ZEISS PRISMO family

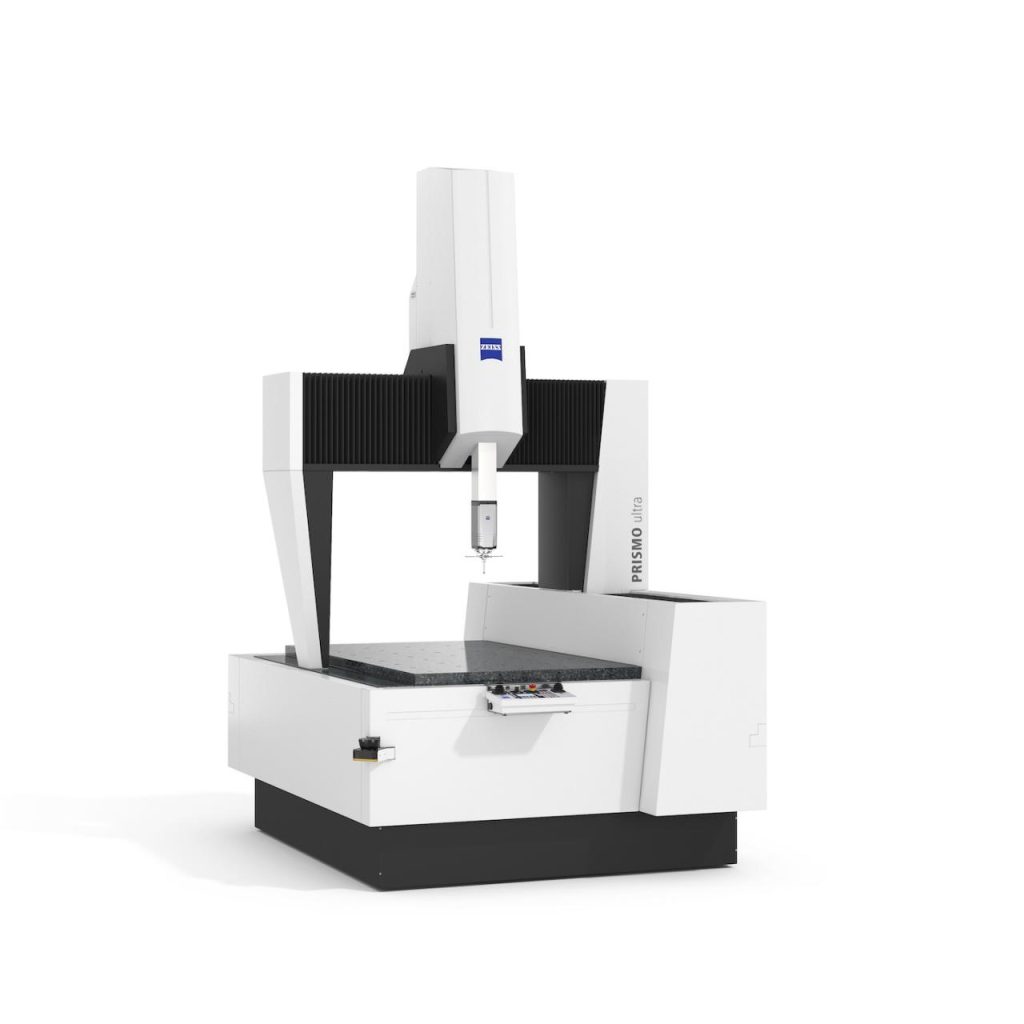

ZEISS PRISMO ultra

Maximum precision

ZEISS PRISMO ultra improves the precision within the ZEISS PRISMO family even further and achieves a length measurement error of only 0.5 + L/500 µm. The coordinate measuring machine is therefore particularly suitable for tasks where maximum precision is required, such as in research, development, quality assurance and when calibrating gauges or test specimens in reference measuring rooms or measuring laboratories.

- Maximum accuracy and reproducibility thanks to numerous modern functions and corrections

- Optional form measurement package with RT-AB select

- Adapted and optimized manufacturing process

Maximum accuracy and reproducibility

High-precision results thanks to improved functions

The high degree of basic accuracy of ZEISS PRISMO ultra is achieved by numerous modern functions and corrections. These include thermal bending compensation, an active pneumatic damping system, improved air bearings and ZERODUR® scales with a resolution of 20 nm – for remarkable precision and stability. Further CAA improvements such as optimized tensor calibration, compensation of the bending of the reference sphere and corrections for RT measurements ensure maximum precision even at high speeds and support excellent stability of the CMM by protecting it from interfering factors.

Optional form measurement package with RT-AB select

Form measurement with quality guarantee

ZEISS PRISMO ultra can be optionally equipped with a form measurement package for optimized form measurement values. In addition to the RT-AB select, this also contains a special probe set and a set for defining the RT axis and guarantees the calibration value of a ring gauge with an accuracy of 0.2 μm or better – confirmed by a leading German institute. Measurement tolerances from 2-3 μm for roundness and cylindricity can be measured with ZEISS PRISMO ultra according to the golden rule of measurement technology.

Adapted and optimized manufacturing process

Customized installation and acceptance

Before delivery, every ZEISS PRISMO ultra granite plate undergoes a three-month acclimatization process. The final inspection takes place in a special air-conditioned chamber. After installation, a precision test is carried out, followed 4 to 6 weeks later by an acceptance test by an expert. This process guarantees maximum accuracy and quality.

ZEISS PRISMO verity

Different sizes for a wide range of applications

ZEISS PRISMO verity is available in various sizes. From the smallest version with a measuring range of 700 x 900 x 500 mm to the largest design of this coordinate measuring machine with a measuring range of 1200 x 1800 x 1000 mm.