VMMs

ZEISS O-DETECT

Entering the world of optical metrology

Intuitive operation, high-quality camera and flexible lighting for precise measurement in an instant. Suitable for a wide variety of components, but mainly for those that are best left untouched. Discover the new generation of optical metrology: ZEISS O-DETECT.

Features

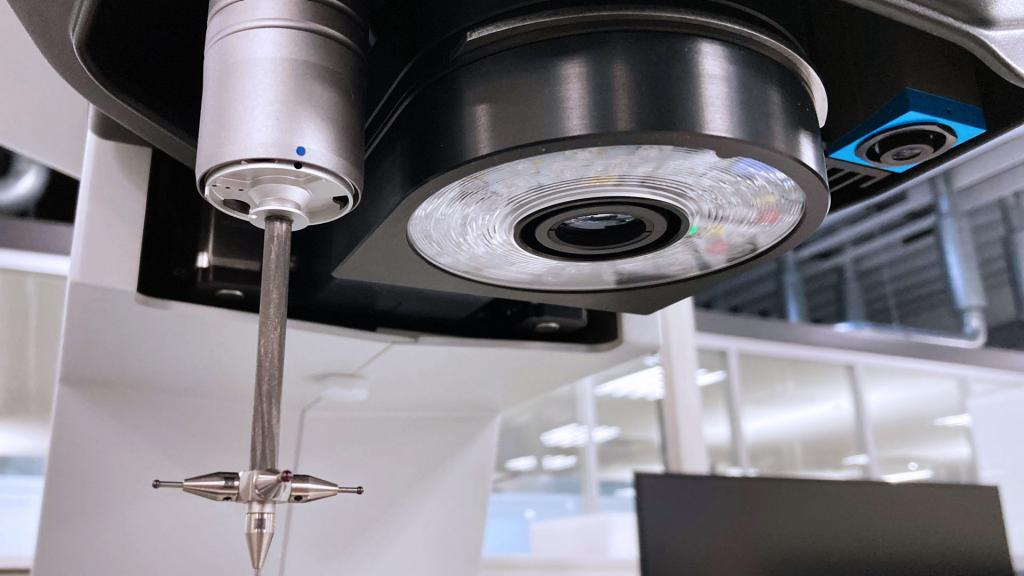

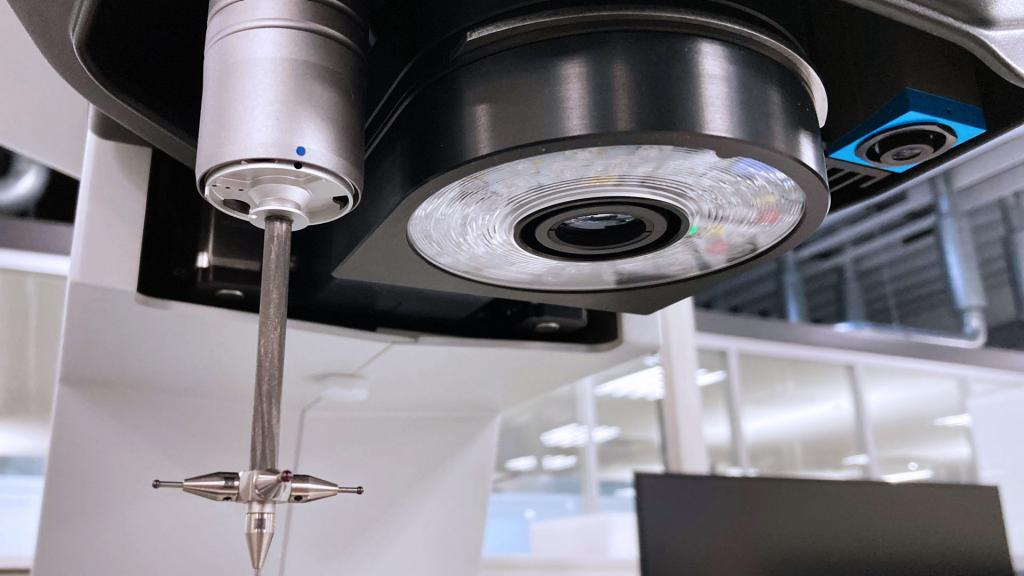

Excellent optics with differenct illumination options

High-end camera in the entry-level segment

A key element of ZEISS O-DETECT is its high-quality camera. Thanks to sophisticated software and the new autofocus function, the image taken by the camera is transformed into precise measurement results.

