Compensating springback in CAD die surfaces

Achieve enormous time savings in die tryout with global surface morphing

The elastic properties of the sheet-metal cause springback after the forming of sheet metal parts. This springback is compensated in the sheet-metal die, so that the part is initially formed to an “incorrect” geometry and then springs back to yield the desired geometry. Manually grinding springback in the die is extremely time-consuming in the tryout presses Process reliability is also affected.

Tebis therefore uses global morphing rules with which individual surfaces can be deformed completely automatically based on FEM analyses, measurements, digitized data or experience – and feedback is compensated, greatly reducing the number of correction loops. The qualitative surface properties such as segmentation, polynomial degree, and transitions are optimally adjusted to the morphing rule in this CAD-based morphing. Analysis functions indicate adherence to the morphing rule and to the quality of the formed surfaces.

- Substantial time savings – Less grinding work and fewer corrections cycles in tryout

- High process reliability – A learning system based on prediction, morphing and subsequent analysis

- High CAD data quality – The quality of the morphed surfaces meets the requirements of active surface and die design

Multiple morphing rules

Tebis offers several options for defining the morphing rule. All morphing rules can be combined together.

From simulation systems

FEM systems specializing in the simulation of sheet metal deformation simulate springback and provide compensation rules, such as with two triangular meshes. Tebis uses these and automatically morphs the affected area of the active surface of the die.

From experience

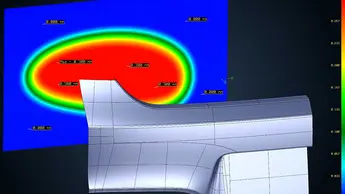

If the expert knows how the sheet metal springs back and how it must be deformed, the morphing rule is created in Tebis with a substitute surface pair (visible in the background) that represents the desired morphing. Rules can also be specified with vectors and rotation.

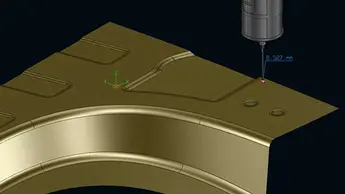

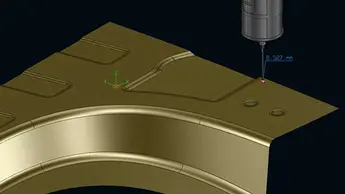

From measurements

Tebis takes the measuring points determined on the test part with springback, calculates the distances from the desired part, and automatically compensates the CAD surfaces in the die.

From digitized data

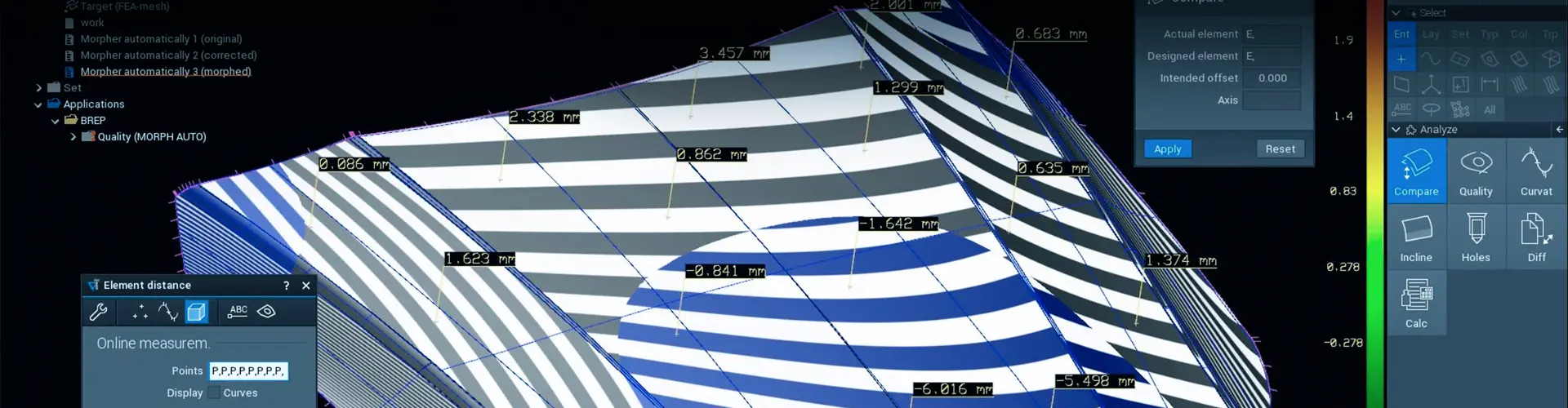

The comparison between the scanned sheet-metal part and the CAD surfaces of the die indicates where springback is occurring. The meshes from the scanning process are used to define the morphing rule. Also: Scanned sheet-metal parts can be quickly and easily reverse engineered to surfaces in Tebis (see Tebis reverse engineering).

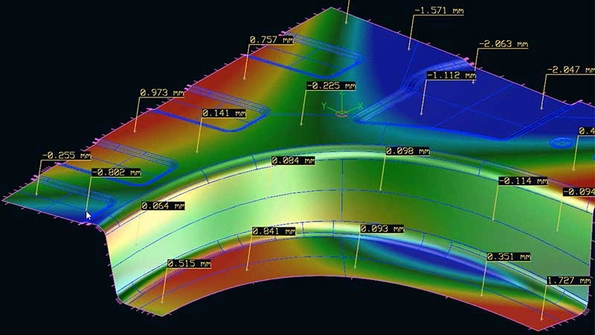

Morphing of outer skin surfaces based on results from forming simulations

The predictions regarding springback are imported in Tebis through interfaces to simulation systems, and the CAD surfaces are automatically morphed. The better the original surfaces are, the better the morphed resulting surfaces will be. Tebis offers an extensive function package for the analysis and optimization of CAD surfaces before and after deformation.

Tebis takes the springback compensation data from the simulation system and forms the class-A surfaces of the outer skin part

The high quality of the deformed surfaces can be seen in the reflection lines

Morphing sheet-metal parts based on measuring points

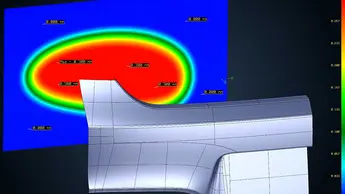

Tebis takes the measuring points determined on the test part with springback, calculates the distances from the desired specified part, and automatically compensates the entire sheet-metal part.

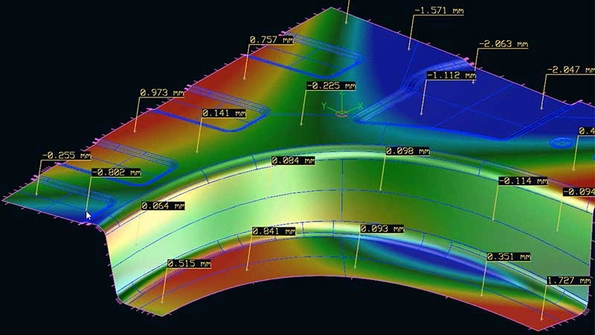

Tebis automatically determines the local individual values for compensating springback from the measuring point coordinates and forms the entire sheet-metal part accordingly.

In the distance analysis, the unchanged areas are shown in green and the deformed areas are shown in blue and red.