VMMs

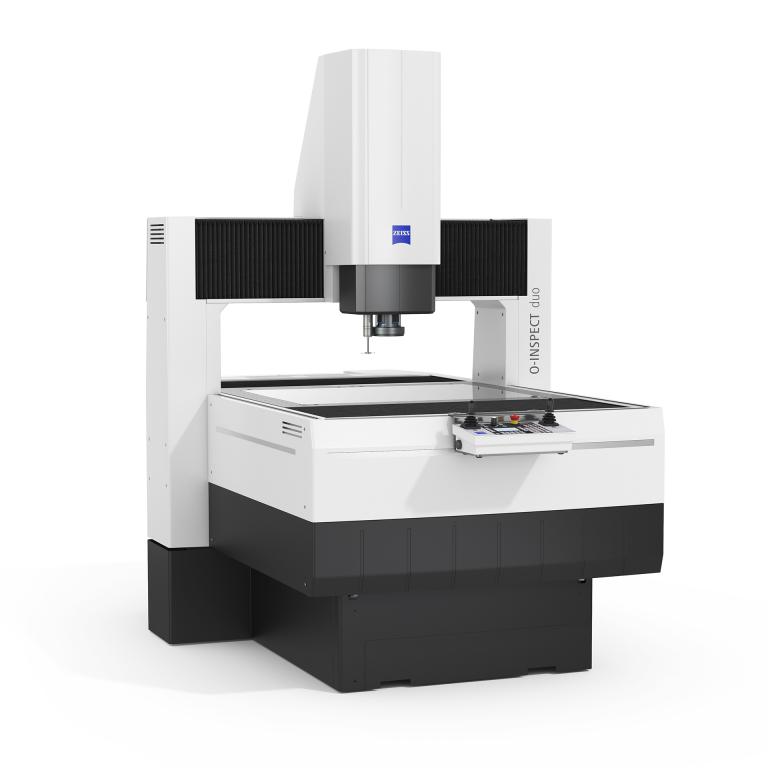

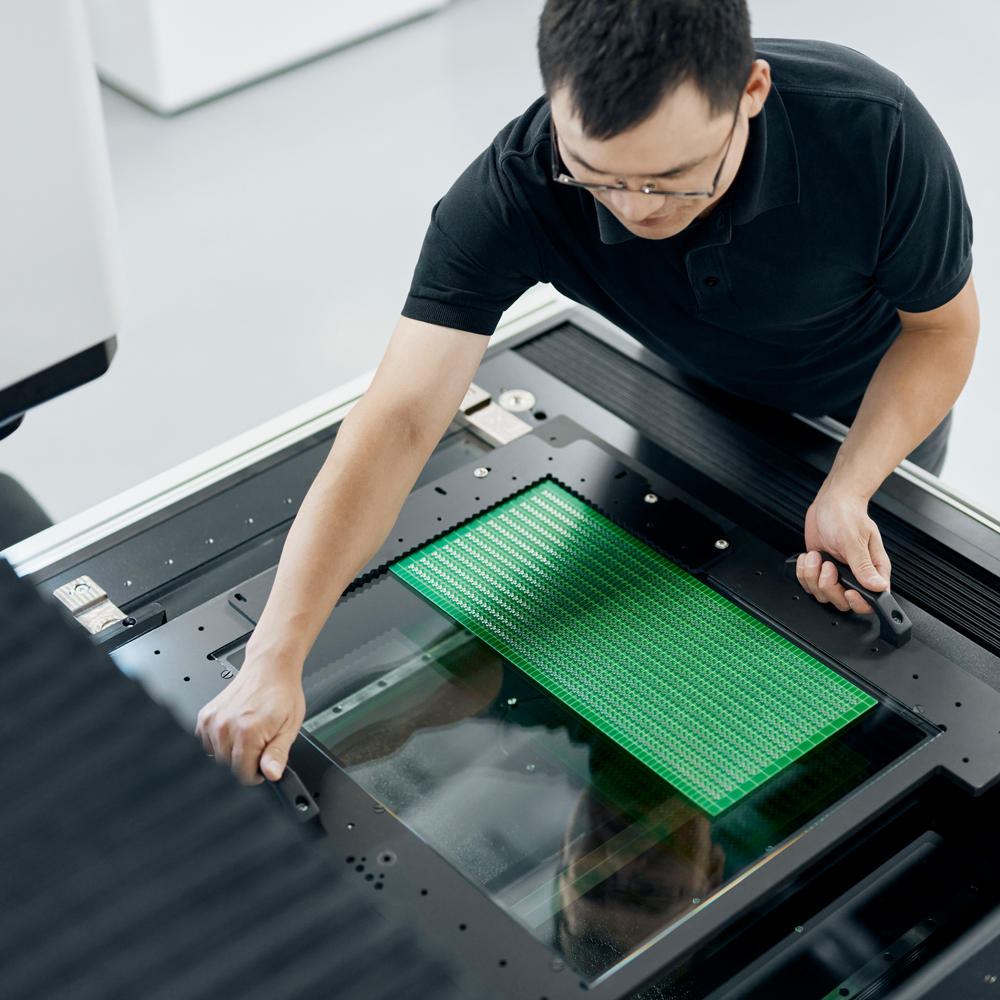

ZEISS O-INSPECT duo

Microscope and measuring machine in one.

ZEISS O-INSPECT duo offers two technologies in one machine: large workpieces such as PCBs, fuel cells or batteries can be both measured and inspected in high resolution in their entirety. The combination of 3D measurement technology and microscopic inspection increases efficiency and saves space in quality laboratories. ZEISS O-INSPECT duo is available in the size 8/6/3.

First multi-technology system from ZEISS

As a ‘VMM microscope’, ZEISS O-INSPECT duo covers two essential applications in quality assurance: Precise measurement and high-resolution inspection of large or many small components. The device has also been specifically developed for applications where a combination of dimensional measurement and inspection is required – including segmentation, stitching and image processing with color images. Instead of having to acquire both a VMM and a microscope, only one device is needed in quality laboratories, saving space and system costs. Find out more about further advantages of the multifunctional device for the respective areas.

