SELFEEDER ELECTRIC SERIES :

PNEUMATIC FEED DRILLING UNIT

SELFEEDER ELECTRIC SSE2

Compact, lightweight pneumatic feed drilling unit!

The “Selfeeder Electric SSE2” is a compact, lightweight pneumatic feed drilling unit.

Max. drilling size … φ2.5(Steel)/ φ5(Aluminum)

Features of the PM motor

1.Energy Saving

Energy consumption can be reduced by approximately 20% compared to a three-phase induction motor with the same output.

2.Global Support

Not subject to overseas high-efficiency motor regulations, making it easy to apply to equipment to be exported overseas.

3.Variable Spindle Rotation

Variable spindle speed eliminates the need for setup changes and can handle a wide range of machining diameters.

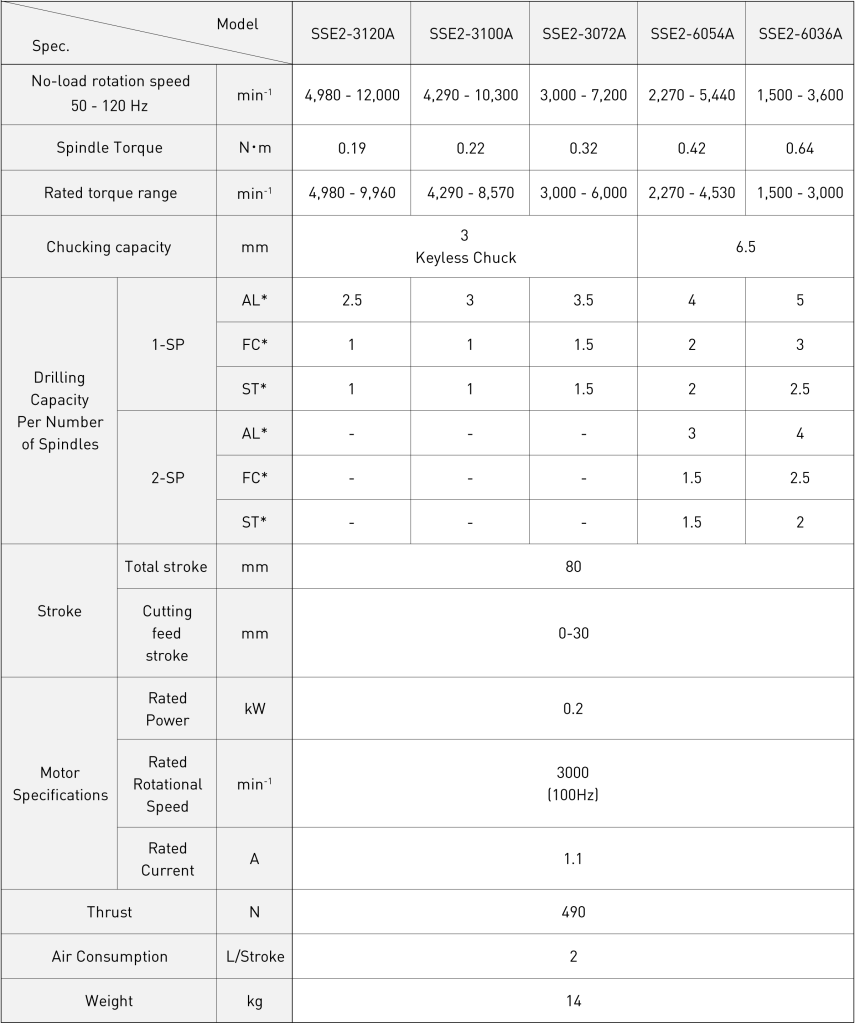

Specifications

Supply air pressure at 0.5 MPa

Notes:

- The selection of models should be based on the shape of the workpiece, material, cutting characteristics, diameter and material of tools, rotation speed (cutting speed), etc.

- The drilling capacity displayed in the above table is based on values representing a drilling depth of two times the diameter of the drill.

- The power voltage of the main shaft inverter has three phases (single phase for the feed shaft controller) AC 200 V ±10% 50/60 Hz.

- For servo motor with holding brake (optional) specifications, make sure to add a “B” to the end of the model number.

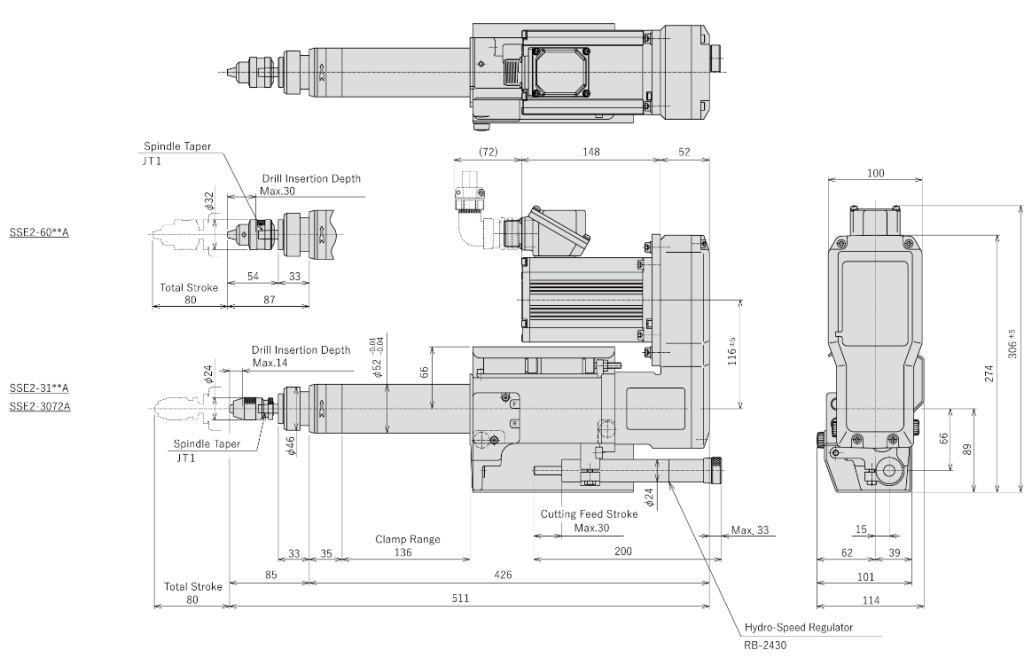

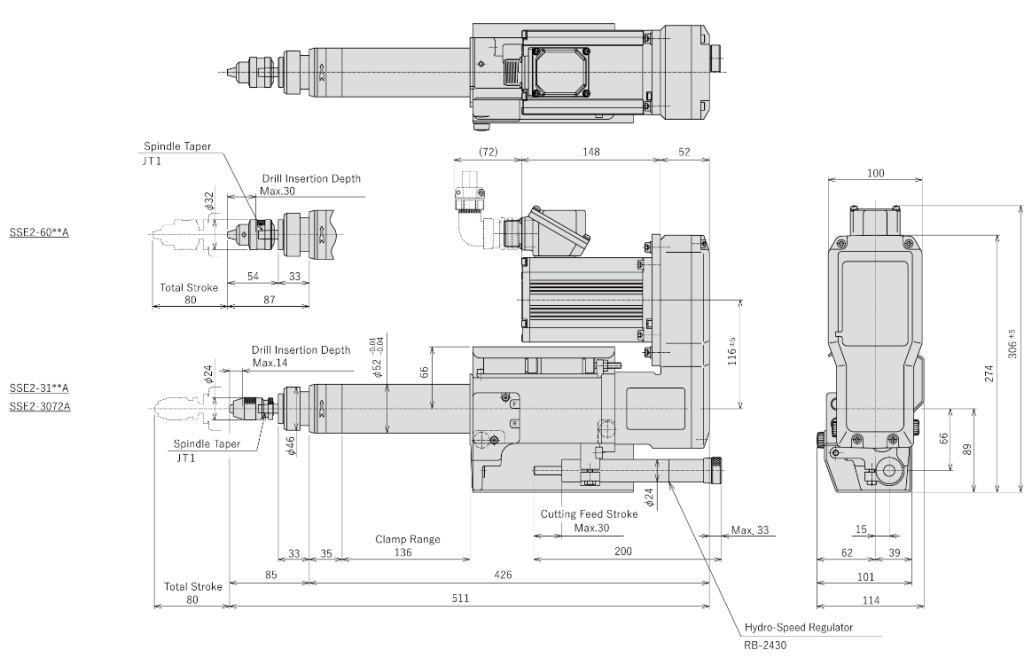

Dimensions

Peripherals (Optional) :

Stand for unit installation

- Angle-adjustable stand “Flex Stand”

- Fixing attachment “Level Clamp”

Forward/reverse end kit

- Operate Signal Kit

Hydraulic feed speed control unit

Hydro-Speed Regulator (spring return type)

Hydro-Speed Regulator (air return type)

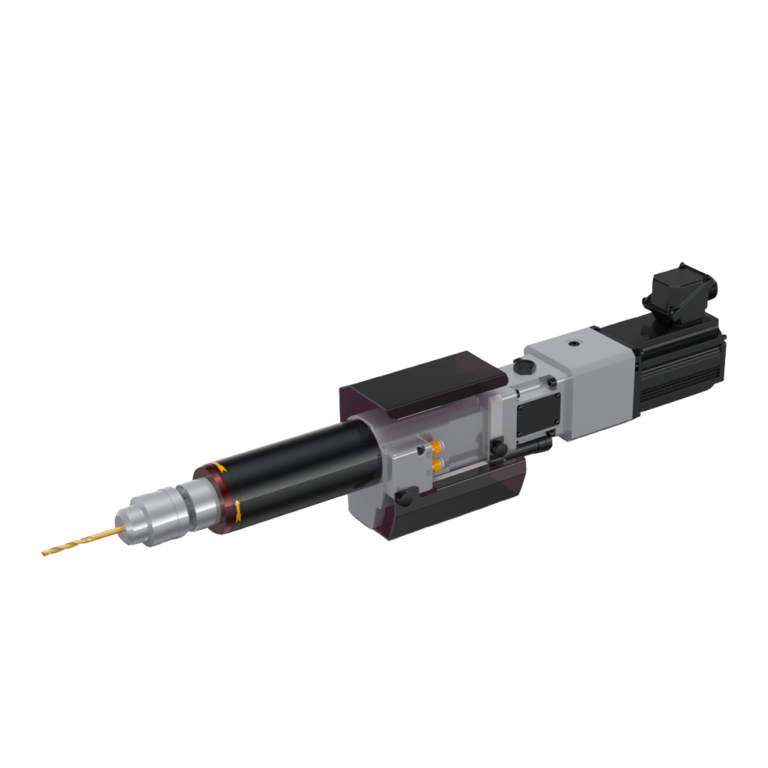

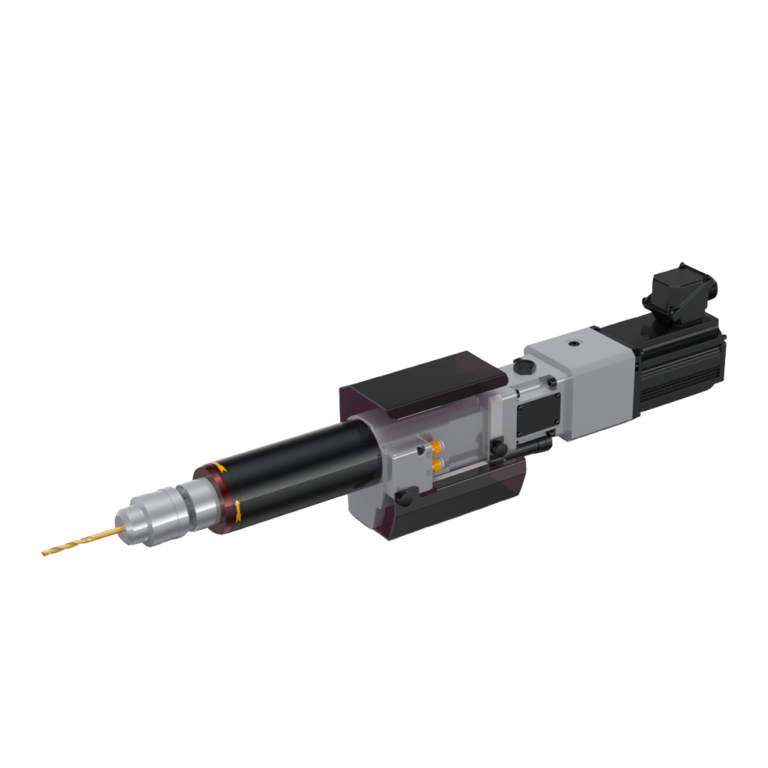

SELFEEDER ELECTRIC SSE3

“Selfeeder Electric SSE3” is the standard specification of the SSE series.

Suited for drilling in high speed rotation range.

Max. drilling size … φ9(Steel)/φ13(Aluminum)

Features of the PM motor

1.Energy Saving

Energy consumption can be reduced by approximately 20% compared to a three-phase induction motor with the same output.

2.Global Support

Not subject to overseas high-efficiency motor regulations, making it easy to apply to equipment to be exported overseas.

3.Variable Spindle Rotation

Variable spindle speed eliminates the need for setup changes and can handle a wide range of machining diameters.

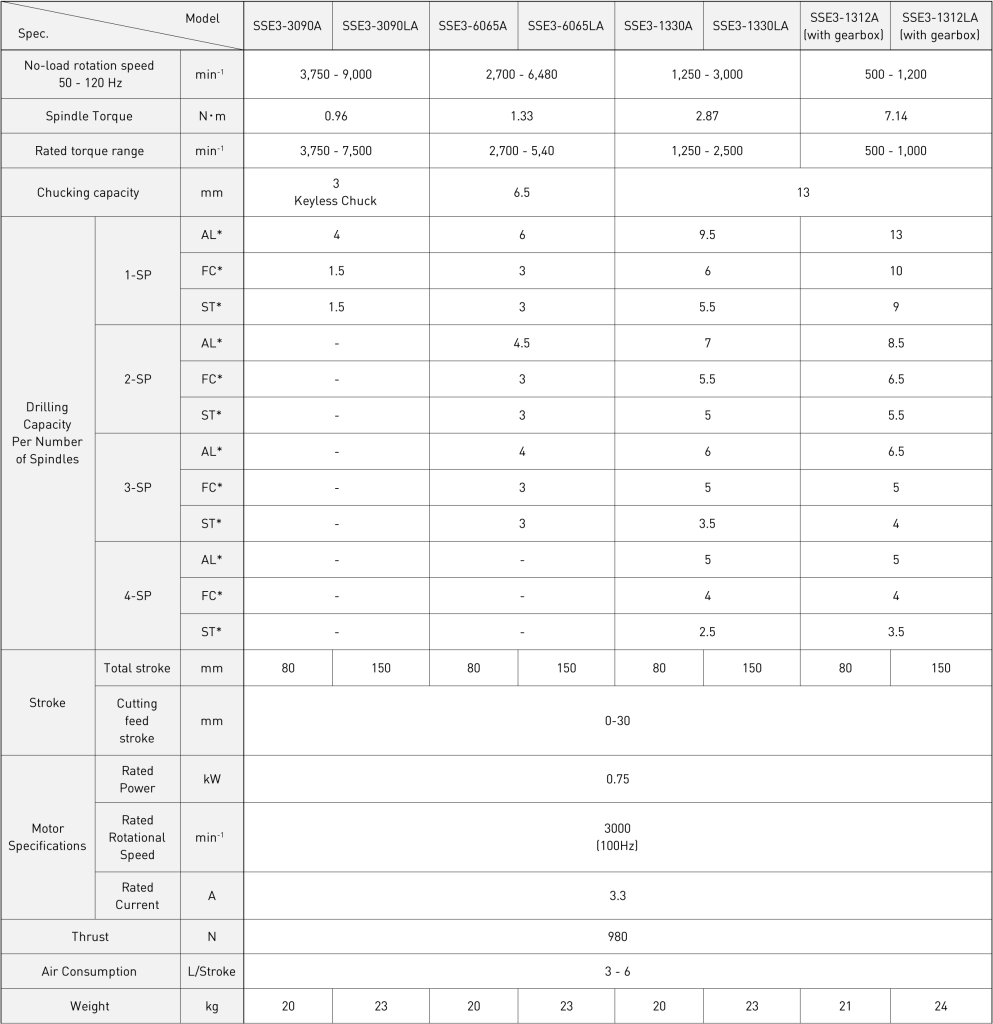

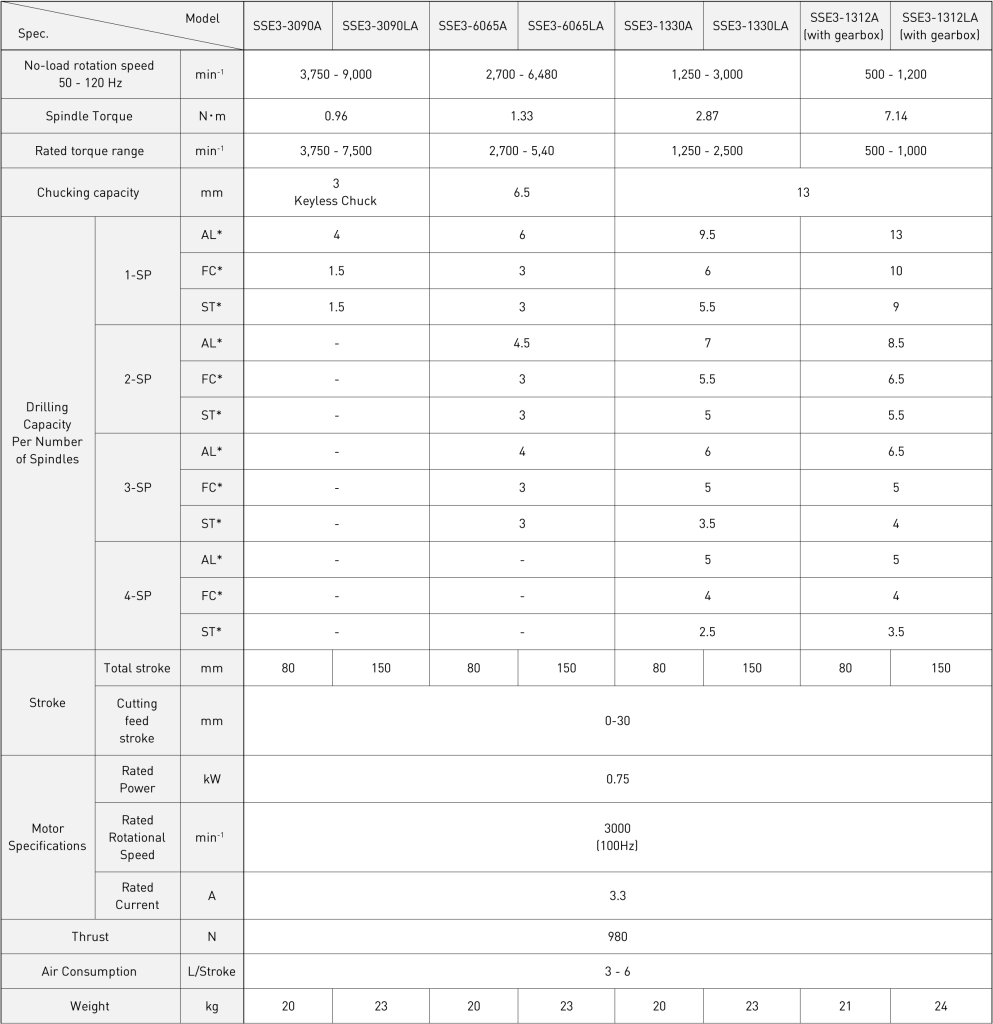

Specifications

Supply air pressure at 0.5 MPa

Notes:

- The selection of models should be based on the shape of the work, material, cutting characteristics, diameter and material of tools, rotational speed (cutting speed), etc.

