Active scanning probes

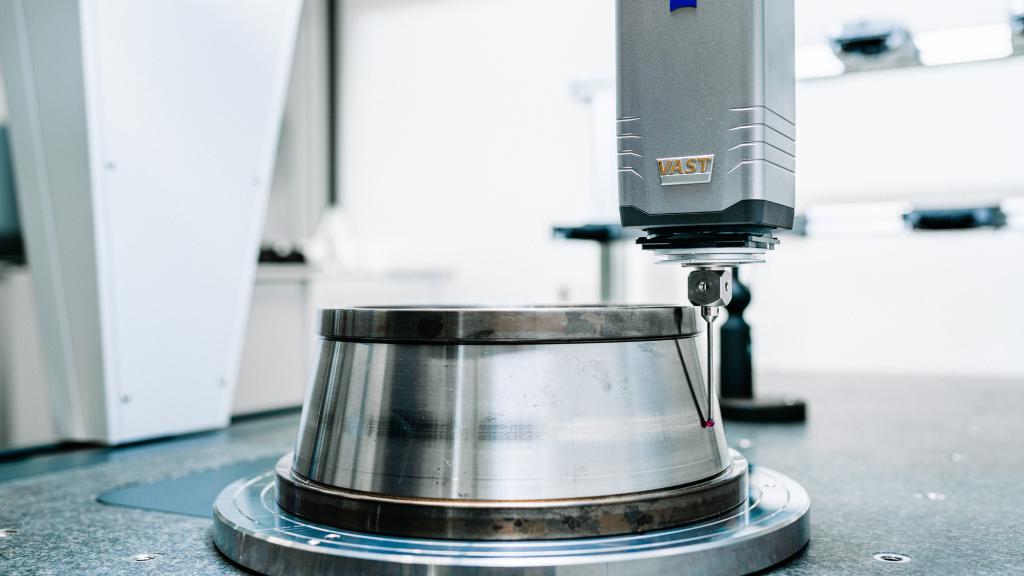

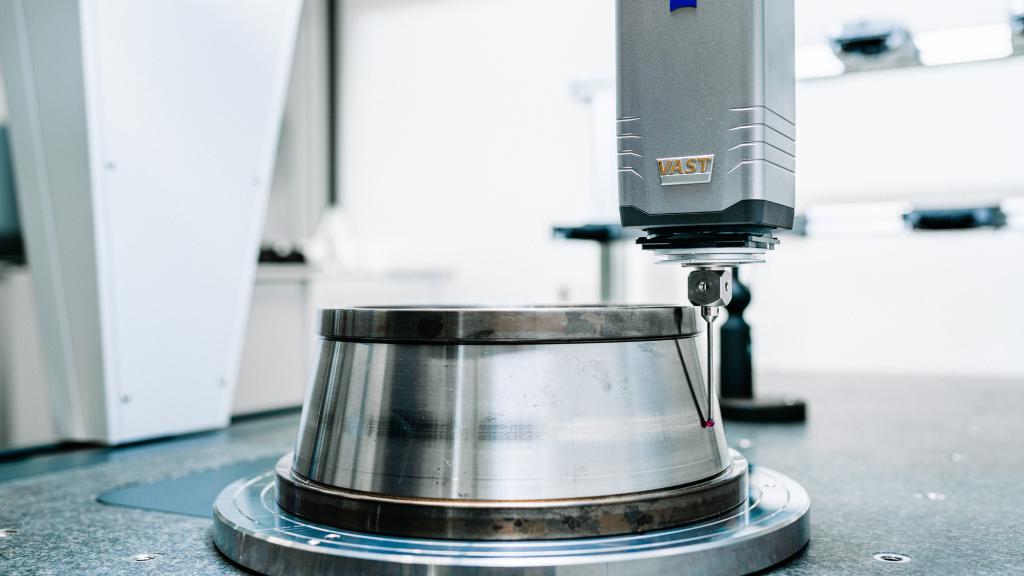

ZEISS VAST XT gold

Entering the world of active scanning technology

The line of active VAST sensors plays a major role in all metrology applications that demand maximum precision with large stylus configurations. ZEISS VAST XT gold provides the foundation for entry into the world of active scanning technology.