Precise measurements – optical and tactile

High accuracy for flat and sensitive workpieces

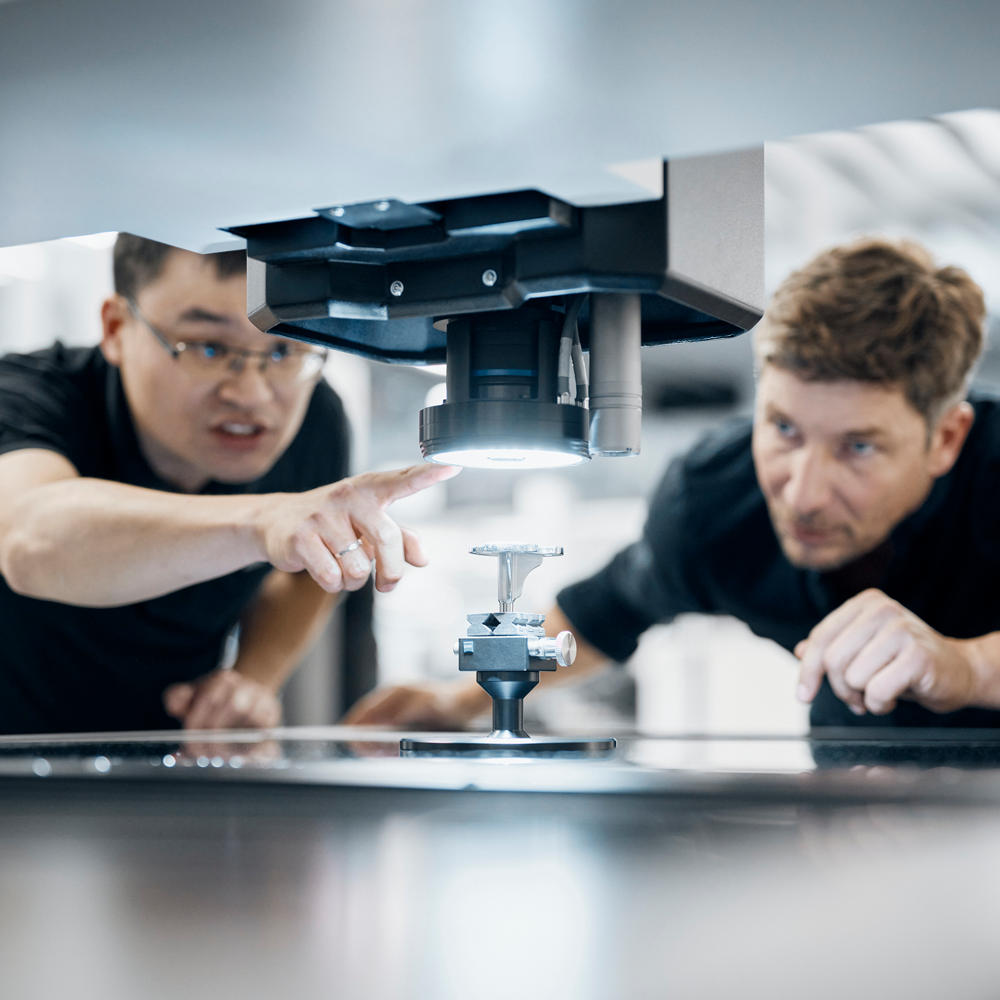

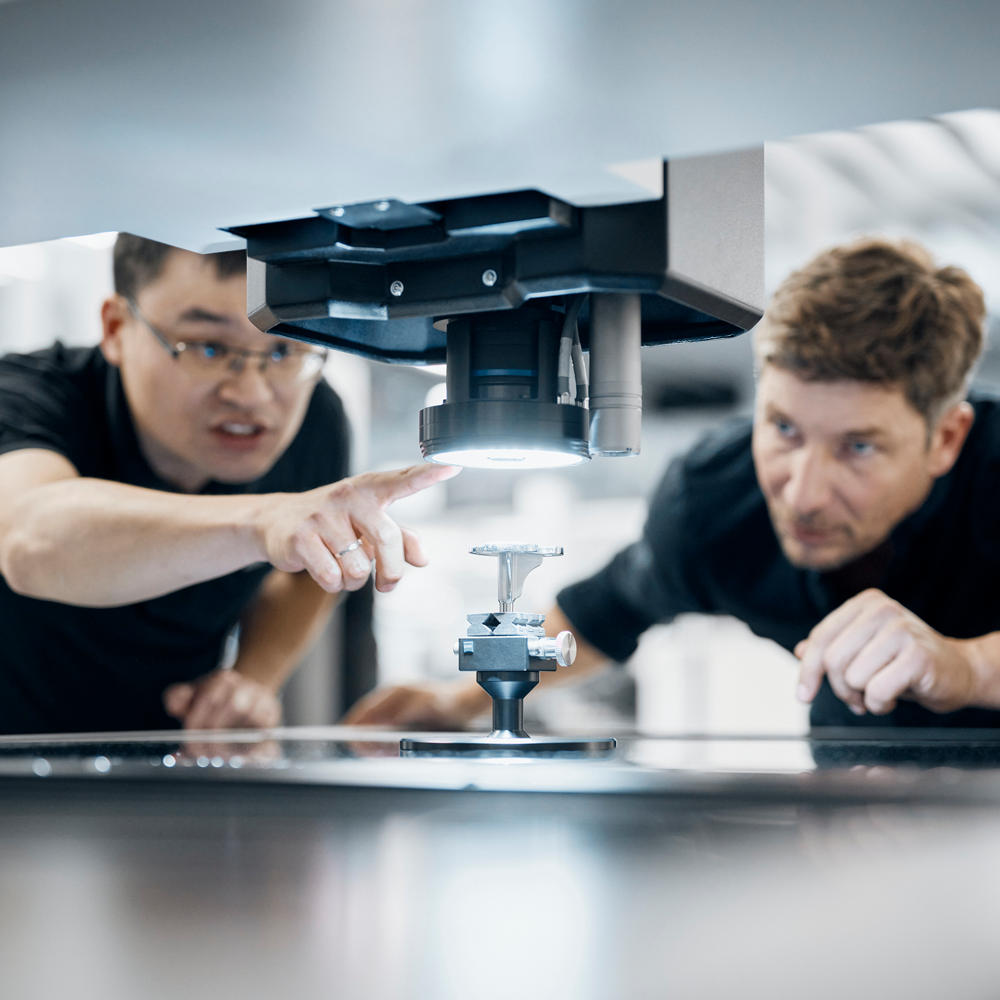

ZEISS O-INSPECT duo is a multisensory measuring machine and impresses with its high-resolution optics paired with the ZEISS VAST XXT tactile scanning sensor. The sensor enables fast and accurate 3D measurements by capturing a large number of measuring points in a single movement.

Very small or sensitive parts can be measured without contact and with excellent accuracy as well as a significant reduction in measuring time thanks to ZEISS VAST probing (ZVP). This is possible thanks to the large field of view with high image resolution and outstanding image fidelity, even in the peripheral areas.