- The drilling capacity displayed in the above table is based on values representing a drilling depth of twice the diameter of the drill.

- The RB-2430 comes standard with a Hydro Speed Regulator. A Hydro Speed Regulator is available as an option upon request.

(Optional Hydro Speed Regulator models are: RB-2460, R-2442A, R-2462A, and R-2482A) - Make sure to use a collet chuck or spindle nose when the hardness of carbide drills and tool shanks is higher than that of general HSS (high-speed steel) drills.

- Valveless specification is standard. If you require valve block specification (former standard specification), please order valve block assʼy separately. (Replacement to be made by customer)

- AL : Aluminum(ADC12) , FC : Cast iron(FC200) , ST : Steel(S45C)

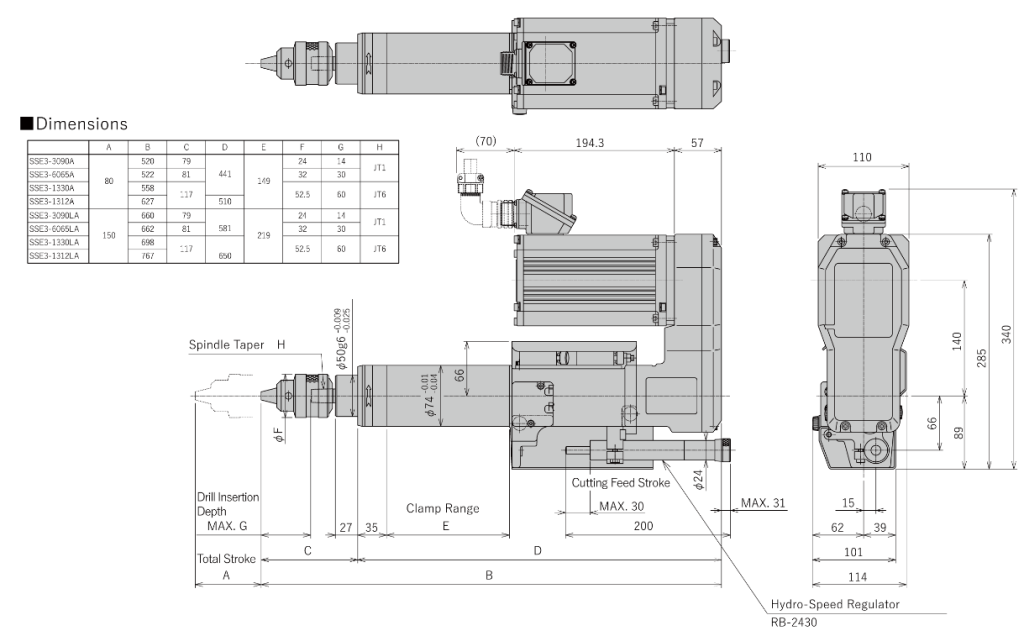

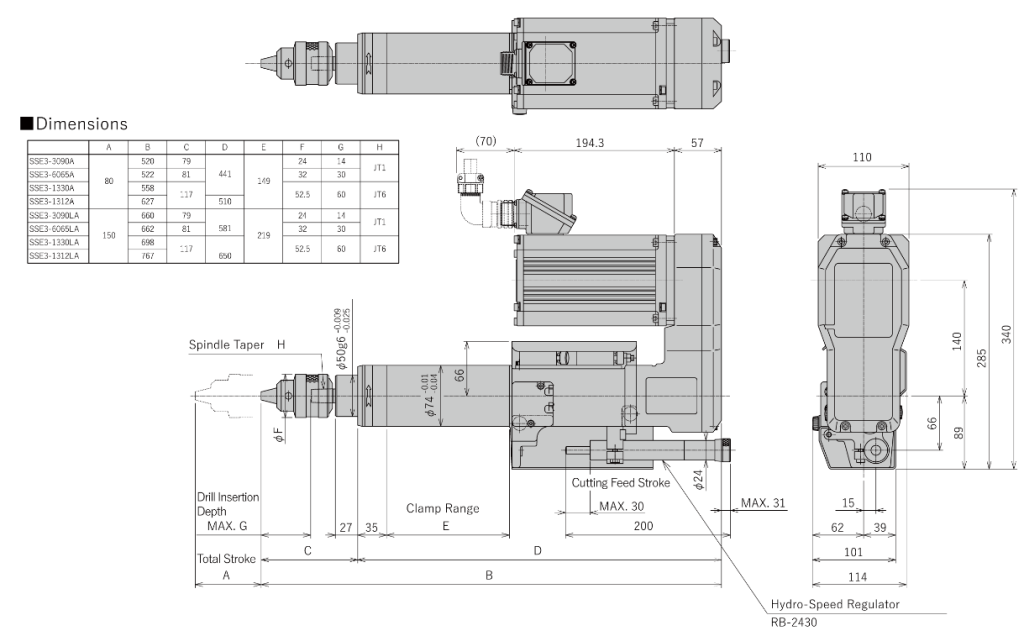

Dimensions

Peripherals (Optional) :

Stand for unit installation

- Angle-adjustable stand “Flex Stand”

- Fixing attachment “Level Clamp”

Forward/reverse end kit

- Operate Signal Kit

Hydraulic feed speed control unit

Hydro-Speed Regulator (spring return type)

Hydro-Speed Regulator (air return type)

SELFEEDER ELECTRIC SSE3C

Slim pneumatic feed drilling unit with rotary drive shaft and drill in the same core!

“Selfeeder Electric SSE3C” is a slim drilling unit with the rotary drive shaft and drill in the same core.Ideal for space-saving parallel placement.

Max. drilling size …φ8(Steel)/ φ10(Aluminum)

Features of the PM motor

1.Energy Saving

Energy consumption can be reduced by approximately 20% compared to a three-phase induction motor with the same output.

2.Global Support

Not subject to overseas high-efficiency motor regulations, making it easy to apply to equipment to be exported overseas.

3.Variable Spindle Rotation

Variable spindle speed eliminates the need for setup changes and can handle a wide range of machining diameters.

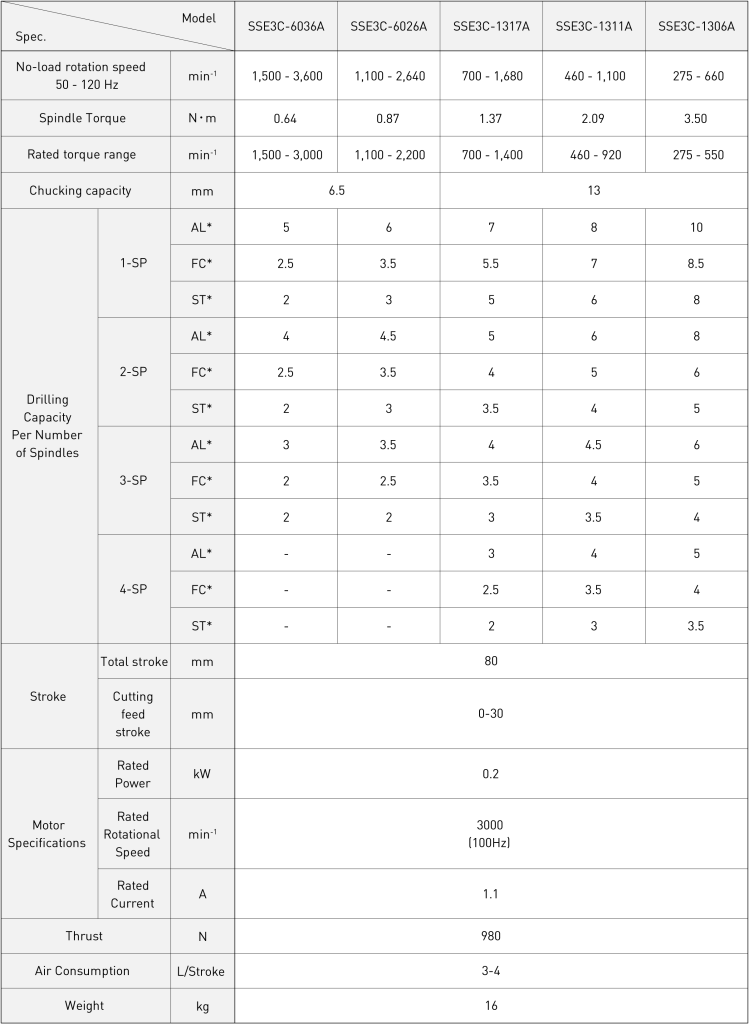

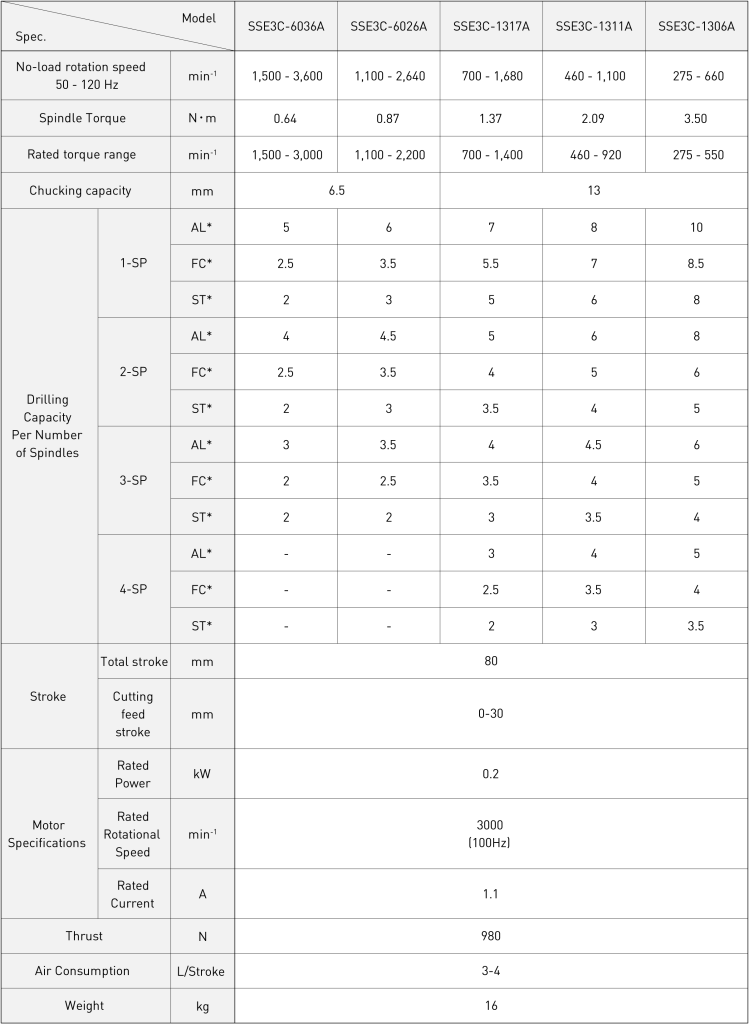

Specifications

Supply air pressure at 0.5 MPa

Notes:

- The selection of models should be based on the shape of the work, material, cutting characteristics, diameter and material of tools, rotational speed (cutting speed), etc.

- The drilling capacity displayed in the above table is based on values representing a drilling depth of twice the diameter of the drill.

- The RB-2430 comes standard with a Hydro Speed Regulator. A Hydro Speed Regulator is available as an option upon request.

(Optional Hydro Speed Regulator models are: RB-2460, R-2442A, R-2462A, and R-2482A) - Make sure to use a collet chuck or spindle nose when the hardness of carbide drills and tool shanks is higher than that of general HSS (high-speed steel) drills.

- Valveless specification is standard. If you require valve block specification (former standard specification), please order valve block assʼy separately. (Replacement to be made by customer)

- AL : Aluminum(ADC12) , FC : Cast iron(FC200) , ST : Steel(S45C)

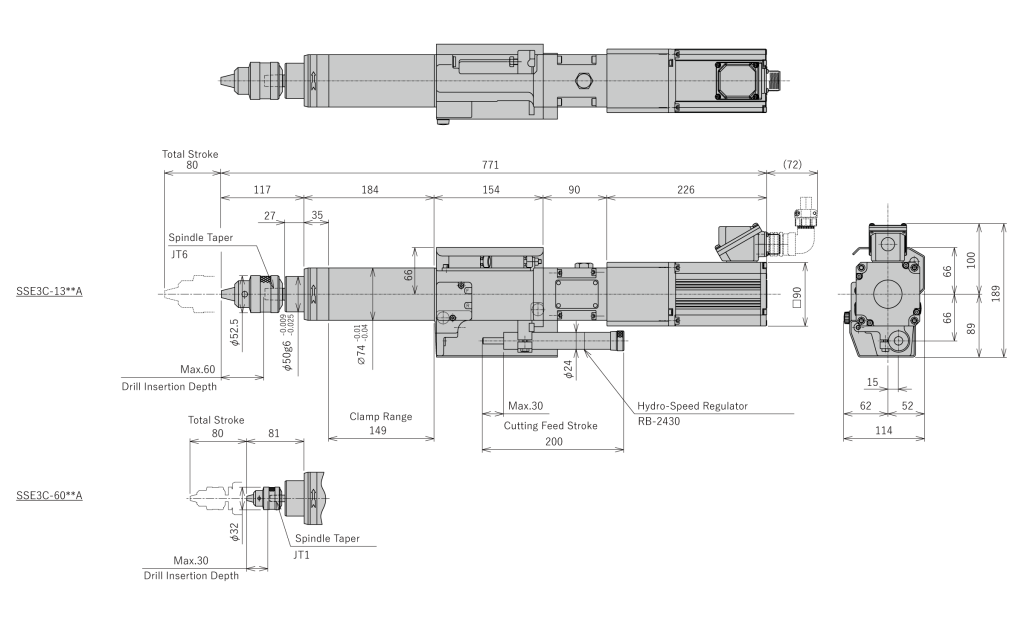

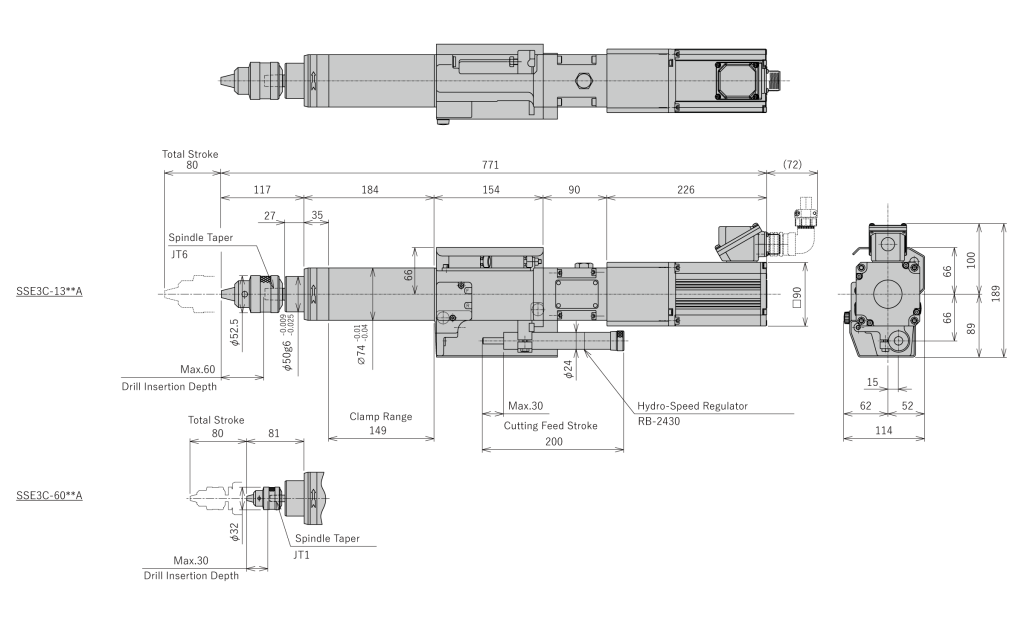

Dimensions

Peripherals (Optional) :

Stand for unit installation

- Angle-adjustable stand “Flex Stand”

- Fixing attachment “Level Clamp”

Forward/reverse end kit

- Operate Signal Kit

Hydraulic feed speed control unit

Hydro-Speed Regulator (spring return type)

Hydro-Speed Regulator (air return type)

SELFEEDER ELECTRIC SSE4

Pneumatic Feed Drilling Unit that aims to enhance the low speed rotation range!

