Coordinate Measuring Machines (CMM)

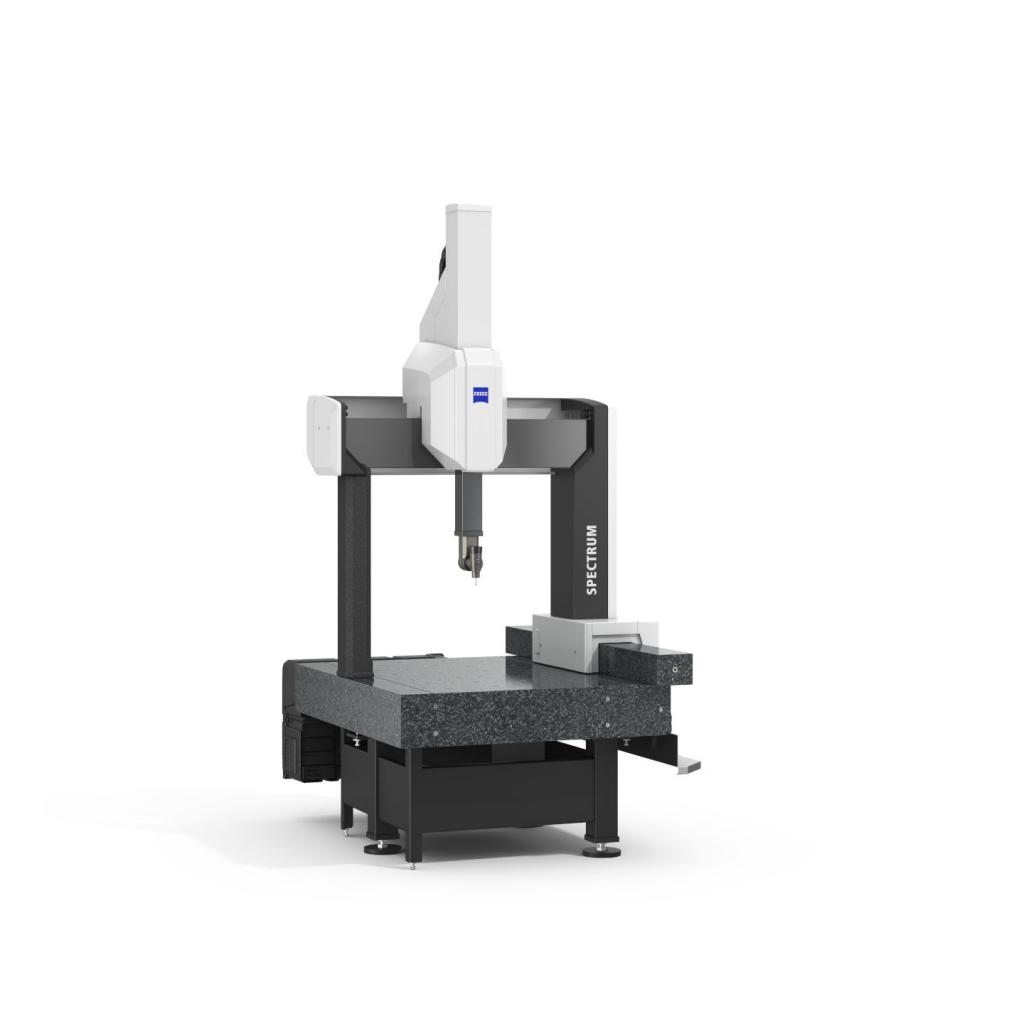

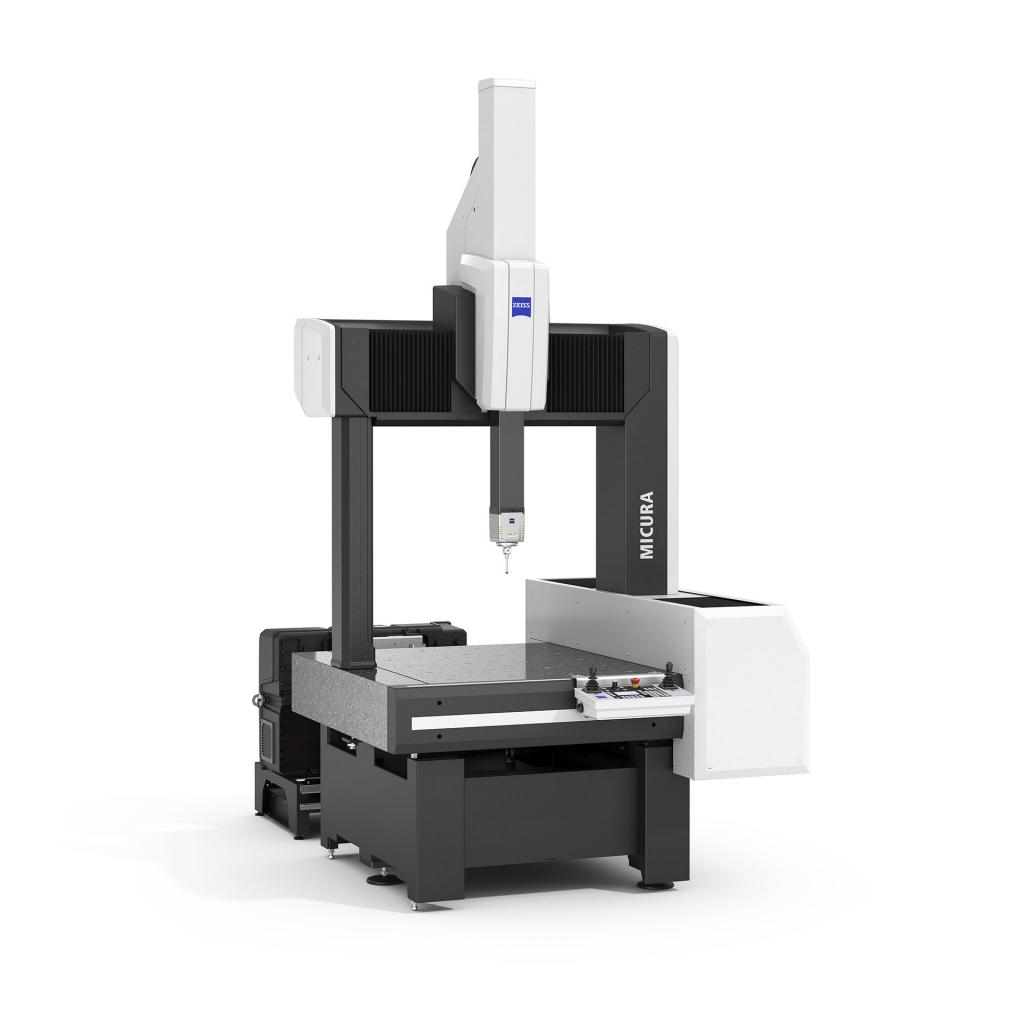

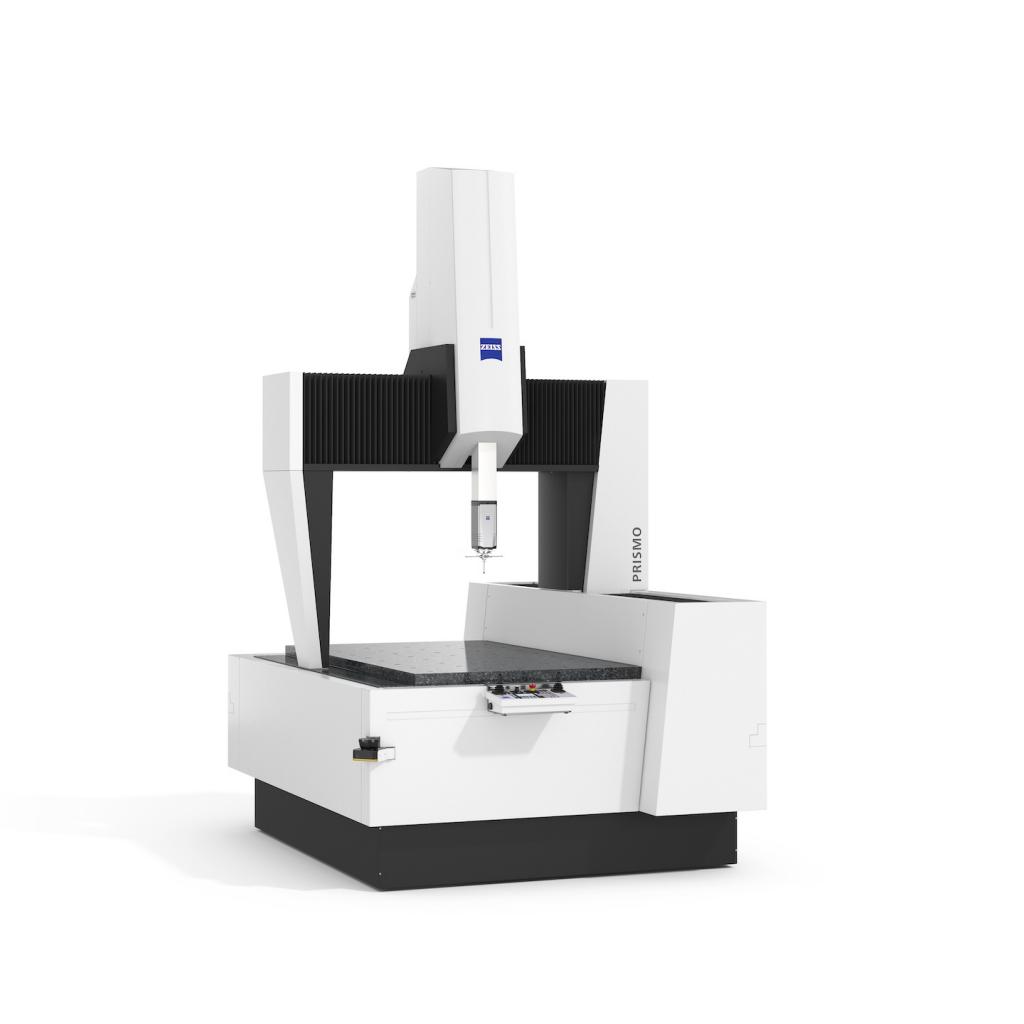

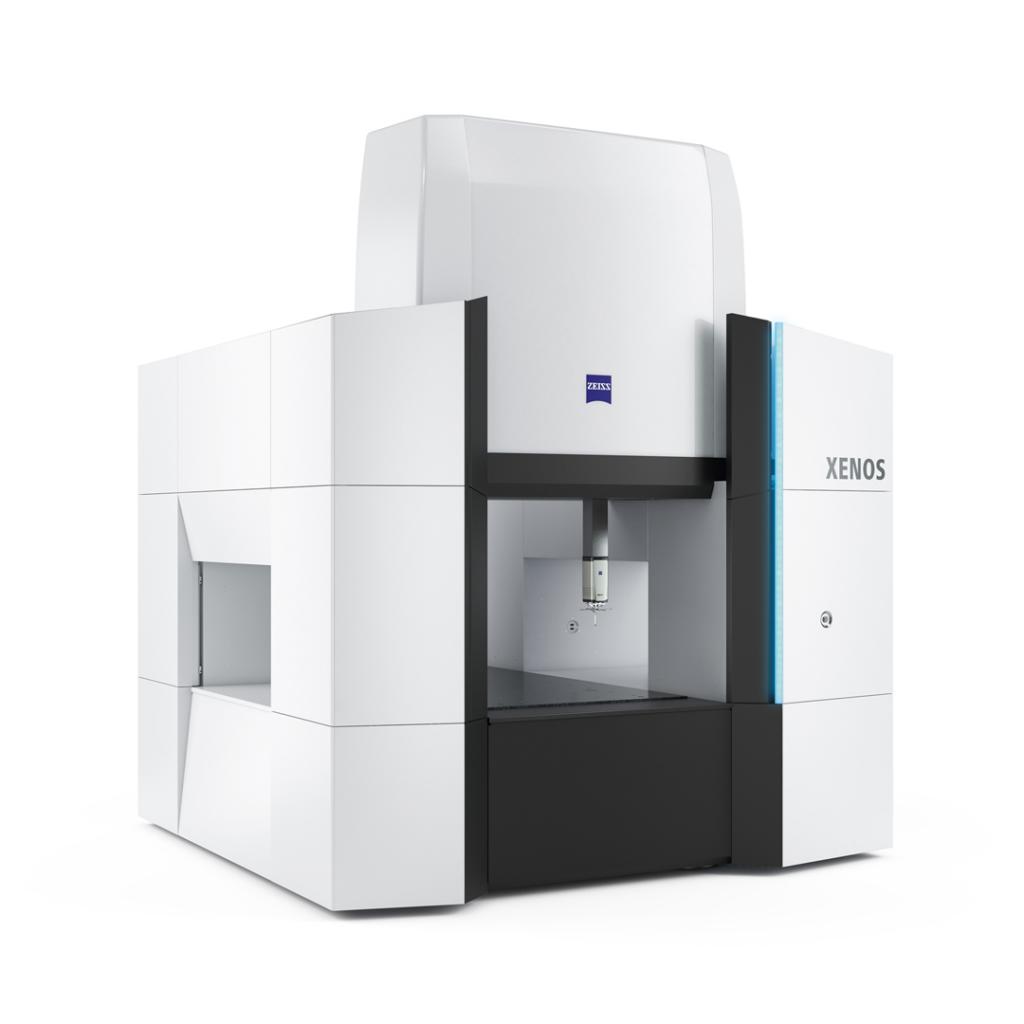

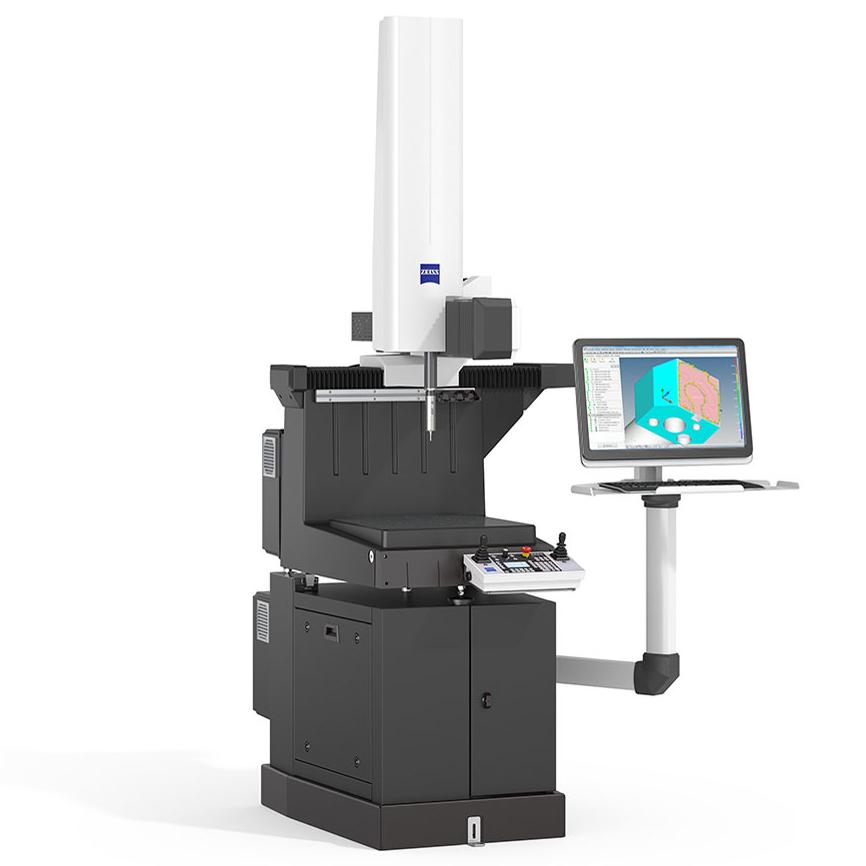

Reliable and high-quality coordinate measuring technology Bridge CMMs

Bridge-Type Coordinate Measuring Machines

Efficient and precise measurement

Tailored to the challenges of industrial measurement technology

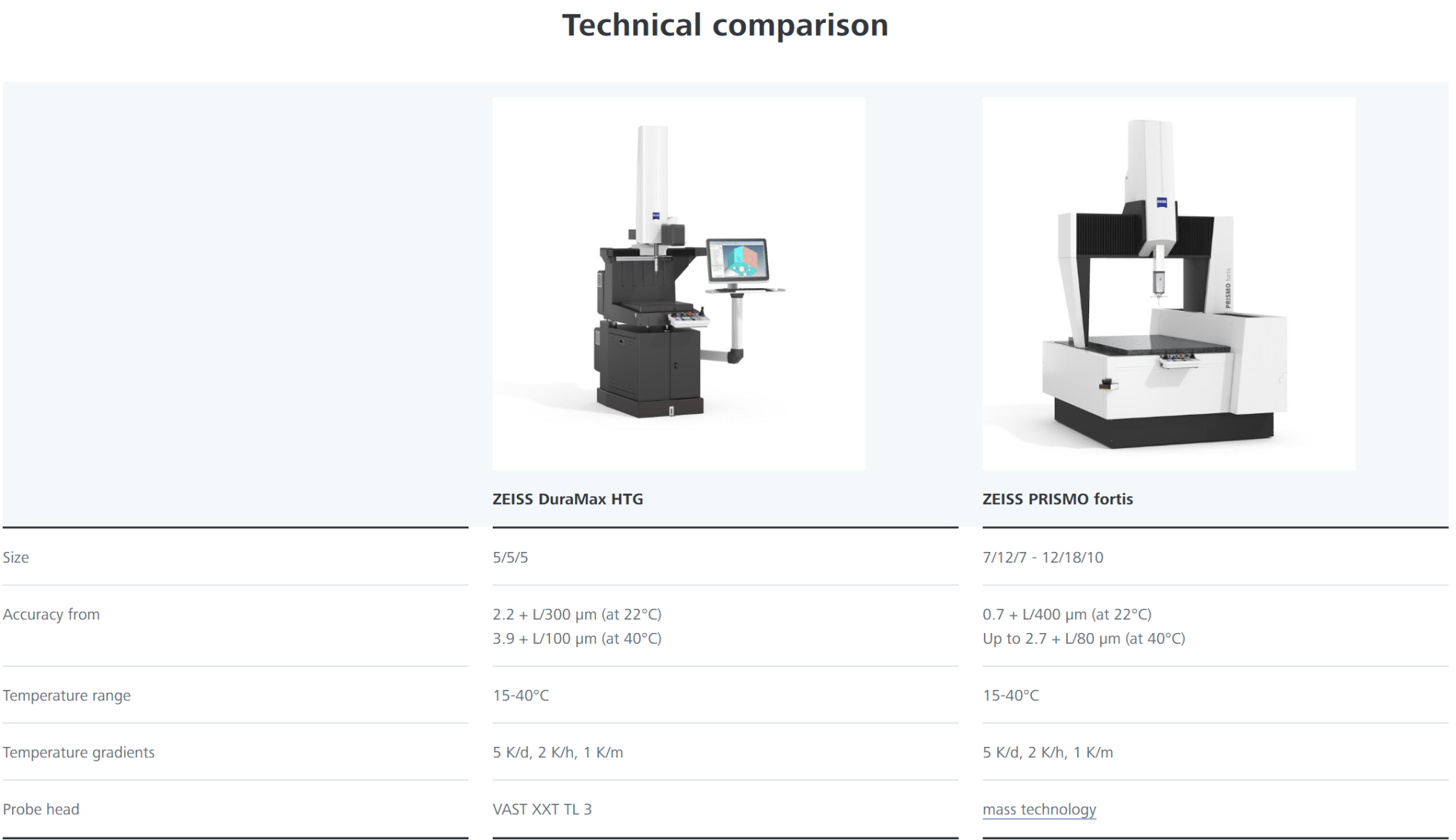

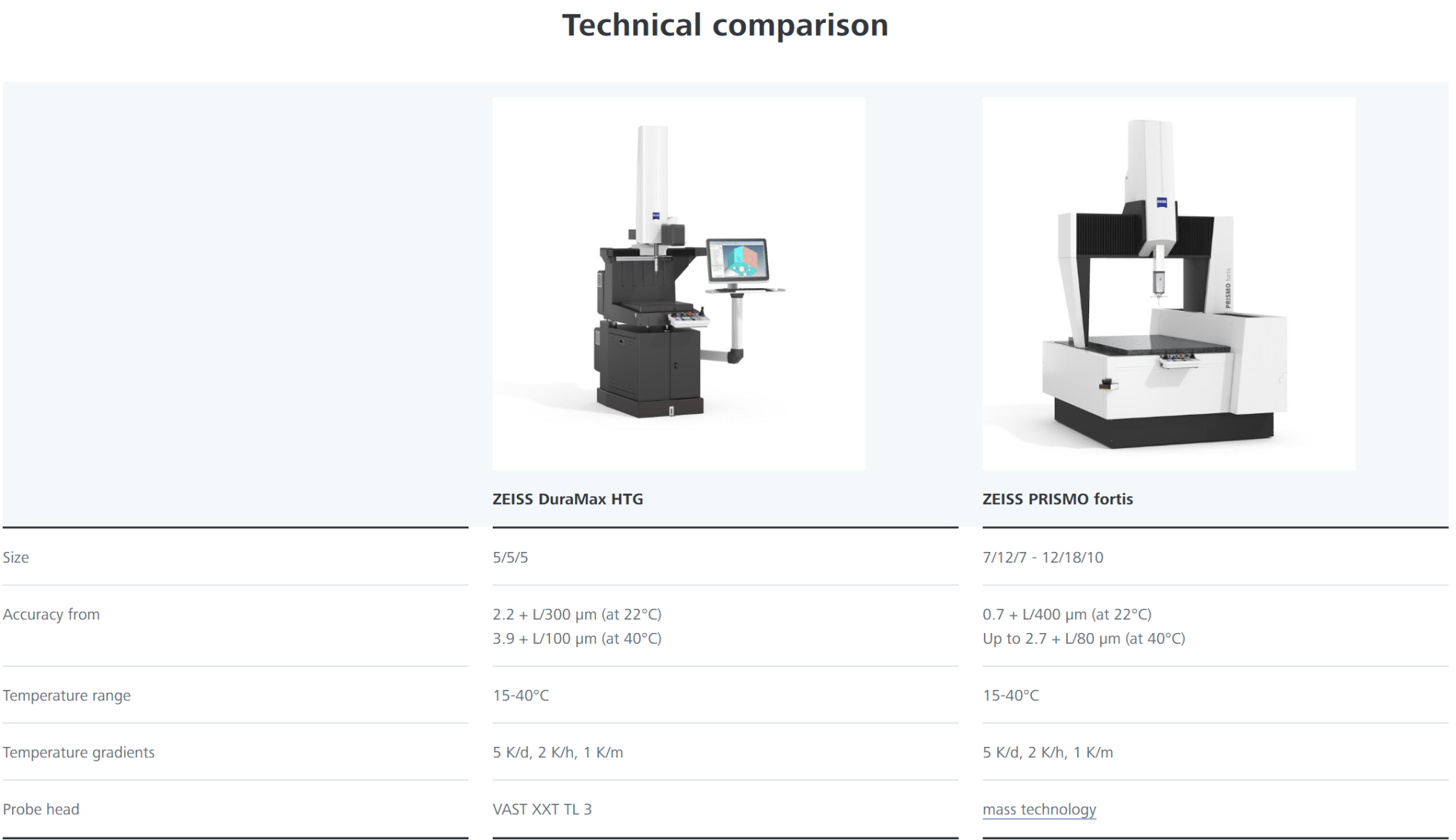

High standards of precision require strict control of production quality. Precise measurement results are required to meet these standards. ZEISS bridge-type coordinate measuring machines are designed to meet these requirements and are characterized by a high degree of accuracy and low measurement deviations and are suitable for a wide range of applications.

Your benefits with bridge-type coordinate measuring machines from ZEISS