Surface inspection and measurement on one machine camera

VMM today, microscope tomorrow

In addition to measuring the dimensions, many workpieces also require surface inspection. Where previously two separate devices were used for measurement and inspection, ZEISS O-INSPECT duo now offers a 2-in-1 solution. Thanks to the intuitive operation of the device and the high-resolution 5 MP Discovery.V12 scout 160 c color camera sensor with 12x zoom lens, inspection tasks can now also be covered on the measuring device. In addition to the usual use with ZEISS CALYPSO, the machine can also be used for microscopy tasks with the ZEISS ZEN core software.

Our largest microscope

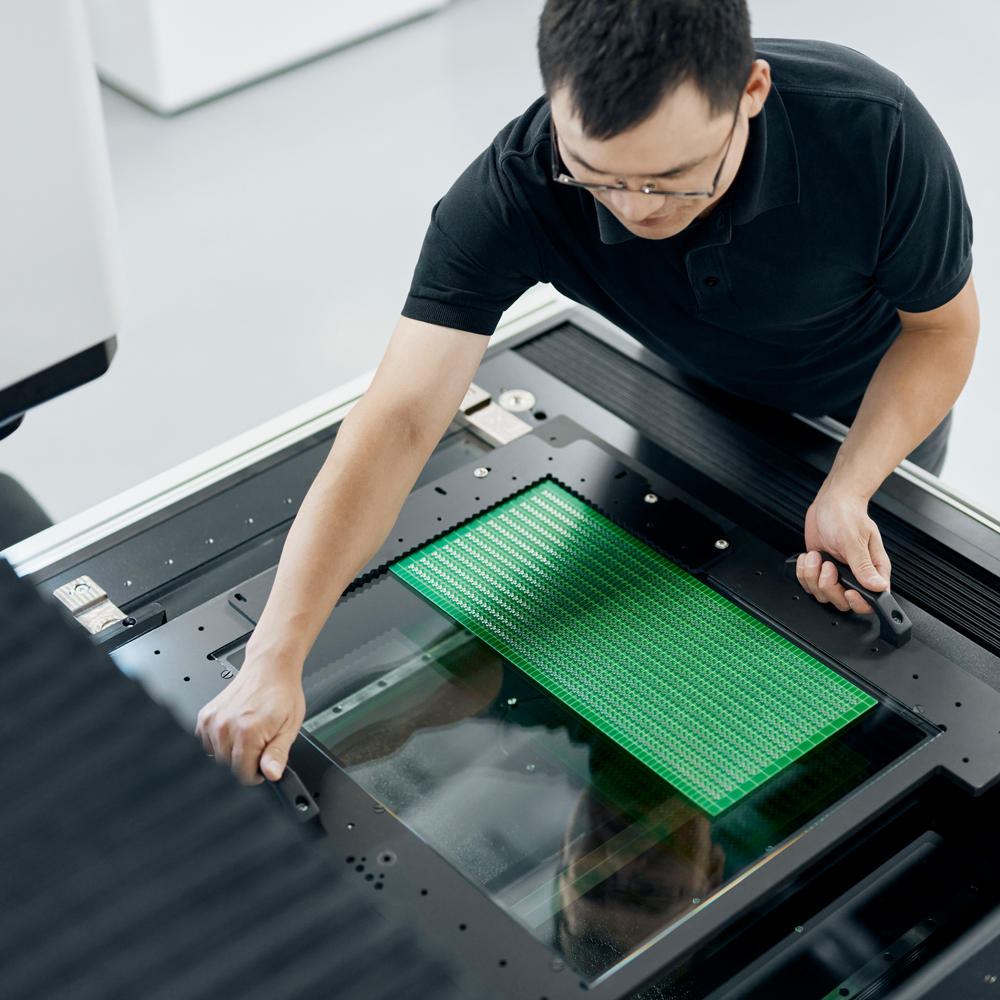

Inspecting large parts as a whole

Cutting up components is a thing of the past: The optical inspection of large workpieces such as PCBs, fuel cells or batteries is now possible in their entirety. This saves valuable resources and time as well as reducing sources of error caused by moving fragmented workpieces back and forth between different systems.

In addition to the inspection of large parts, ZEISS O-INSPECT duo is also suitable for the automated inspection of many small parts. This means that the measuring microscope only needs to be loaded once – the inspection itself is then carried out in a single step without changing the individual samples.