“Selfeeder Electric SSE4” covers the high-torque range not covered by the SSE3.

The long stroke type is the longest in the SSE series.

Max. drilling size … φ12(Steel)/ φ16(Aluminum)

Features of the PM motor

1.Energy Saving

Energy consumption can be reduced by approximately 20% compared to a three-phase induction motor with the same output.

2.Global Support

Not subject to overseas high-efficiency motor regulations, making it easy to apply to equipment to be exported overseas.

3.Variable Spindle Rotation

Variable spindle speed eliminates the need for setup changes and can handle a wide range of machining diameters.

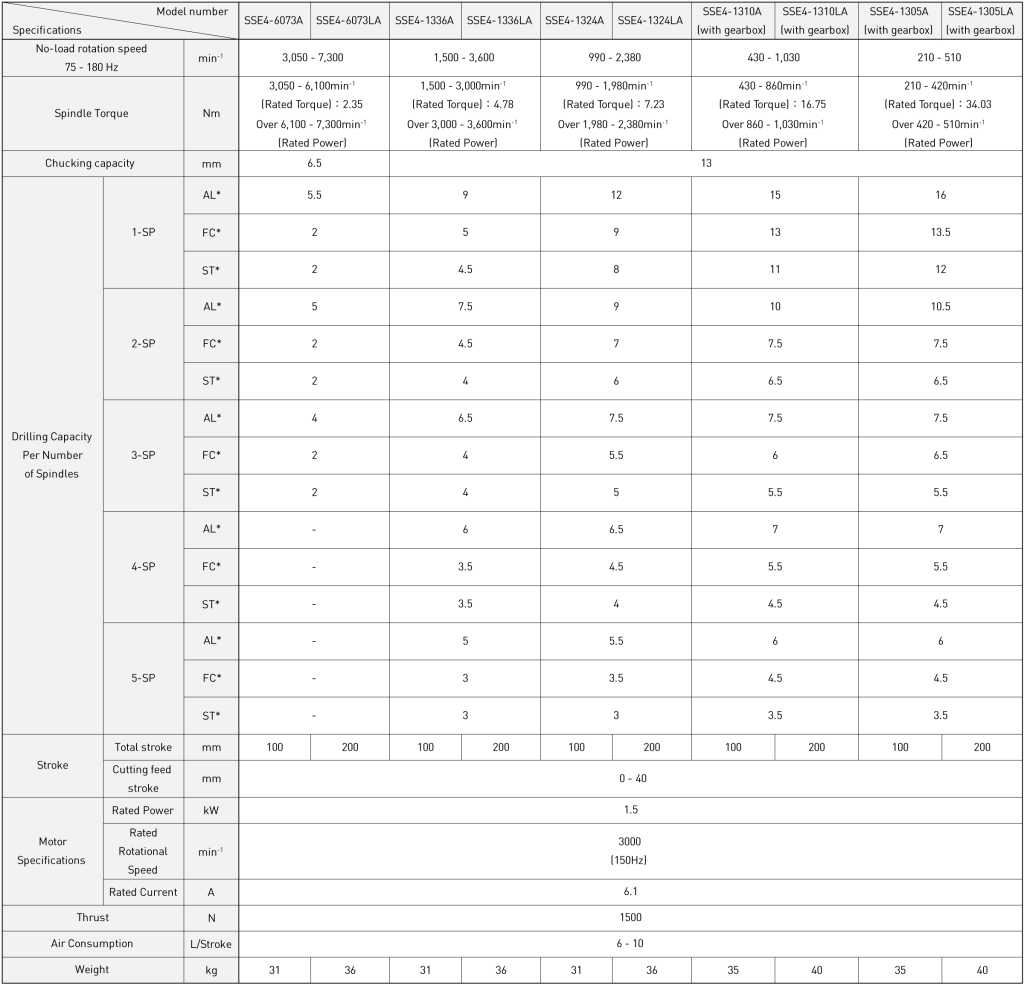

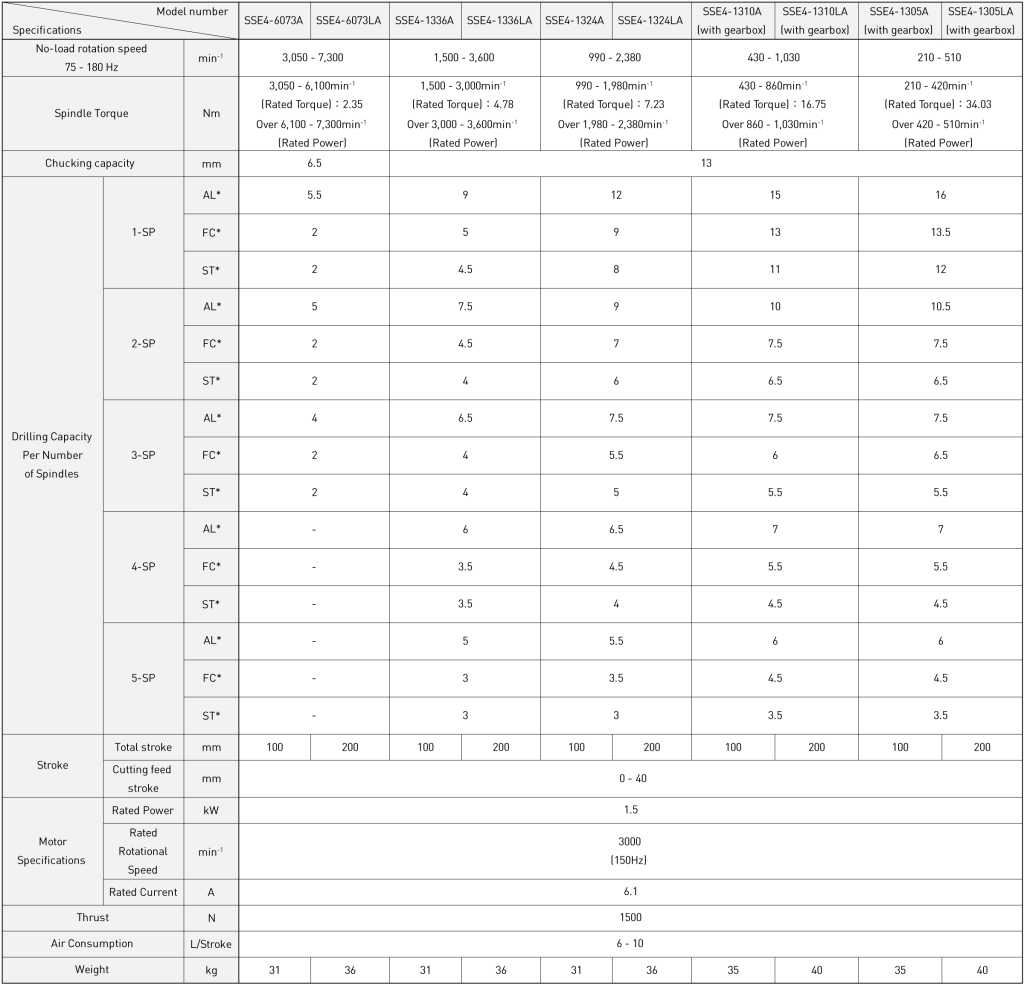

Specifications

Supply air pressure at 0.5 MPa

Notes:

- The selection of models should be based on the shape of the work, material, cutting characteristics, diameter and material of tools, rotational speed (cutting speed), etc.

- The drilling capacity displayed in the above table is based on values representing a drilling depth of twice the diameter of the drill.

- The standard attachment for the Hydro Speed Regulator is RB-3140. Please specify an optional Hydro Speed Regulator if required.

(Optional Hydro Speed Regulator Models: RB-3160, R-3182A, R-31132A) - Make sure to use a collet chuck or spindle nose when the hardness of carbide drills and tool shanks is higher than that of general HSS (high-speed steel) drills.

- Valveless specification is standard. If you require valve block specification (former standard specification), please order valve block assʼy separately. (Replacement to be made by customer)

- AL : Aluminum(ADC12) , FC : Cast iron(FC200) , ST : Steel(S45C)

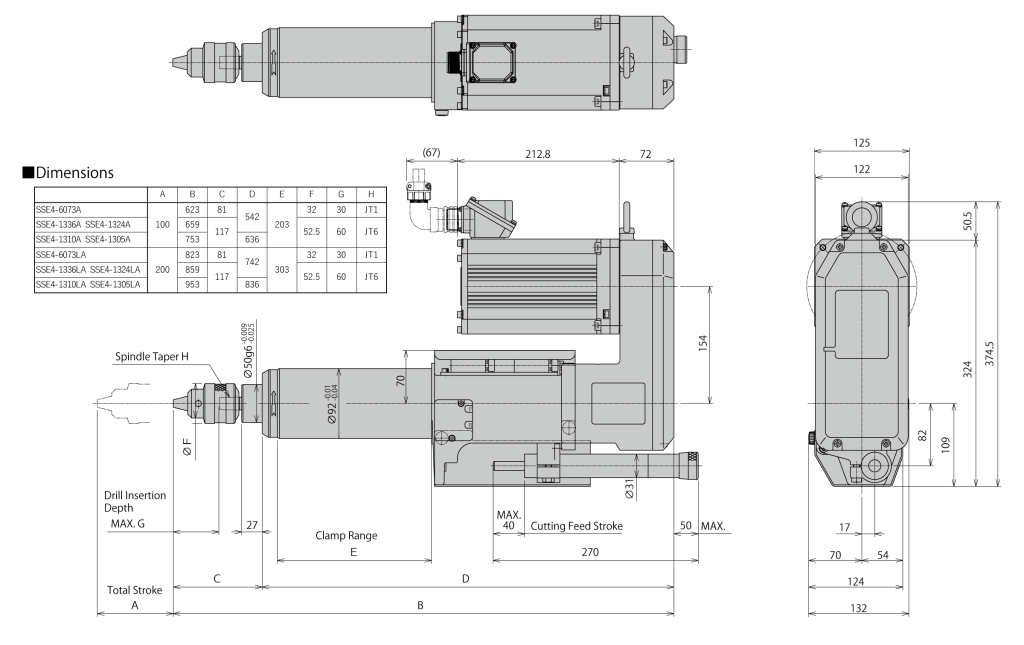

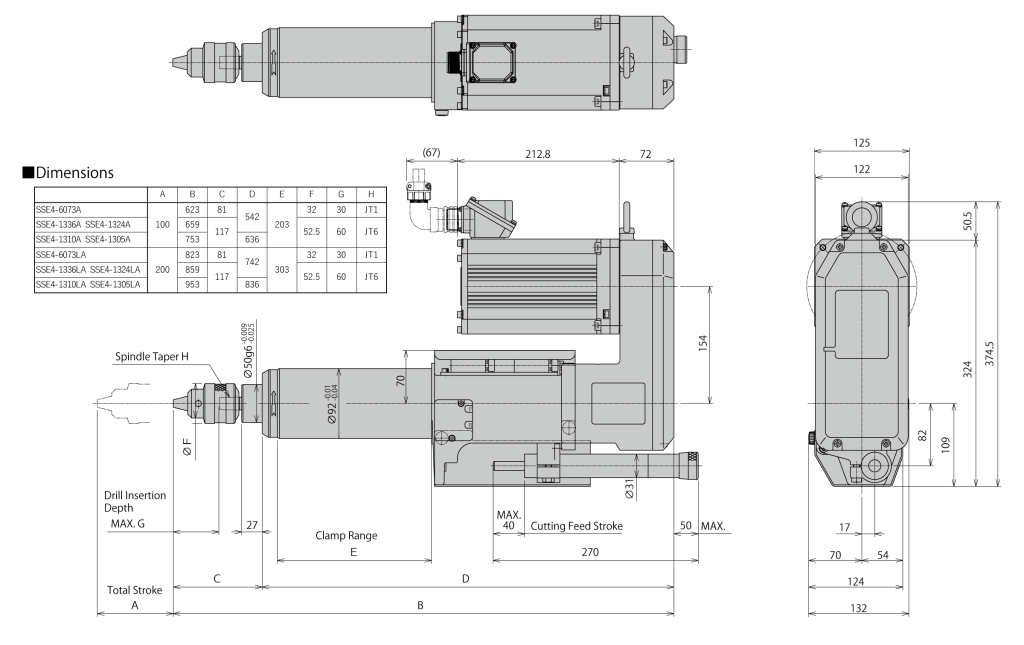

Dimensions

Peripherals (Optional) :

Stand for unit installation

- Angle-adjustable stand “Flex Stand”

- Fixing attachment “Level Clamp”

Forward/reverse end kit

- Operate Signal Kit

Hydraulic feed speed control unit

Hydro-Speed Regulator (spring return type)

Hydro-Speed Regulator (air return type)

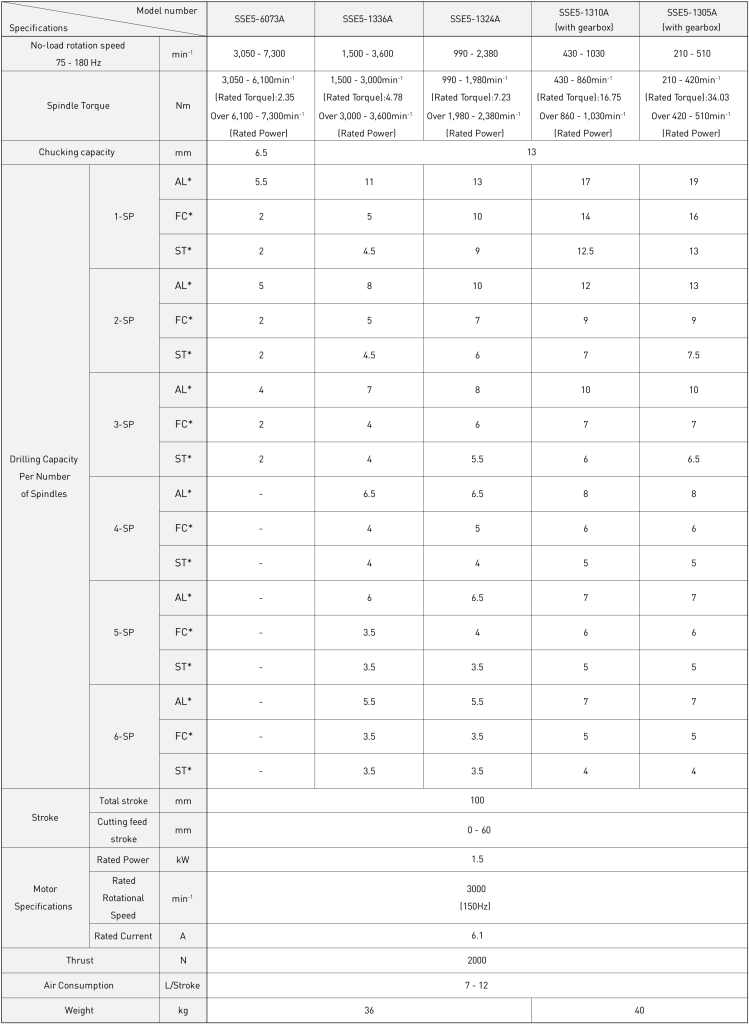

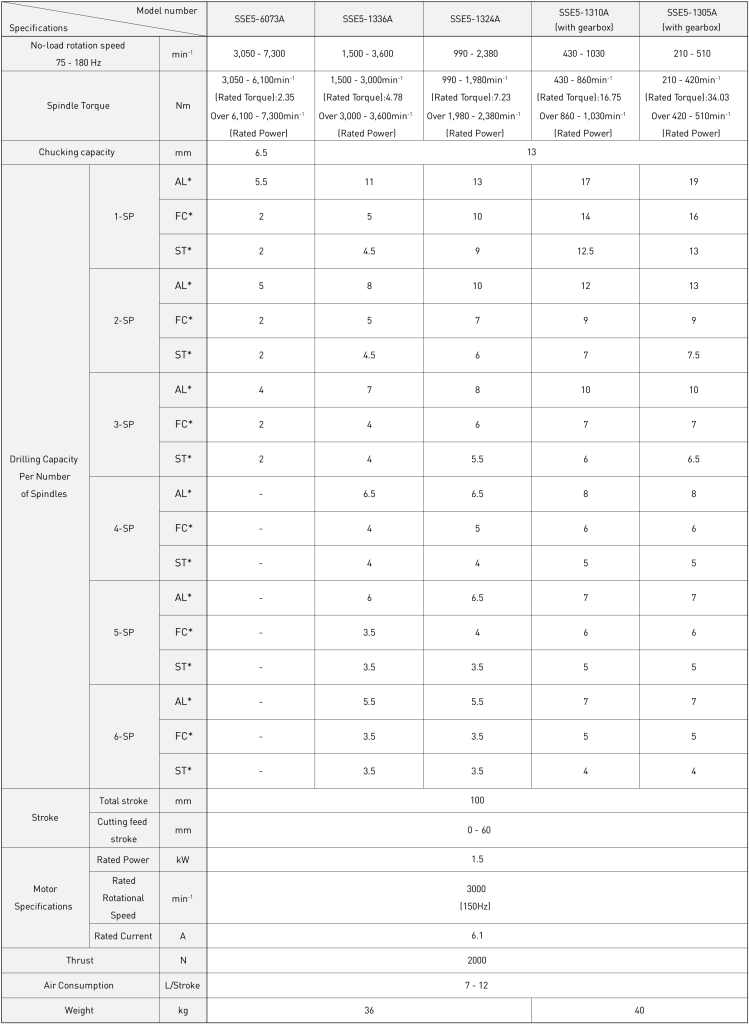

SELFEEDER ELECTRIC SSE5

High-torque, high-thrust, round body unit.

“Selfeeder Electric SSE5” covers a higher torque and thrust range than the SSE4.

Multi-spindle heads are also available up to 6 spindles.

Max. drilling size … φ13(Steel)/ φ19(Aluminum)

Features of the PM motor

1.Energy Saving

Energy consumption can be reduced by approximately 20% compared to a three-phase induction motor with the same output.

