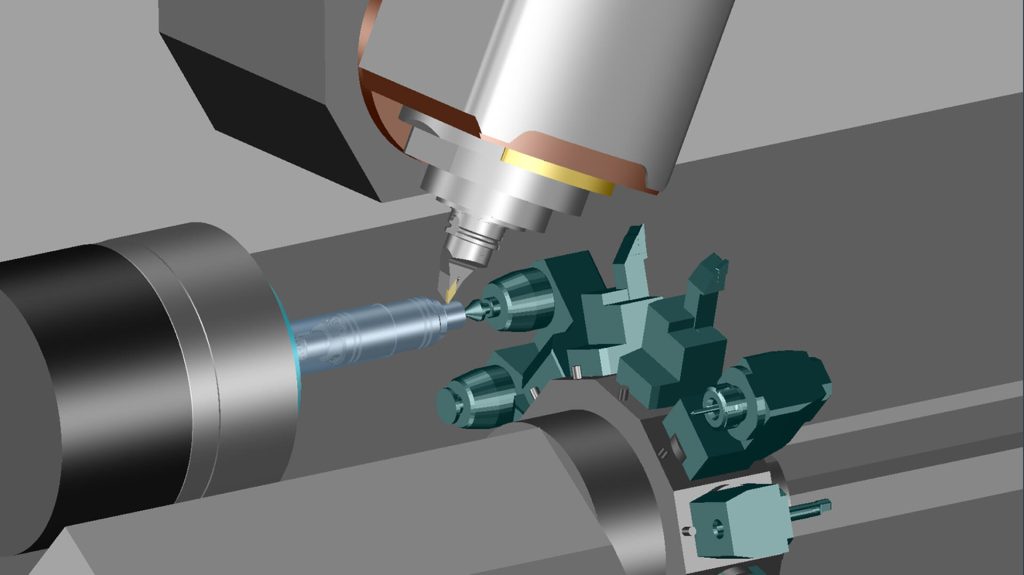

Turn-milling

Maximize the efficiency of advanced complete turn-mill machining centers

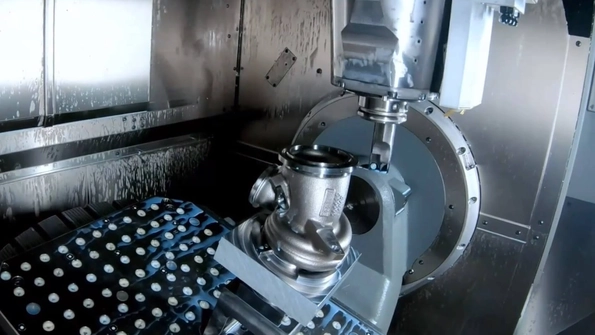

Tebis enables you to enhance the utilization of machines equipped for turning, milling and drilling operations. It eliminates the need for frequent machine changes and reclamping, consequently reducing logistical overheads in achieving the finished part. Furthermore, you gain improved accuracy in mill-turning, as the workpiece undergoes turning, drilling and milling in the same setup. On machines with a main and sub spindle, you can automatically transfer parts and complete them on all sides without manual reclamping. Leveraging these options safely and efficiently streamlines the operation of turn-milling machines, minimizing user intervention and monitoring is among the special strengths in the CAD/CAM process with Tebis.

- An end-to-end system – Program all machining operations from end to end

- Collision-free – Collision avoidance with virtual tool and machine models

- Material model – End-to-end material model for calculating toolpaths

- Fewer setups – Greater accuracy and reduced planning and logistical efforts

Sample application

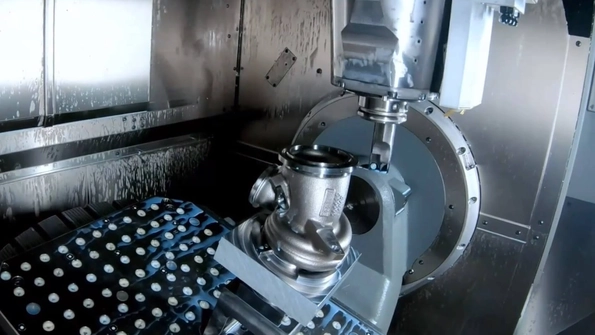

Turn-milling: Tebis heart wheel rim

This video shows the turn-milling of a high-quality aluminum wheel rim with a heart in the hub. The heart wheel rim weighs just two kilograms and is created from a 20-kilogram blank with only two setups for turning and milling. 2-axis to 5-axis milling is used, and virtual machine technology ensures maximum safety.

