Sinker EDM

For shorter lead times and greater process reliability

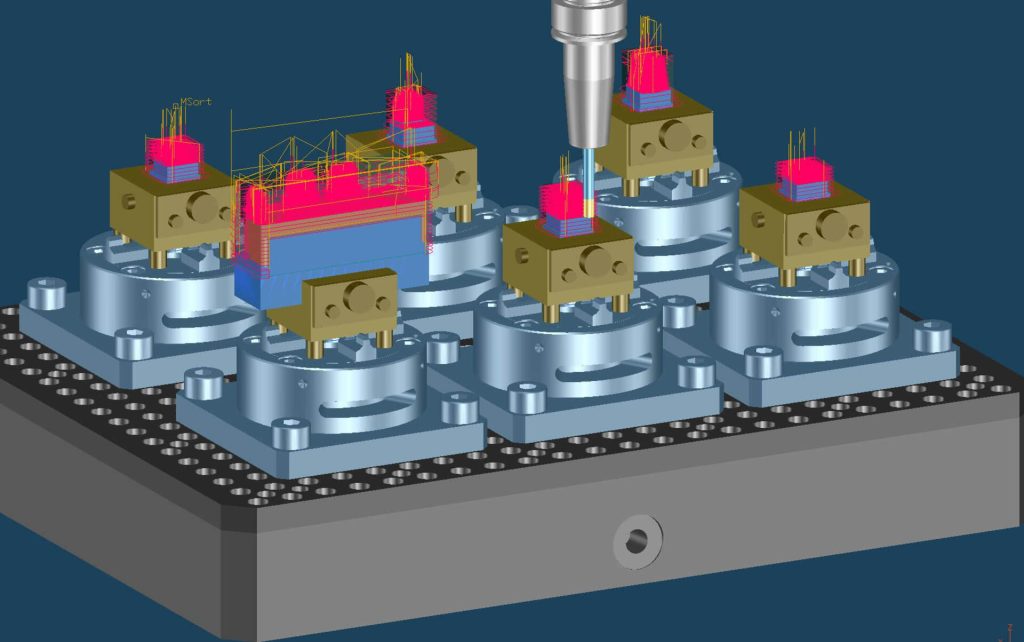

Tebis puts you in control of the complexities of sinker EDM. Tebis supports the entire process from automatic detection of the areas to be eroded to convenient object-oriented design of the electrodes, their methodical NC machining, to measurement of the finished electrodes. All parameters that are important for manufacturing and use of the electrodes are automatically managed in electrode projects.

- Fast – Quickly and easily assemble complete electrodes

- Automated – Fully automated electrode process with flexible manufacturing cells

- Integrated – Quality control integrated in the process

- Comprehensive – Comprehensive NC functions with automation

Functions

Automatically detect areas for sinker EDM

Let Tebis support you in the automatic search for all areas that still need to be machined after milling. This analysis before sinker EDM is based on the smallest milling tool used.

