3D laser cutting

Offline programming avoids teach-in and blocking of expensive production equipment

Tebis helps you handle the challenges in 3D laser cutting: You can quickly and reliably create NC toolpaths for cutting your sheet-metal parts no matter how complex the geometry. Collisions with other component areas, clamping devices or machine components are ruled out. Offline programming lets you avoid tedious teach-in and unproductive use of the machine. Increase your productivity with NC programming in the Tebis CAD/CAM system.

- Fast and reliable – Quickly and reliably produce collision-free CNC programs

- Correct problem areas – Detect and correct all problem areas before machining

- Short cycle times – Short cycle times in 3D laser cutting on the machine

- High quality – High quality of the cut parts

Functions

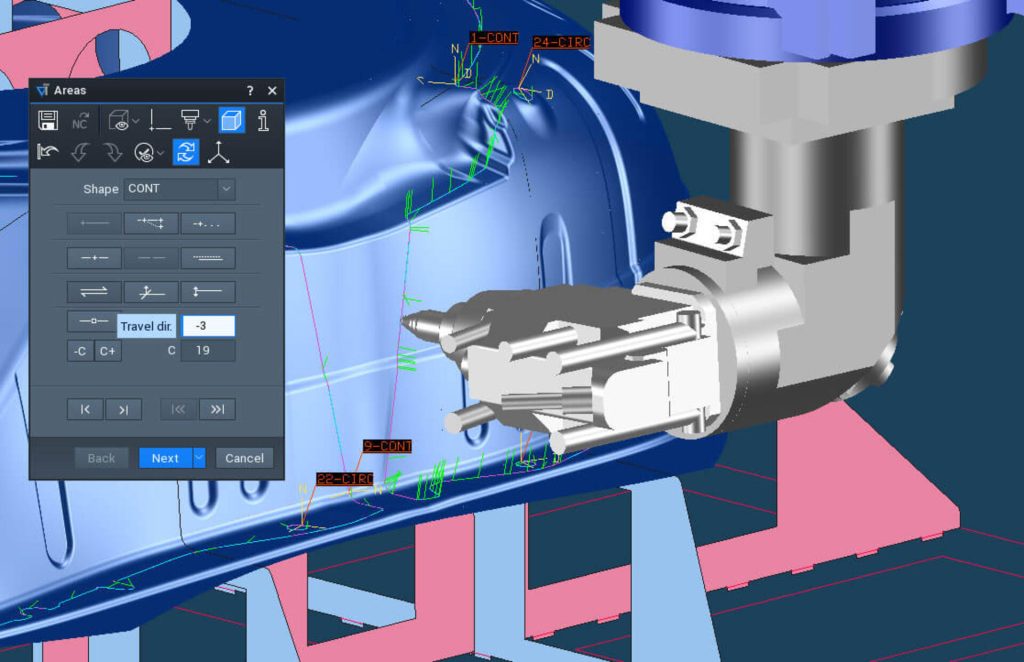

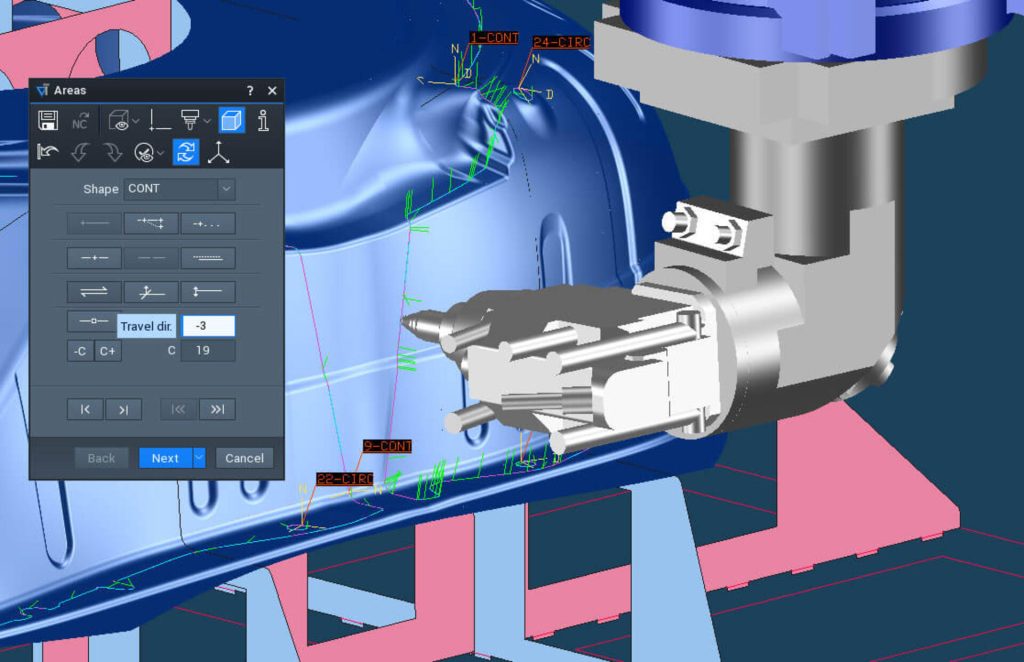

Simultaneously automated and flexible

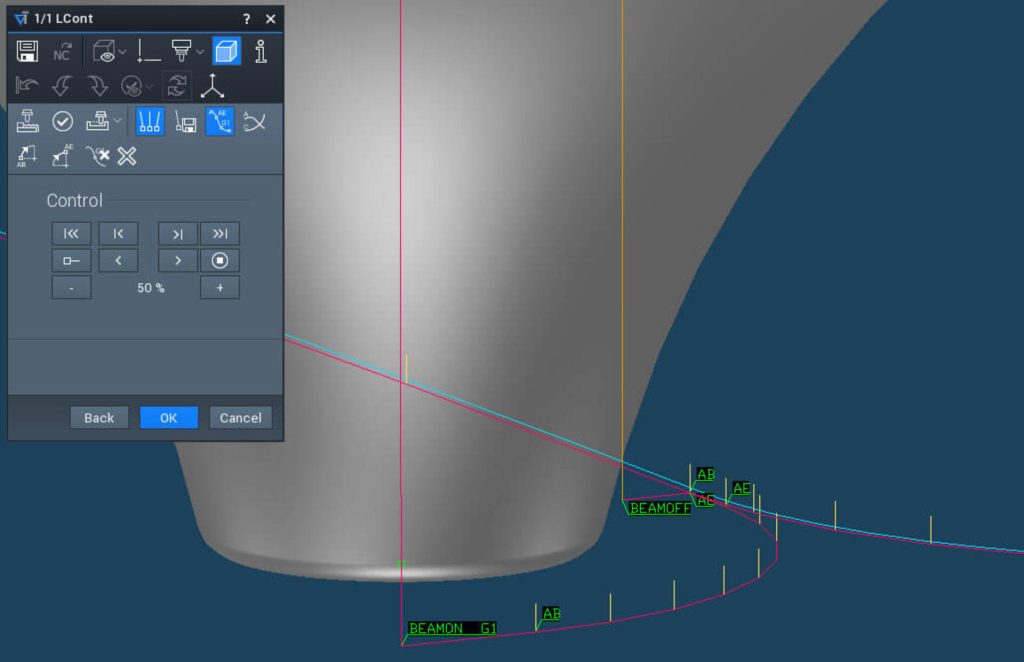

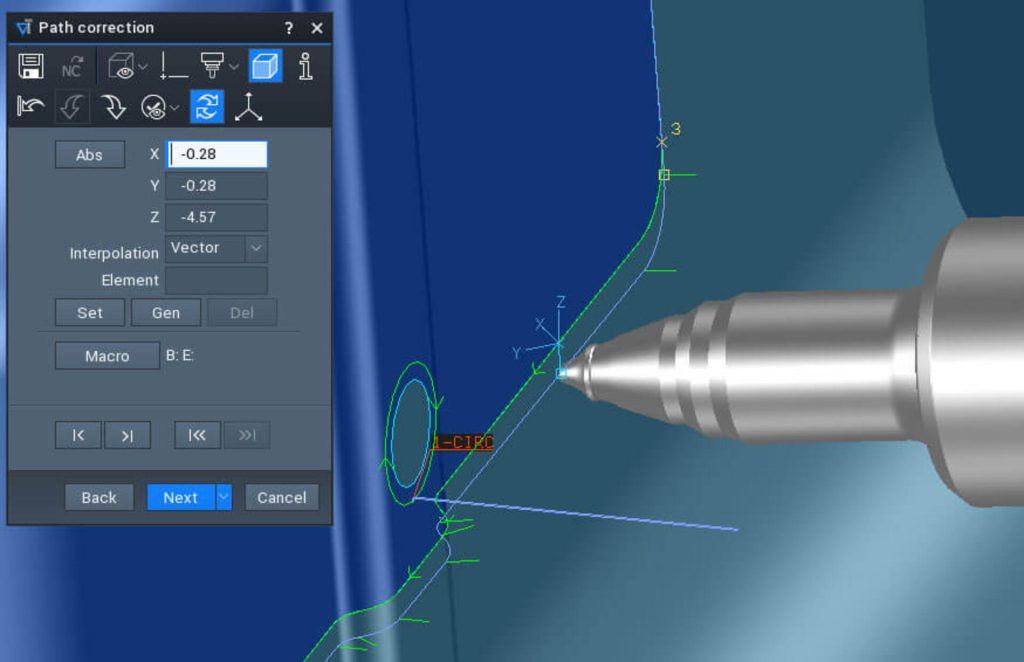

Tebis automatically calculates results for 3D laser cutting that you can always modify interactively. You can flexibly adjust the starting position and the spatial position of the machine head, just like the areas to be trimmed and their machining sequence. This lets you integrate your own manufacturing expertise in the programming. You can also easily handle deviations between CAD data and the actual part (springback etc.).

