Optical Scanning Probes

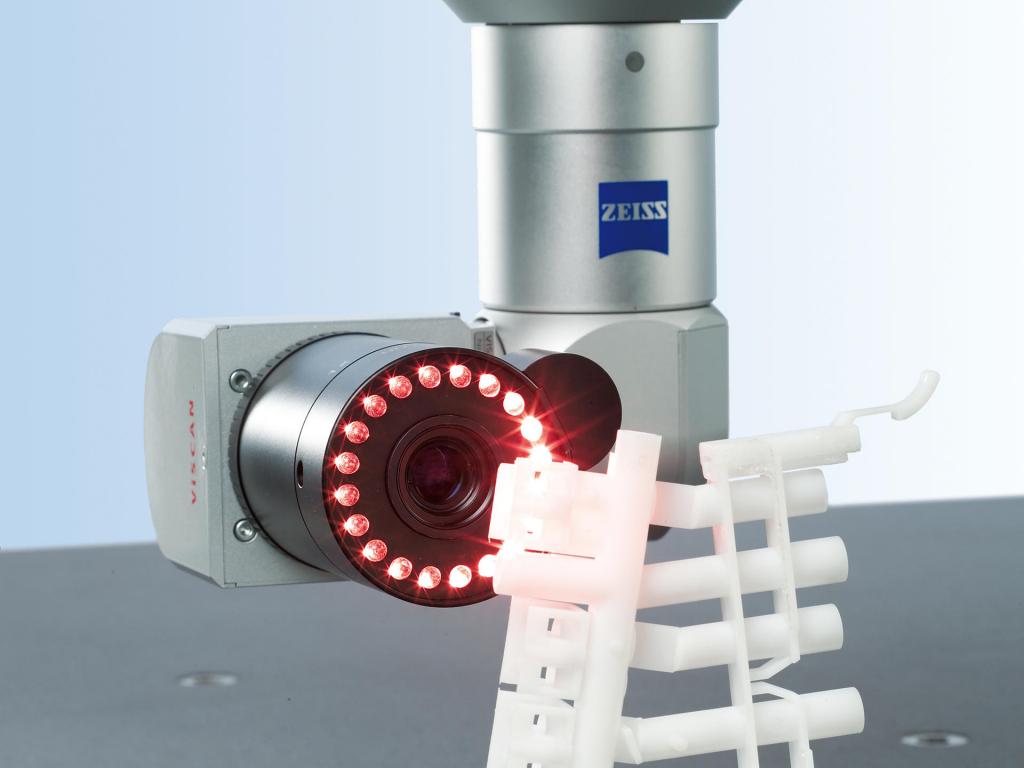

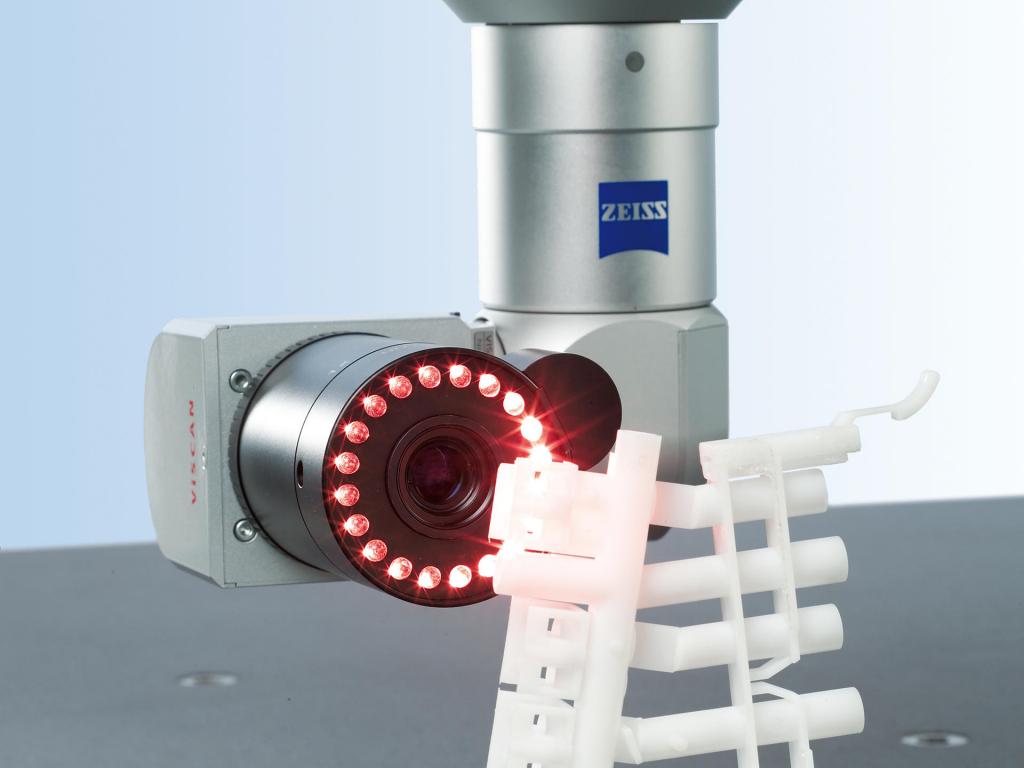

ZEISS ViScan

Spotlight on two dimensions

The use of optical sensors is indispensable for highly complex specimens – this is where the ZEISS ViScan optical 2D image sensor comes into its own.

- Flexible measurement in all spatial directions

- Optimal for small or 2D geometries

- Reliable auto-focus for depth measurement

Features

Performing optical measurements

The hallmark of ZEISS ViScan is its flexibility in all aspects: combined with RDS, it permits measurements in all spatial directions without rechucking the part. Different lenses are also available.

ZEISS ViScan is particularly well-suited for the measurement of parts with very small or two-dimensional geometries and/or soft materials such as sheet metal, rubber or plastic parts. Difficult measurements can also be performed on low-contrast test pieces such as punched components or printed circuit boards using the optional, mobile transmitted light stages with LED illumination.

The working distance is practically independent of the lens used, thus allowing the measurement of deep features. In addition to the measurement in the image, the auto-focus system also permits measurements perpendicular to the camera plane.

ZEISS DotScan

Optical sensor for capturing freeform surfaces

Chromatic white light sensors enable the non-contact capture of workpiece topography. These are generally used when sensitive, reflective or low-contrast surfaces make it difficult to use other optical sensors.

- Non-contact measurement of sensitive, soft, reflective or low-contrast surfaces

- Suitable for a wide variety of materials

- Available in three sizes

Features

ZEISS DotScan is an outstanding option for capturing freeform surfaces and even for minute structures. Chromatic white light sensors – and hence also the ZEISS DotScan – are the method of choice, especially when styli or camera sensors reach their limits on sensitive, soft, reflective or low-contrast surfaces.

