In-process measurement

Reliability for automated manufacturing

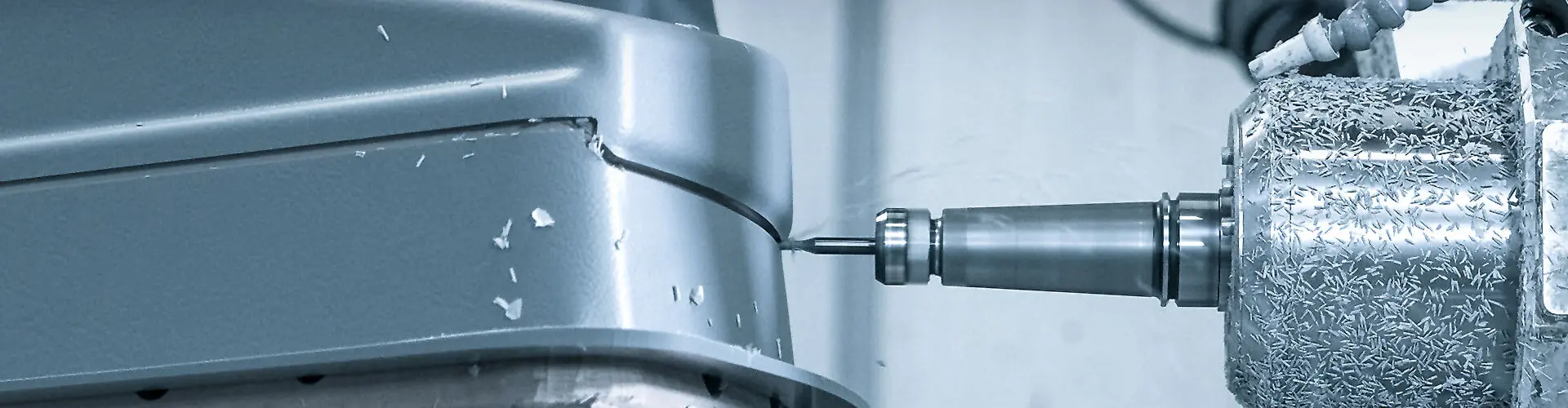

You want to make the best use of your investments in highly automated machine centers. Optimal utilization therefore requires unattended operation during late shifts and night shifts. “In-process measurement” gives you the necessary process reliability by checking part orientation and blank dimensions. You can integrate quality controls in the machining process independent of measuring cycles in the control for production with no reworking. This results in complete NC programs with toolpaths for turning, milling and drilling – including measurement cycles – with which your machining centers can run unattended for as long as necessary. Because all movements of the measuring probes, tools and machines can be realistically simulated and checked for collisions.

- Reliable – Safeguards the manufacturing processes

- Time savings – Reduces setup time and reworking

- Integrated – Complete process-integrated solution in a single system

- High quality – Improves part quality

Functions

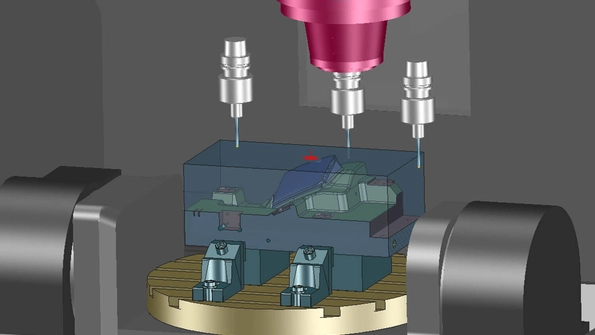

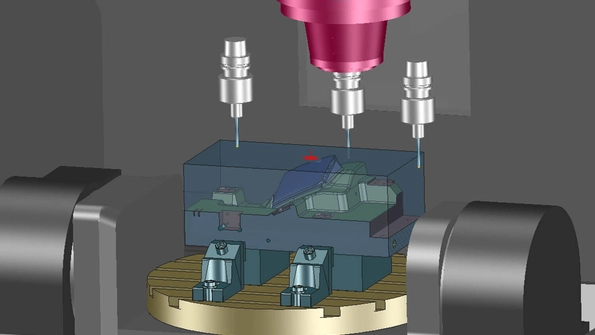

Determine reference point and blank dimensions

Integrate the determination of the reference point in your NC program so your machining centers can start working immediately after setup. The Tebis Job Manager lets you control the measuring cycles for the reference point, automatically determine part rotation and correct the reference point. This prevents user errors and results in a reliable, highly automated process that shortens setup time.

You can also check the blank dimensions. If the dimensions are outside the tolerance for your machining operation, it can be stopped at an early stage. This allows you to prevent tool breakage, damage to the machine or worse.

Checking and correcting standard geometries

You can use functions that check whether the manufacturing result is within tolerance for measuring standard geometries like bores, rectangular pockets and cylinders. If the checked elements still have a stock allowance, the machine center can automatically start another machining operation for correction. This lets you integrate quality control in the manufacturing process, increase the degree of automation and reduce quality loops and overall machining time. You can also save a log file on the control.

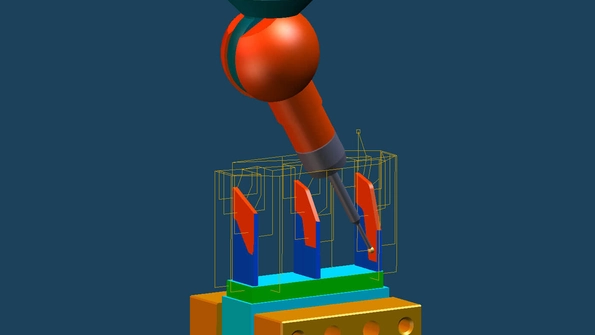

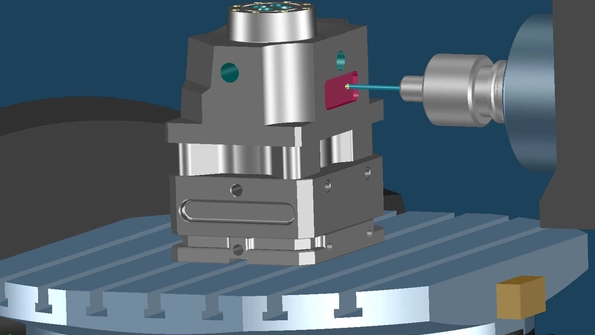

Check electrodes completely automatically

Many individual workpieces with special quality requirements are generated in electrode manufacturing. You therefore want to completely integrate quality control in the process to prevent errors and lost time. You can do this using templates in Tebis to create measuring paths for the specific areas of an electrode that you want to check. The defined arc gap is automatically taken into account. You can even have measuring paths for the setup probe created completely automatically. All movements of the measuring probe and the machine can be simulated and checked for collisions. Because measuring machines can be directly integrated, the specified/actual comparison of completed electrodes and the CAD geometry works every time. Tebis outputs the measuring result directly as correction values for the EDM machine.