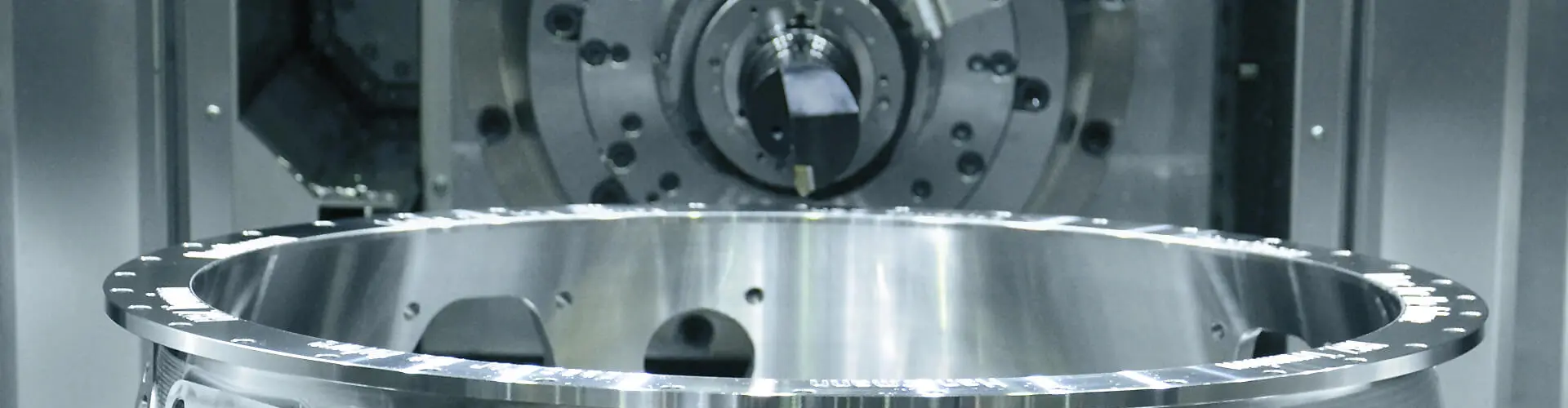

Interpolation turning: The new upcoming manufacturing method

Manufacture symmetrical part areas up to 80% faster

Interpolation turning is a highly efficient manufacturing method for combined machining on modern multitasking machines.

For example, this method lets you manufacture symmetrical part areas on appropriate milling machines or on turn-milling machines.

Machining is fast and ensures low tool wear. This method produces outstanding surface quality.

Tebis also integrates off-center turning, which is especially suitable for manufacturing eccentric turned parts.

Functions

Standardized tool management

Manage all your tools for turning, drilling and milling in a single tool library. DIN/ISO cutters and holders can quickly be created by specifying the type. Special tools like shaping, striking and side-milling tools are also supported. You can see realistic images of all the individual components and combine them to form tool assemblies which enable the performance of all collision checks.