High measuring speed due to high level of rigidity of the coordinate measuring machine

To guarantee high quality standards, ZEISS relies on three key features: dynamic rigidity, low weight of the moving workpieces and reliable insulation from environmental influences.

The dynamic rigidity of the coordinate measuring machine is crucial for accuracy. This is the only way to avoid measurement deviations even when scanning at high speeds. To ensure high performance in every application, ZEISS bridge-type coordinate measuring machines are characterized by temperature and vibration insulation as well as shielding covers to protect the coordinate measuring machine from environmental influences. The measuring table of the bridge-type CMMs is made of granite. In order to make the moving parts as light and yet rigid as possible, ZEISS uses ceramic and DLC aluminum. In addition, bridge-type coordinate measuring machines from ZEISS are fitted with air bearings. The optimum distribution of these air bearings guarantees friction-free and wear-free sliding in many applications.

Shorter measuring times thanks to individual stylus system from ZEISS

The ZEISS VAST scanning probes also allow the use of long and heavy stylus systems, enabling time-saving scanning of deep-set features on workpieces. Complex stylus systems with differently aligned probes can also be used for maximum flexibility and measuring speed. This allows stylus system changes to be optimized and the measuring times of complex workpieces to be shortened.

The original accessories from ZEISS will help you to achieve the best possible measurement results with every measurement. This is because the tested combination of materials, design and technology only realizes its full potential when the individual components of the coordinate measuring machine are perfectly matched.

You can find the right accessories for your bridge-type coordinate measuring machines in the ZEISS webshop.

