VMMs

ZEISS O-INSPECT

The optical solution with the right touch

ZEISS O-INSPECT multi-sensor measuring machines enable to optimally measure each characteristic in compliance with ISO-10360 – optically or by contact.

Features

Excellent optics

Large field of view

High image definition

ZEISS Discovery.V12 camera sensor offers a variable degree of magnification. Compared to conventional lenses, it offers a four times larger field of view as well as excellent imaging fidelity even in the peripheral areas. The result: reduced measuring time and maximum accuracy.

The two new sensor options, scout 160 and scout 240, enable even higher optical resolution. The use of the alternative sensor units enables 1.6 or 2.4 times the optical resolution of the standard 100 variant.

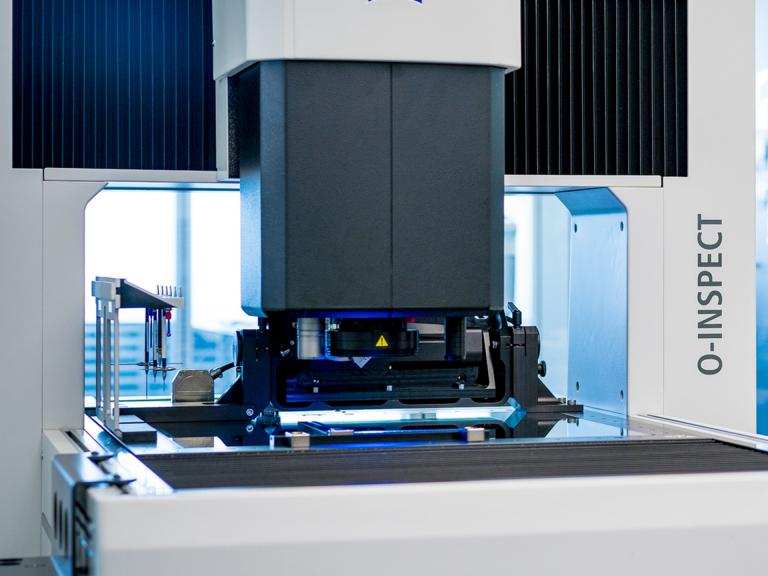

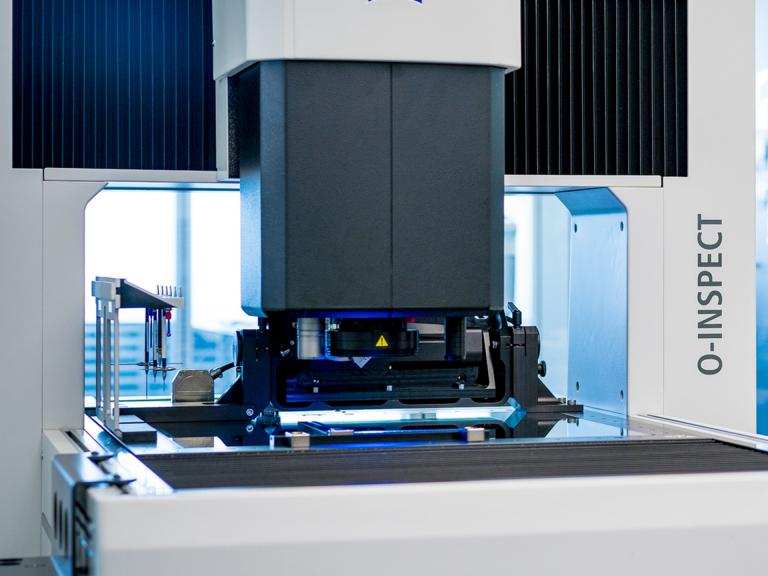

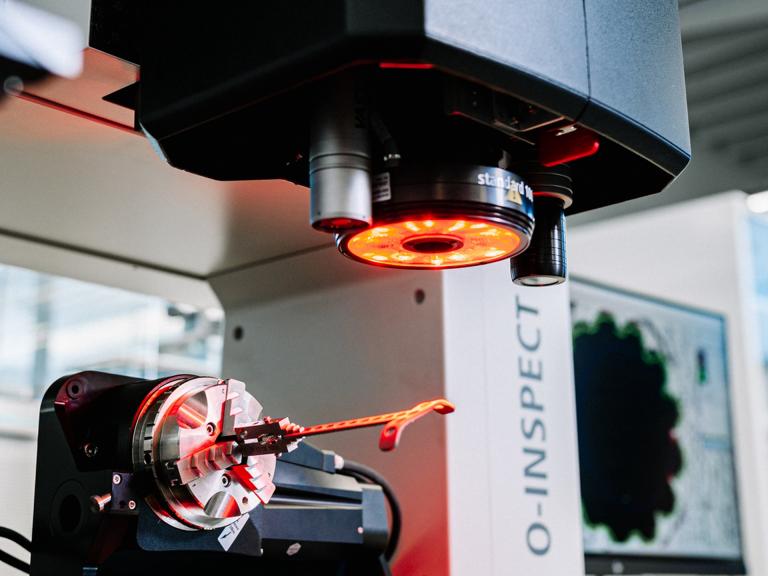

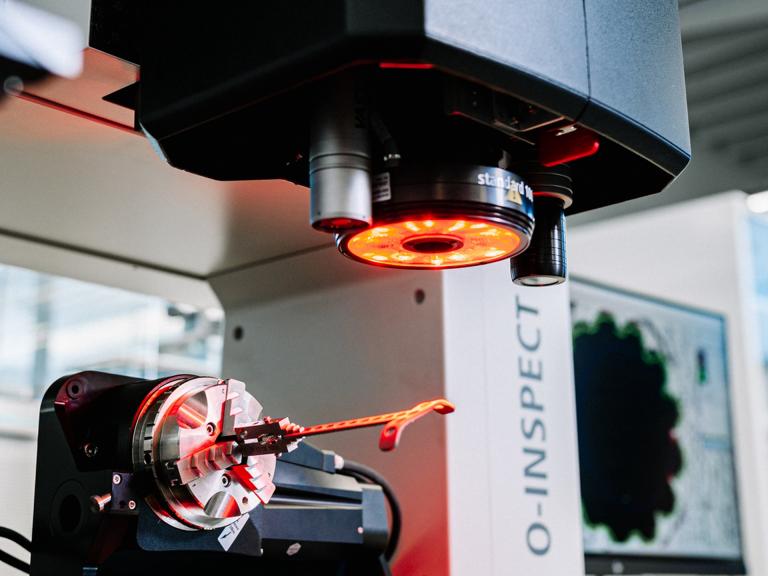

Optimal contrast

ZEISS O-INSPECT illumination system

A high-contrast image is necessary for precise results. ZEISS O-INSPECT features a highly versatile illumination system for this purpose. Extremely different shapes, textures and surface colors can be illuminated so that different angles of incidence can be realized, clearly accentuating edges.

Multisensor technology

Tactile measurement

The right choice where very high accuracies are required. Tactile probes like ZEISS VAST XXT scan the component’s surface point by point. It also adds scanning functionality, thus providing information on the form of the features.