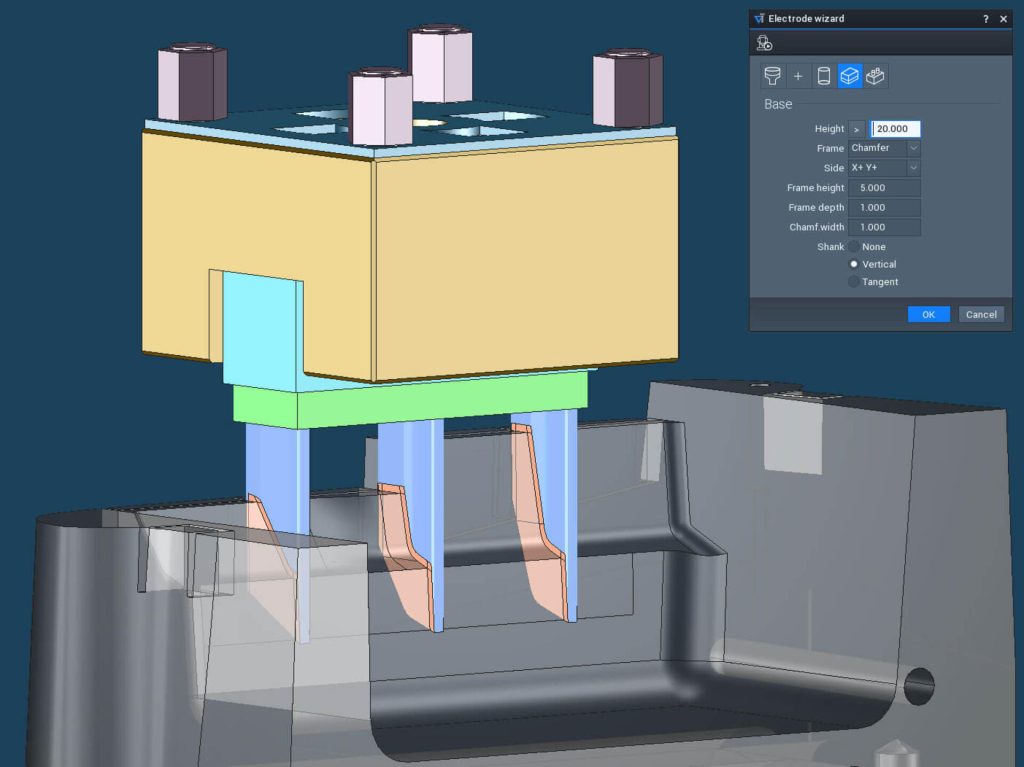

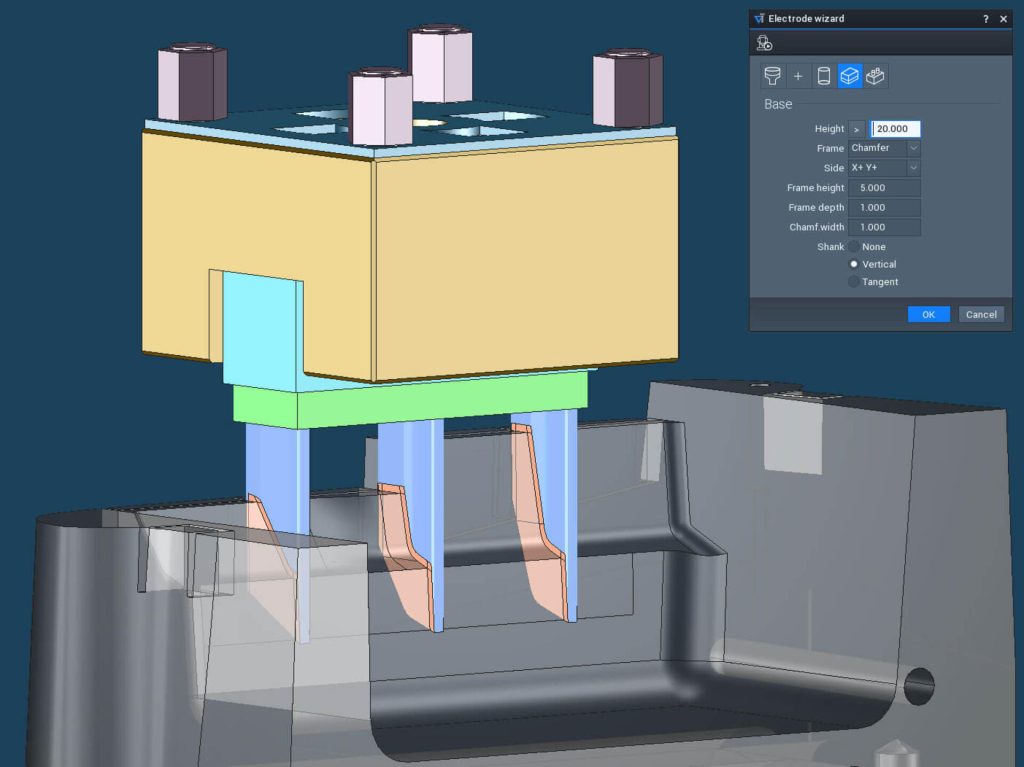

Quickly assemble complete electrode

The burn surfaces of the electrode can be resolved from the geometry at the click of a button. Use powerful interactive graphical functions to lengthen and complete the electrode. A wizard guides the user through assembly of the complete electrode for sinker EDM – including the probe frame, base, holder and the requisite raw material.

