CNC automation

Automatic manufacturing of single parts and small series with Tebis Automill®

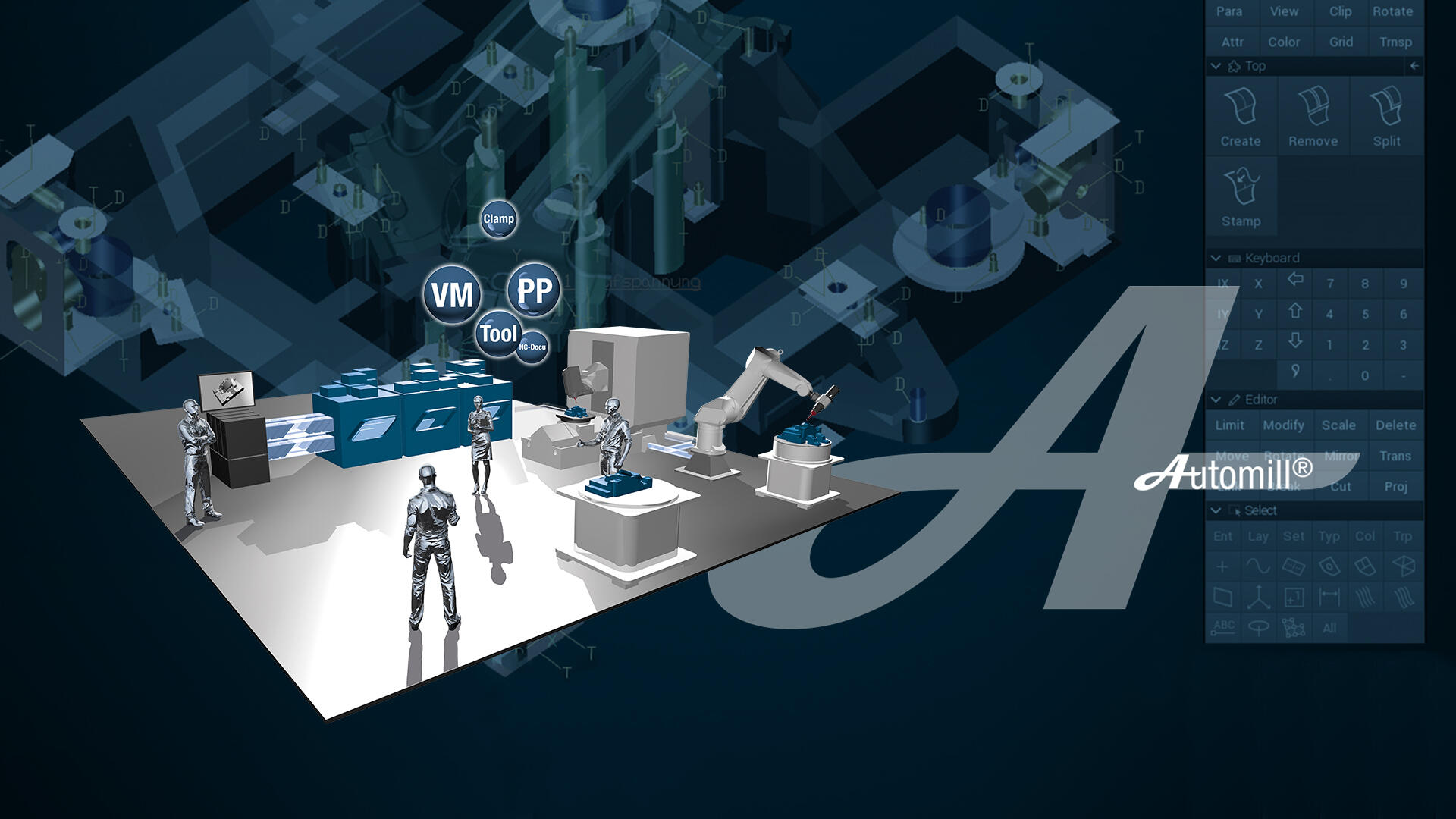

In modern manufacturing companies, NC programs for CNC machine centers are no longer created by conventional means with individual manual operations by an NC programmer on CNC controls and CNC programming systems. Instead, a CAM system like Tebis evaluates the digital CAD part model and accesses a previously stored structure of digital representations of the company’s manufacturing environment and the manufacturing knowledge stored in templates to calculate the NC programs. This forms the basis for automated CNC programming and highly efficient manufacturing.