2.Global Support

Not subject to overseas high-efficiency motor regulations, making it easy to apply to equipment to be exported overseas.

3.Variable Spindle Rotation

Variable spindle speed eliminates the need for setup changes and can handle a wide range of machining diameters.

Specifications

Supply air pressure at 0.5 MPa

Notes:

- The selection of models should be based on the shape of the work, material, cutting characteristics, diameter and material of tools, rotational speed (cutting speed), etc.

- The drilling capacity displayed in the above table is based on values representing a drilling depth of twice the diameter of the drill.

- The standard attachment for the Hydro Speed Regulator is RB-3140. Please specify an optional Hydro Speed Regulator if required.

(Optional Hydro Speed Regulator Models: RB-3160, R-3182A, R-31132A) - Make sure to use a collet chuck or spindle nose when the hardness of carbide drills and tool shanks is higher than that of general HSS (high-speed steel) drills.

- Valveless specification is standard. If you require valve block specification (former standard specification), please order valve block assʼy separately. (Replacement to be made by customer)

- AL : Aluminum(ADC12) , FC : Cast iron(FC200) , ST : Steel(S45C)

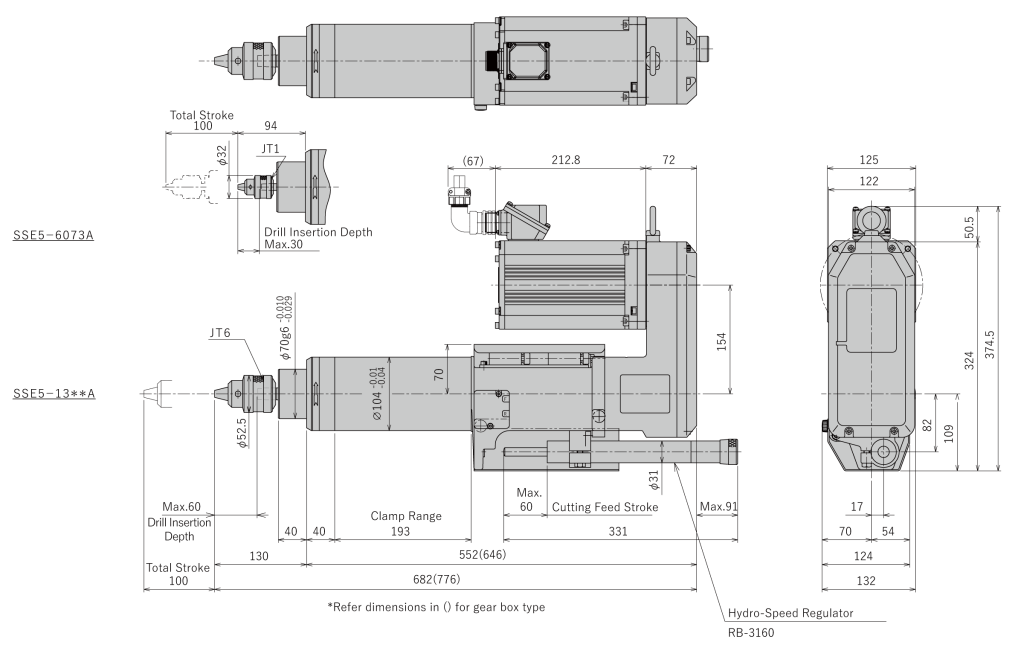

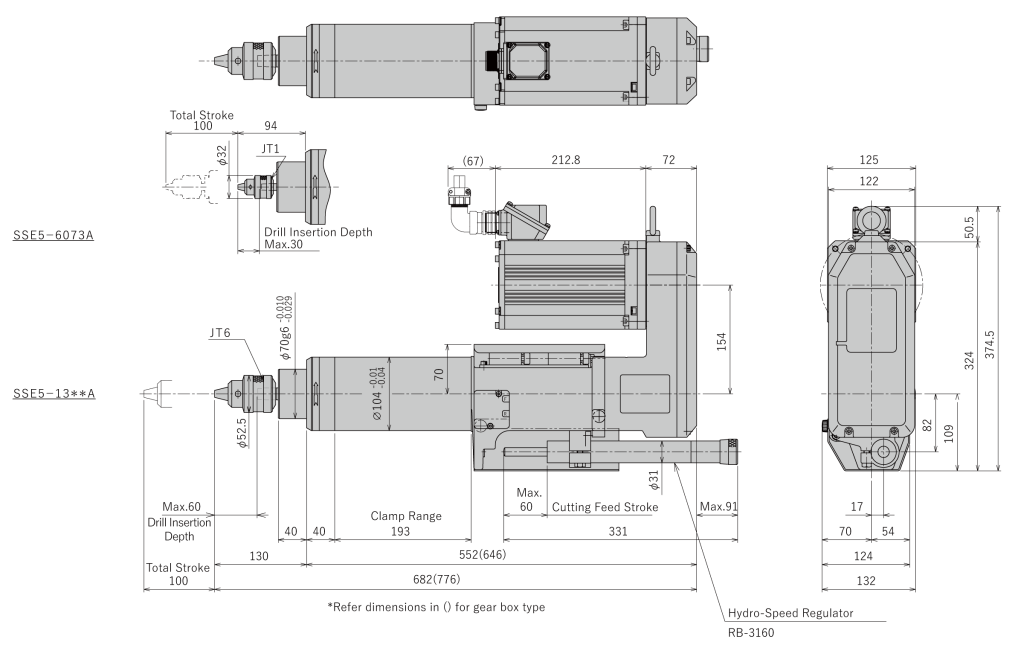

Dimensions

Peripherals (Optional) :

Stand for unit installation

- Angle-adjustable stand “Flex Stand”

- Fixing attachment “Level Clamp”

Forward/reverse end kit

- Operate Signal Kit

Hydraulic feed speed control unit

Hydro-Speed Regulator (spring return type)

Hydro-Speed Regulator (air return type)

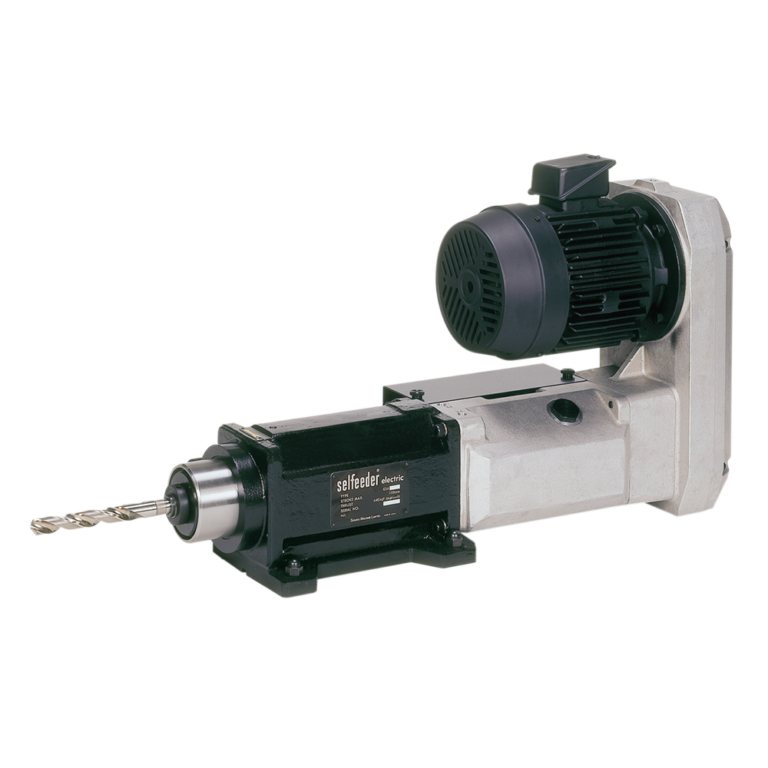

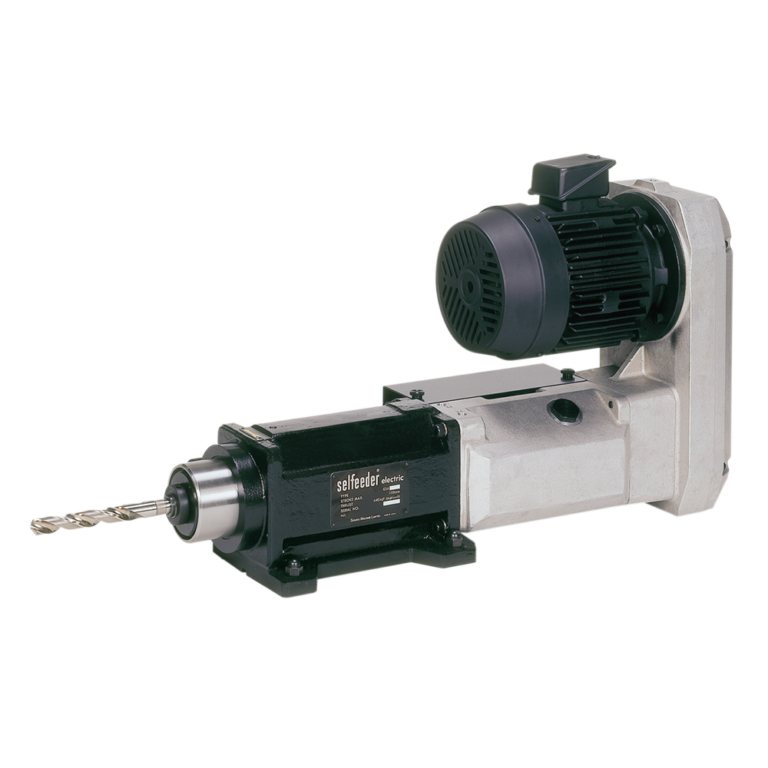

SELFEEDER ELECTRIC ES6

High-rigidity drilling unit capable of heavy-duty cutting.

The “SELFEEDER ELECTRIC ES6” is a high-rigidity, body-mounting drilling unit with a maximum motor output of 2.2 kW.

It is capable of heavy-duty cutting.

Max. drilling size … φ19(Steel)/ φ24(Aluminum)

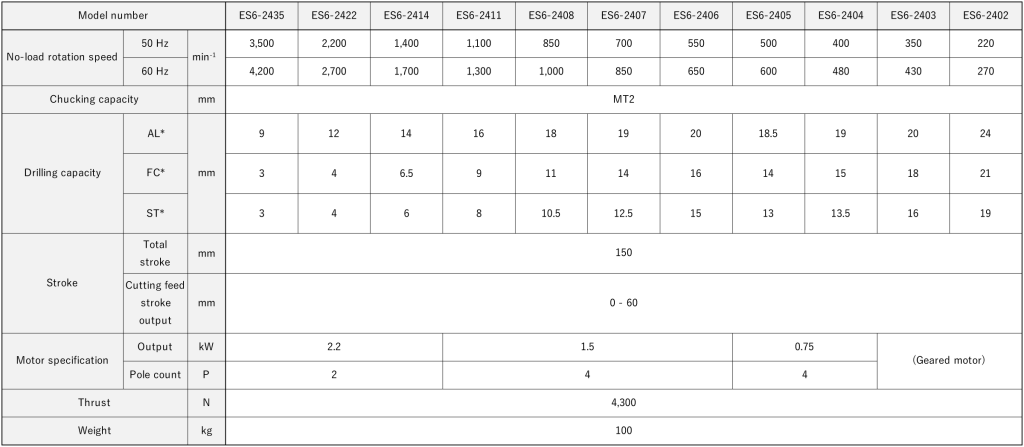

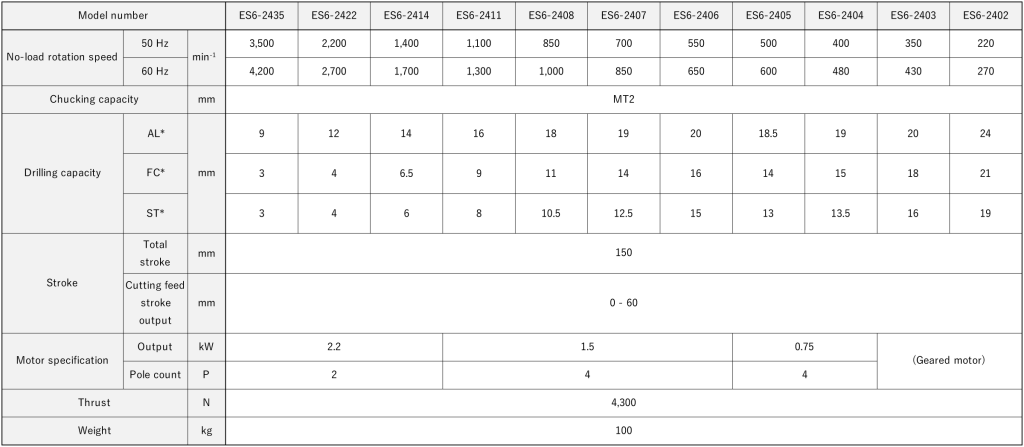

Specifications

Supply air pressure at 0.5 MPa

Notes:

- The selection of models should be based on the shape of the workpiece, material, cutting characteristics, diameter and material of tools, rotation speed (cutting speed), etc.

- The drilling capacity displayed in the above table is based on values representing a drilling depth of two times the diameter of the drill.

- The RB-3860 comes standard with a hydro-speed regulator. A hydro-speed regulator is available as an option upon request. (Optional hydro-speed regulator model: R-38100AC)

- The maximum mass of the installable attachment at downward processing is 50 kg.

- A ram fall-preventing mechanism is available as an option. Please indicate your specifications when placing an order.

- AL : Aluminum(ADC12) , FC : Cast iron(FC200) , ST : Steel(S45C)

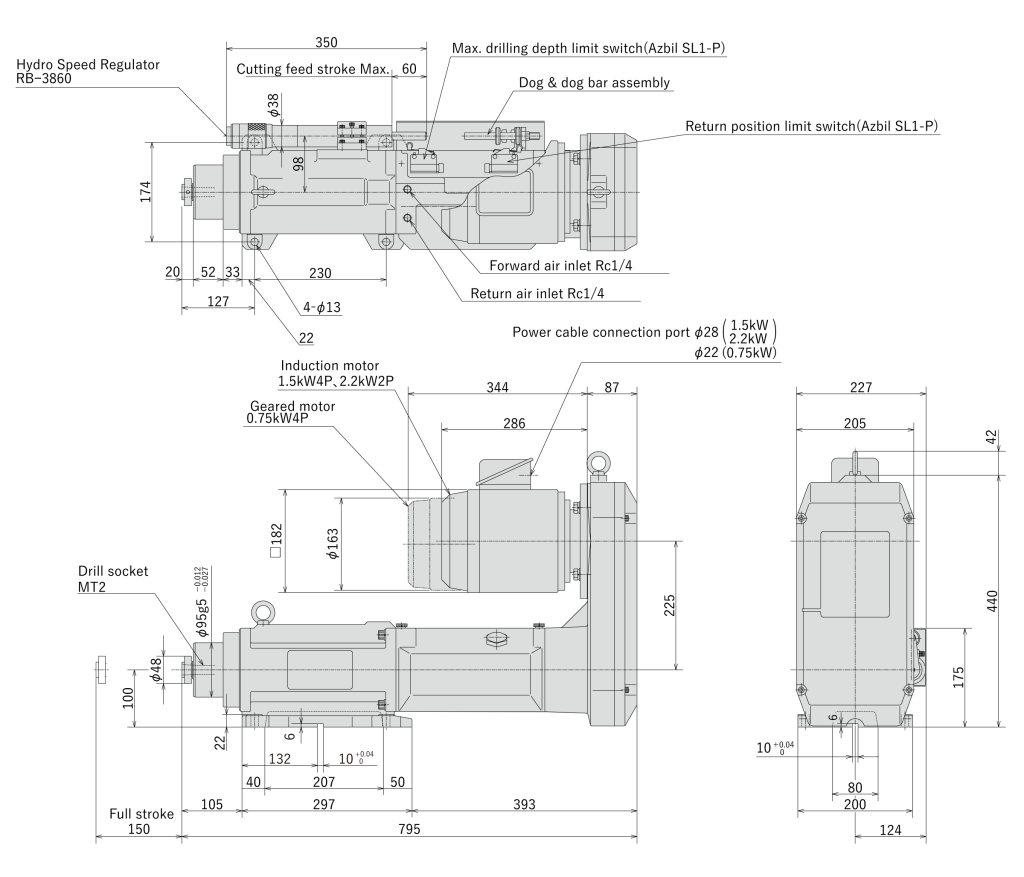

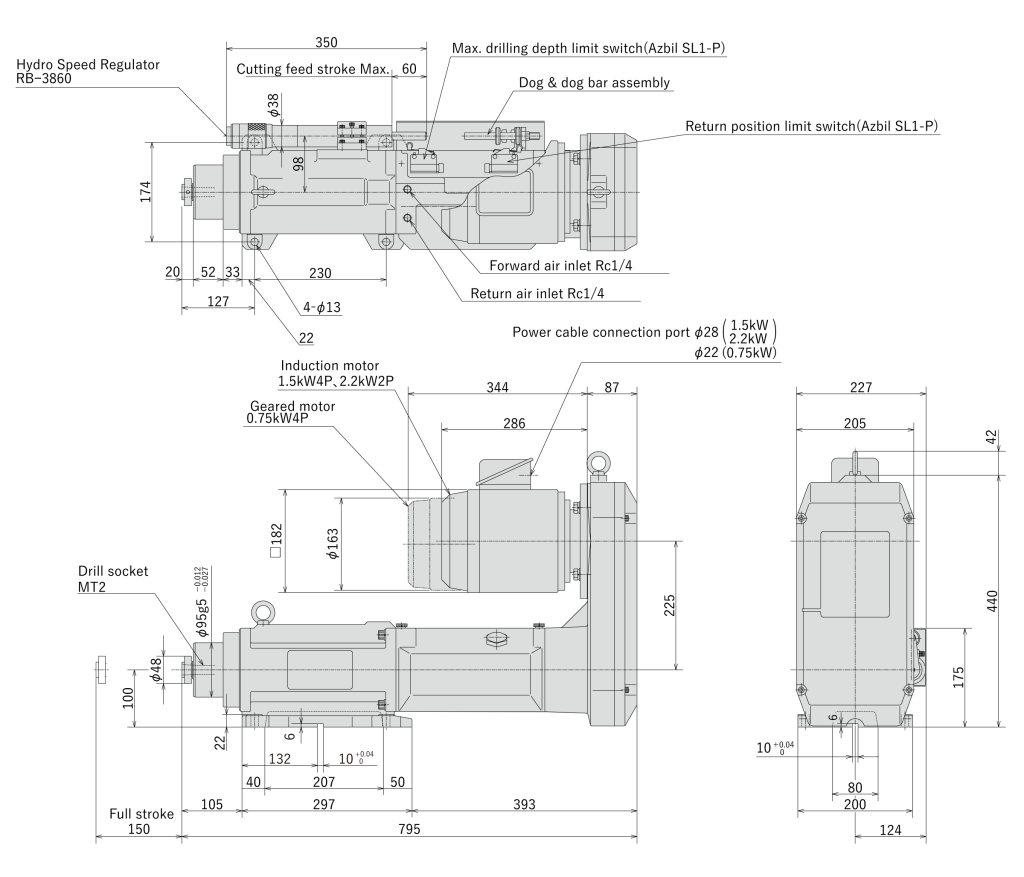

Dimensions

Note: The ES6 comes standard with limit switches (Azbil SL1-P) for checking the forward and backward ends.

