Attachment :

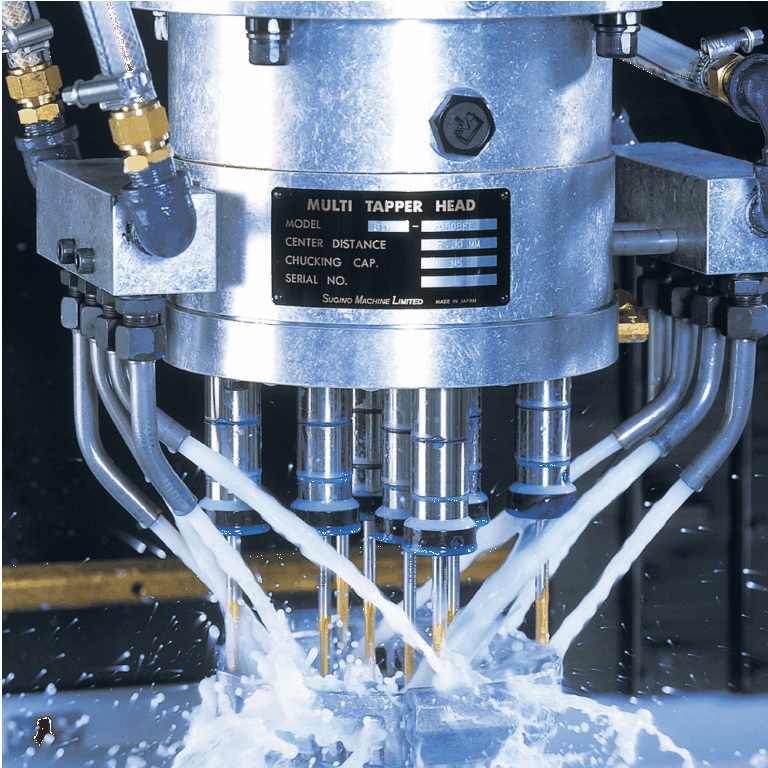

MULTI-AXIS

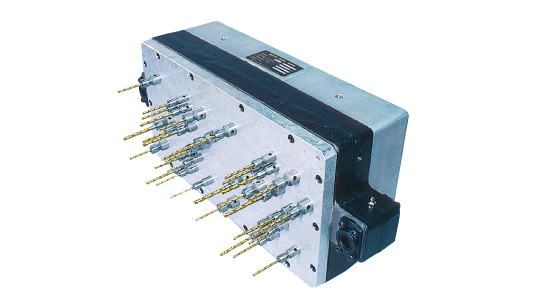

Multi-axis Drill Head

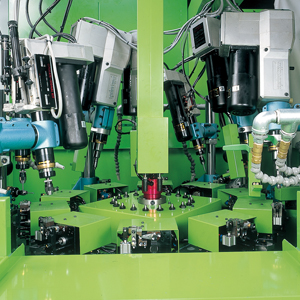

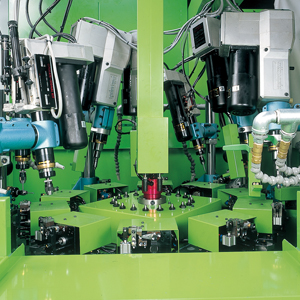

We offer various drill heads according to the application, such as adjustable axial pitch, exchange and offset types.

A taper collet system connects to the SELFEEDER for high precision and high rigidity.

Standard Specification Models :

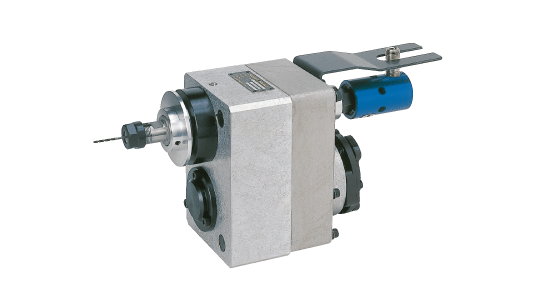

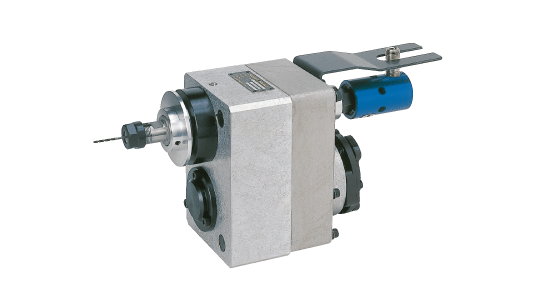

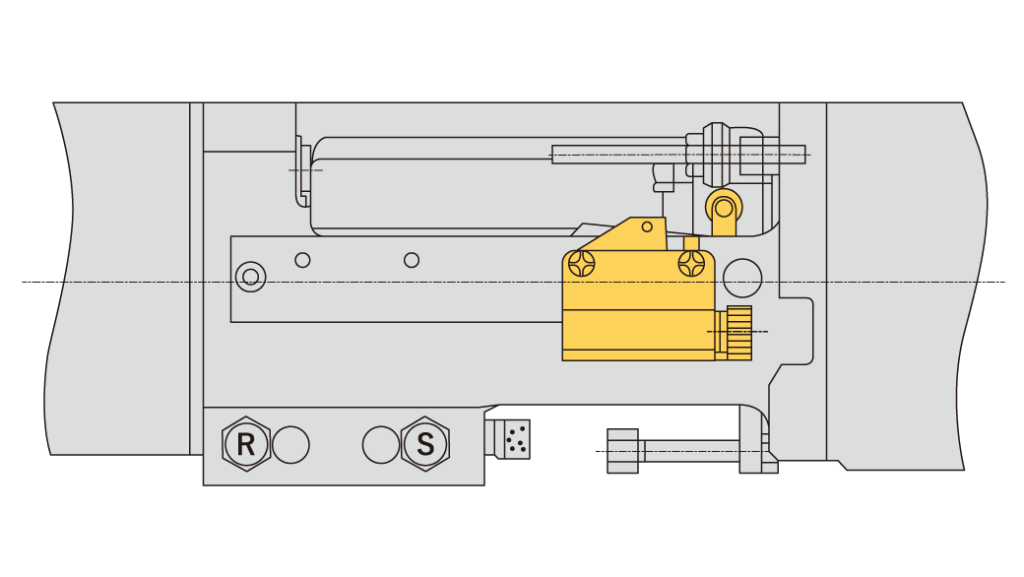

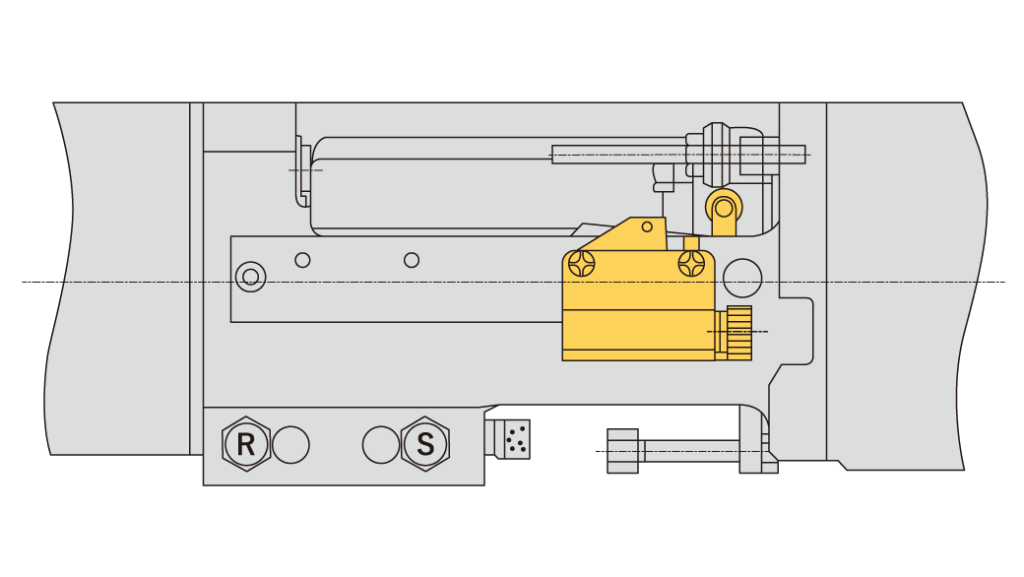

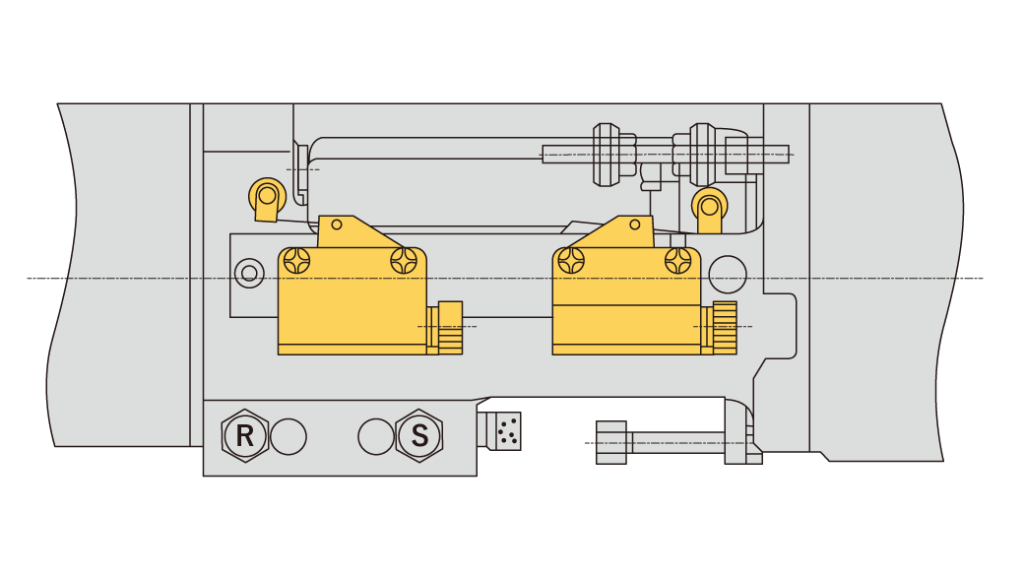

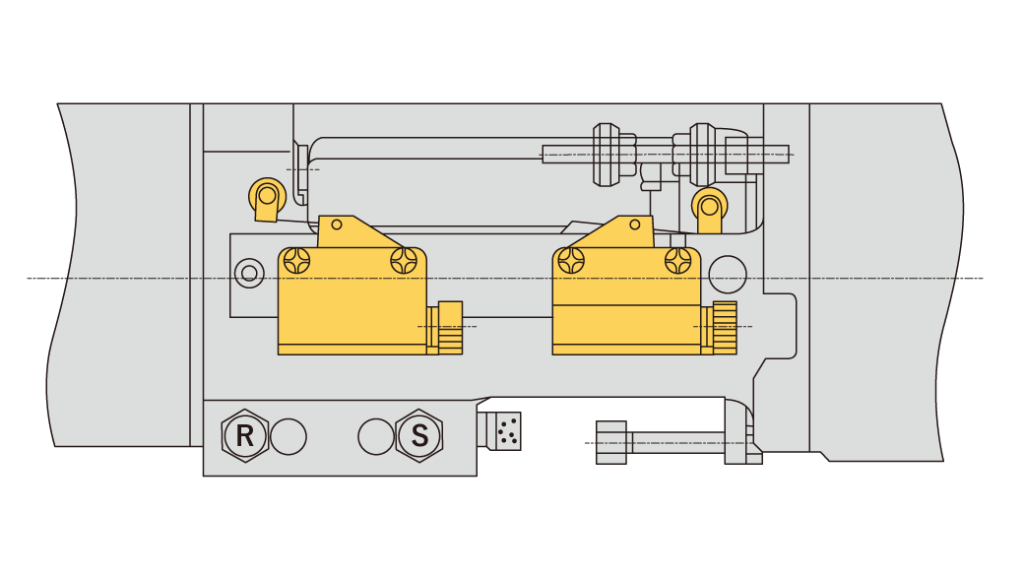

Adjustable Axial Pitch Type

A convenient drill Head with an arbitrarily adjustable axial pitch

Fixed Axial Pitch Type

An order-made drill head, designed and built to the customer’s specifications with a fixed axial pitch axis

Offset Type

A drill head for use when the drill unit could interfere with the jig or work

Exchange Type

A drill head that facilitates single-tough release from the main unit

Specialized Models :

Narrow Drill Head

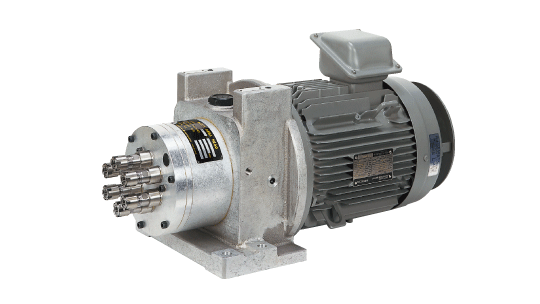

6-axis Drill Head with direct connection to motor

Coolant Holder

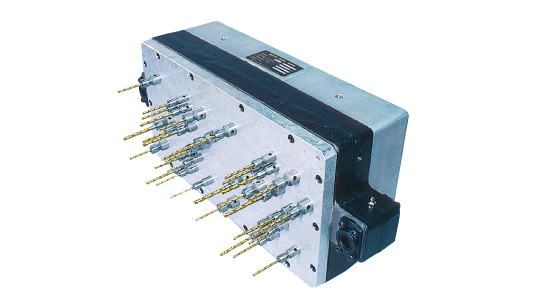

34-axis Drill Head

Enhanced Speed 1-axis Drill Head

Milling Head

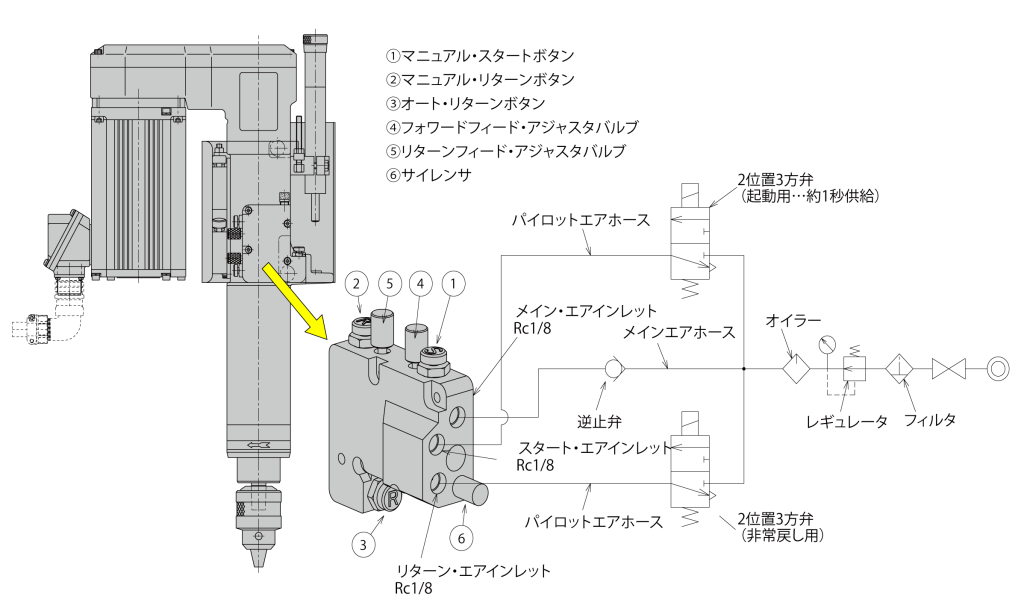

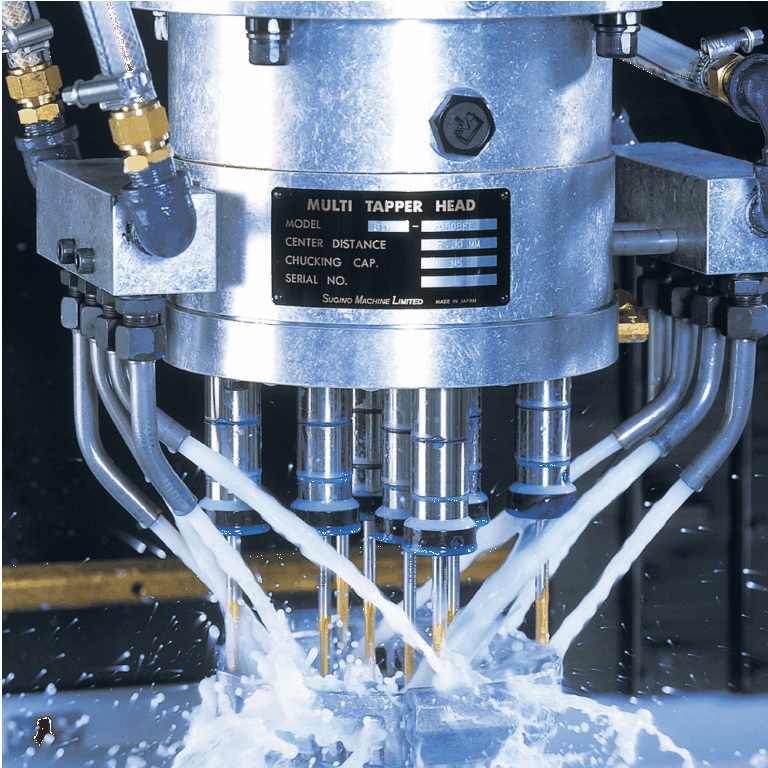

Multi-axis Tapper Head

We offer various tapper heads according to the application, such as adjustable axial pitch, exchange and offset types.

Standard Specification Models :

Adjustable Axial Pitch Type

A convenient tapper head with an arbitrarily adjustable axial pitch.

Fixed Pitch Axis Model

A made-to-order tapper head, designed and built to the customer’s specifications with a fixed axial pitch

Offset Model

A tapper head for use when the tapping unit could interfere with the jig or work.

Exchange Model

A tapper head that facilitates single-touch release from the main unit.

Specialized Models :

Adjustable Axial Pitch model

Narrow Tapper Head(min. axial pitch 8.0 mm)

STANDRILL

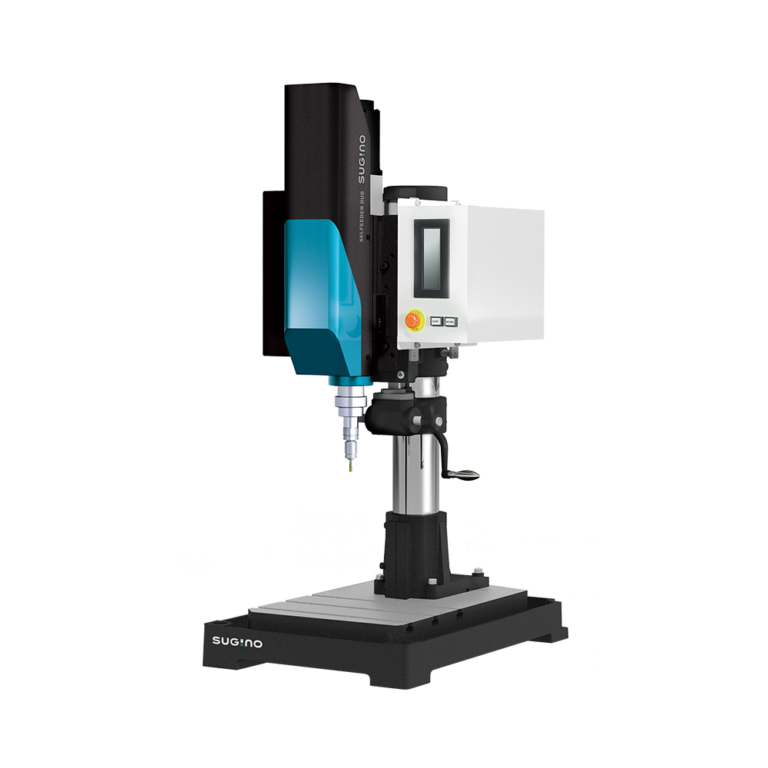

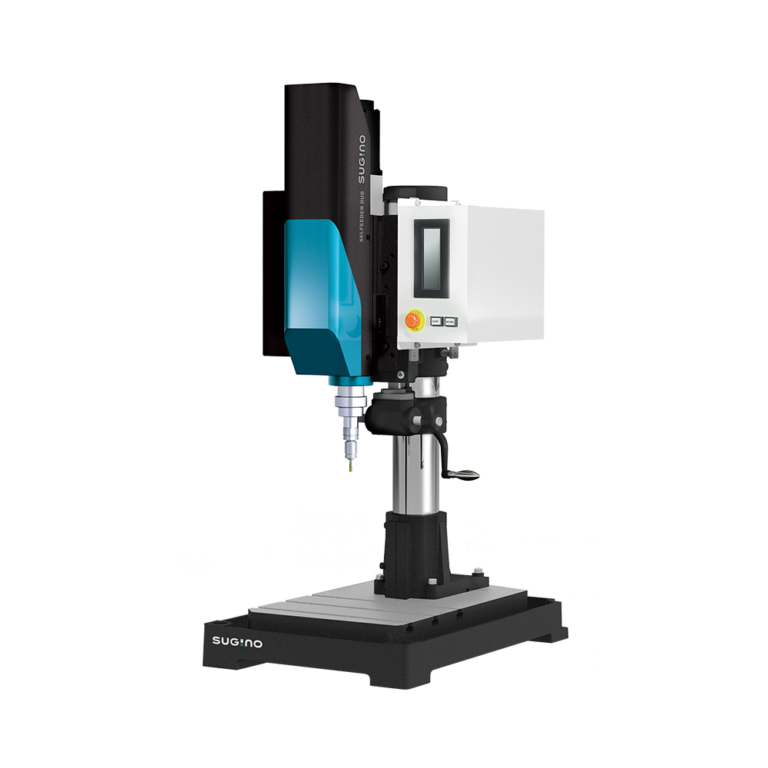

STANDRILL SELFEEDER DUO : Automatic Drilling and Tapping Stand

Same-day operation is possible! Drilling and tapping can be easily automated with a single unit.

This is an automatic drill press type stand.

Max. drilling size ……… φ13(Steel)/ φ18(Aluminum)

Max. tapping size ……… M10(Steel)/ M14(Aluminum)

Max. stroke ……………… 150mm

Max. rotation speed…… 10,000min-1

Feature

Leave it to us for renewal of aging tapping drilling machines and after-sales service.

Easy and safe operation

200V power supply for immediate operation

After delivery, you can start operating immediately.

Easy programming

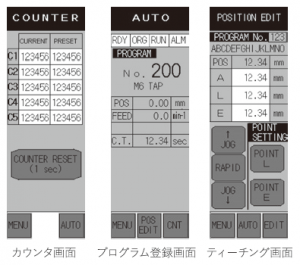

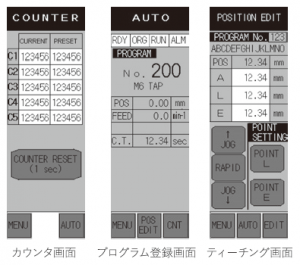

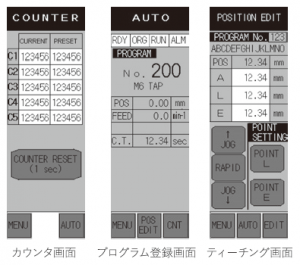

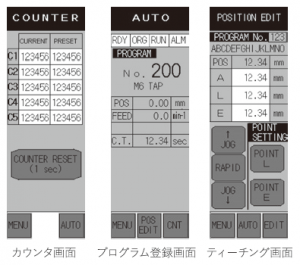

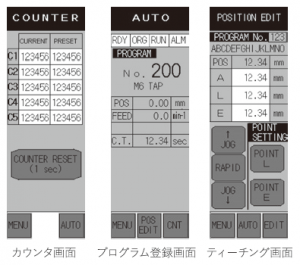

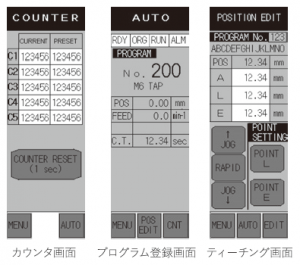

4.5 inches small touch panel for manual operation and program setting.

Preloaded programs of machining patterns required for drilling and tapping, easy to program by entering cutting start or end point, spindle speed and so on

Various functions

Preset counters 6 digitsx5

Capacity of total program records 200 records

Easy teaching function included

Easy and intuitive setting buttons

Additional options available for customization

By adding external I/O signals (optional), continuous control of customer-provided jigs and safety doors is possible.

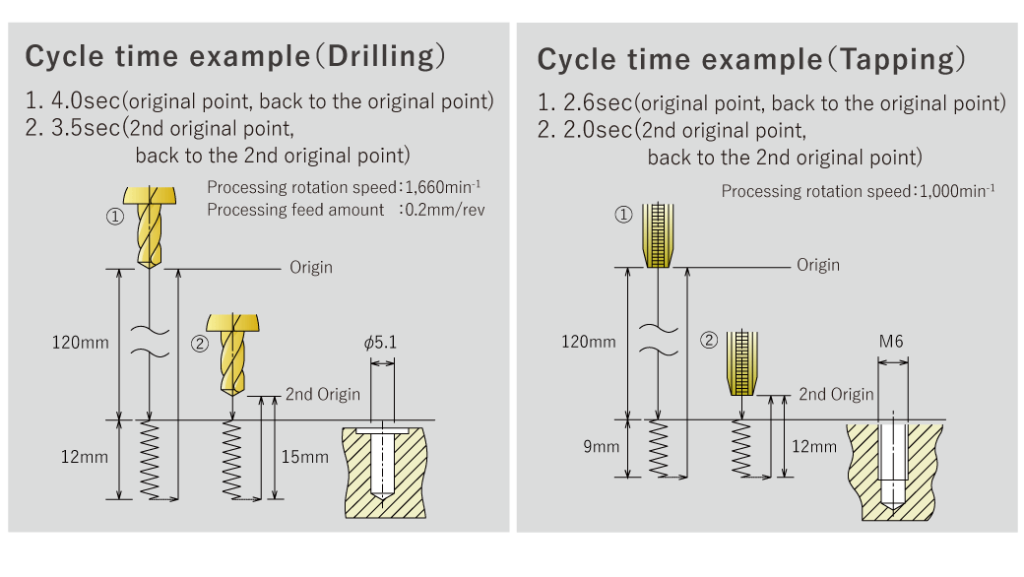

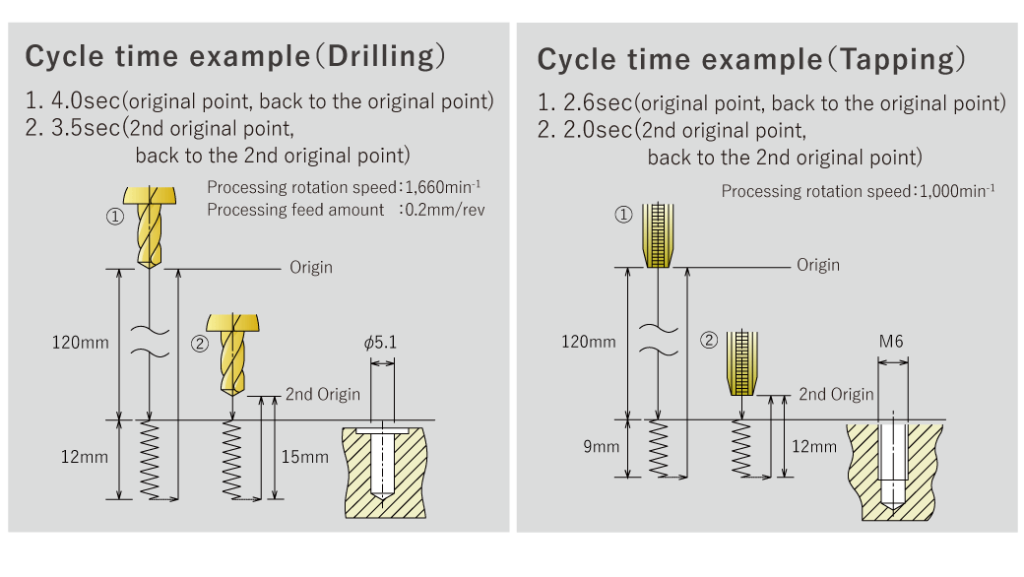

Drilling and tapping by a single unit

High power servo motors for main spindle and feed axis enable very easily to change programs,

from drilling to tapping, or change thread pitch just by a touch panel.