Tebis Automill

This is how CNC automation with Tebis works:

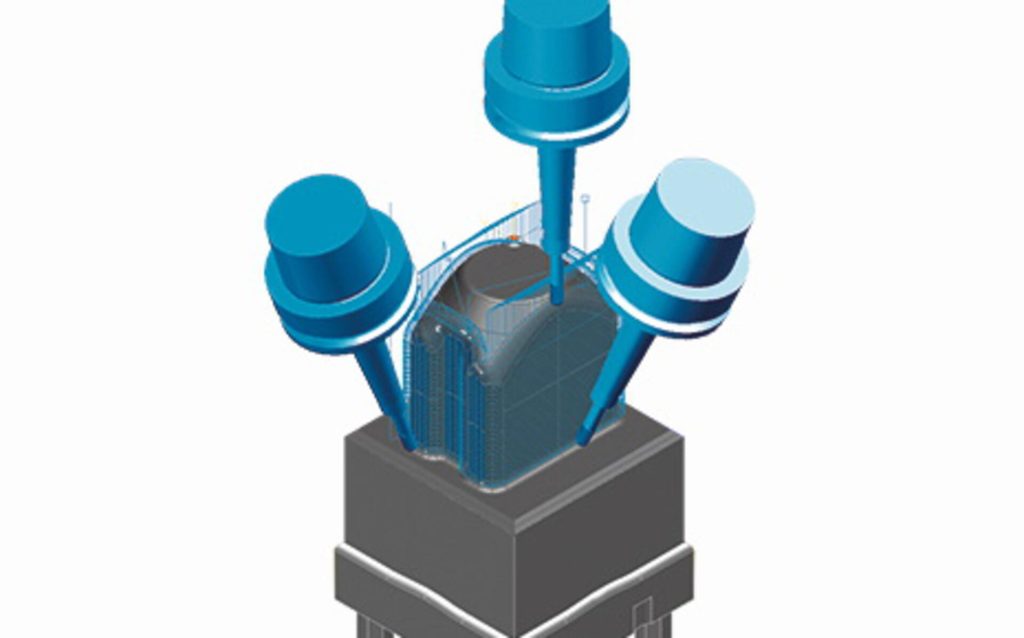

Your NC programmers use process libraries, containing your machines, controls, tools and clamping devices as individual digital objects. Your Tebis software therefore knows your specific manufacturing environment in detail (virtual machines = VM, clamping devices = Clamp).

Still more: NC templates also contain your optimized manufacturing knowledge and enable standardized work and automatic functions for your NC programming (technology packages = TP).

- Knowledge base with your own proven manufacturing knowledge – Fast learning curve for employees during NC programming

- Reliable and efficient – NC programs High collision protection Minimized idle toolpaths Optimized path speeds

- Standardized and automated work – Shorter programming times High manufacturing quality

