Shop floor CMMs

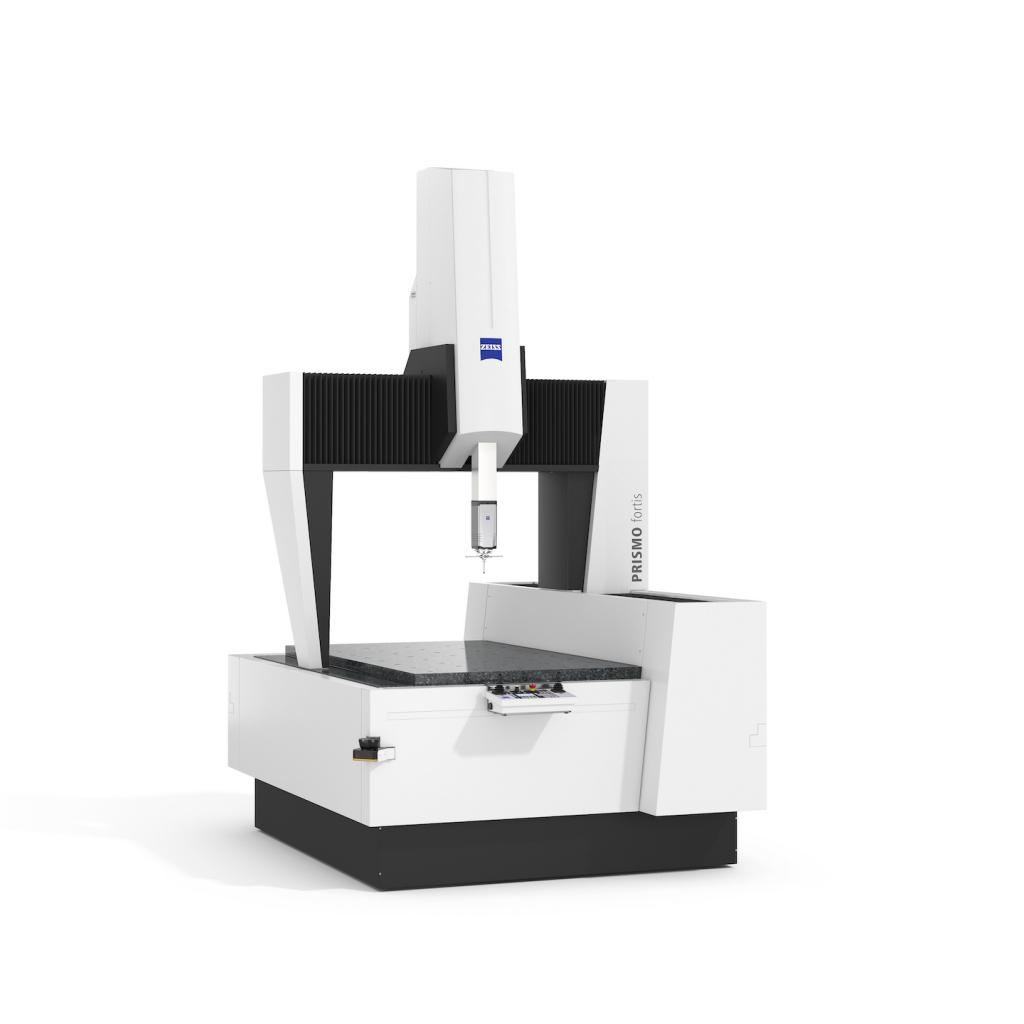

ZEISS PRISMO fortis

Precision in production environments

Thanks to optimized materials and newly developed corrections, ZEISS PRISMO fortis guarantees maximum precision at temperatures of up to 40°C. The coordinate measuring machine can therefore also be used directly in production environments. By using the optional ZEISS VAST Rotary Table (ZVR), the measuring times for certain applications can be significantly reduced due to the faster movements of the rotary table.

High degree of precision in production environments

Maximum temperature gradient for measurements up to 40°C

Thanks to the consistent further development of the individual components, ZEISS PRISMO fortis is suitable for use in production environments. The newly developed corrections including additional temperature sensors in the granite plate, the vibration-damping pneumatic damping system and the floating ZERODUR® scales with a resolution of 80 nm guarantee temperature stability up to 40°C. The measuring device is therefore suitable for use in production environments with temperature gradients of up to 5 K/d, 2 K/h and 1 K/m – but can also be used in a quality laboratory if required.

Definition of the rotary table axis by ZEISS VAST Rotary Table Axis (ZVRA)

For greater accuracy, safety and productivity

ZEISS VAST Rotary Table Axis (ZVRA) defines the rotary table axis and thus lays the foundation for accurate and reliable measurements. Where previously six discrete-point measurements were required for axis definition, taking up to 60 seconds, ZVRA now performs a single continuous movement with a 75% reduction in set-up time. The new method differs in that the probe moves on a rail at a constant height. This means that the entire process consists of a single uniform movement, with no unnecessary travel paths. ZVRA offers a time saving of 75% and thus favors a more frequent definition of the rotary table axis. This ensures even greater accuracy, safety and productivity.

Technical data

Accuracy from | 0.7 + L/400 µm (at 22°C) |

|---|---|

Temperature range | 15-40°C with TVA (Temperature Variable Accuracy) |

ZEISS mass technology | ✔ |

DGUV-compliant | ✔ |

Retrofit of older models possible | ✔ |

ZEISS PowerSaver | ✔ |

ZVRA and ZVR compatibility | ZVRA (optionally available) |

Glass ceramic scale | ZERODUR®: Resolution 80 nm |

Sizes | From 7/12/7 to 12/18/10* |