standard geometries easy, fast and reliably. ZEISS offers you numerous software options for the software for special applications and measuring tasks to expand ZEISS CALYPSO. Would you like to measure curve-related characteristics? Or simply create inspection plans offline? Then use one or more options. You can purchase these in addition to ZEISS CALYPSO to adapt the software to your individual measurement requirements.

- Adapted to your needs

- Even more powerful

- Automated processes

General Options

Discover how you can make ZEISS CALYPSO even more powerful and increase your productivity.

ZEISS CALYPSO planner

With ZEISS CALYPSO planner, measurement plans can be created offline. This way, your measuring machine is not tied up and ready for other tasks.

With the software option, you have the ability to create complete CNC measurement plans on a workstation remote from the CMM. Your advantage: Measurement plans created with CALYPSO planner can be opened and executed at any time directly on the CMM. The benefit: The CMM is not blocked for programming and can be used for measuring. The overall process throughput is thus retained and your productivity is increased.

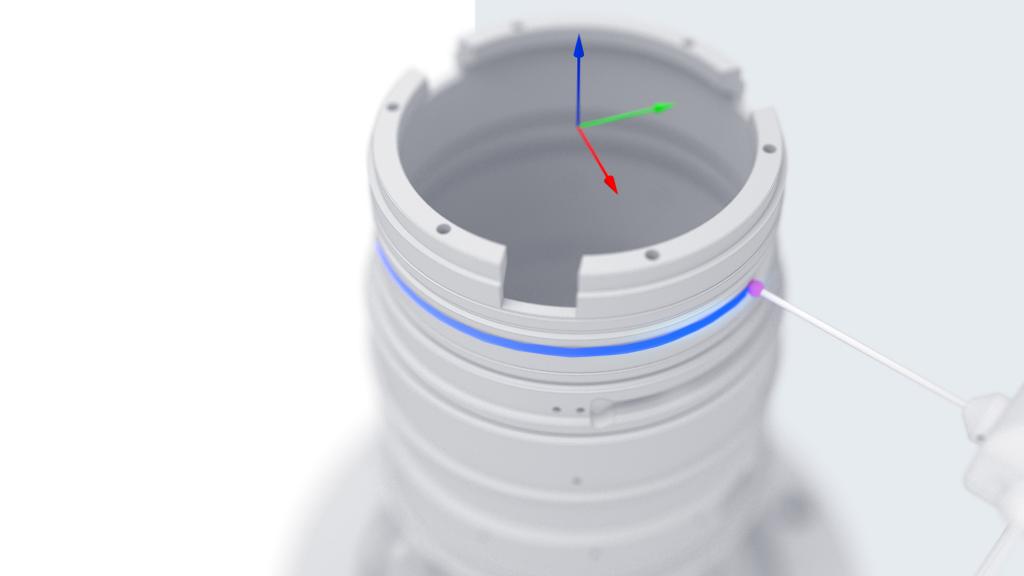

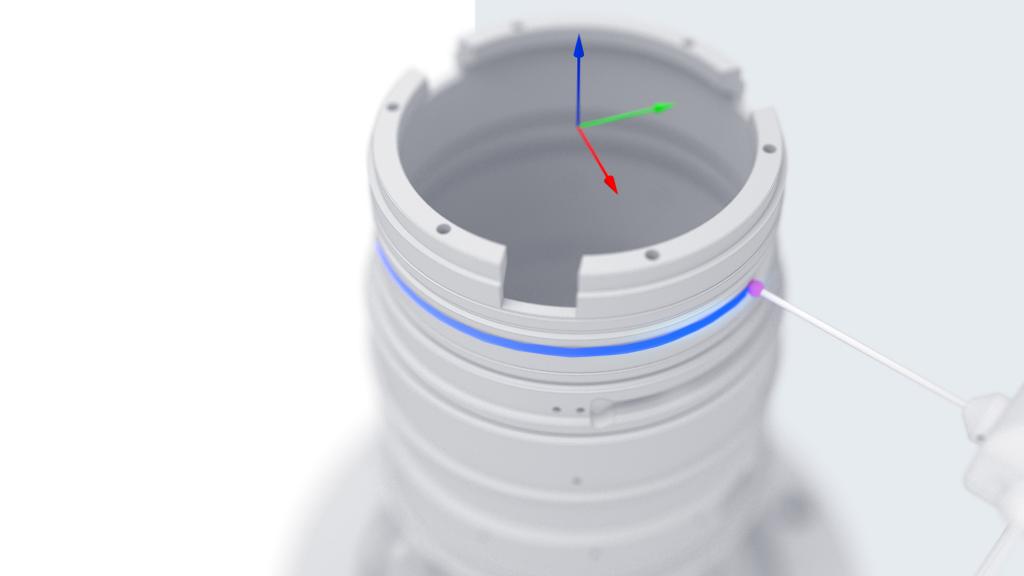

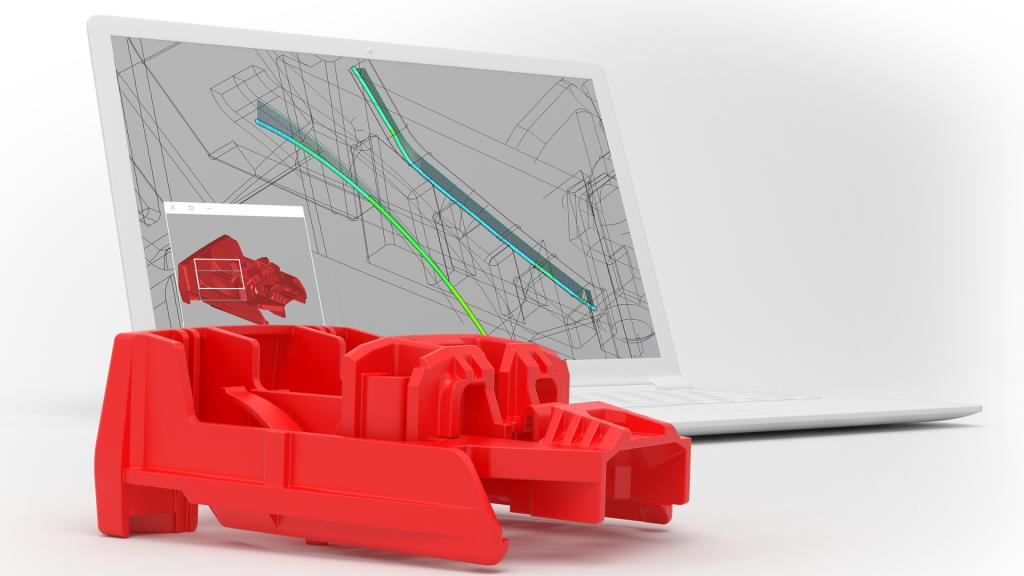

ZEISS CALYPSO simulation

ZEISS CALYPSO simulation software option makes it possible to simulate the complete measuring program, including the CMM travel paths. Measurement plans can thus be optimized without CMM connection. The visualization on the CAD window helps users to identify whether the measurement sequence or stylus systems should be altered in order to achieve a better result in less time.

The CAD simulation includes the CMM environment and the workspace on the CMM. Critical situations, such as collisions, can be identified and eliminated up front.