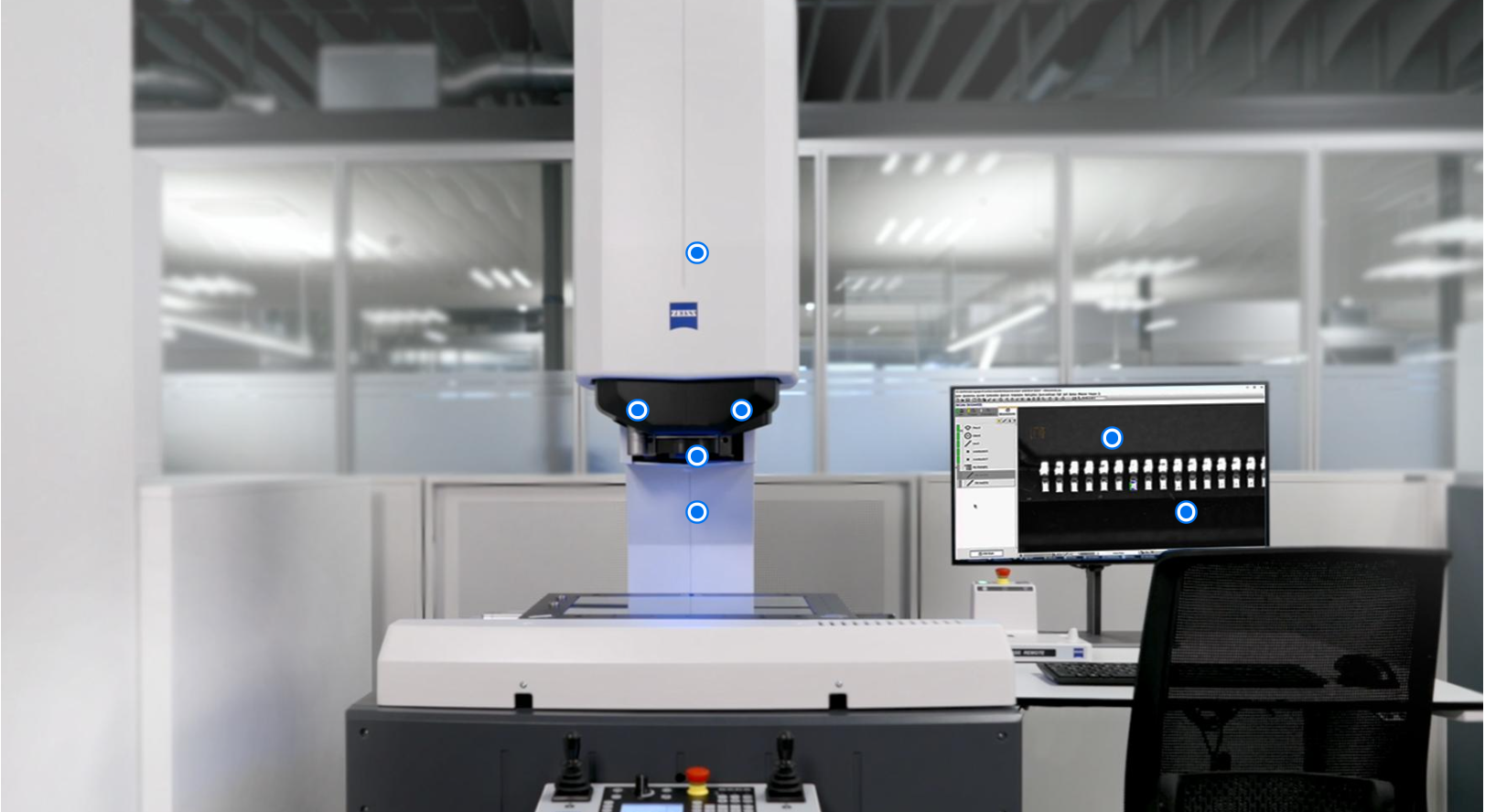

Quick, precise and intuitive – thanks to the overview camera

Another essential component of ZEISS O-DETECT is the first in its class: an overview camera with integrated 5-megapixel camera sensor. The overview camera captures the entire measuring area including all workpieces that are placed on the measuring table. The acquired overview image is used to navigate the measurement camera to the appropriate position without having to use the control panel. This enables intuitive and fast programming.

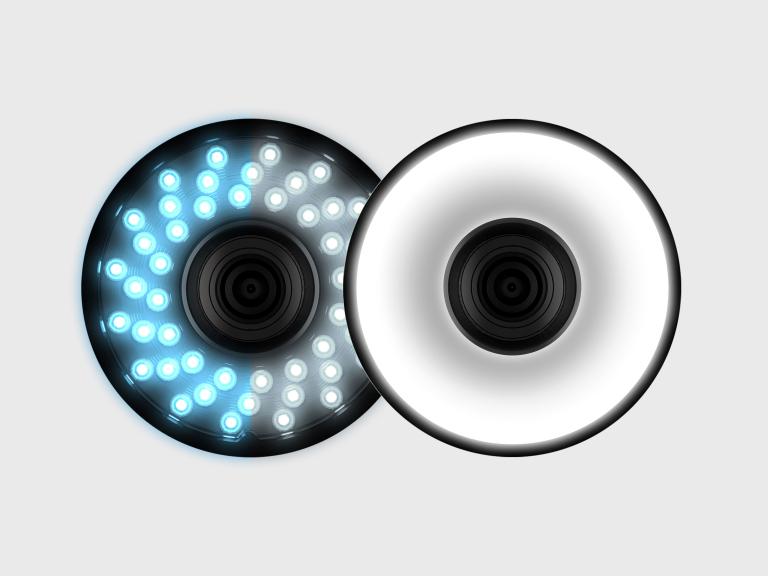

Illumination options for every task

ZEISS O-DETECT provides different illumination options for every challenge that you might face with some measuring tasks. A ring light with blue and white LED-segments for flexible illumination of general workpieces and a diffuse light option for shiny workpieces and challenging edges.