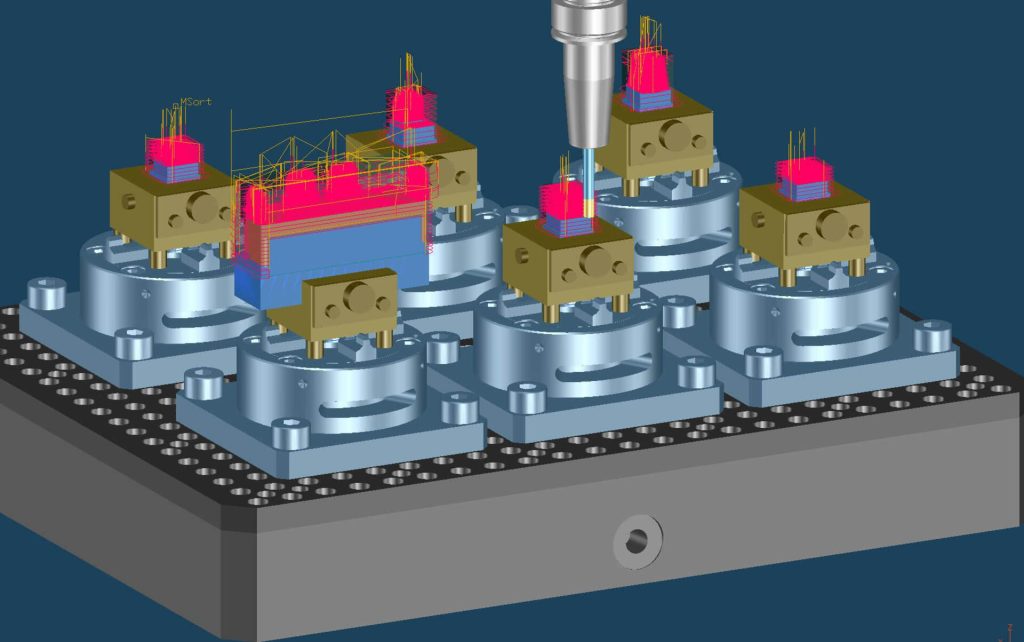

Automated NC programming

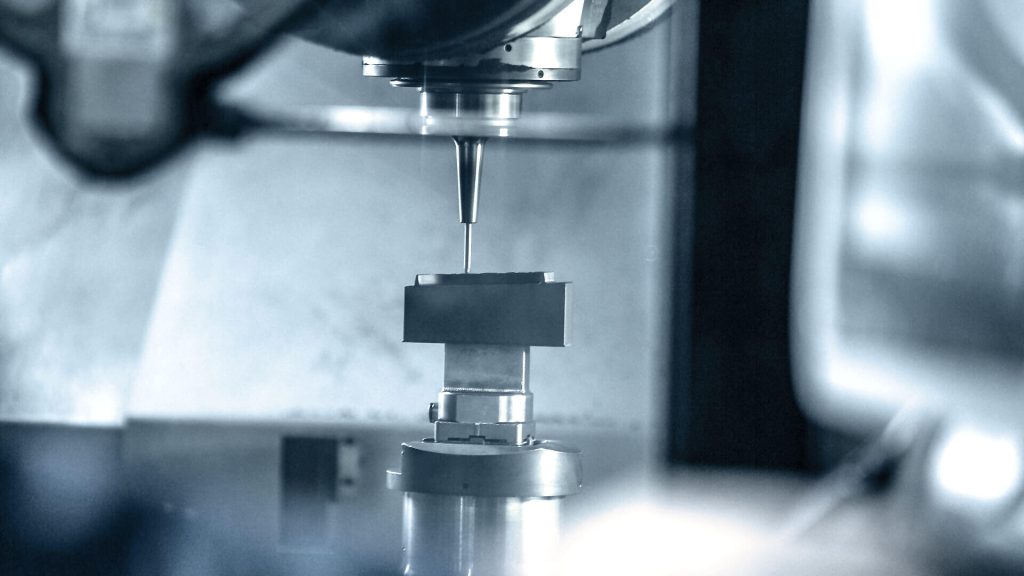

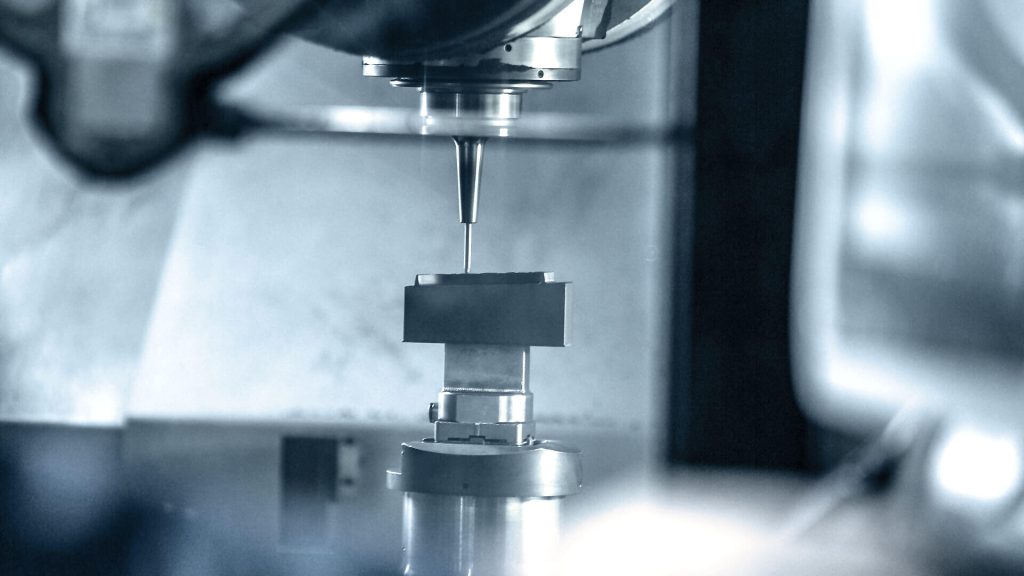

Integrated quality control

Tebis supports you in sinker EDM with quality control integrated in the process so you can produce maximum quality. This is achieved by measuring the electrode and transmitting offset data and the actual spark gap to the sinker EDM machine.