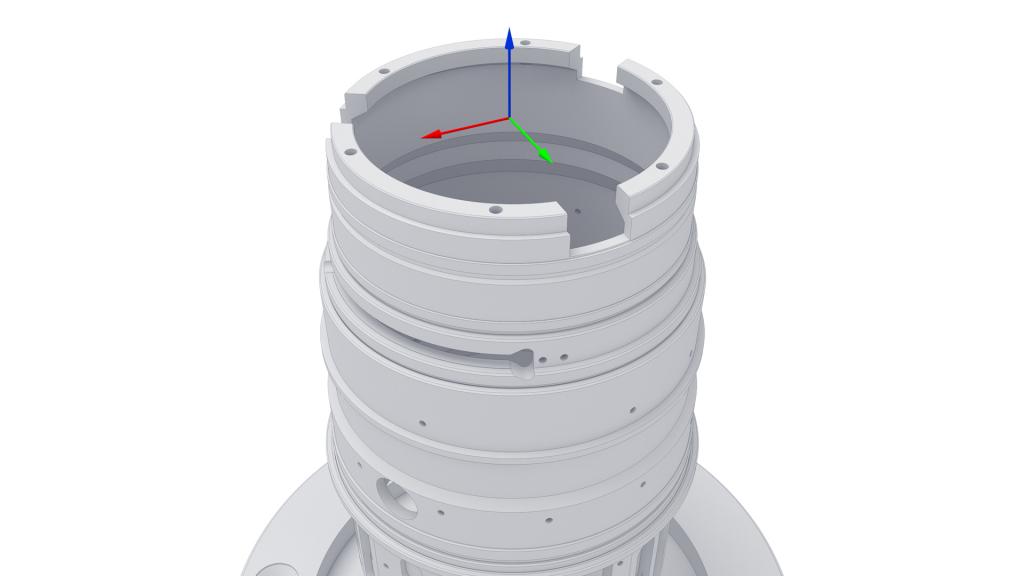

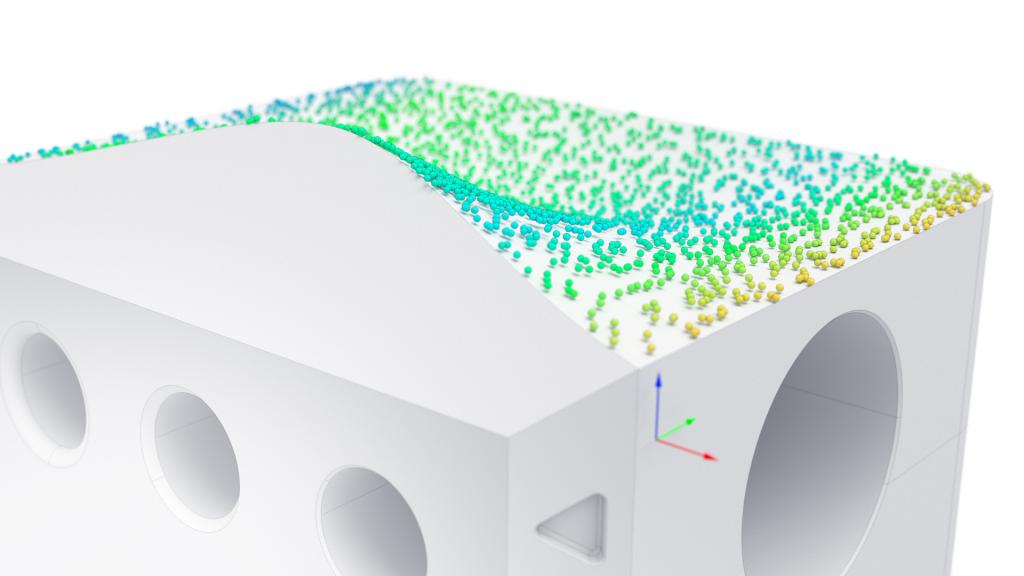

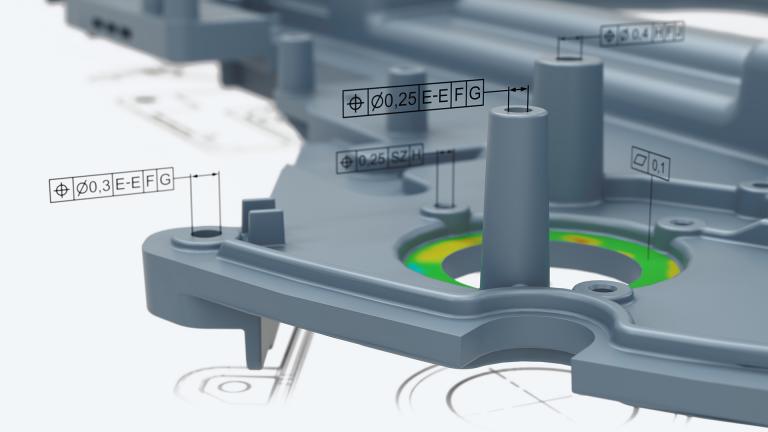

ZEISS CALYPSO freeform

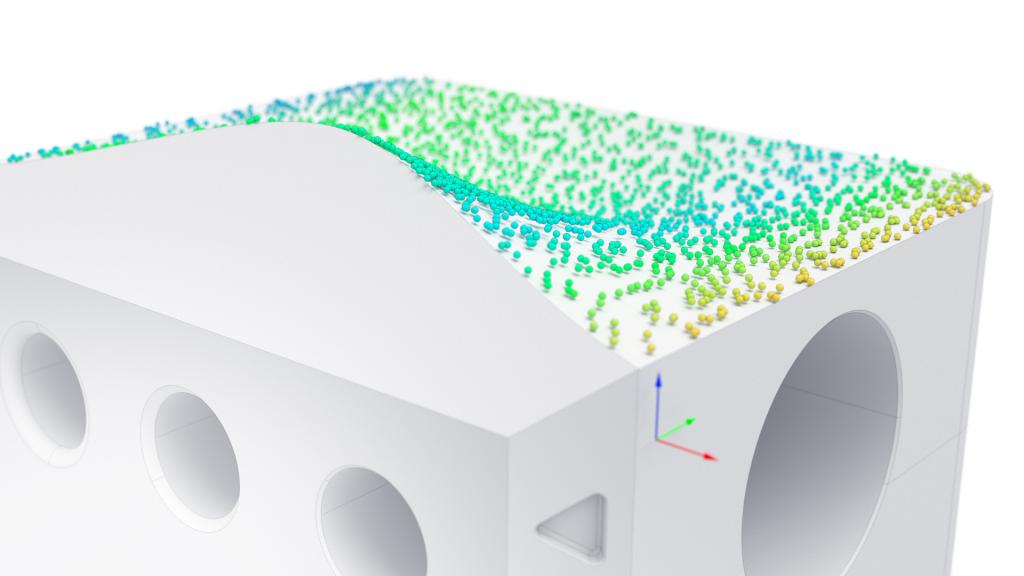

ZEISS CALYPSO freeform is a software option for measuring, inspecting and analyzing workpieces with non-standard 3D geometries and performing surface analysis.

The software option calculates the distance between measurement points and the CAD model. The measurement results can be used to show the differences between the nominal and actual surfaces. ZEISS CALYPSO offers an improved mathematical algorithm for even better performance. The measurement results are now available 20 times faster than before.

ZEISS CALYPSO curve

ZEISS CALYPSO curve enables measurements and analyses of 2D curves (intersection on one plane), 3D curves (intersection on a cylinder or freeform surface), lift curves, known and unknown contours and symmetry curves. Numerous curve-related characteristics can also be reported, including curve slope, curve stroke, curve distance, curve expansion, curve length, surface area, speed and acceleration.

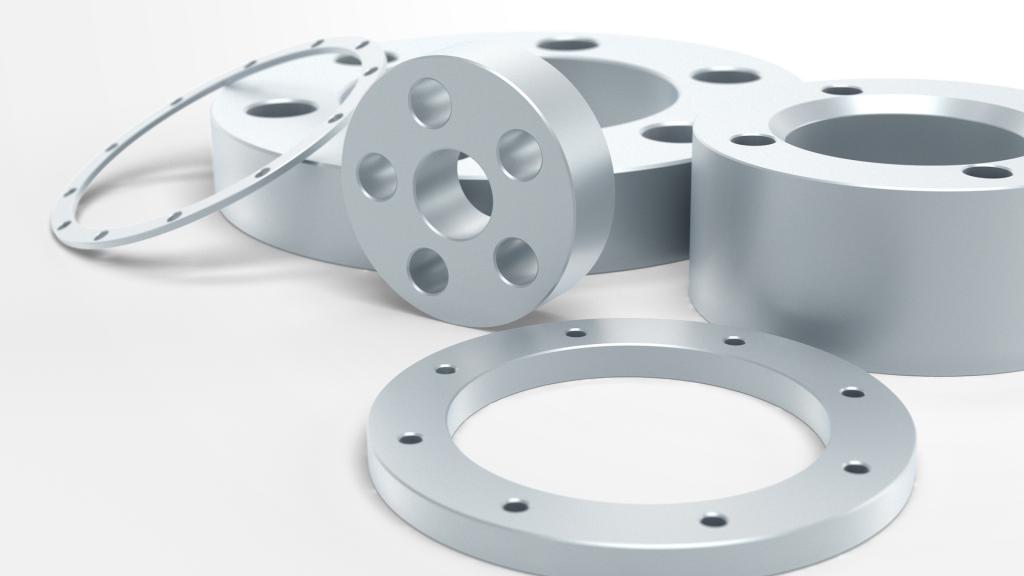

ZEISS CALYPSO PCM

ZEISS CALYPSO PCM (Parameter-Coded Measurement) significantly decreases the amount of time needed to measure workpieces of the same part family.

The software option is ideal for manufacturers that produce workpieces similar in shape, function, and production process, but only differ by a few dimensions. With CALYPSO PCM there is no need for creating a measurement plan for each individual workpiece in a family anymore. With this, you can save time in the overall programming process for a family of workpieces.

ZEISS CALYPSO roughness

ZEISS CALYPSO roughness is a software option for determining and graphically displaying roughness parameters as a function of selected parameters.

The complete integration of the roughness measurement ensures that you capture all the characteristics of your component in one measurement run – in full compliance with the standards.

Automation

Improve your productivity

ZEISS CALYPSO basic automation

With this software option, ZEISS measuring devices can be easily integrated into partially or fully automated production processes.

ZEISS CALYPSO FACS

FACS is a job management/SCADA software that coordinates and automates the entire measurement and inspection process — ideal for complex manufacturing processes.

ZEISS CALYPSO barcode reader

This software option removes the need to manually select the inspection plan and enter the protocol parameters of a part to be inspected.

Reporting

Software options to optimize your reporting

ZEISS CALYPSO PiWeb reporting plus

This software option provides an external application of ZEISS PiWeb reporting with many additional functionalities, statistical analysis and enlarged database for optimized report generation.

ZEISS CALYPSO Q-DAS and QIF export

Measurement results from ZEISS CALYPSO can also be exported in a format that is compatible with Q-DAS or QIF.

CAD interfaces

Use manufacturer-specific CAD files

ZEISS CALYPSO CAD converter

There are two categories of CAD converters offered with ZEISS CALYPSO. Standard interfaces allow ZEISS CALYPSO to import neutral types of CAD files, such as QIF MBD, STEP or IGES. Direct interfaces enable ZEISS CALYPSO to read manufacturer-specific CAD files. The most important benefits of CAD converters are maximum and their availability to all the functionalities in ZEISS CALYPSO for working with a CAD file.

Inspection made easy

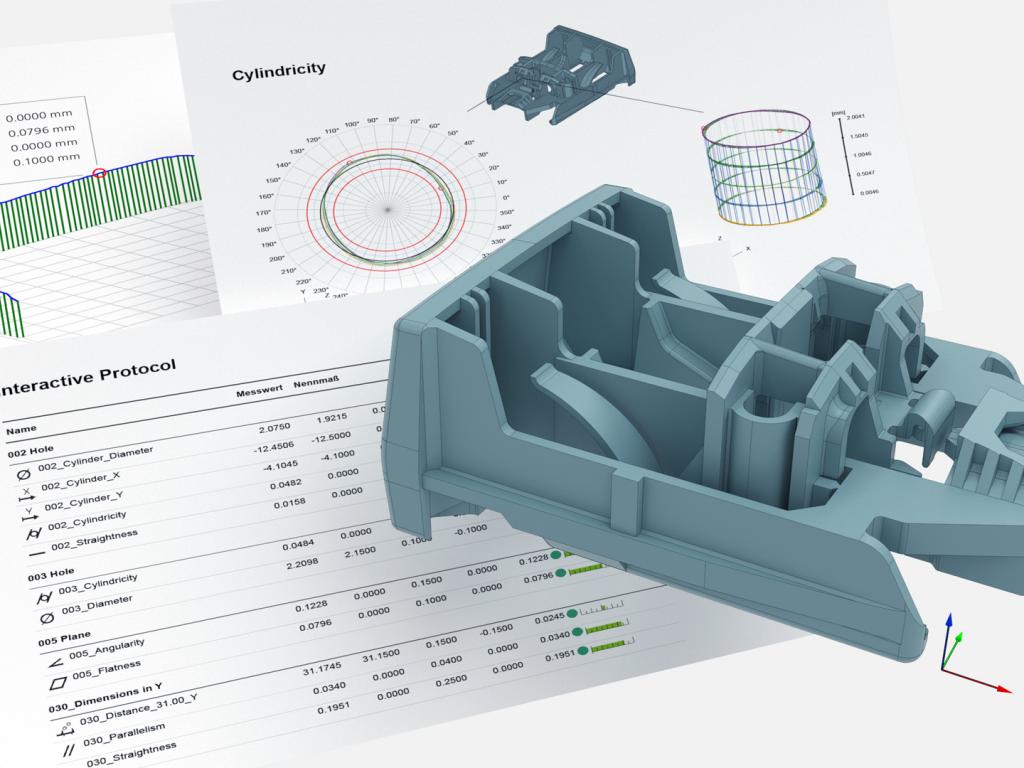

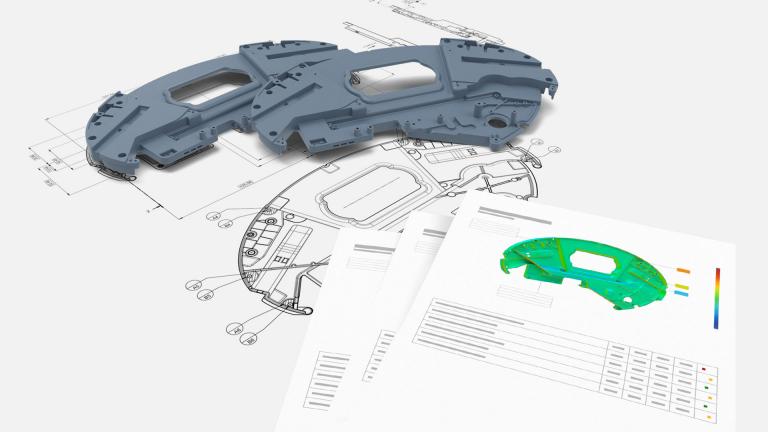

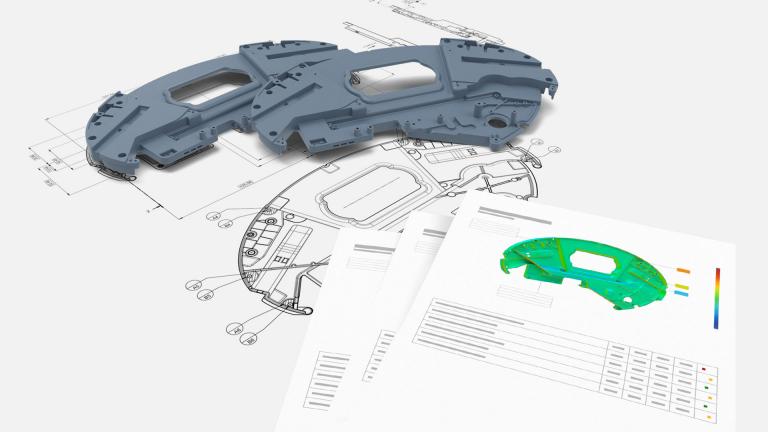

ZEISS INSPECT

One Metrology Software. Intuitive. Customizable. Automated.

The world of measurement technology is complex. There is a multitude of hardware devices, extensive analyses, and software solutions. Additionally, development, quality control, and manufacturing are subject to high competitive pressure. ZEISS INSPECT is your software to analyze multiple data sources efficiently.

What is ZEISS INSPECT?

The answer to your metrological challenges.

Simply more efficient with ZEISS INSPECT

Saves time: The all-in-one software guides you throughout the entire workflow. Convenient: All parts of the software work with the same concept. This makes learning and using the software easy and minimizes training effort. Adaptable to your needs: Customize ZEISS INSPECT based on your requirements using our pre-built apps or easily program your own apps.

Intelligent tools

To boost efficiency, ZEISS INSPECT provides many options for process automation. From classical project templates and automatic measurement sequences to AI-based applications – the software will enhance your productivity.