Also high precision tapping is possible by perfect synchronization.

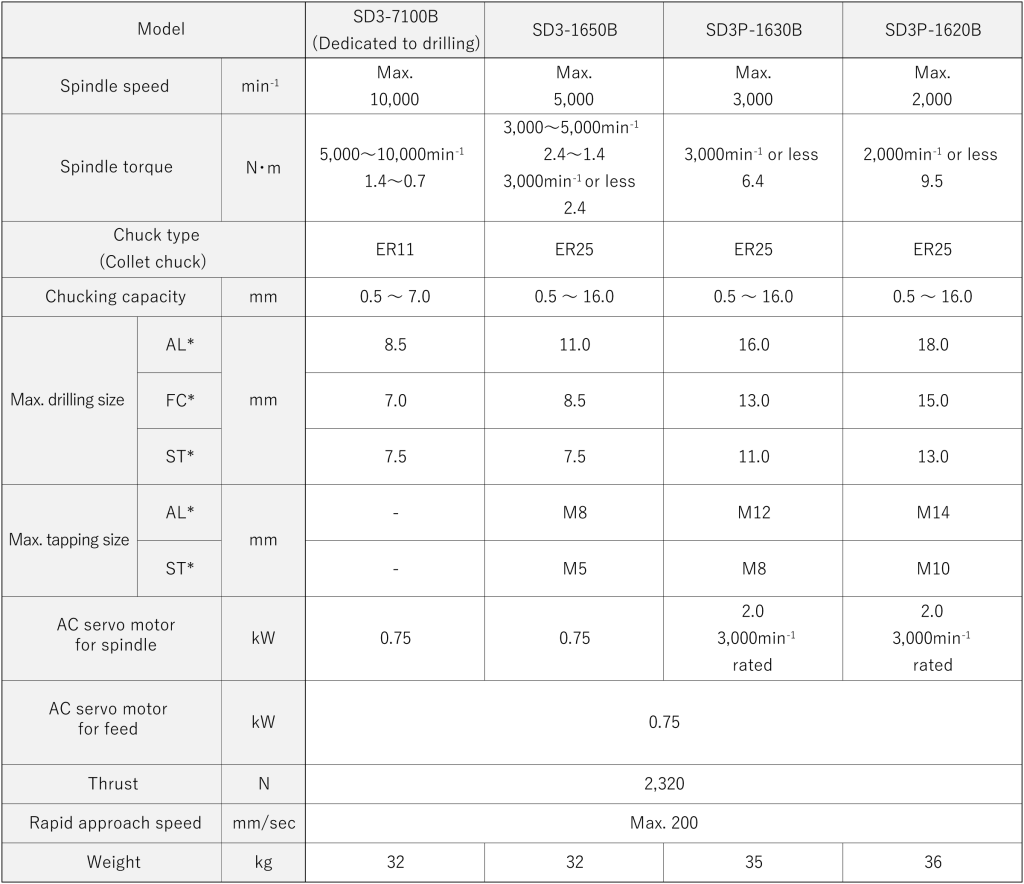

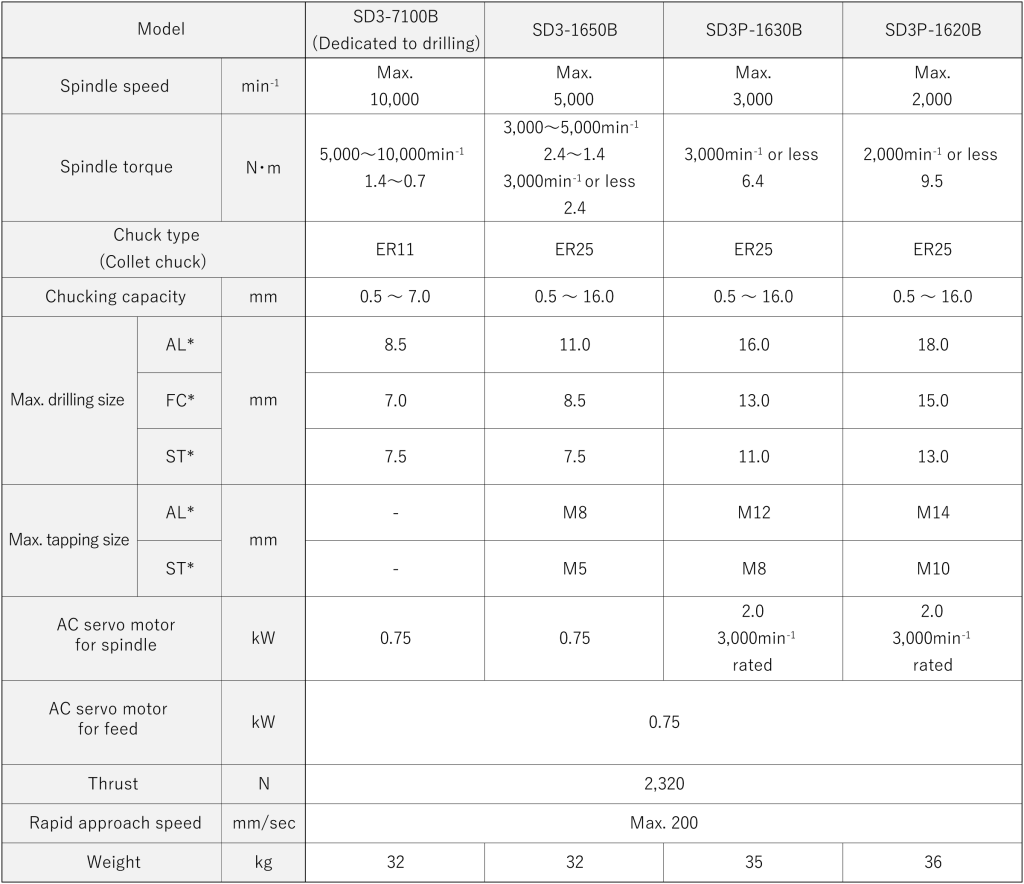

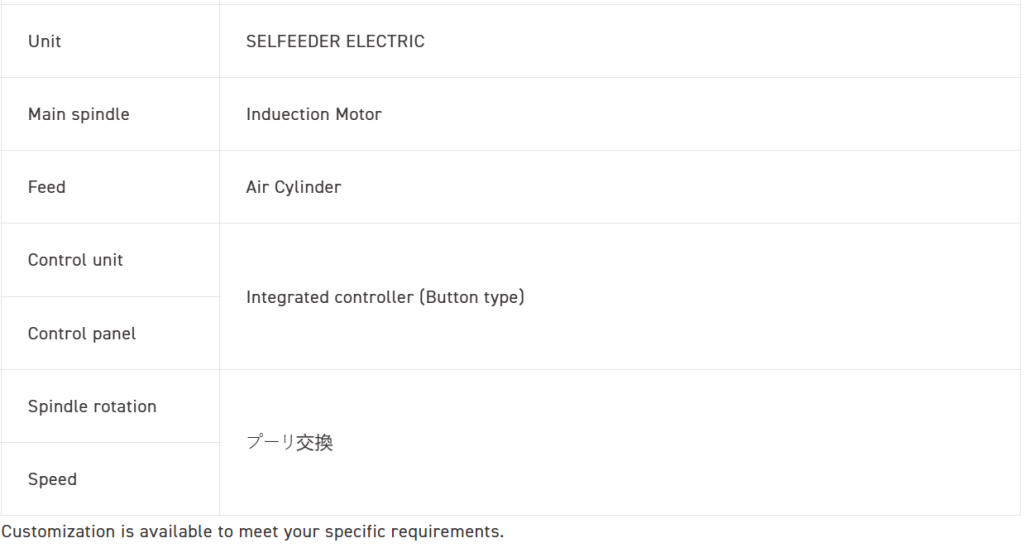

Specifications

Notes:

- Select a model based on workpiece specifications, machinability, tool specifications and cutting speed.The maximum drilling capacity shown above is the value at a drilling depth of twice the drill diameter.Tapping capacities are conditional on the depth of tapping being limited to 1.5 times of the tap diameter.

- If the maximum drilling capacity exceeds the chucking capacity, special tools (with steps) shall be prepared by the customer.

- If your drilling and tapping needs exceed the figures in the capacity chart, please contact the nearest sales office.

- ER collet is adopted for spindle nose. Use collet ER-GB when chucking a tap.

- Misalignment between a pre-hole and a tap can cause early tap damage, select a tap holder.

- A servo motor for feed is with a holding brake, “B” is added to the end of SELFEEDER DUO model number.

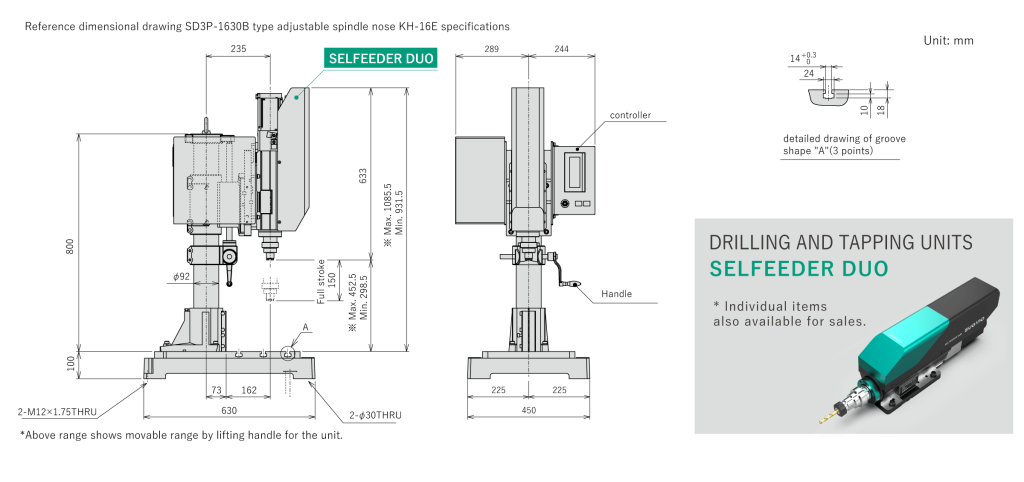

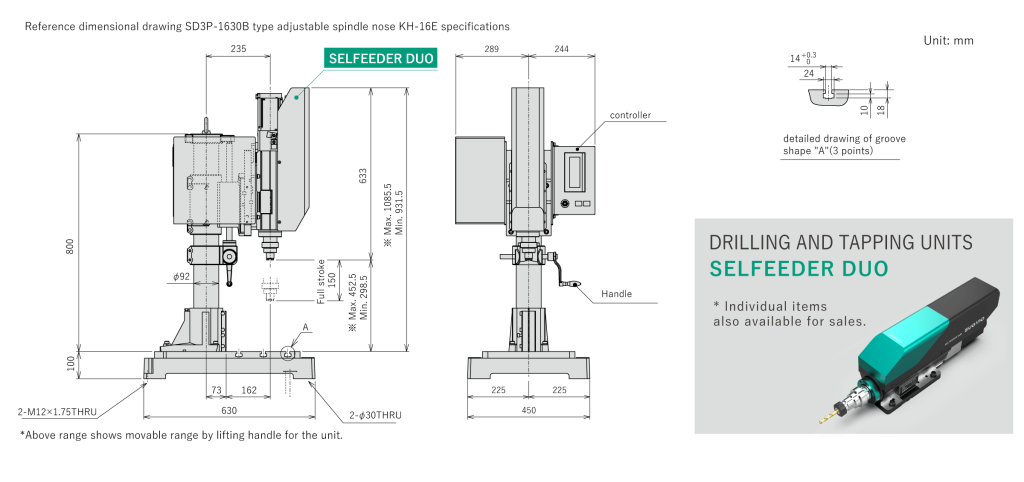

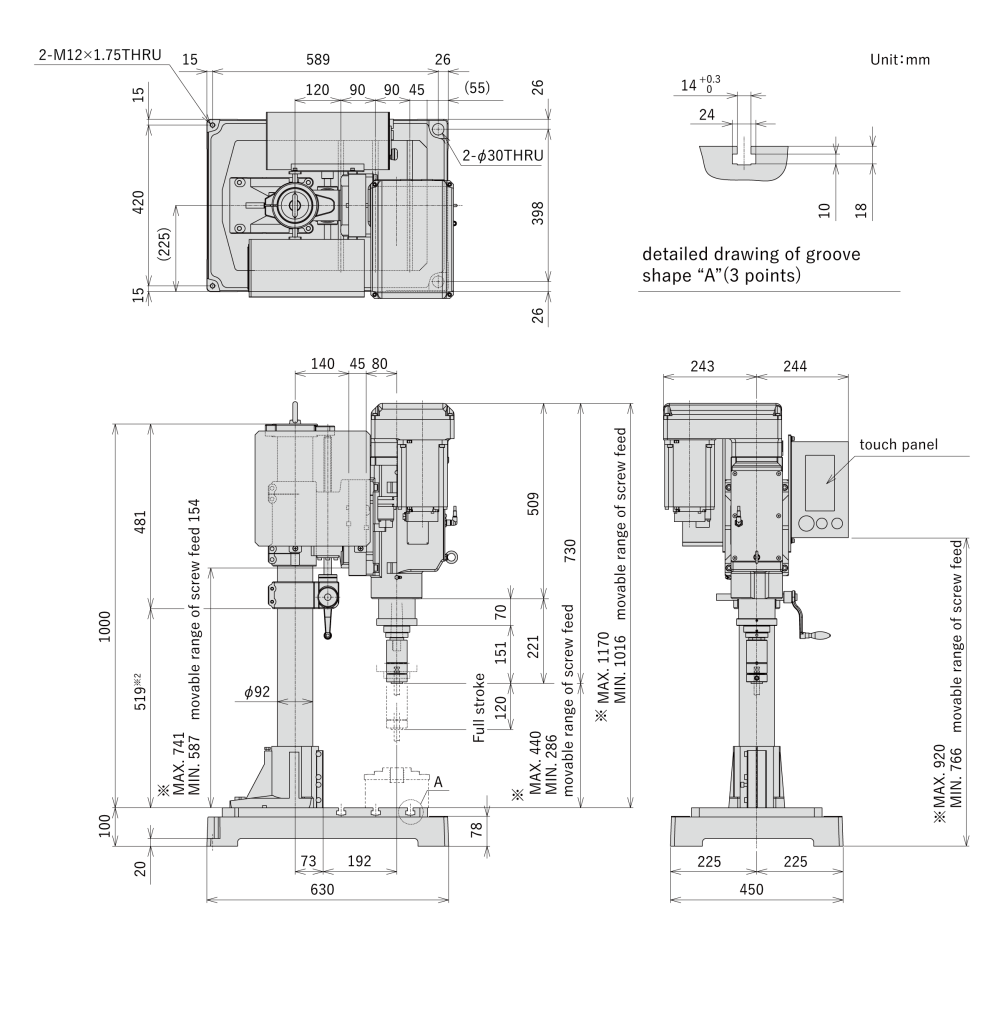

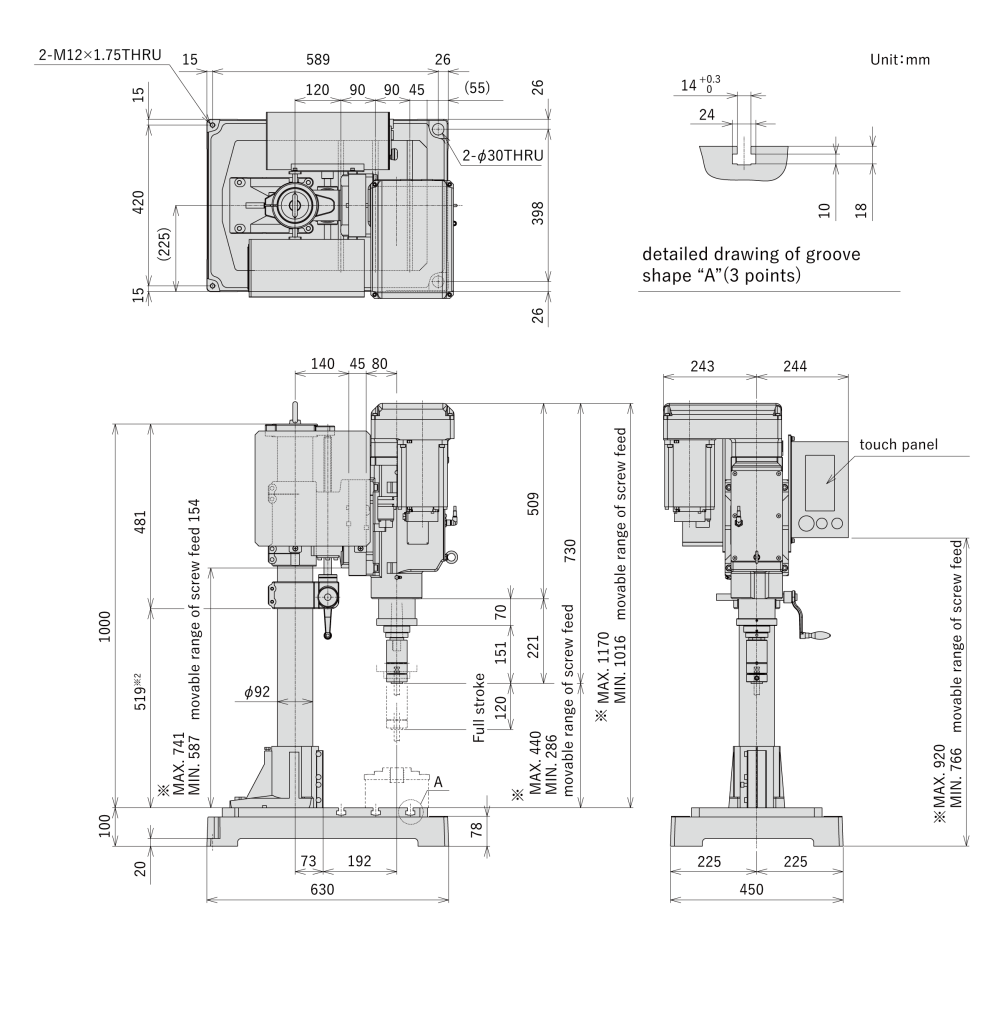

Dimensions

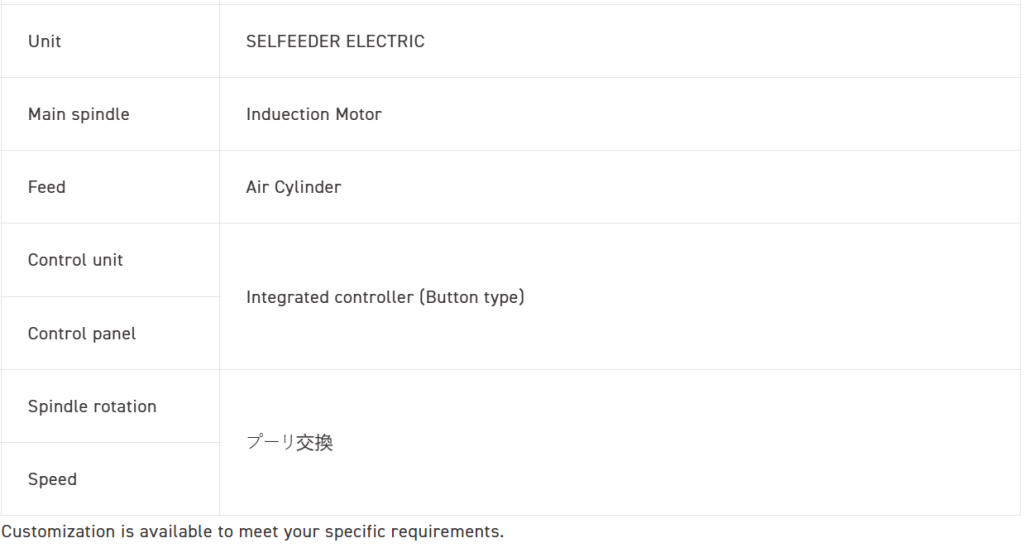

STANDRILL SELFEEDER ELECTRIC : Automatic tapping stand

It is a high-precision automatic drilling stand equipped with vertical adjustment and swiveling mechanisms for versatile use of devices like SELFEEEDER and SYNCHROTAPPER.

The standard controller allows for the free selection of standard, dwell, and step operations, making it ideal as a processing machine for small-lot production of various products or as a secondary machining process after machining center.

Feature

Units can be selected according to the application.

Suitable units can be selected from the extensive lineup of drilling units in the SELFEEDER series.

Flexible layout

Dedicated stands are available in a diverse lineup, featuring options with vertical adjustment and swiveling mechanisms. These stands can be selected and designed according to the customer’s specific application needs.

Additionally, the control and operating devices can be customized in terms of placement and type.

The layout can be adapted to fit the customer’s work environment.

Simply connect the power and air to start operation on the same day.

Customers can start operation on the same day by simply connecting the main air and power cables.

*Excludes fixture installation and adjustment, setting processing conditions, and creating processing programs.

Example of Combinations

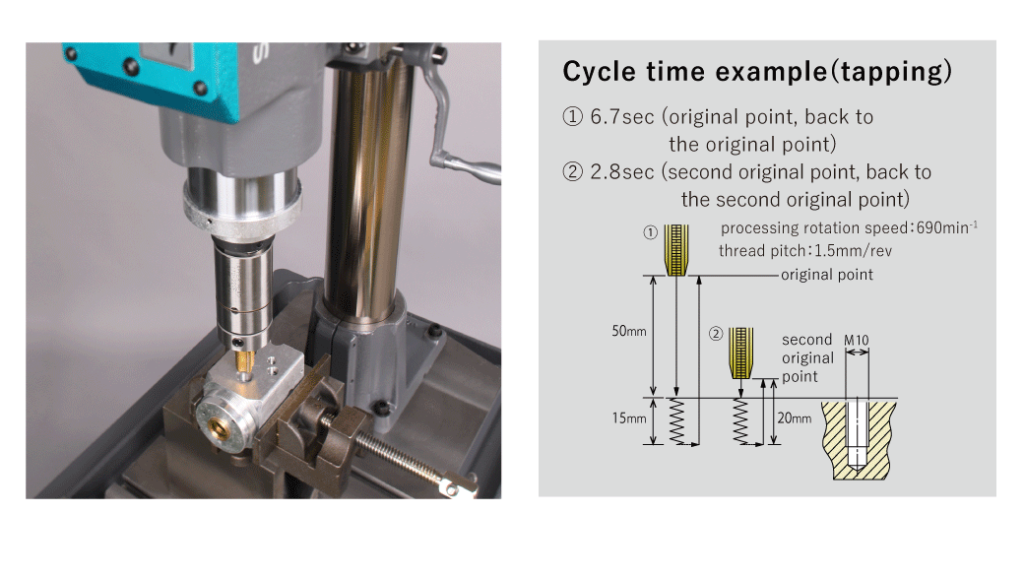

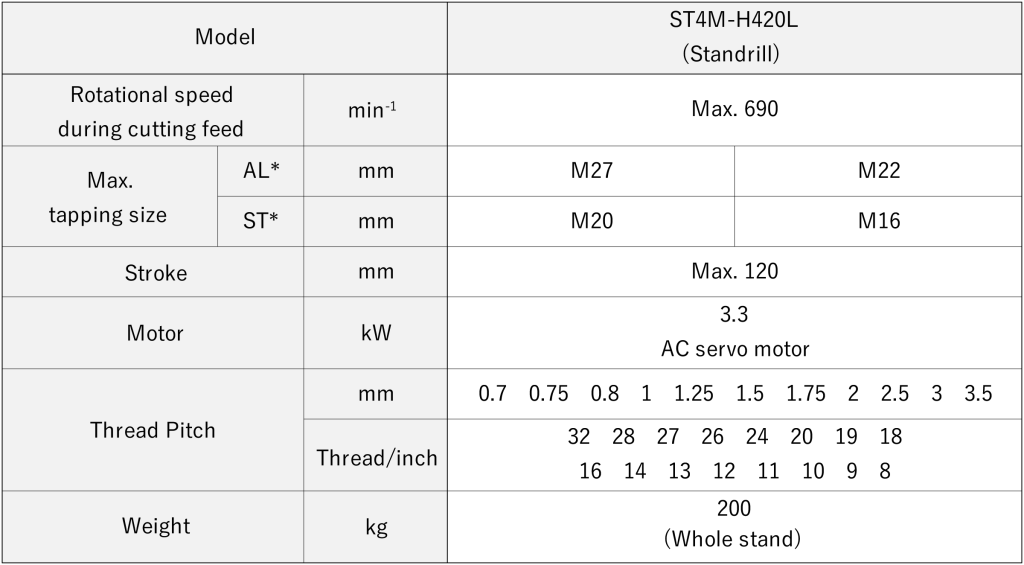

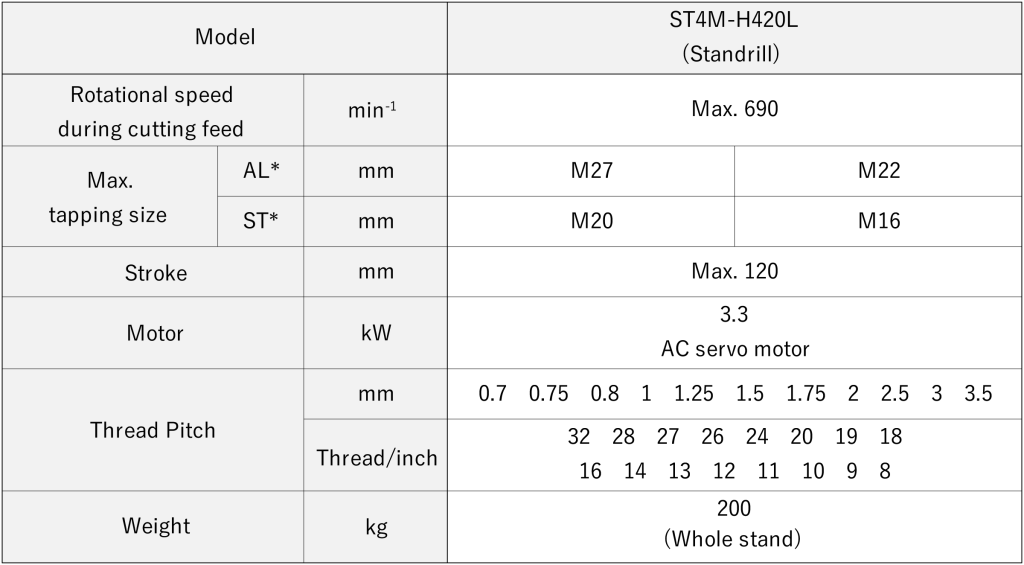

STANDRILL SYNCHROTAPPER ST4M : Automatic tapping stand

Operational on the same day!

It is a high-precision automatic tapping stand.

Max. tapping capacity ——- Steel M20 / Aluminum M27

Maximum stroke ——- 120mm

Maximum spindle speed —– 690min-1

Feature

Equipped with a 4.5-inch compact touch panel for manual operation and processing program settings.

No programming knowledge is required; operation is possible with just input for stroke and rotation speed.

Therefore, it is also easy to update from outdated tapping ball screw machines.