Exchangeable toplights

High-quality lighting plays a key role in achieving precise measurement results. The versatile and easily exchangeable ZEISS O-DETECT toplight provides the best conditions for this. The toplight operates automatically and according to user-defined settings.

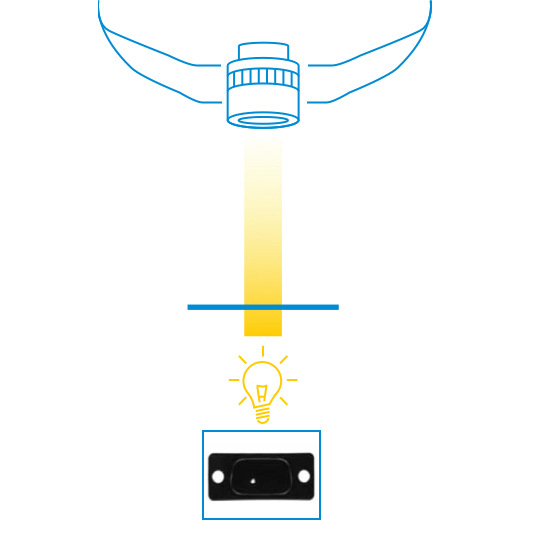

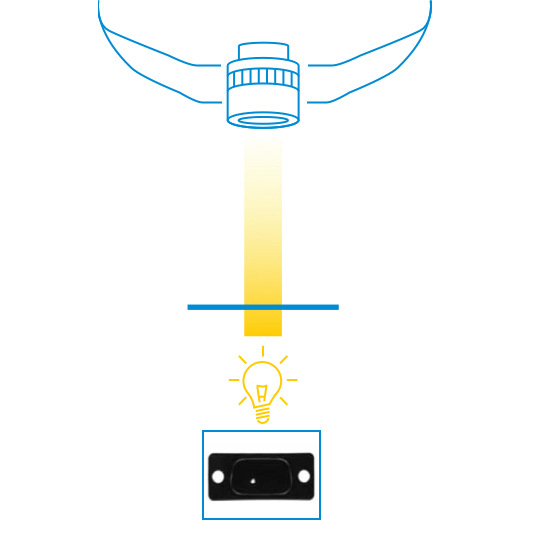

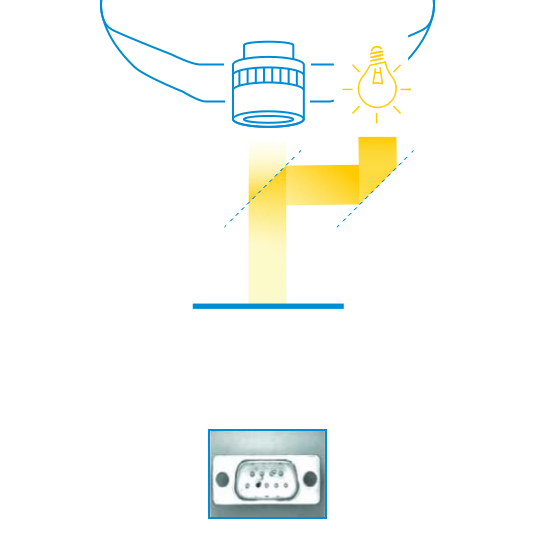

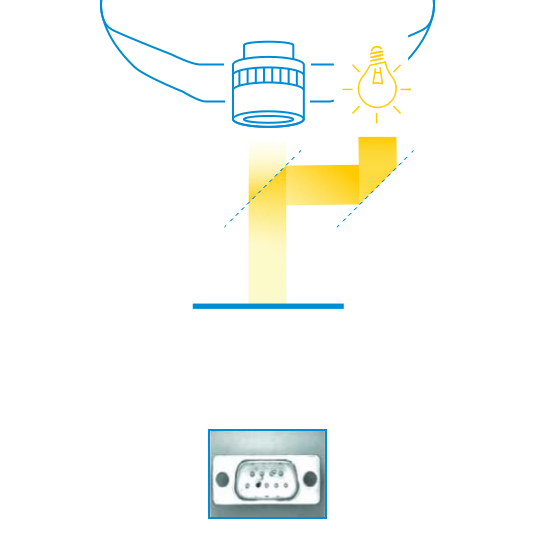

Backlight

Coaxial light

Top light

Multisensoric option with ZEISS XDT

Fast and precise tactile 3D measurements

With the option ZEISS XDT, it is possible to add a tactile single-point sensor to ZEISS O-DETECT. The use of the tactile sensor enables to easily reach lateral bores or undercuts that cannot be detected with an optical camera sensor. Depending on the measuring task, individual stylus configurations can be mounted and exchanged in the CNC-capable measuring program. As a passively measuring sensor, ZEISS XDT delivers reproducible measurement results, as for each individual probing point, a large number of measurement points are determined and a stable mean value is calculated.

Technical Data for ZEISS O-DETECT