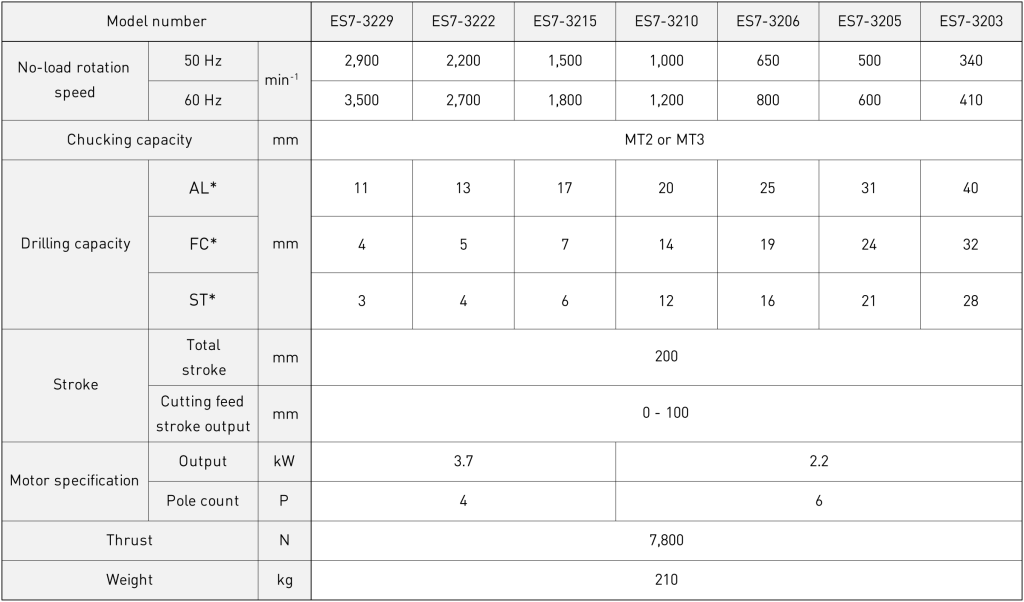

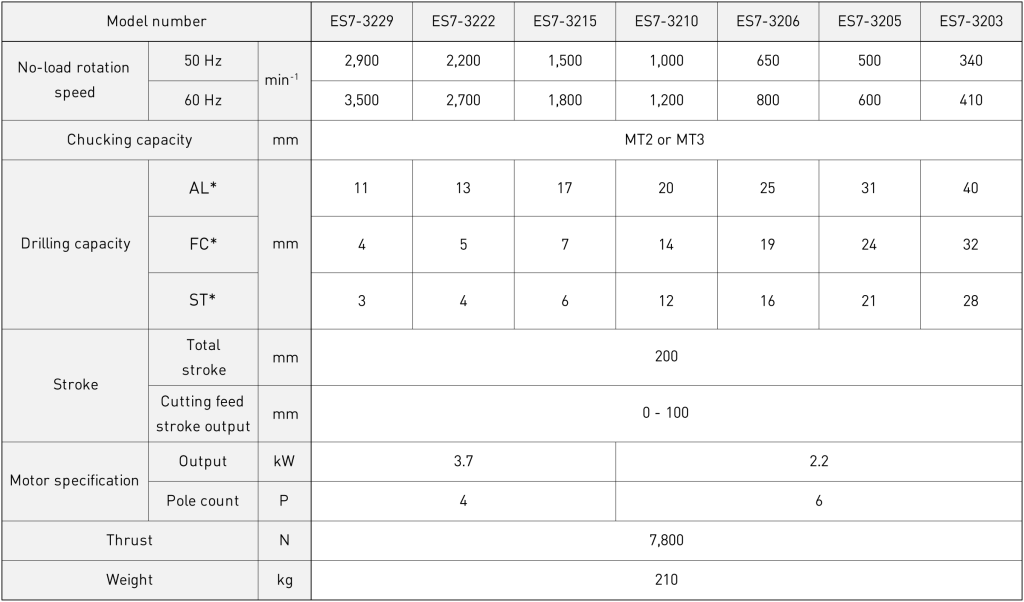

SELFEEDER ELECTRIC ES7

A pneumatic feed drilling unit with a maximum motor output of 3.7 kW and thrust of 7,800 N!

The “SELFEEDER ELECTRIC ES7” is a large drilling unit with a maximum motor output of 3.7 kW and thrust of 7,800 N.

It can perform drilling on steel with a maximum diameter of 28 mm.

Max. drilling size … φ28(Steel)/ φ40(Aluminum)

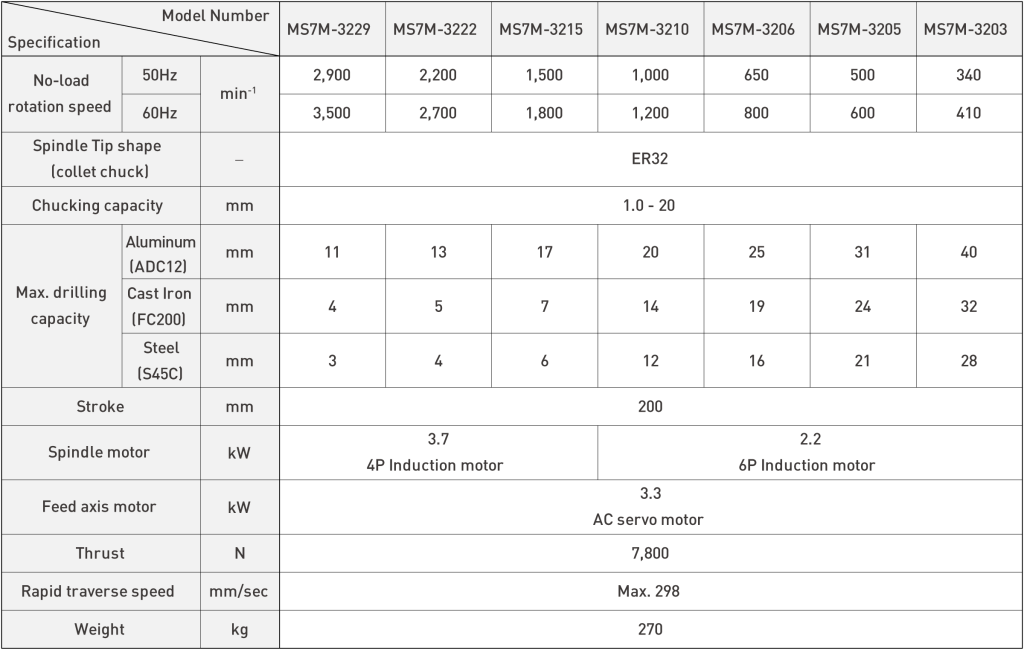

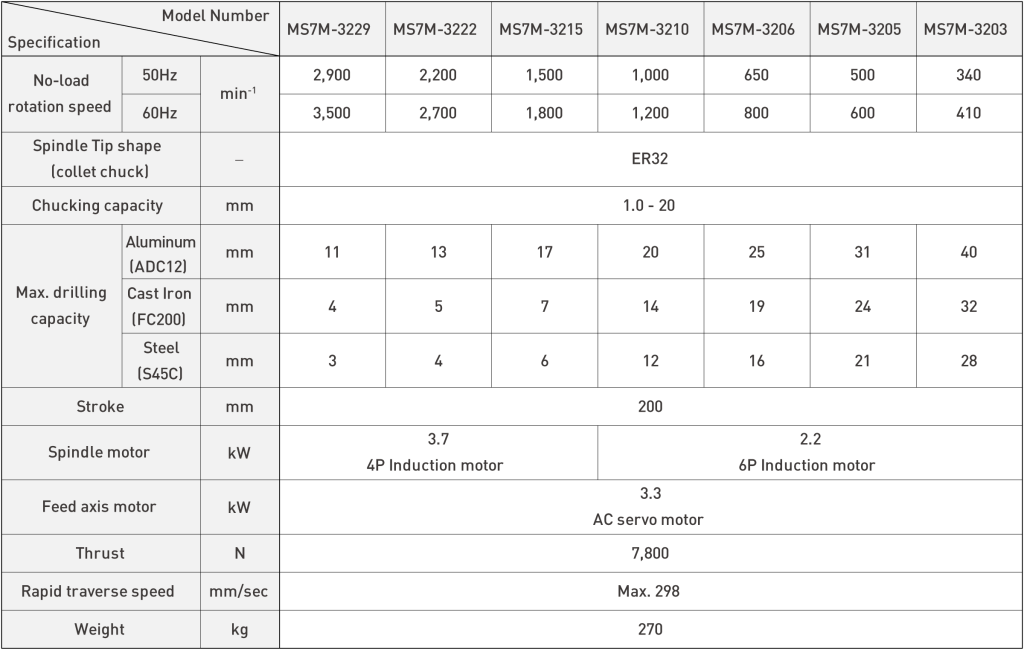

Specifications

Supply air pressure at 0.5 MPa

Notes:

- The selection of models should be based on the shape of the workpiece, material, cutting characteristics, diameter and material of tools, rotation speed (cutting speed), etc.

- The drilling capacity displayed in the above table is based on values representing a drilling depth of two times the diameter of the drill.

- The R-55100AC comes standard with a Hydro Speed Regulator. A Hydro Speed Regulator is available as an option upon request. (Optional Hydro Speed Regulator model: R-55150AC)

- The maximum mass of the installable attachment at downward processing is 100 kg

- A ram fall-preventing mechanism is available as an option. Please indicate your specifications when placing an order.

- AL : Aluminum(ADC12) , FC : Cast iron(FC200) , ST : Steel(S45C)

Dimensions

Preparing now….

SELFEEDER VARIMEC SERIES :

SERVO FEED DRILLING UNIT

SELFEEDER VARIMEC SSV2M

This servo feed drilling unit is equipped with a small, high-powered, highly-efficient motor!

The “Selfeeder Varimec SSV2 Type” is a compact, highly-efficient servo feed drilling unit equipped with a small, high-speed, high-powered, and highly-efficient motor.

Great for machining of small components and drilling small holes.

Max. drilling size … φ6.5(Steel)/ φ8.5(Aluminum)

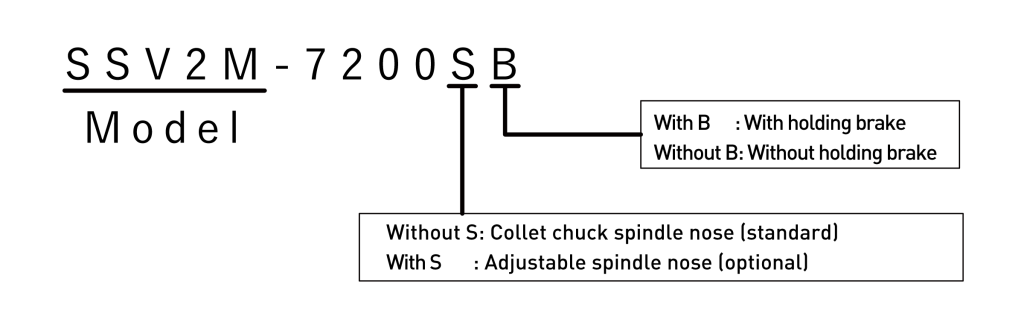

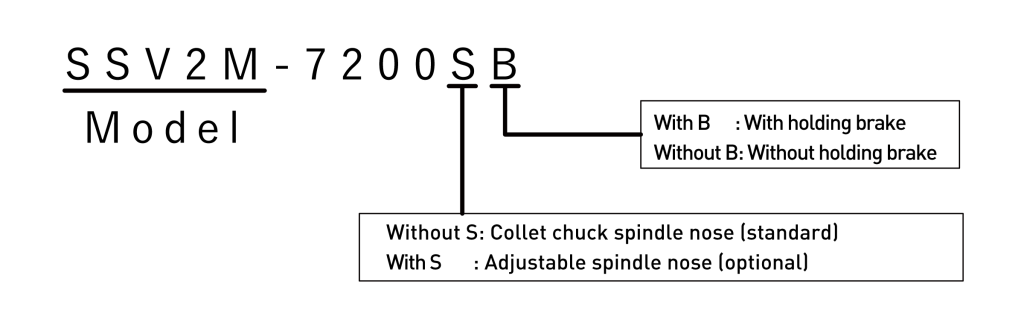

Model

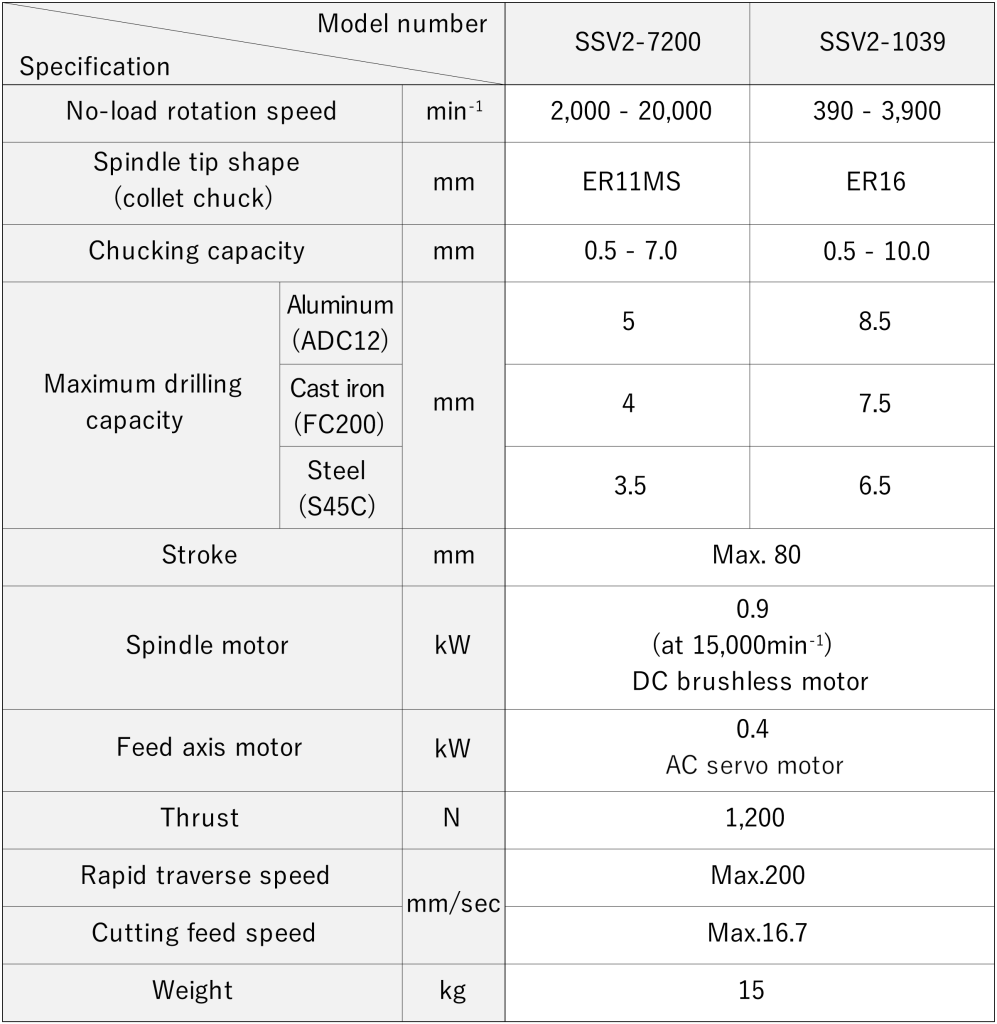

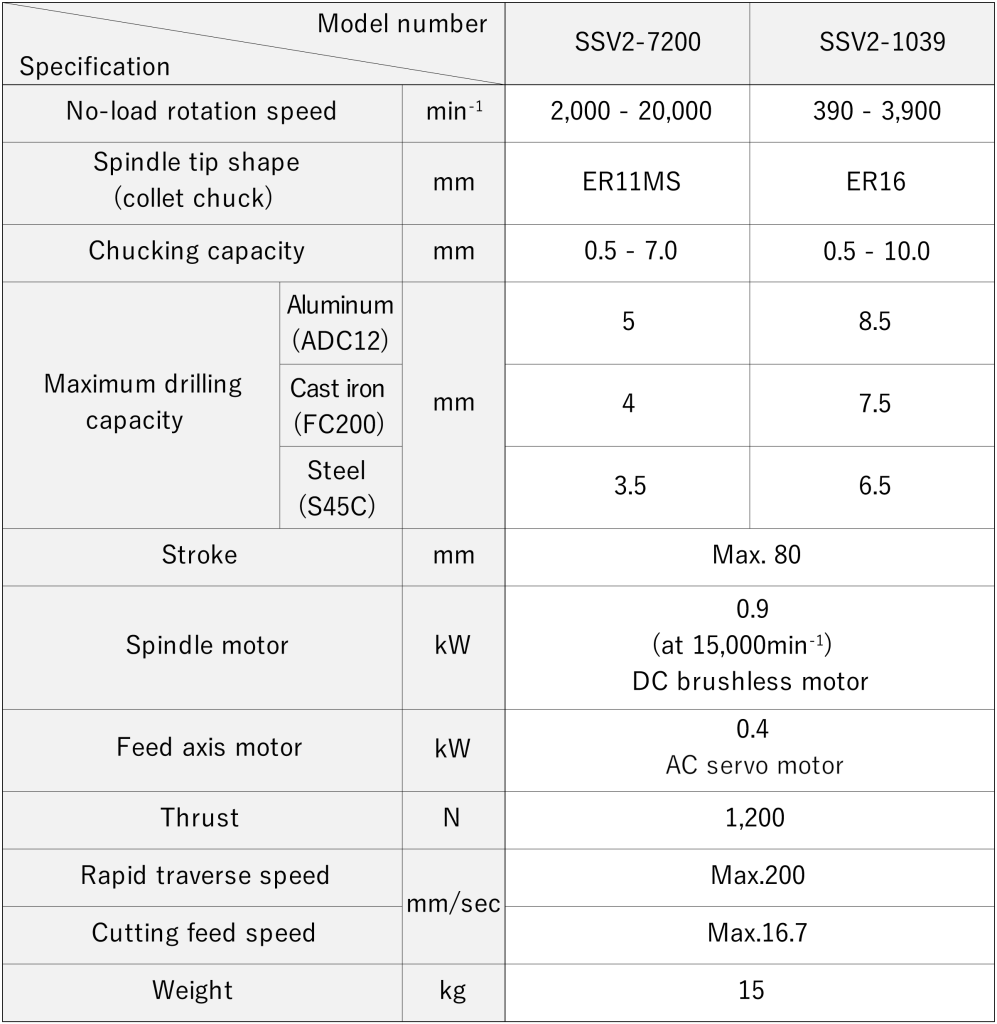

Specifications

Spindle motor: 0.9 kW (1,500 min-1) DC brushless motor / Feed shaft motor: 0.4 kW (1,500 min-1) Servo motor