Easy operation

Operates on the same day with a 200V power supply

It can be operational from the day of delivery.

Easy programming

We have pre-prepared the processing patterns required for tapping, so you can easily create processing programs by simply inputting the cutting start and end points, as well as the spindle rotation speed at each point.

Abundant functions

Preset counters 6 digitsx5

Program registration capacity: 200 units

Equipped with a simple teaching function

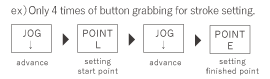

With the JOG feed and the setting buttons for cutting start and end points, you can intuitively set the stroke.

Customization available

By adding service input/output signals (optional), continuous control of customer-prepared jigs and safety doors is possible.

Labor-saving for various types of nut threading processes

It is possible to easily automate tasks that were previously done manually, such as removing spatter from welded nuts and re-tapping the plating that has adhered to the inner diameter.

Specifications (Performance Chart & Dimensional Drawing)

Note:

- The upper column of the chart is for a spiral tap and a point tap. The lower column is for hand tap No.2. Tapping capacities are conditional on the depth of tapping being limited to 1.5 times of the tap diameter.

- Please determine the cutting feed rate and rotational speed based on factors such as workpiece material, machinability, tap diameter, tap material, and cutting speed.

- Please specify the pitch of the tap you will be using. Changing the pitch will require replacing the feed gears.”

- The rapid feed and cutting feed rate vary depending on the thread pitch and rotation speed.

For more details, please contact the nearest sales office. - Depending on the tap size, the single tapper head will come with either the 1TD-220F (with a sleeve for M12 to M22) or the 1TD-160F (with a sleeve for M4 to M16).

*The dimensions are based on the installation of the screw set FS-92SS at the dimensions specified in section 2.

The above illustration shows the single tapper head 1TD-220F. Dimensions will differ when using the 1TD-160F.

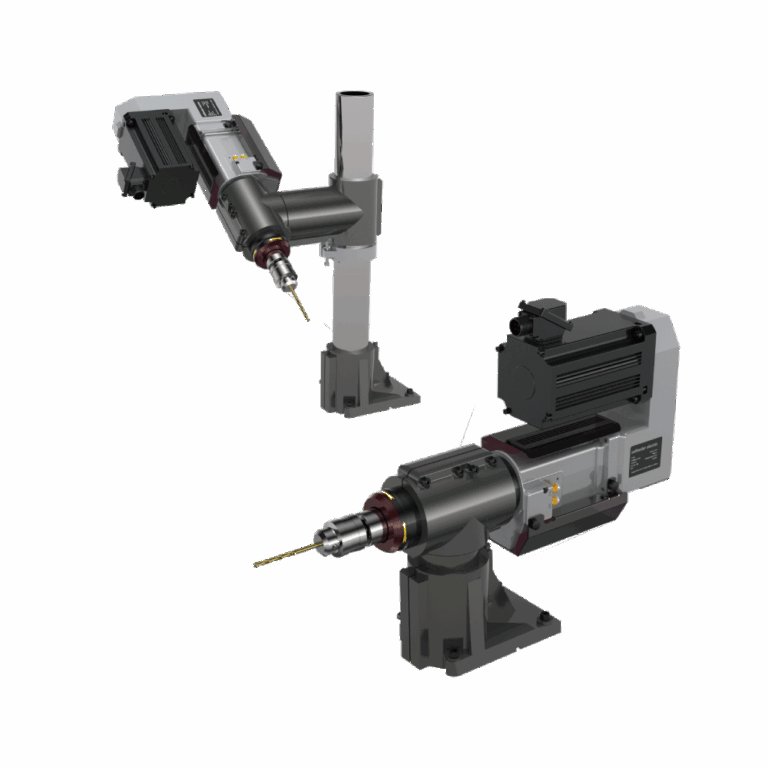

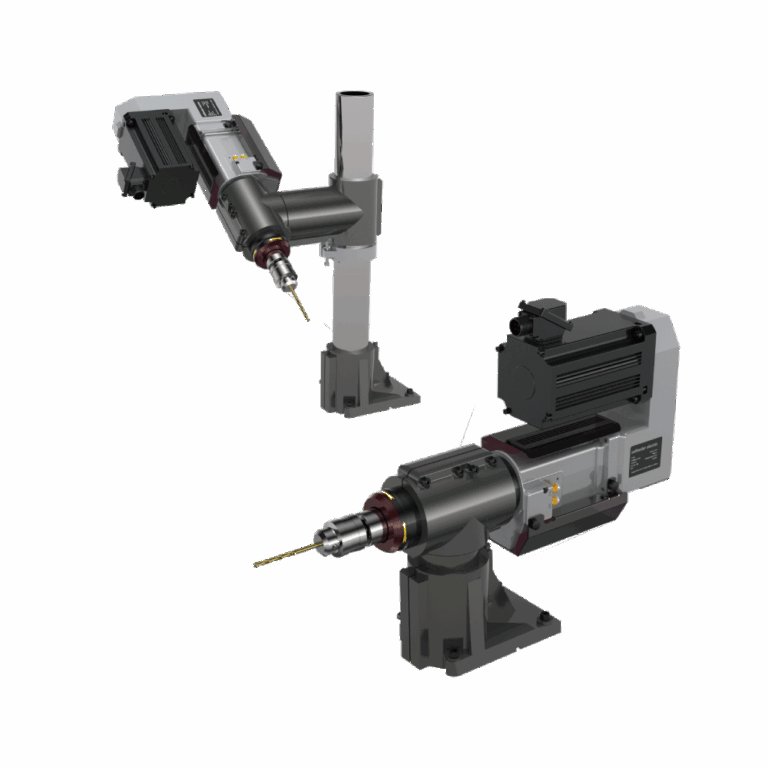

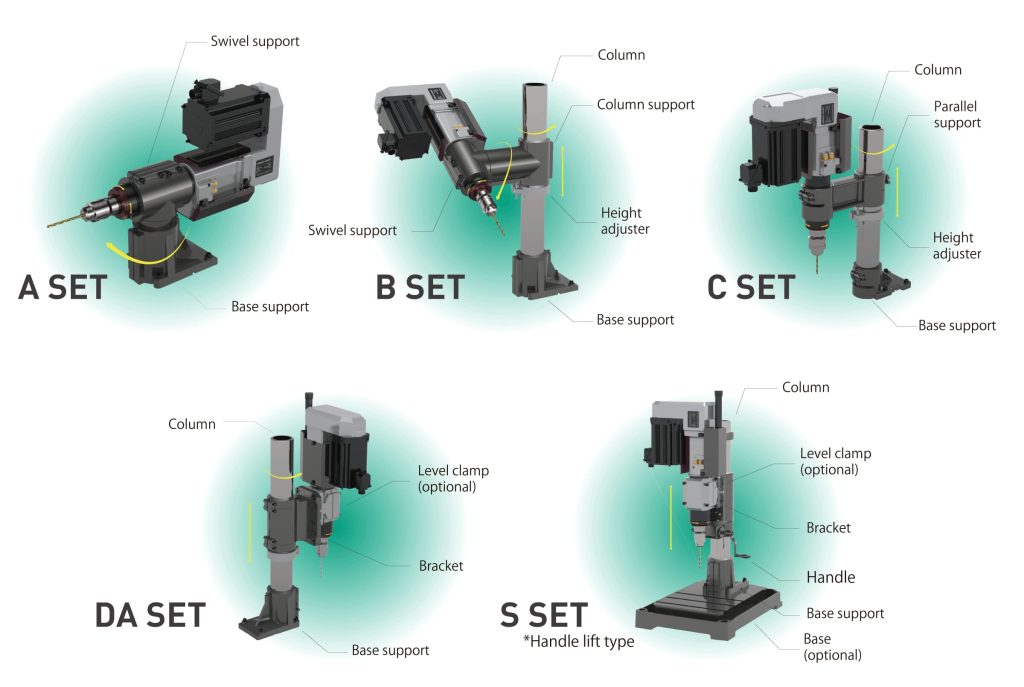

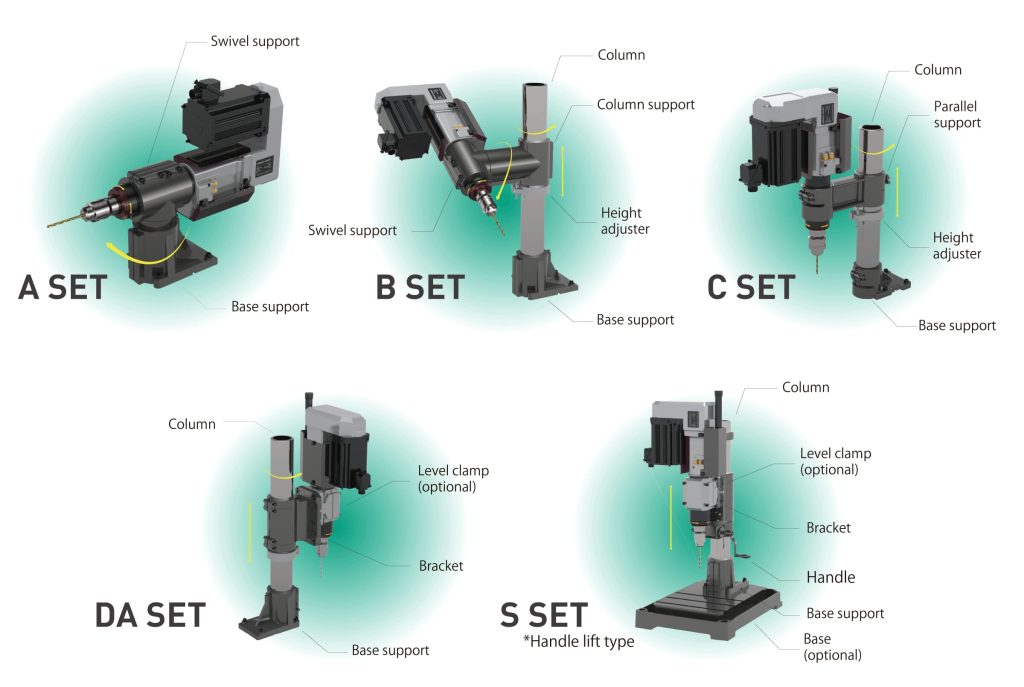

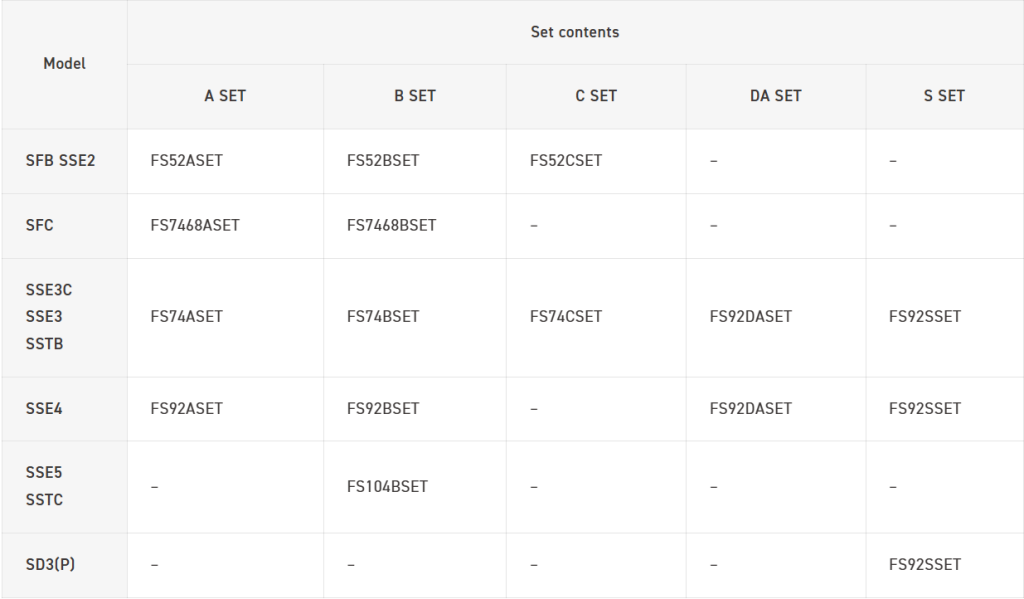

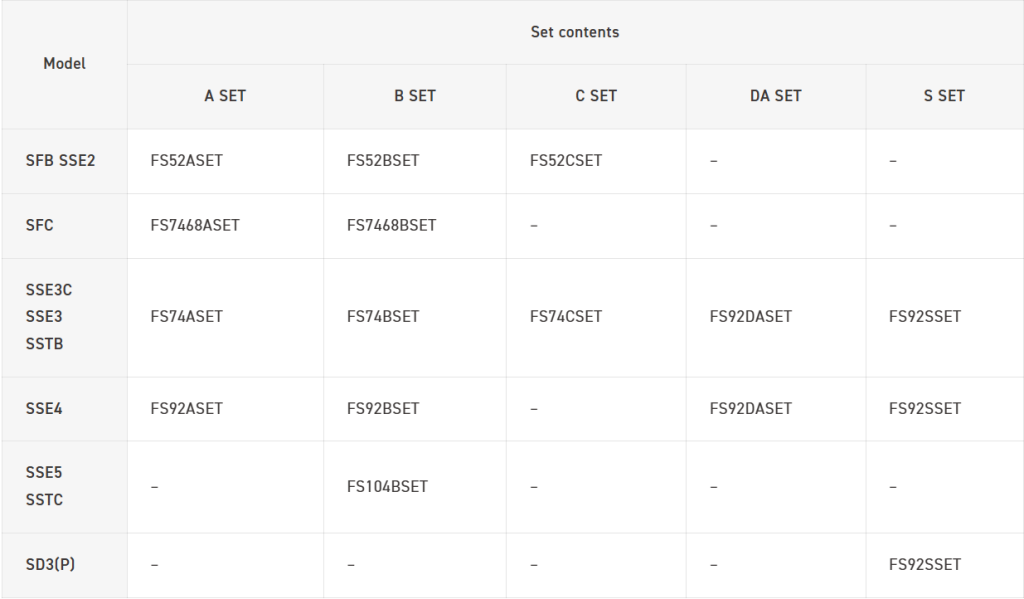

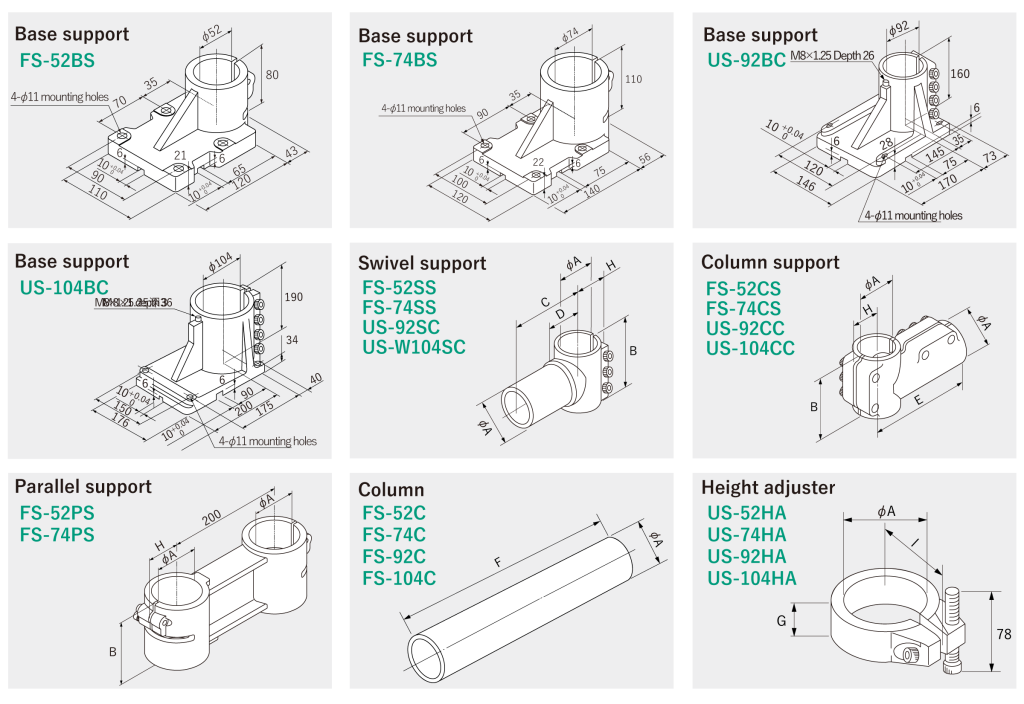

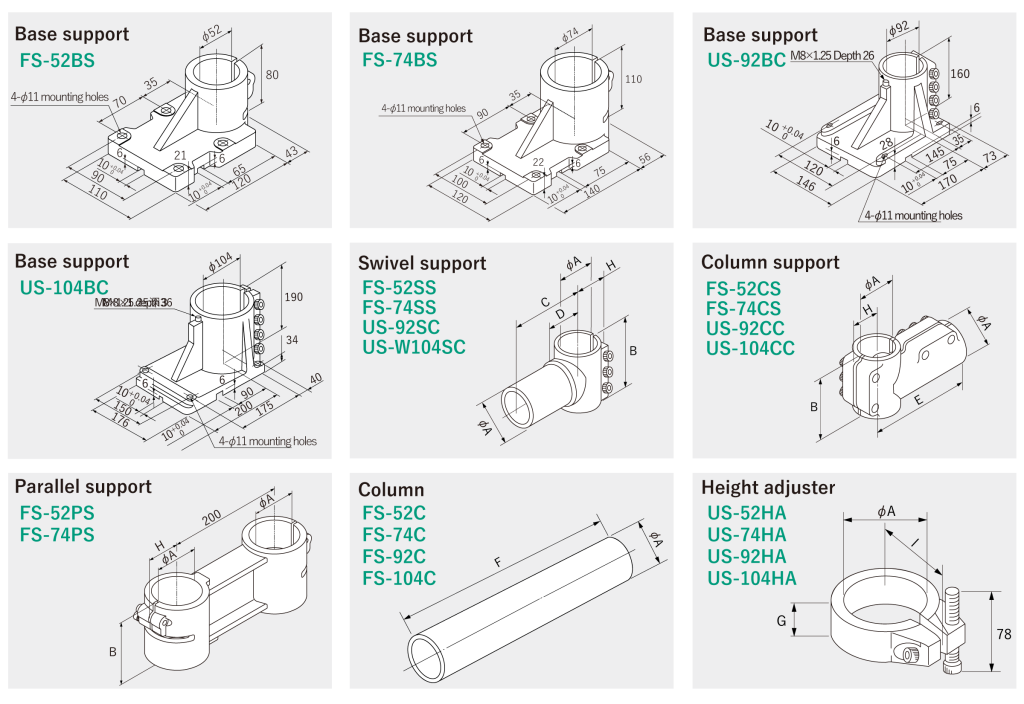

FLEX STAND : Angle/height adjustable stand

FLEX STAND

Fixtures capable of holding round body type SELFEEDER or SYNCHROTAPPER at any angle and height.

Combination Examples

Various combinations can be selected depending on the machine layout.

Note:

- Items other than S SET will be shipped unassembled.

- When installing a unit other than SD3(P) type to DA SET or S SET, Level Clamp (see reverse side) is required additionally.

Please note that depending on the mounting position and orientation of the unit, it may interfere with the bracket.

In that case,please use an “H” specification level clamp. - There are restrictions on the mounting orientation of the unit. For details, please refer to the instruction manual for each unit.

Applicable Models

- SELFEEDER DUO SD3

- SELFEEDER ELECTRIC

- SELFEEDER PNEUMATIC

- SYNCHROTAPPER SSTB/SSTC

LEVEL CLAMPS : Fixed attachment

LEVEL CLAMPS

Fixtures capable of holding round body type SELFEEDER or SYNCHROTAPPER parallel to the machine base.

