Machining Center

Vertical Type

Features

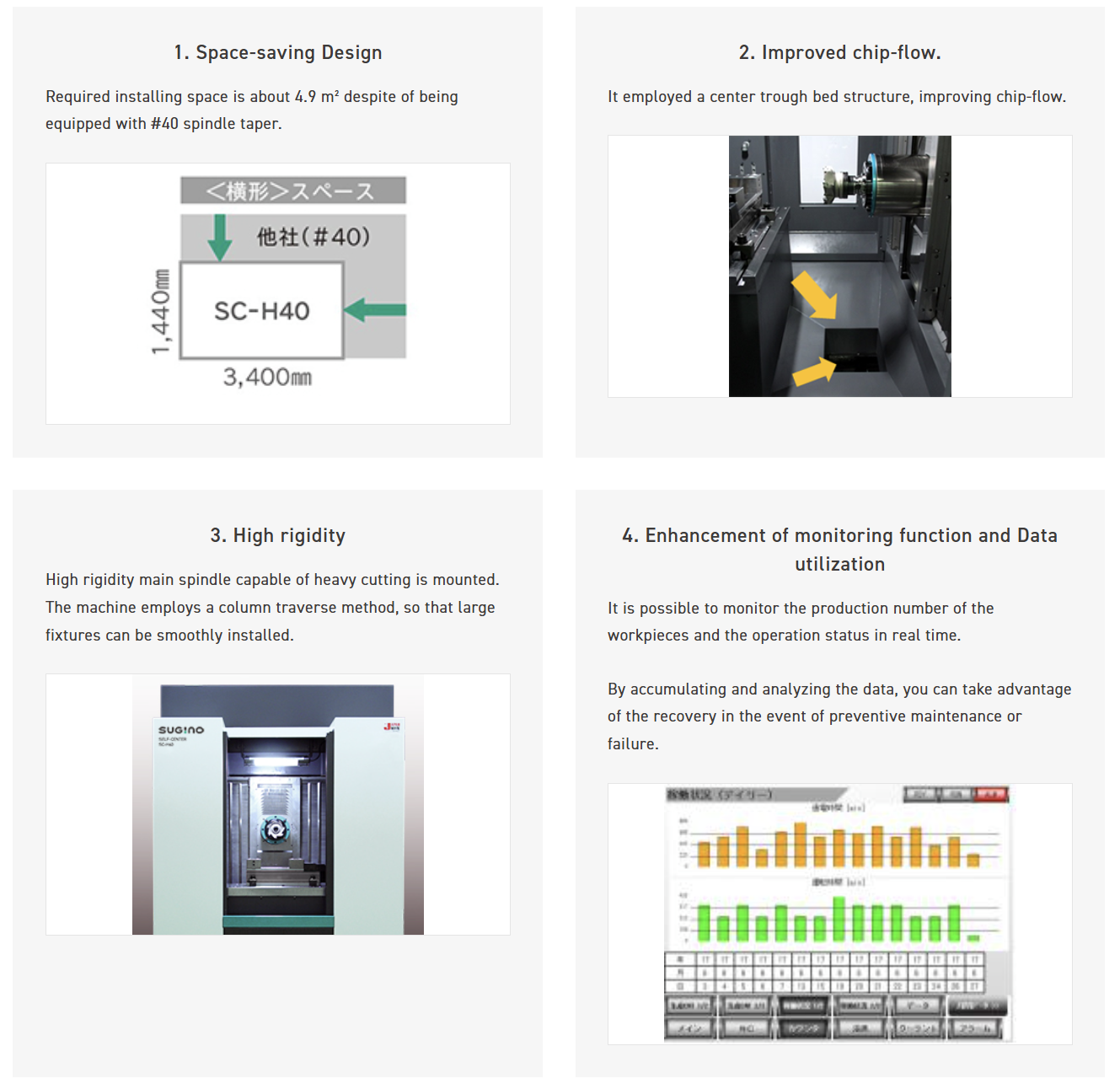

1.Industry’s smallest class #40 compact machining center

A space-saving design with the smallest footprint among #40 machining centers.

The main unit has a footprint of just 1,440 x 3,245 mm, allowing you to maximize the use of your factory space.

For example, in the space previously occupied by three #40 machining centers from other manufacturers, the compact SC-V40a allows for the installation of four units. Even a single unit is easy to install, allowing for effective use of available space within the factory.

2. Spacious machining area

Despite its compact width of 1,440 mm, it achieves an impressive machining area with an X-axis stroke of 700 mm. This allows for the machining of large workpieces in a space-saving design, enhancing productivity per unit of installation footprint.

3. High-speed, Short-cycle machining

By reducing the distance from the spindle center to the sliding surface to one-third of that in conventional machines, we have minimized the moment load on the main unit. Through thorough structural analysis and simulation using CAE, we have lightweighted the moving parts while maintaining rigidity.

Featuring top-class high-speed performance among #40 machining centers, it reduces non-cutting time by 25% compared to competitors’ products. This contributes to shorter cycle times for a wide range of materials, including aluminum, steel, plastics, and brittle materials.

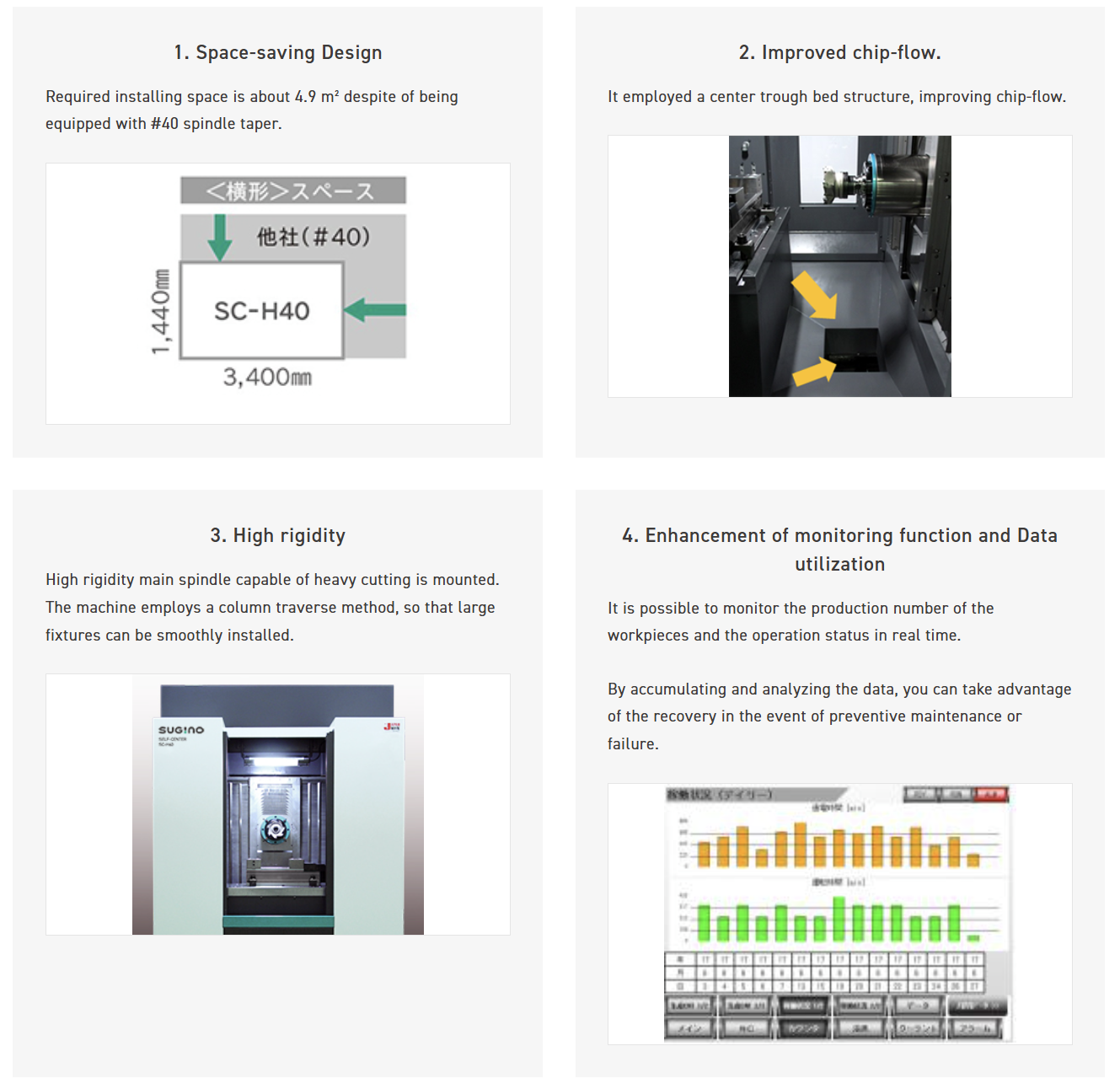

4. Thorough chip control

By ensuring effective chip removal and disposal, we prevent processing quality issues and minimize unexpected downtime, thereby enhancing productivity.

Tool magazine and feed axes are completely separated from the machining area to prevent issues caused by chips.

Despite being a vertical machining center, a center trough bed structure is adopted to double the chip discharge capability compared to conventional machines.

5. Contribution to the environment and sustainability

A space-saving design, which is the smallest class among #40 machining centers, also contributes to reducing CO2 emissions.

By miniaturizing the equipment, the moving parts and motors are smaller, allowing for minimal power requirements.Additionally, by controlling auxiliary equipment such as motors and pumps with proprietary software, we have reduced operating time. This has resulted in approximately a 35% reduction in power consumption compared to typical #40 machining centers from other manufacturers.