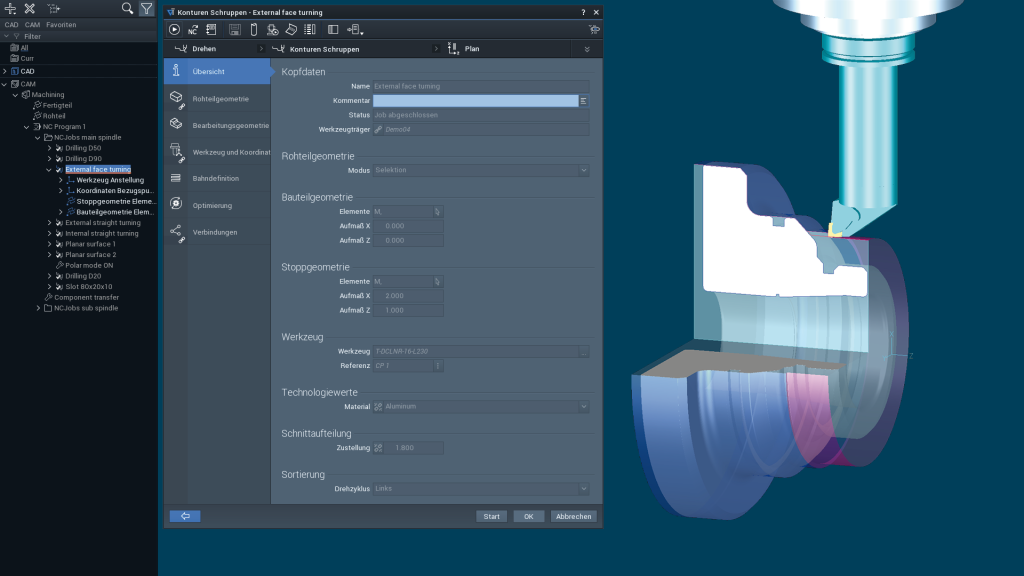

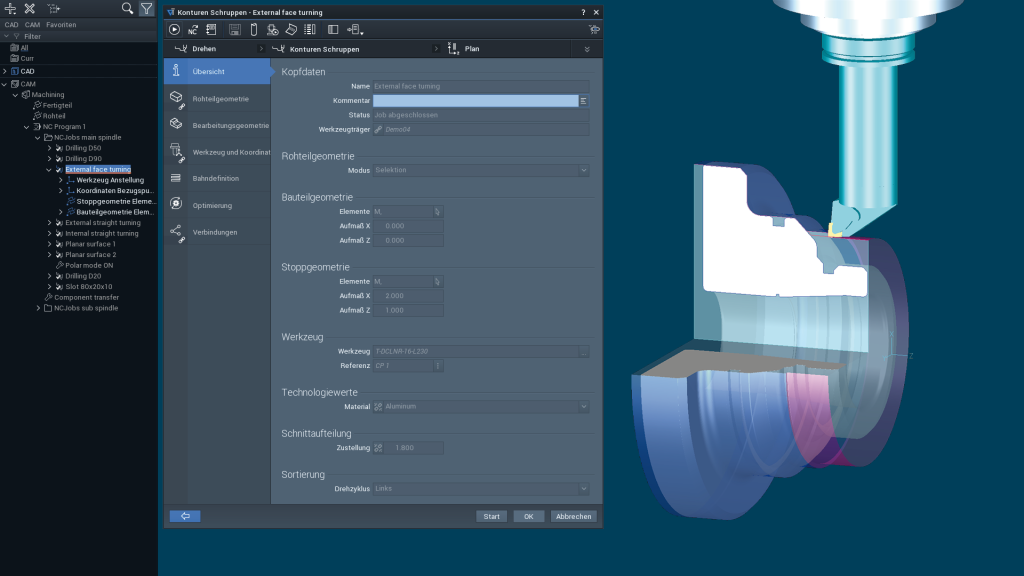

End-to-end Job Manager for turn-milling

You can combine the machining operations of turning, drilling and milling in the Tebis Job Manager as needed to produce workpieces suitable for manufacturing. In the end-to-end material model, material removal in mill-turning is documented from the blank to the finished part. Then the currently available material can be used as the starting point for the next machining operation – from turning to milling and back again. In conjunction with the implemented automation, the machining functions automatically find the geometries that will be machined in the part and calculate the toolpaths.