High-resolution 5 MP color camera

Detecting defects accurately

While black and white images provide high contrast differences in measurement technology, color images offer an advantage in microscopic analysis: With 5-megapixel image resolution in color, even small defects are depicted clearly and enable precise inspection and evaluation. ZEISS O-INSPECT duo can be used with the familiar ZEISS ZEN core microscopy software.

Discover the details

Click on the circle markers on the image to open the information box with more details.

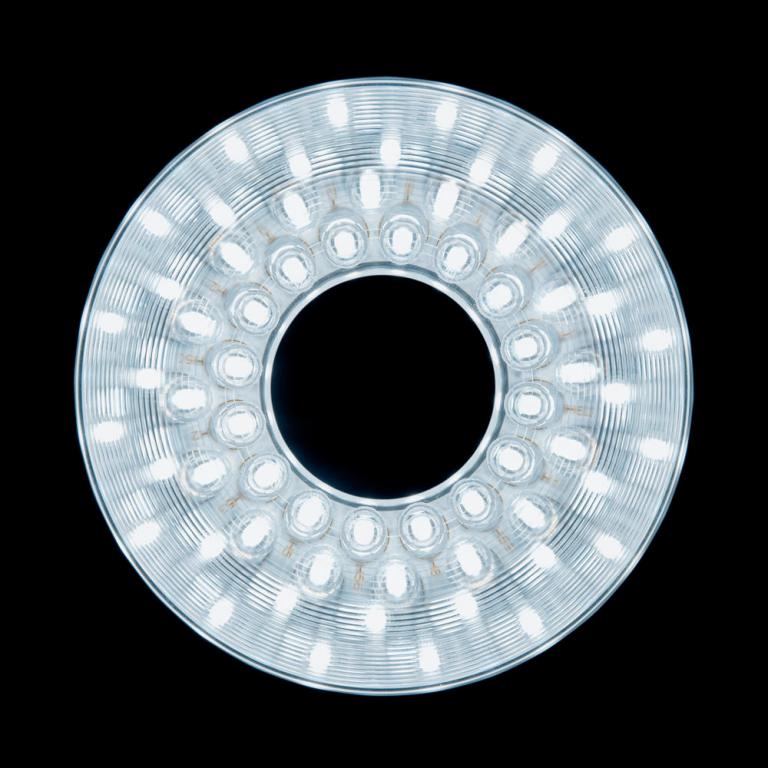

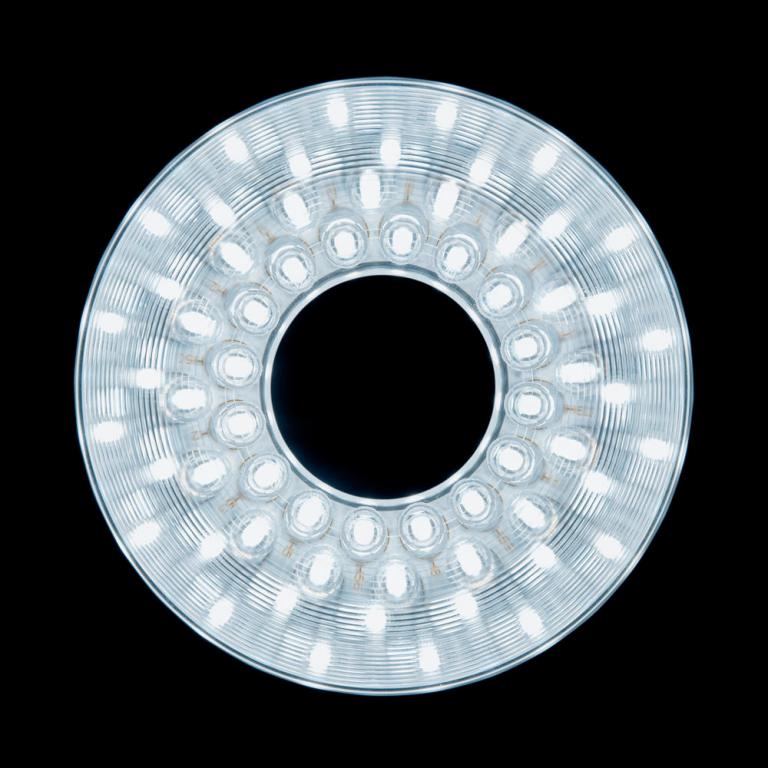

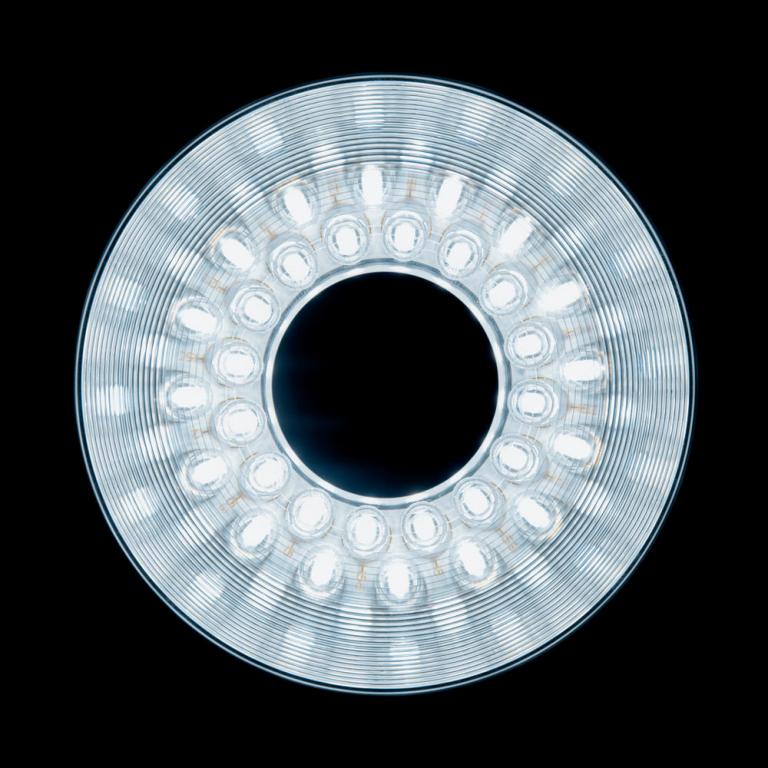

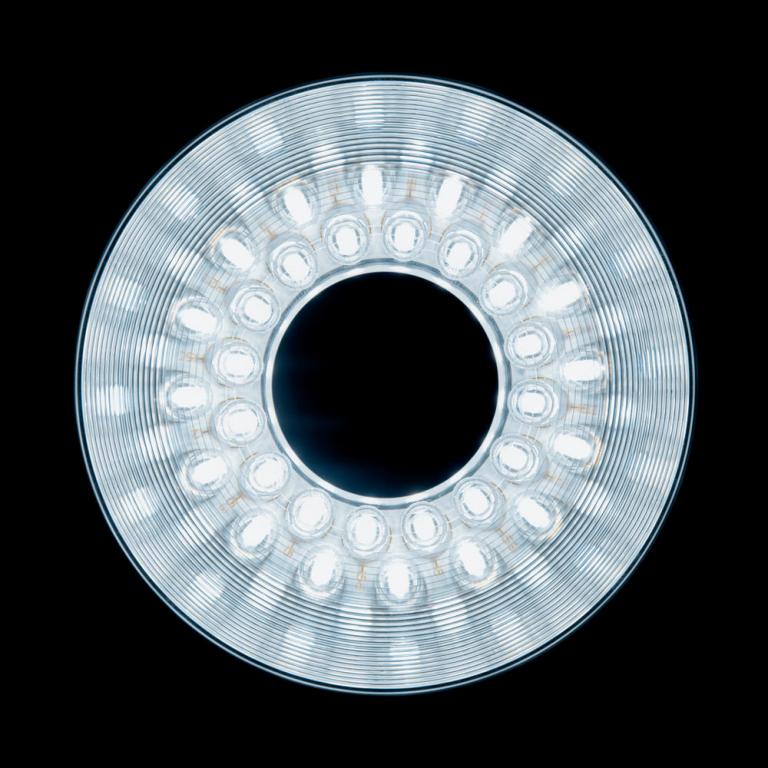

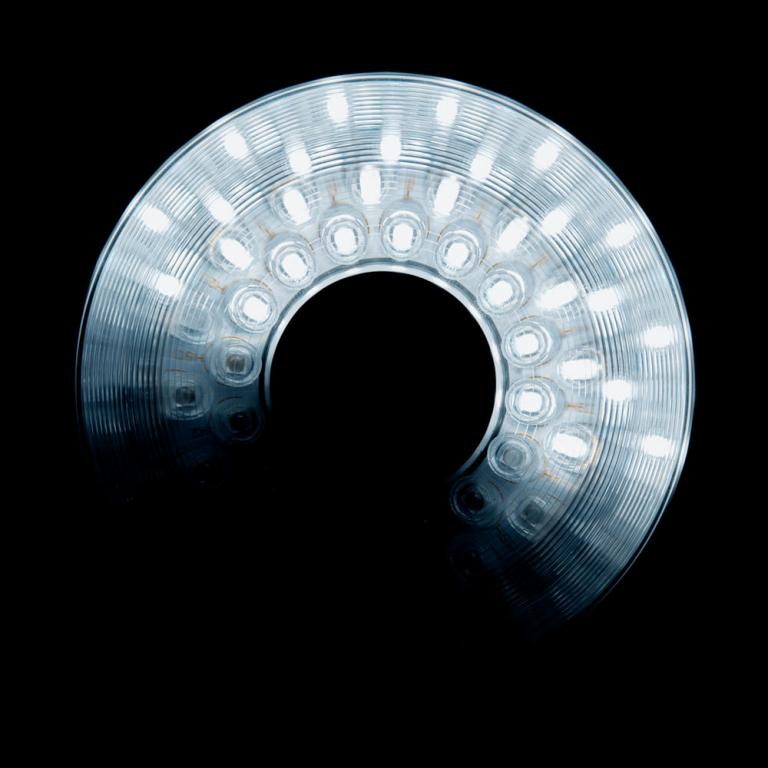

Optimal contrasts

In addition to coaxial uplight and backlight, ZEISS O-INSPECT duo also offers various control options for the ring light. The inner and outer LED rings can be