6. One-stop solution available for jig design and transport systems

Sugino Machine not only provides machining centers but also handles the setup of jigs and transport systems as a comprehensive service. From initial consideration during installation to adjustments after delivery, Sugino Machine offers a one-stop solution.

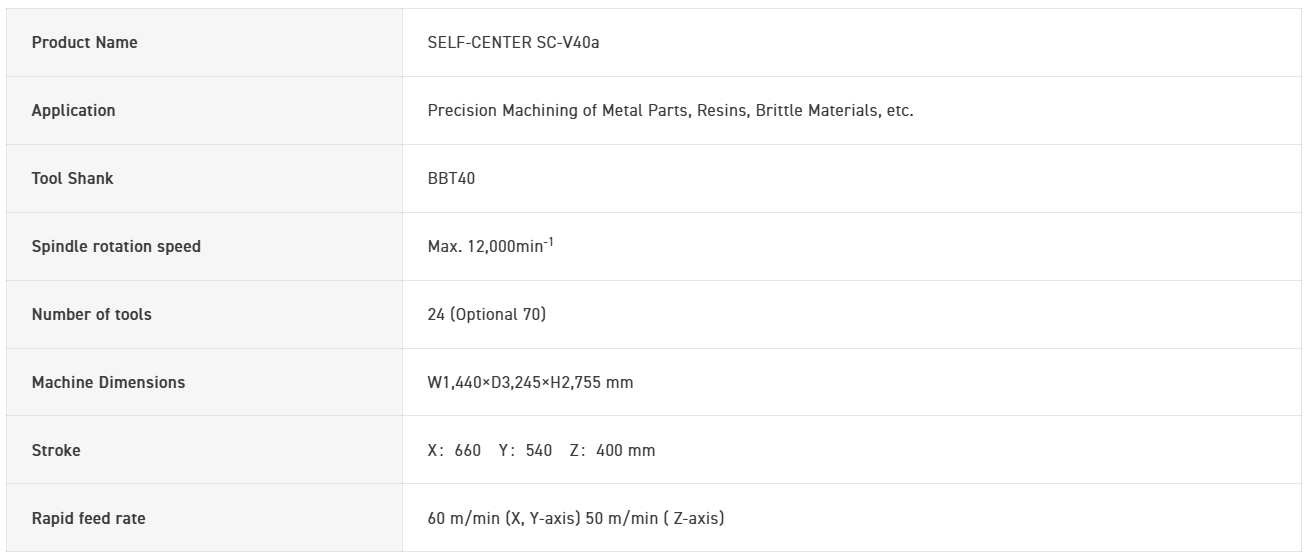

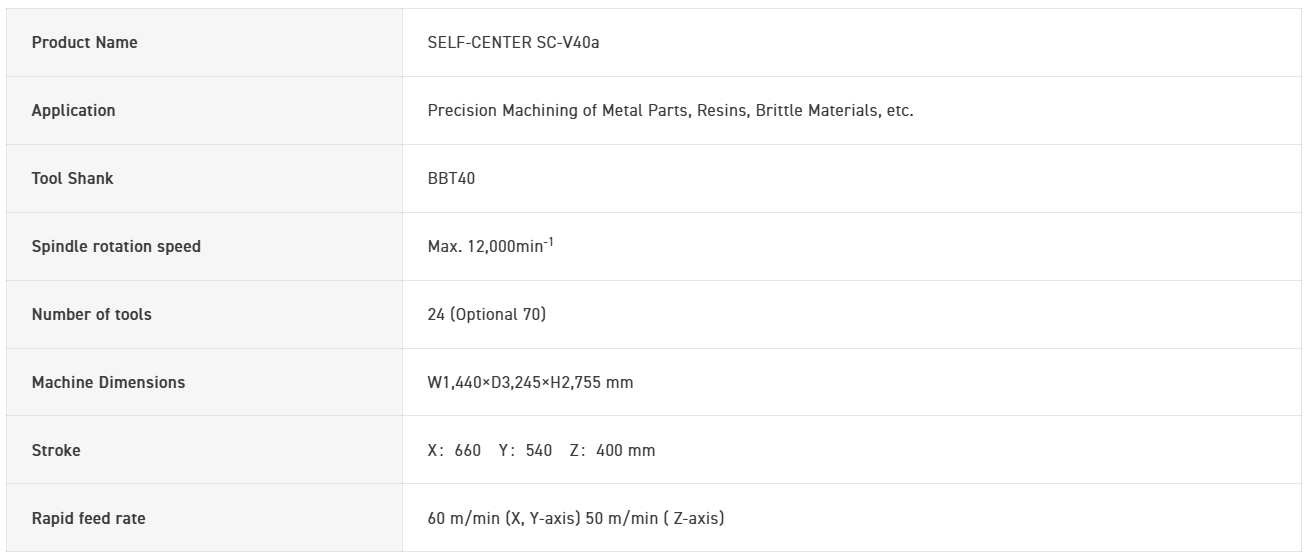

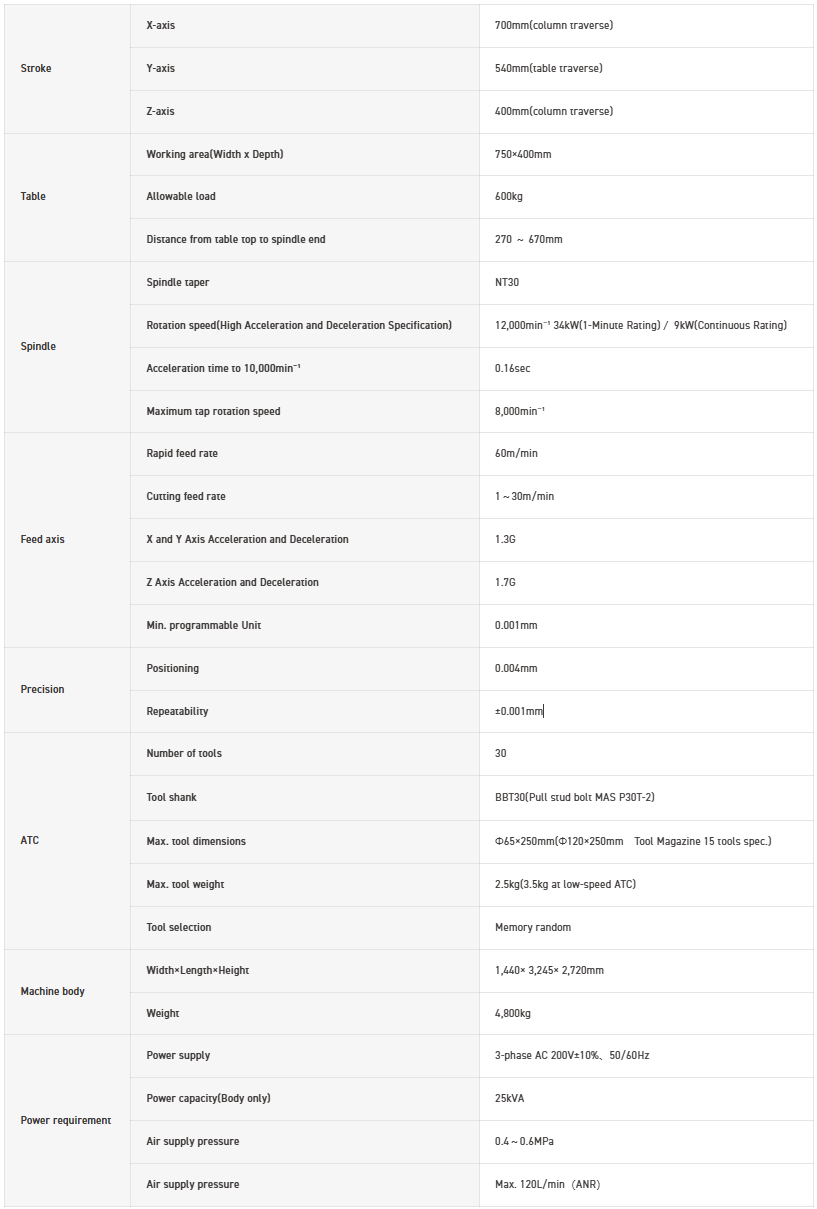

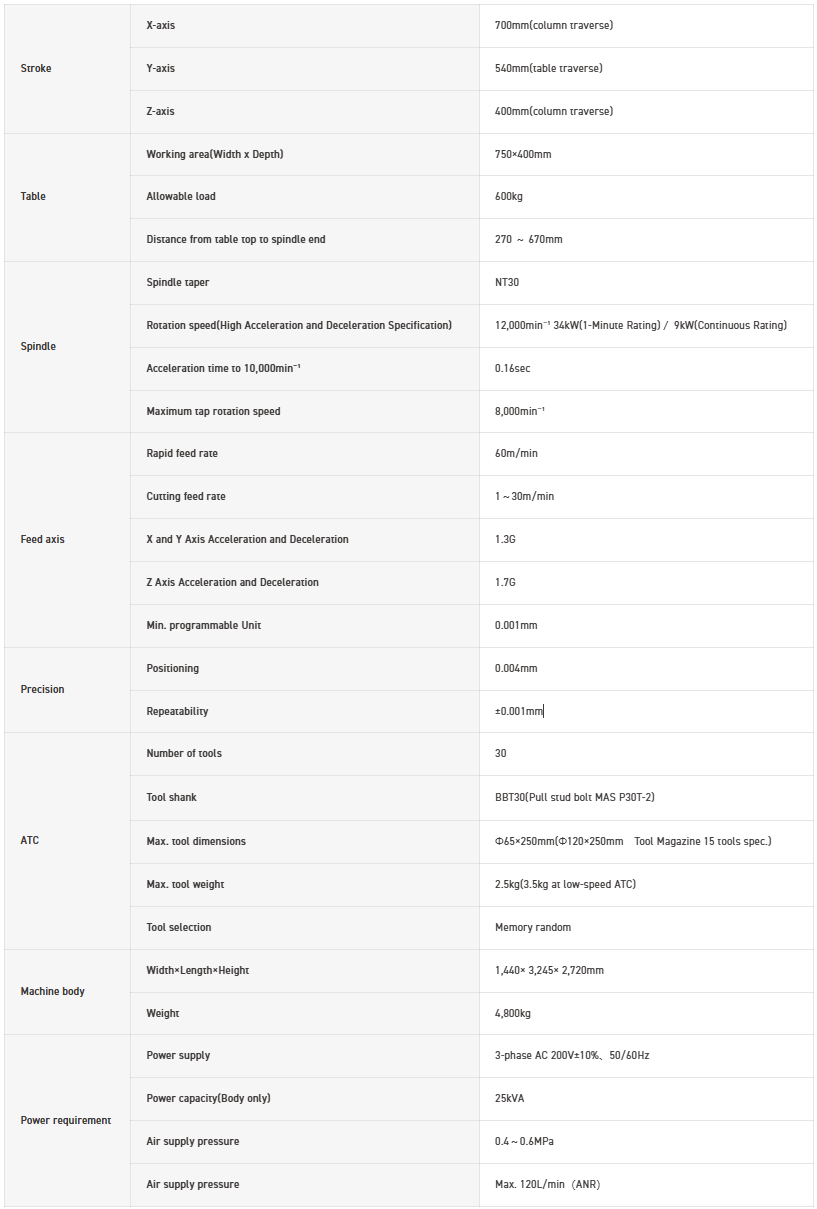

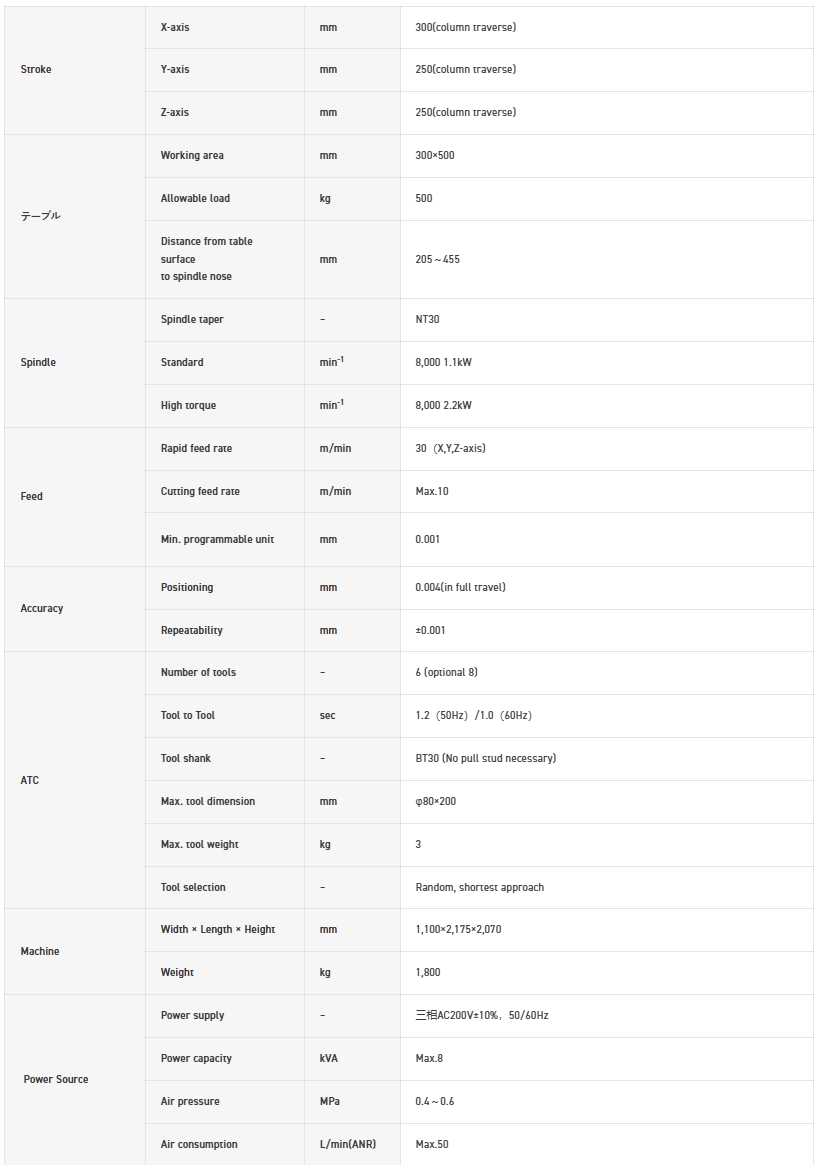