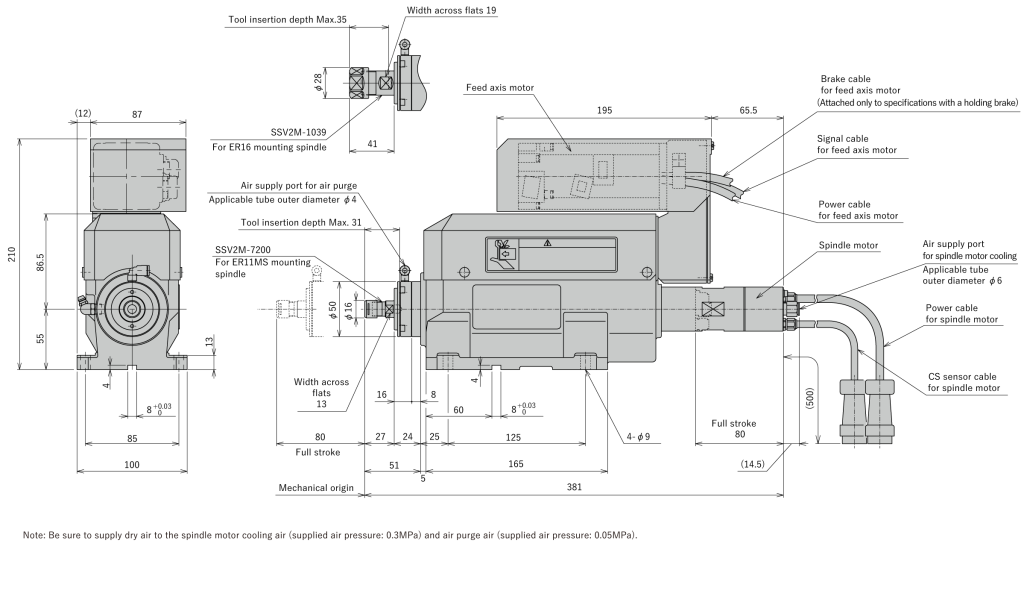

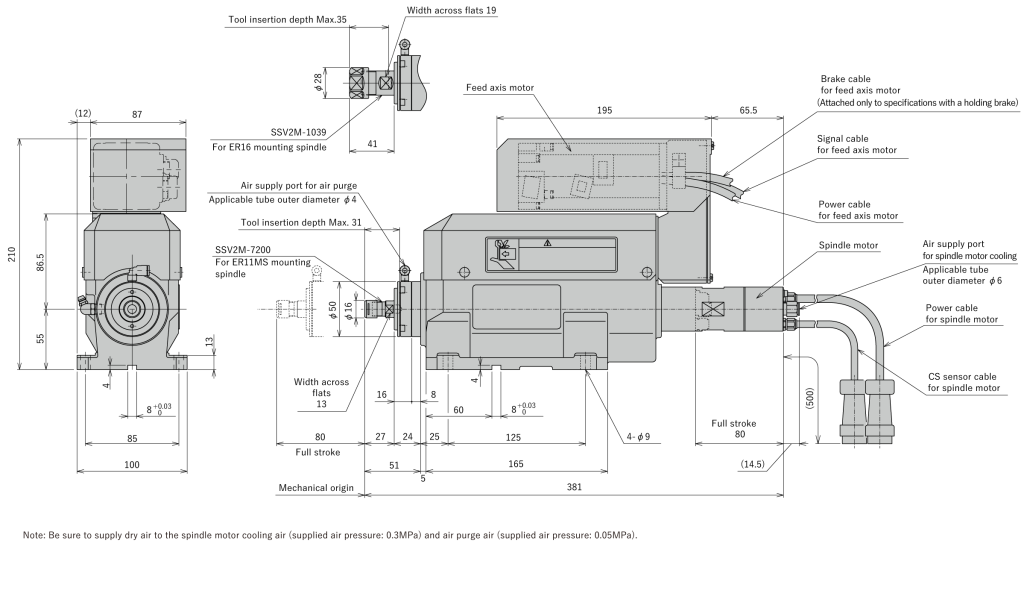

Dimensions

SELFEEDER MECHATRIC SERIES :

SERVO FEED DRILLING UNIT

SELFEEDER MECHATRIC MS7M

High output servo feed type drilling unit is capable of drilling max of φ28 with steel !

High-power model which has a 3.7kW spindle motor and 7,800N thrust.

This unit can perform facing, end-milling and max of 28mm diameter drilling in steel.

Max. drilling size … φ28(Steel)/ φ40(Aluminum)

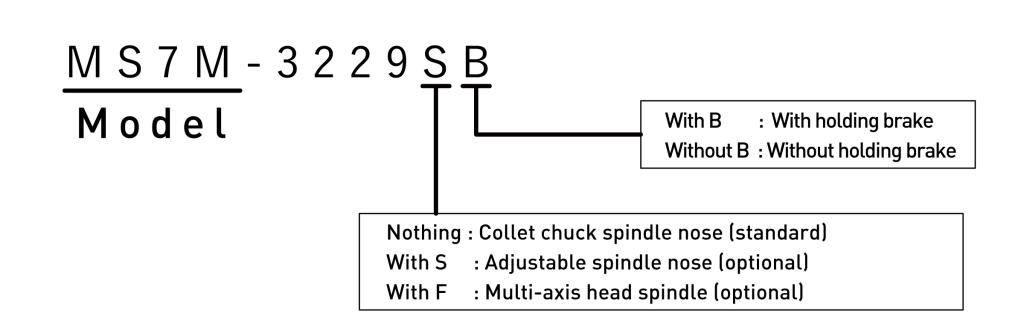

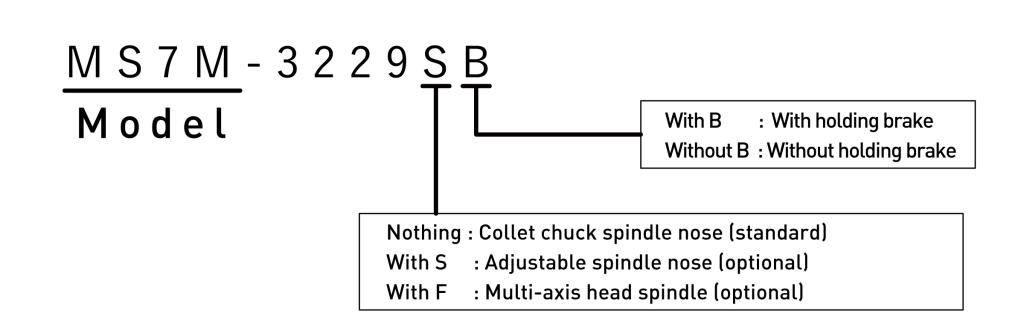

Model

Specifications

Feed shaft motor: 2.7 kW AC servo motor

Notes:

- To select your model, refer to the workpiece configurations, material, cutting properties, diameter of the hole, and rotation speed.(cutting speed)

- The drilling capacity shown above corresponds to a depth equivalent to the drill diameter times two.

- The power voltage of the feed controller and main spindle motor is a 3-phase 200V AC±10%, 50/60Hz.

- In the case of a servo motor with a holding brake (optional), add “B” to the end of the model number.

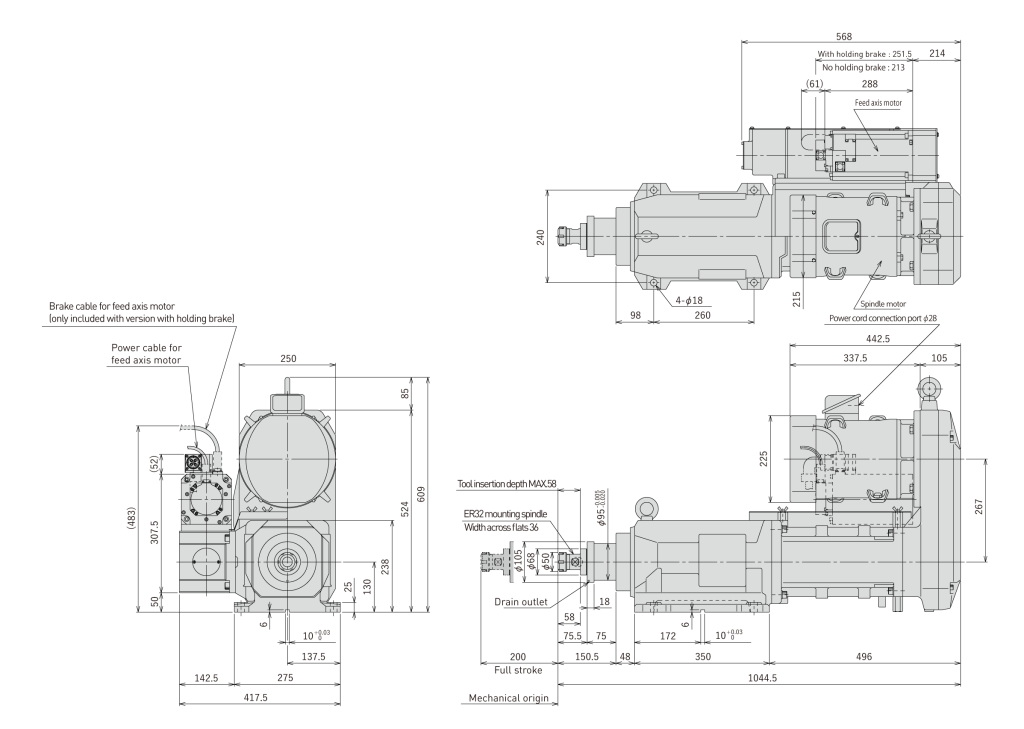

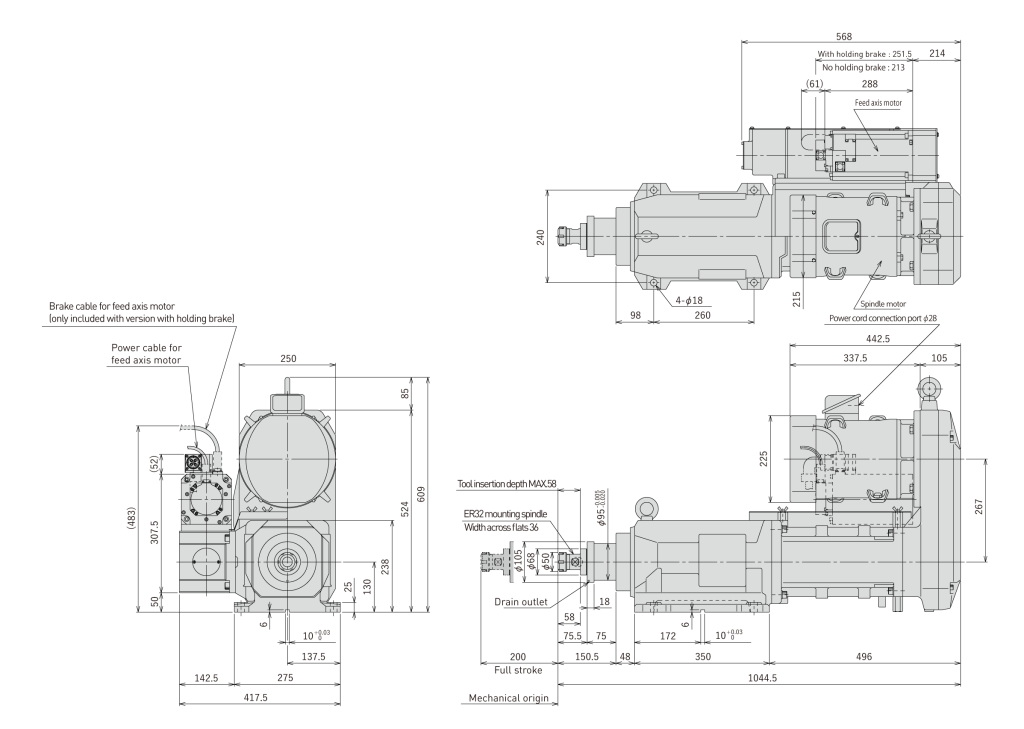

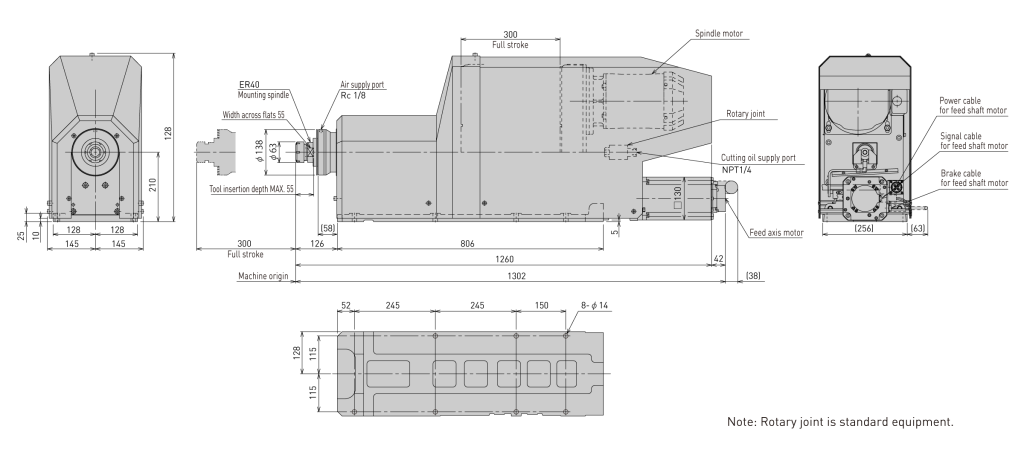

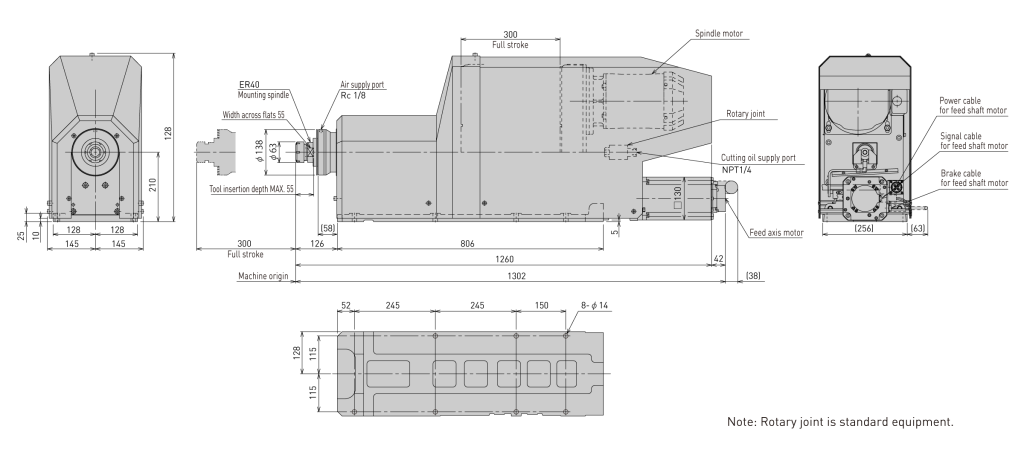

Dimensions

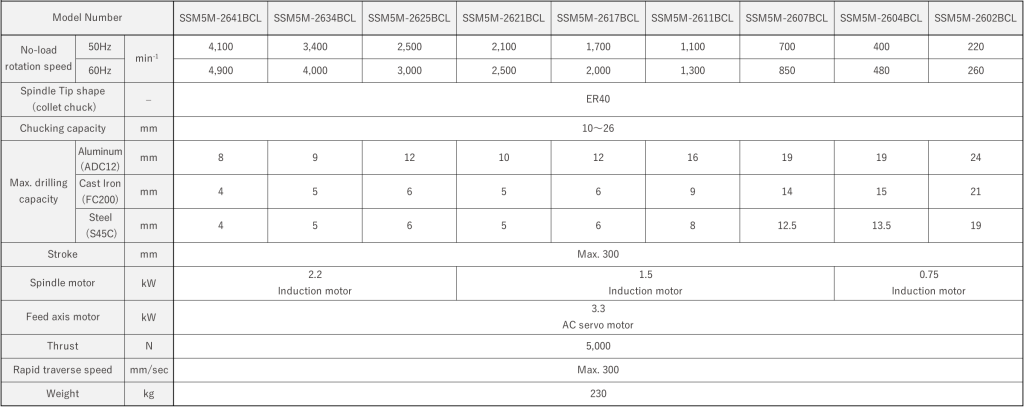

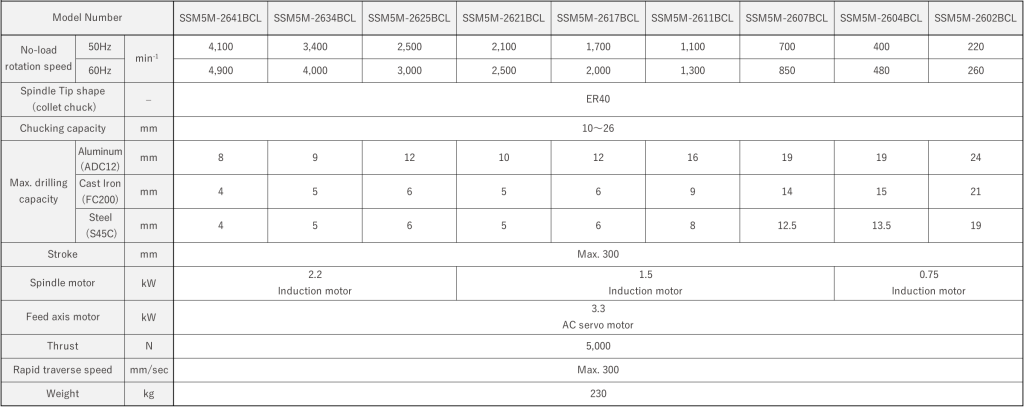

SELFEEDER MECHATRIC SSM5M

High-precision and high-rigidity servo feed drilling unit with a long stroke of 300 mm, which is appropriate for deep hole drilling.

