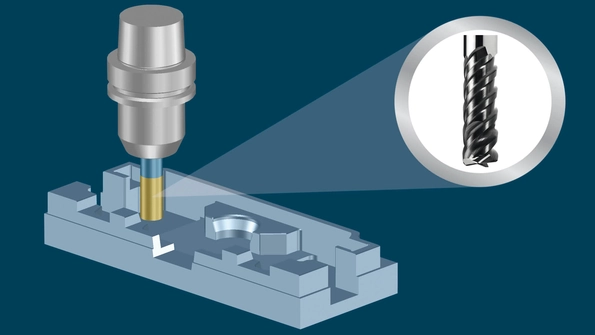

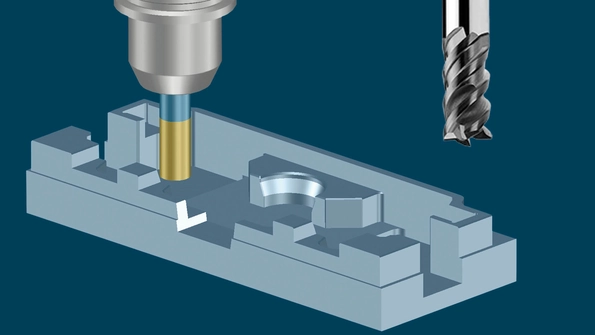

High-efficiency roughing with HPC milling machines

High-performance cutting (HPC) for maximum material removal rate

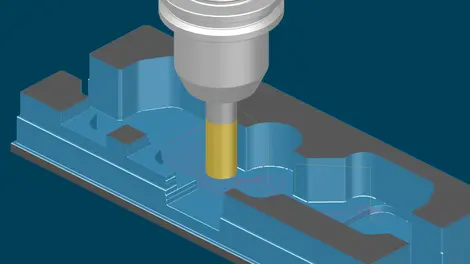

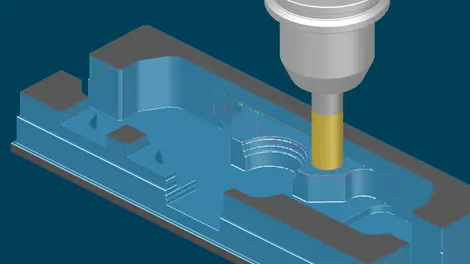

The goal of every roughing operation is to remove as much material as possible within the shortest possible time. This is an enormous stress test for the cutter, which often ends up in full contact. Tebis therefore uses options for full-cut handling as well as for full-cut avoidance. In full-cut handling, feed rates are automatically reduced, or full-cut areas are machined trochoidally. In full-cut avoidance, the path layout is automatically adapted to the geometry without full cuts.