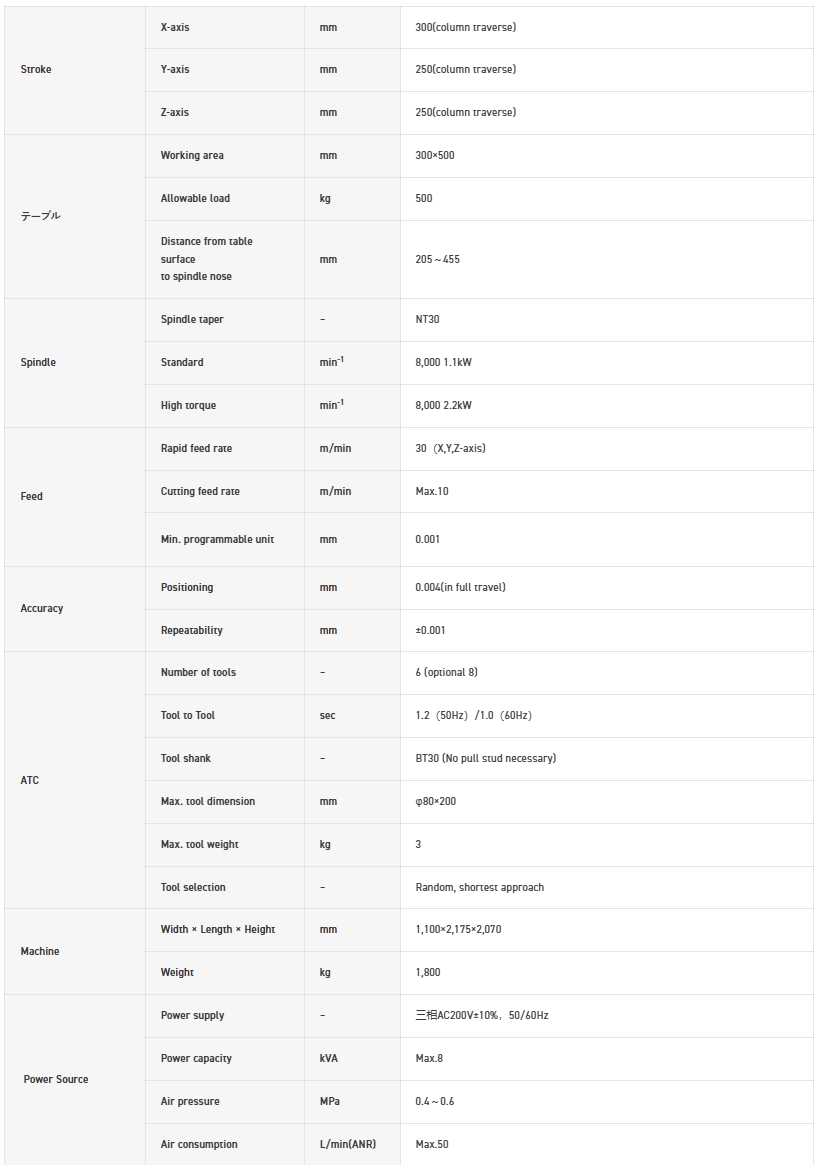

Specifications

Specifications

Basic Specifications

Main Features

- Column traverse

- High pressure coolant through

- High speed/high torque

- Turntable

- Automation compatible

- Unit specifications

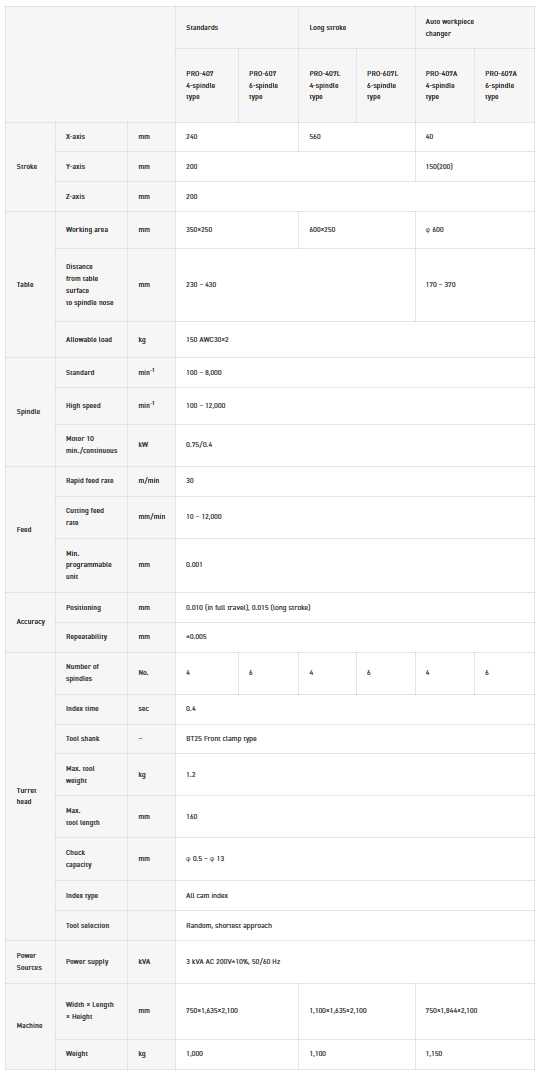

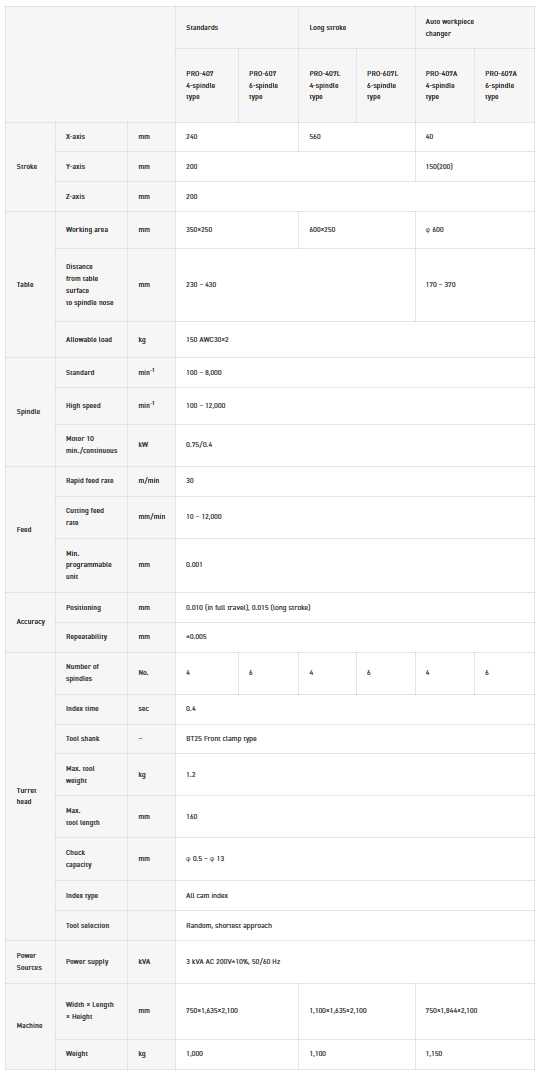

Specifications

Specifications

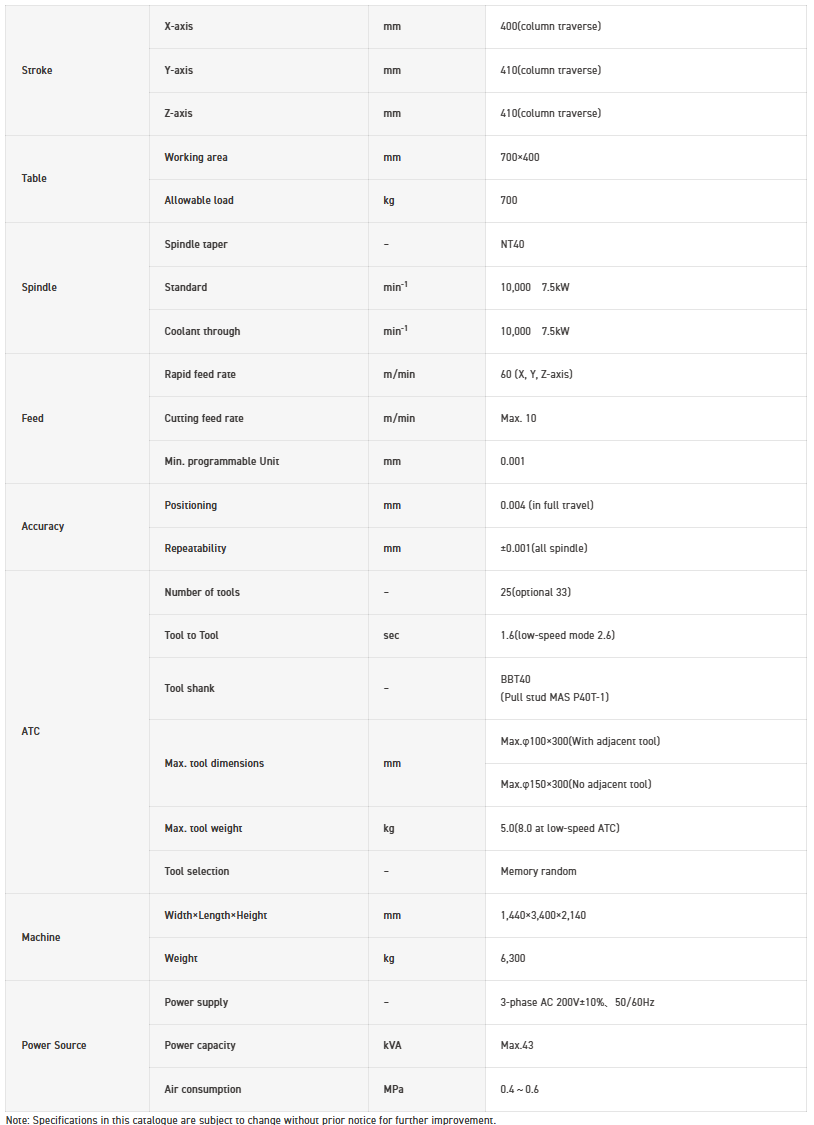

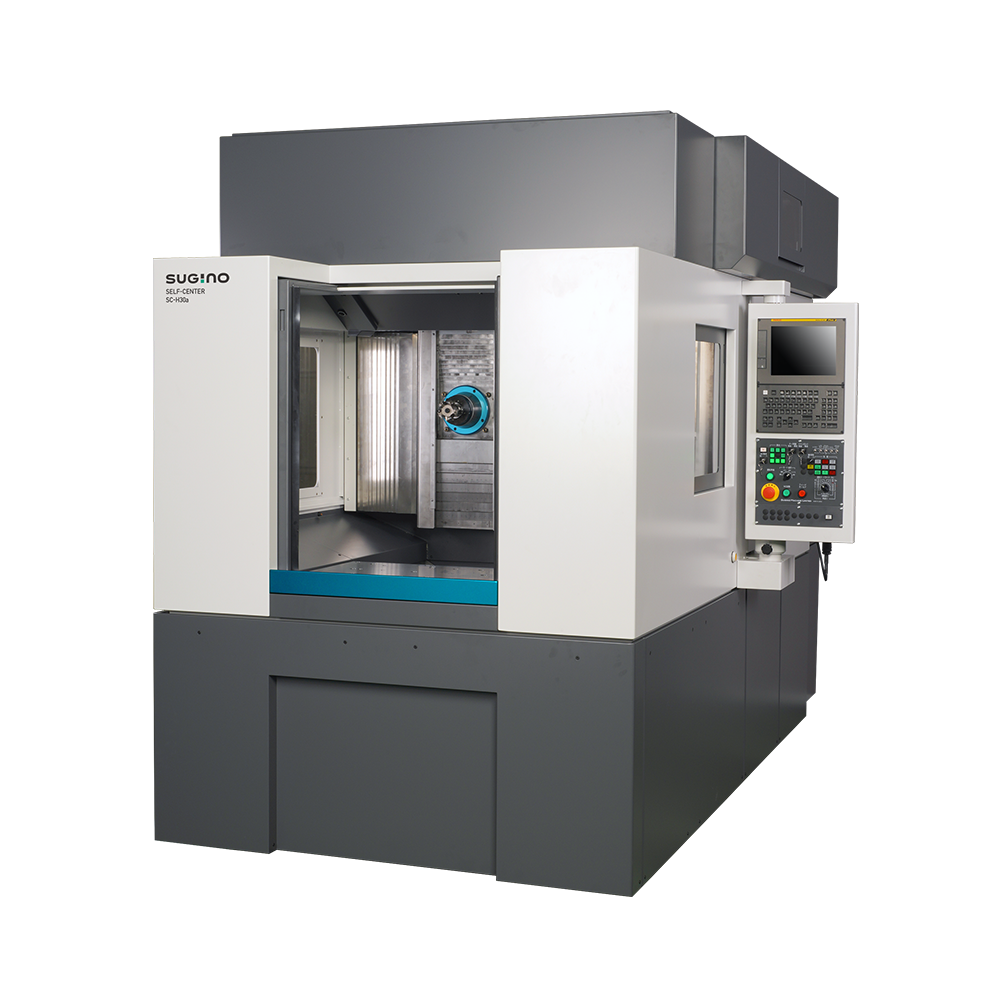

Horizontal Type

Features

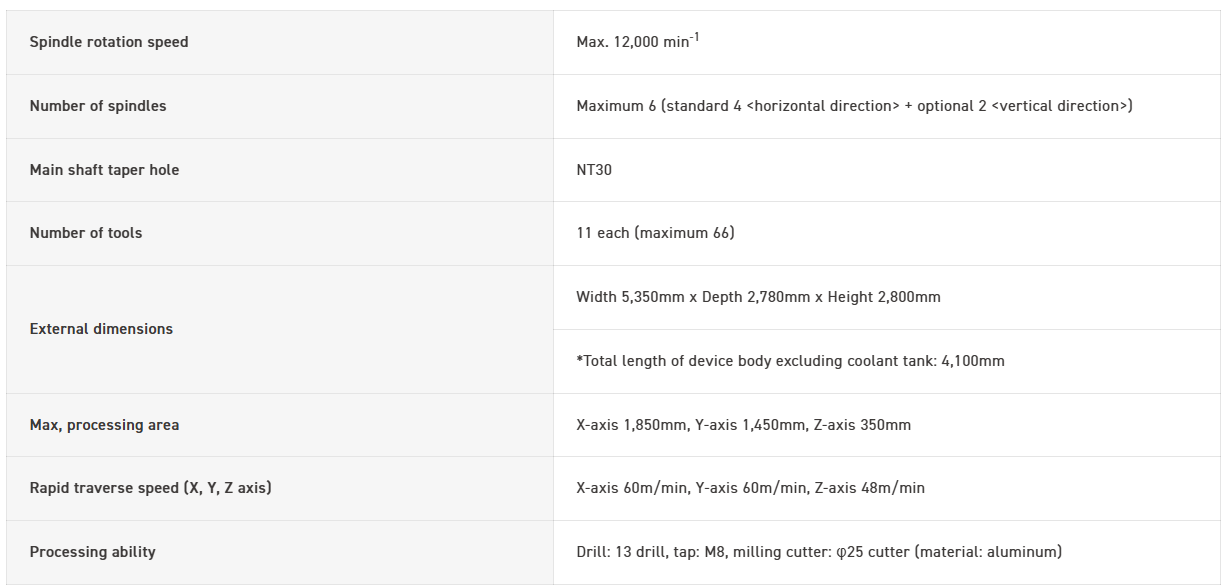