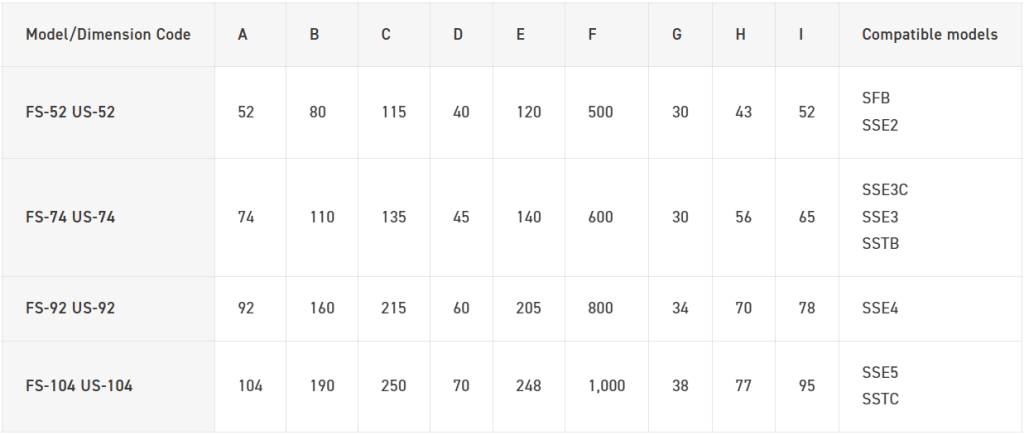

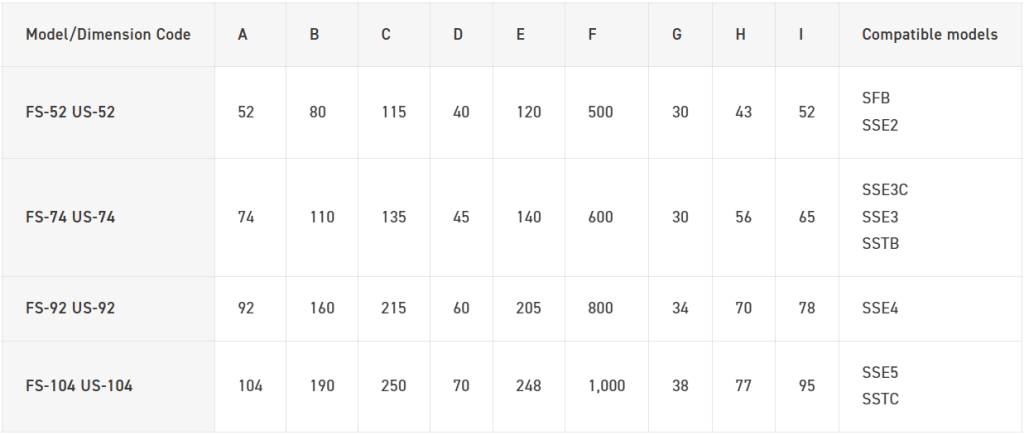

Dimensions

Applicable Models

- SELFEEDER ELECTRIC

- SELFEEDER PNEUMATIC

- SYNCHROTAPPER SSTB/SSTC

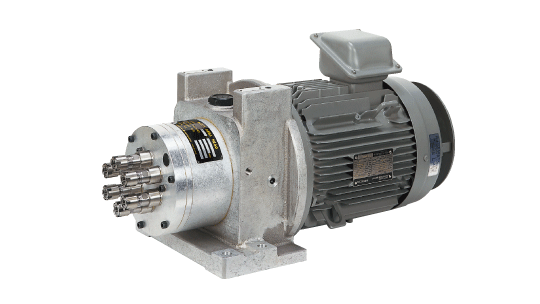

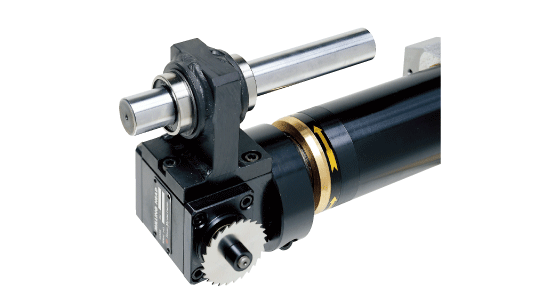

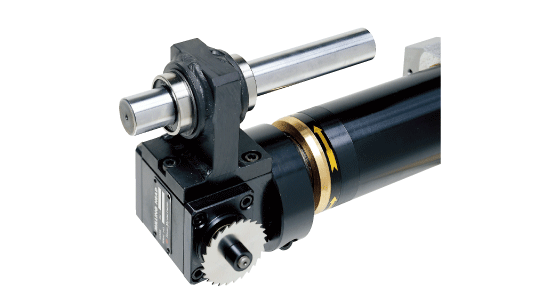

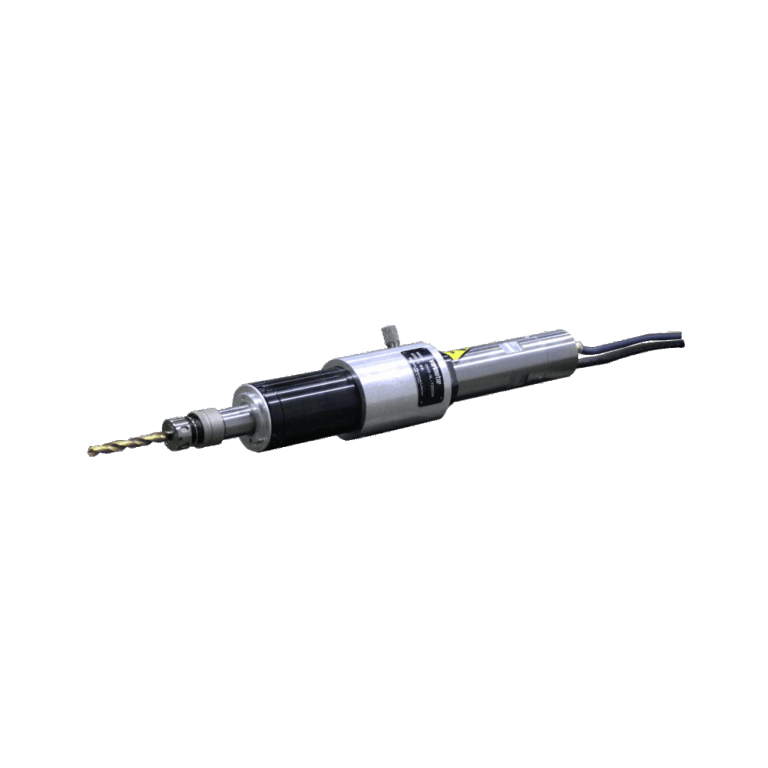

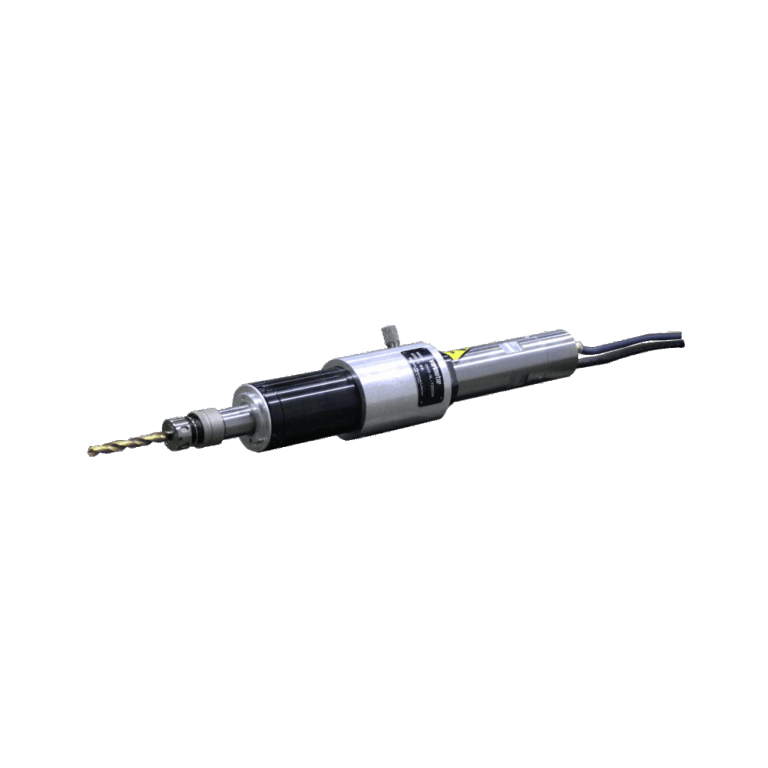

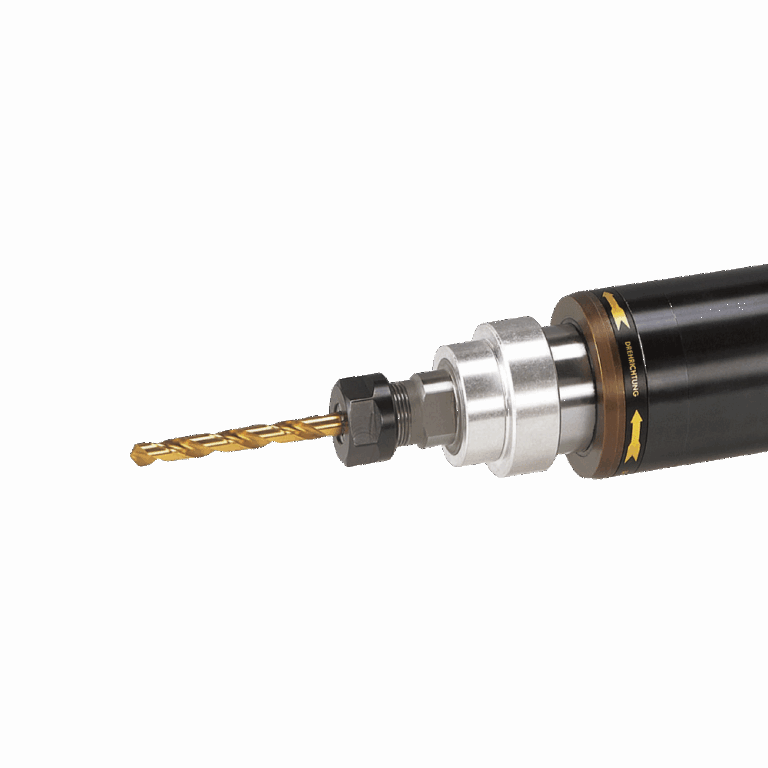

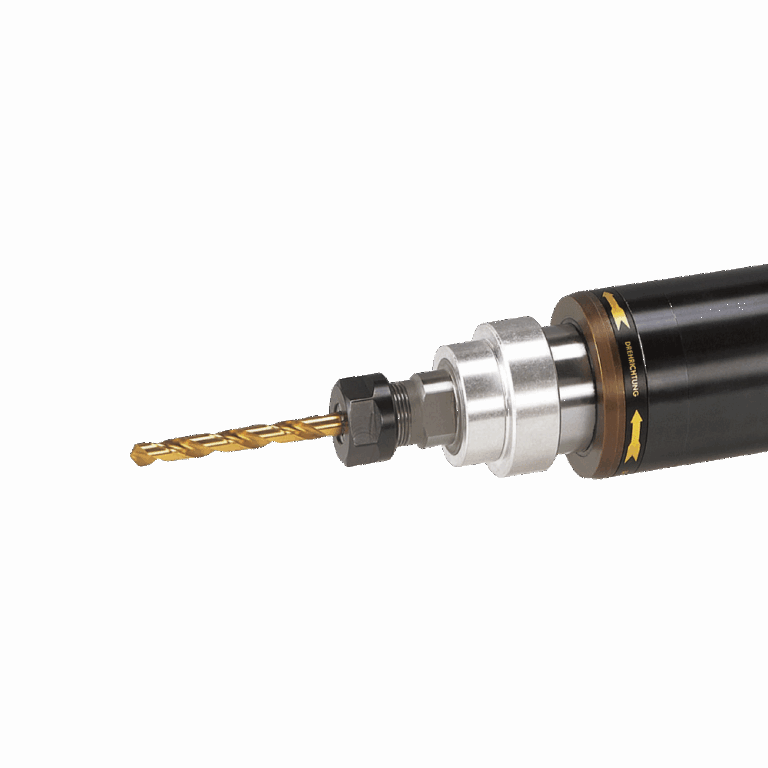

VARIMOTOR : High-speed Spindle Motor

VARIMOTOR

Features

High Precision and High Rigidity

This is a compact spindle motor with a built-in high-precision, high-power DC brushless motor. The unit comes with a precision angular bearing built into the main shaft and this allows the unit to perform deep-cut processing.

Dedicated High Performance

The rotation speed of the main shaft can be arbitrarily set by the inverter. High-level waterproof performance is obtained by combining air purge, via the motor cooling air, and labyrinth seals.

Application Examples

- Work such as drilling and end milling is done in combination with a slide unit.

- Deburring is done in combination with a robot.

- Various types of cutting can be done by mounting the unit on special purpose machines.

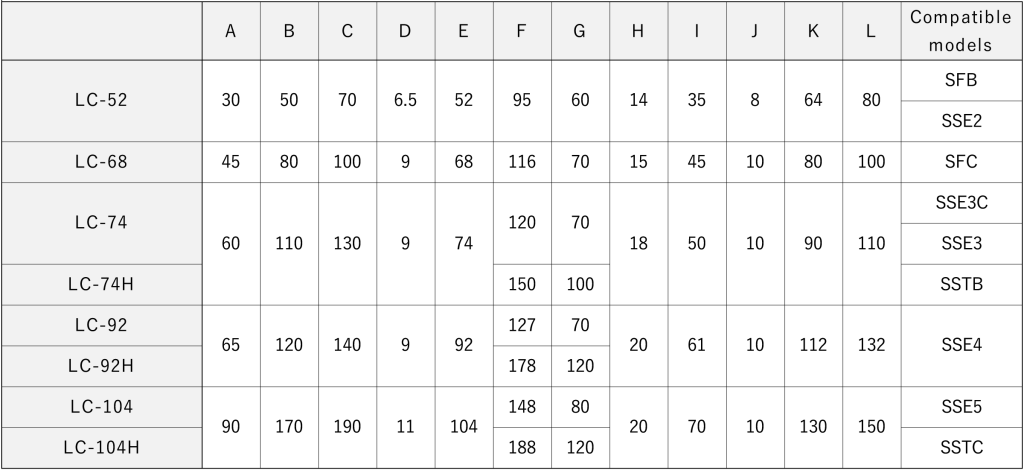

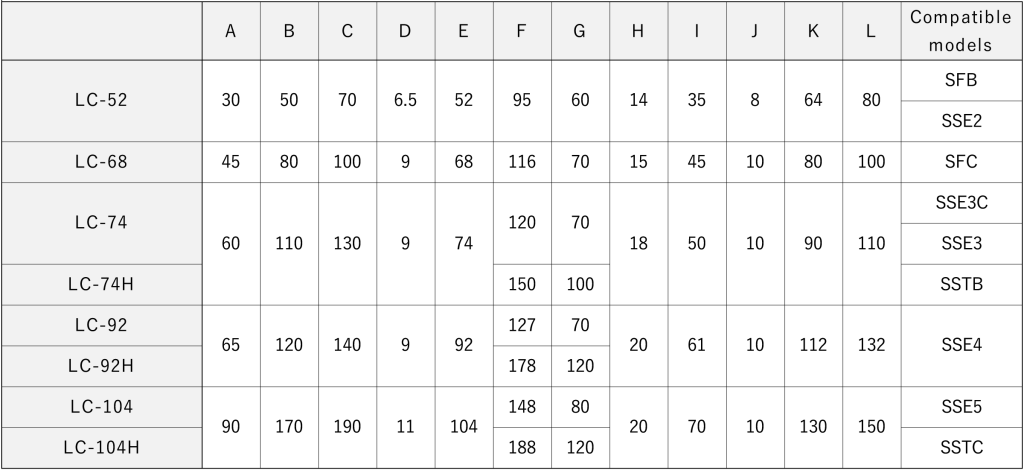

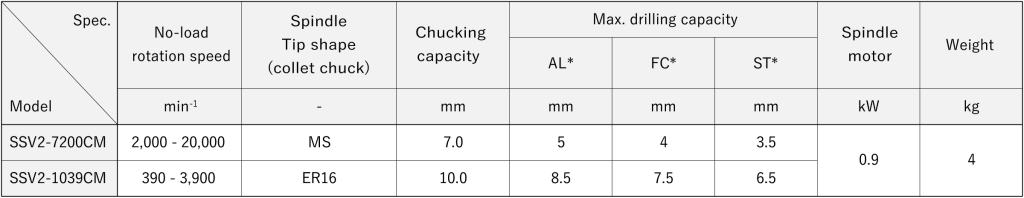

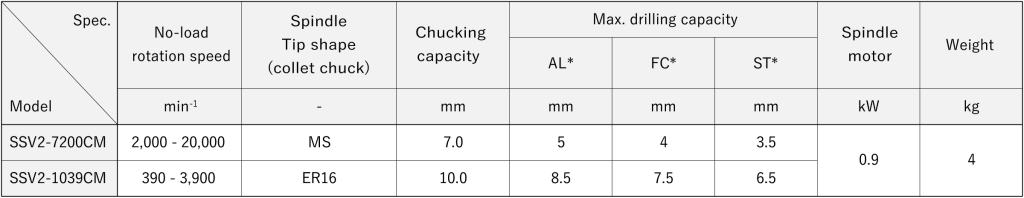

Specifications :

Notes:

- The selection of models should be based on the shape of the workpiece, material, cutting characteristics, diameter and material of tools, rotation speed (cutting speed), etc.

- The drilling capacity displayed in the above table is based on values representing a drilling depth of two times the diameter of the drill.

- Power-supply voltage is 3-phase AC200V±10%, 50/60 Hz.

- To cool the built-in motor, please supply clean, dry air from the air supply aperture.

- Make sure not to block air vents used for motor cooling with clamps, etc.

Furthermore, please make sure that the vents are always facing in the downward direction. - Cable pull-out direction differs depending on the the model number.

For more information, please contact your nearest sales office. - AL : Aluminum(ADC12) , FC : Cast iron(FC200) , ST : Steel(S45C)

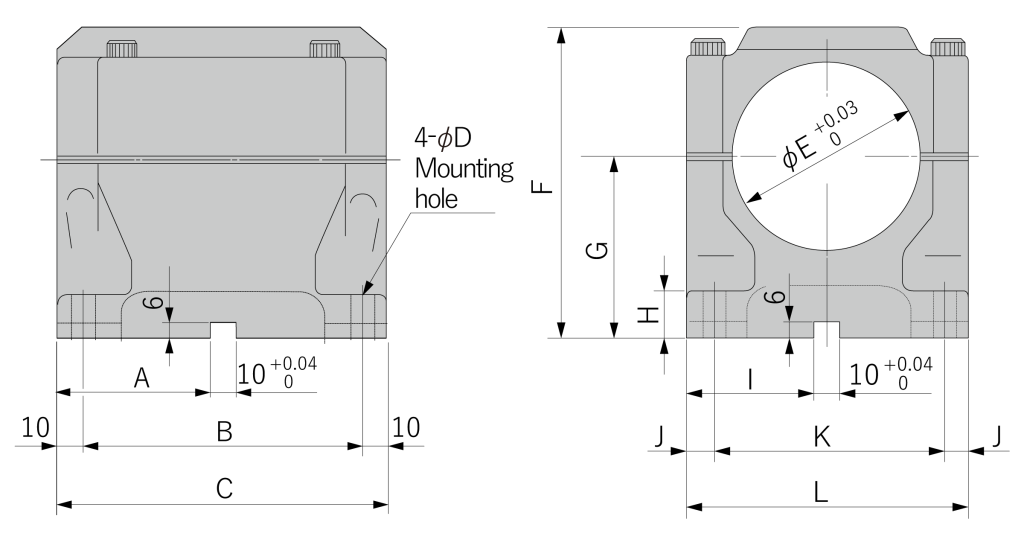

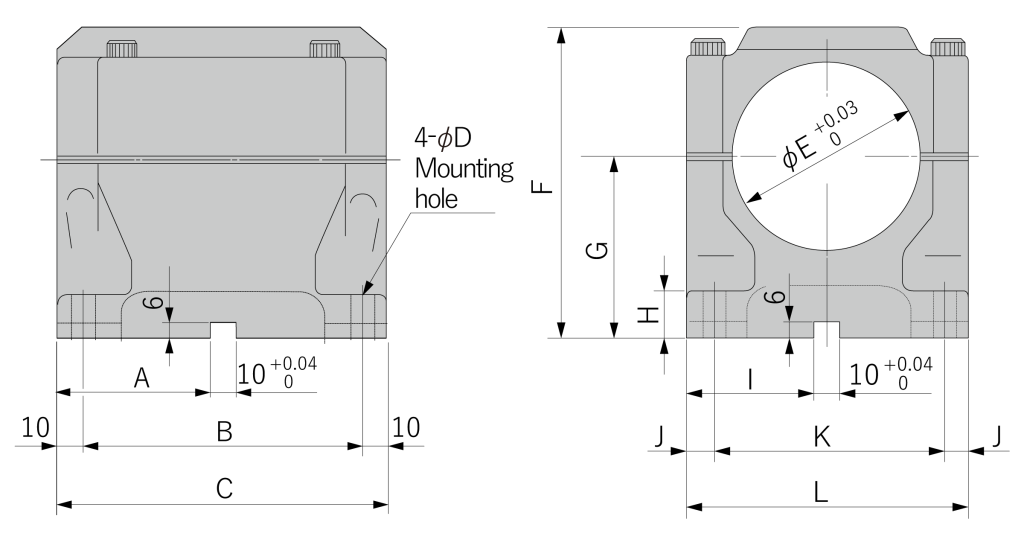

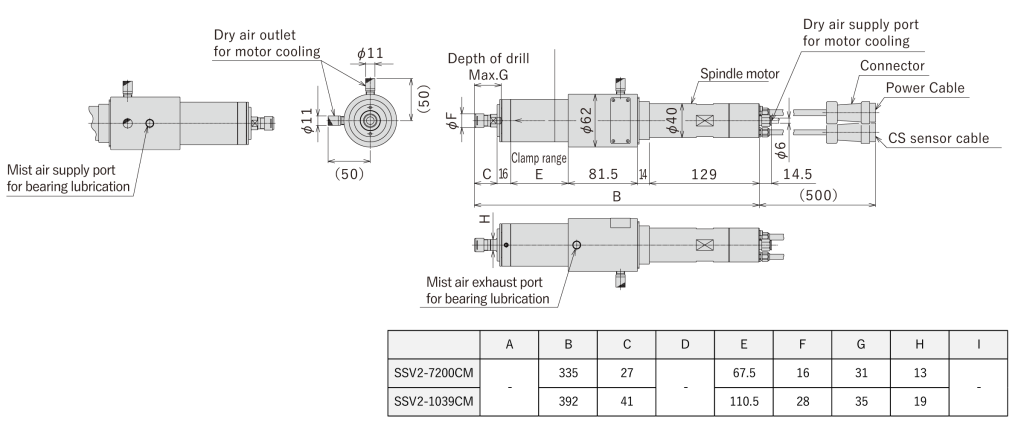

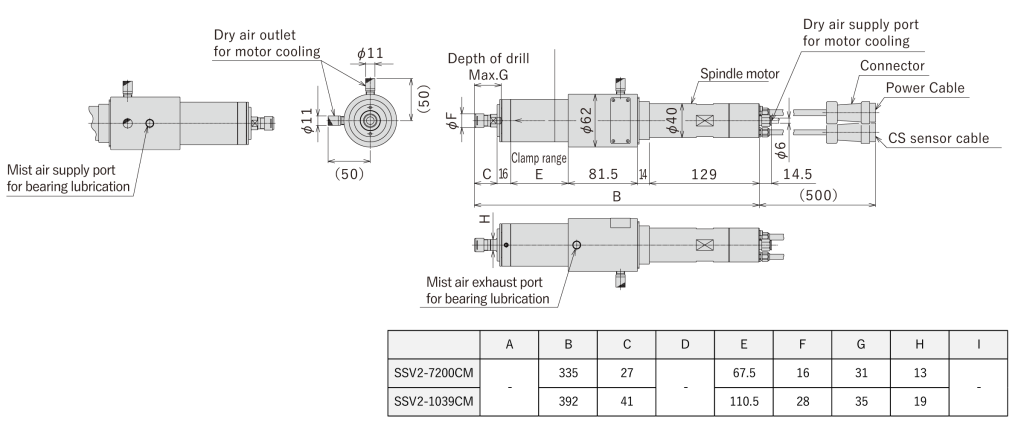

Dimensions :