“Selfeeder Mechatric SSM5” is a high-precision and high-rigidity cutting unit with an integrated slide table and spindle unit.

Deep hole drilling can be efficiently performed with long stroke of 300 mm and coolant center through.

Max. drilling size … φ19(Steel)/ φ24(Aluminum)

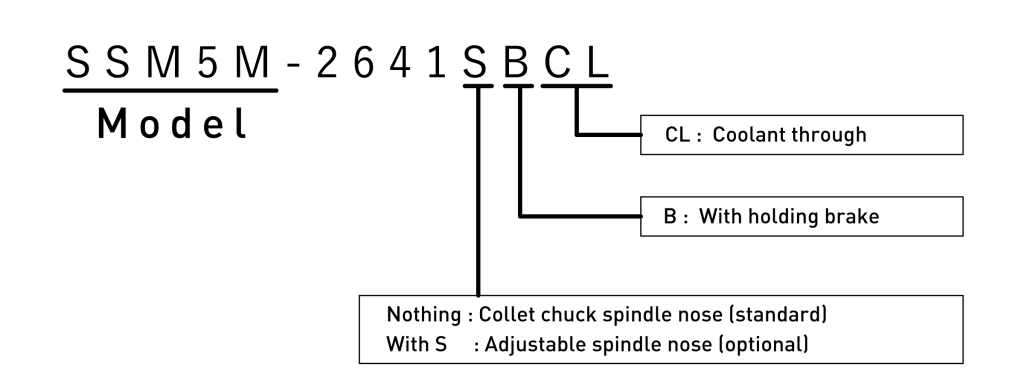

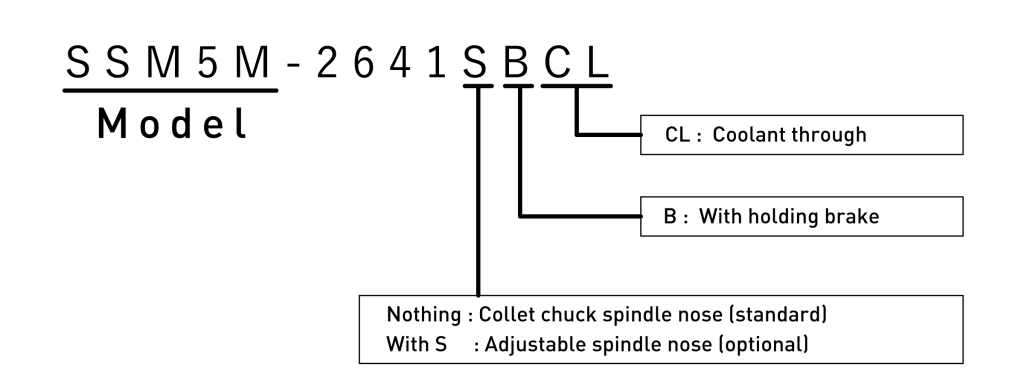

Model

Specifications

Feed shaft motor: 2.7 kW AC servo motor

Notes:

- The selection of models should be based on the shape of the workpiece, material, cutting characteristics, diameter and material of tools, rotation speed (cutting speed), etc.

- The drilling capacity displayed in the above table is based on values representing a drilling depth of two times the diameter of the drill.

- The power voltage of feed shaft controller and main shaft inverter has three phases AC 200 V ±10% 50/60 Hz.

- The servo motor for feed shaft is equipped with a holding brake.

- For SSM5, coolant center through specification is standard. Please contact us if this is not necessary.

Dimensions

SELFEEDER PNEUMATIC :

ALL AIR DRILLING UNIT

SELFEEDER PNEUMATIC SFB

Completely pneumatically driven small, light weight and low cost drilling unit!

“Selfeeder Pneumatic SFB” is a completely pneumatically driven drilling unit that uses air together with feed and rotation and has been evaluated in the market for more than 40 years.

Compact and does not take up space, allowing free installation direction of the arrangement.

Max. drilling size … φ7(Steel)/ φ8(Aluminum)

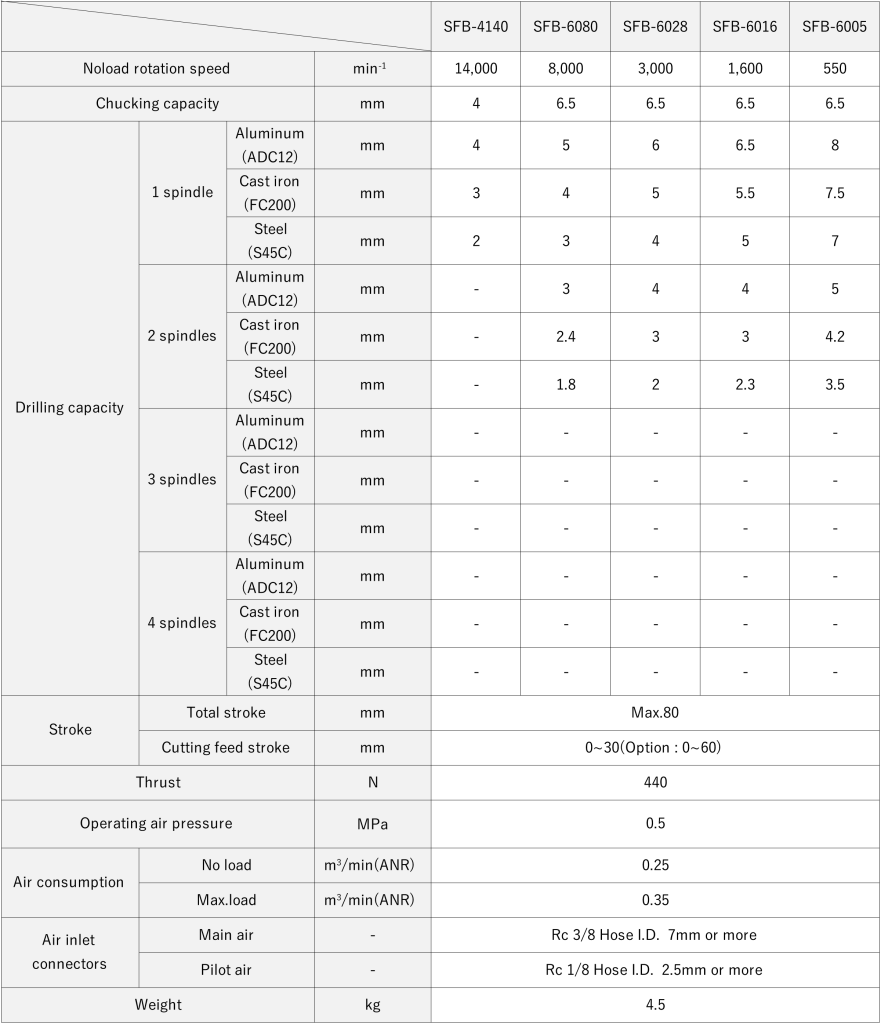

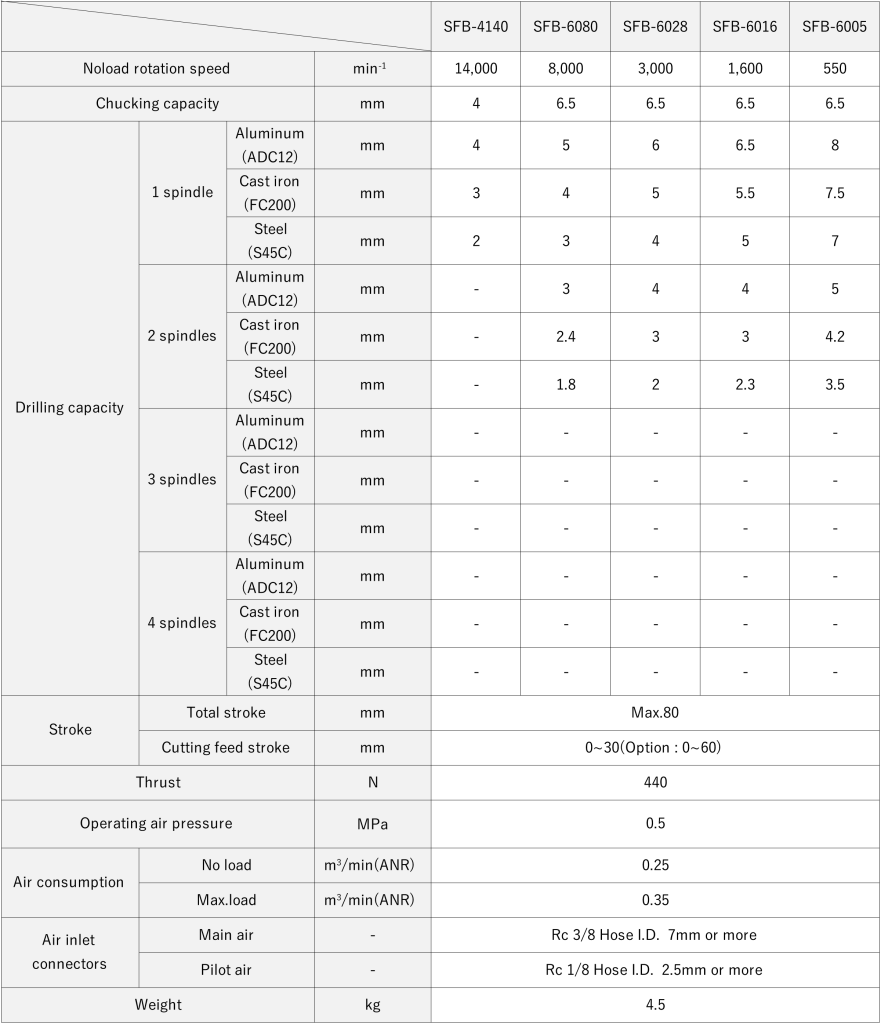

Specifications

Supplied air pressure: 0.5 MPa

Note:

- Maximum capacity drill size will vary depending on input operating air pressure. (Operating air pressure: 0.5MPa)

- In most cases of small hole drilling (φ1mm or less) except plastic; spindle speeds of 7,000min-1 or less are generally recommended.

- The RB-2430 is installed as a standard type Hydro-Speed Regulator. Specify an optional Hydro-Speed Regulator as necessary.

(Optional Hydro Speed Regulator models are: RB-2412, R-2460, R-2442A, and R-2462A)

*When installing a product other than RB-2430 or RB-2412, some parts will be changed. - Model selection should be done from the above chart, based on workpiece specifications, material hardness, diameter of hole and cutting speed.

- To achieve maximum power, it is necessary for the spindle to progress forward 7mm or more.

- When the hardness of the cemented carbide drill and tool shank is higher than that of a high speed steels, please contact our local distributor or subsidiary for detailed specifications.