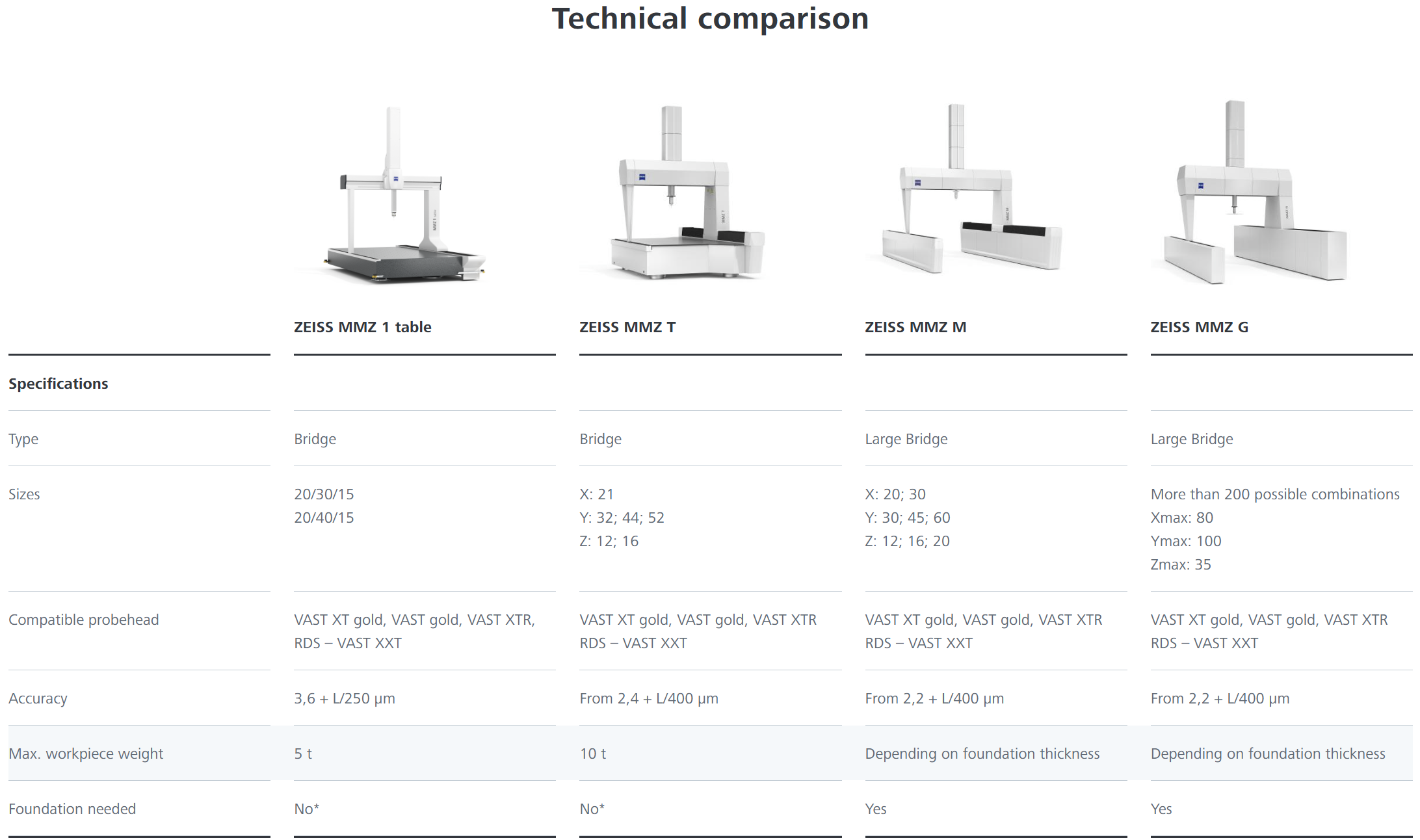

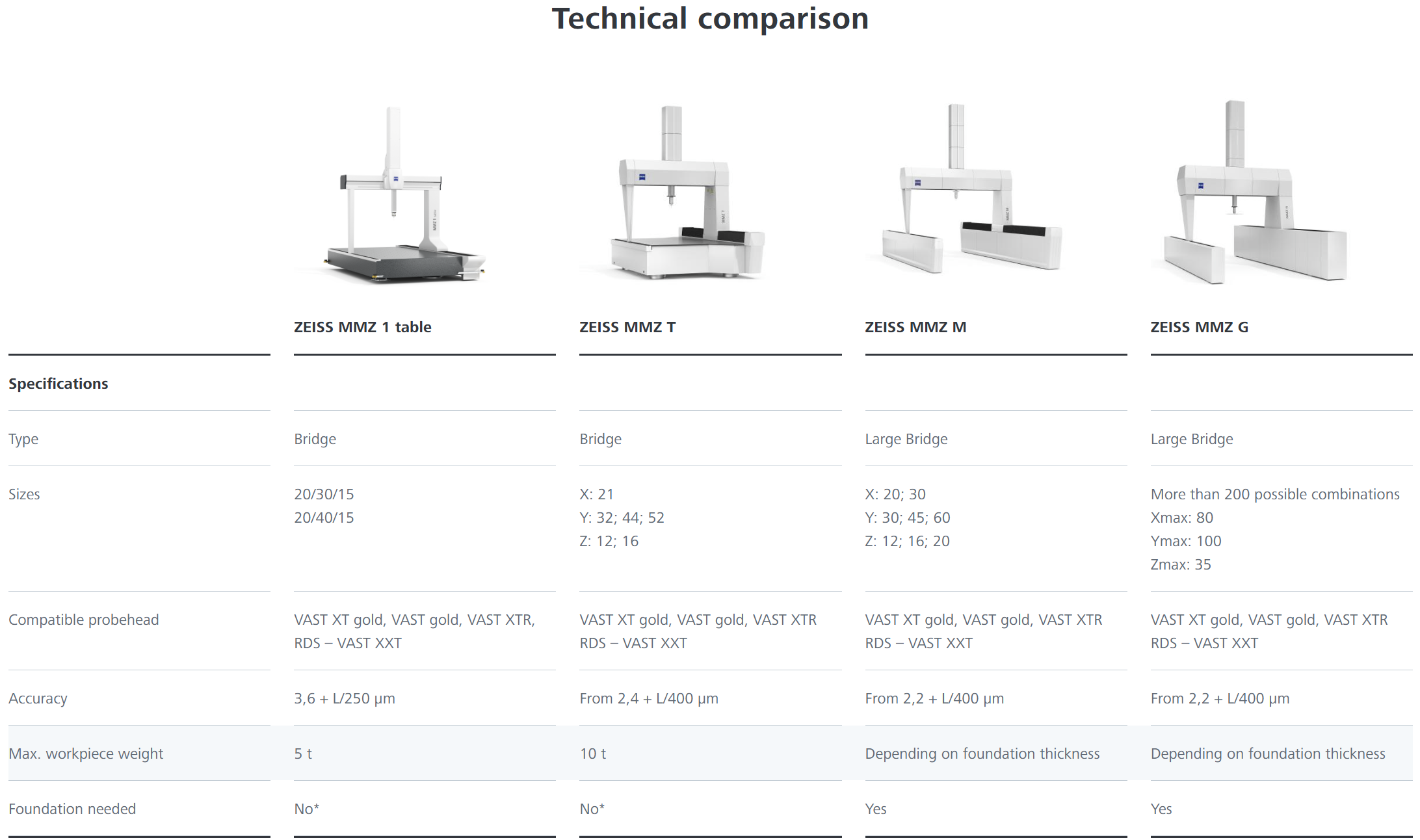

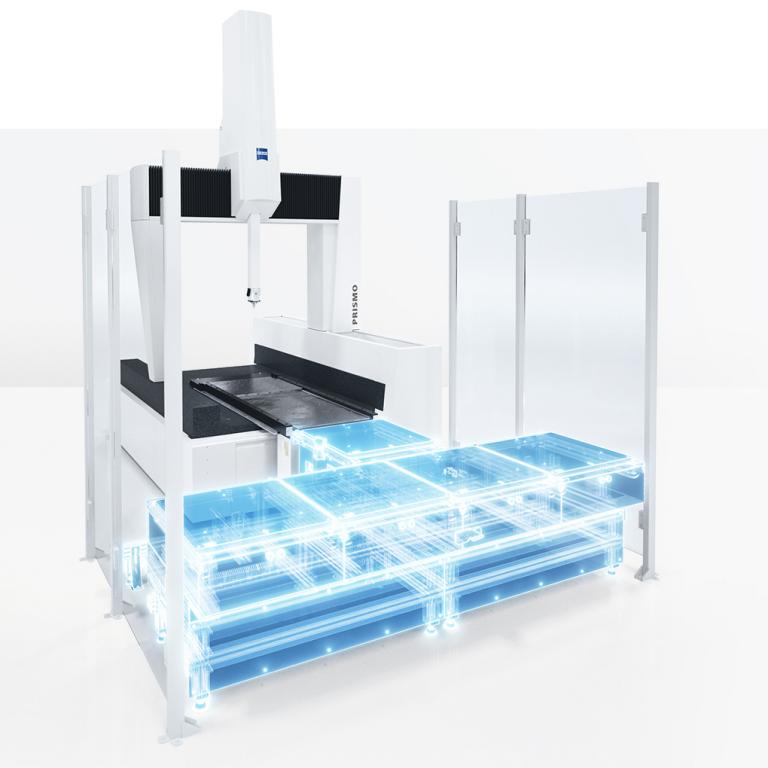

Large CMMs

Large Coordinate Measuring Machines

Reliable testing of large components

Quality assurance of large components with the ZEISS MMZ family

Coordinate measuring machines with a large measuring range and high load capacity are essential in various sectors such as energy and power generation, mechanical engineering and aerospace. The products of the ZEISS MMZ family can be configured in various sizes and thus guarantee the measurement of the largest workpieces – without compromising on precision.

Shop floor CMMs

Production Measuring Machines

Maximum flexibility under the heaviest loads

Coordinate measuring machines for the production area

Coordinate measuring machines that are used in production or manufacturing must meet special requirements. Environmental influences such as dust, oil, floor vibrations or temperature fluctuations must only have a minor effect on the measurement results. The production measuring machines from ZEISS were designed for precisely these loads and enable use in production environments – in order to measure where production takes place.