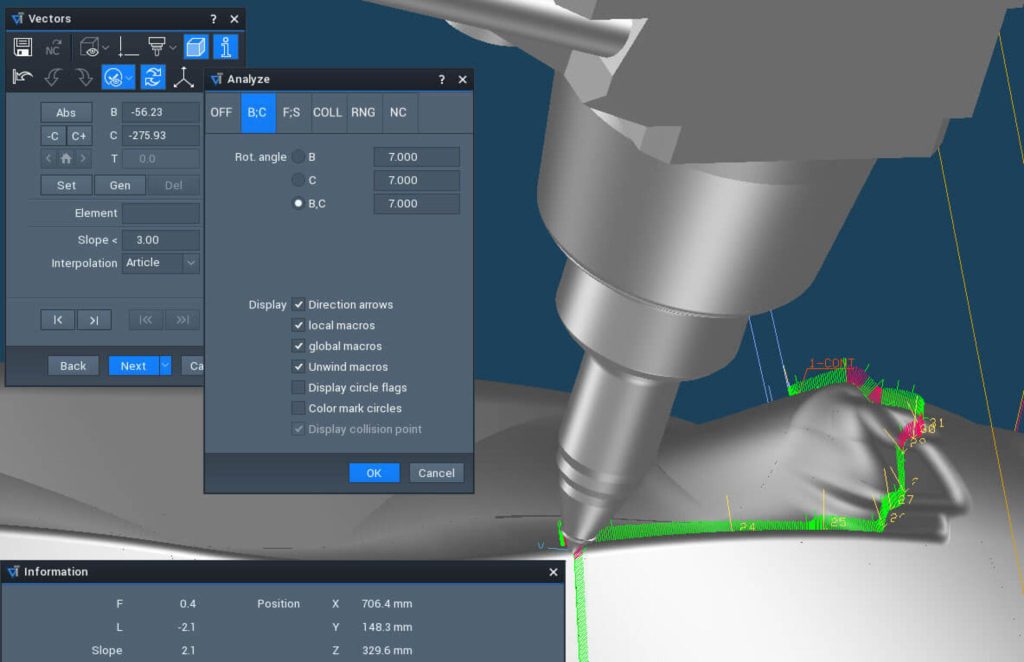

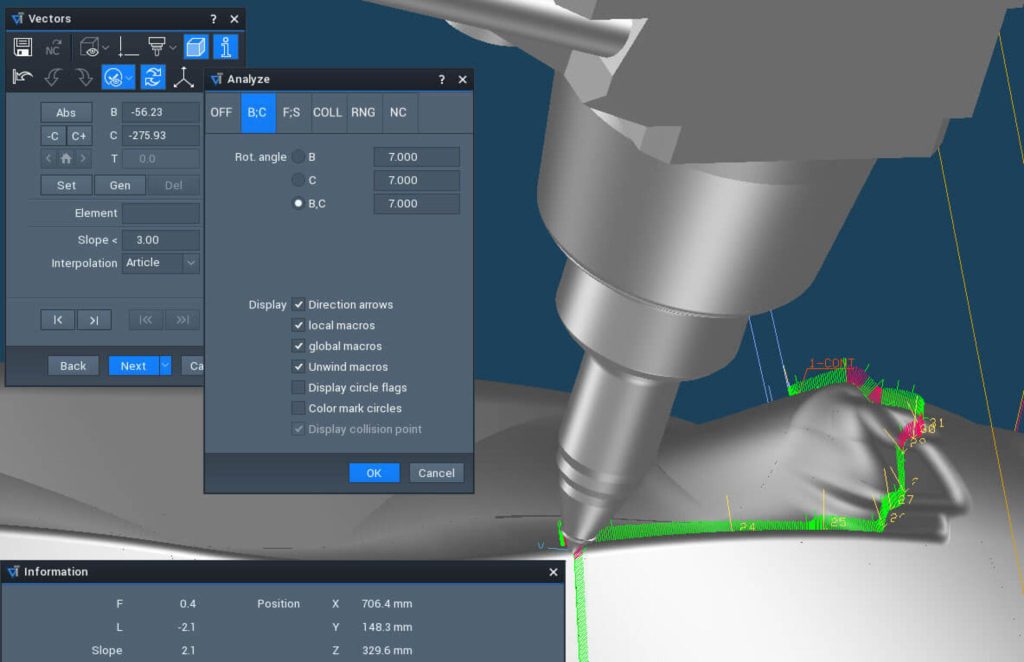

Analyzes for quality and efficiency

Tebis supports you with many analysis functions during interactive programming for 3D laser cutting. You always retain an overview of the rotation angle and area, beam angle and collisions. As a result, it is easy to optimize the rotation movements of the machine for fast and smooth machining. You can also adapt your manufacturing projects to the axis angle limitations and unavoidable unwind movements of the machine.