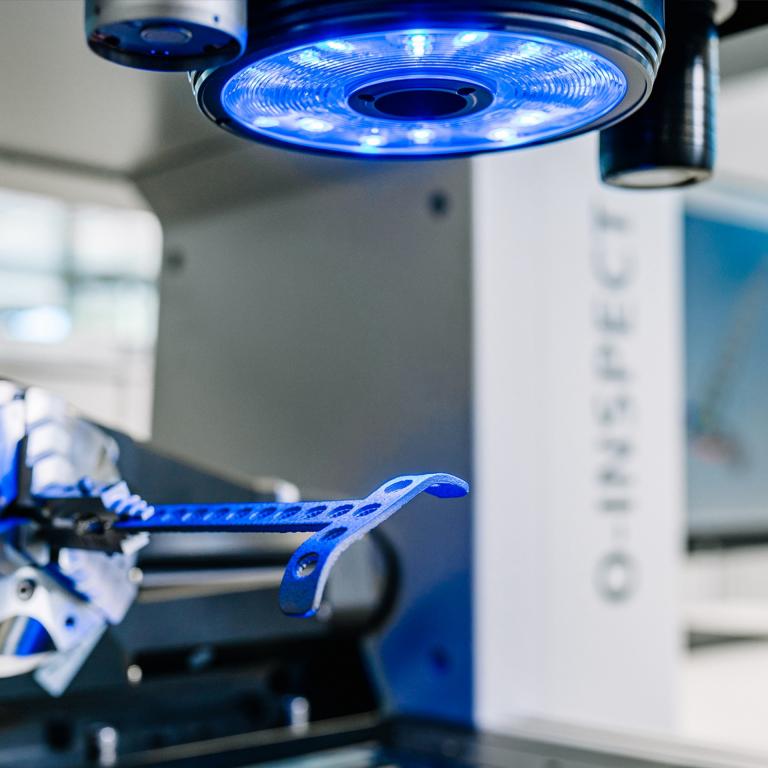

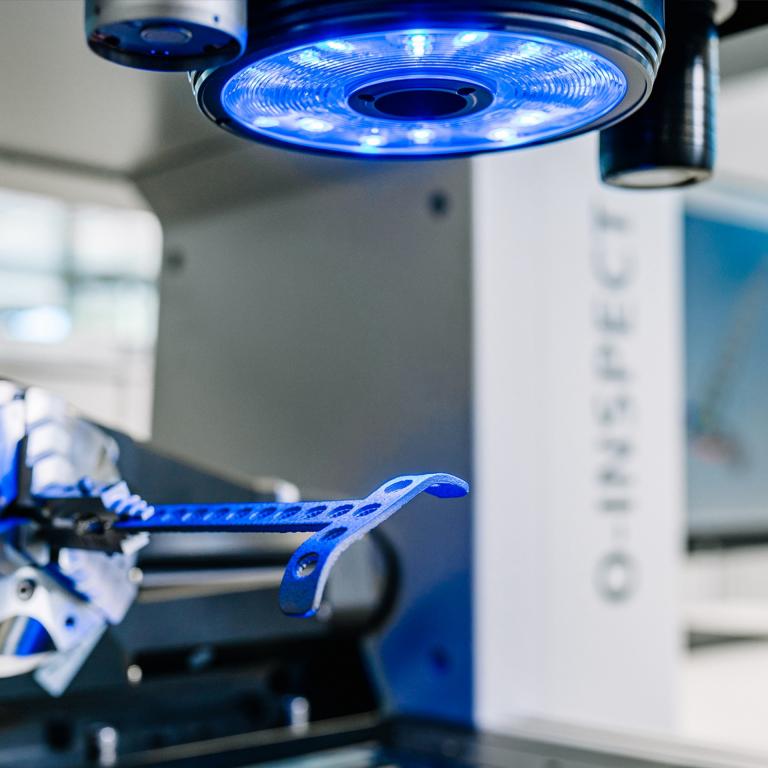

Optical measurement

ZEISS Discovery.V12 zoom lens provides a large, distortion-free field of view for measuring results with excellent accuracy and a significant reduction in measuring time.

White light

ZEISS DotScan a chromatic white light sensor enables the non-contact capture of workpiece topography. Used when sensitive, reflective or low-contrast surfaces make it difficult to use other sensors.