Automatically and safely calculate NC programs

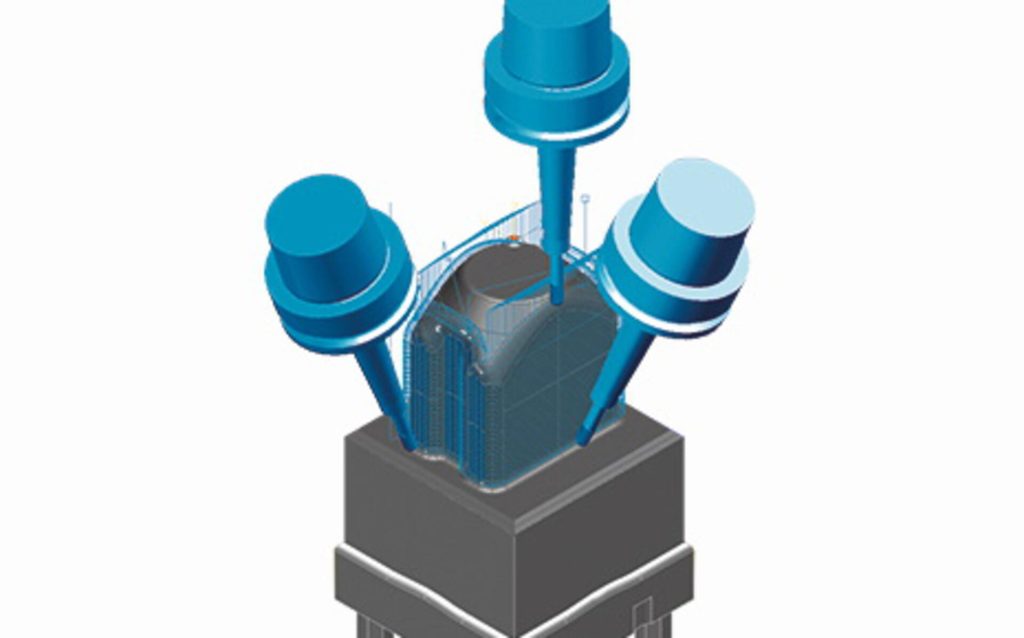

Planning and programming in the virtual manufacturing environment

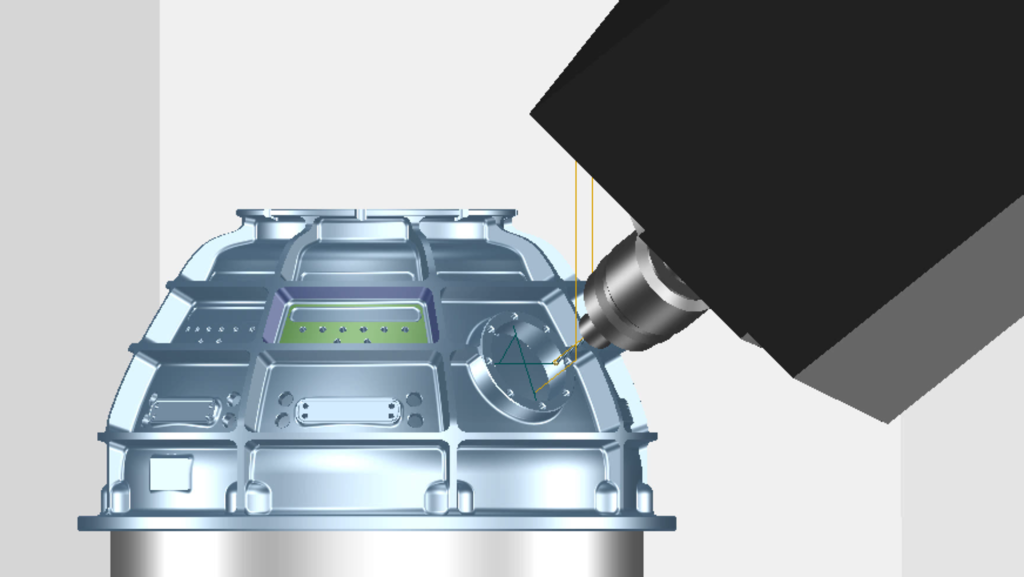

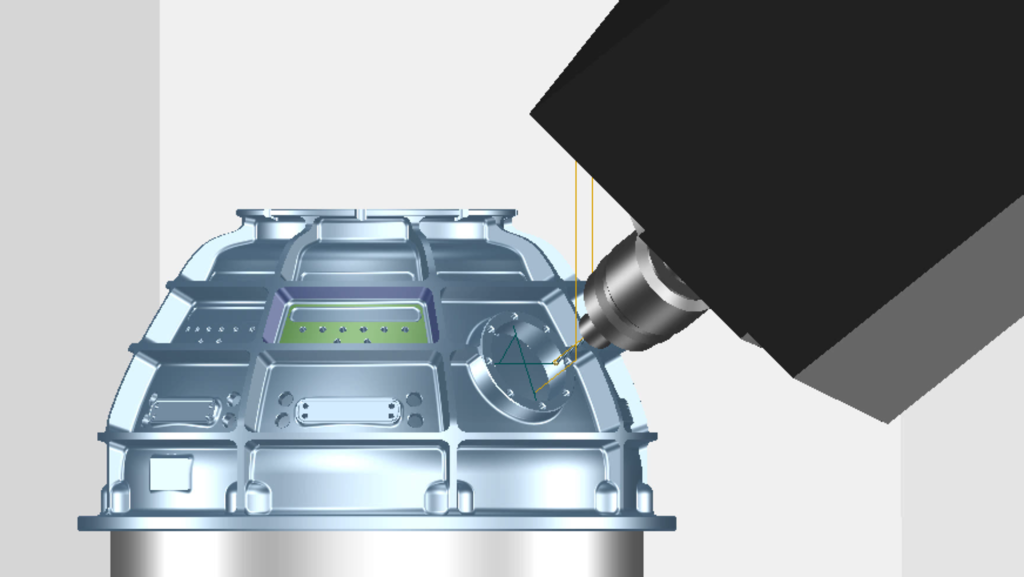

Use your virtual workspace before and during NC programming. Specify suitable tools and find the best setup and tilt directions. You can select digital twins for the machine, machine head, clamping devices, shuttle tables, units, tools and reference points. You can calculate and plan right from the start in your own digital manufacturing environment that you can also use for NC programming.