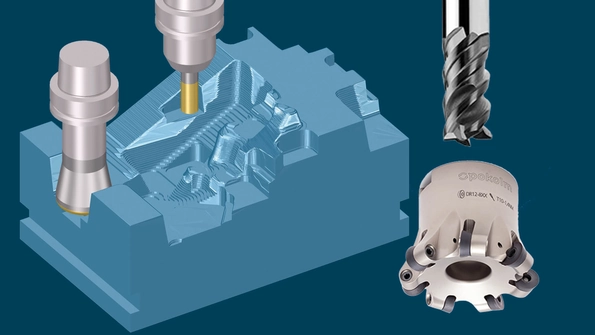

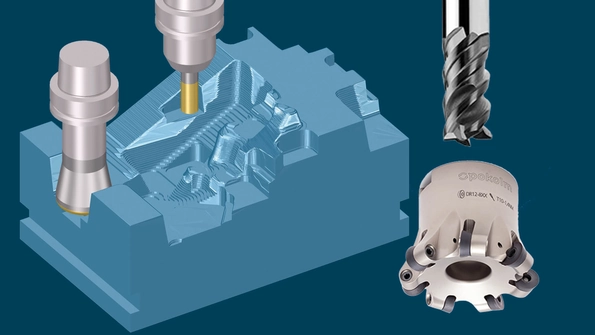

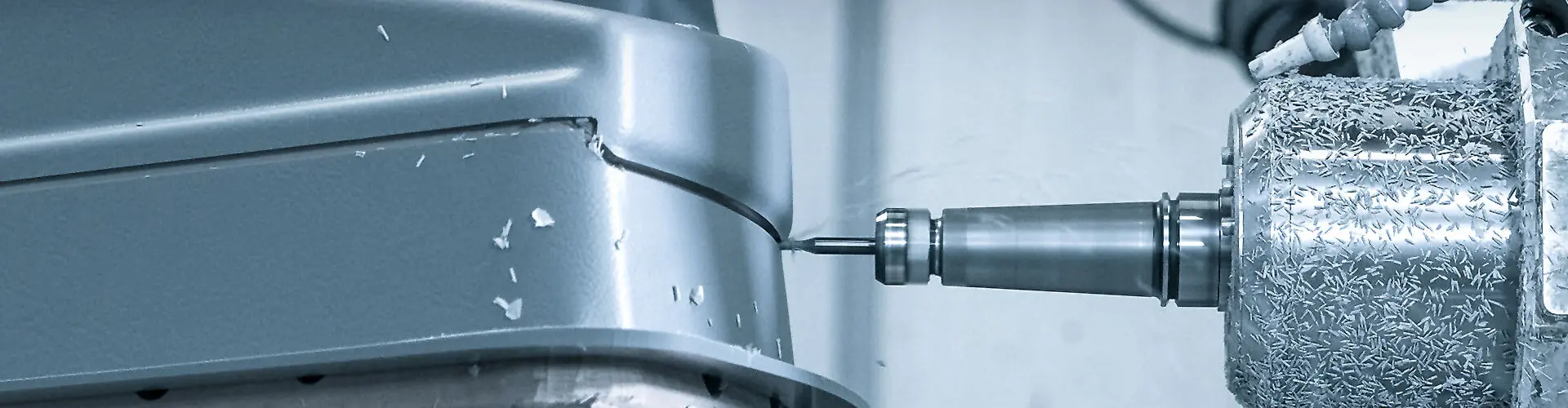

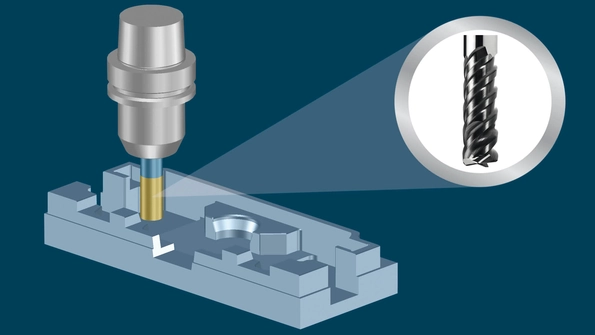

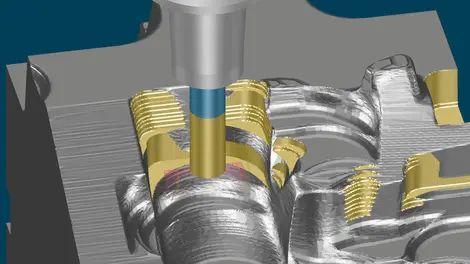

Full-cut avoidance is used in adaptive roughing. This is where it really counts: Compared with conventional roughing, special HPC cutters achieve extremely high material removal rates at constant cutting conditions with higher cutting speeds and feed rates, smaller lateral stepovers and very large cutting depths – and time savings of over 60 percent are easily possible. Adaptive roughing strategies for HPC milling are especially suitable for parts with many deep cavities. Hard materials can also be machined very easily in this way.