By using ZEISS DotScan, strongly reflective surfaces, such as metal components in knee implants, can be scanned without any need to inject them with a contrast medium. This also makes it possible to distinguish transparent lacquered surfaces from other underlying metallic layers.

Flexible use

ZEISS DotScan is available in three sizes for three different measuring ranges: 10, 3 and 1 mm. The sensor can be exchanged fully automatically for other contact or optical sensors within a single CNC run. With increments of 2.5 degrees, the articulated axis can align the ZEISS DotScan so that it is perpendicular to the surface of the component being scanned.

And since the maximum measuring angle of the ZEISS DotScan 1 mm is plus/minus 30 degrees, even more strongly curved components can be scanned. Thanks to the sensor’s mode of operation, a wide variety of materials can be scanned from all sides without difficulty. In conjunction with a rotary table, even measuring jobs with 4-axis scanning can be performed.

ZEISS EagleEye

Keen eyes in car body measurement

ZEISS EagleEye is based on a completely new optical measuring technology that precisely meets these demands.

- Up to 85% time savings in car body measurement

- Elimination of labor-intensive steps

- Quality enhancement for pressed parts

Features

Fast quality assurance in car body construction

Automobile manufacturing requires measurements of countless bores in addition to edges, sections or transitions. Checking boreholes is extremely timeconsuming work, particularly for serial inspection. ZEISS EagleEye leads to time savings of almost 50% for the entire car body.

Typical, labor-intensive steps in traditional measuring methods are completely eliminated: no assembly and disassembly of threaded adapters, no material and storage or handling costs.

Furthermore, the use of ZEISS EagleEye immediately reduces throughput times and simultaneously increases the quality of pressed parts. This results in top-quality evaluations of the results with information on the diameter, position and form of the part feature down to the micrometer.