Horizontal Arm CMMs

Horizontal Arm CMMs

For inspection of hard-to-reach parts

Coordinate measuring machines for the production area

As a system provider, ZEISS offers just the solutions for the changing conditions of day-to-day measuring tasks with impressive accuracy, effectiveness, and above all, dependability. From the first consultation on the installation, to the maintenance of your measuring machines, ZEISS takes charge of your metrology. You get all the services and products from the same partner – and all optimally matched to each other.

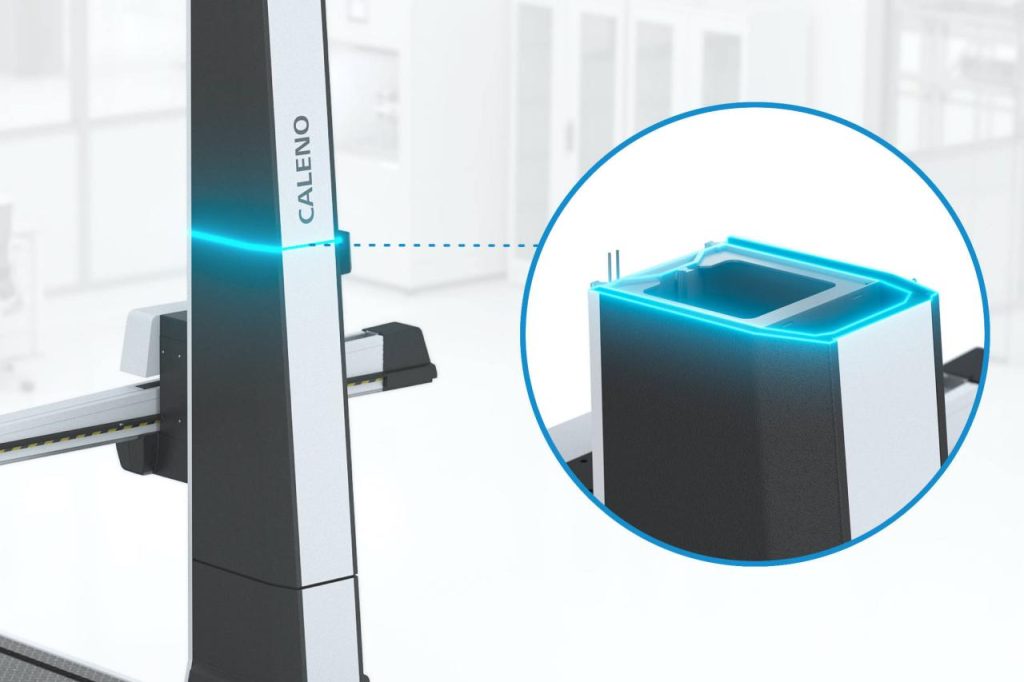

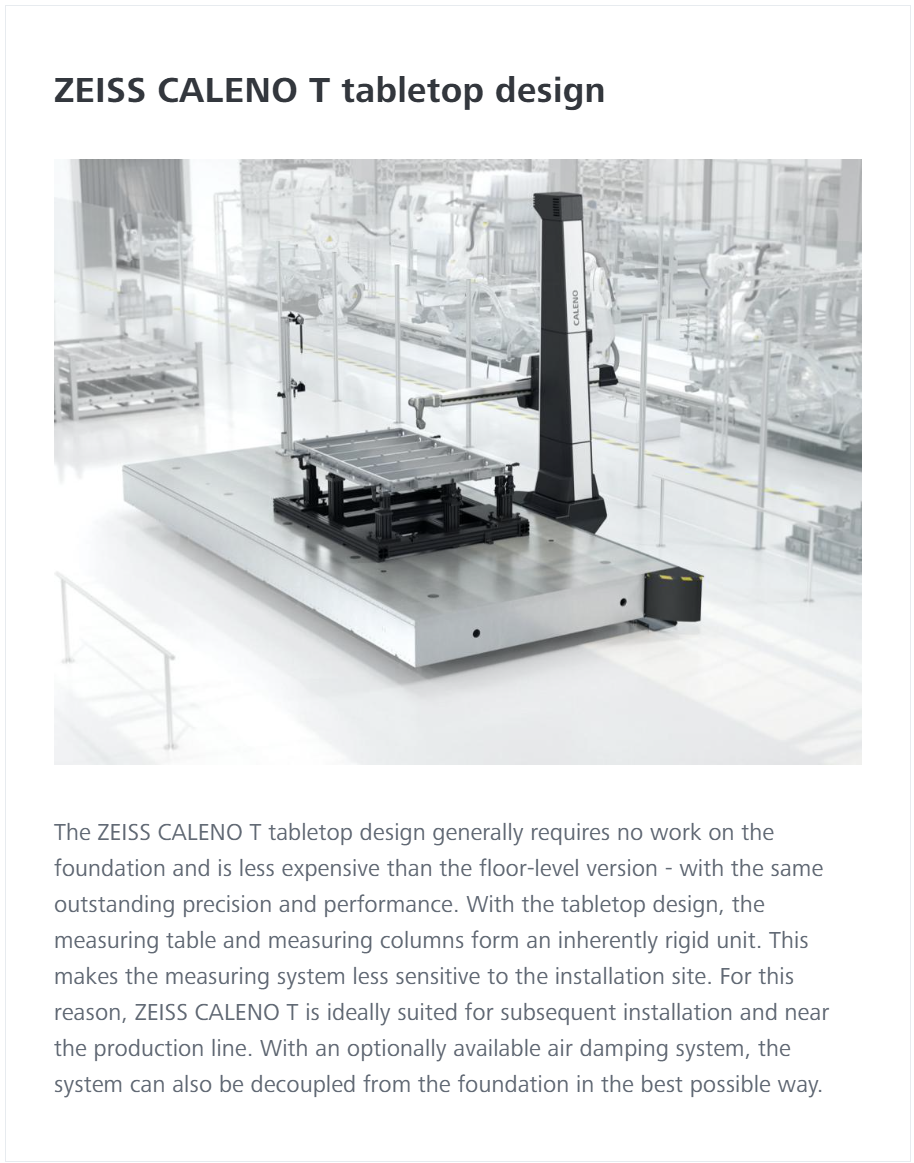

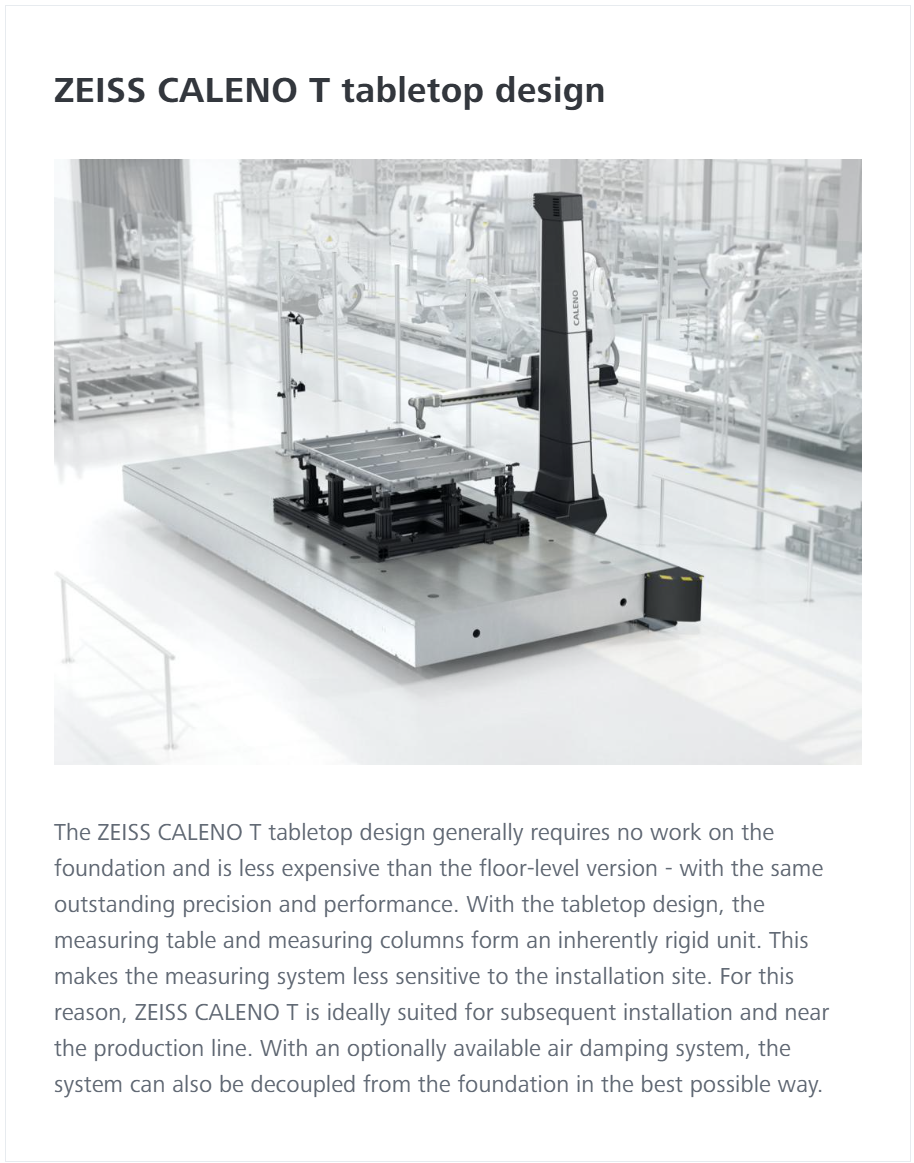

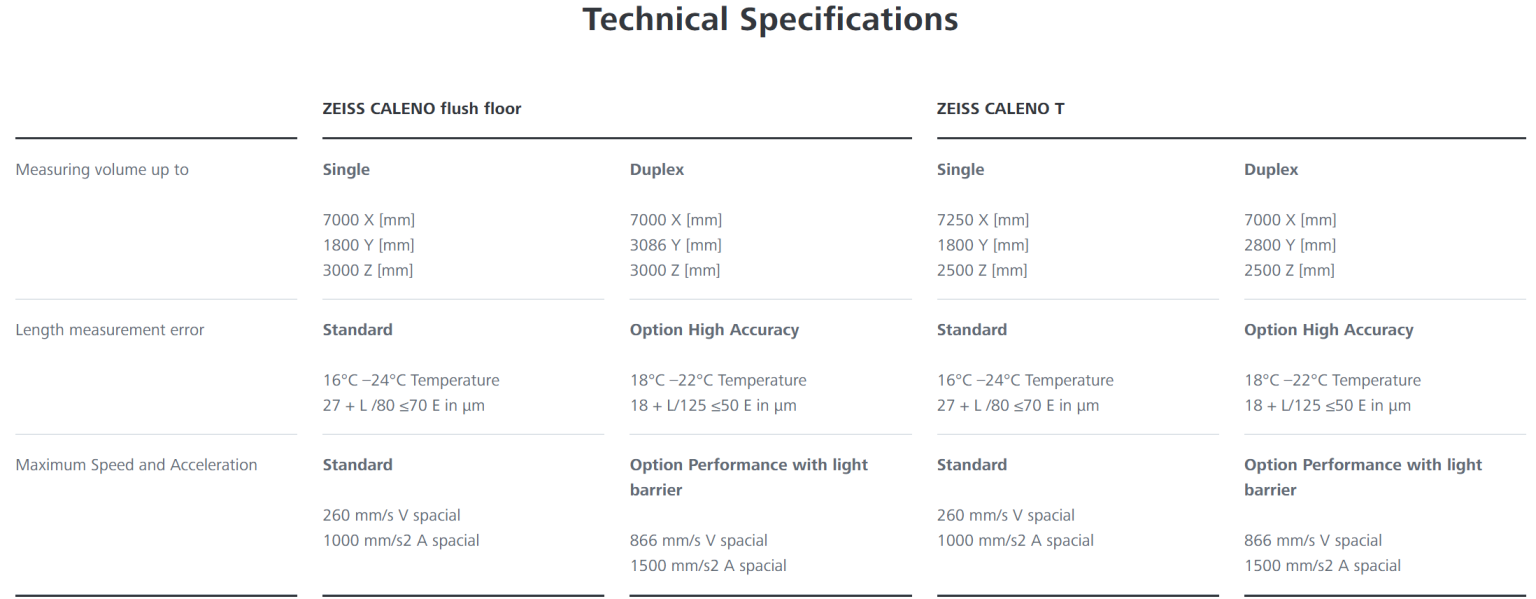

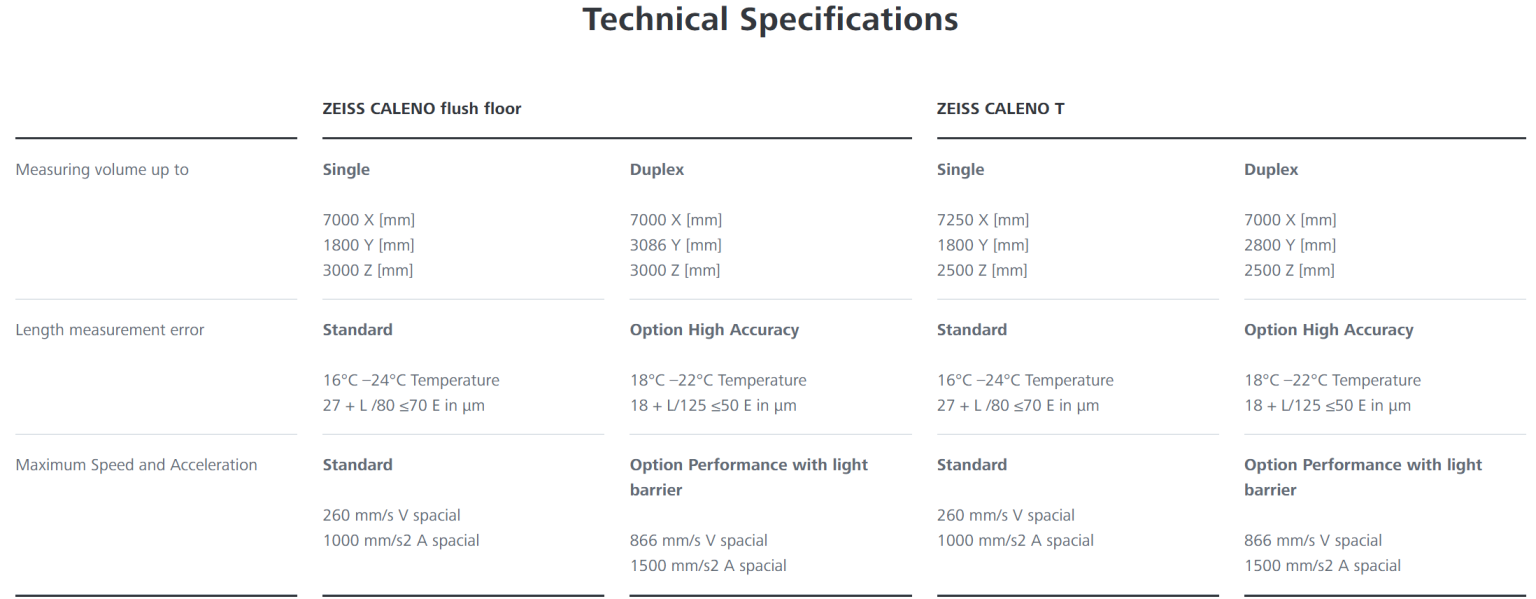

ZEISS CALENO

Multisensor horizontal arm machine

With its combination of high-performance optical and tactile sensors ZEISS CALENO ensures maximum productivity and precision.

- Enhanced accuracy with multisensor technology

- Superior productivity with high-speed measurements

- Optimal safety with integrated protection systems

More than a robot. It’s a Hambot.