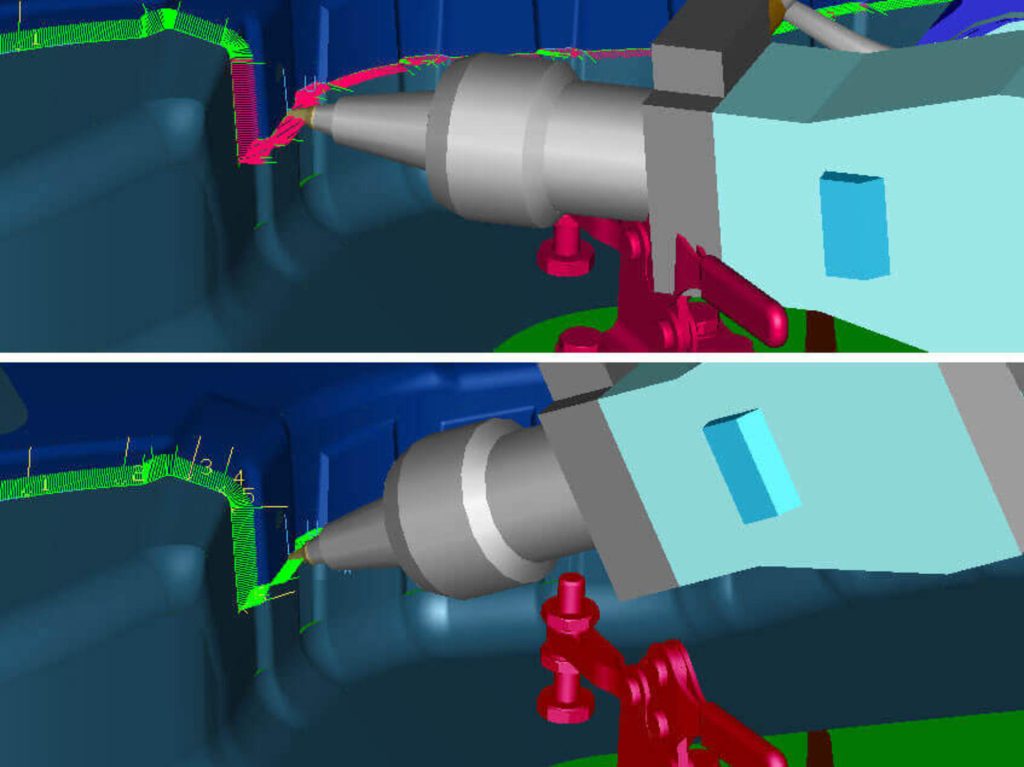

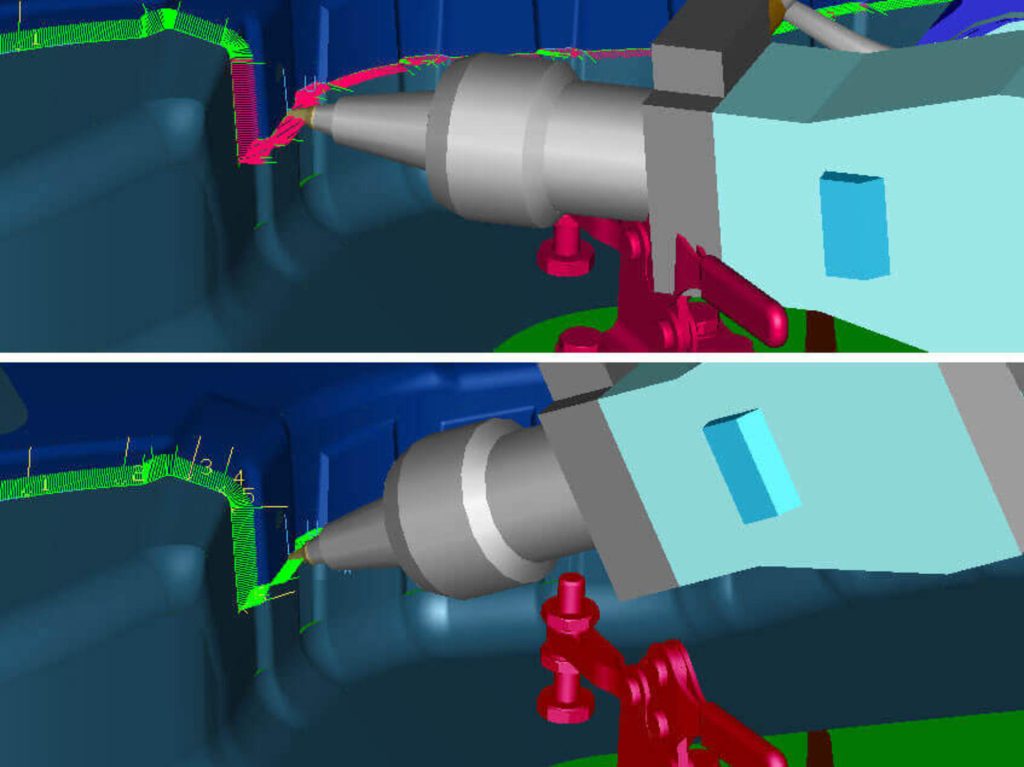

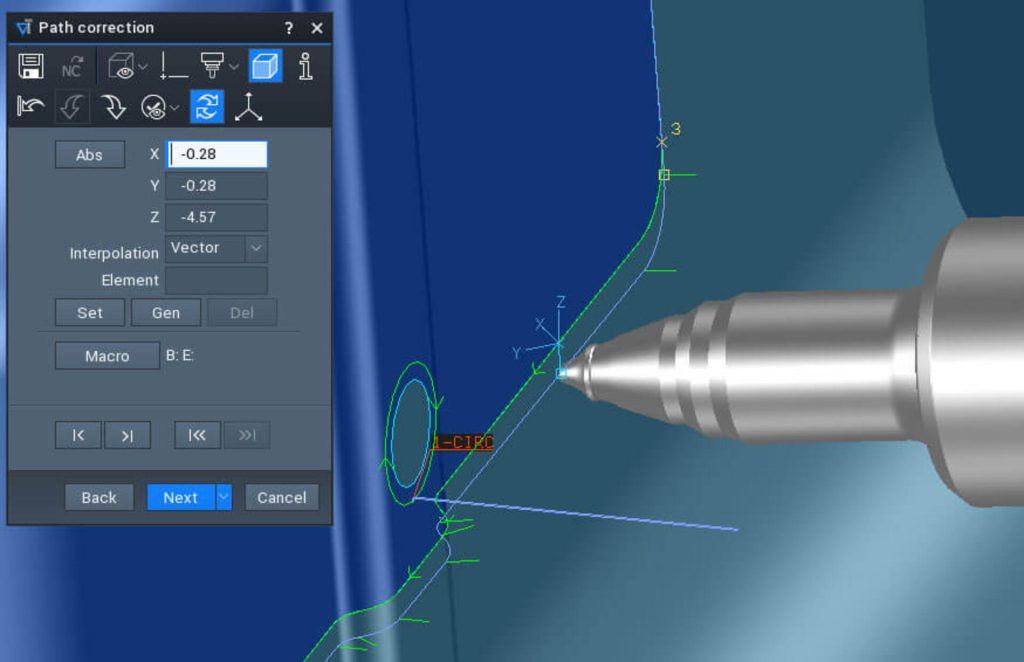

No lost time due to collisions

Because Tebis models all of your manufacturing resources for 3D laser cutting as digital twins, you have a continuous overview of the entire machine situation. This means that you never fail to catch any collision of the machine head with the part or clamping