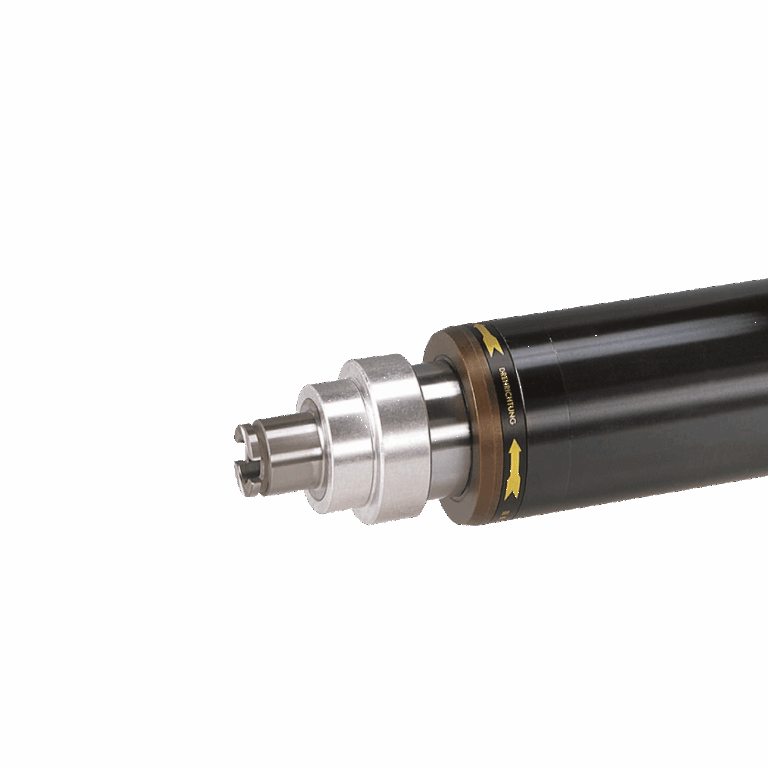

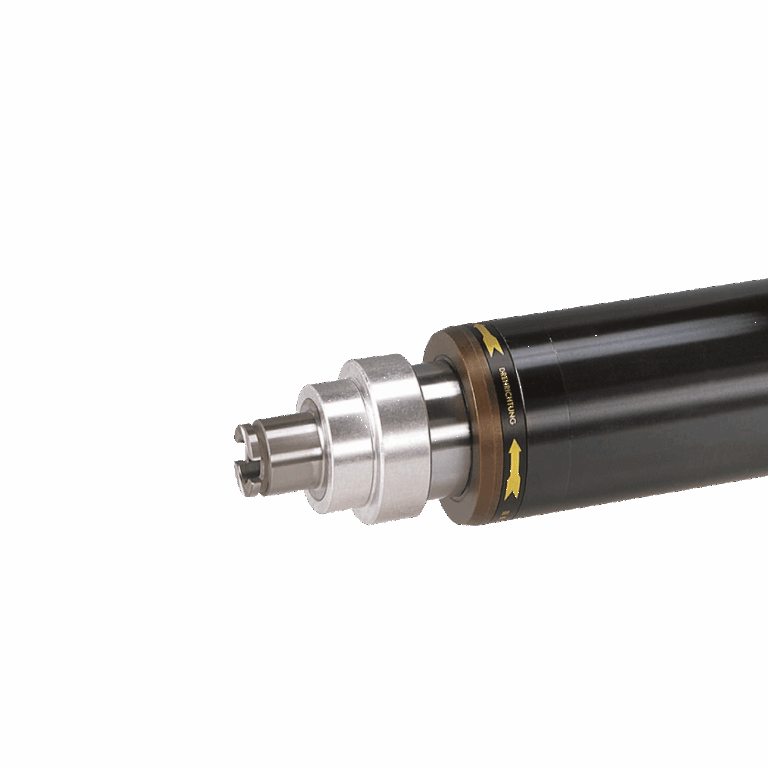

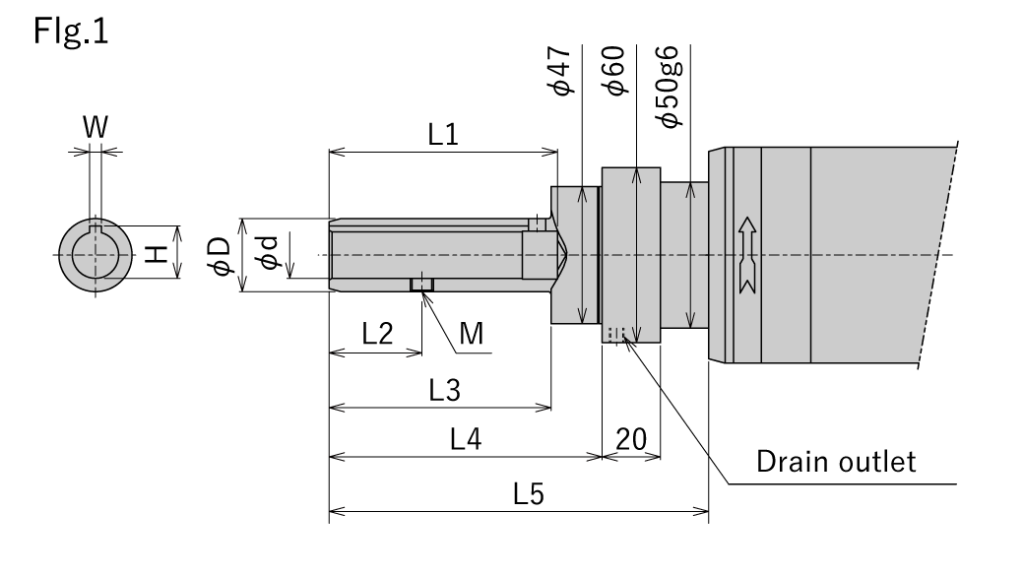

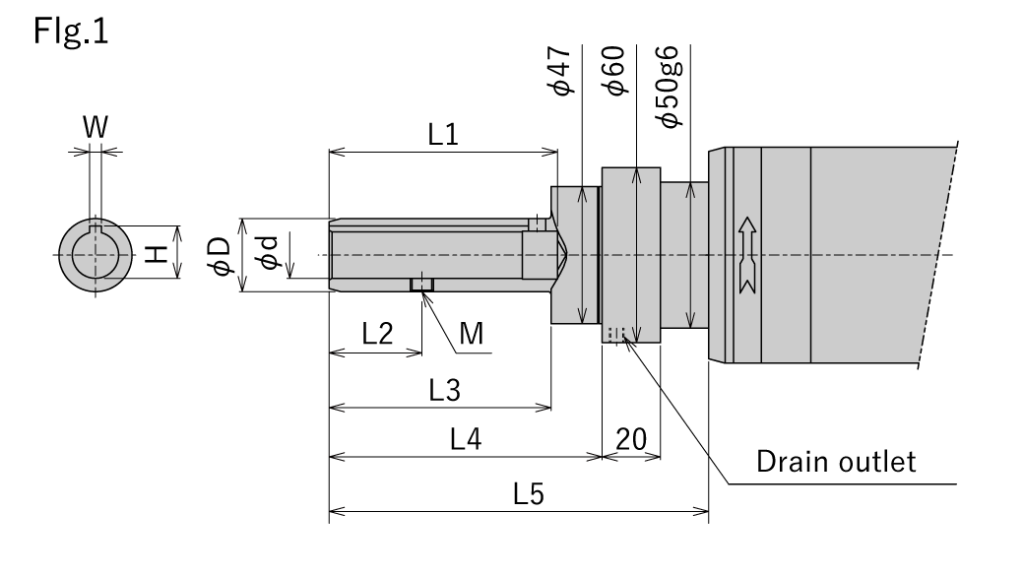

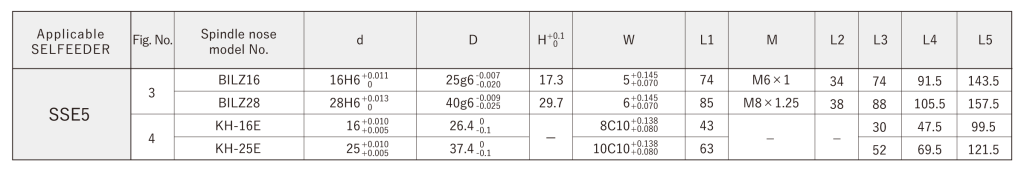

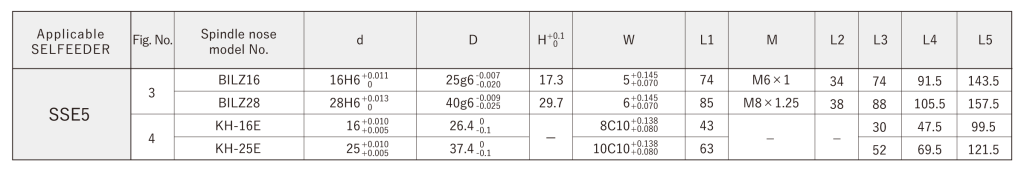

SPINDLE NOSES

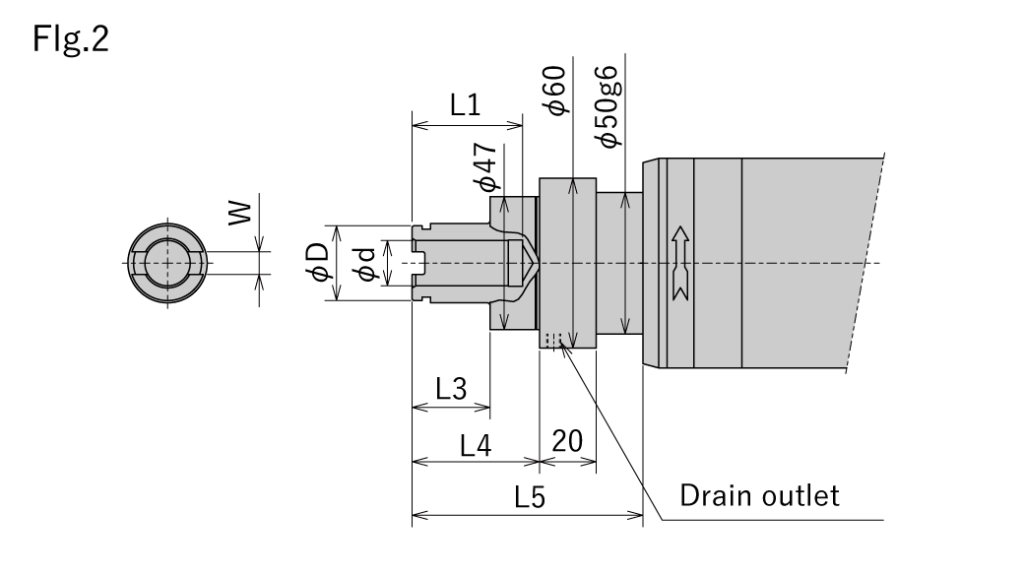

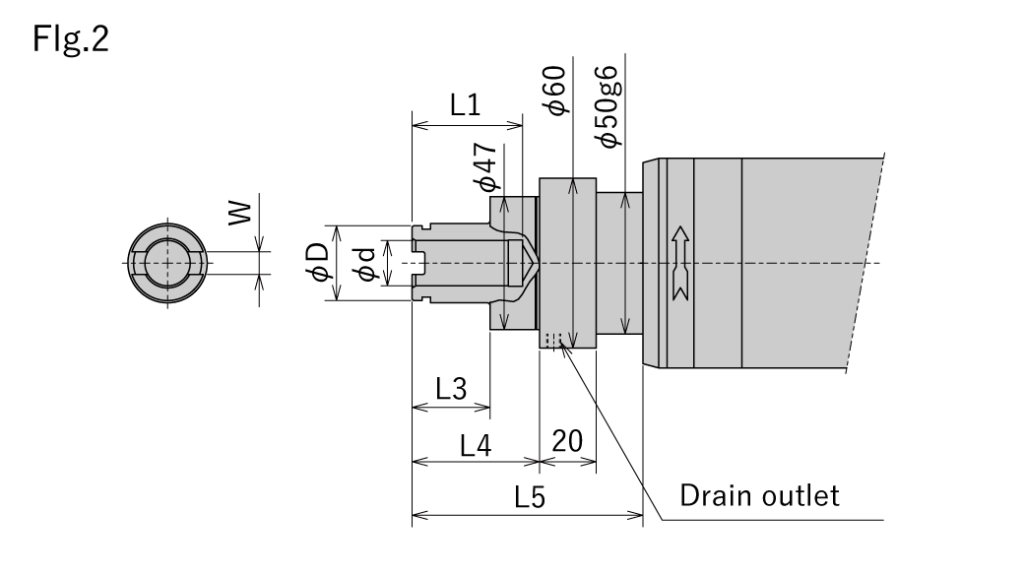

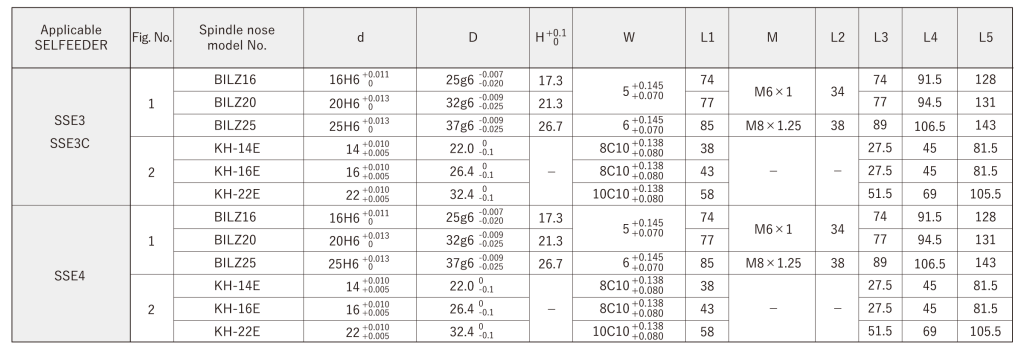

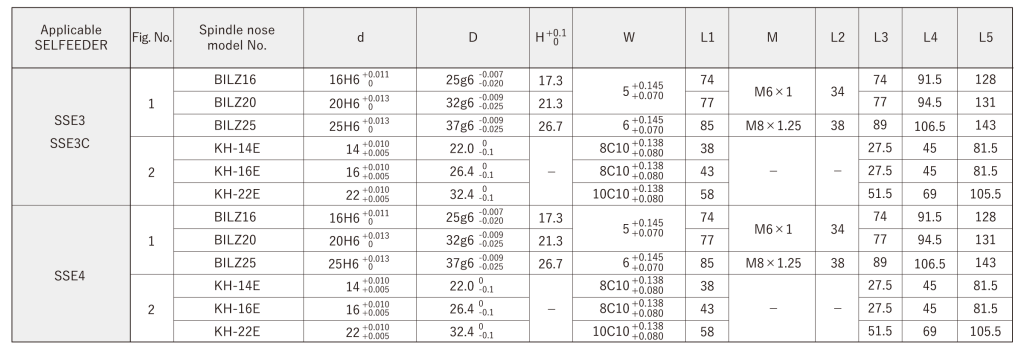

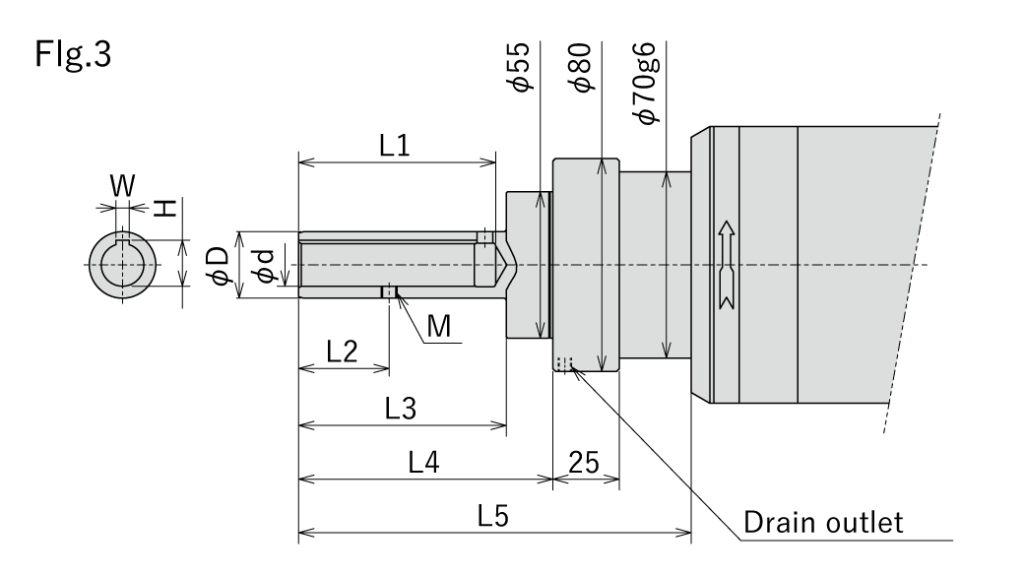

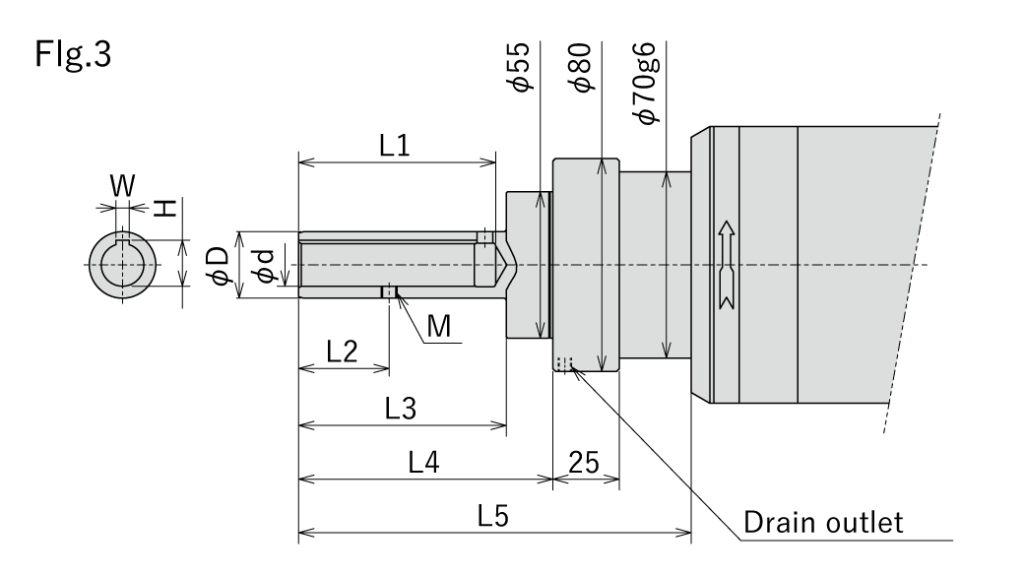

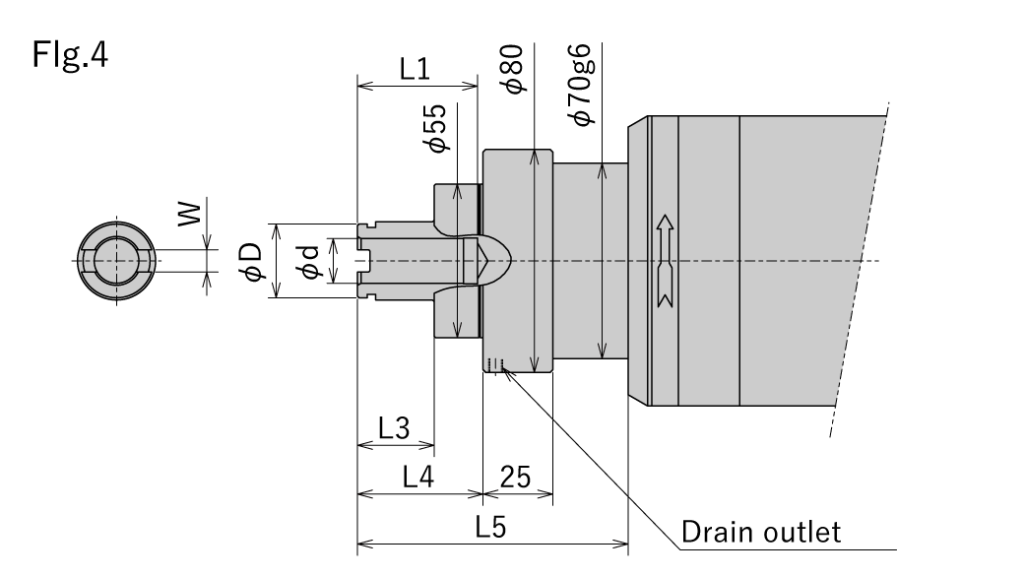

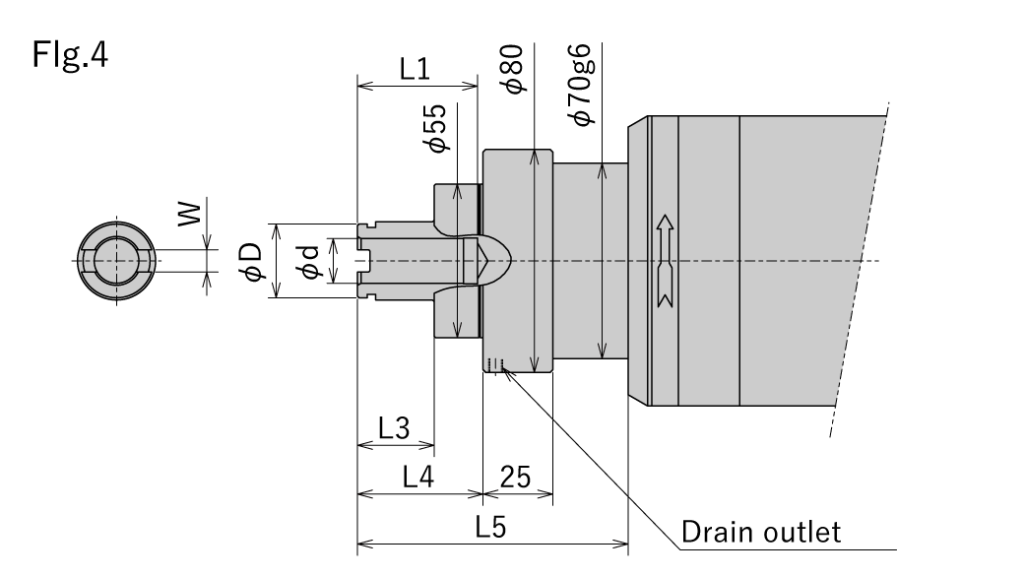

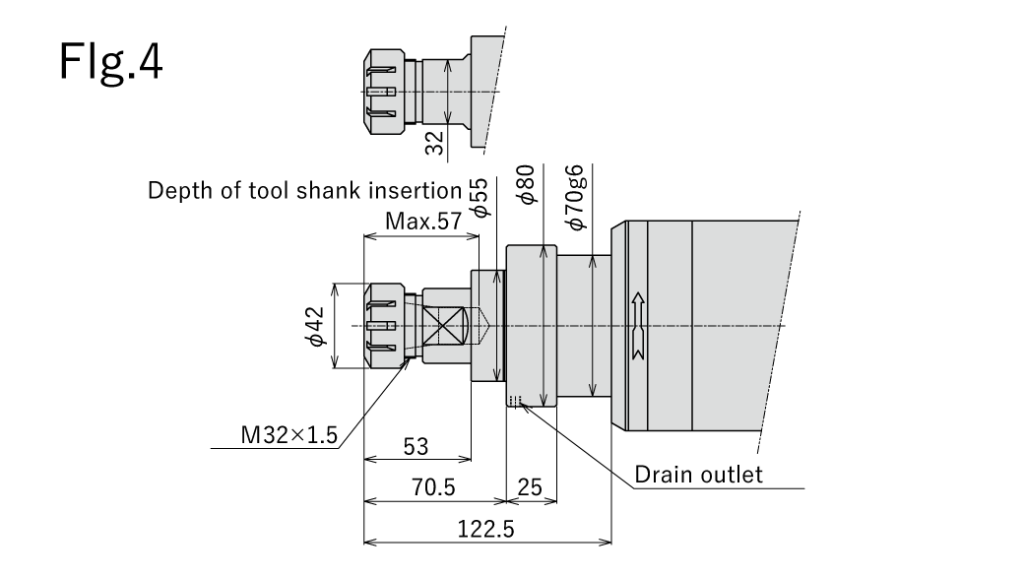

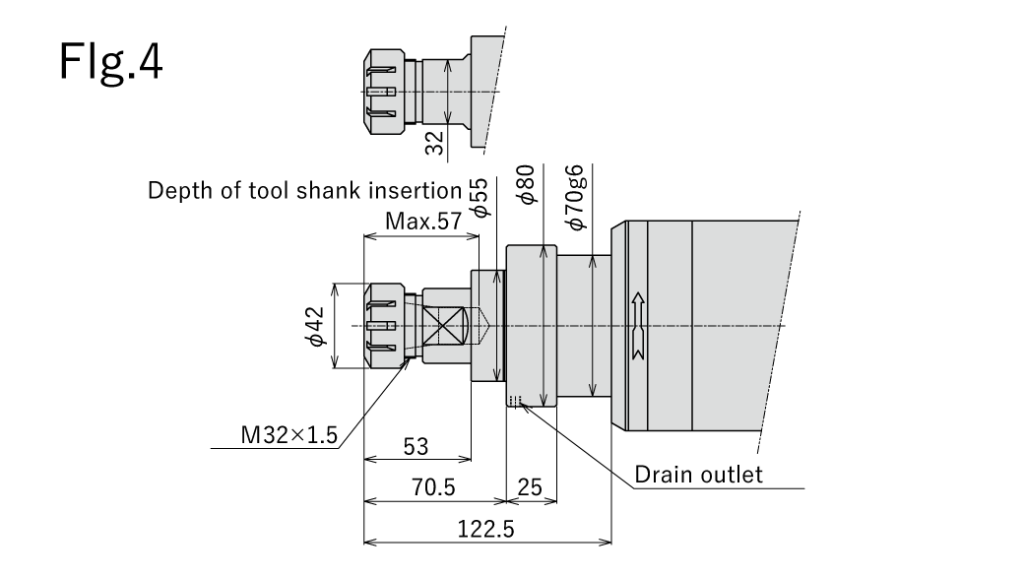

ADJUSTABLE SPINDLE NOSES For ELECTRIC

Adjustable Spindle Noses are applicable to all models of the SELFEEDER ELECTRIC series.

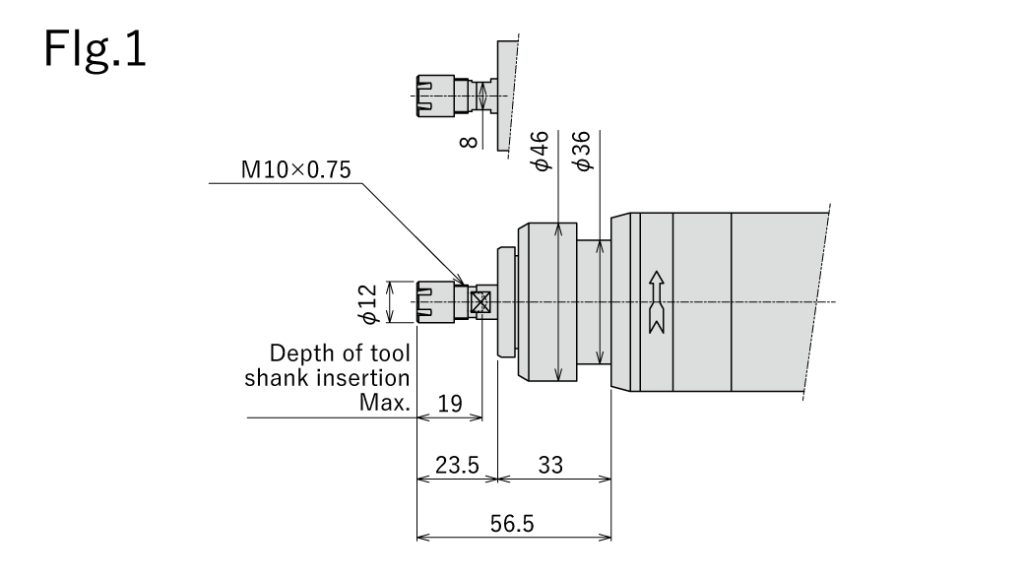

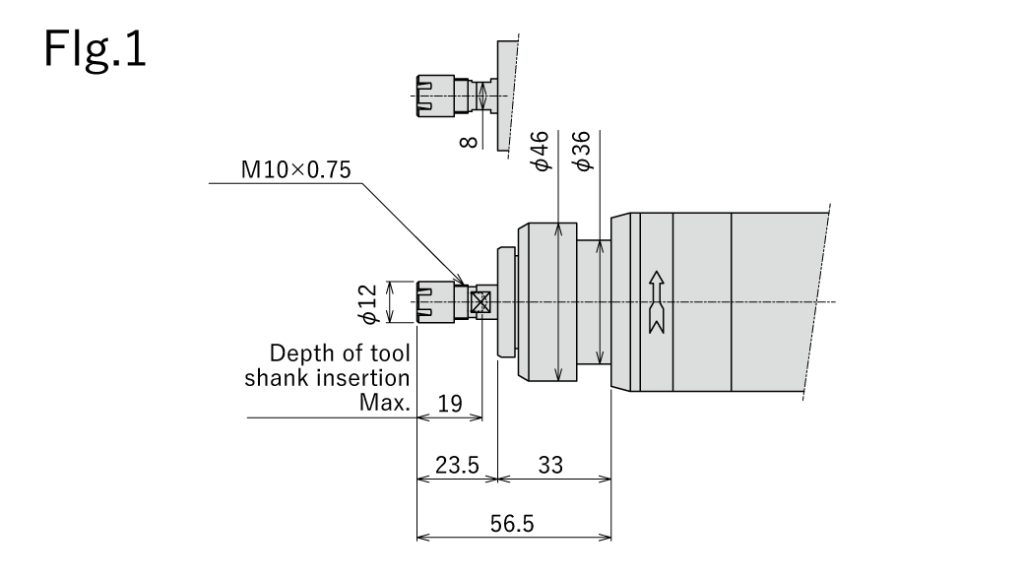

Dimensions :

Notes

- Dimensions of spindle nose shown here are as per recommendation of NT Tool Corporation.

- Spindle noses of KH-E model are applicable to the quick change stub holder of KH-A or KH-E model of NT Tool Corporation.

- Adjustable Spindle Noses cannot be used in Selfeeders at the idling speed above 5,000min-1.

- Adjust the direction so that the drain outlet facing downward, when installing SELFEEDER ELECTRIC in a horizontal position.

- Specific products other than shown above are also available upon your requests.

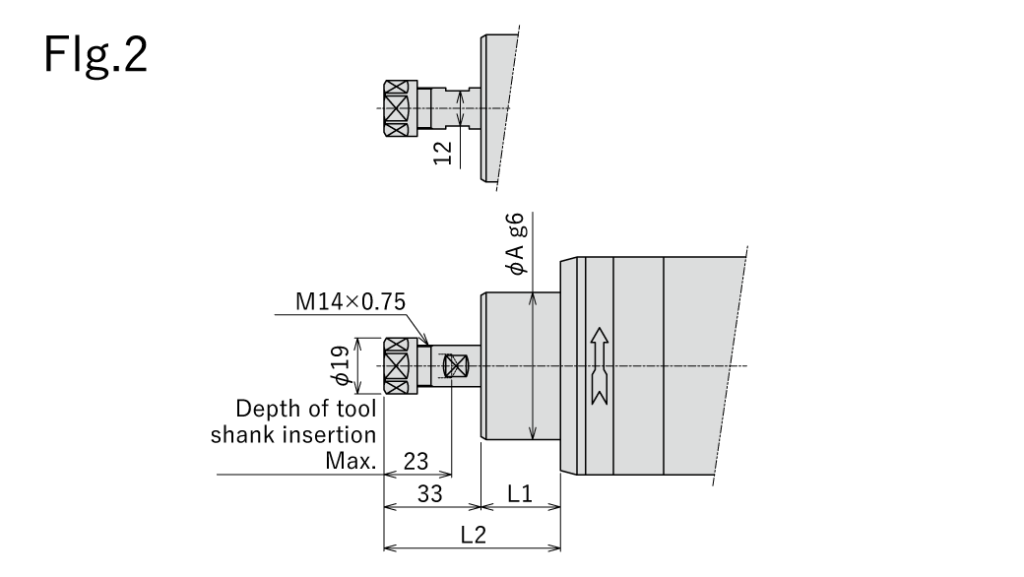

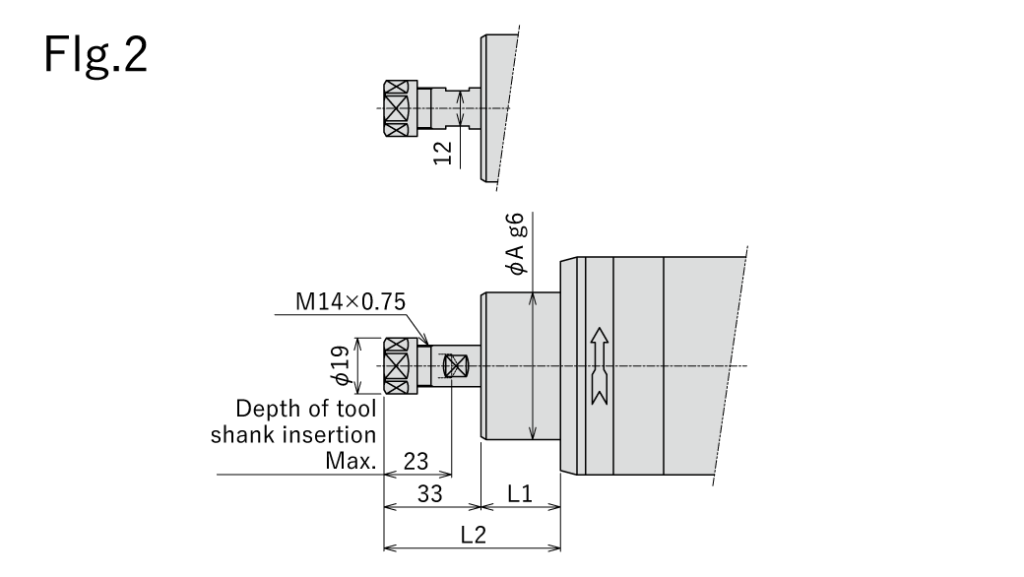

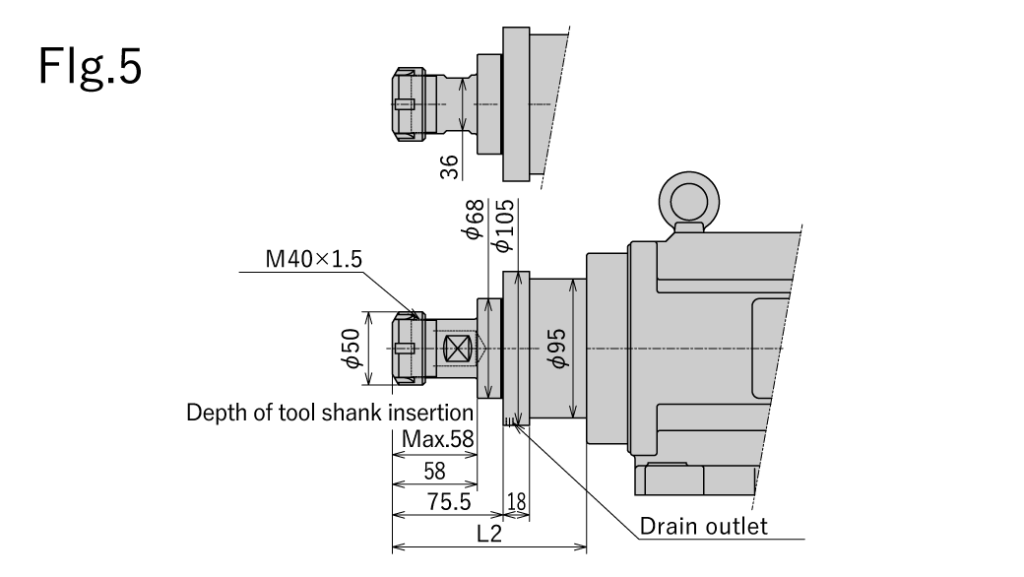

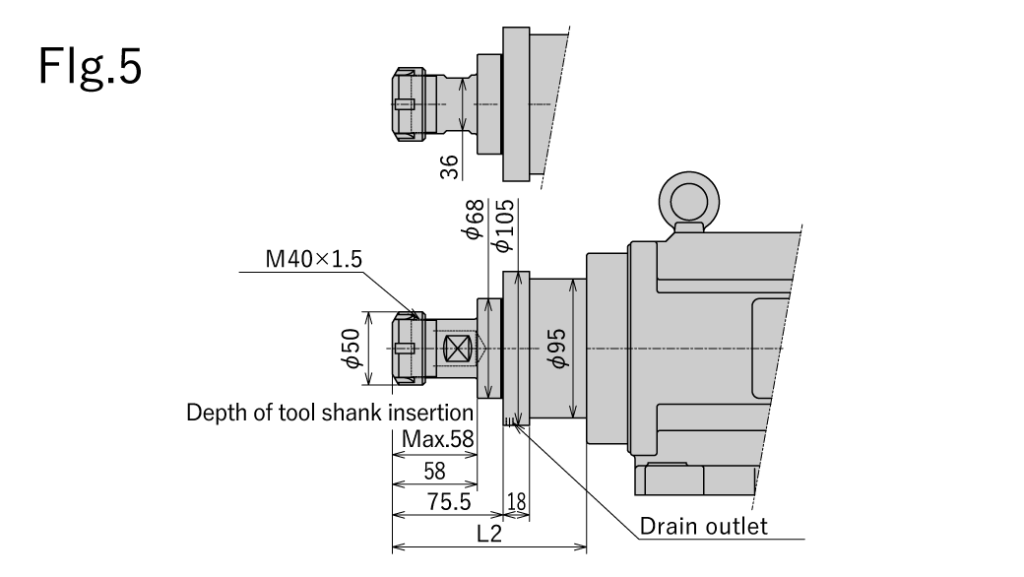

Notes

- Dimensions of spindle nose shown here are as per recommendation of NT Tool Corporation.

- Spindle noses of KH-E model are applicable to the quick change stub holder of KH-A or KH-E model of NT Tool Corporation.

- Adjustable Spindle Noses cannot be used in Selfeeders at the idling speed above 5,000min-1.

- Adjust the direction so that the drain outlet facing downward, when installing SELFEEDER ELECTRIC in a horizontal position.

- Specific products other than shown above are also available upon your requests.