Scripts for your needs – fast and efficient

Using the script recorder, you can turn all actions in the software into editable Python scripts. This considerably reduces the effort required for repetitive tasks. Are you still missing a particular function? Just include the function you need via freely available Python libraries or develop it internally.

Measure, analyze, repeat – no problem

Do you need to perform the same task multiple times? Not with the parametric approach of ZEISS INSPECT. The software saves each inspection step, thereby making measurement plans traceable, repeatable, and editable. With the cluster & pattern function, multiple elements can be easily adapted.

Level up your software with apps

Need a little more? Whenever the basic functions of ZEISS INSPECT are not enough, there is certainly a suitable extension. Benefit from more than 100 pre-built apps or program your individual apps to adapt the software to your specific needs.

ZEISS INSPECT at a glance

The most important basic functions that inspire metrologists.

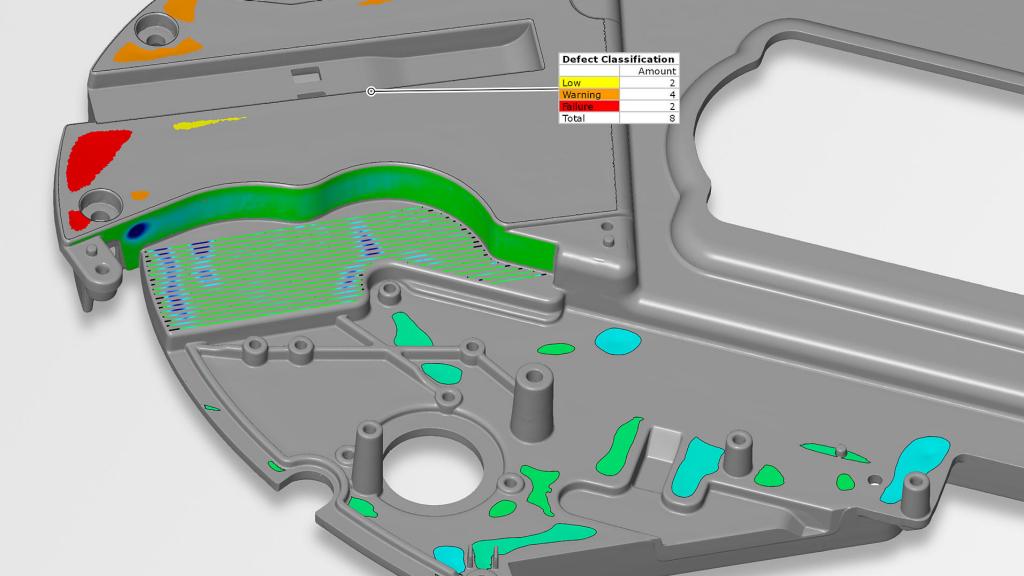

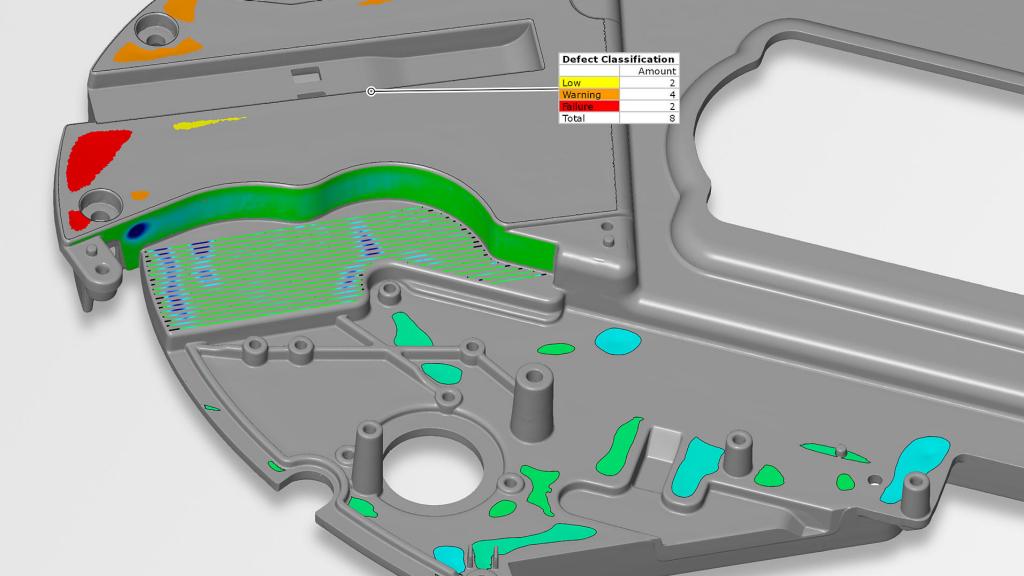

Defect inspections

Simple and fast evaluation

Using assisted defect inspection tools, ZEISS INSPECT automatically detects quality issues and categorizes them, revealing even smallest defects fast and efficiently.

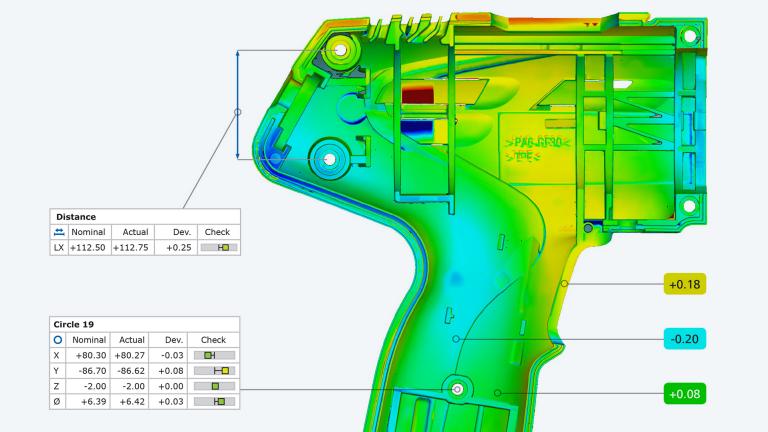

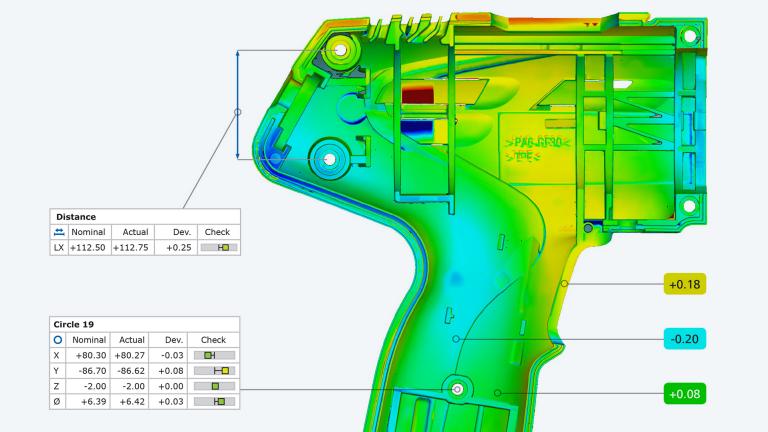

Nominal-actual comparison

Identify deviations immediately

Match polygon meshes to CAD data and visualize deviations using a highly intuitive color scale.

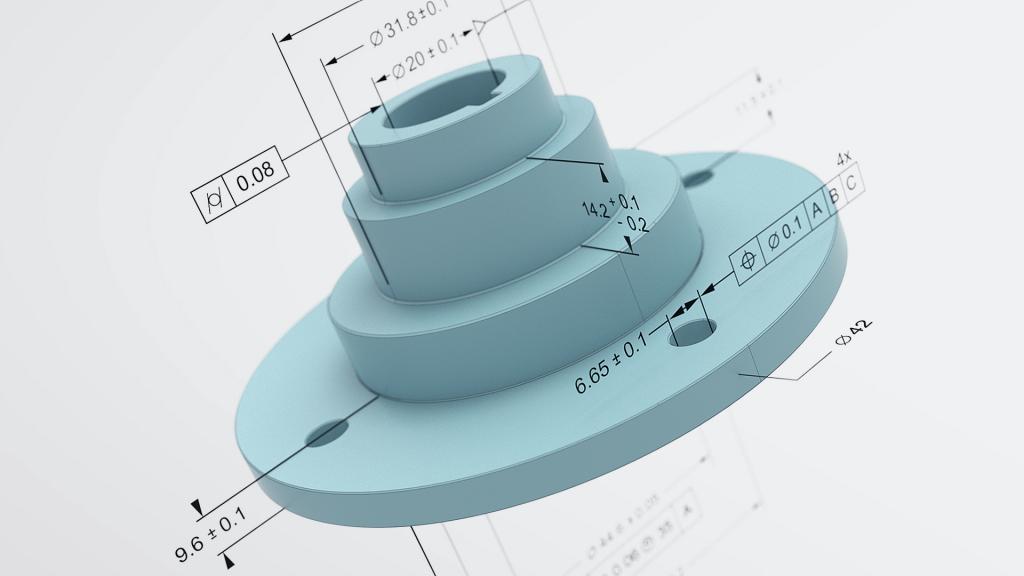

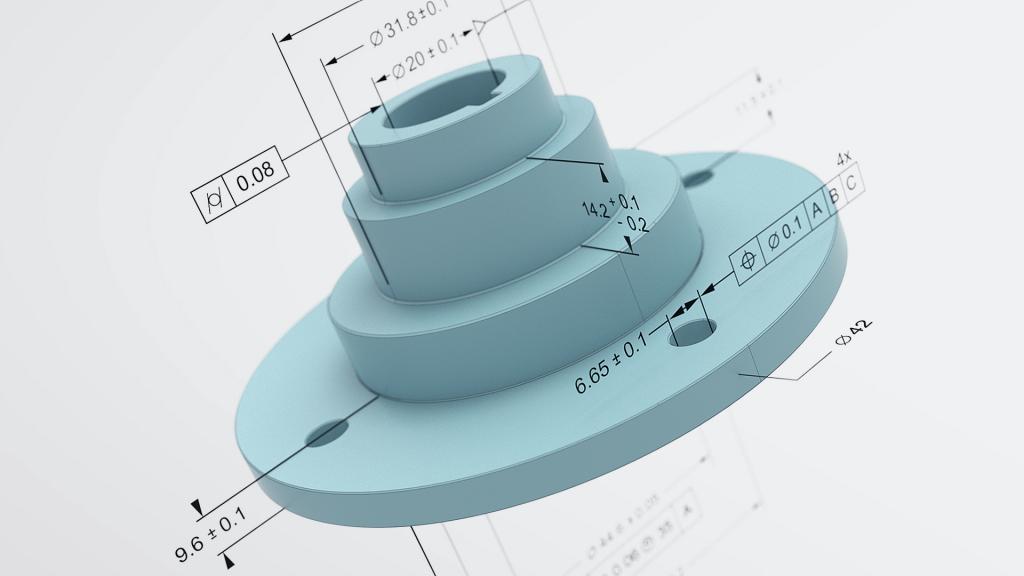

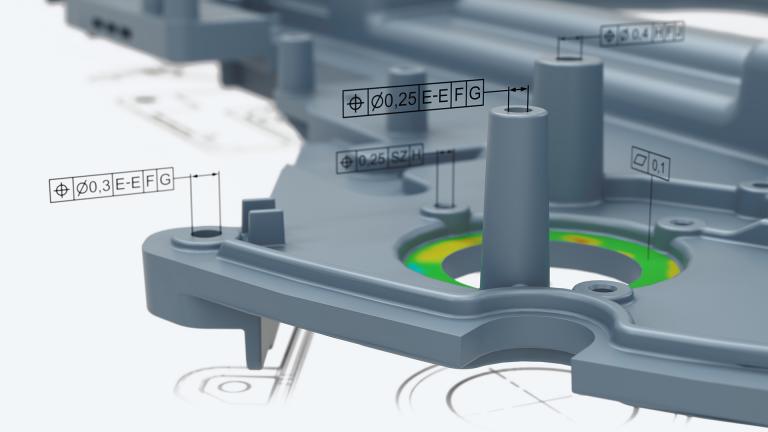

Geometric dimensioning

Is everything within tolerance?