devices. Tebis prevents many collisions with automatic interpolation. The collision analysis is always updated on all interactive changes in the laser cutting paths. All machining operations are therefore safely planned on the 5-axis machines. Lost time and money due to collisions are a thing of the past.

Technology for all machines

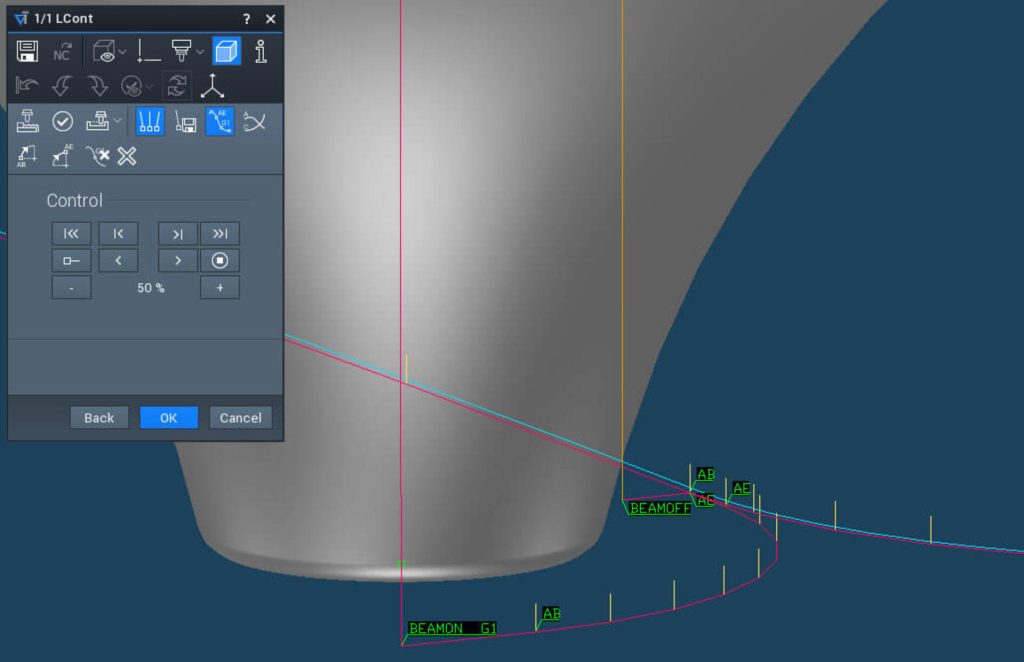

Tebis supports technical subprograms, such as for transferring cutting parameters like ignition and closing positions, distance sensors, speed, power, beam width and gas composition to the NC program. PLC commands can also be integrated in the NC program, such as for repositioning the clamping system. This lets you create complete CNC programs for 3D laser cutting for all your machines using your own company-specific technology parameters.

