Probes & Sensors

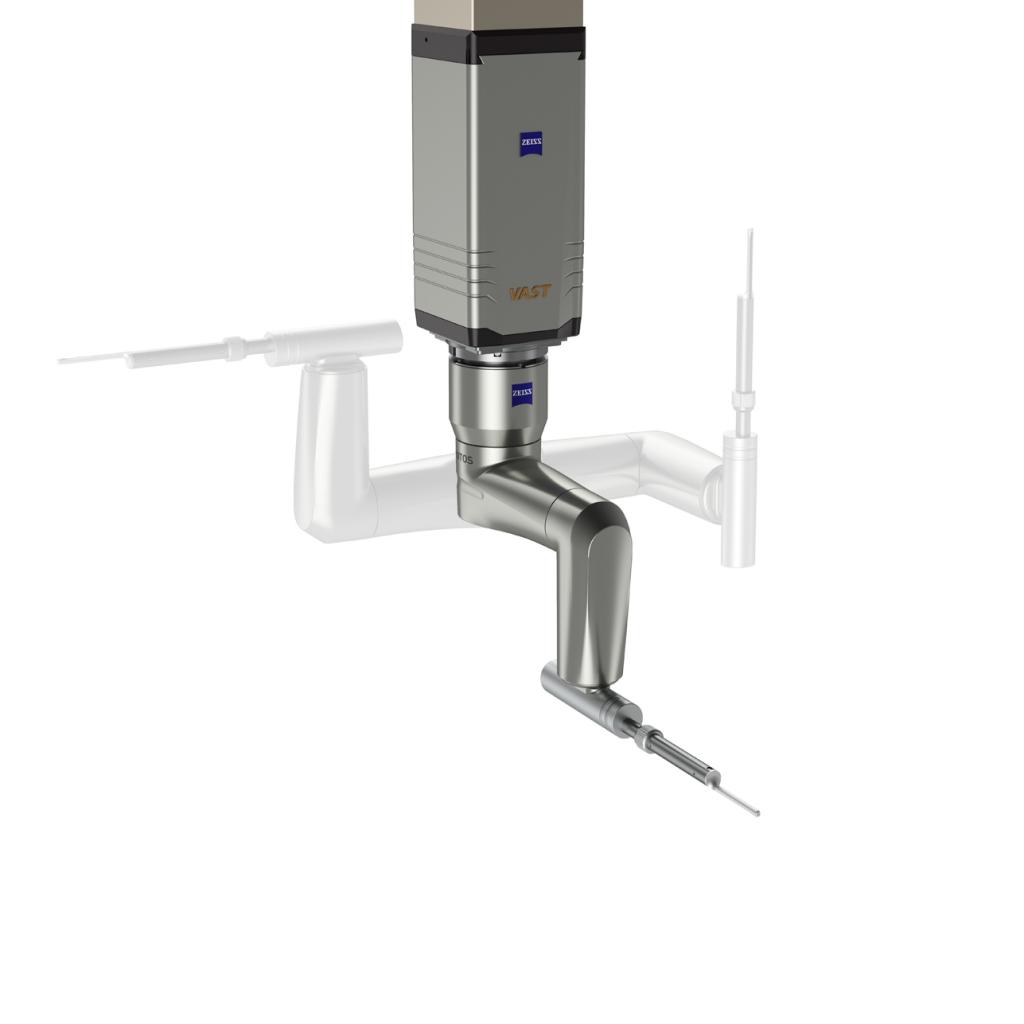

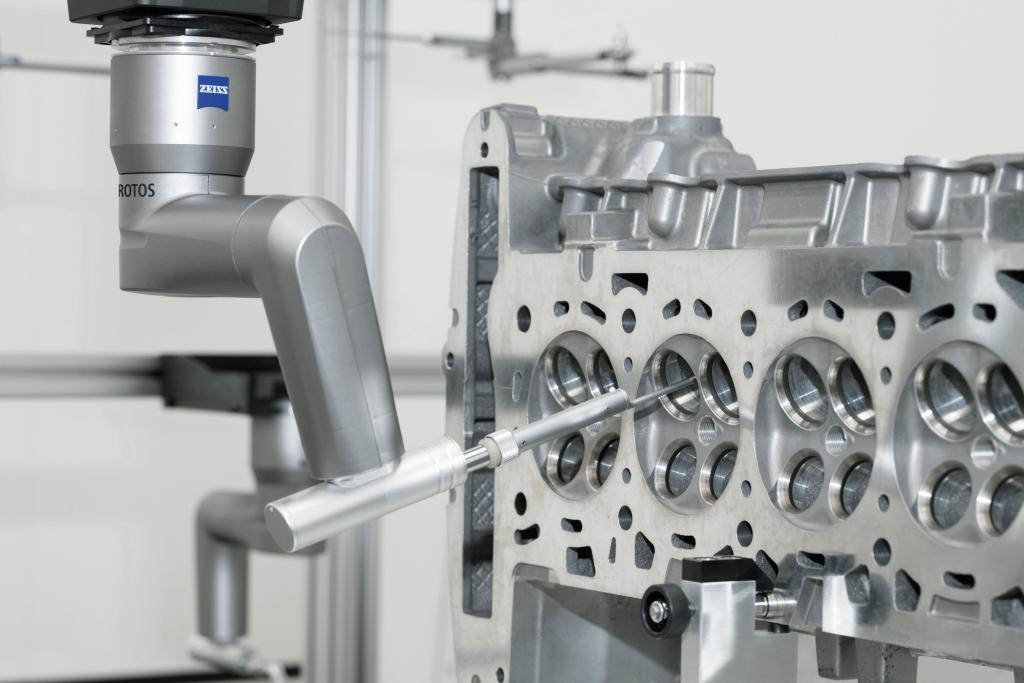

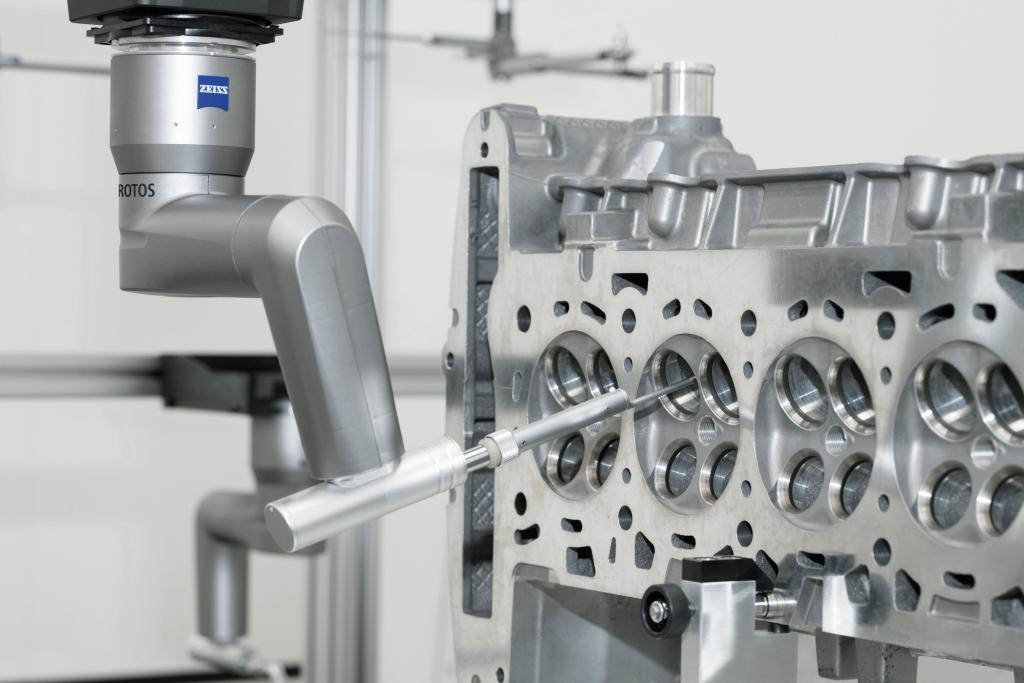

ZEISS ROTOS

A whole new dimension for roughness measurements

ZEISS ROTOS offers optimum precision and maximum flexibility when performing roughness measurements thanks to its modular design and rotation in three axes: easy-to-change stylus arms further expand the range of possible applications.

Features

Your benefits at a glance

- No reclamping on different machines

- Minimum set-up times

- Measurement controlled by CNC program

- Programmable via offline simulation

- Standardized measurement report with ZEISS PiWeb

- Accessibility: three axes each featuring +/- 180°

- Overhead measurements

- Modular design with three stylus arms: RS1, RS2, RS3