Automation & Integration

Loading products

Manual and automatic loading systems

The feeding systems from ZEISS can be used in the measuring room as well as on or directly in the production line. They are compatible with various CMMs according to your requirements. To optimize parts flow and operating times and for more efficiency in your measurement processes.

Automatic loading systems

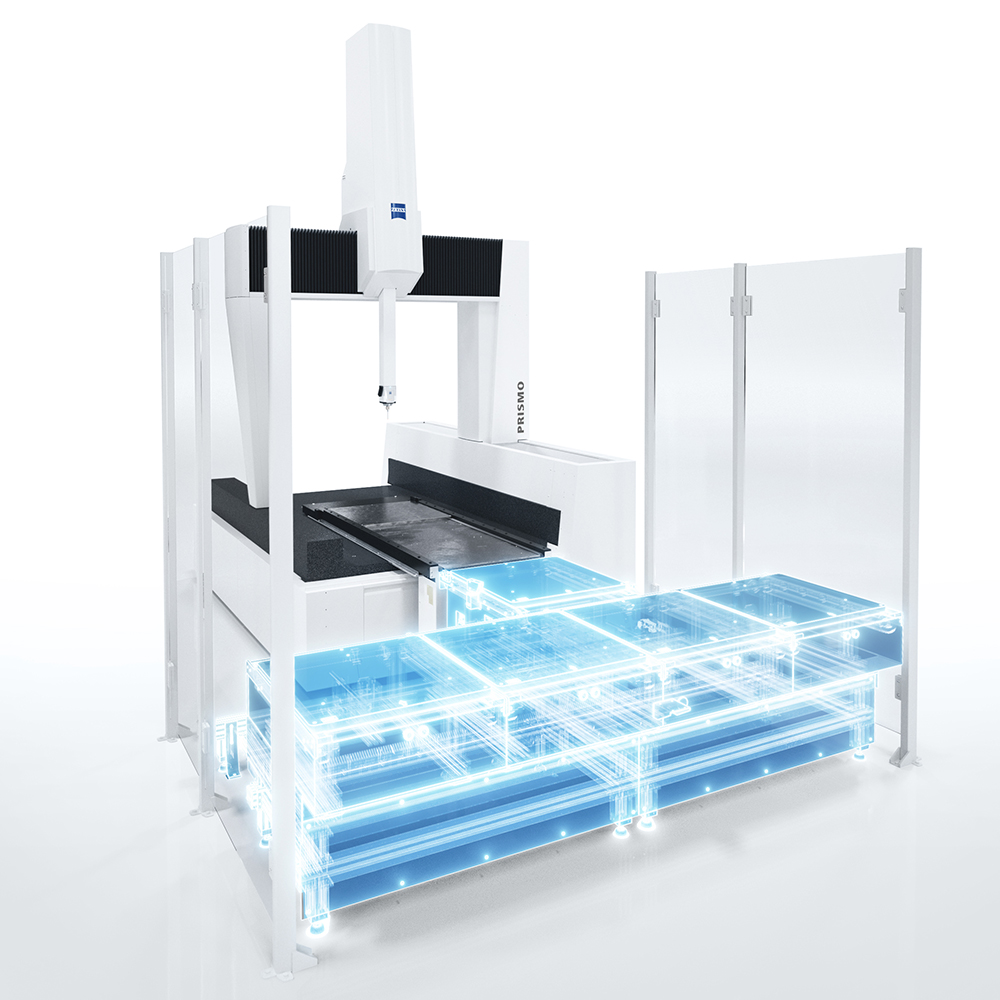

ZEISS ShuttleLoad

Automatic workpiece change

With the ZEISS ShuttleLoad, your coordinate measuring machine can be automatically loaded and unloaded with pre-loaded pallets. This increases part throughput on the machine and reduces downtimes. This also enables unmanned shifts, as the workpiece changeover is fully automatic. The ShuttleLoad is operated via a simple user interface and a handheld scanner – meaning that the system can also be used by untrained personnel.

Compatible with ZEISS PRISMO and ZEISS CONTURA. Other machines on request.

- ZEISS PRISMO

- ZEISS CONTURA

ZEISS MultiLoad

Loading system with workpiece storage

With the ZEISS MultiLoad, up to four CMMs can be loaded with workpieces simultaneously and fully automatically. The workpiece storage has 16 storage locations and can be loaded with numerous pallets. The automatic exchange of components between the storage area and the CMM also enables completely unmanned shifts. The part throughput can thus be maximized. The design with storage towers means that only a small footprint is required.

Compatible with ZEISS PRISMO, ZEISS MICURA, ZEISS CONTURA, ZEISS DuraMax and ZEISS O-INSPECT.

Manual loading systems

Simplifies parts handling by setting up components remotely from the machine for fewer loading blockages on the CMM and increased throughput.

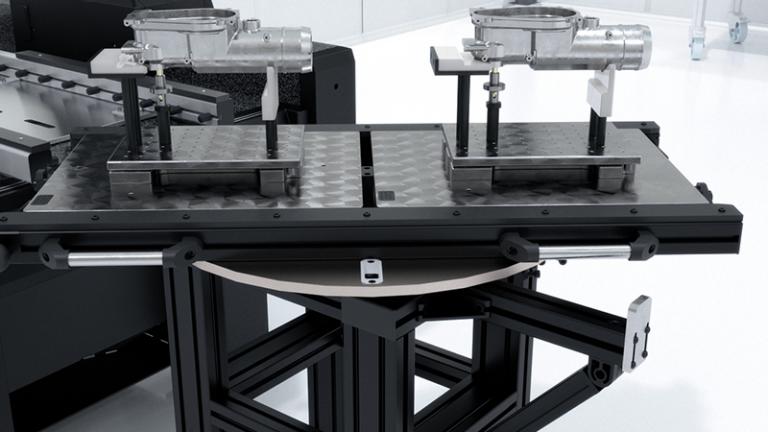

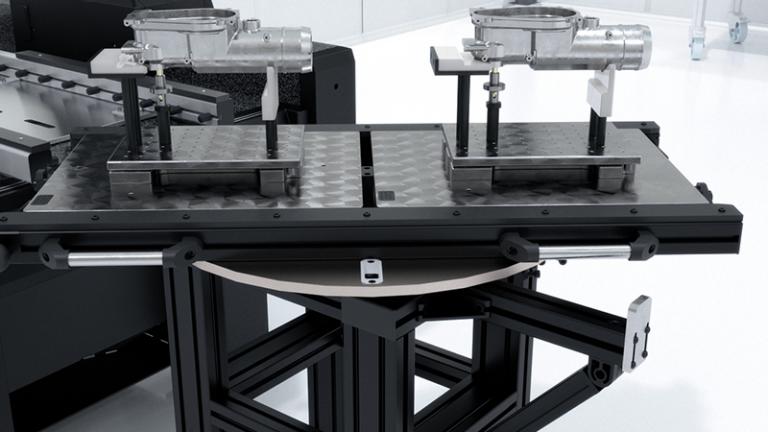

Pallet feeding system

Optimizes the measurement process and enables reproducible workpiece positions by means of a three-point support.

Set-up table & pallet transport trolley

Simplifies parts handling by setting up components remotely from the machine for fewer loading blockages on the CMM and increased throughput.

Turntable station

Enables two pallets to be exchanged quickly and increases CMM utilization with a minimal footprint.

ShuttleLoad manual

Speeds up pallet changes by providing storage spaces for pre-equipped pallets and enables measurements with different measuring devices on one CMM.