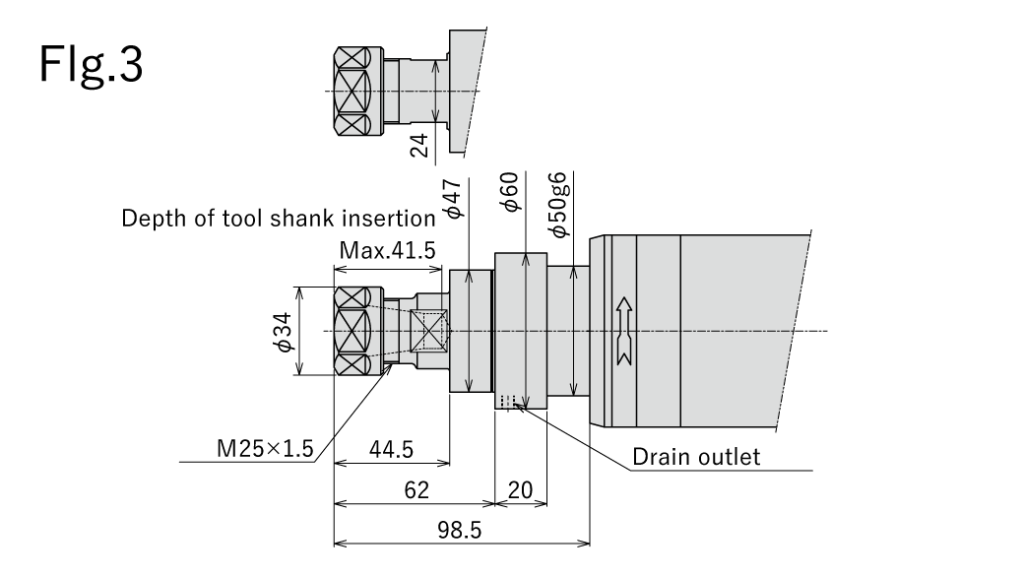

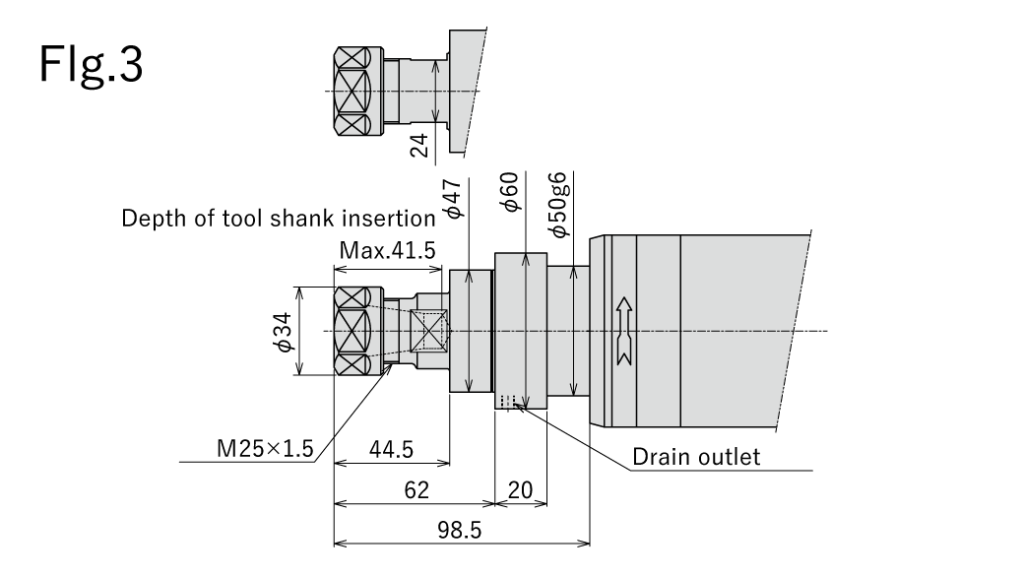

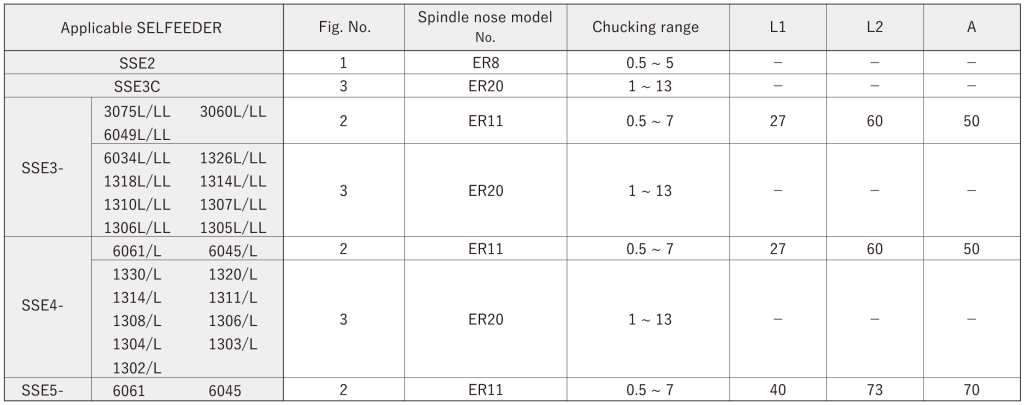

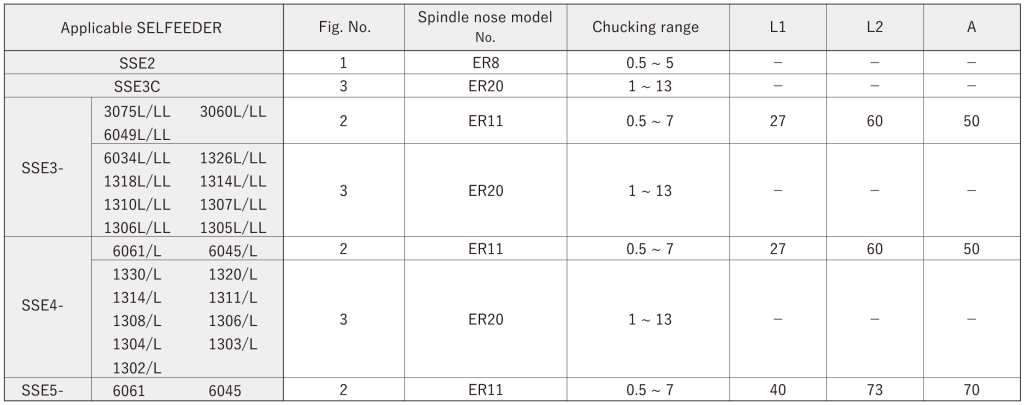

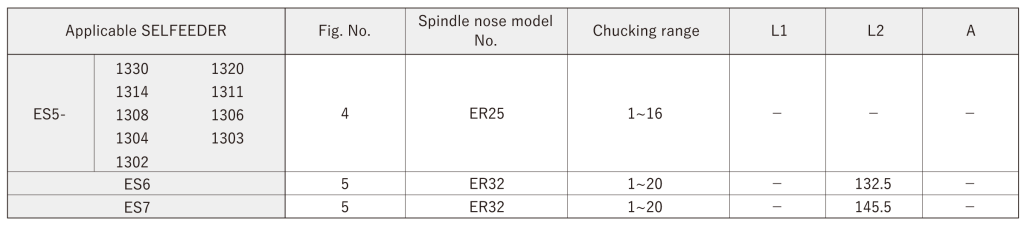

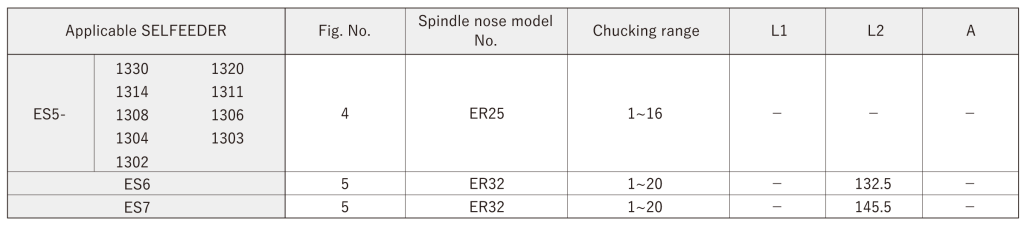

COLLET CHUCK SPINDLE NOSES For ELECTRIC

Collet Chuck Spindle Noses are applicable to ER collet of REGO-FIX AG and provided for all models of the SELFEEDER ELECTRIC series

Dimensions :

Notes:

- Dimensions of spindle nose shown here are as per recommendation of ER collet of REGO-FIX AG.

- Collet, collet nut and spanner are not supplied as standard ones. Please order if required.

- Adjust the direction so that the drain outlet facing downward, when installing SELFEEDER ELECTRIC in a horizontal position.

Notes:

- Dimensions of spindle nose shown here are as per recommendation of ER collet of REGO-FIX AG.

- Collet, collet nut and spanner are not supplied as standard ones. Please order if required.

- Adjust the direction so that the drain outlet facing downward, when installing SELFEEDER ELECTRIC in a horizontal position.

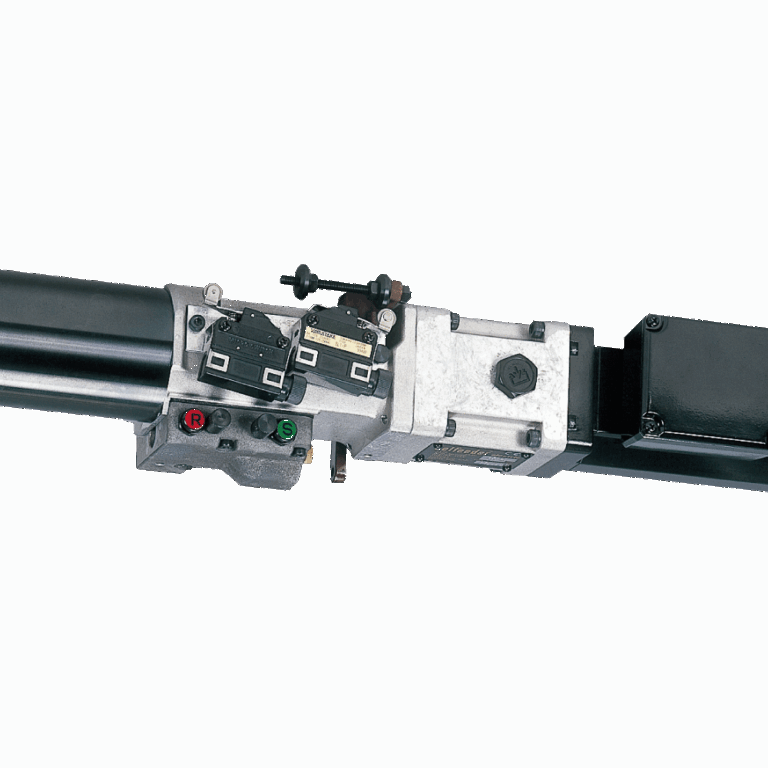

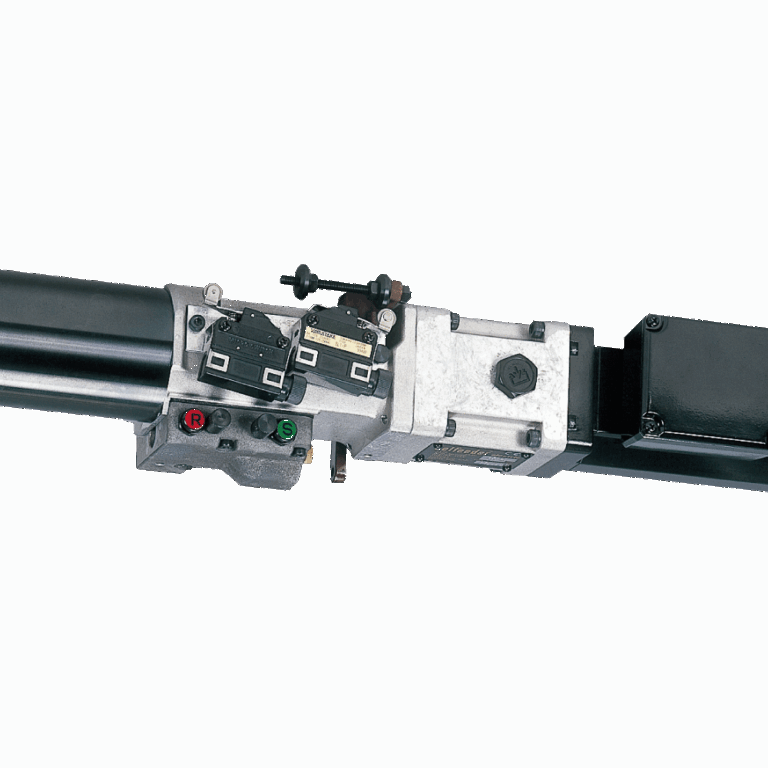

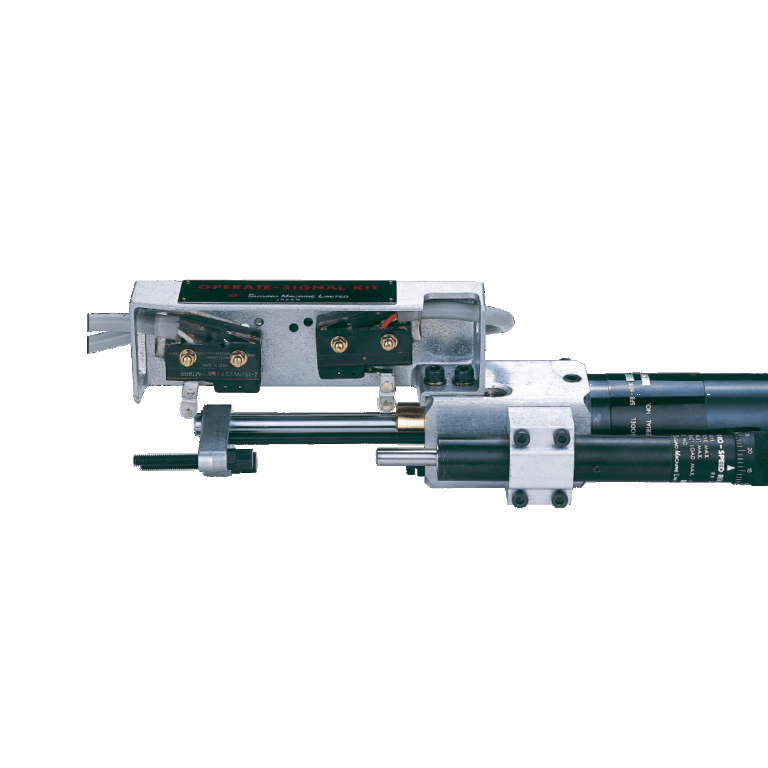

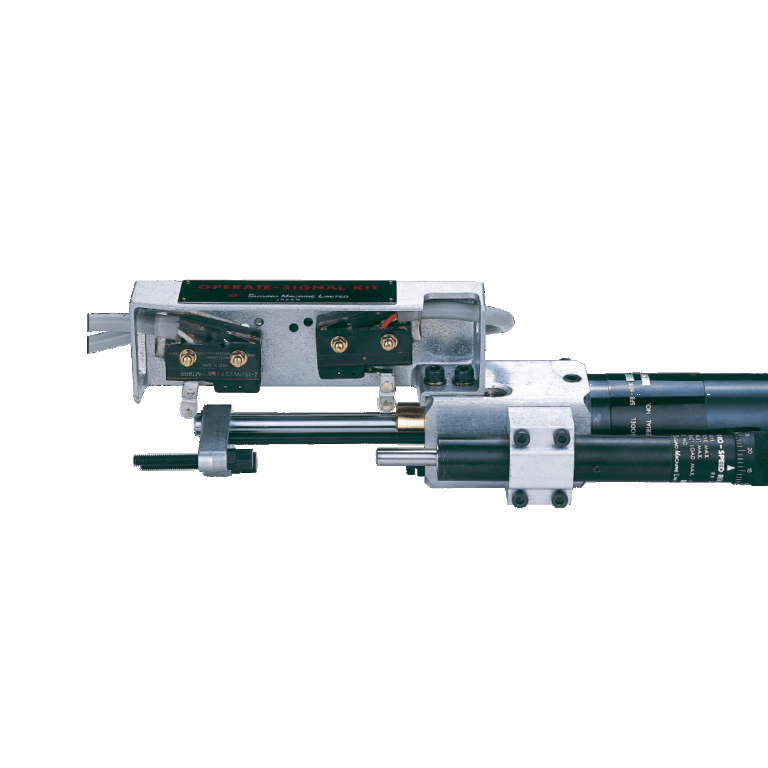

OPERATE-SIGNAL KITS : Forward/reverse end kit

OPERATE-SIGNAL KITS For ELECTRIC

This kit is designed to accurately detect the operation of the air-feed drilling unit “Selfeeder Electric” and control synchronized operation with other equipment (index table and automatic clamping device) by sending out an electrical signal.

Ex 1: Detection of return position

Ex 2: Detection of max. drilling depth position and return position

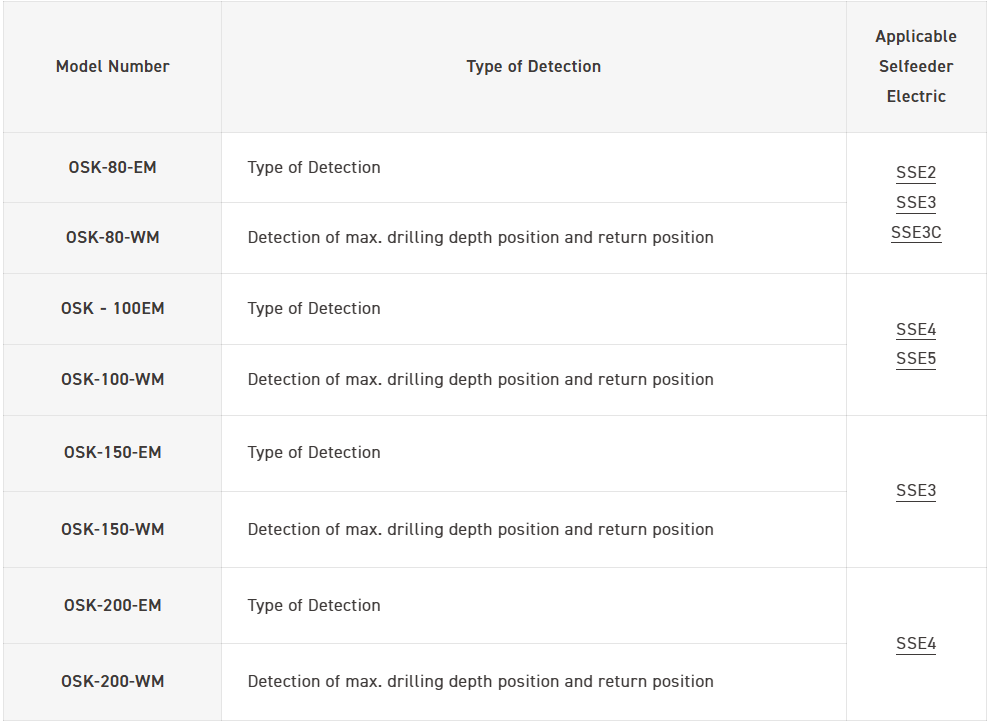

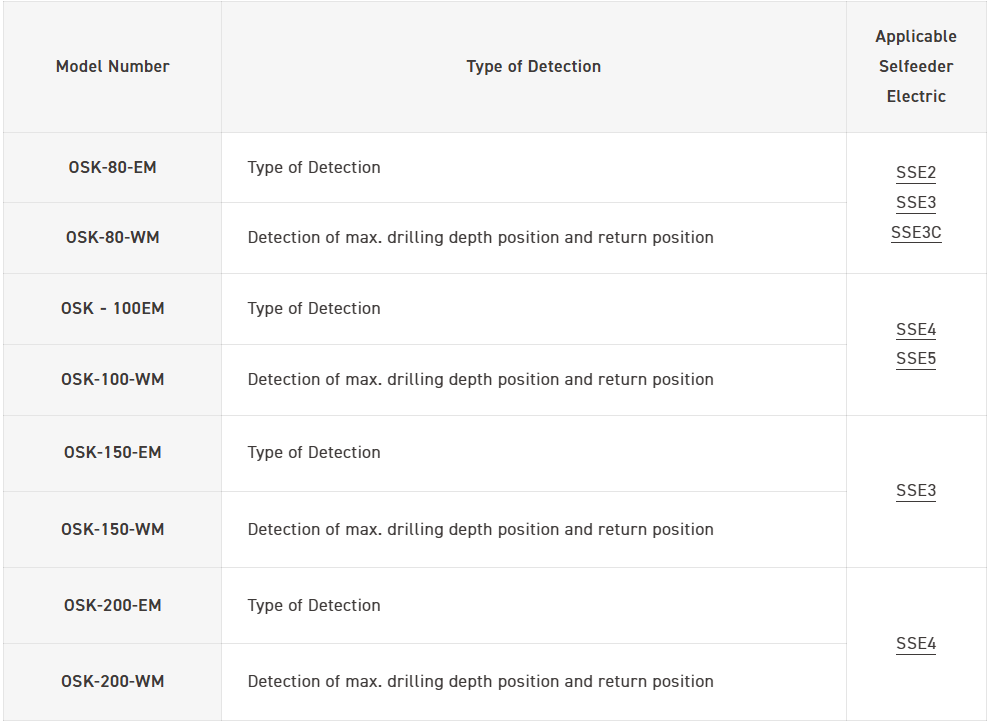

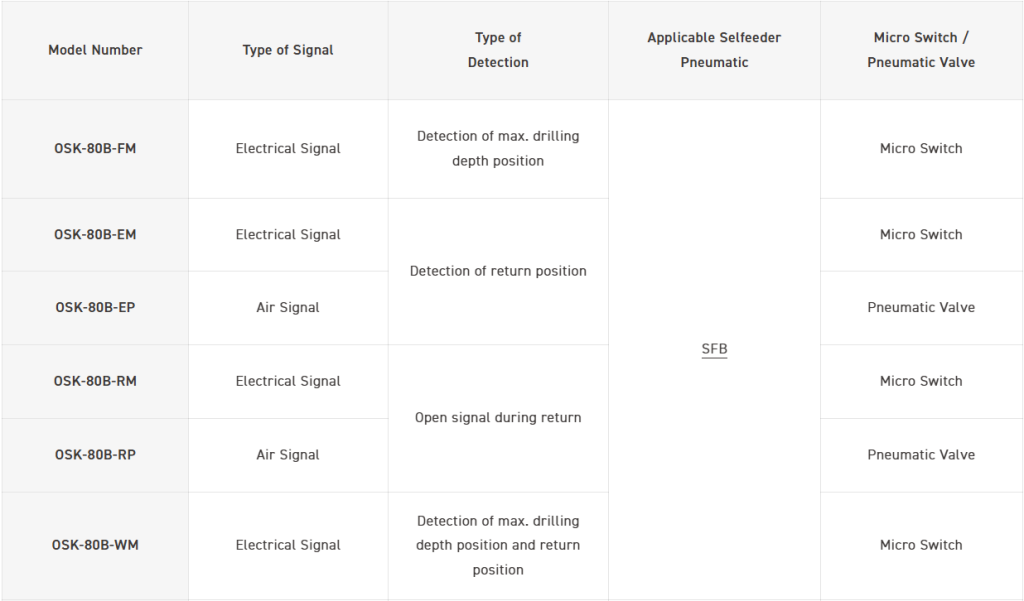

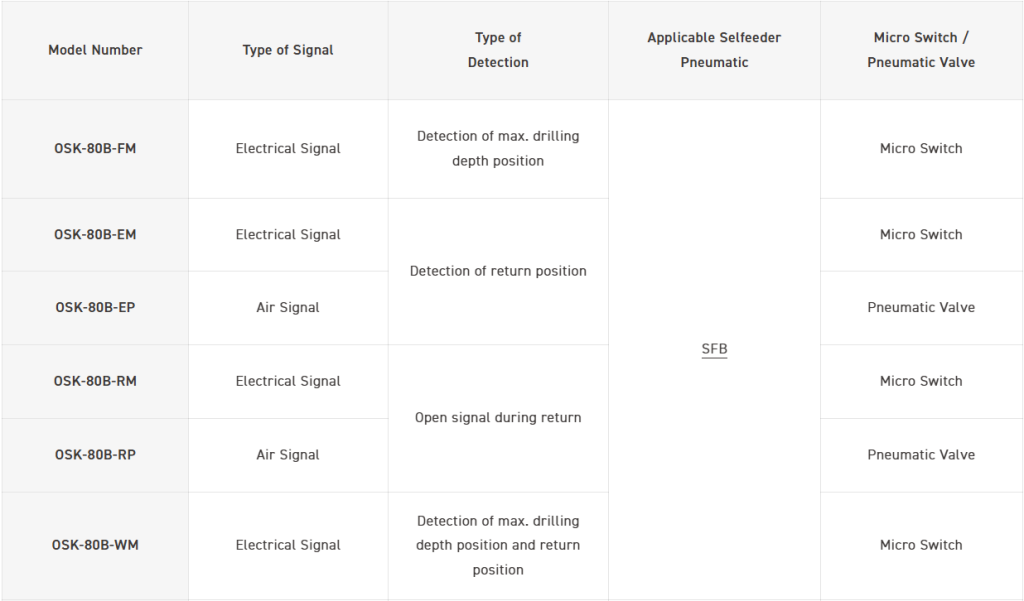

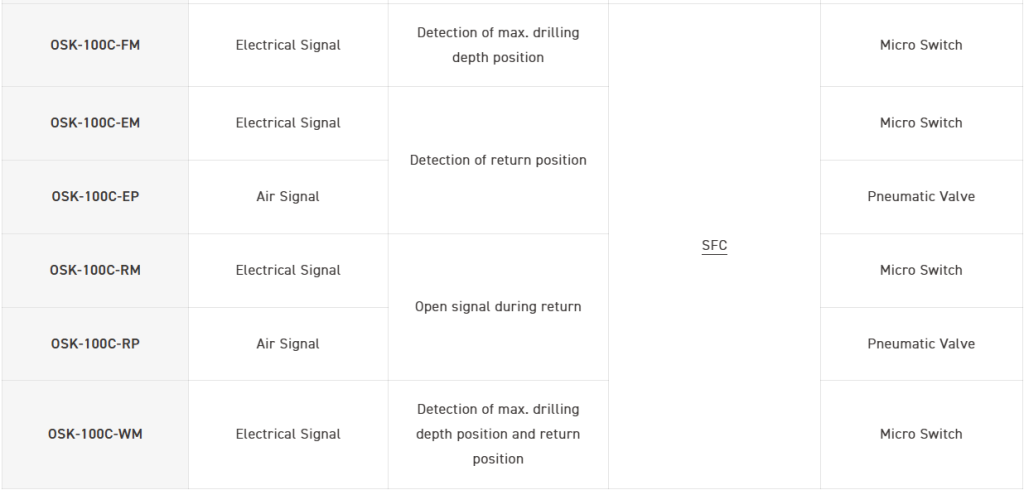

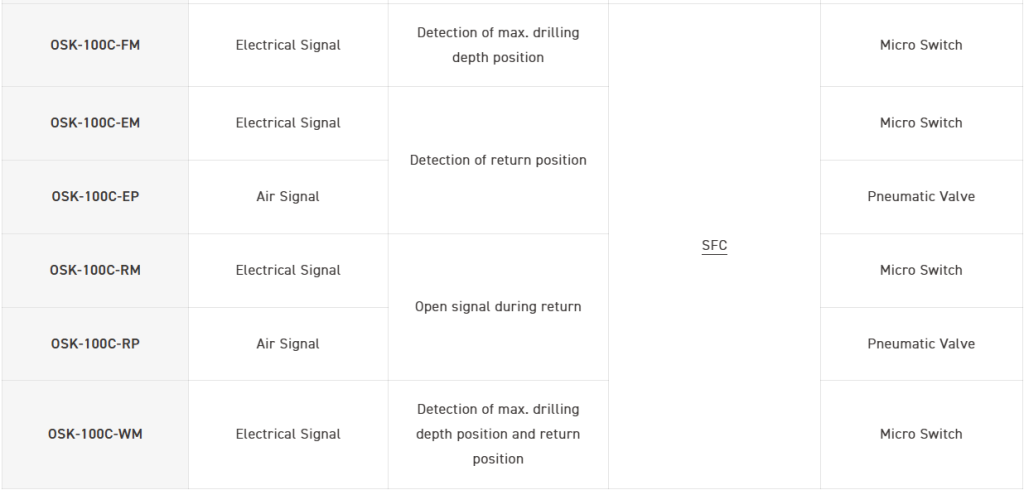

Model and Type of Detection

OPERATE-SIGNAL KITS For PNEUMATIC

This kit is designed to accurately detect the operation of the air-feed drilling unit “Selfeeder Pneumatic” and control synchronized operation with other equipment (index table and automatic clamping device) by sending out an electrical signal.