Check in just a few steps whether the shape and position of your components are within the defined tolerances.

Reporting

Your results presented in an understandable way

Do you prefer graphics or tables? Presentations or PDFs? The various reporting options of ZEISS INSPECT enable you to represent your results in the way most appropriate for the respective situation.

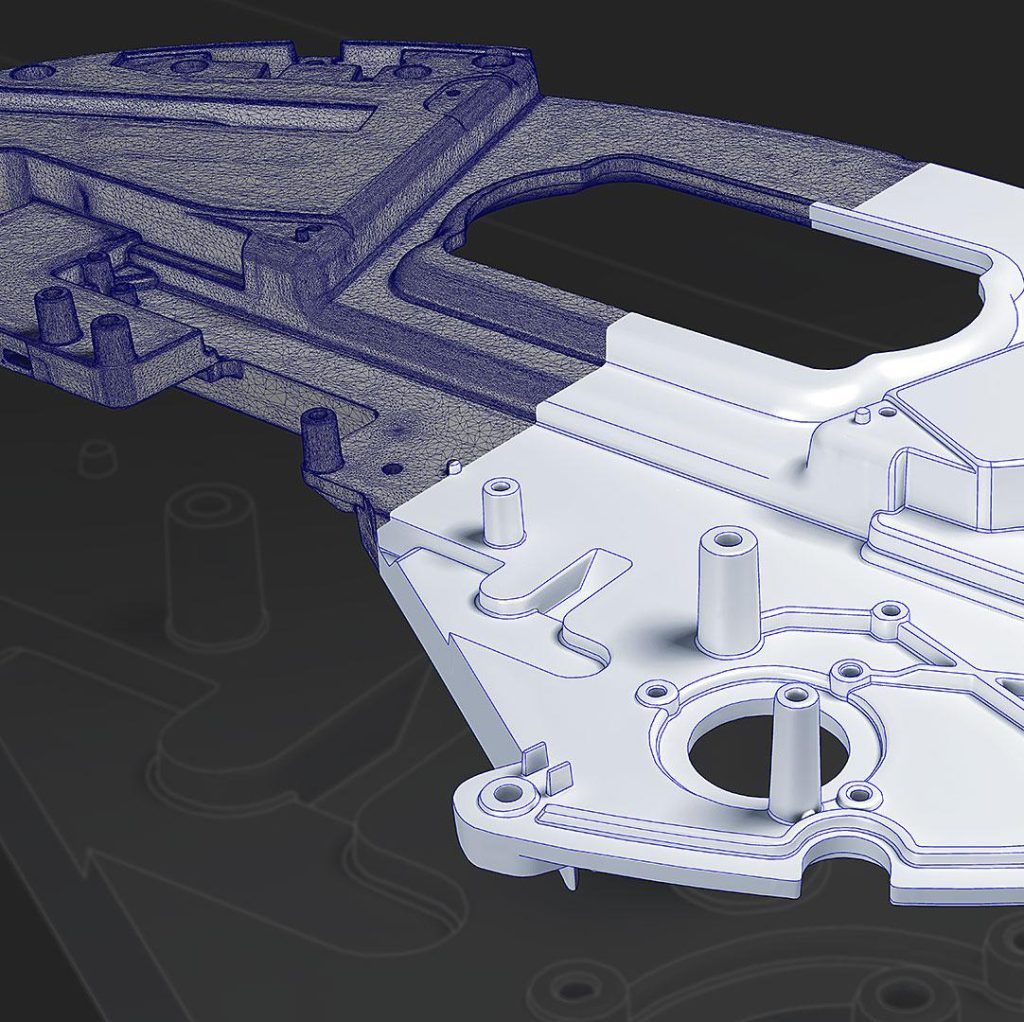

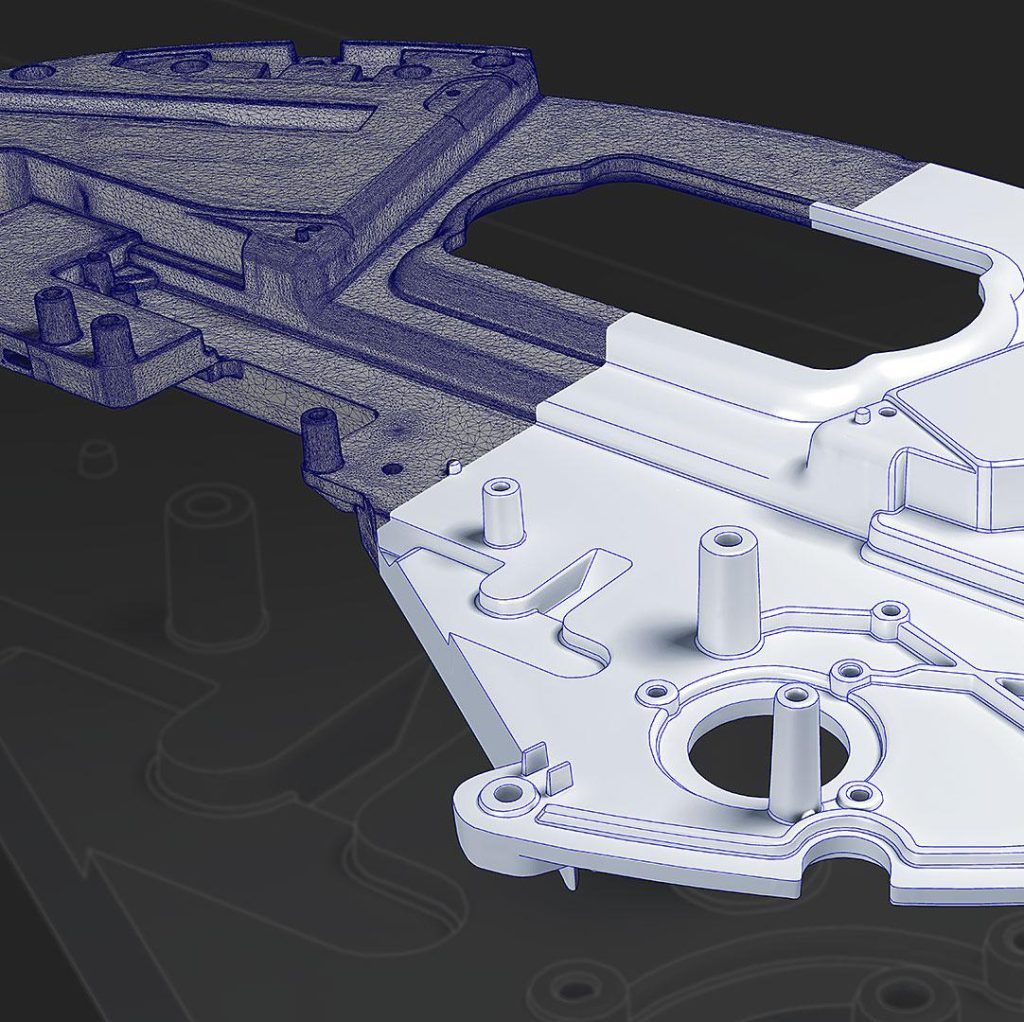

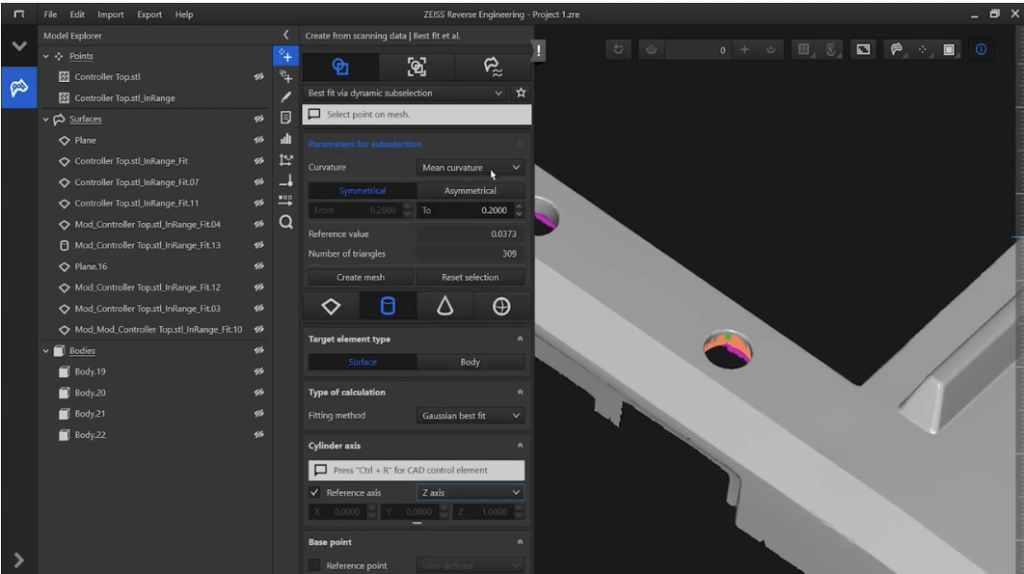

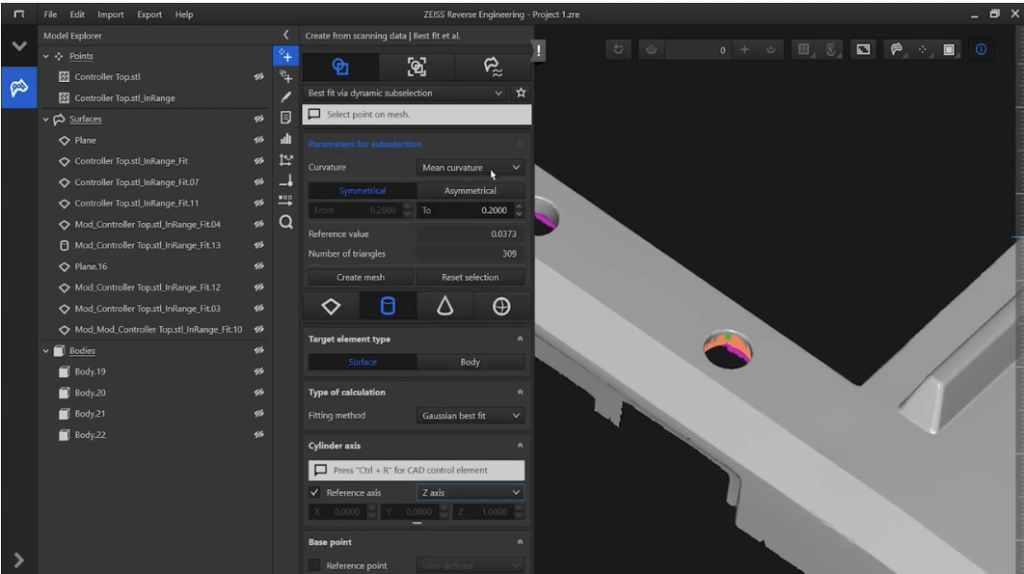

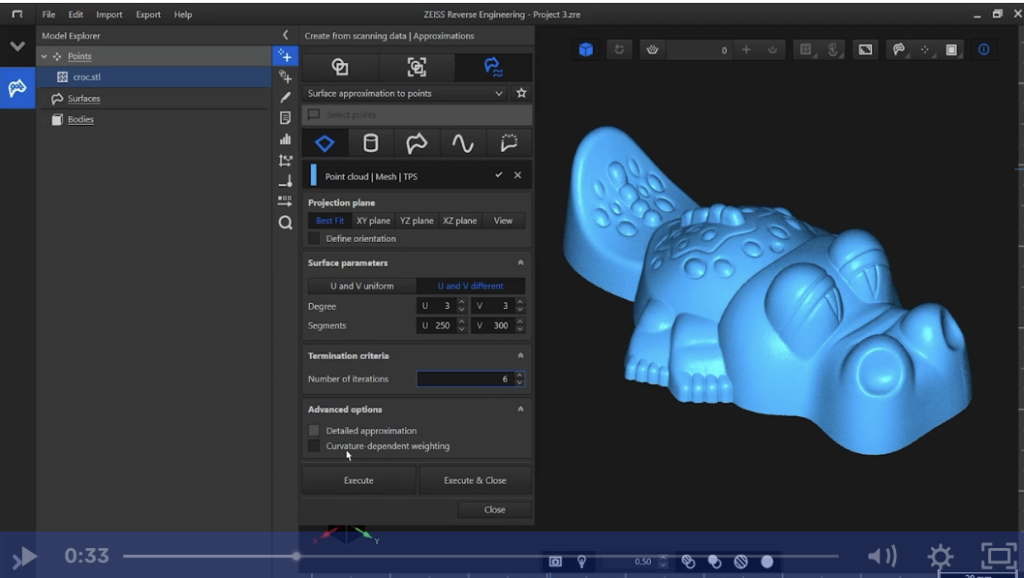

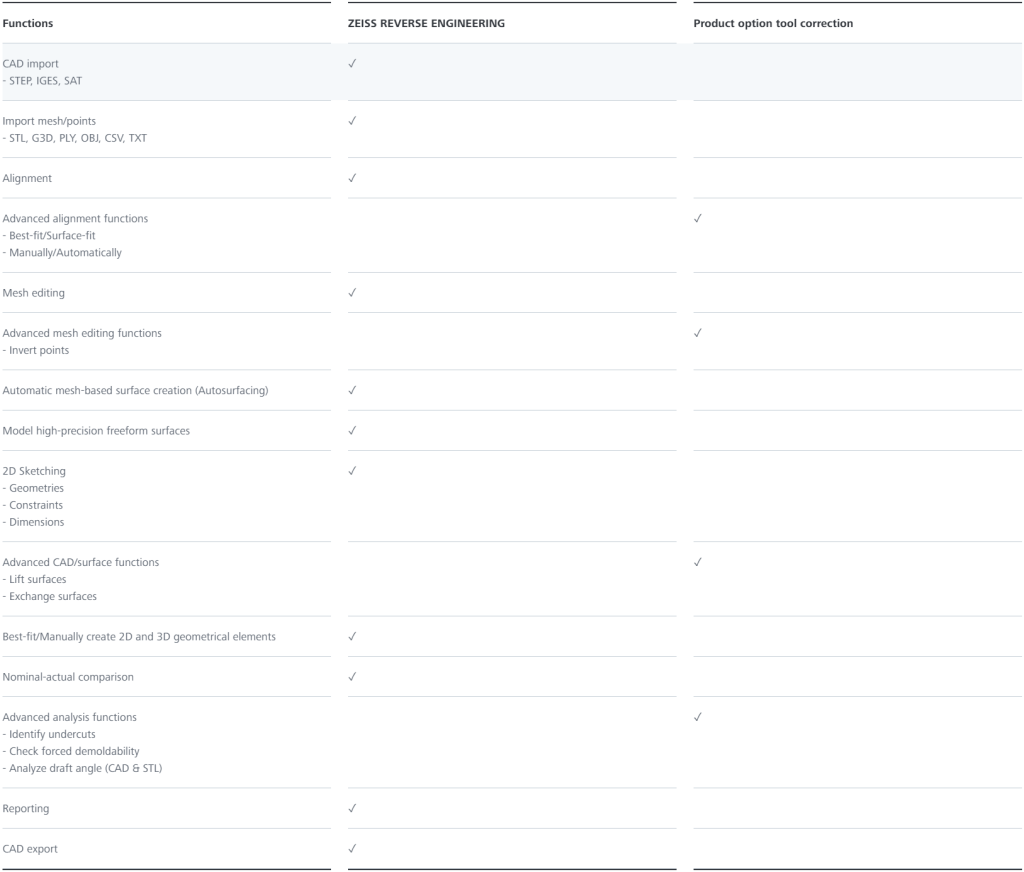

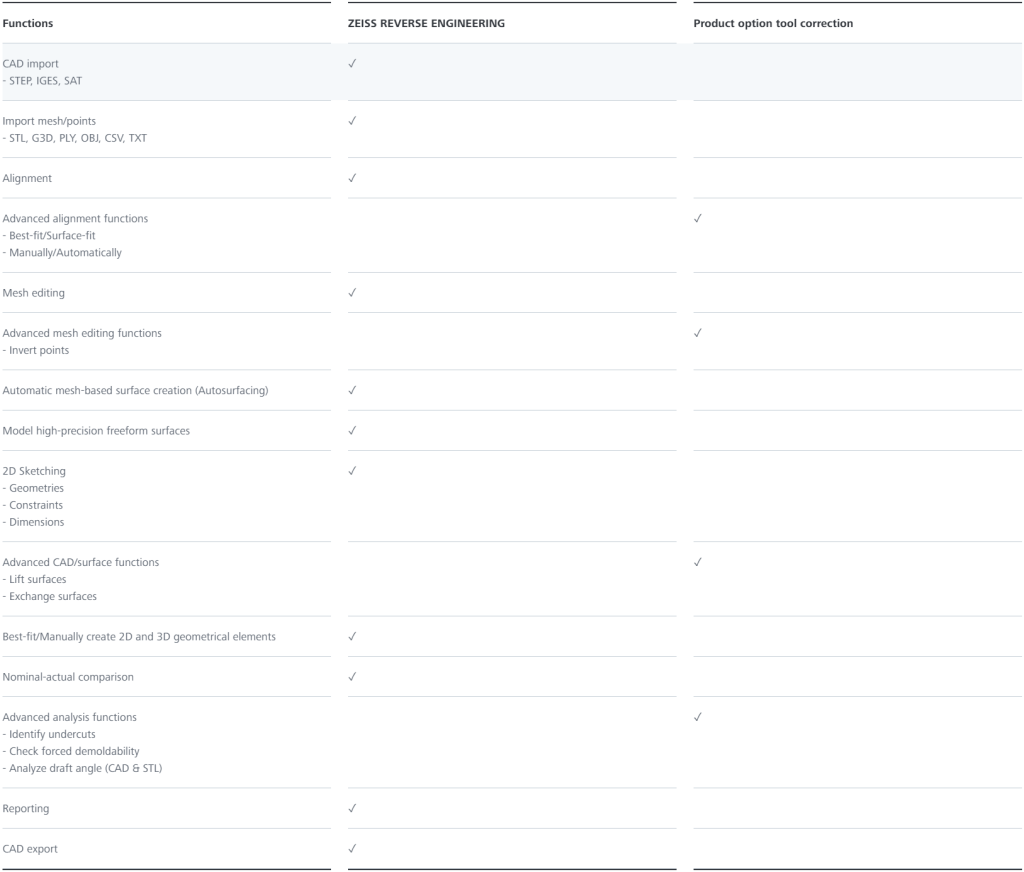

ZEISS REVERSE ENGINEERING

Surface reconstruction and tool correction

Do you want to create CAD models quickly and simply from polygon meshes or point clouds? Or do you want to reduce tool optimization iterations in mold making and improve your CAD data for additive manufacturing?

All this is possible with ZEISS REVERSE ENGINEERING.

On this page, you learn how to create CAD models for components with ZEISS REVERSE ENGINEERING. To correct CAD data of tools and printed parts, go here to learn everything about the tool correction option.

- Automated

- Interactive in a guided workflow

- Highly precise – even in case of sophisticated freeform surfaces