ZEISS EagleEye turns your measuring machine into production equipment.

ZEISS LineScan

Point clouds at the speed of light

ZEISS LineScan is the tool of choice when capturing the entire surface of forms using point clouds – whether for a comparison with available nominal CAD data sets or for the creation of a new CAD model.

- High speed and comprehensive surface detection increase productivity

- Large sensor selection with different measuring ranges and accuracies for a wide range of applications

- ZEISS LineScan 2-8 is the world’s most precise line scanner on CMMs and ensures outstanding measurement results

- Powerful software integration in ZEISS CALYPSO – for a standardized uniform, easy-to-use user interface

Benefits

Greater productivity

The sensor ensures the swift, complete capture of the surface structure and a high point density, making it possible to reduce the measuring time by up to 70%. This increases productivity considerably.

Flexibility

The bespoke sensors for particular applications assist the operator by simplifying the measurement strategy. Invest only in the sensor that best fits the application.

Trust in measurement data

Users trust their measurement results because of accurate, high resolution images. This reduces iterations, resulting in lower part costs and higher machine productivity through reduced measurement time.

Exceptional user-friendliness

No change in how users work: the assessments are displayed together with the standard geometry evaluations in the report. Users gain a wider range of measurement possibilities with ZEISS CALYPSO.

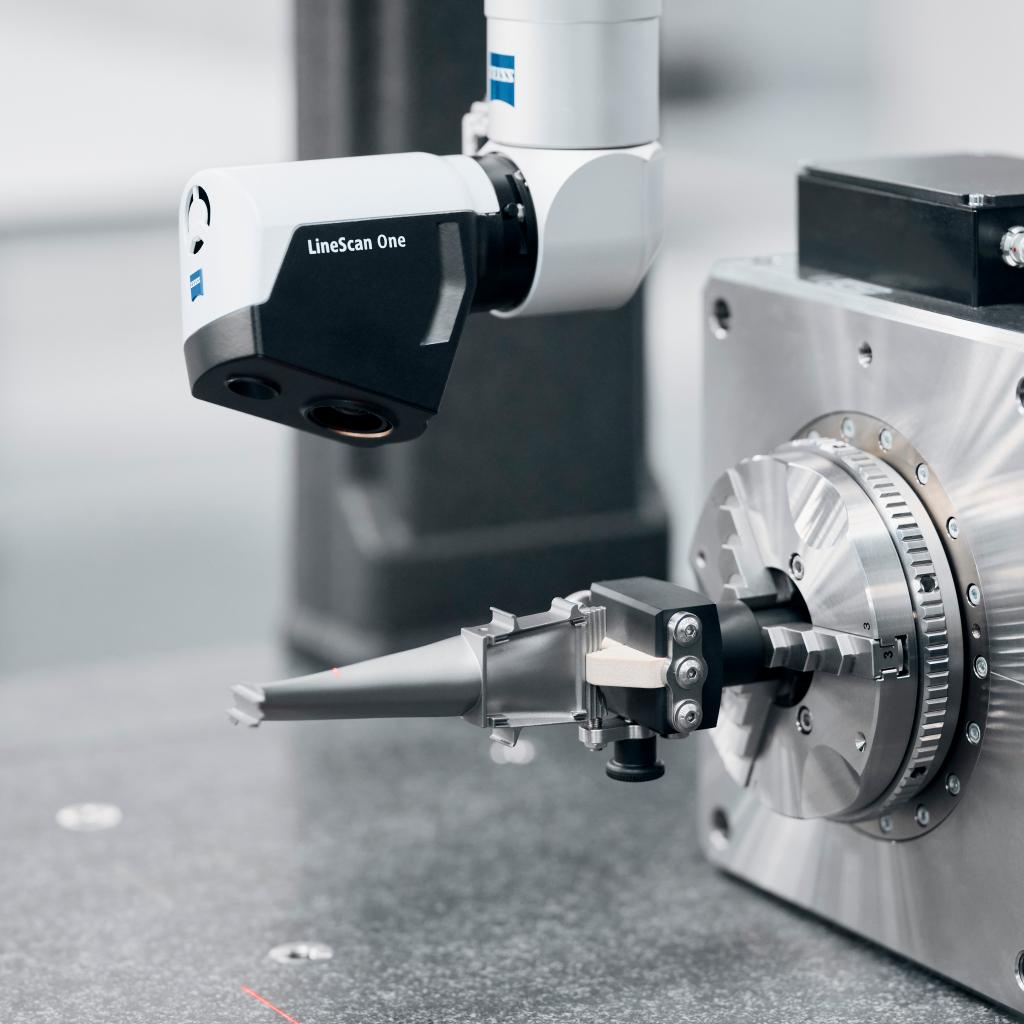

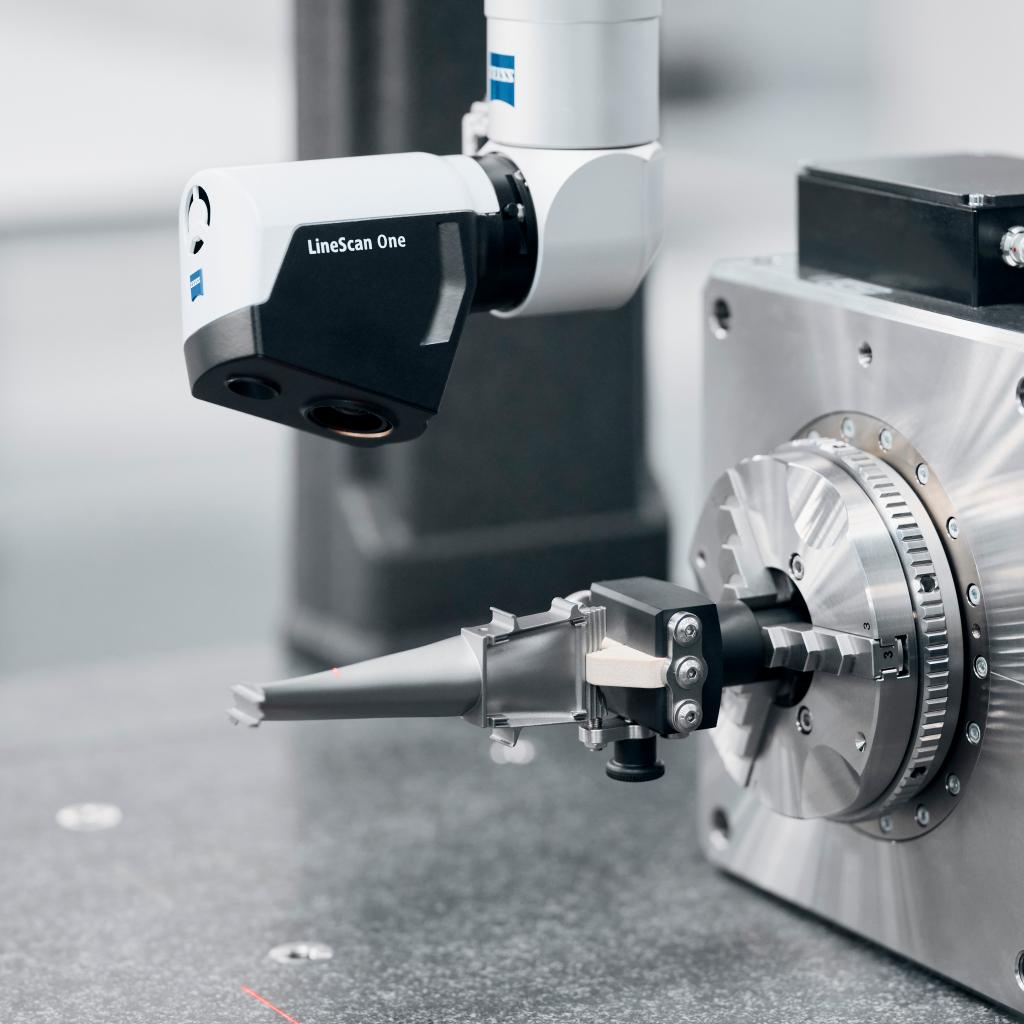

ZEISS LineScan One

ZEISS LineScan One is the entry into optical measurement technology for the complete and efficient measurement of free-form surfaces. The laser triangulation sensor captures a large number of points to compare nominal with actual geometry precisely.

- High accuracy (20 microns)

- Very fast (232 960 points per second)

- Direct powerful software integration in ZEISS CALYPSO for a single ease-of-use interface