Model and Type of Detection

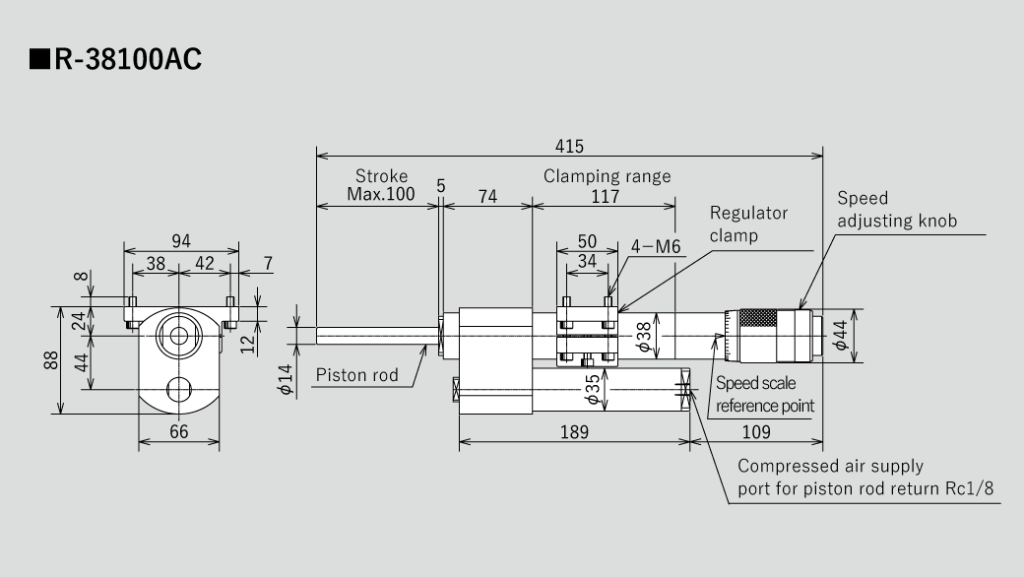

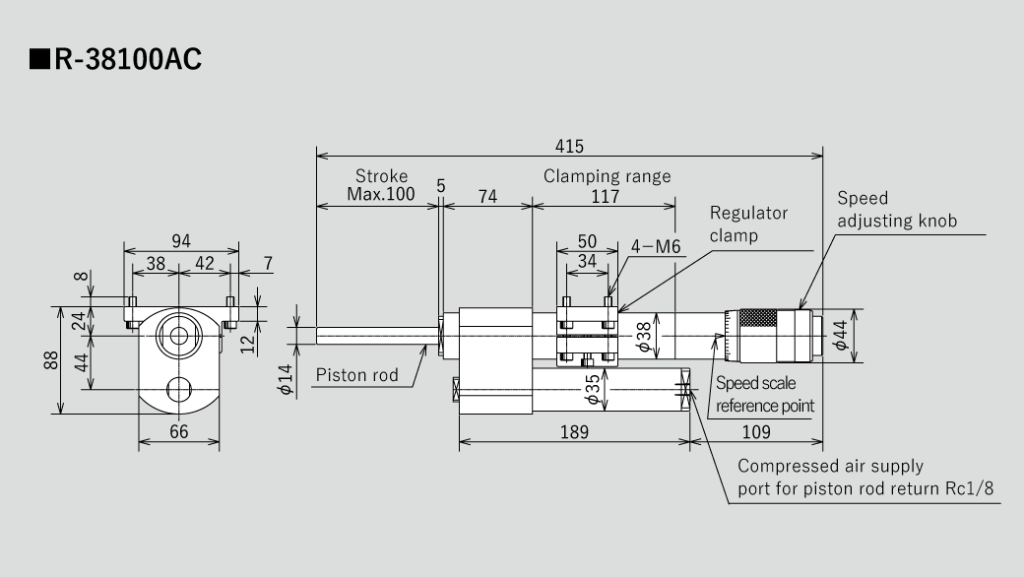

Hydraulic Feed Speed Control Unit

Hydro-Speed Regulator Air Return Type R-A

The “Hydro-Speed Regulator” is a hydraulic feed speed control unit that can freely adjust the feed rate of an air cylinder to any desired speed from low to high.

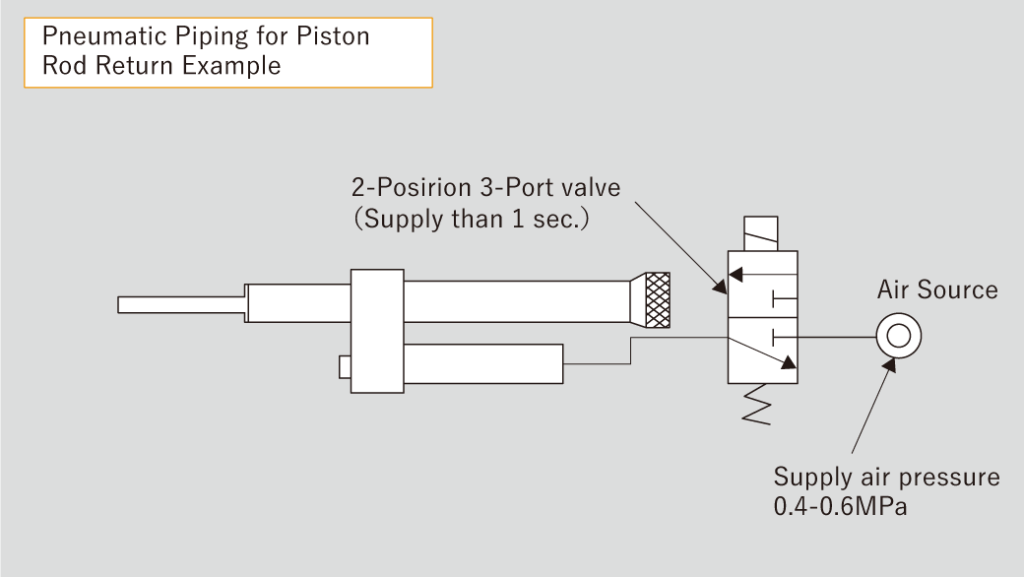

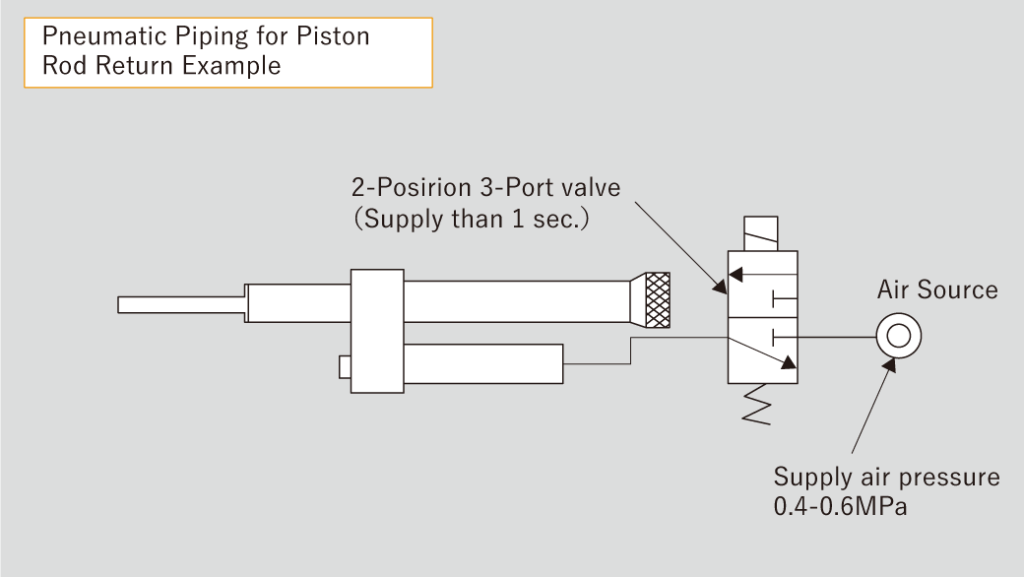

Two types of control methods are available: spring return type and air return type, which can be selected according to the application.

A skip-motion type hydro-speed regulator, ideal for drilling pipe materials, is also available.

Features

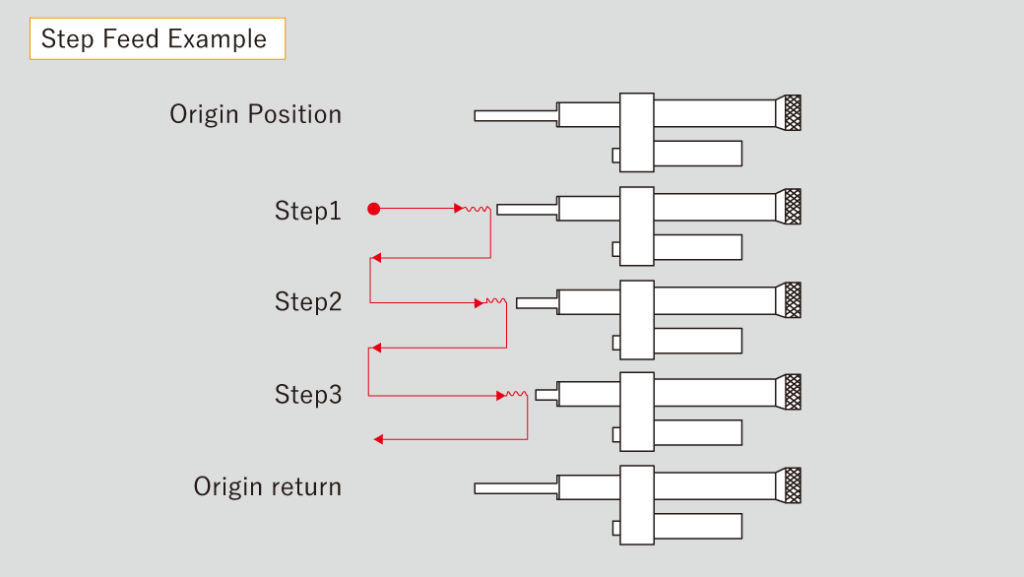

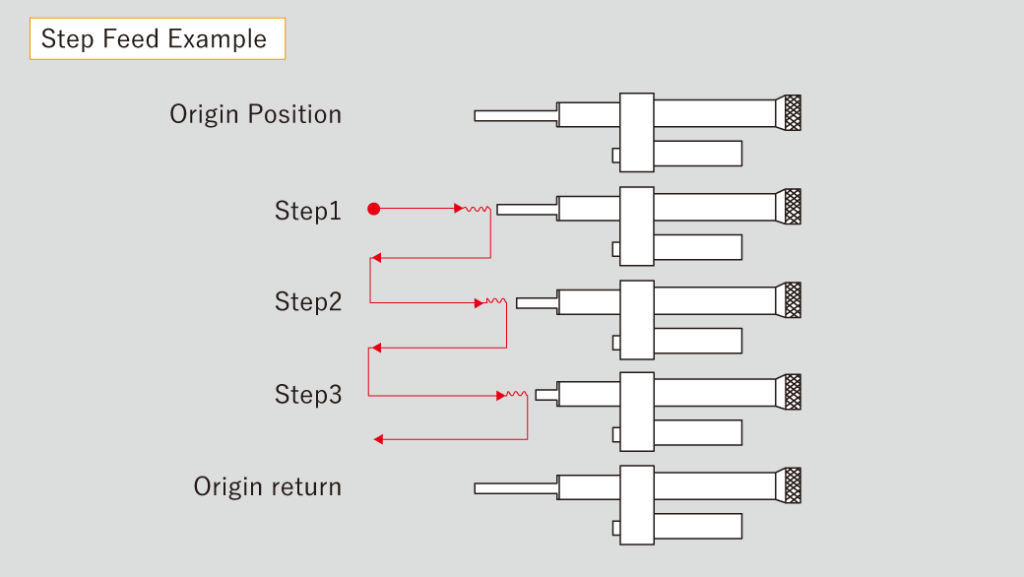

- The piston rod can be held at any position during the stroke for efficient step feeding.

- Long stroke type is available for versatile use.When the load on the piston rod is removed, the piston rod stops in that position, and the piston rod is returned by supplying air. This is effective for step feed control.

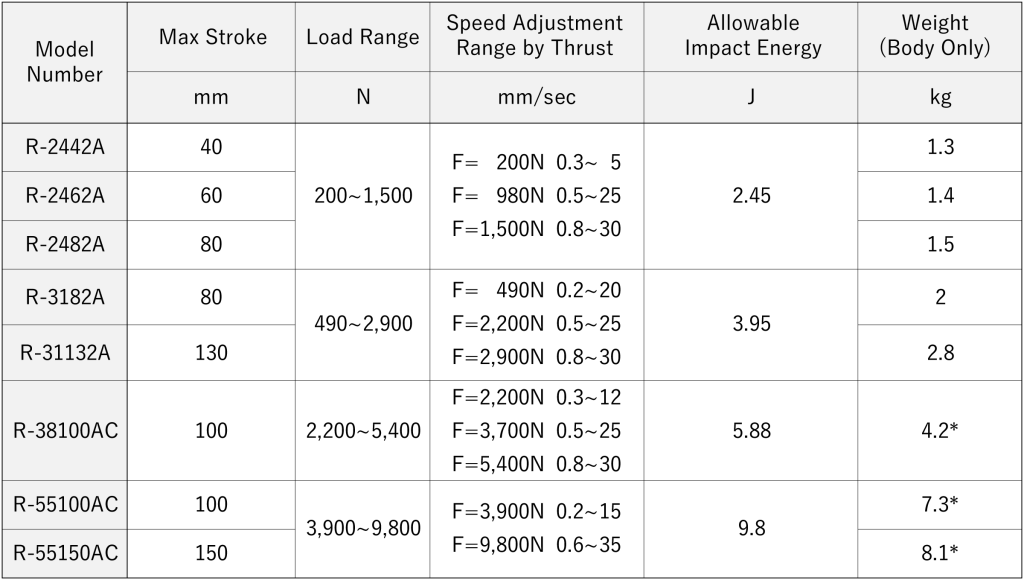

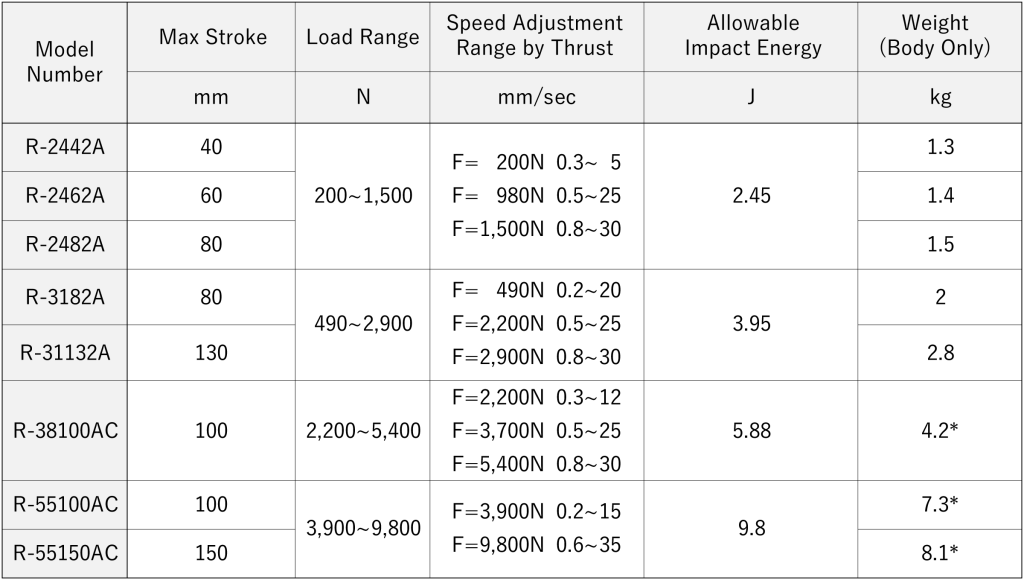

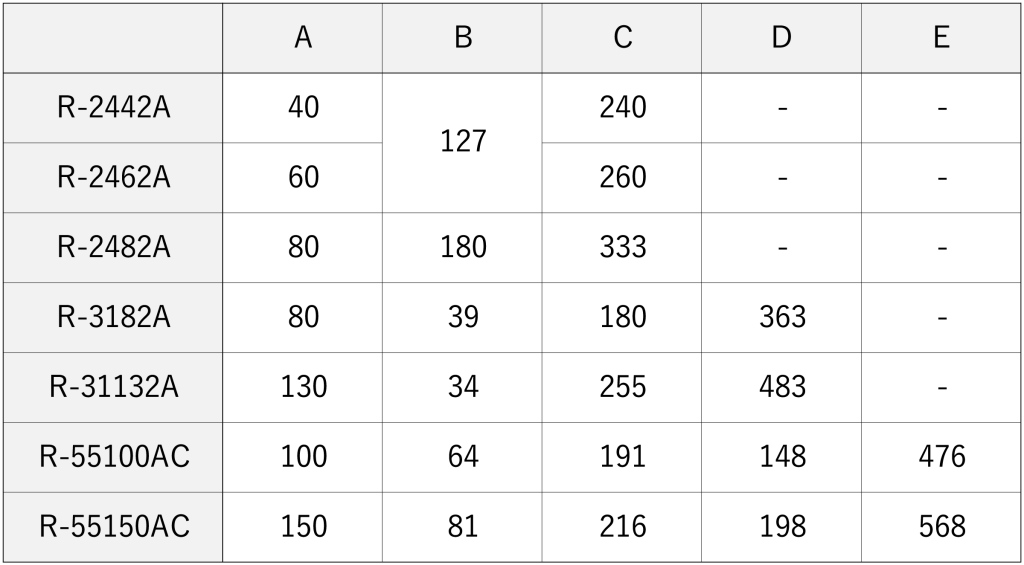

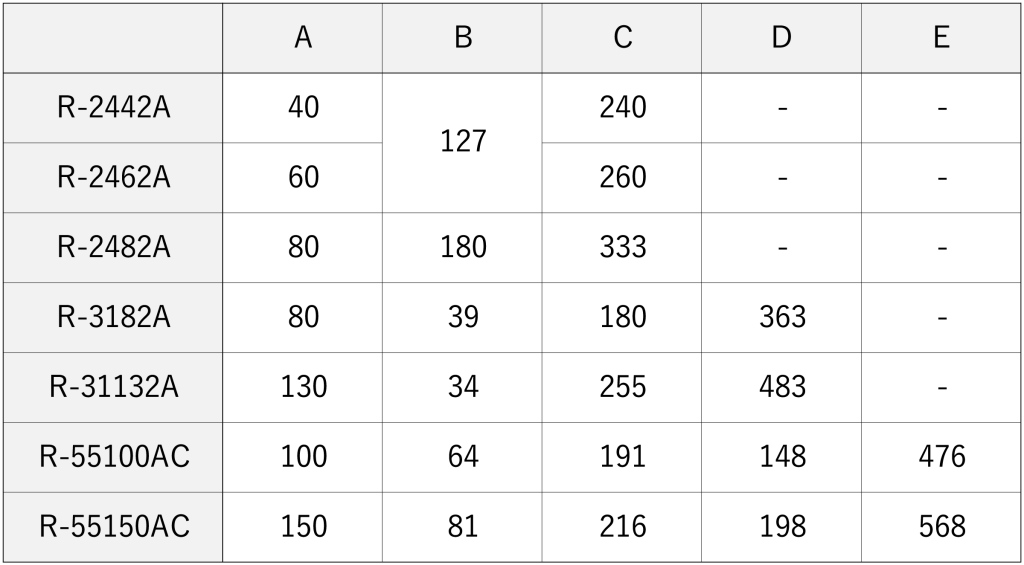

Specifications

Note:

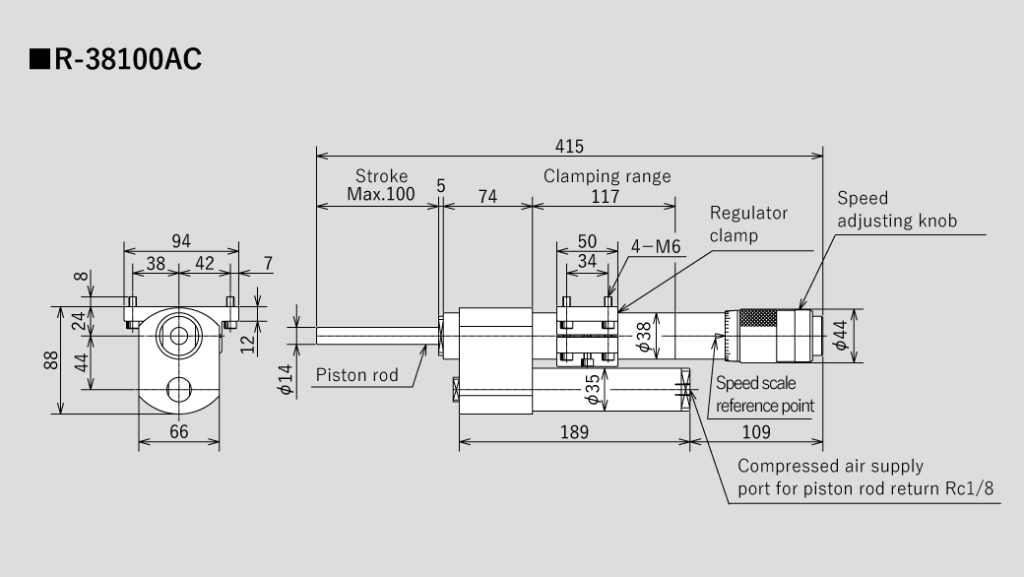

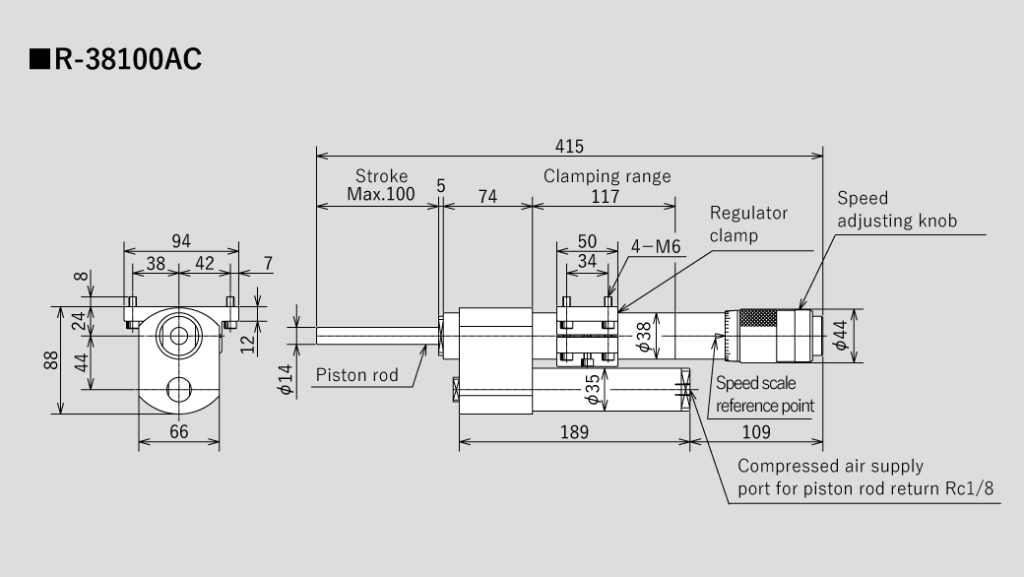

- R-38100AC, R-55100AC, and R-55150AC come standard with a regulator clamp.

This regulator clamp cannot be removed due to its structure. - Hydro-speed regulators other than the above specifications are also available. Please contact our nearest sales office.

- The weight in * includes the regulator clamp.