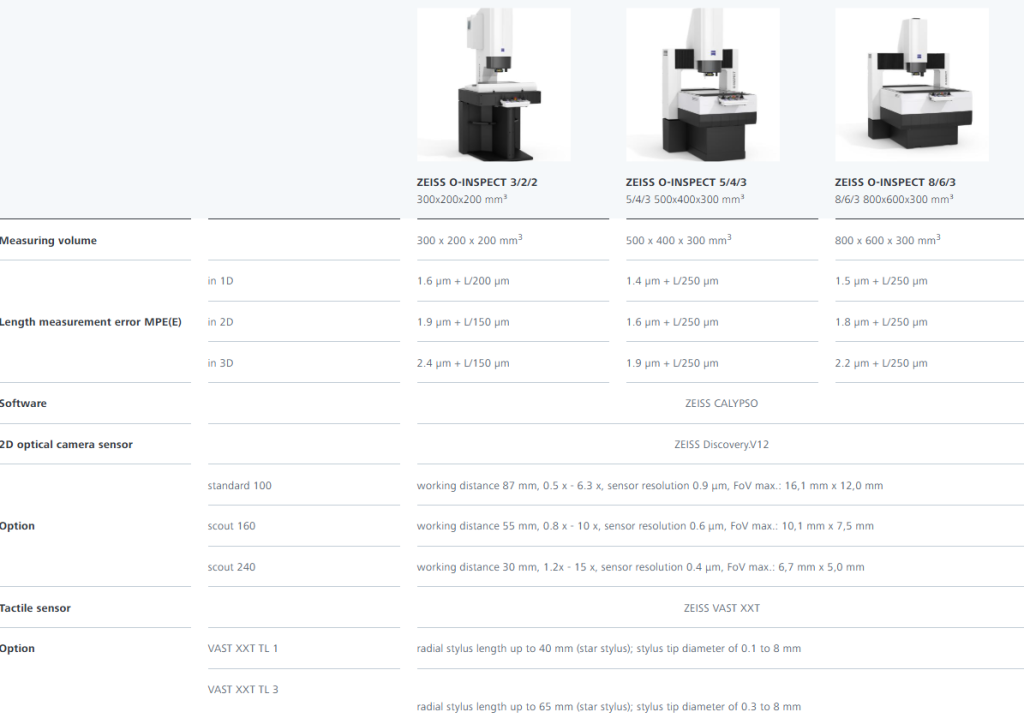

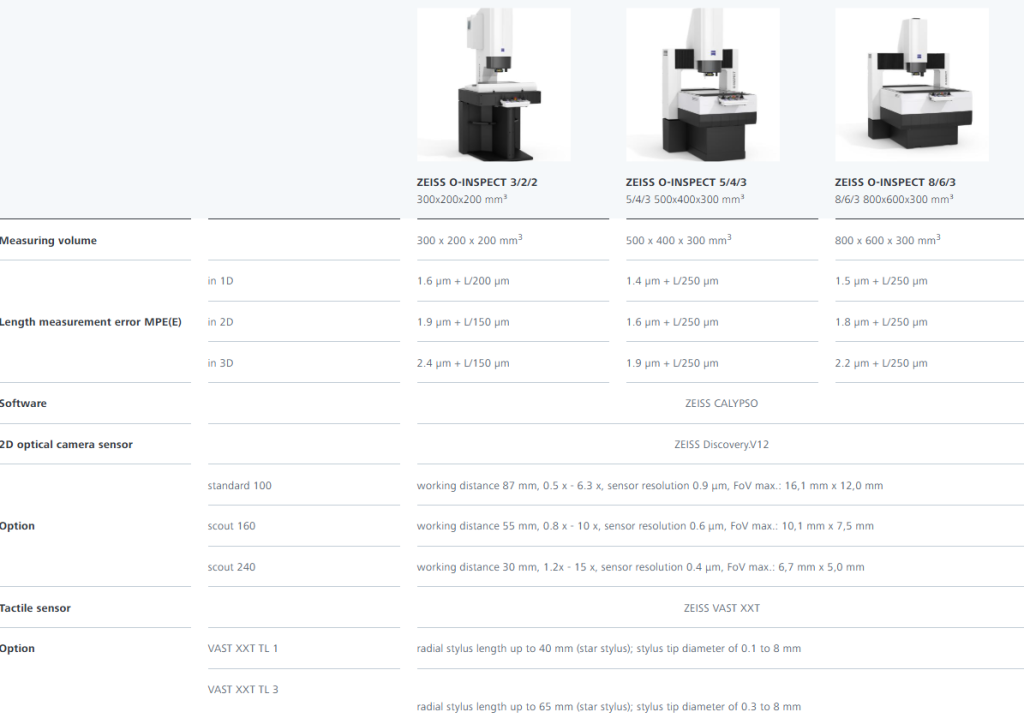

Technical data for ZEISS O-INSPECT