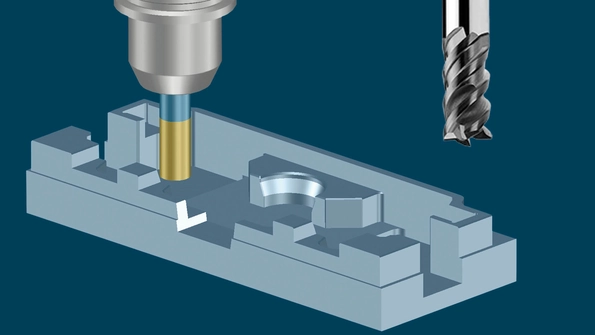

HPC cutters with long cutting edges for large downfeed

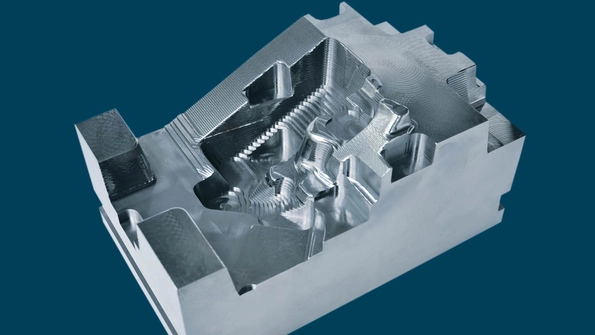

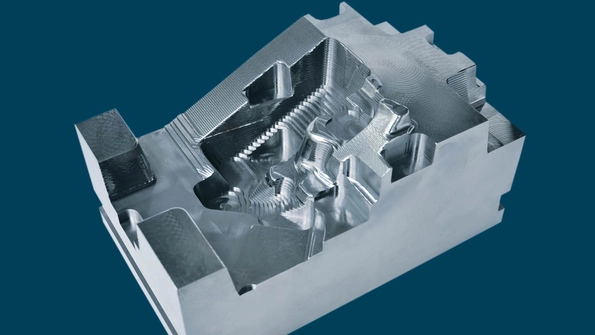

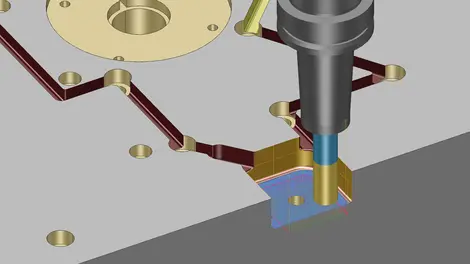

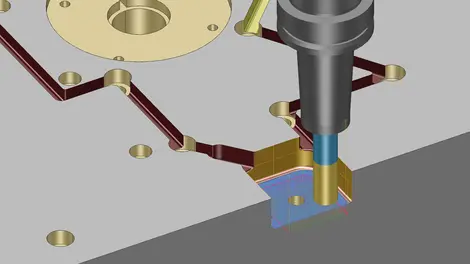

Adaptive roughing of free-form pockets

HPC milling with Tebis

- Highly efficient – Feed rates and paths are always optimized • Longer machine uptime • Lace cut machining is also possible

- An end-to-end system – Blank tracking across machining operations

- Protects tool materials – Long tool life

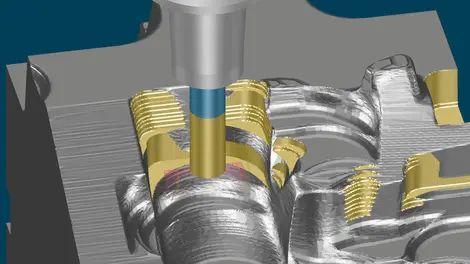

Suitable for 2.5 D, 3D and 5-axis machining operations

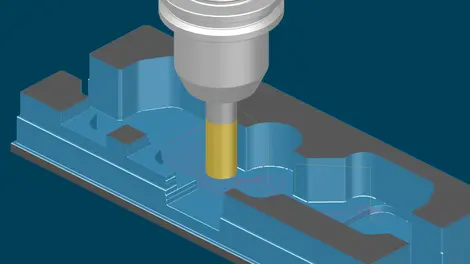

Adaptive trochoidal roughing strategies can be implemented in Tebis in 2.5D, 3D and 5-axis machining operations. The tool can be quickly repositioned, even at high feed rates. Integrated blank transfer enables a simple combination of all milling operations.

2.5D HPC roughing

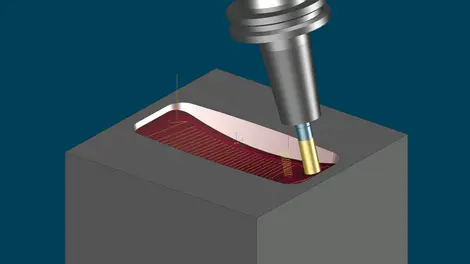

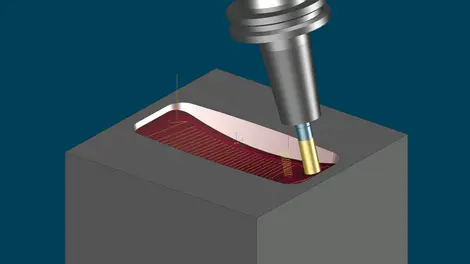

3D HPC roughing

5-axis simultaneous HPC roughing

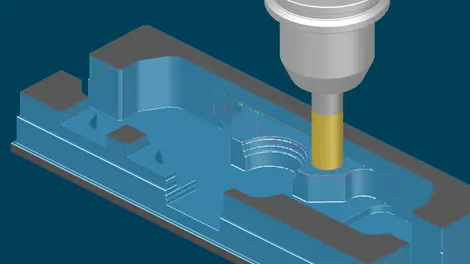

Integrated re-roughing for even better results

The additional “Re-roughing upwards” option enables remachining of residual stock areas with a smaller depth of cut from the bottom upwards with no difficulties.

Clear pocket adaptively or trochoidally in a single step...

... Machine residual stock on the pocket walls...

... from bottom to top.