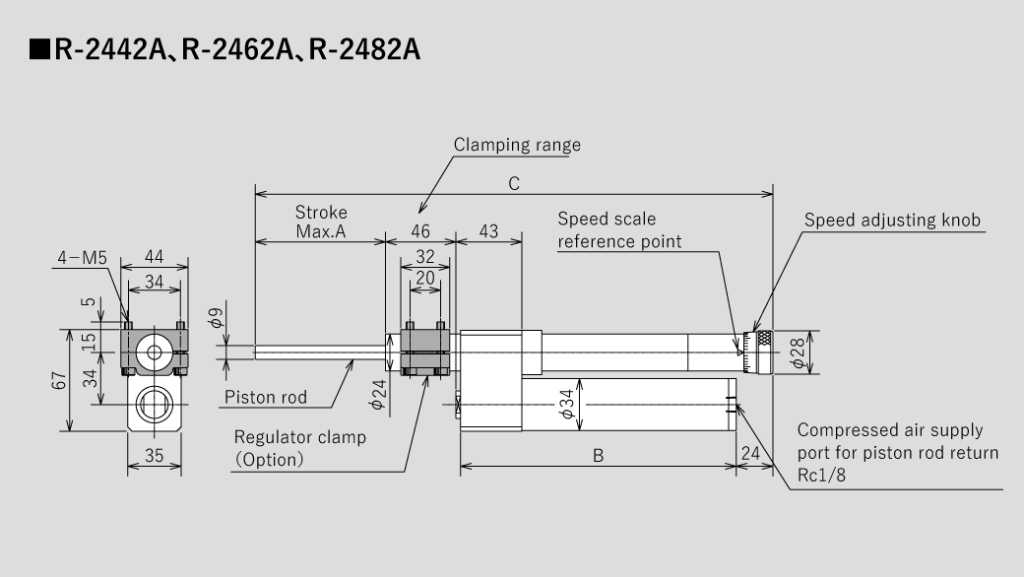

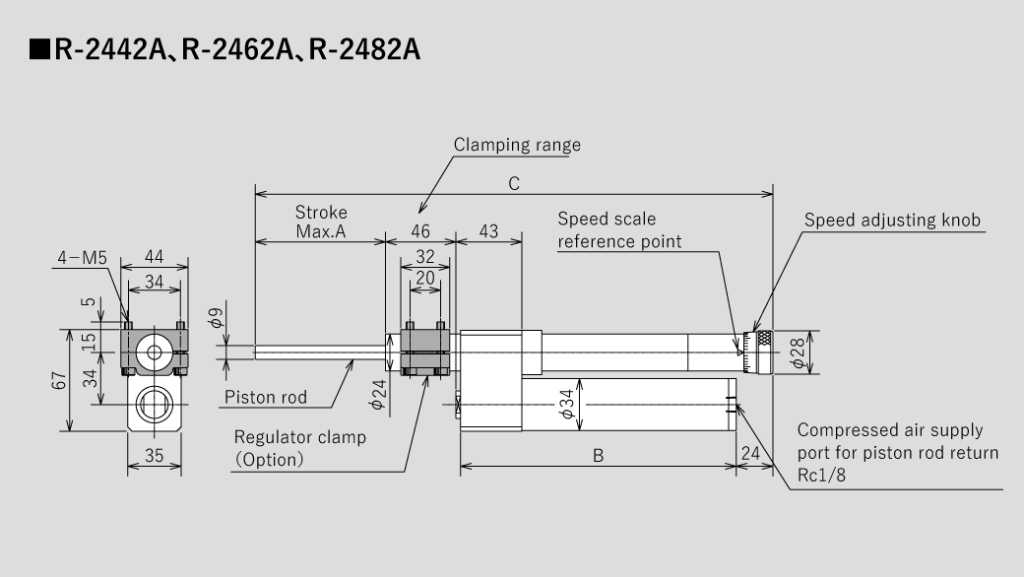

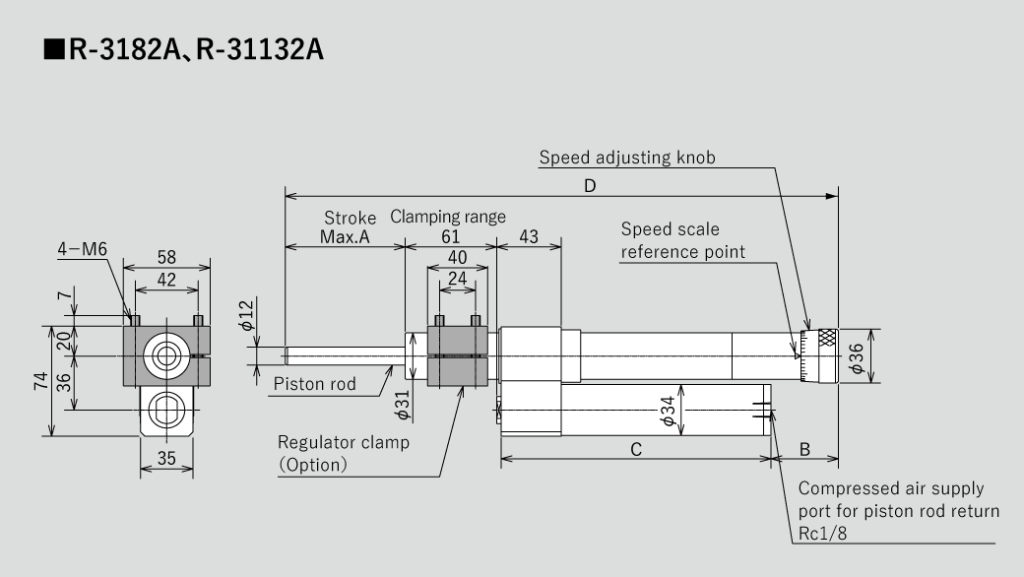

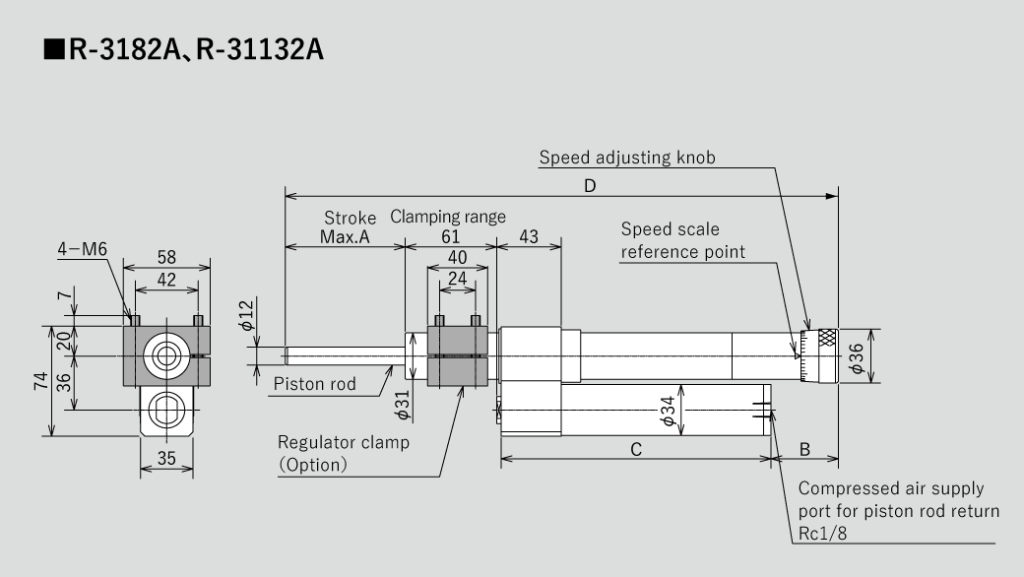

Dimensions :

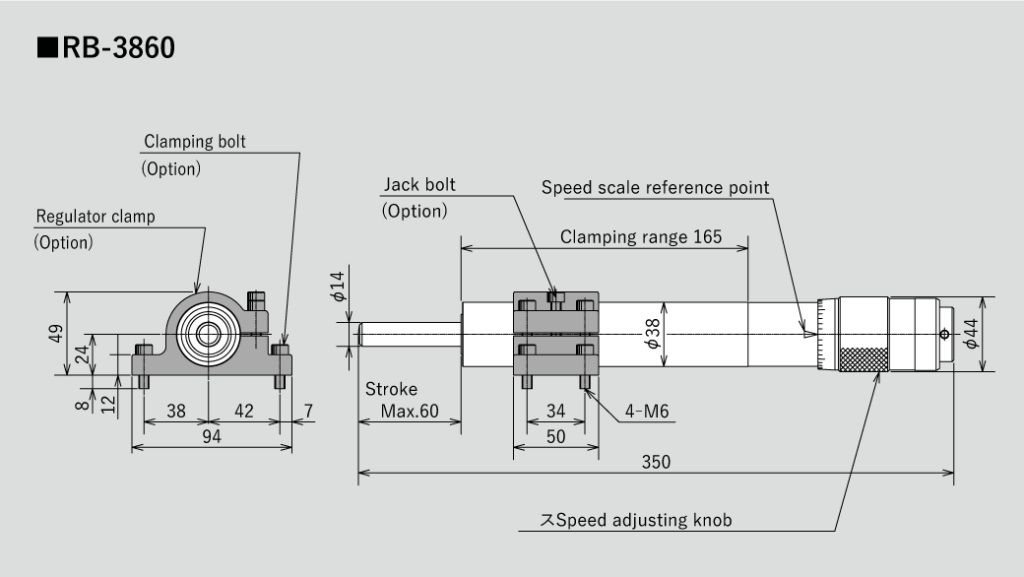

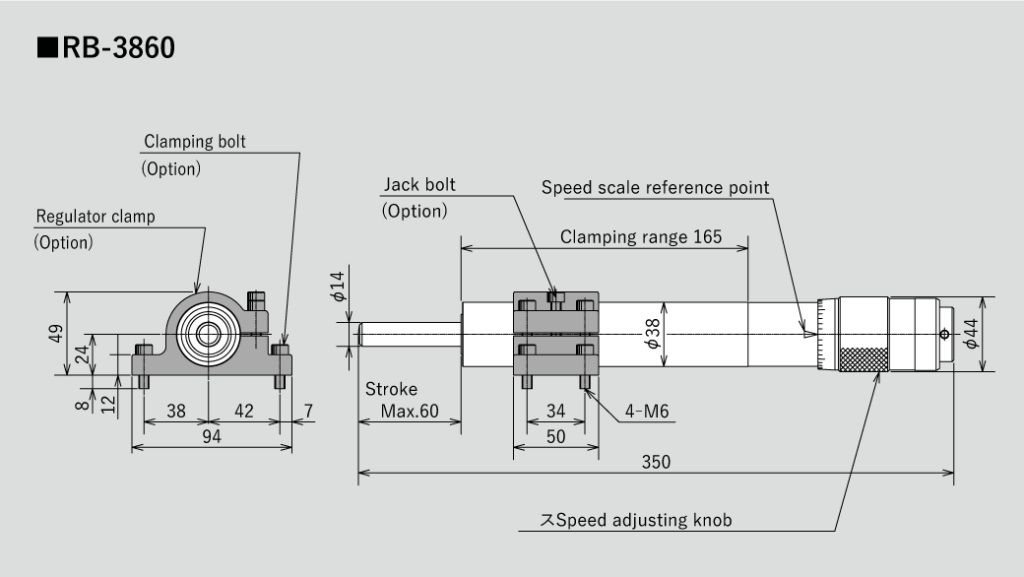

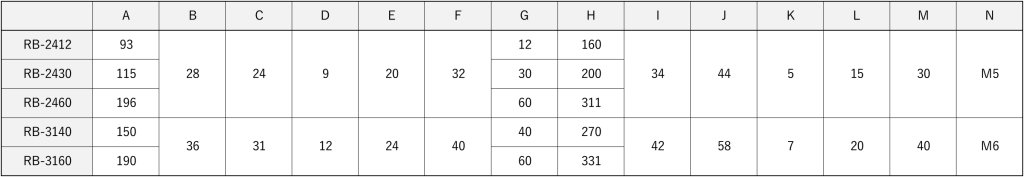

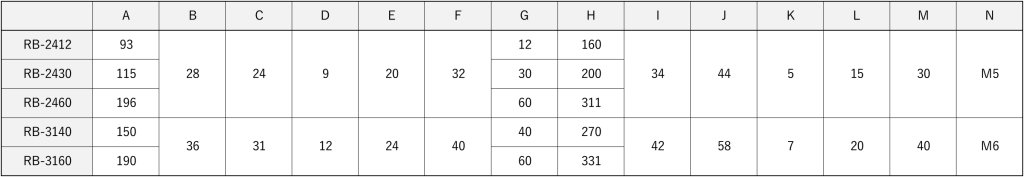

Hydro- Speed Regulator Spring-Return Type RB

The “Hydro-Speed Regulator” is a hydraulic feed speed control unit that can freely adjust the feed rate of an air cylinder to any desired speed from low to high.

Two types of control methods are available: spring return type and air return type, which can be selected according to the application.

A skip-motion type hydro-speed regulator, ideal for drilling pipe materials, is also available.

Features

- Compact and can be installed in any direction.

- Completely sealed construction eliminates the need for hydraulic fluid replenishment, ensuring stable control over a long period of time.

- Even with sudden load fluctuations, control speed changes are extremely small, resulting in stable feed rates.

- The feed rate can be easily adjusted with the speed adjusting knob.

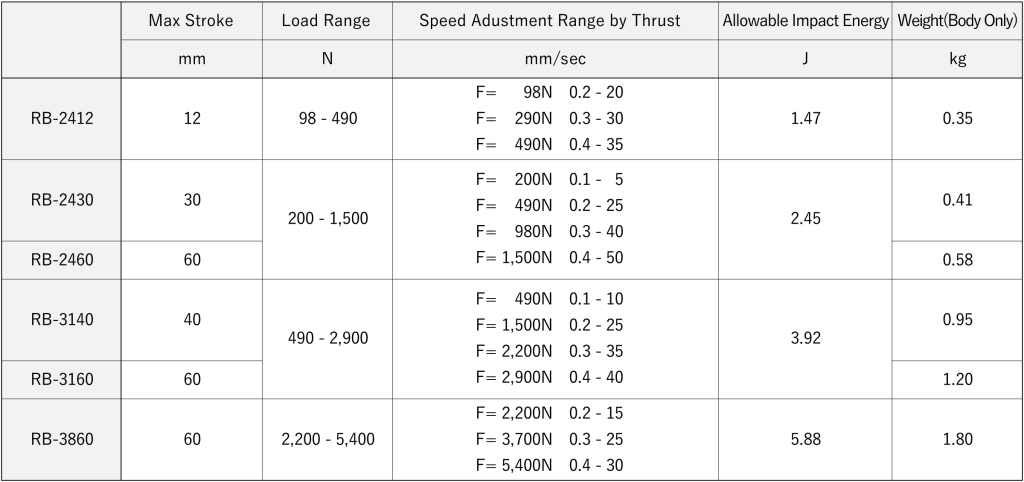

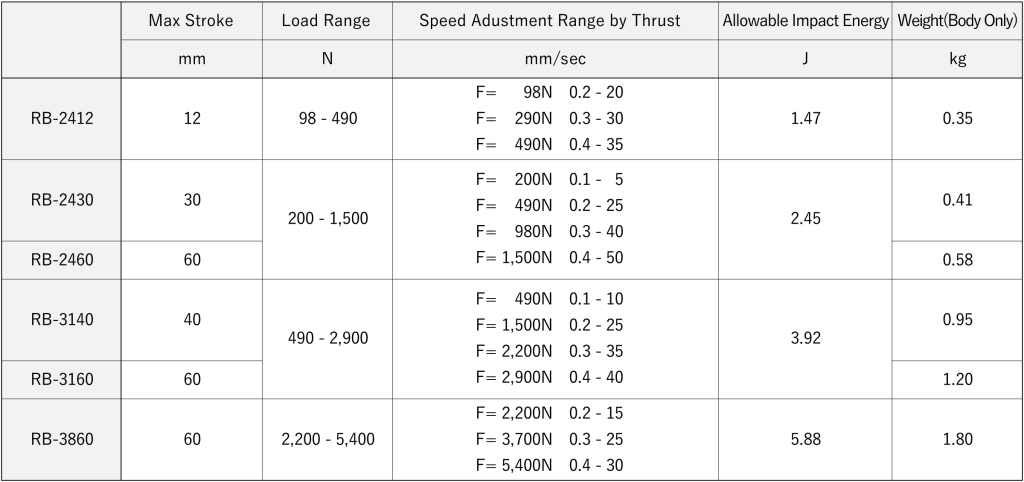

Specifications

Note:

- Hydro-speed regulators other than the above specifications are also available.

- Regulator clamp is optional.

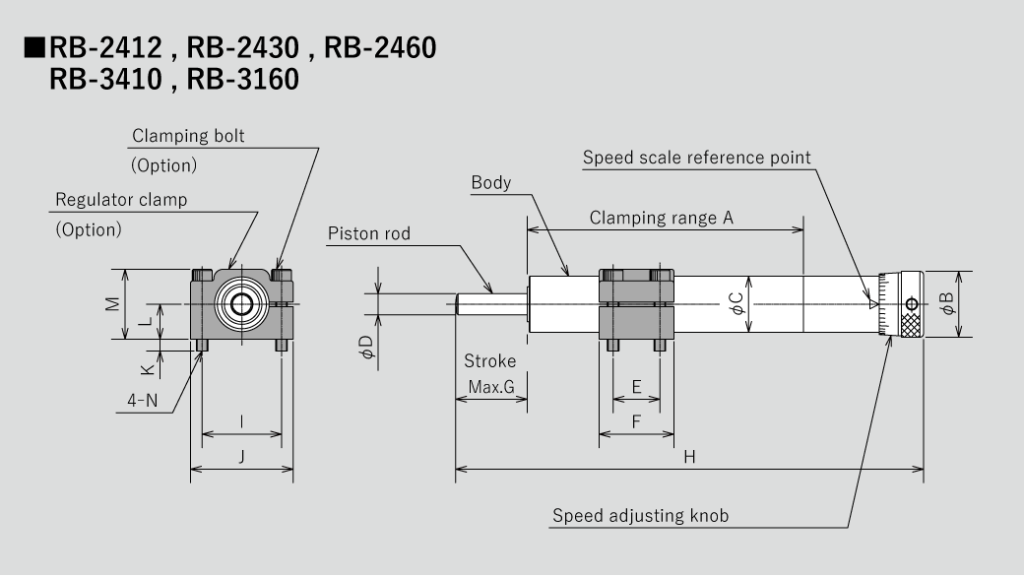

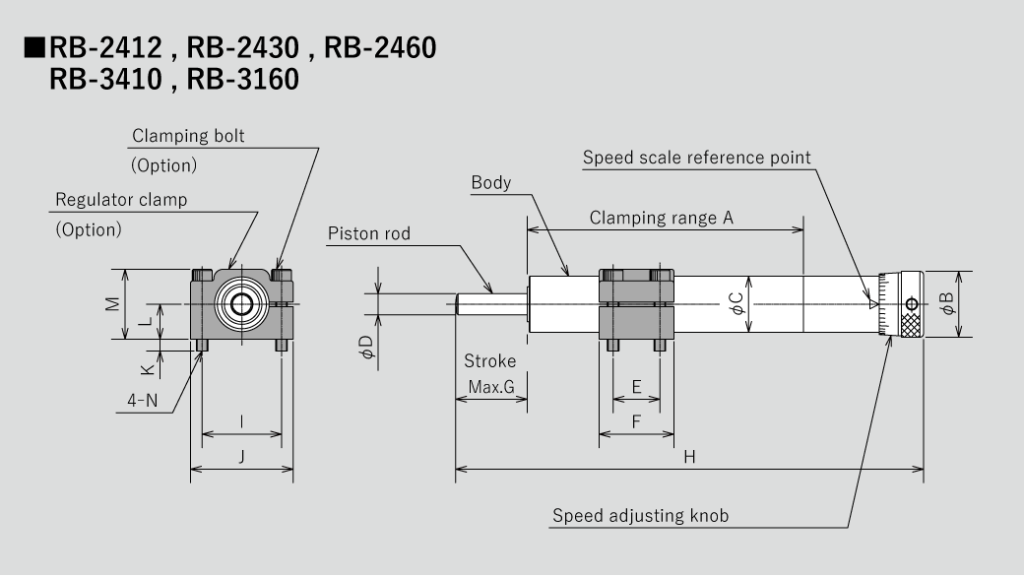

Dimensions :

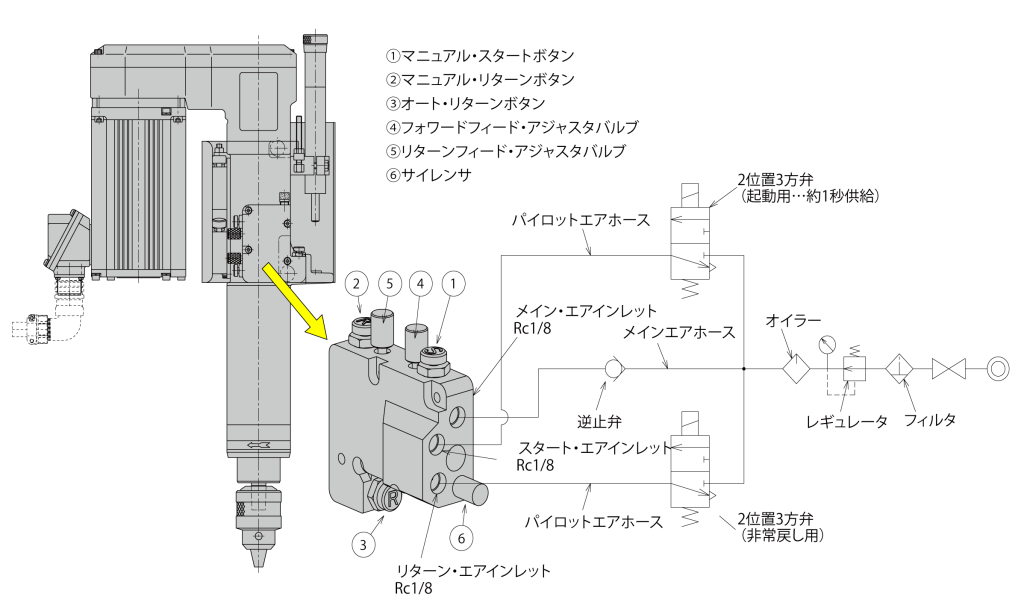

Pneumatic control circuit

Pneumatic control circuit :

The standard version is valveless with the air connecting block installed.The standard valveless type can be switched to the valve block type (former standard type) by purchasing an optional valve block and replacing it with an air connecting block.

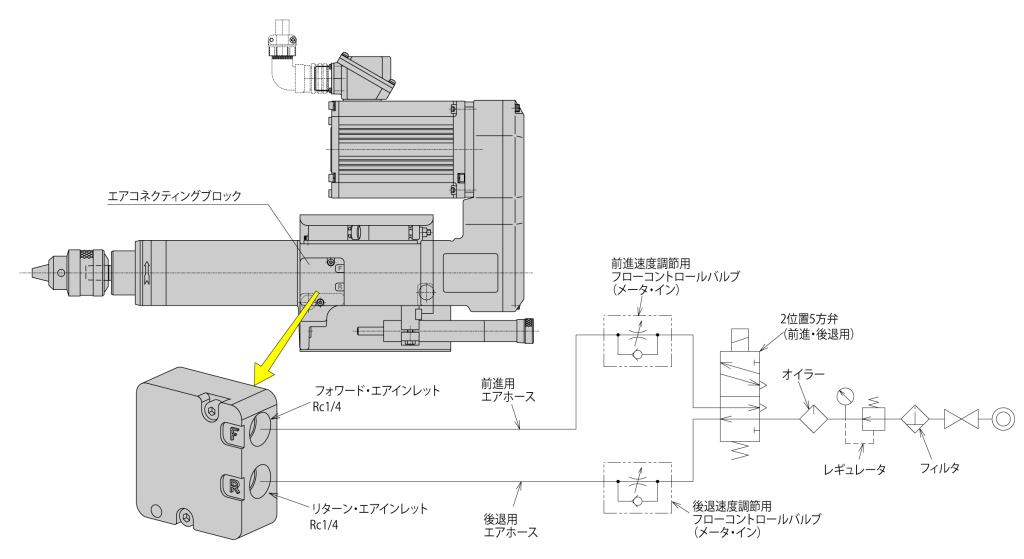

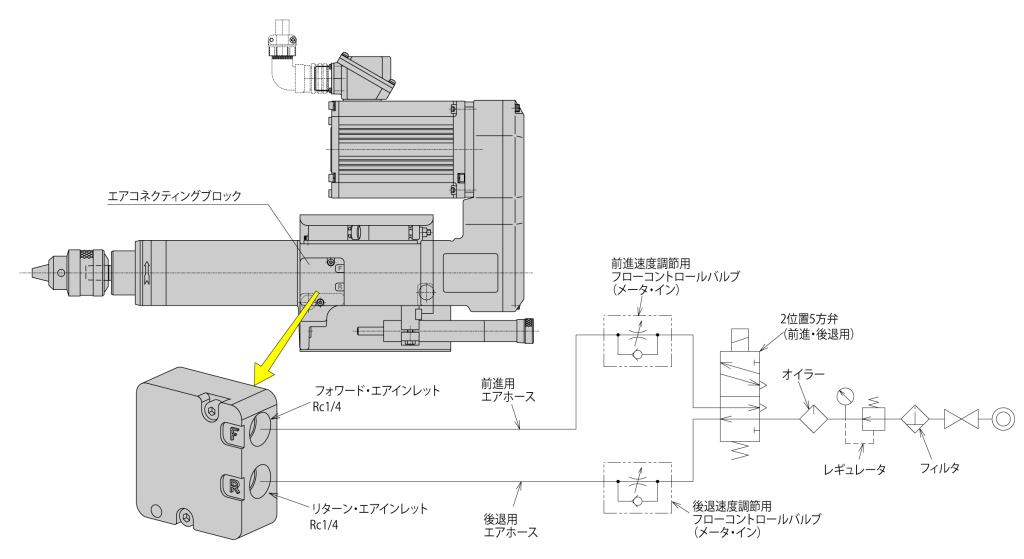

Standard” Valveless specification (with air connecting block)

This type eliminates the manual operation mechanism for forward and return movement and has a simplified control mechanism.

To control the forward and return speeds, be sure to use a meter-in flow control valve.

Note: For valveless models, “A” is appended at the end of each model number.

Example of pneumatic control circuit :

Note: Air equipment up to the air connecting block must be provided by the customer.

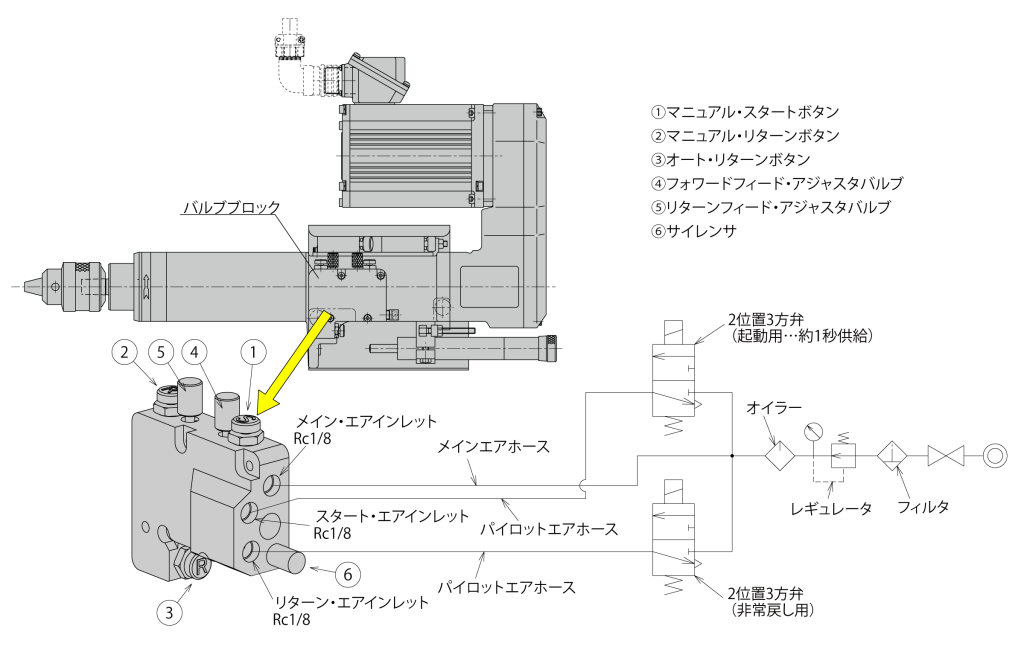

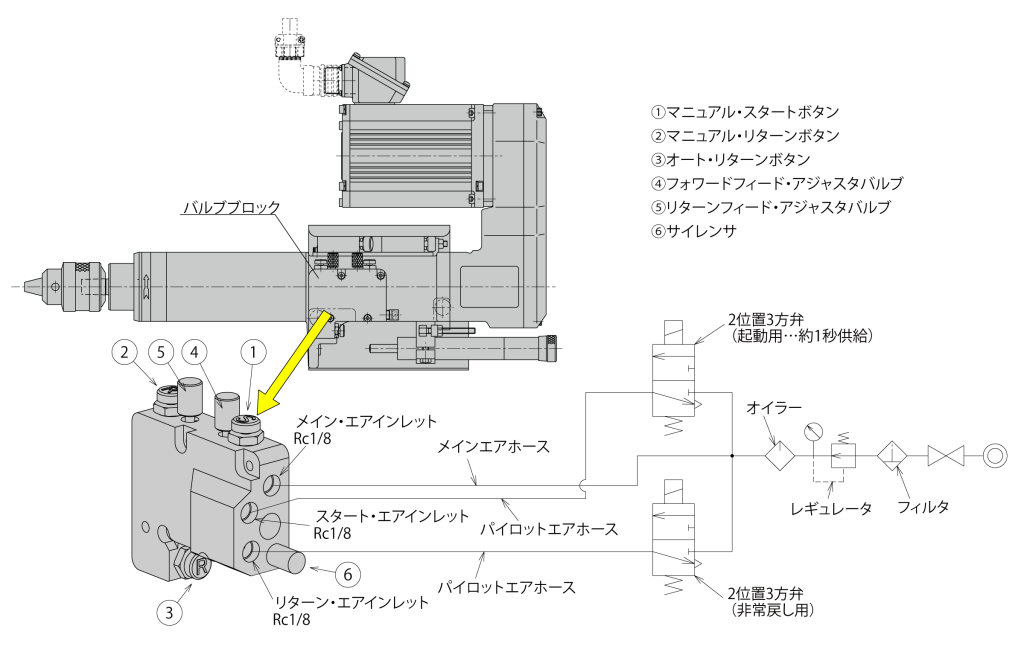

“Optional” Valve block specification

Example of pneumatic control circuit :

Example of pneumatic control circuit for ram drop prevention :