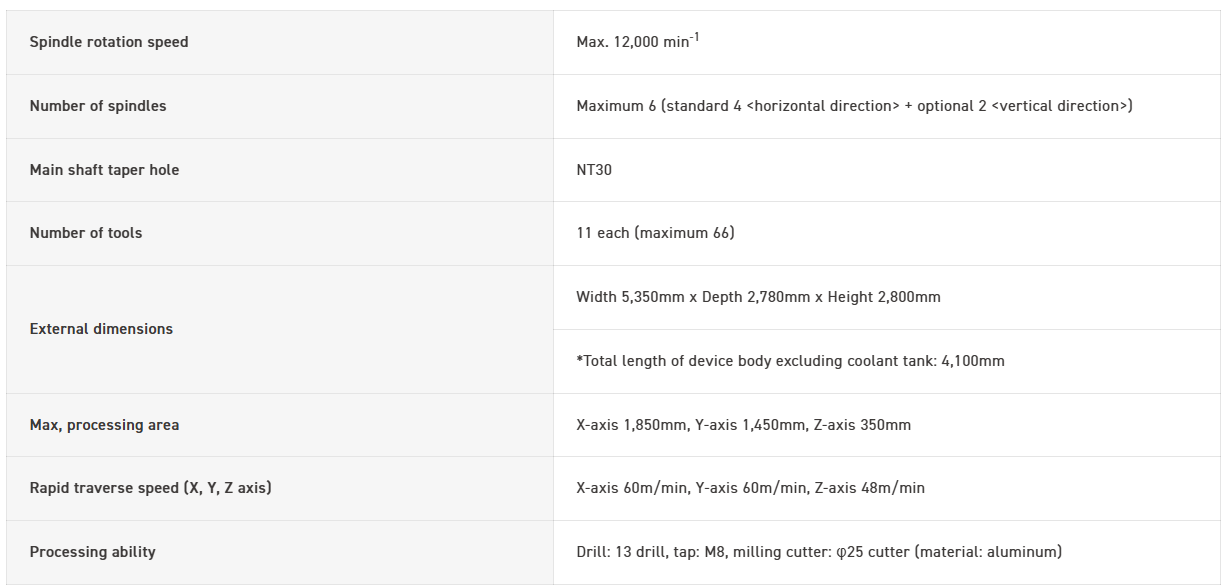

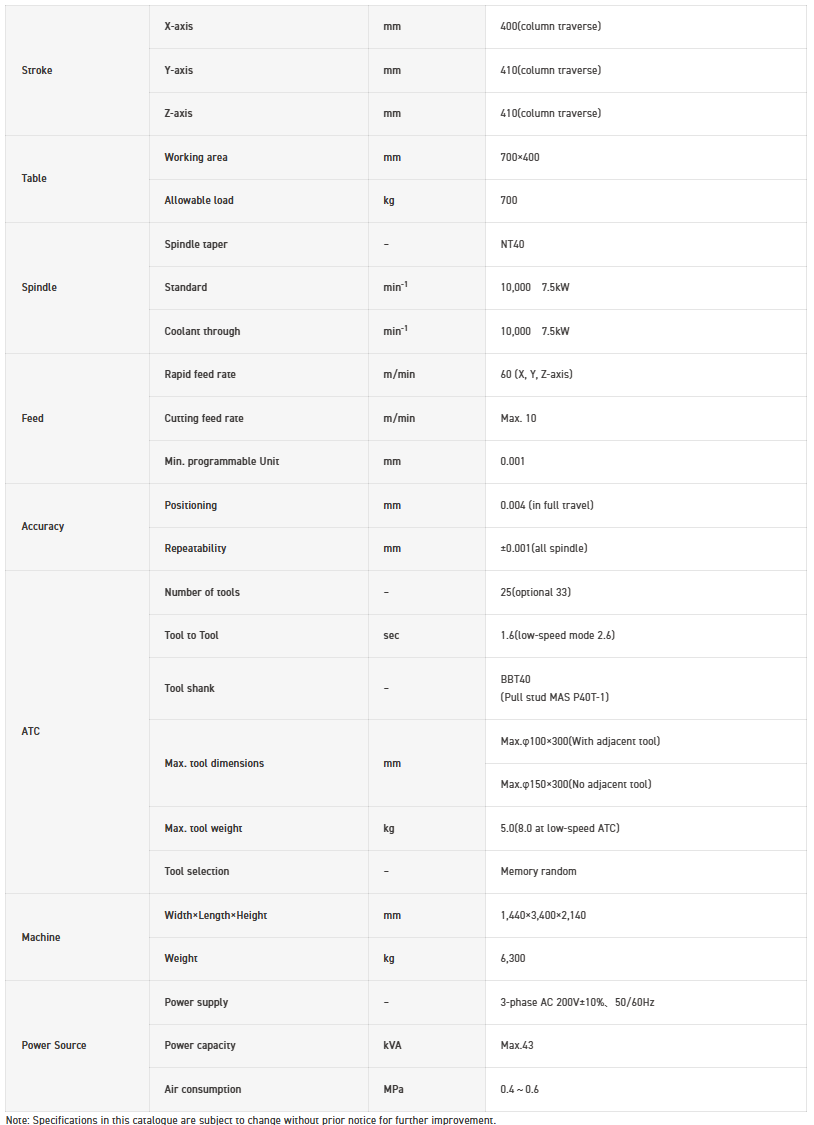

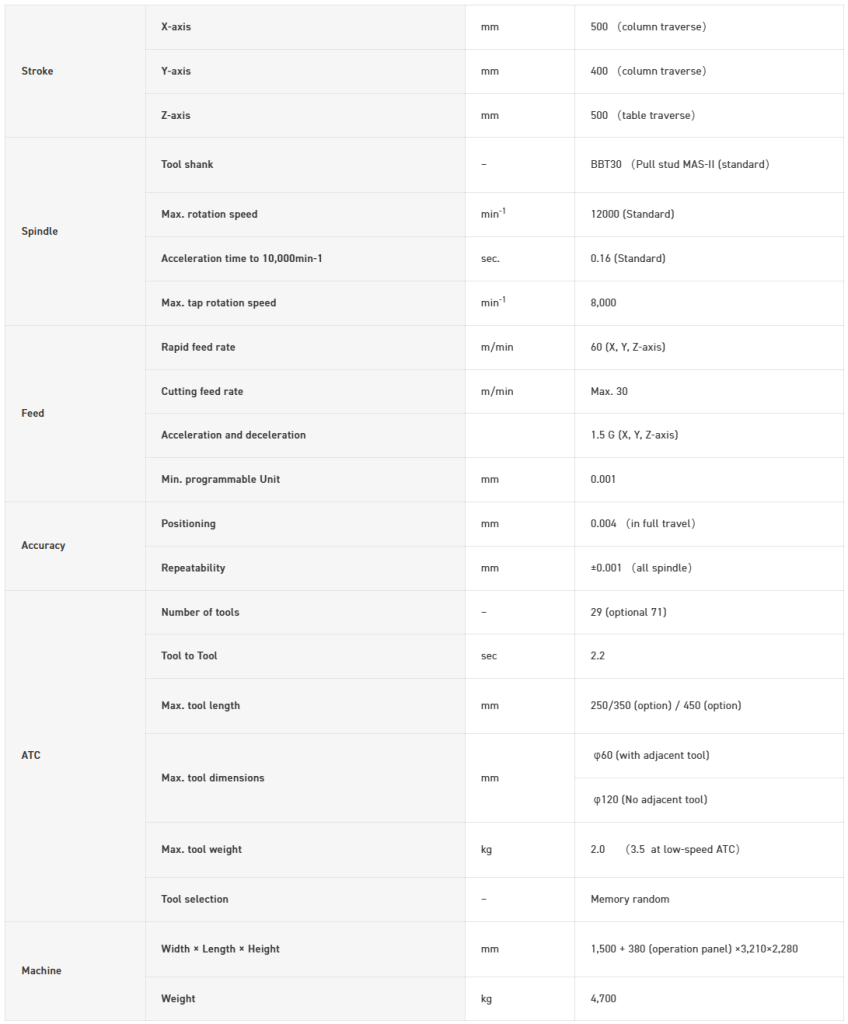

Specifications

Specifications

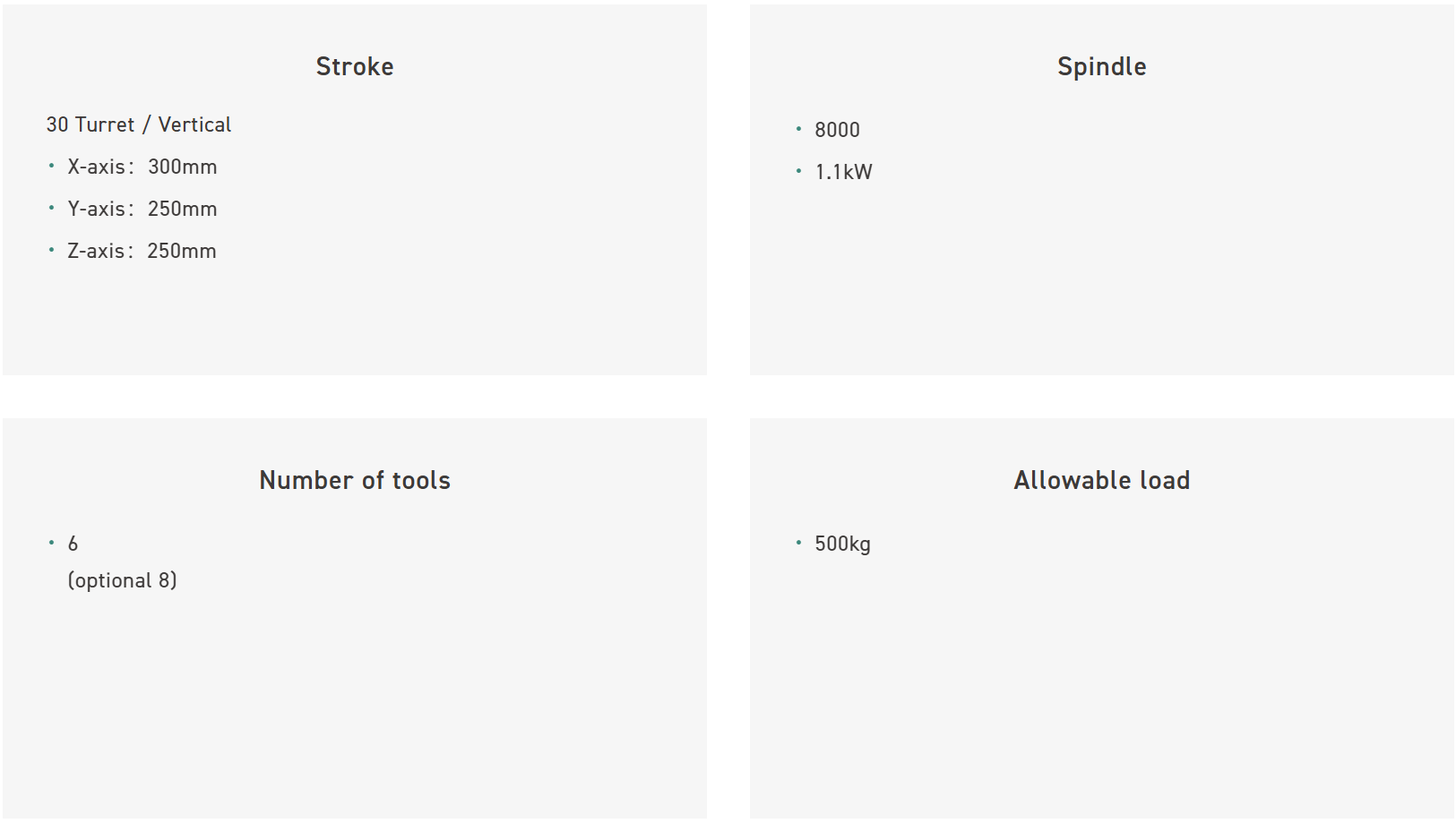

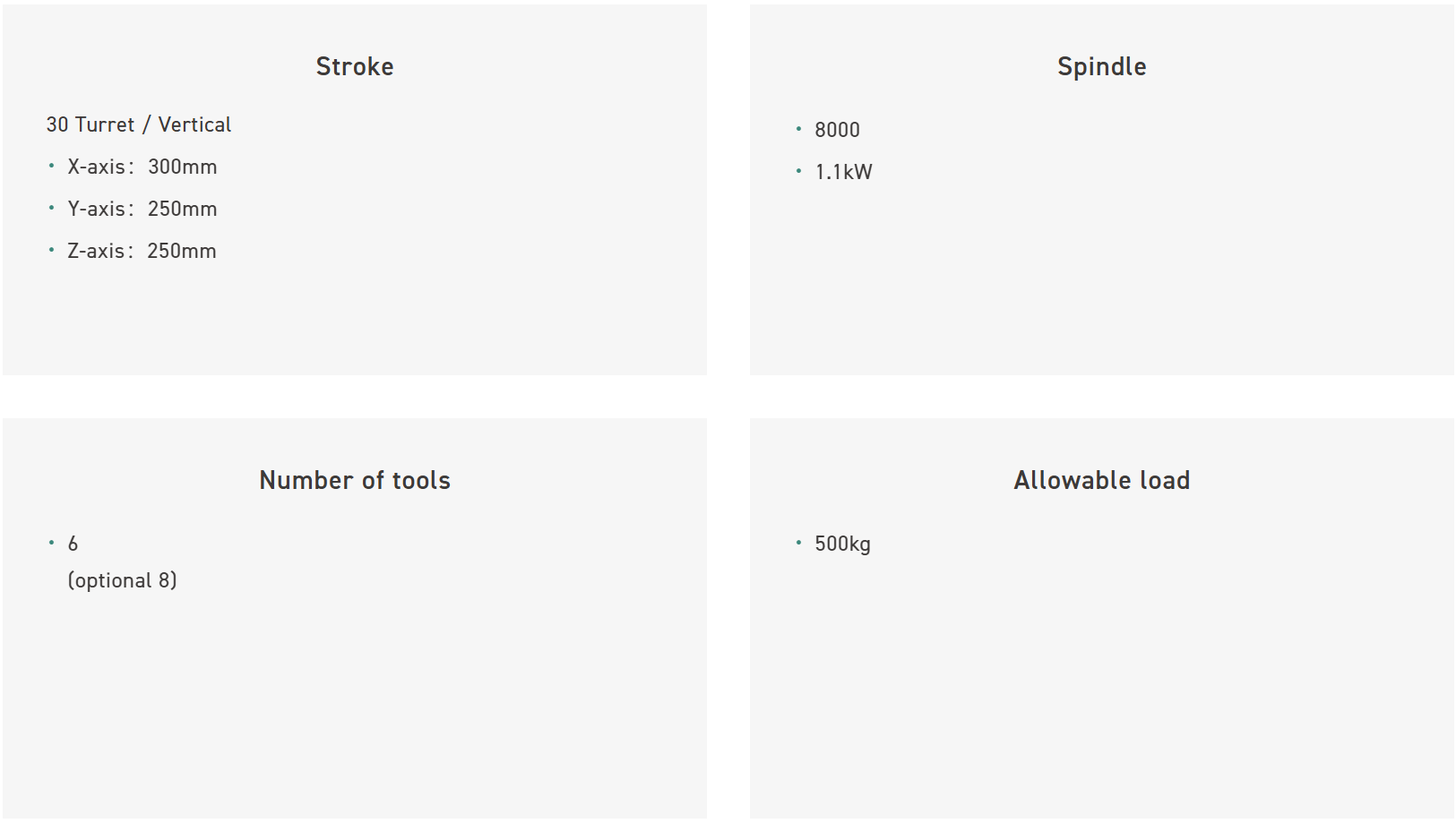

Unit Type

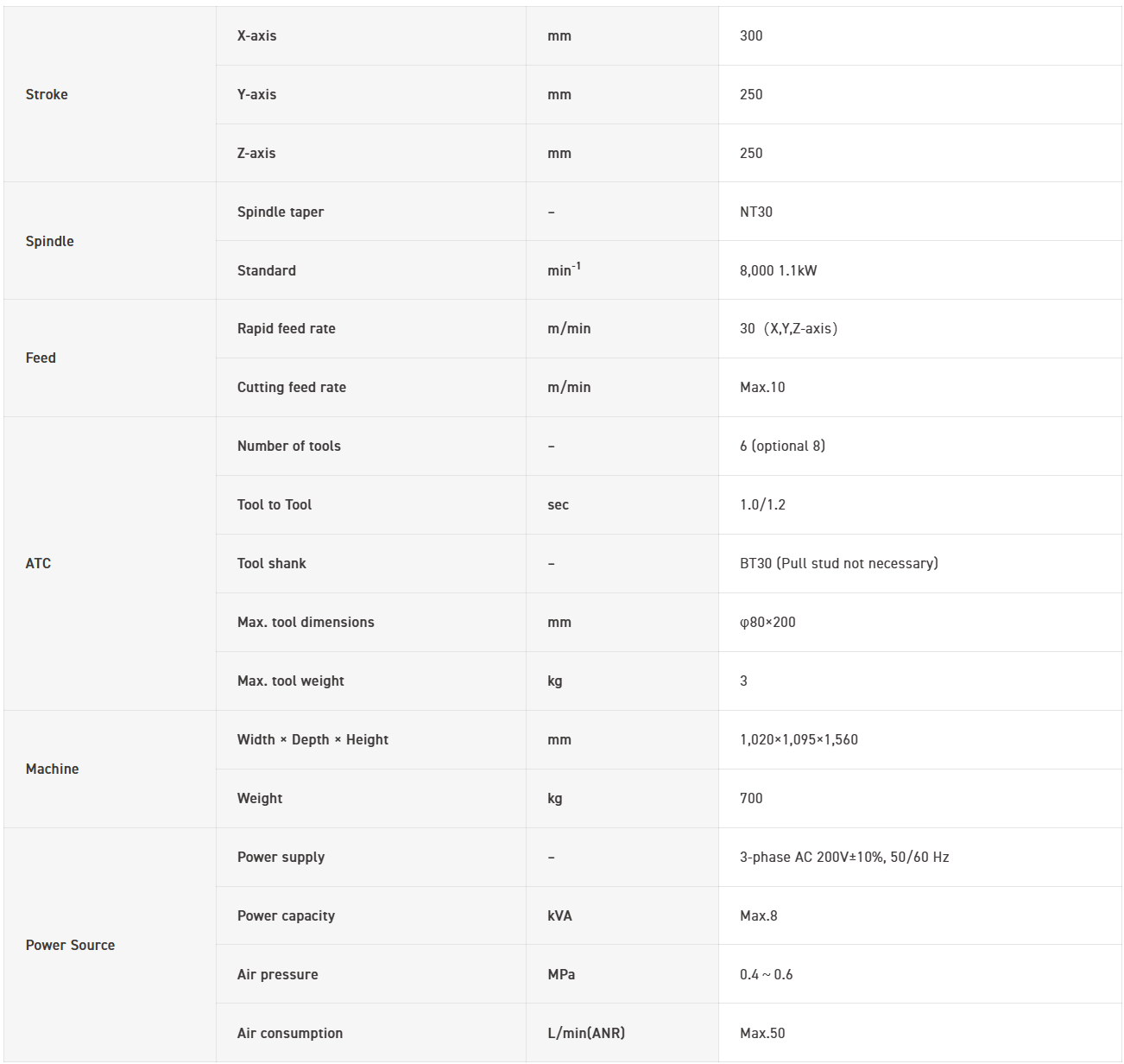

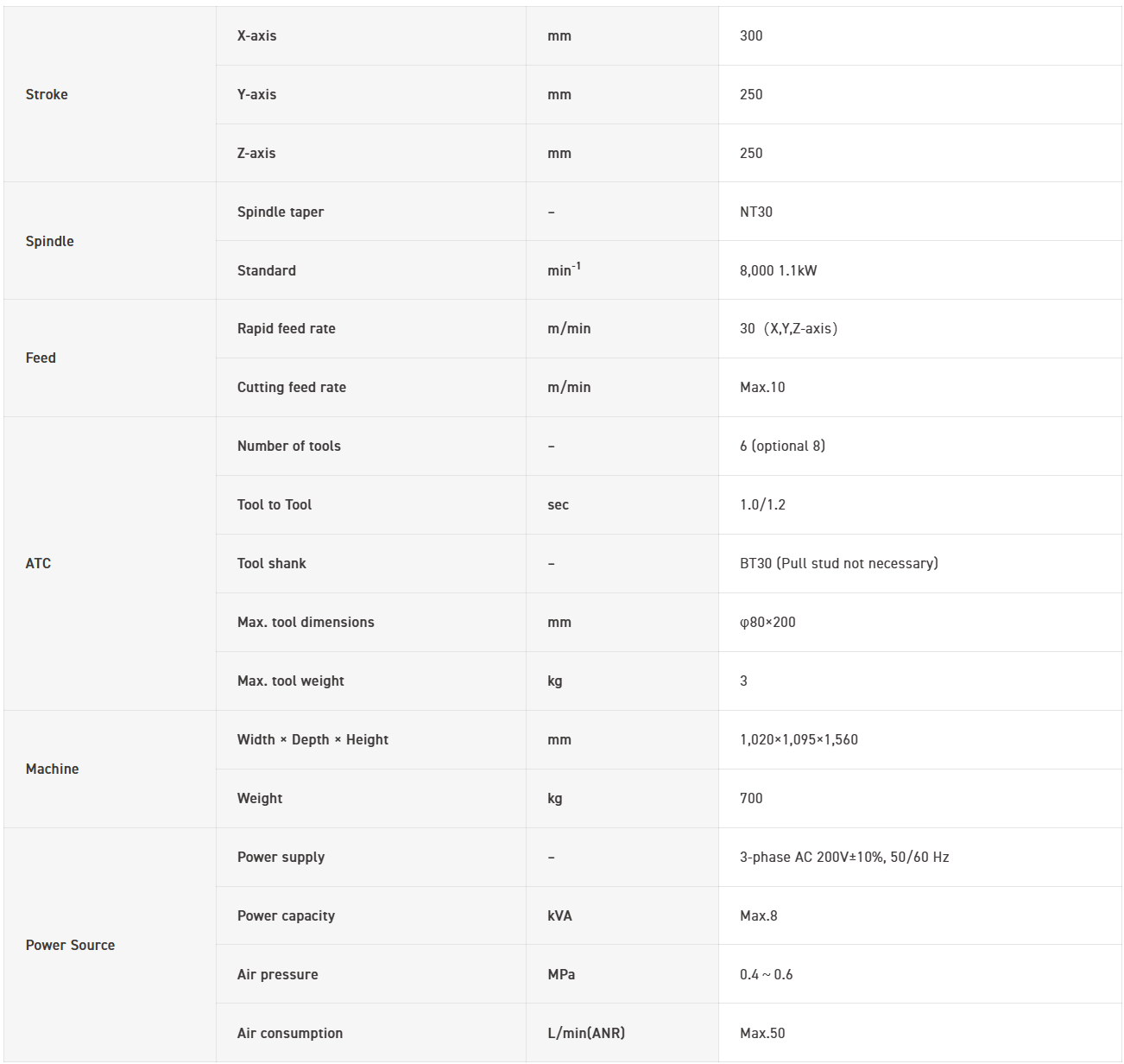

Self-Unit V6

Main Features

- Column traverse

- High pressure coolant through

- High speed/high torque

- Automation compatible

Specifications

Grinding Center

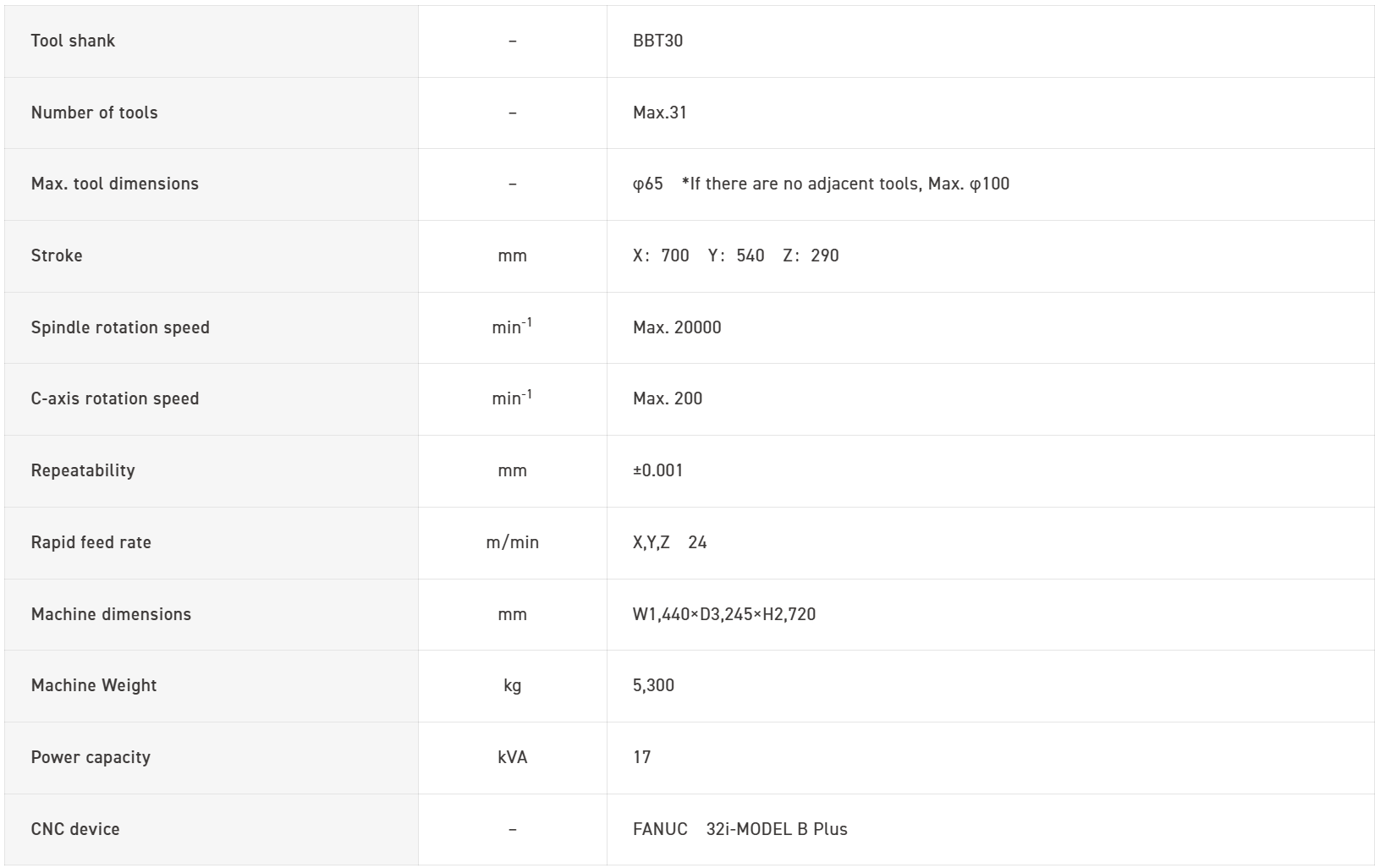

