Wire EDM

From the CAD model to the cutting program – fast, reliable and optimized

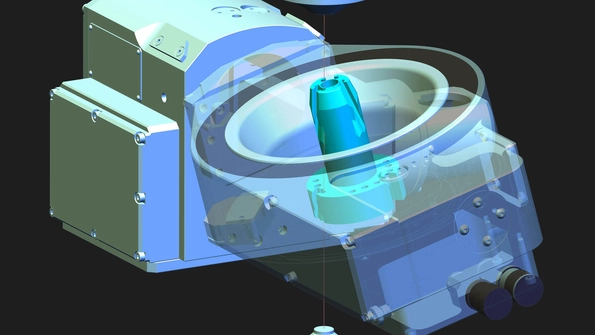

Tebis has wire EDM functions for precisely manufactured parts with highly complex geometry, maximum quality requirements and the smallest corner radii: for example, components in die and mold manufacturing and the medical and aerospace industries. Tebis uses the wire EDM functions in DCAMCUT Expert’s integral NC programming environment to generate collision-tested NC programs for 4-axis wire EDM.

- Simple – Fast, standardized and automated NC programming

- Reliable – Maximum reliability and greater productivity on the machine

- Convenient – Use the full capacity of the machine controls

- Comprehensive – Optimal use of machines with additional rotary/tilt tables

Functions

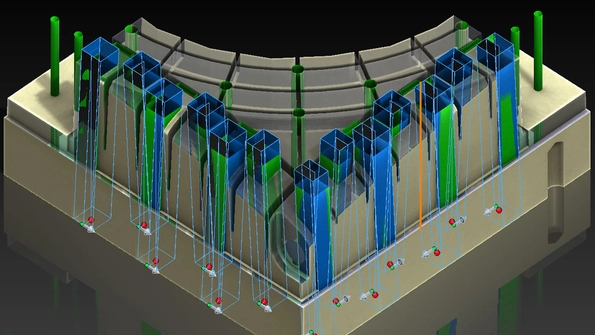

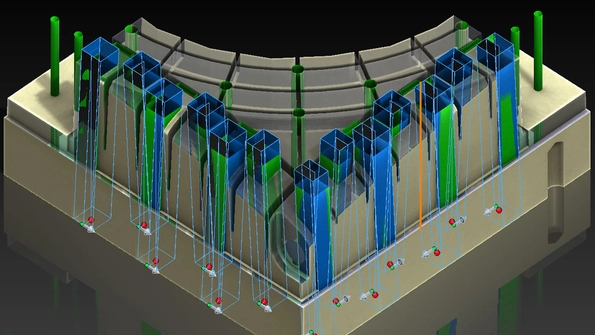

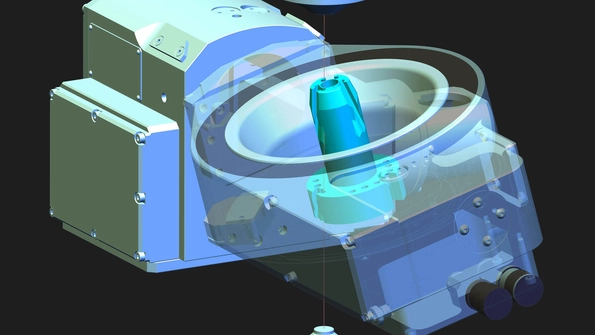

DCAMCUT Expert recognizes your EDM contours in 3D data in any size completely automatically. The unique NC processor technology checks every one of your programming steps during creation and before NC program output. The software accounts for the capacity of your machines to avoid unnecessary work on the control. Cutting paths and waste cuts as well as an updated material model are generated based on templates and technology databases. This is done using powerful NC strategies and optimized clearing cycles. Simulate the calculated NC programs for the selected machine, detect drop-out parts and create the NC documentation.

Wire EDM can be extended with many productive options for especially demanding applications. These include indexed multi-sited machining, simultaneous multi-axis machining and an NC processor upgrade and material removal simulation upgrade for multi-axis machining – all the way to erosive grinding. You can optimally tap the potential of your machines with additional rotary and tilt tables.