Hambot is the new generation of horizontal arm machines in metrology combining high performance of a robot with possibilities of traditional horizontal arm machines.

ZEISS CALENO is a combination of CMM accuracy, collaborative system and an outstanding multi-sensor system with an automatic tool changer. Maximum versatility and highest performance capabilities ensure higher travel speed, acceleration and accuracy in the measuring room and near production. With its combination of high-performance optical and tactile sensors ZEISS CALENO ensures maximum productivity and precision.

The Optical system ZEISS EagleEye in ZEISS CALENO enables to reduce the measuring time for up to 85%1 with no compromise on quality and accuracy.

Full Cover is standard

Every ZEISS CALENO has a full enclosure in a modern design. It ensures thermal insulation and protection against contamination. This also makes ZEISS CALENO suitable for use in a production environment. In addition, active temperature compensation is optionally available for all machine axes and the part.

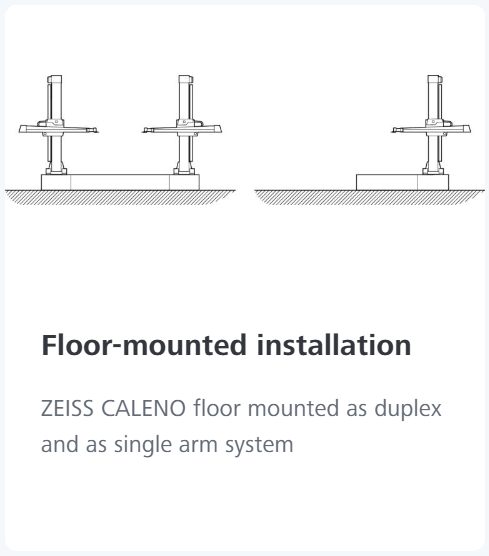

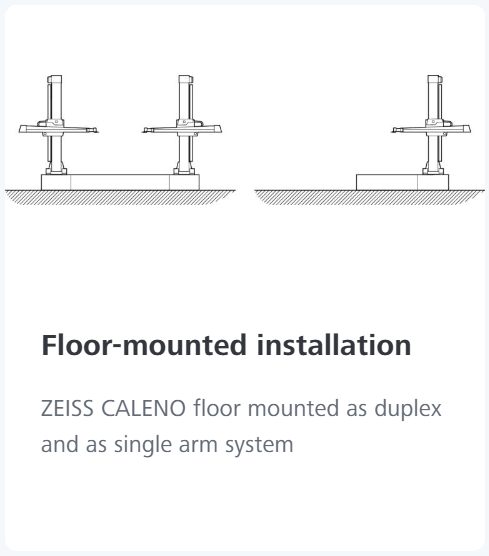

ZEISS CALENO Designs

Upgrade from ZEISS PRO T

You would like to upgrade the sensor technology of your ZEISS PRO T?