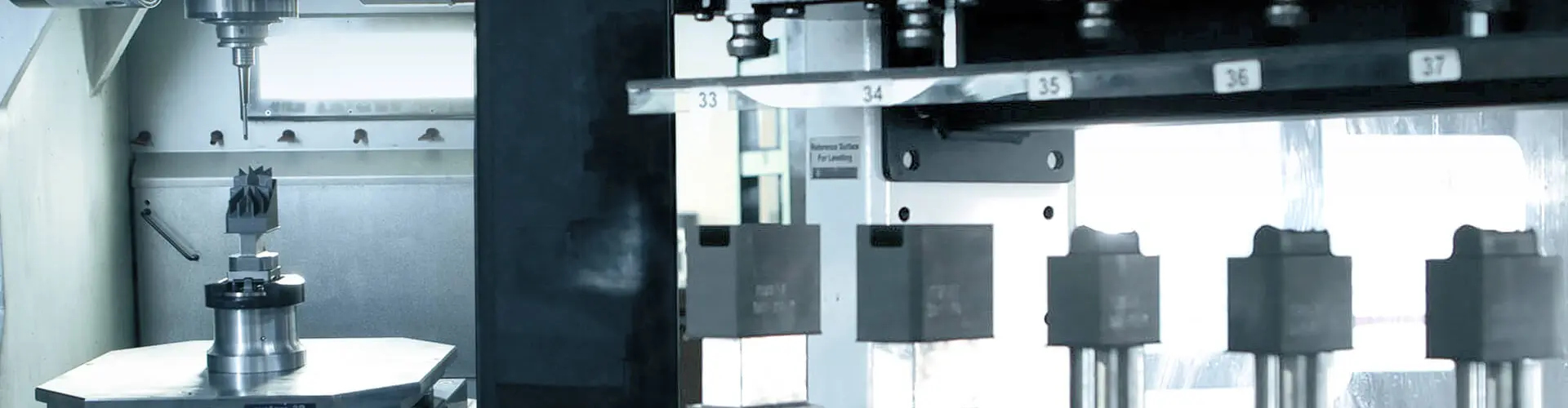

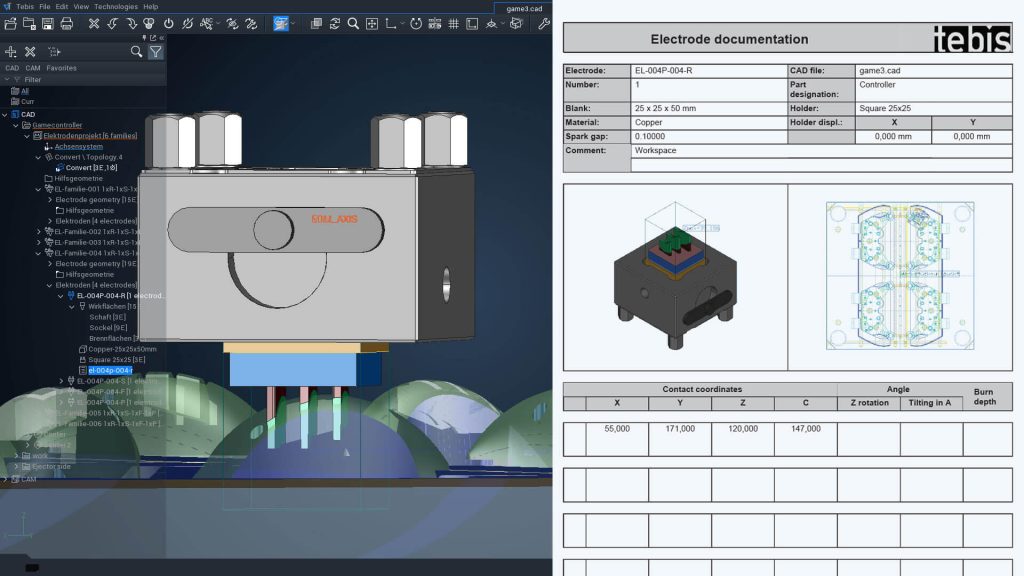

Management and process integration

You can manage all information for sinker EDM in the clearly structured object-oriented electrode projects. In addition to the electrode, holder and blank, this includes the NC programs for milling, eroding paths, NC programs for measurement and the documentation. And if you want maximum automation – with flexible manufacturing cells for electrodes and sinker electrodes – all the necessary information for cell control is available in the electrode project. This ensures a reliable automated electrode process.

Additional functions

- Create EDM paths

- Create repeat electrodes

- Generate documentation

- Holder and blank library

- Completeness analysis

- Multiple setup of electrodes

Machining methods

Learn more here about the possible machining methods for sinker electrodes:

- 2.5D milling

- 3D milling

- 5-axis milling

- HFC milling

- Circle-segment cutters

- Slot milling

- Wire EDM