Powerful surface reconstruction software

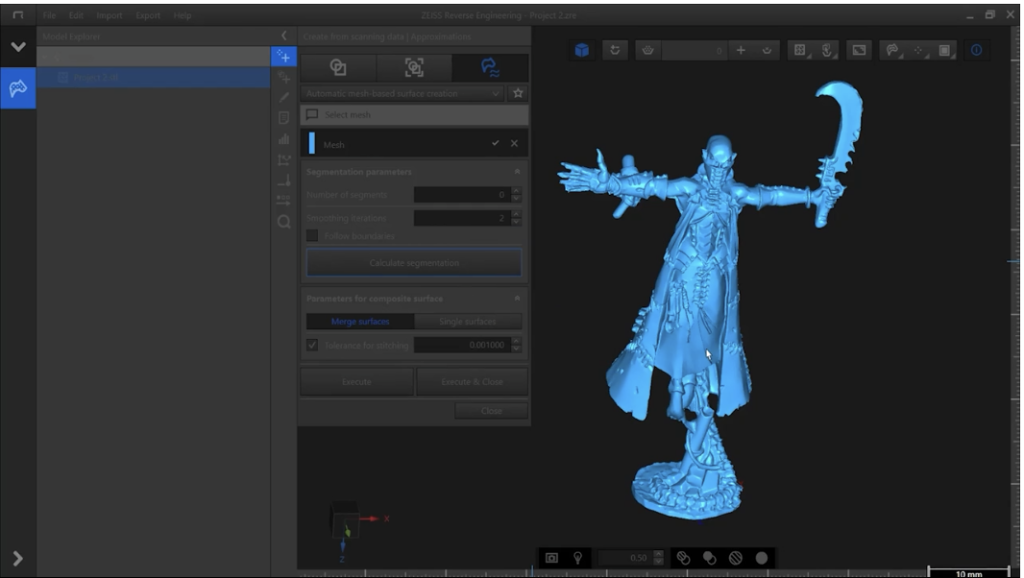

Scan a component in ZEISS INSPECT or any other software and import your STL or PLY data and ASCII formats into ZEISS REVERSE ENGINEERING. Just a few guided steps result in a highly precise CAD model that you can export into common formats such as IGESa, STEP or SAT.

CAD models for any conceivable shape

Geometrical parts

Powerful functions for components with standard geometrical shapes: Export your data into ZEISS REVERSE ENGINEERING and get busy creating, combining, extracting and adjusting them. The software guides you through the entire process – until you achieve exactly the result that you want.

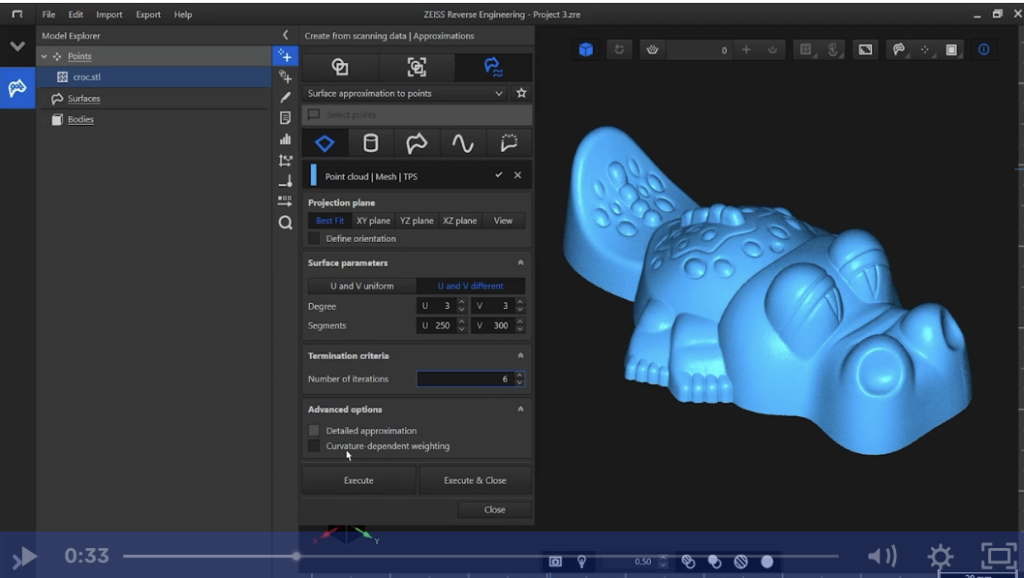

Freeform surfaces

ZEISS REVERSE ENGINEERING offers various functionalities for achieving highly precise freeform surfaces. For instance, use “Surface approximation to points” when converting your data, and let the software guide you through the process step by step until your component has been created.

Organic shapes

The software is equipped with special engineering tools for accurately remodeling flowing, organic shapes. The best thing about this is: It takes only a few clicks from importing the scan data to the complete 3D model – even in case of sophisticated object designs. Watch this video to see how it works.