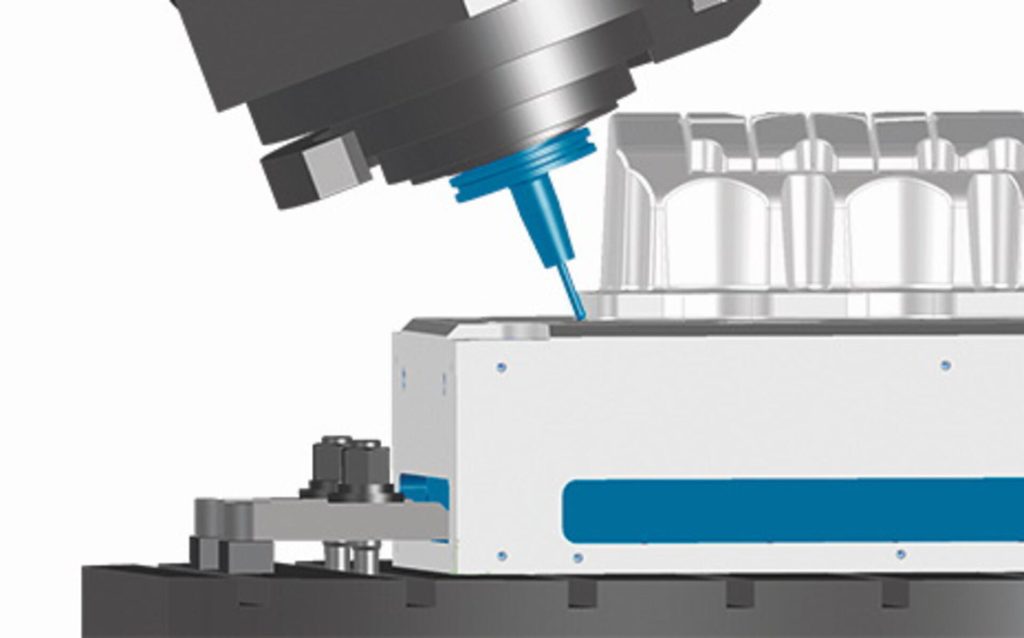

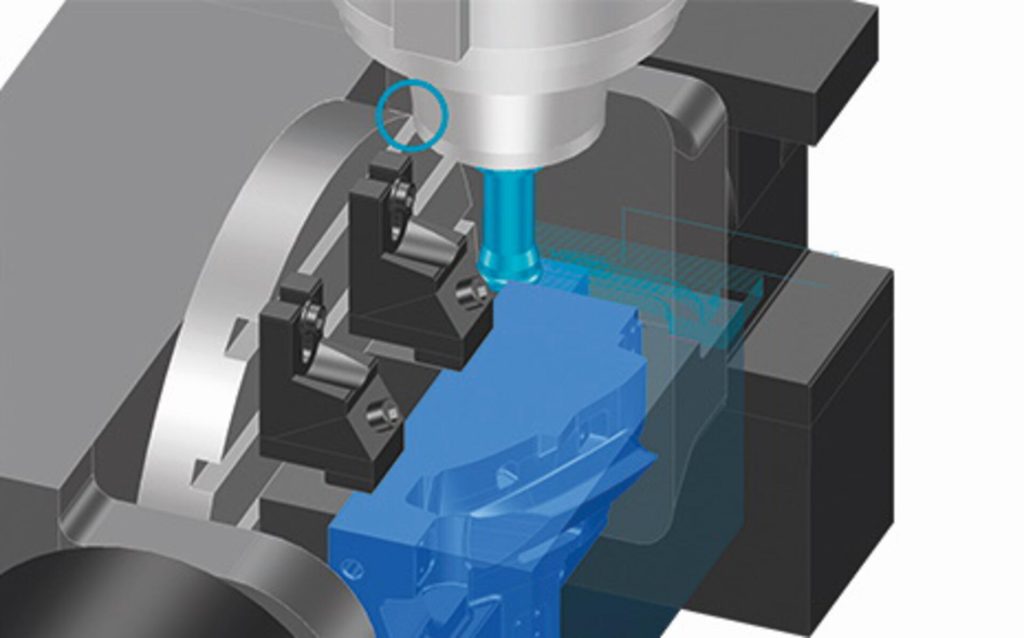

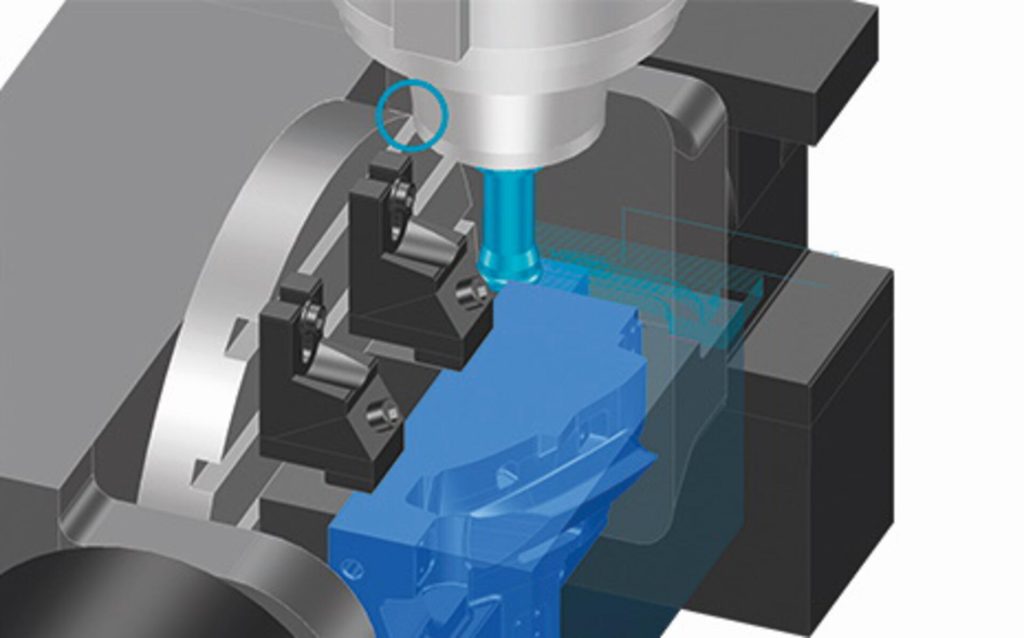

Automatic collision avoidance

When calculating toolpaths, Tebis detects collision hazards for the tool holder and machine head and automatically reduces the milling area to prevent collisions. Tebis prevents collisions in 5-axis machines by automatically generating 5-axis avoidance movements.

Collision detection with integrated CNC simulator

Calculated toolpaths are still verified in the CAM environment for collisions with all components of the part, clamping devices and machine components involved and are corrected before the NC programs are sent to real manufacturing. Adherence to the working space of the machine with its limit switches is also checked virtually.

Integral process measurement in the milling machine

You can fully integrate your measurement tasks in the manufacturing process. In this way, you can check to ensure that the component is correctly set up and that the blank is correctly dimensioned and oriented. After machining, you can ensure that the component does not require any reworking that would otherwise not be detected until after unclamping. All the required functions are combined in a clear structure:

- Probe calibration

- Point measurement

- Angle measurement based on points or circles

- Circle and rectangle measurement

- Checking of grooves and ribs

Integrated tolerance checking can be performed to determine whether the order can continue to be machined of has to be interrupted. This results in a safe and highly automated process with combined milling, turning and measurement operations that prevent damage to tools and machines.

- Shorter setup and machining times

- Higher component quality

- Fewer correction loops

You can benefit from these functions even on controls without their own measurement cycles.