- Active scanning for maximum accuracy

- Customizable measuring force

- Versatile sensor for diverse applications

Features

Additional measuring system

ZEISS VAST XT gold features an additional measuring system. The measuring force can be configured depending on the measuring job. It is also used for a line of correction procedures.

In addition to active scanning, this sensor also allows single-point measurements: for example, the sensor enables the flexible use of complex stylus configurations and self-centering.

One sensor for many applications

Thanks to its high-speed scanning capabilities, ZEISS VAST XT gold can complete practically any job: form and position measurements, curve and freeform measurements, and reverse engineering. The applications cover plastic machined parts and Styrofoam, brake components, crankshafts, engine blocks, and turbine blades.

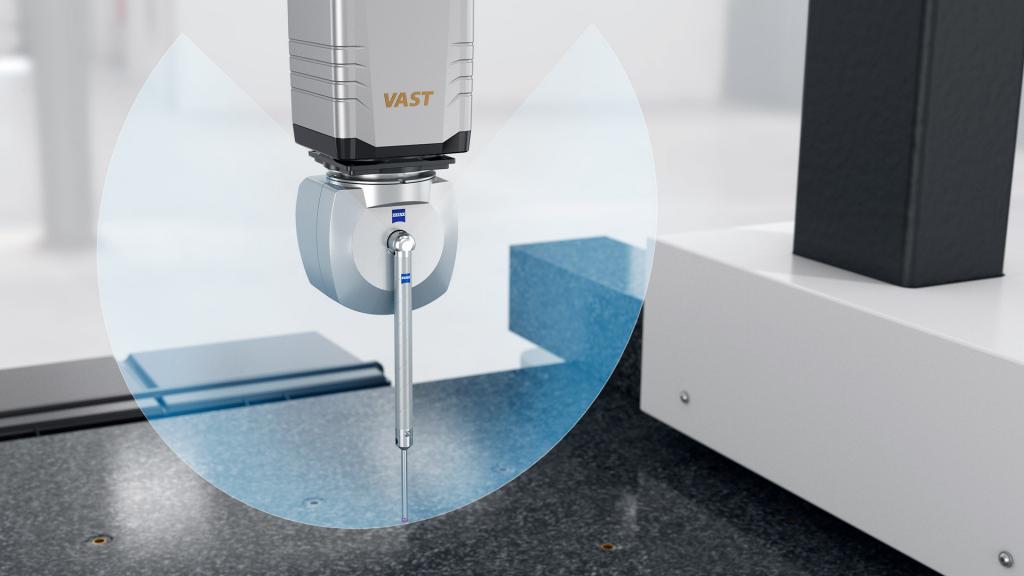

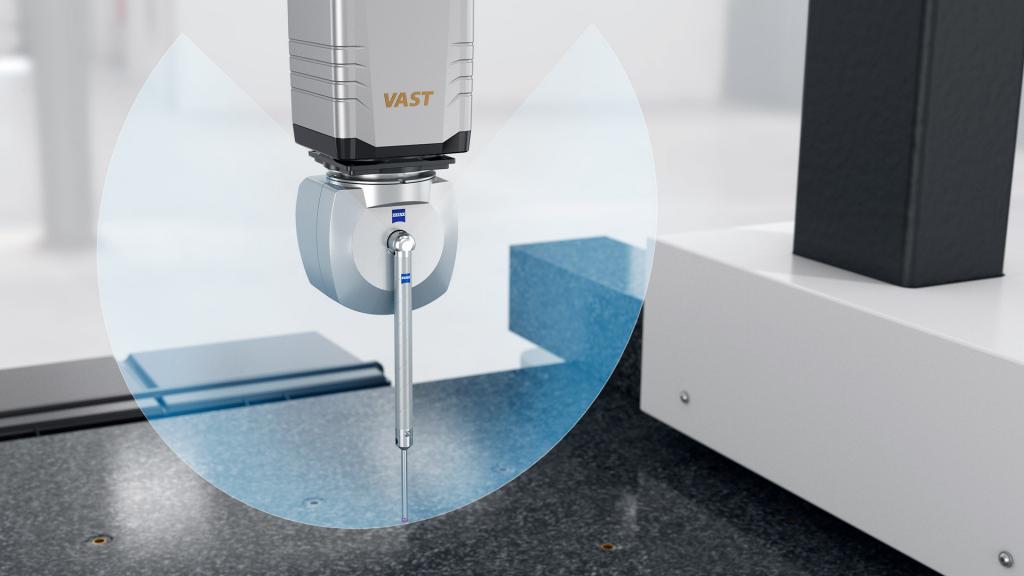

ZEISS VAST XTR gold

Scoring points with speed

Thanks to the integrated rotary axis, the new ZEISS VAST XTR gold probe always positions the stylus in the direction of the feature being measured, maneuvers effortlessly through gaps and thus gets wherever it is needed.

Features

VAST navigator technology

ZEISS VAST XTR gold is based on the ZEISS VAST XT gold design. The navigator and performance functions are fully supported by ZEISS VAST XTR. VAST navigator from ZEISS is an expert system that recommends the optimal measuring speed for the desired accuracy.

The VAST performance function enables the stylus to scan interrupted contours without sacrificing speed or precision.

Integrated swivel joint

The key differentiating feature is the integrated swivel joint. It enables the stylus mount to turn as far as possible in 15 degree increments and thus always be positioned at the right angle to the part. ZEISS VAST XTR with the integrated swivel joint is as reliable and accurate as traditional “fixed” styli. Users can rely on the precision they are accustomed to.

There are a wide range of workpieces on which the probe flexes its muscles. These include parts with many features and angular positions such as those on gear housings for helicopters and locomotives. ZEISS VAST XTR gold is also suitable for rotationally symmetric workpieces such as ventilation gears or turbines. Thanks to the swivel joint, the probe reaches interior gears that until now could only be measured using complex stylus configurations.