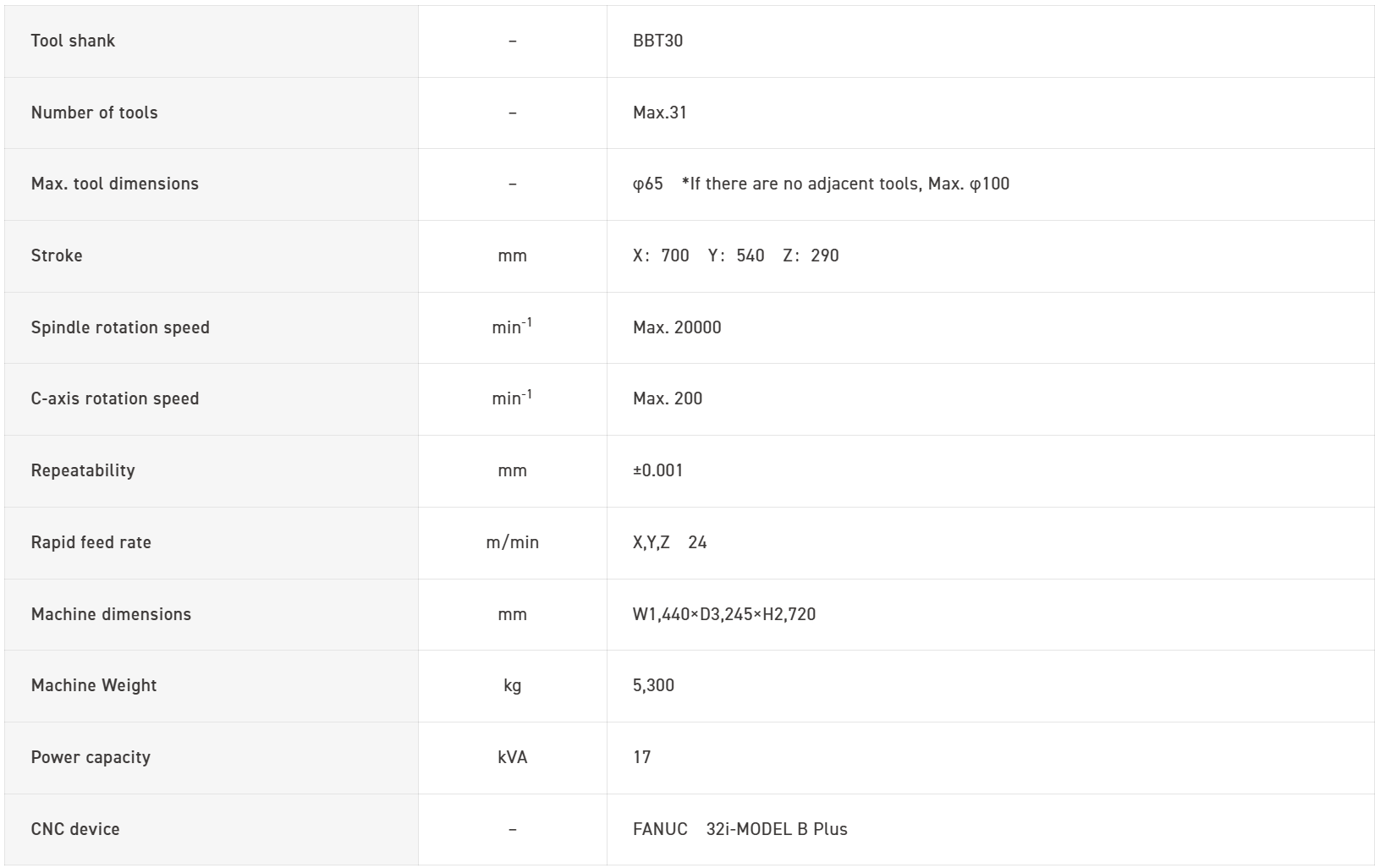

Self-Center SC-V30aG

Features

1.Process integration

Capable of small diameter hole and outer diameter machining with a single chuck.

With a maximum spindle speed of 20,000 min-1 and a maximum C-axis rotary table speed of 200 min-1, this machine enables machining of small diameter holes and outer diameters on brittle materials with a single machine.

Reducing alignment and adjustment tasks leads to automation and stable quality.

i.Equipped with a workpiece measurement camera