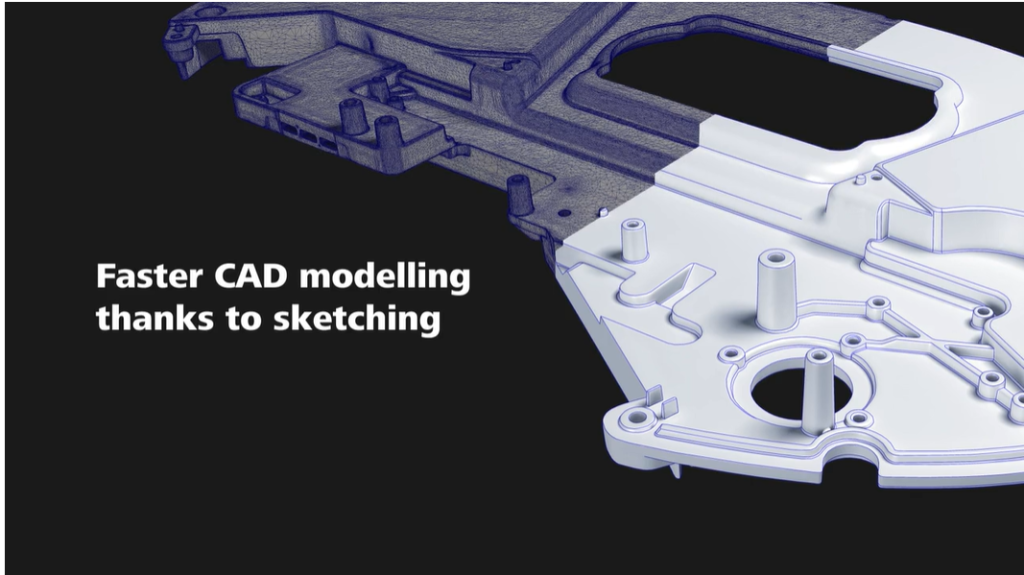

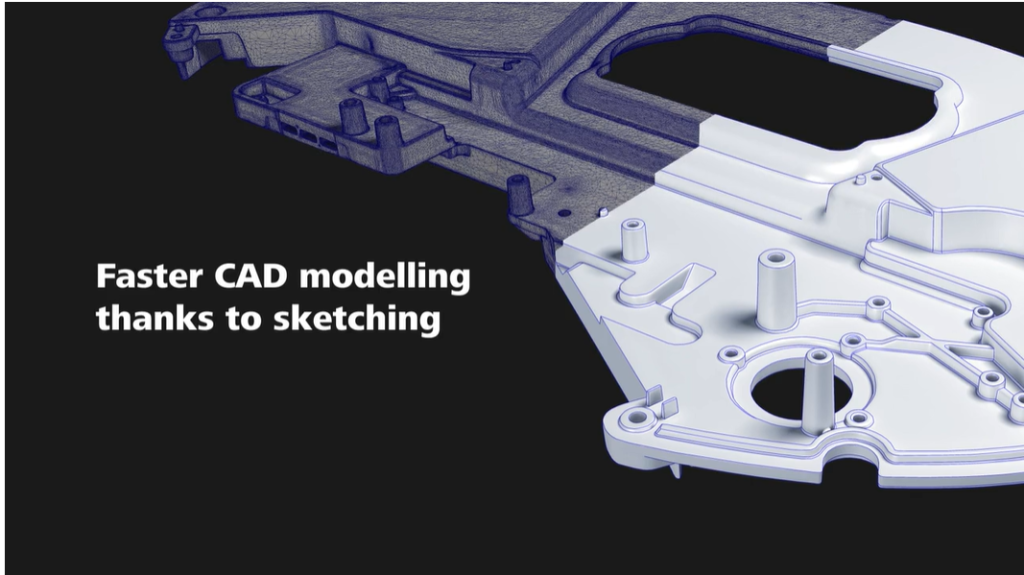

Even faster to CAD thanks to 2D-Sketching

The new feature saves you even more time when creating your CAD model – especially when it comes to complex geometries. The principle of the sketch function: Sketches are created in sectional planes, which are optimized by defining dimensions and constraints. In the final step, bodies can then be created from the sketches simply with a mouse click.

Everything you need

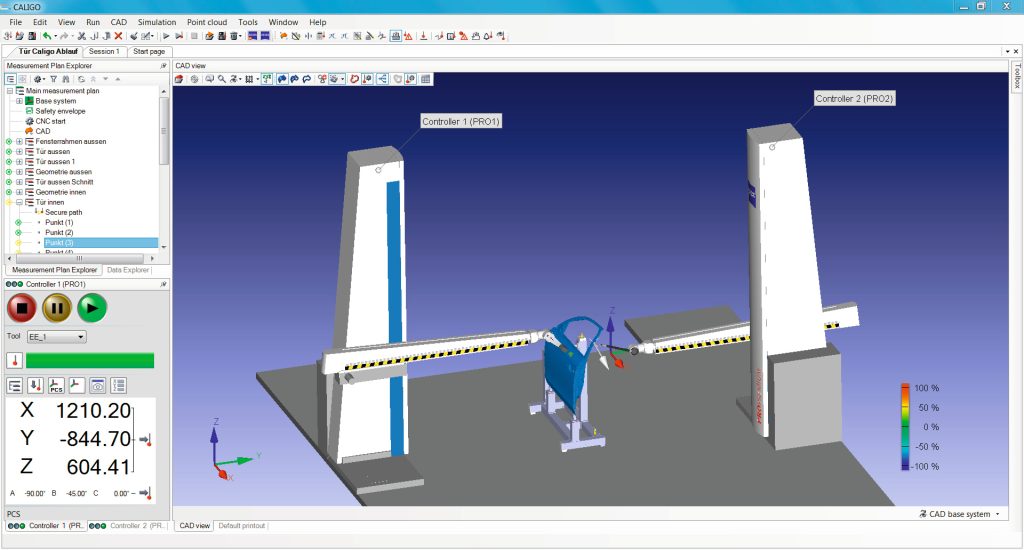

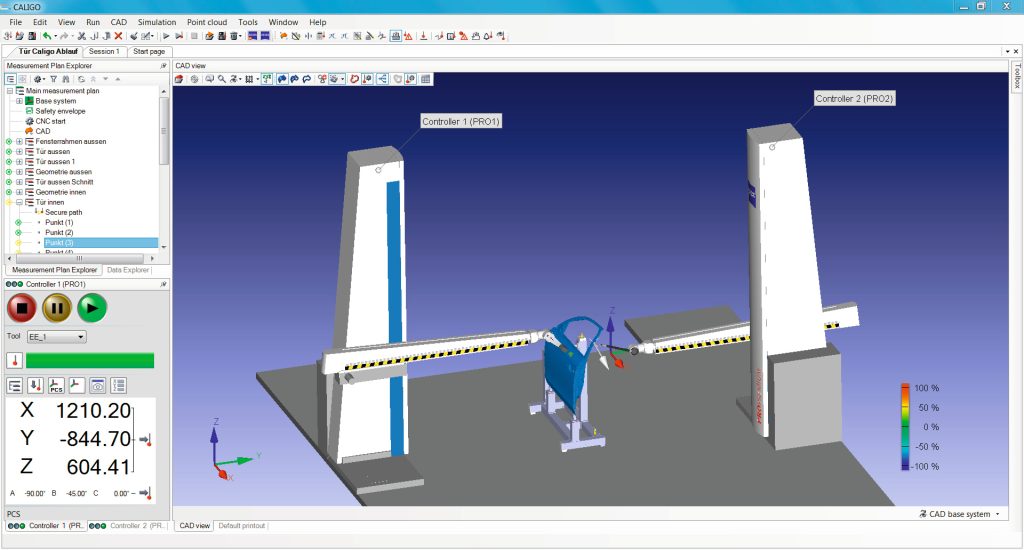

ZEISS CALIGO

Specialist for freeform surfaces

A large number of measuring points is needed for testing freeform surfaces. The software architecture of ZEISS CALIGO is specially designed for this purpose.

Highlights

- Efficient tools for testing freeform surfaces and standard geometries in car body construction

- Ease of use

- Powerful software architecture for processing large amounts of data

- Efficient change management

- Integrated simulation functions for off-line programming

- Collision protection through automatic travel paths

- Path-in / Path-out

- Includes ZEISS PiWeb reporting

Efficient tools for users in car body construction

By focusing on the measurement of freeform surfaces, ZEISS CALIGO is primarily intended for users in car body construction. They receive a total solution that enables them to measure and evaluate standard geometries in addition to freeform surfaces.

ZEISS CALIGO is easy to use, has a short learning curve, and offers powerful data processing tools and many functions that simplify quality assurance.

Tailor-made for large amounts of data

With its modern, modular system architecture, ZEISS CALIGO is designed to meet future challenges.

Optimal usage of the system resources available enables fast processing and provision of the extensive data generated during the measurement of freeform surfaces.

Simulation of the measurement run

The simulation functions in ZEISS CALIGO provide you with many ways of analyzing measuring programs off-line. The measuring run is displayed as an animation in the CAD window. Functions such as collision control, travel path track and collision ball will help you to optimize programming and to troubleshoot. Various horizontal arm measuring machines and duplex systems can be completely simulated in ZEISS CALIGO. The ZEISS EagleEye optical sensor has also been taken into consideration. This allows you to set up a run with the ZEISS EagleEye off-line.

Automatic travel paths

ZEISS CALIGO can generate travel paths automatically around a protective cover to prevent collisions with the workpiece and automatically finds the path from feature to feature. Furthermore, the new “Path in / Path out” navigation function is integrated into ZEISS CALIGO.

This enables you to program a safe path into and back out of an interior space. Certain features from an extensive measurement plan or new features can be programmed quickly and measured reliably.

ZEISS PiWeb reporting included

ZEISS PiWeb reporting is included with ZEISS CALIGO on delivery. Use the report templates or generate your own reports or templates.

The option ZEISS PiWeb reporting plus allows you to extend the contained statistics function from 10 to 1,000 measurements. The packages ZEISS PiWeb sbs and ZEISS PiWeb enterprise provide you with a complete system for web-based quality data management.