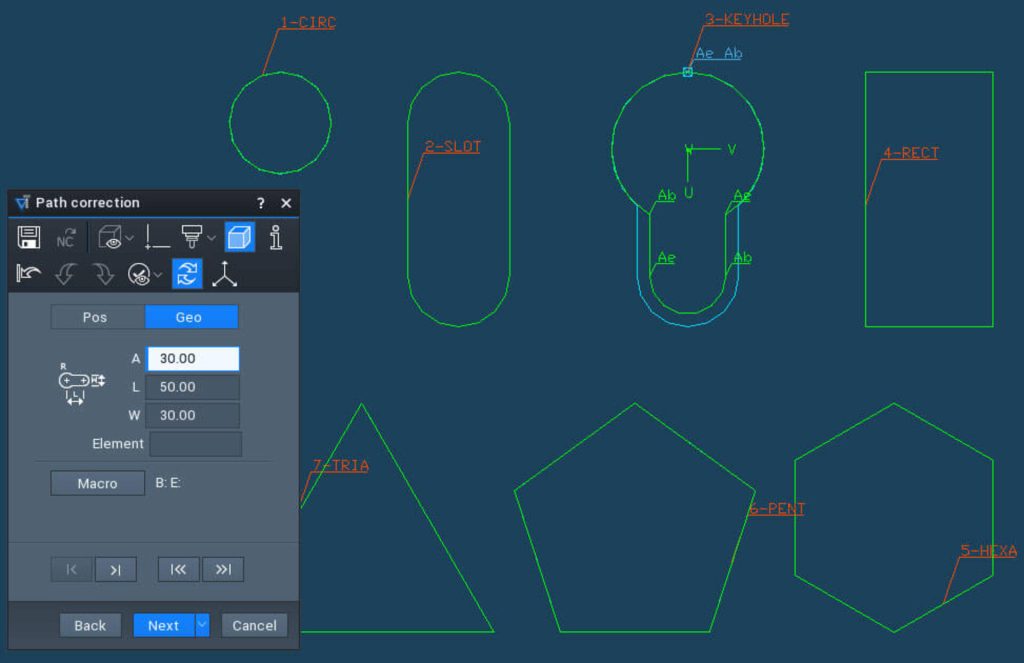

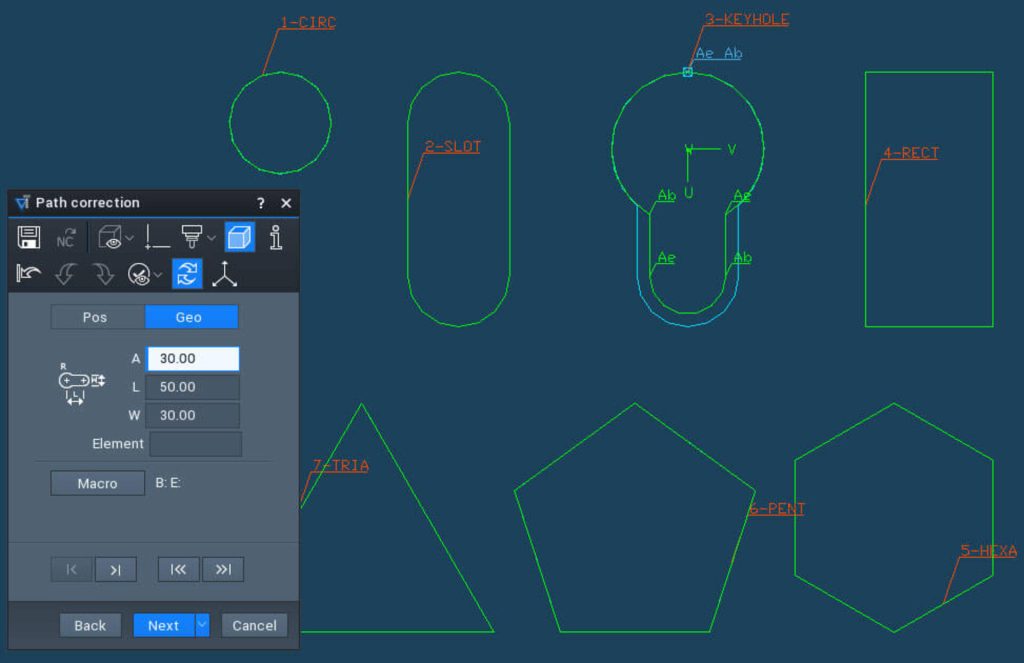

Quickly achieve your goals with form elements

Standard form elements like holes, slots, rectangles, triangles, pentagons, hexagons and keyholes are automatically detected. Your benefit: These geometry standards are exported as subprograms to the NC program. This enables the control and 5-axis machine to work in a more targeted and efficient manner.

Adjust existing machining operations

Your machining operations are saved with all adjustments and individual settings in Tebis NCJob management. You can use the transformation functions to quickly and easily generate NC programs from these for 3D laser cutting of workpieces with mirrored symmetry. The machine’s kinematic limits are continuously monitored.

If you already have laser cutting programs from the past for which there are no CAD/CAM data, you still have options with Tebis. In only a few steps, reverse processors can transform the NC data back into NCJobs for further development. The same applies for all the changes you have made to the CNC control in the NC program for 3D laser cutting.