We recommend a complete upgrade to ZEISS CALENO T.

The new ZEISS CALENO T has been designed so that its improved Z-columns are compatible with the ZEISS PRO T measuring plate. By exchanging the column, a ZEISS PRO T can be converted to a ZEISS CALENO T with the latest ZEISS sensor technology.

This gives you the most accurate and efficient ZEISS horizontal arm measuring system ever. The reason: the new Z-columns of the CALENO T provide higher rigidity, first-class temperature isolation as standard and minimized maintenance. And they are the future-proof basis for future further developments in swivel joints and sensor technology.

New non-indexing head DSC

High dynamics, excellent precision and accuracy enable DSC to perform various measuring tasks. It works with both tactile and optical sensor systems, allows to work with extensions of up to 800mm and offers fast rotation speed. Passive probe charger requires neither compressed air nor electricity.

VMMs

Optical Coordinate Measuring Machines

High-precision optics for flexible measuring tasks

Non-contact measurement with tactile options

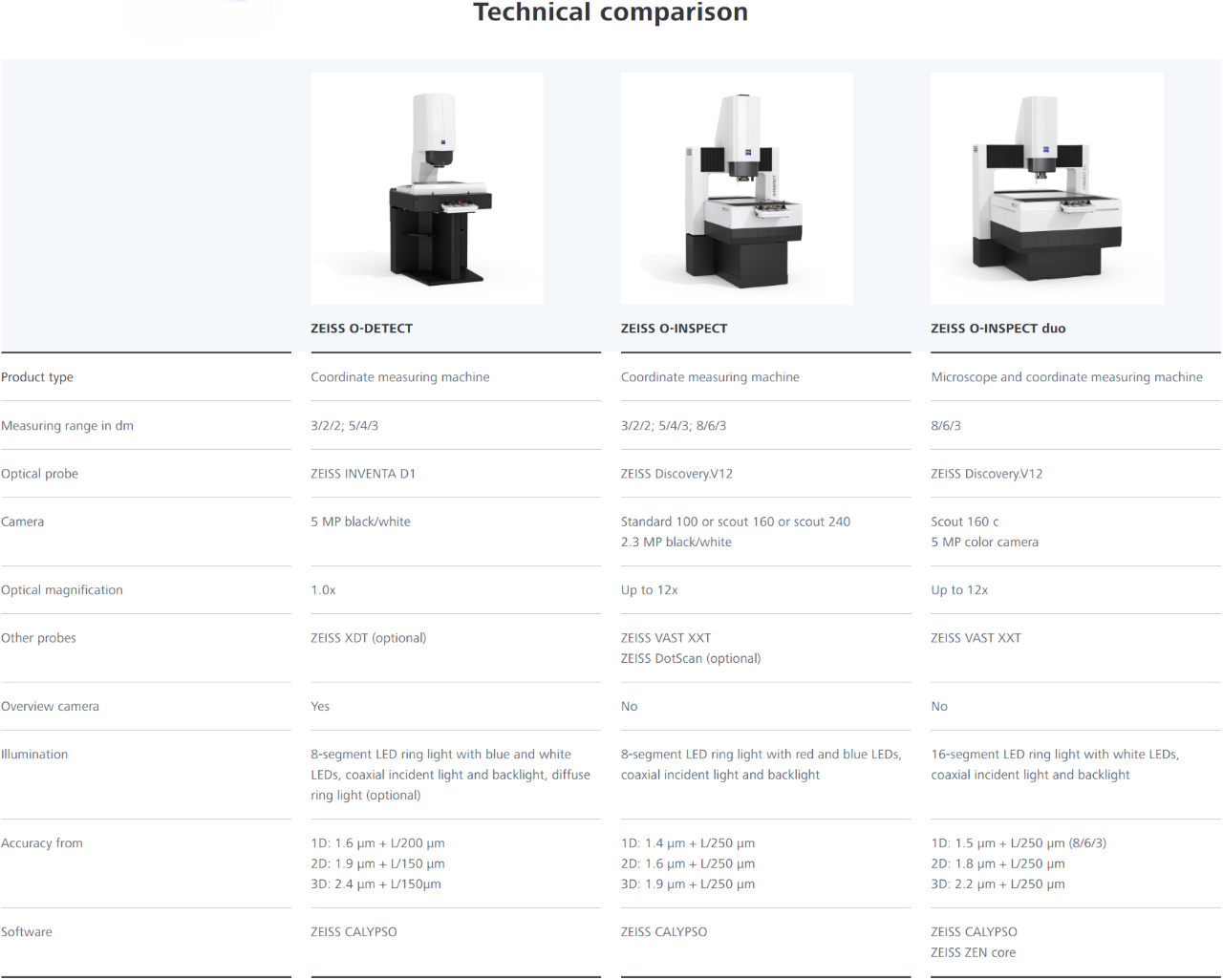

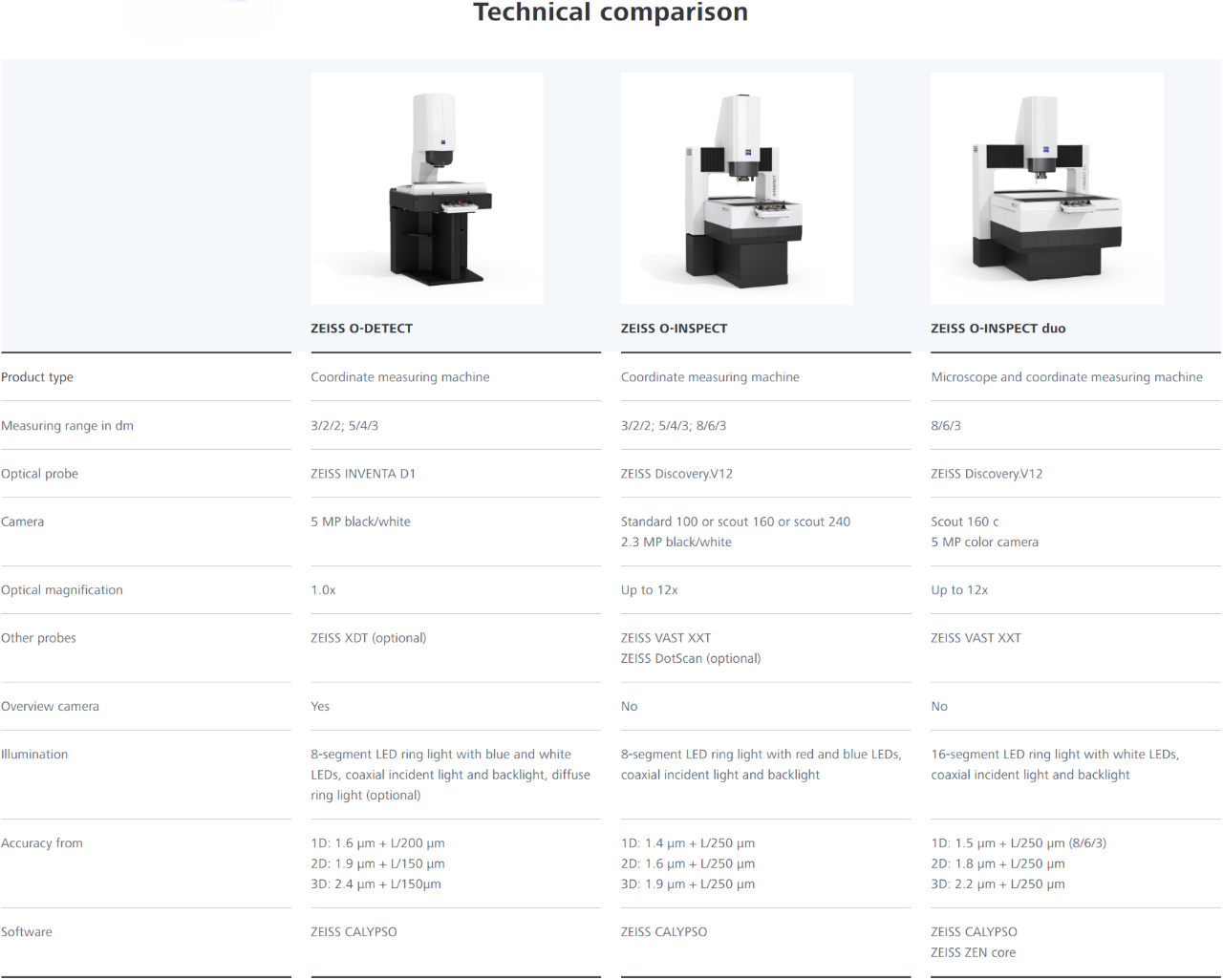

The optical coordinate measuring machines (VMM) in the ZEISS Optical Series impress with their high-resolution camera systems, variable illumination and sophisticated software for fast and precise measuring results. The non-contact, optical measuring technology means that even particularly sensitive, thin-walled or flat workpieces, such as optics, injection-molded workpieces, foils, punched and bent parts, can be measured with a high degree of precision. To extend the range of applications, the ZEISS Optical Series systems can be supplemented with additional probes – for high-precision optical and tactile measurements in just one CMM.