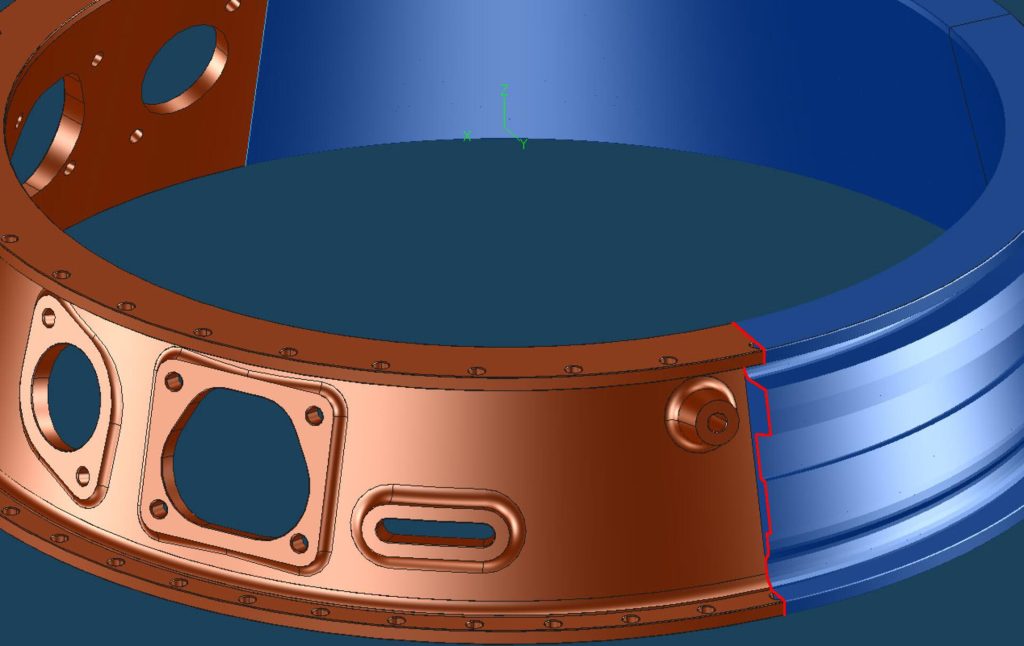

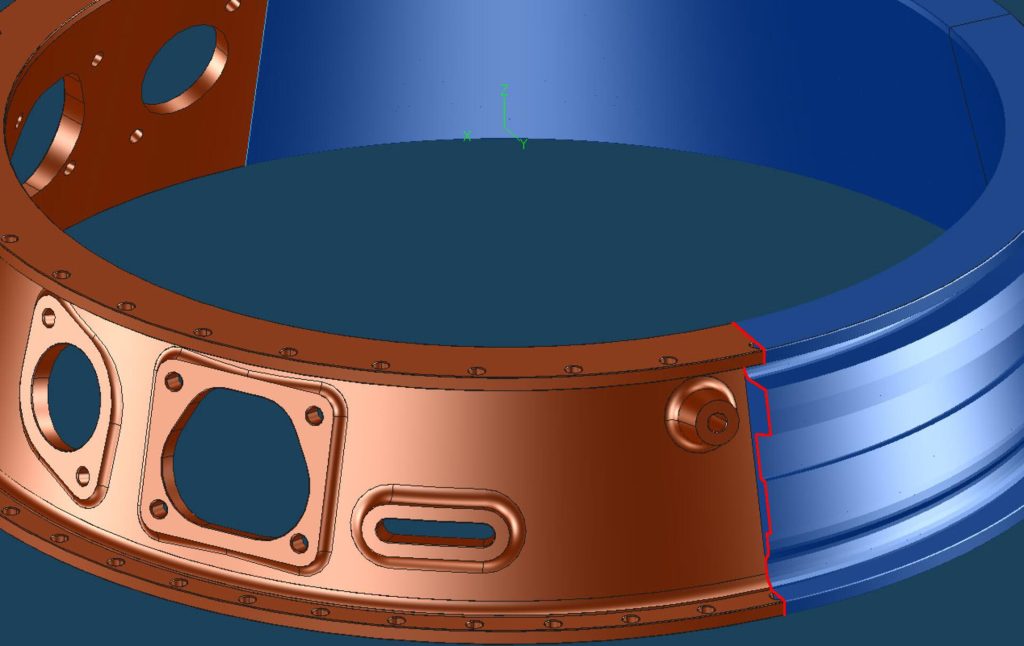

Determine the turning profile

It’s especially important in turn-milling to know the maximum possible contour for turning: in other words, the rotationally symmetrical envelope of the overall geometry. Tebis determines this with the click of a button.