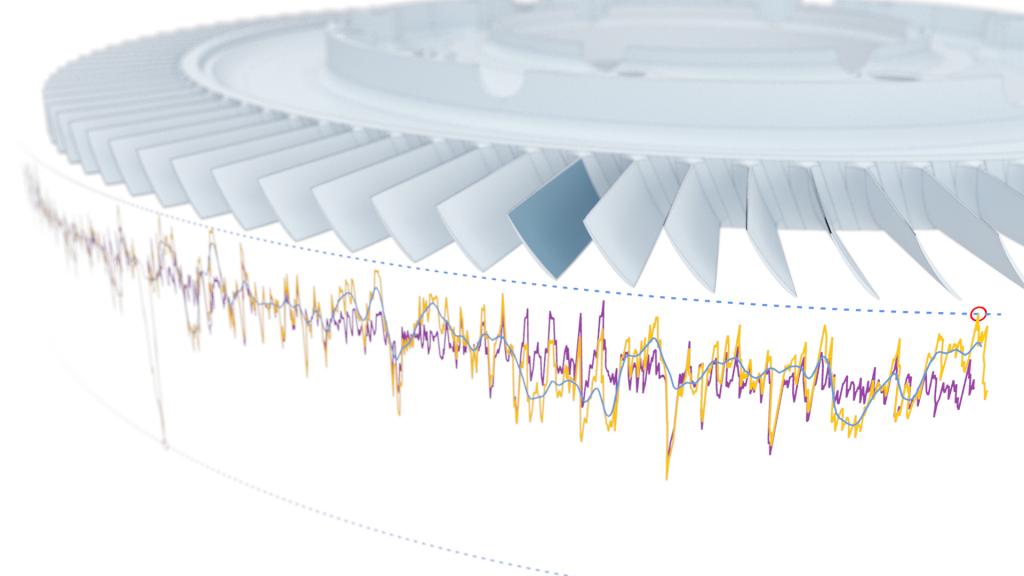

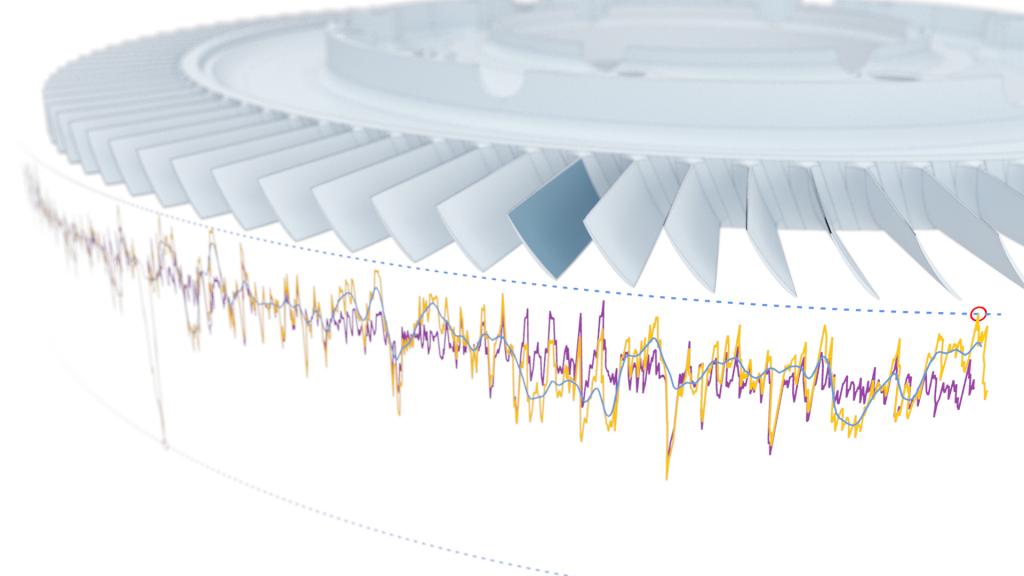

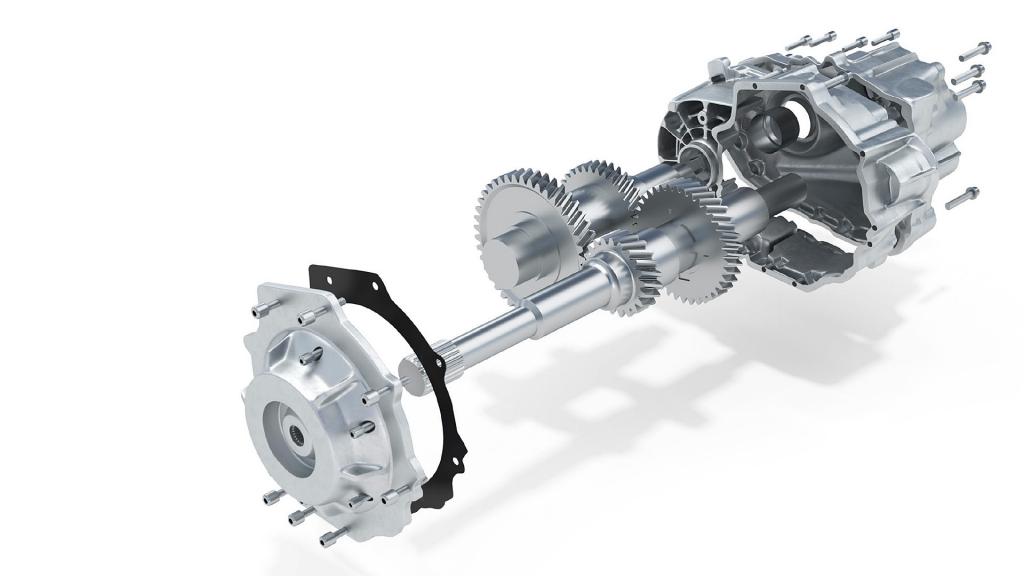

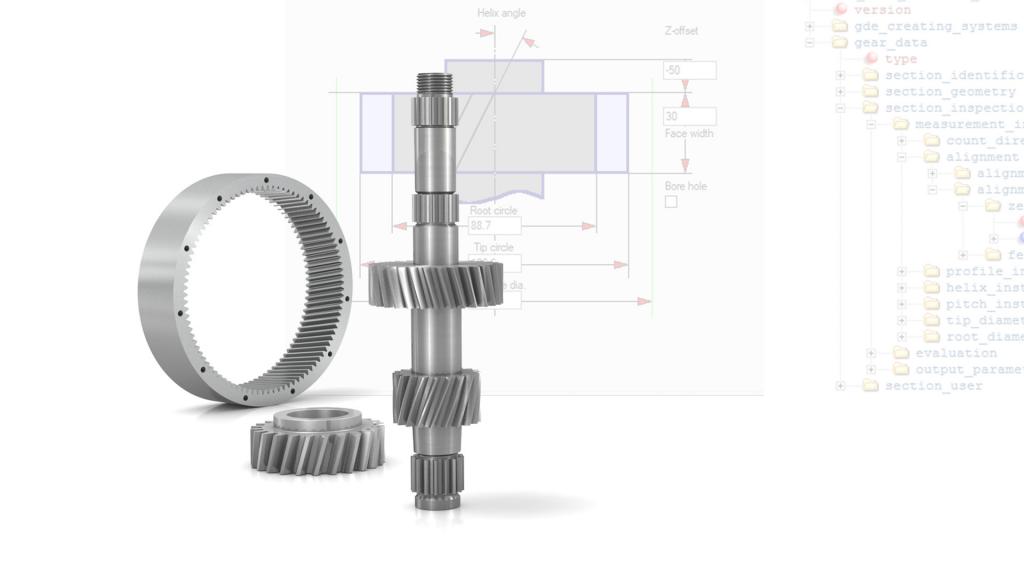

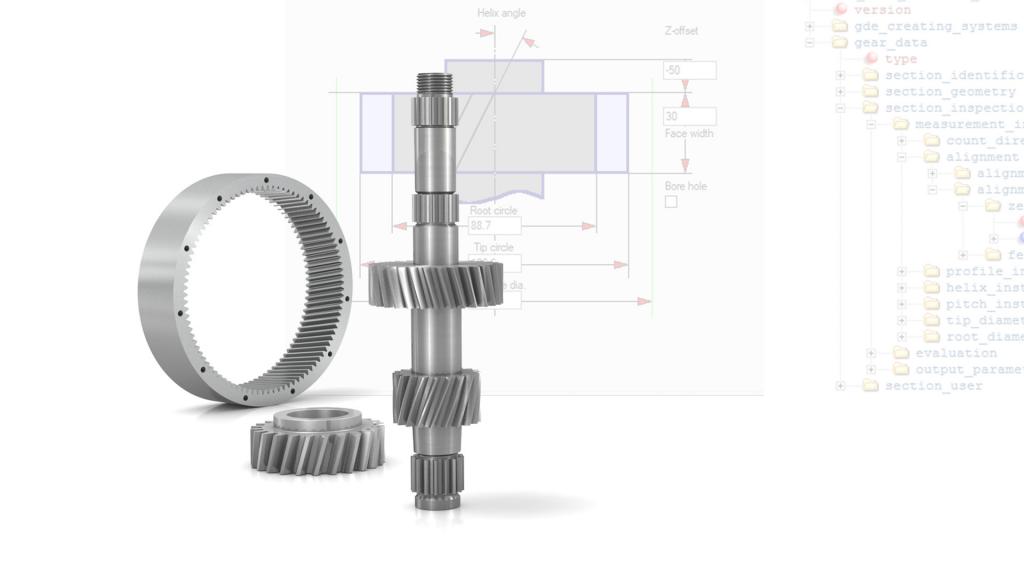

GEAR® PRO

The easy way to get from the drawing to the measurement

ZEISS CALYPSO Options

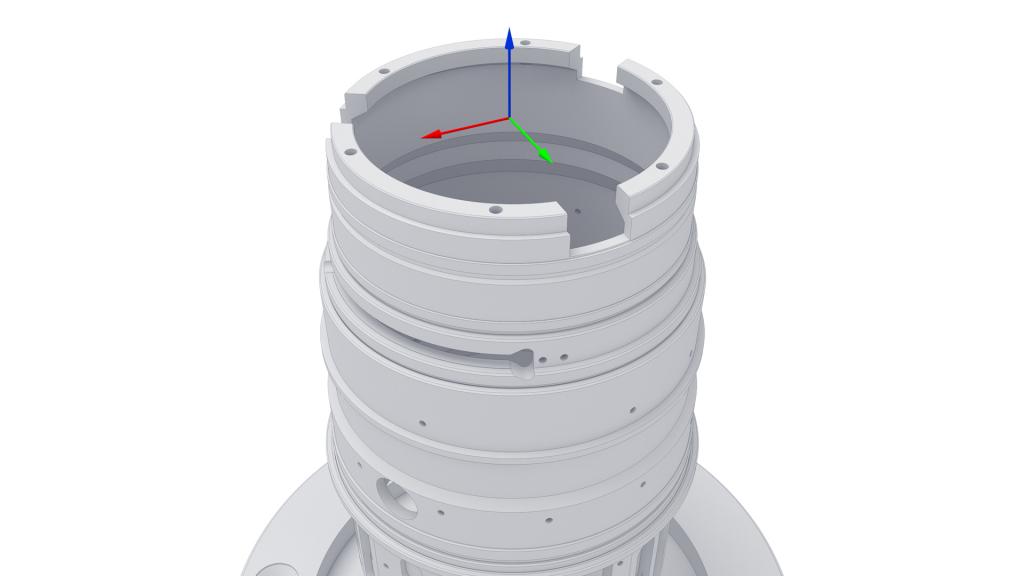

Gear metrology on the CMM

Narrow tolerances are the only way for gear wheels to transfer forces quietly with almost no loss. The precision of production and gear metrology must go hand in hand.

The GEAR PRO option for ZEISS CALYPSO enables gear metrology on coordinate measuring machines. The analytical 3D gear model and the graphic-supported input windows make measuring with GEAR PRO highly effective.

Highlights

- Graphic-supported input

- CAD simulation of the measuring run

- Active and passive sensors

- Measurement with and without rotary table

- Standard-compliant, automatic evaluation

- Application-oriented reporting

Visual inspection

Through the interaction of the software core and the graphic user interface, the option GEAR PRO generates a CAD model of the gear from the definition of the geometry.

The graphic display of the CAD model allows you to quickly and visually check the input values. A standard measurement can already be started on the basis of the geometry definition.

Available packages

- Cylindrical gears – GEAR PRO involute

- Bevel gears – GEAR PRO bevel

- Worm gears – GEAR PRO worm

- Rotors – GEAR PRO rotor

- Gear hobs – GEAR PRO hob

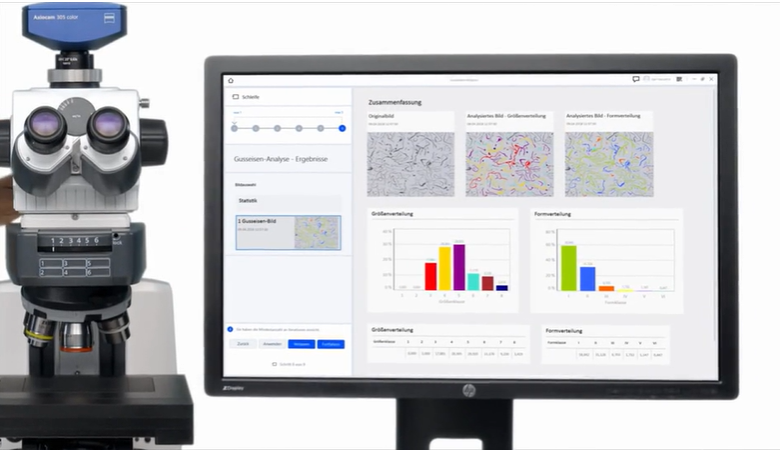

ZEN core

Industrial image processingImage analysis for industrial microscopy

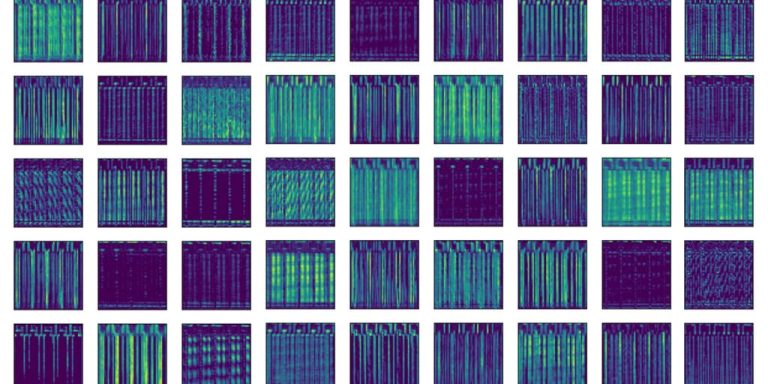

For the industry, the true value of an image is not in the optics, but in the data. To capture these, industrial image processing systems are used in combination with software. Using various methods, such as gray value analysis, simple image segmentation is possible, but reaches its limits in some places. Artificial intelligence (AI) is the perfect complement to this. AI-based software for industrial image processing, such as ZEISS ZEN core, is the key to automated, fast, reliable, scalable and, above all, reproducible results.