ZEISS O-DETECT

Entering the world of optical metrology

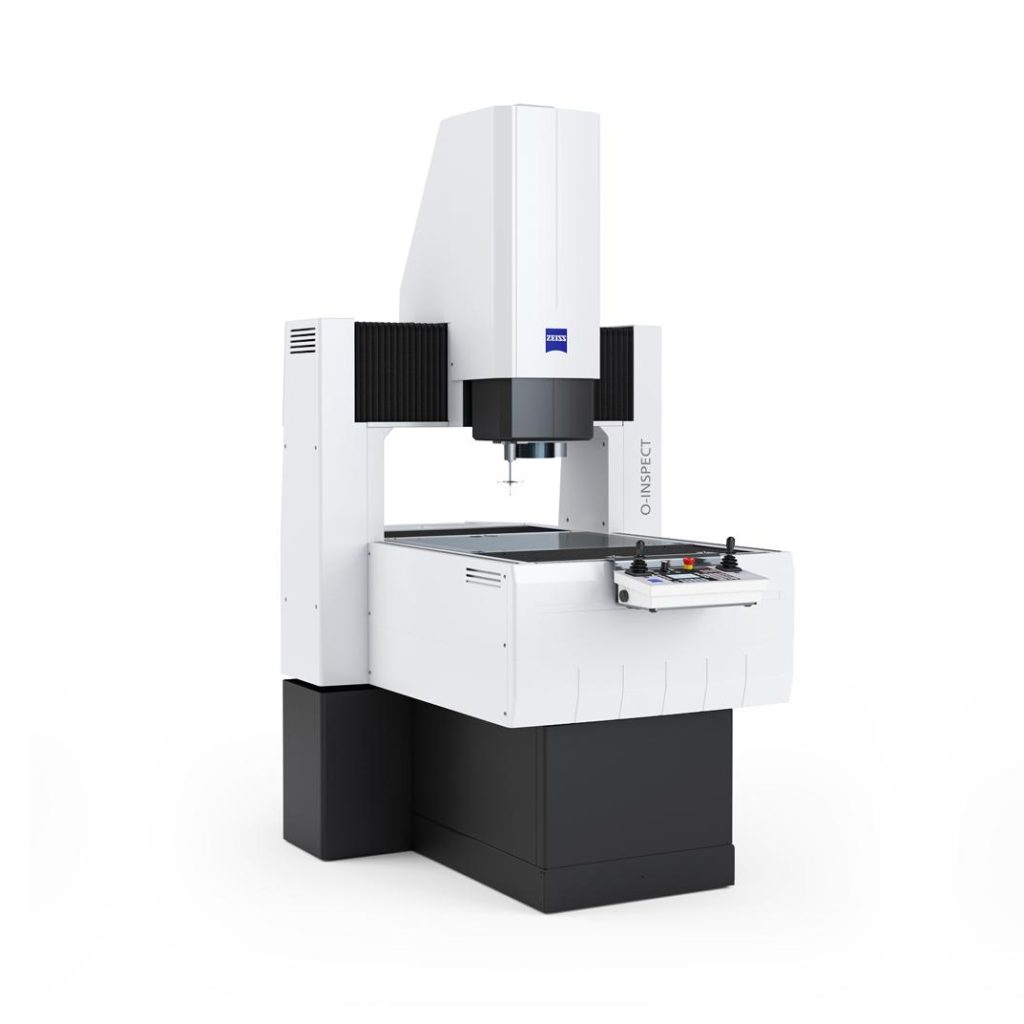

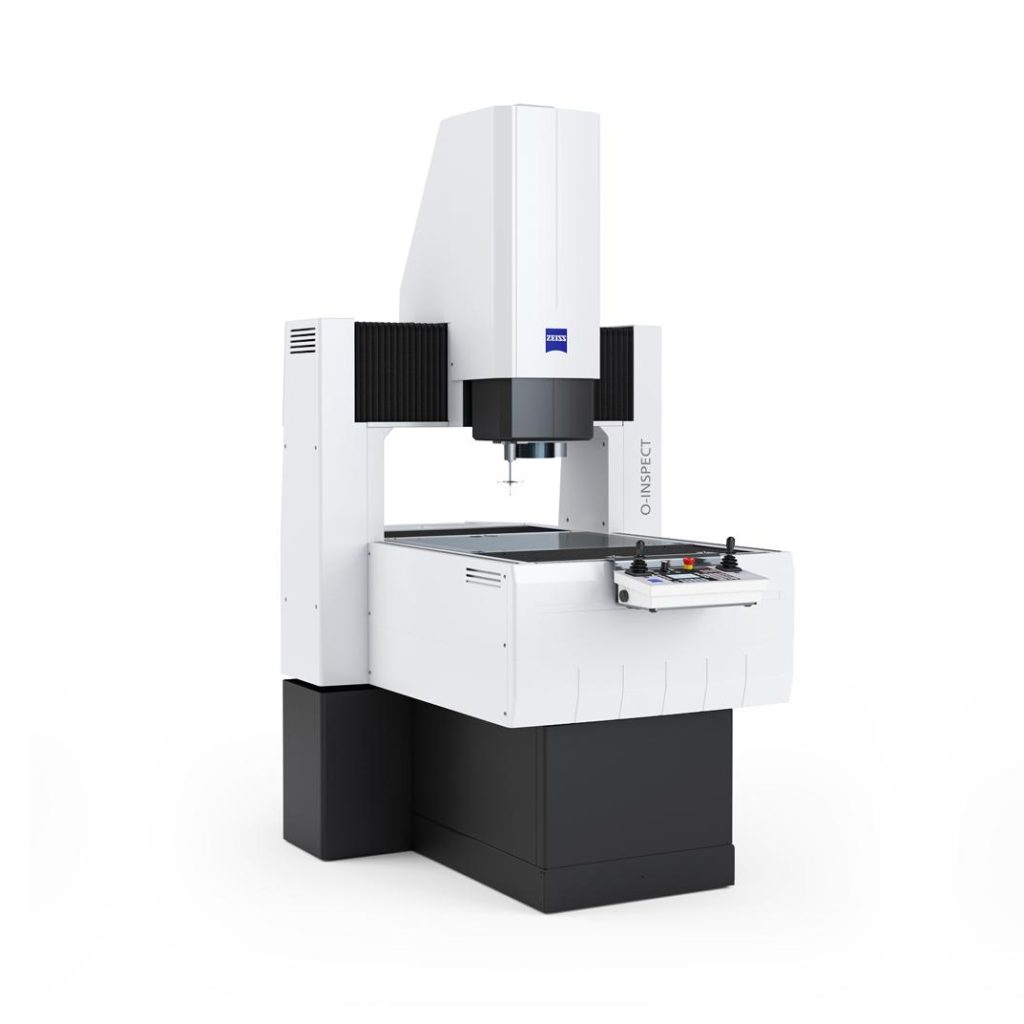

ZEISS O-INSPECT

The optical solution with the right touch

ZEISS O-INSPECT duo

Microscope and measuring machine in one.

Multi-sensor technology

Optical and tactile measurement technology combined

All products in the Optical Series are compatible with a tactile sensor and therefore enable the acquisition of 3D tactile measurement data in addition to high-precision 2D optical measurements. Depending on the model, the tactile probe head is available as an option or included in the standard package.

Variety of sizes

Different sizes for different requirements

ZEISS O-DETECT and ZEISS O-INSPECT are available in different sizes and are suitable for a wide range of applications – from small, delicate parts to larger workpieces.

Probes and Sensors

Tactile and Optical Probes on CMM

The perfect solution for your application

Probes and Sensors

Explore our range of tactile and optical probe heads, probe carriers and roughness sensors to fully utilize your CMM’s capabilities.

Automation Integration

ZEISS Integration Series

Unleash the full efficiency of your process

Increase the efficiency of your measurement processes

ZEISS Integration Series integrates your quality assurance, optimizes your processes and thus increases your productivity by selecting the right loading system or the ideal integration and automation solution for your CMM. The broad spectrum of ZEISS solutions ranges from manual loading systems with ergonomic advantages to fully automated cells that increase the throughput of your quality assurance by maximizing machine utilization.

Automating

Simple interfaces that integrate your coordinate measuring machines into an automation system

Operating

Solutions for measuring close to production by adapting quality assurance to the production environment

Loading

Manual and automated loading systems to optimize part throughput and operator effort