switched on and off separately or only activated in individual segments.

Inner and outer LEDs

The ring light is made up of inner and outer LEDs in white color. The combination of inner and outer LEDs results in maximum illumination of your workpiece.

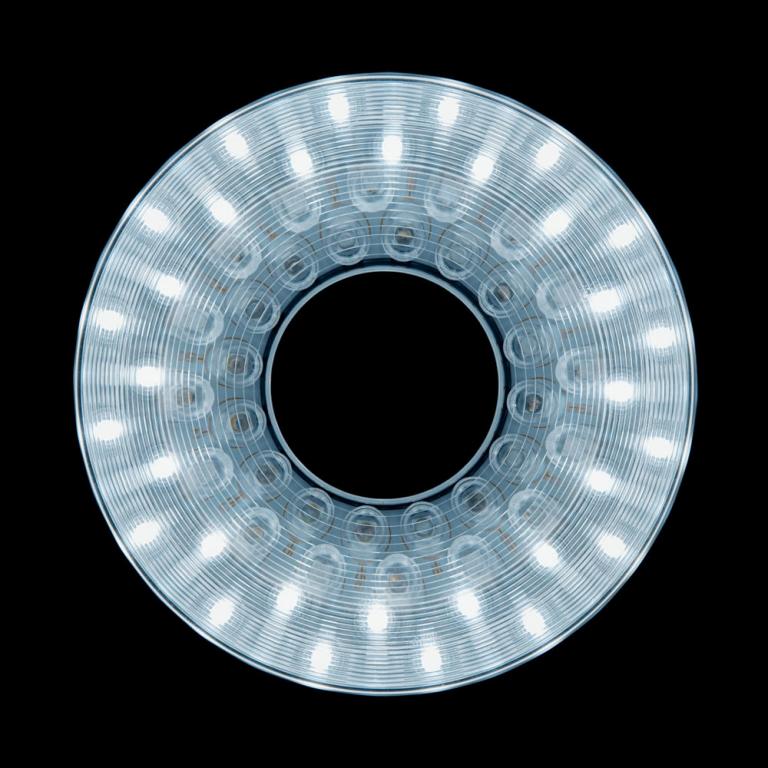

Inner LEDs

The inner ring light increases contrasts in the surface texture, leading to improvements such as better focusing – for even more precise measurement results.