With ZEN core, ZEISS offers the solution for complex image processing. The software combines imaging, segmentation, analysis and data connectivity and enables automated image analysis of microscopic images. The intuitive user interface of the ZEN core software makes it easy to perform complex image analyses. Predefined workflows reduce the time required for analysis and generate reliable and reproducible results. Take advantage of the optional integration of a ZEISS microscope with live image acquisition and device control for advanced automated analyses. ZEN core offers you the opportunity to share your know-how throughout the company. The entire company benefits from automated image segmentation and analysis and achieves maximum quality assurance. Convince yourself of ZEISS ZEN core and test the software for industrial image processing free of charge and without obligation for up to 60 days.

Image analysis for industrial microscopy

For the industry, the true value of an image is not in the optics, but in the data. To capture these, industrial image processing systems are used in combination with software. Using various methods, such as gray value analysis, simple image segmentation is possible, but reaches its limits in some places. Artificial intelligence (AI) is the perfect complement to this. AI-based software for industrial image processing, such as ZEISS ZEN core, is the key to automated, fast, reliable, scalable and, above all, reproducible results.

With ZEN core, ZEISS offers the solution for complex image processing. The software combines imaging, segmentation, analysis and data connectivity and enables automated image analysis of microscopic images. The intuitive user interface of the ZEN core software makes it easy to perform complex image analyses. Predefined workflows reduce the time required for analysis and generate reliable and reproducible results. Take advantage of the optional integration of a ZEISS microscope with live image acquisition and device control for advanced automated analyses. ZEN core offers you the opportunity to share your know-how throughout the company. The entire company benefits from automated image segmentation and analysis and achieves maximum quality assurance. Convince yourself of ZEISS ZEN core and test the software for industrial image processing free of charge and without obligation for up to 60 days.

The facets of industrial image processing

For industrial image processing, 2D and 3D images are first divided into different areas (image segmentation), which are then analyzed and provide important information. Industrial image processing is used for defect detection, structure and material analysis and also provides other data that is essential for quality control and assurance. If image processing is carried out manually in industrial applications, a great deal of experience and time is required for segmentation and analysis of the images. The solution: Artificial intelligence. Scalable, reliable and reproducible results can be achieved with automated image analysis. ZEISS ZEN core offers you exactly these advantages – and much more.

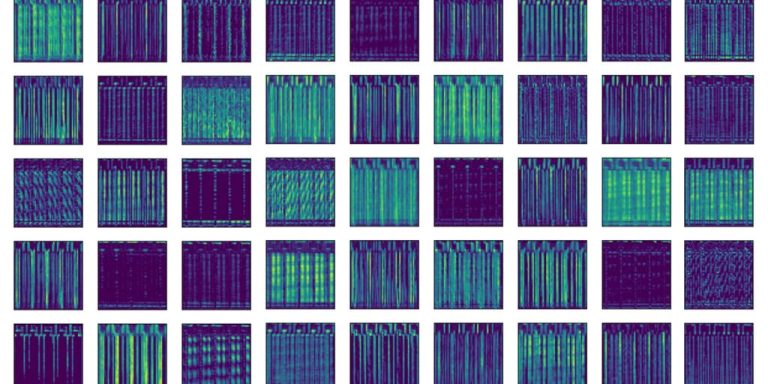

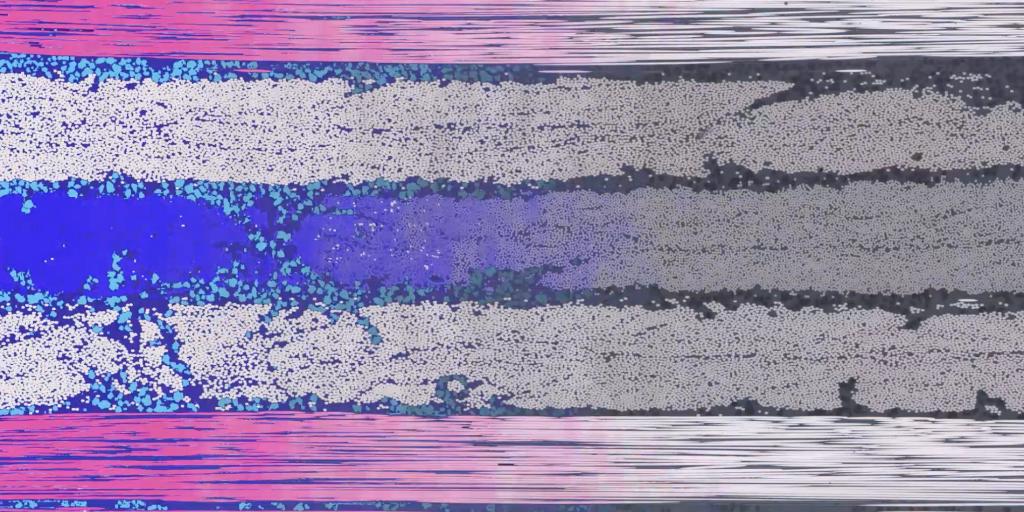

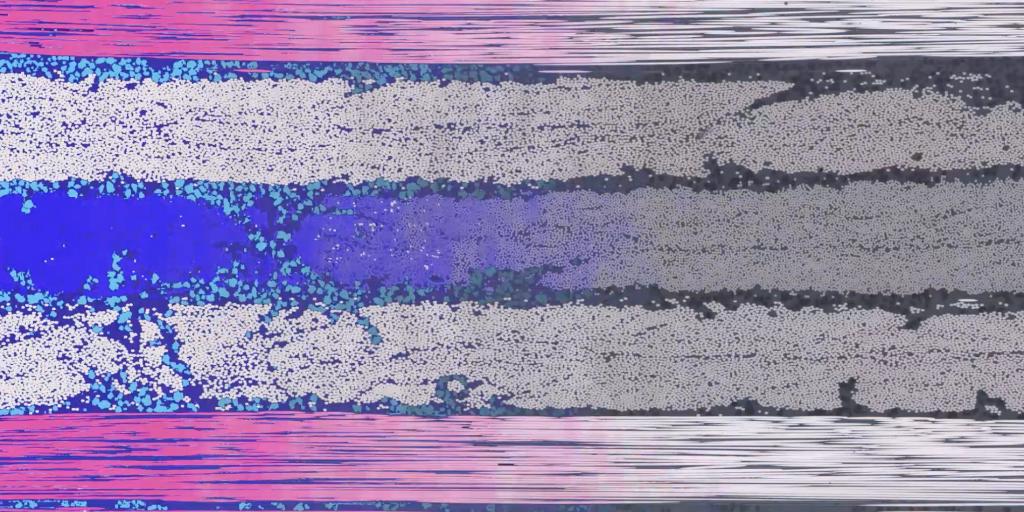

Deep learning for automated analyses

Deep learning is used to train an artificial intelligence that performs image segmentation and analysis of 2D and 3D images in an automated manner, quickly and with reliable results.

Intelligent material analysis

Complex analyses are required to examine the material properties and structure of an object. With ZEN core, complex analyses can be carried out easily and step-by-step based on a workflow.

Image analysis

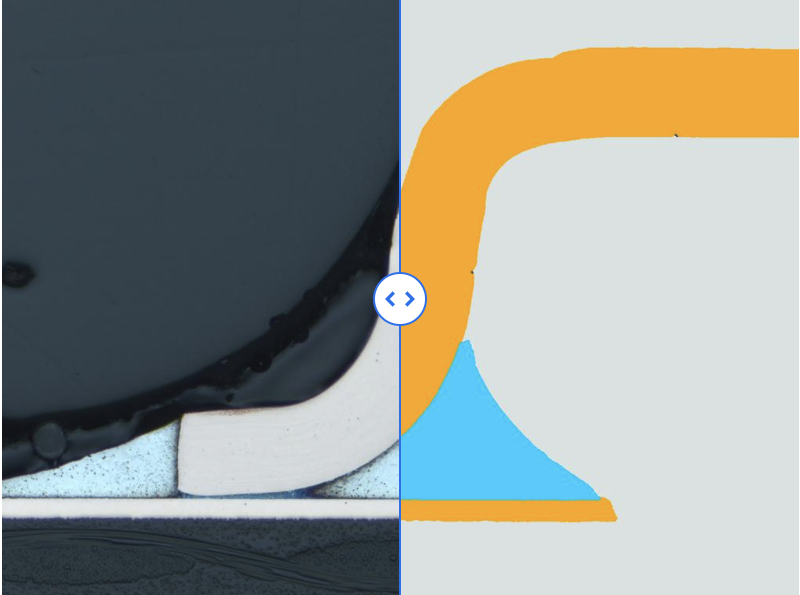

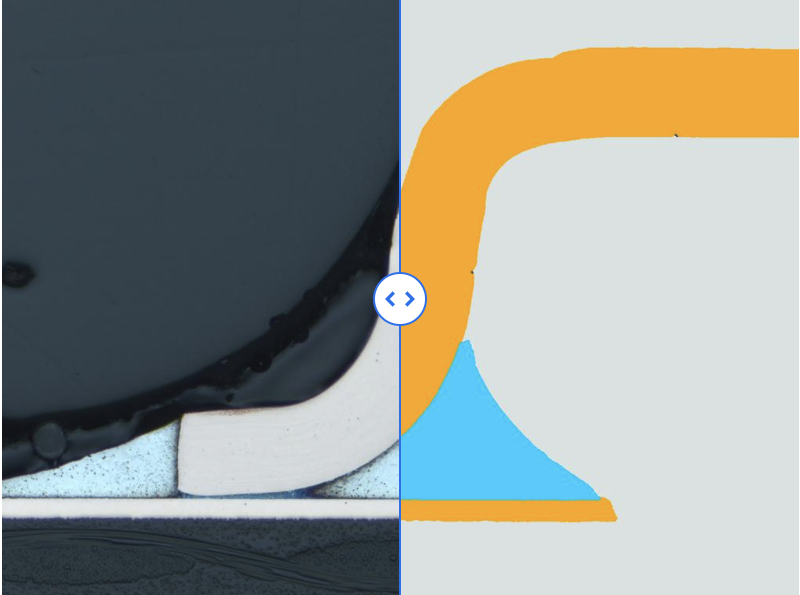

Image segmentation of an IC (integrated controller) in cross-section

In an industrial environment, image analysis is usually carried out in the form of image segmentation of microscopic images. To do this, the image is divided into several areas that are separated from each other. These areas and the boundaries between the different areas are analyzed, e.g. to identify defects and ensure product quality. Depending on the object, however, special cases must be taken into account. Connected areas are only relevant above a certain size and shape, for example, or it is important how far apart the areas are. This makes manual analysis very complex and time-consuming. Image processing software is used here, replacing manual analysis with an automated process. This reduces user influence and minimizes the time required to obtain information. Image analysis can work in connectivity with gray value analysis (thresholding) or via AI-based models.

Artificial intelligence

Artificial intelligence (AI) comprises automation and machine learning. Human thinking and learning is imitated by a computer. In industry, AI models are trained to recognize structures, defects and features and to solve complex problems graphically on their own.

ZEISS uses AI for image segmentation and holistic image analysis. By simply training a model using ZEISS ZEN core, segmentation and classification can be performed automatically for one or more images. This makes routine work more efficient, user-independent and saves time and costs.