The camera automatically reads marks and sets the workpiece coordinates.

ii.Equipped with tool measurement and dressing device

With the tool measurement system, it manages the wear of grinding wheels and enables automatic truing and dressing.”

iii.Free from depending on individual skills by automation

Automating work coordinate setting and grinding wheel wear management moves away from manual tasks dependent on individual skills.

2.Space-saving

Achieving a large processing area while being a slim machine

The machine width is 1,440mm × depth 3,245mm, with a significantly wide stroke: X-axis 700mm, Y-axis 540mm, Z-axis 290mm, ensuring expansive travel relative to its width. Improving productivity per unit area.

3.High-precision support

High -precision specification with 8mm lead ball screw.

Switching the ball screw lead from 20mm to 8mm to achieve improved accuracy.

XYZ axis with scale feedback specification

Installing scale feedback devices to achieve high-precision positioning.

4.Thorough dust and rust prevention measures.

Bellows for Y and Z axes feature PVC-coating

Seamless PVC-coated fabric bellows are adopted.

Preventing sludge intrusion to protect LM guides and ball screws.

Surface treatment for ball screws and LM guides.

Performing reindent treatment on ball screws and LM guides to enhance corrosion resistance.

*Reindent treatment : Industrial black chrome plating

Electroplating technique for creating alloyed metallic surfaces.

Specifications

Large Parts Processing Machine

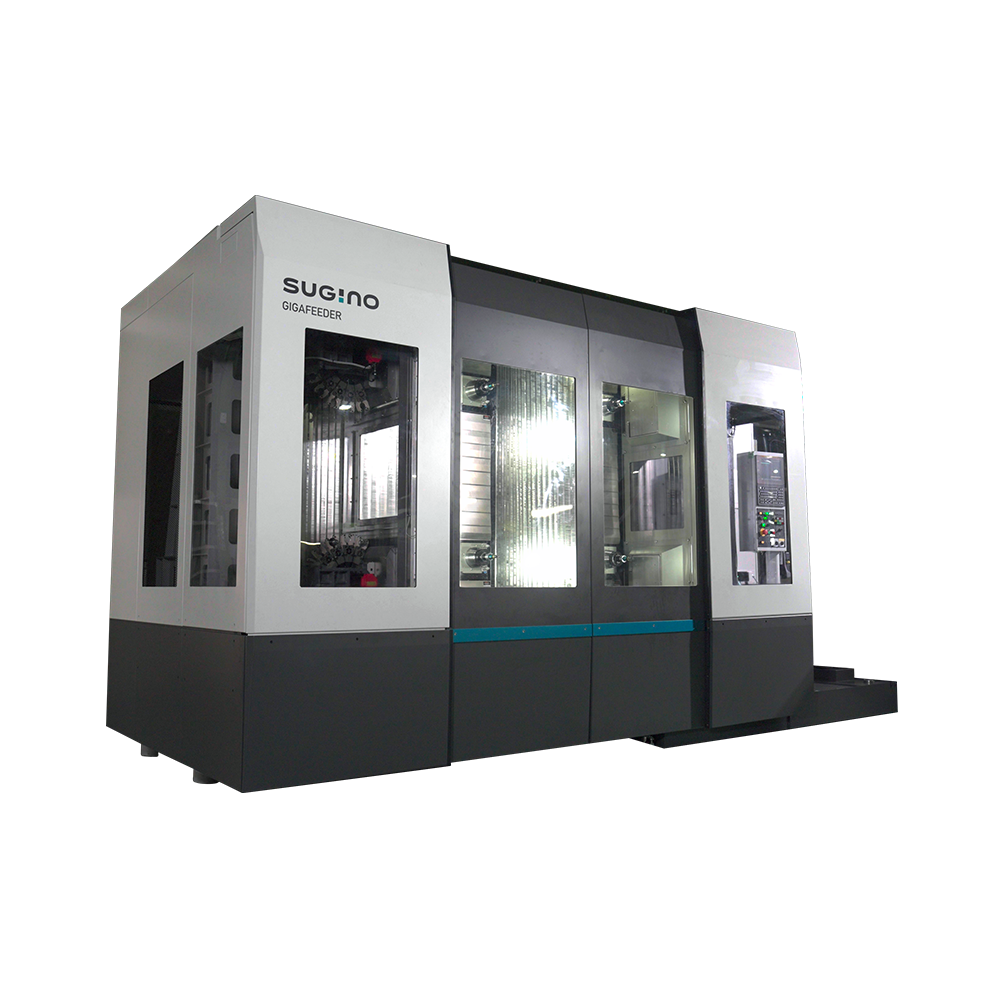

GIGAFEEDER

Features

Specifications