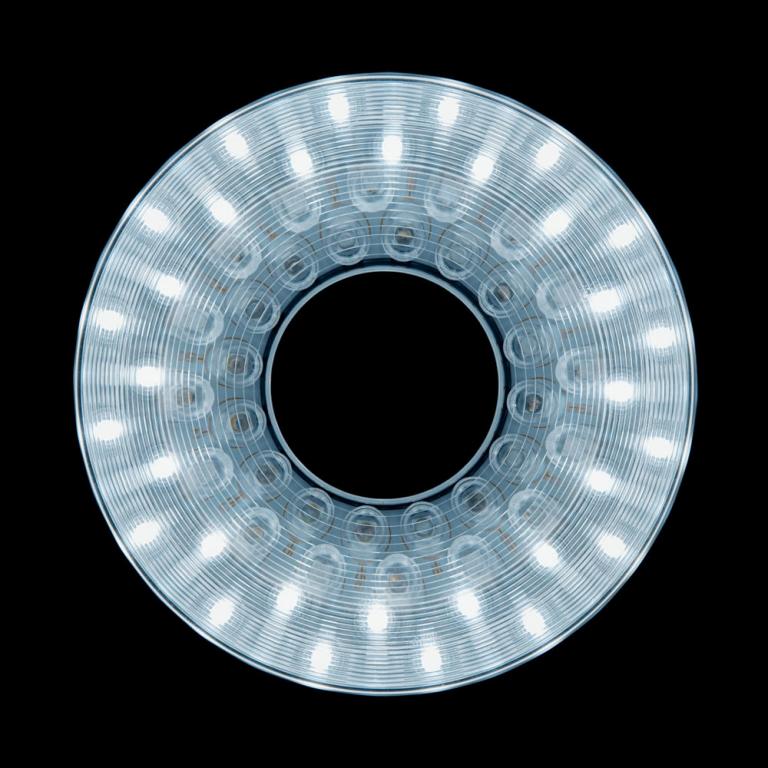

Cell frame

The LEDs of the outer ring light make it possible to filter out interfering ambient light. This provides benefits such as illuminating colored materials with high contrast.

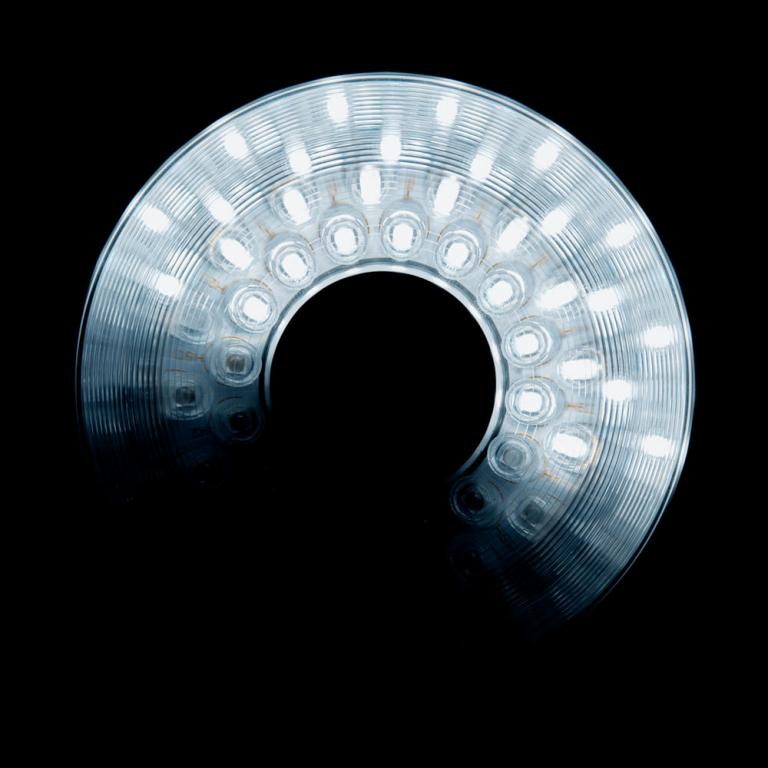

Segment lighting

The ring light consists of 16 segments that can be controlled individually. This ensures optimized lighting in accordance with the properties of your workpiece.

Technical details

Size | 8/6/3 |

Camera | ZEISS Discovery.V12 scout 160 c, 5 MP color camera, 2646 x 2056 pixel |

Illumination | 16 segment LED ring light with white LEDs, coaxial uplight and backlight |

Working distance in mm | 55 |

Mechanical zoom | 12 x |

Field of view max. in mm | 16,1 x 12 |

Compatible tactile probehead | ZEISS VAST XXT – TL1/TL3 |

Capacity | 100 kg |

Accuracy tactile and optical | 1D: 1,5 μm + L/250 2D: 1,8 μm + L/250 μm 3D: 2,2 μm + L/250 μm |

Software | ZEISS CALYPSO (for metrology) ZEISS ZEN core (for microscopy) |