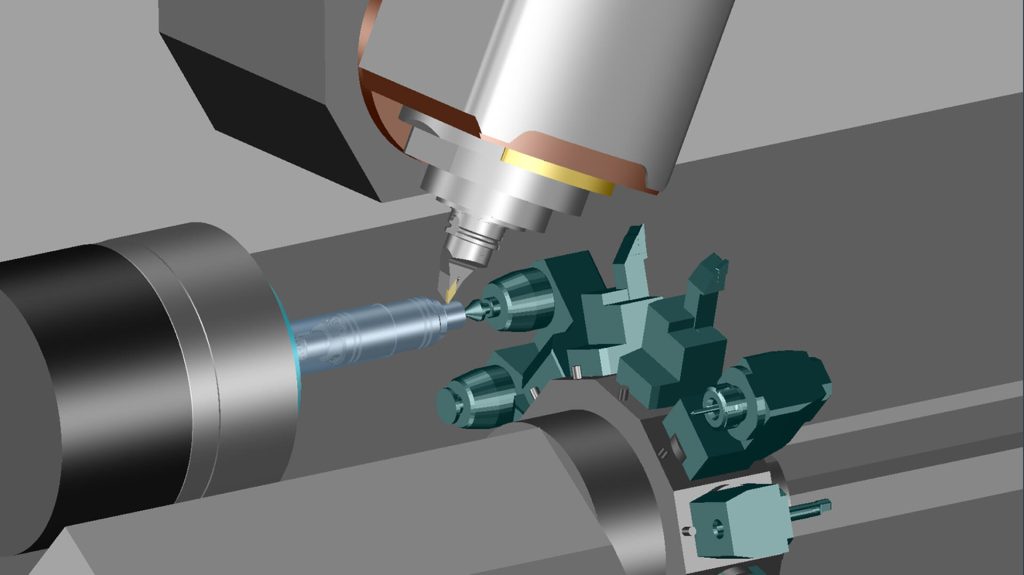

Support for multi-channel machine tools

Ideal for parts with a large milling fraction: Tebis can be used to program toolpaths for sequential processing on machines with multiple tool and part holders. The individual steps – including milling with a milling head or turret, stabilizing with a centering tip and clamping with a sub spindle – can be combined in any way.

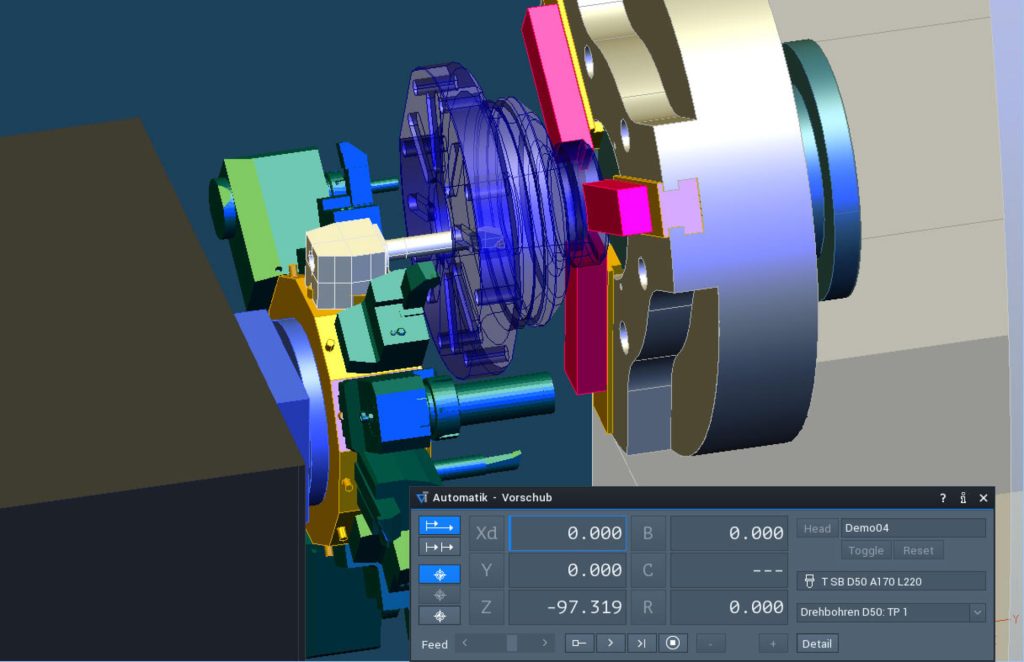

Simulation and NC output for turn-milling

Tebis reliably rules out collisions with all tool components during program calculation for turn-milling. The subsequent collision check analyzes machine components and the traverse paths between individual toolpaths. This results in an end-to-end collision-free CNC program for all turning, drilling and milling operations. The CNC program also controls the machine units, including clamping elements, tailstocks and steady rests. Tebis automatically generates NC code for any machines and supports all control-specific program structures: for example, as Gildemeister structure programs.