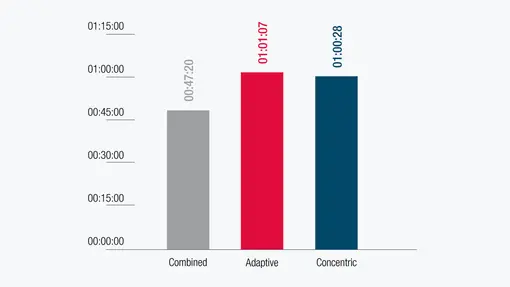

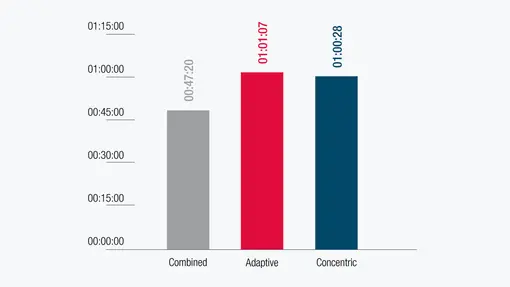

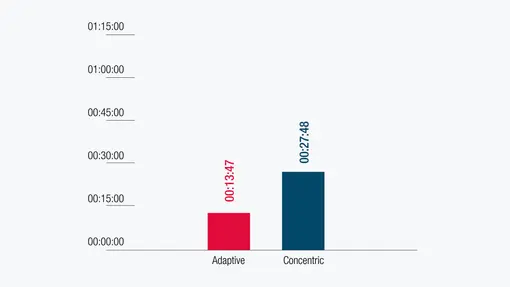

How it’s done! Practical test of run time calculation

Without a doubt: The adaptive roughing strategy is the one that achieves the highest material removal rate. In many cases it is also the most efficient strategy – but not always. Because how a part is best machined depends on the geometry, the material and the machine tool. Technology parameters such as cutting data and feed rates must exactly match the machining operation.

In our practical test, we compared different roughing strategies taking part geometry and the technology parameters into account. Results: The right combination is critical!

Practical test

Practical test of run time calculation

Everything must fit together

Whether adaptive roughing is appropriate for a part depends primarily on the geometry. This machining type is best suited to parts with deep cavities.

Very important: Technology parameters like cutting data must be optimally matched to the part, the material, the machine and the tools used. Only then can the best possible result be achieved.

In our practical test, we compare various machining types for the example of two parts.

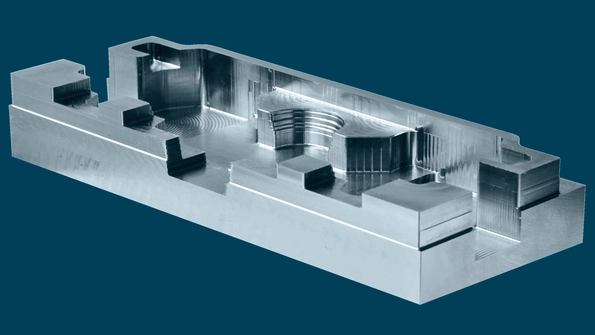

Example 1: Part with many deep cavities

| Tool | Pokolm D16 HPC cutter |

| Machine | DMG HSC105 linear |

| Material | Steel |

| Strategy | Adaptive |

| Cutting data | ae: 1.6 mm ap: 30 mm vc: 175 m/min fz: 0.3 mm |

Adaptive machining is more than 60 percent faster than concentric roughing.

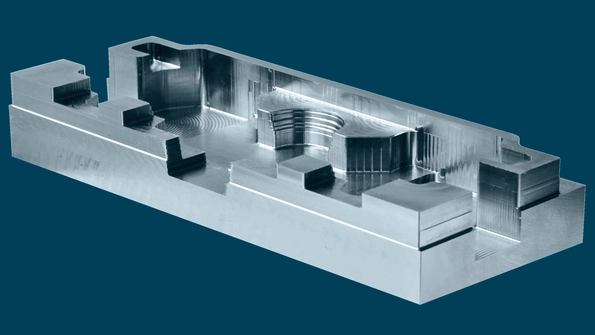

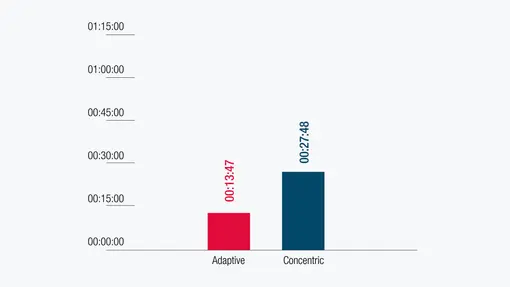

Example 2: Complex part with flat and steep areas

| 1st machining operation | 2nd machining operation | |

| Tool | Pokolm Spinworx D52 R6 | Pokolm D16 HPC cutter |

| Machine | DMG HSC105 linear | DMG HSC105 linear |

| Material | Steel | Steel |

| Strategy | Concentric | Adaptive |

| Cutting data | ae: 36 mm ap: 0.9 mm vc: 215 m/min fz: 0.7 mm | ae: 1.6 mm ap: 30 mm vc: 175 m/min fz: 0.3 mm |