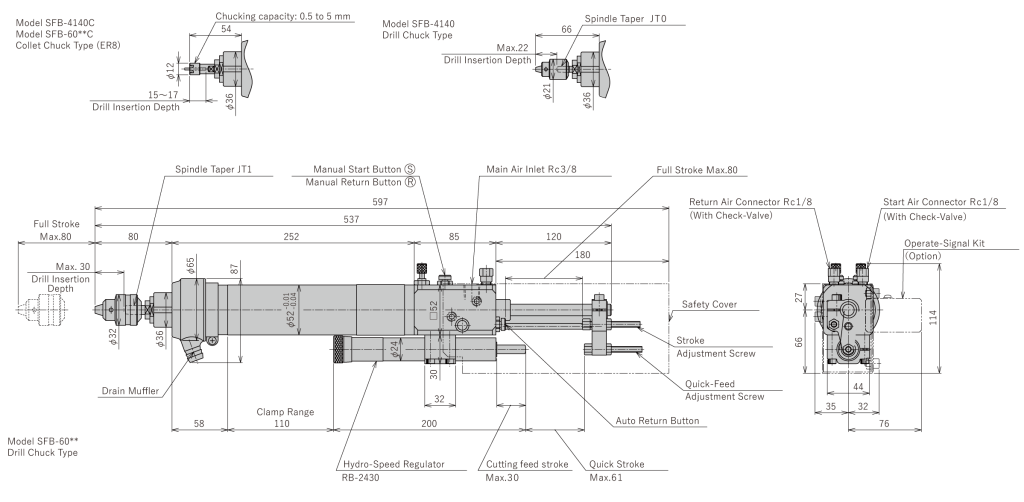

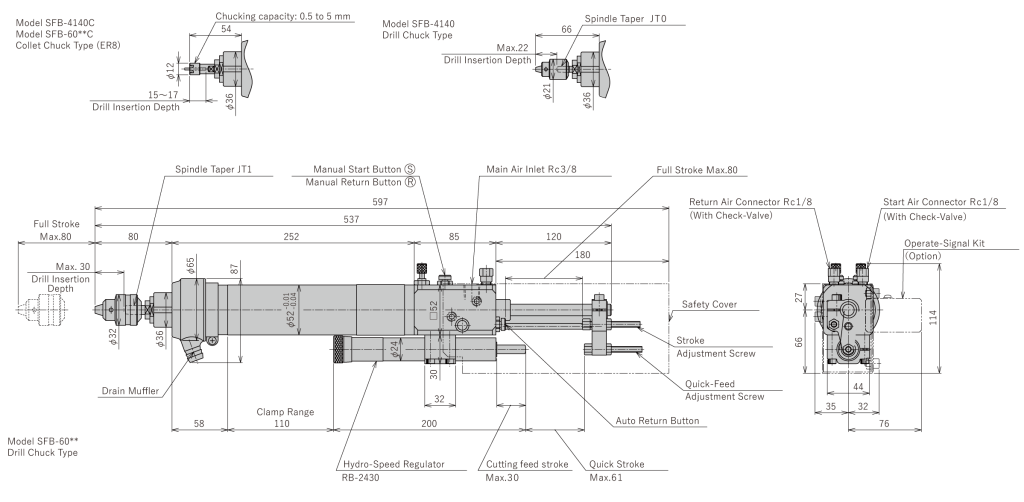

Dimensions

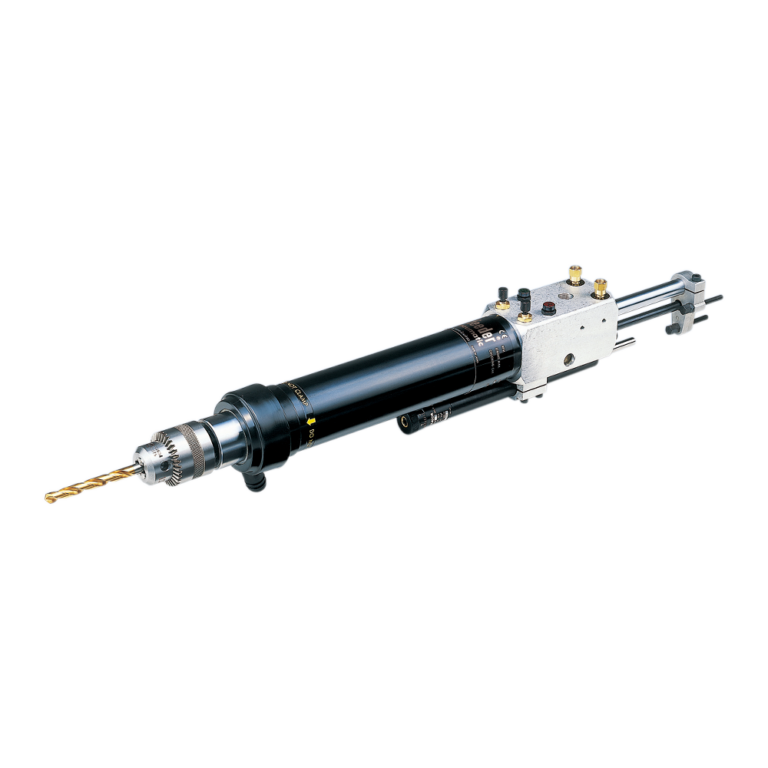

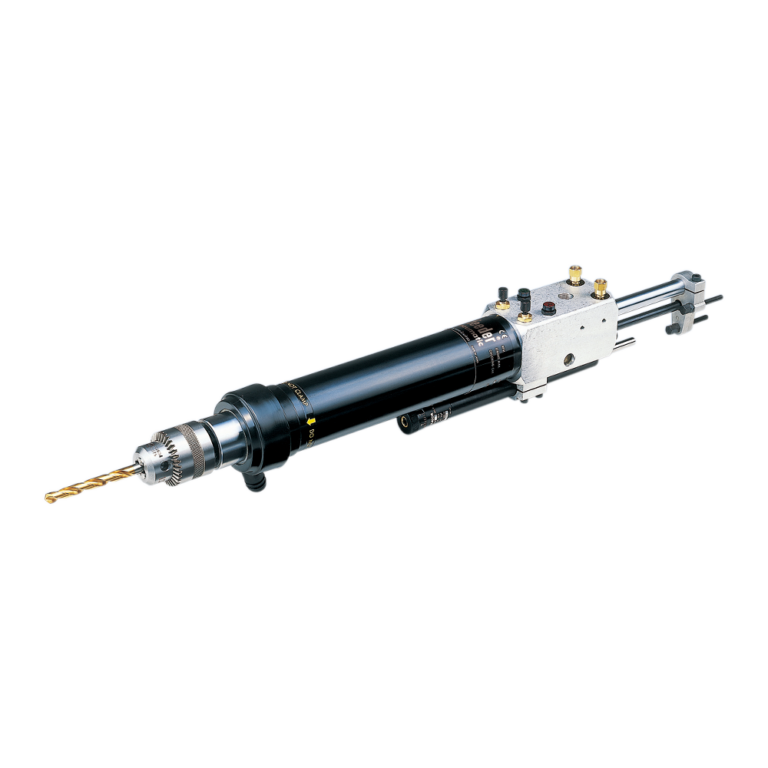

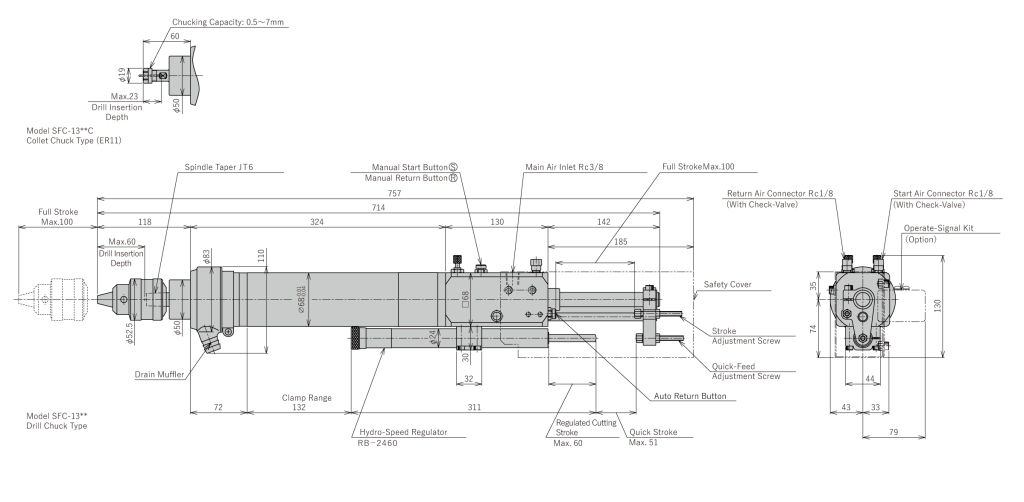

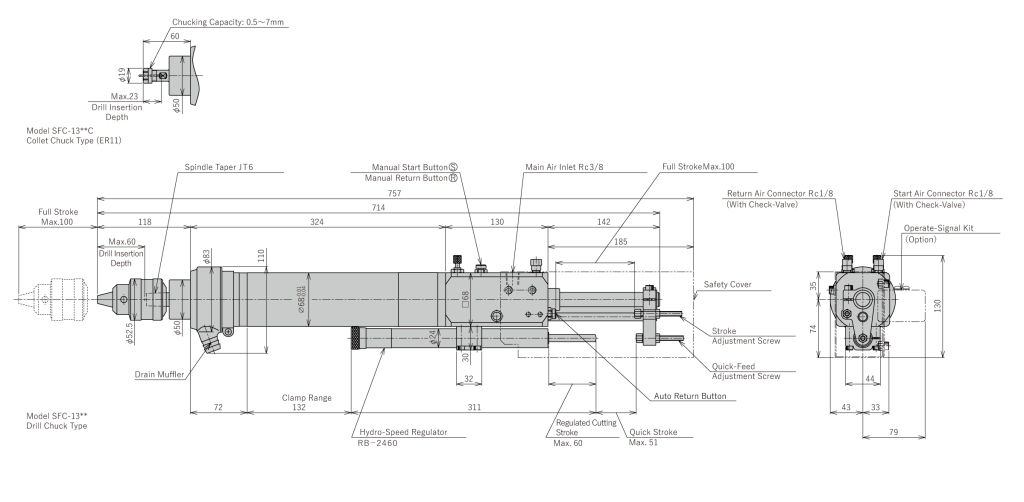

SELFEEDER PNEUMATIC SFC

Completely pneumatically driven drilling unit. Though it is compact, it also supports a multi-axis head!

“Selfeeder Pneumatic SFC” is a completely pneumatically driven drilling unit. In spite of the compact design, it is capable of drilling processing and supports a multi-axis head.

Max. drilling size … φ10(Steel)/ φ14(Aluminum)

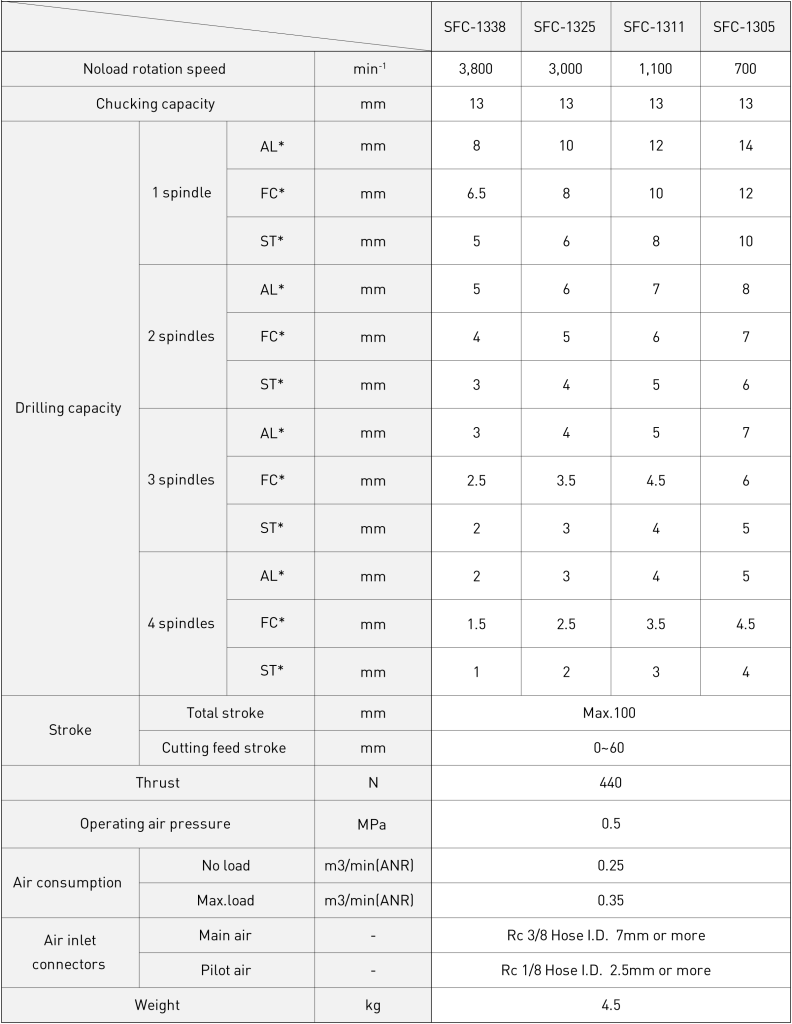

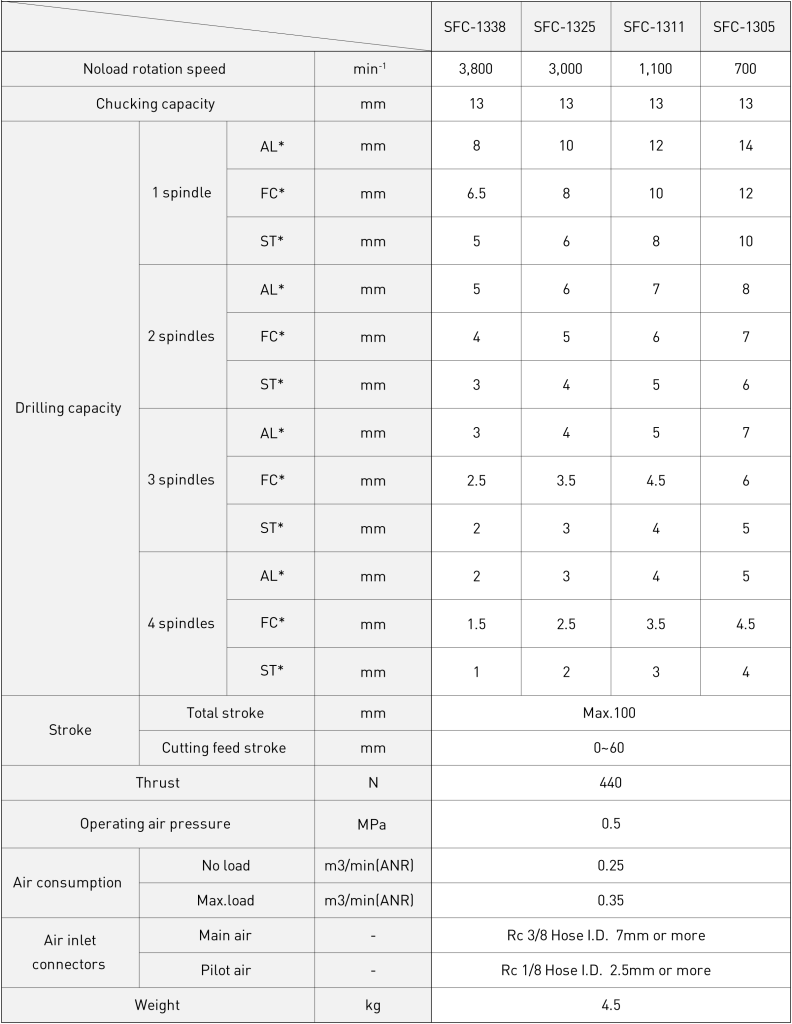

Specifications

Supply air pressure at 0.5 MPa

Notes:

- Maximum capacity drill size will vary depending on input operating air pressure. (Operating air pressure: 0.5MPa)

- The RB-2460 is installed as a standard type Hydro-Speed Regulator. Specify an optional Hydro-Speed Regulator as necessary.

(Optional Hydro Speed Regulator models are: R-2442A, R-2462A, and R-2482A)

*When installing a product other than RB-2460, some parts will be changed. - Model selection should be done from the above chart , based on workpiece specifications, material hardness, diameter of hole and cutting speed.

- To achieve maximum power, it is necessary for the spindle to progress forward 7mm or more.

- When the hardness of the cemented carbide drill and tool shank is higher than that of a high speed steels, please contact our local distributor or

subsidiary for detailed specifications. - AL : Aluminum(ADC12) , FC : Cast iron(FC200) , ST : Steel(S45C)

Dimensions

PNEUCONFEEDER AND ELECONFEEDER :

DRILLING UNIT FOR AEROSPACE

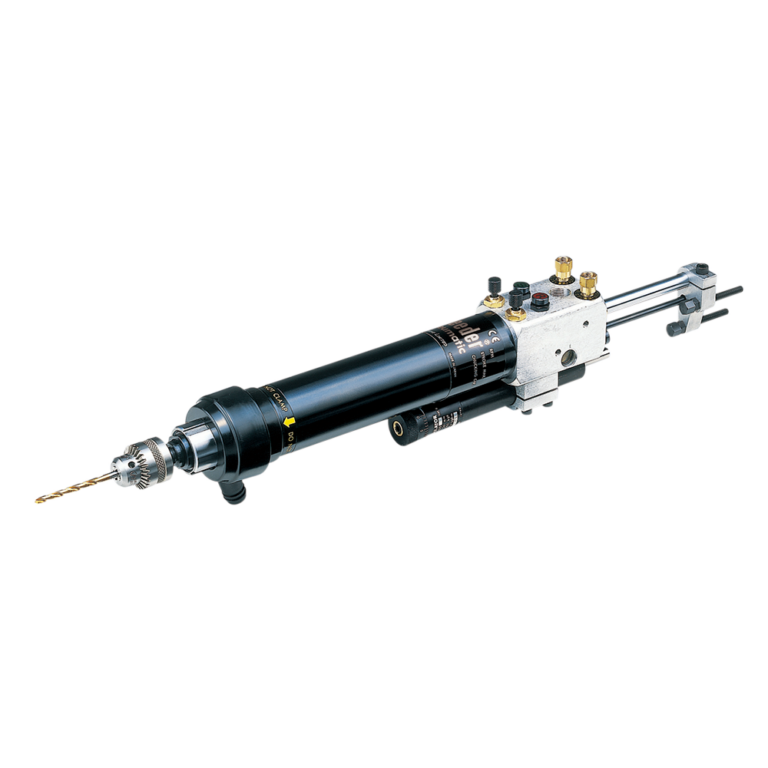

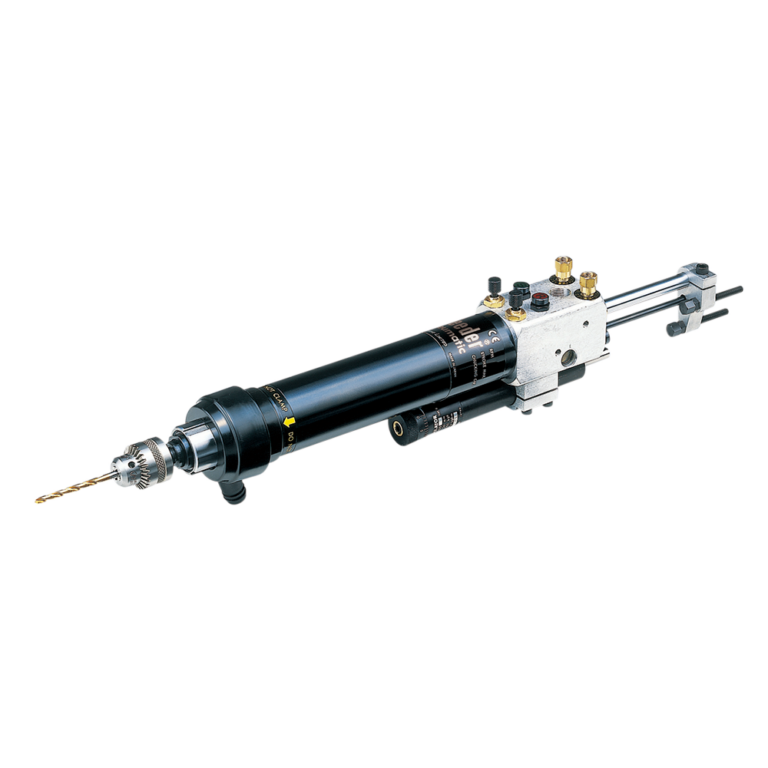

PNEUCONFEEDER

ELECONFEEDER

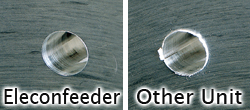

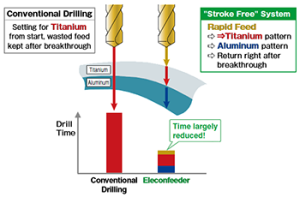

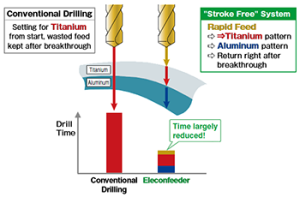

Achieving high precision and high efficiency in the drilling processes for aerospace composite structural material!

Two types of drilling unit are available, all air type and servo feed type.

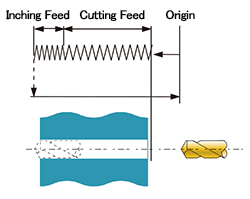

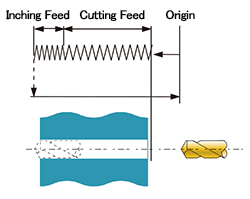

Portable Drilling Unit [Air-driven Type] "Pneuconfeeder"

All air-driven and portable drilling unit for aerospace!

Pneuconfeeder is air-driven type equipped with a durable high torque air motor.

This compact and lightweight unit utilizes Sugino Machine’s drilling technology.

Features

1.All Air-Driven

On-board adjustments for the air feed and rotation enable laminated materials to be drilled efficiently.

2. Control Delamination and Burr Generation

And 2-step speed control can provide inching feed drill mode at the exit of the drilled hole to minimize the occurrence of burrs at break through and material delamination.

Portable Drilling Unit [Servo-driven Type] "ELECONFEEDER"

No stroke setting is required even for laminated materials.

Portable drilling unit for aerospace!

The Eleconfeeder is servo-driven type equipped with a compact yet high power motor.

This very flexible, high-end model can achieve drilling processes at the best cutting conditions.

Features

1.Even drilling complex laminated materials with high precision and high efficiency.

It is equipped with Sugino’s original “Stroke free” system.

For laminations consisting of different materials and thickness, the drill mode switches to its best condition automatically per material hence the drilling precision and drill bit life improve.

2.Control Delamination and Burr Generation

Eleconfeeder can adjust the feed rate automatically at drill bit breakthrough which minimizes an exit burr and delamination.