Measuring large and heavy parts

The new sensor also has a particularly positive effect on large and heavy parts, e.g. in shipbuilding, in wind power or in the heavy equipment industry.

With workpieces weighing more than five tons, it is difficult to find a rotary table suitable for the required accuracy and workpiece weight.

ZEISS VAST gold

Peak scanning performance guaranteed

The active scanning sensor ZEISS VAST gold offers higher dynamics through optimized moving masses and higher rigidity resulting from optimized joints. The sensor is the ideal choice for contact scanning and single-point measurements.

- Fast scanning with navigator technology

- Increased measuring performance and productivity

- High flexibility with ZEISS Articulating Stylus

Features

Fast scanning with navigator technology

ZEISS VAST gold is the ideal sensor for contact scanning and single-point measurements with long styli up to 800 mm and stylus weights up to 800 g. Asymmetrical stylus configurations can also be used with ZEISS VAST gold.

ZEISS VAST gold is also known for its high scanning speeds with navigator technology. Thanks to the integrated collision protection, ZEISS VAST gold is extremely robust. Dynamic damping enables continuous operation.

The probing force can be adjusted to the stylus geometry and the workpiece material, and is always constant – it can be programmed between 50 and 1,000 millinewtons.

Increased measuring performance

In combination with navigator technology in particular – object-oriented ZEISS CALYPSO software featuring automatically generated measurement strategies – ZEISS VAST gold increases the measuring performance and thus productivity considerably. The FlyScan and QuickChange technologies in the Performance Package ensure maximum productivity.

The short travel path on FlyScan results in time savings of up to 40 percent. The QuickChange function accelerates the automatic change out of measuring styli by up to 60 percent.

Highest flexibility

With the ZEISS Articulating Stylus, the stylus can be adjusted to any angular position between -135° and 135°. A new angular position can be set in just a few seconds, saving both time and storage space for fixed position stylus systems.

Due to the combination with the high-precision ZEISS VAST gold measuring head, the stability of the articulating stylus delivers high accuracy.